Abstract

Evaluation of the cutting and wear performance of cutting tools in full-face tunnel boring machines (TBMs) for soil and rock formations is critical for accurate project scheduling and cost estimation. The significant investment costs associated with mechanized tunneling necessitate comprehensive laboratory and numerical tests, such as linear cutting tests, to guide machine selection and cutterhead configuration. This study investigates the performance of cutting tools using a novel small-scale Linear Cutting Machine (LCM). To achieve this, a small-scale LCM was developed, and linear cutting tests were performed on nine rock specimens of varying geological origins. Each rock specimen measured 200 mm × 150 mm × 80 mm. The shear disk studied in this research is located 3.5 m from the center of the cutterhead. This shear disk travels a distance of 22 m with each rotation of the TBM cutterhead, considering the circumference of the circle. Based on the 1:10 scale conversion applied in this study, the constructed shear disk should also travel 2.2 m across the rock. Several cutting components are analyzed in linear cutting tests, including specific energy (SE), cutting coefficient (CC), and disk wear. Additionally, all laboratory tests were numerically modeled using the finite element method under identical boundary conditions. Results indicated that Basalt-1, due to its high porosity, required the highest specific energy, while softer rocks like travertine-1 exhibited the lowest. Also, the cutting coefficient increased with penetration depth, emphasizing its role in controlling friction and optimizing disc bearing performance. Fossiliferous limestone demonstrated the highest cutting coefficient due to its fine-grained structure and high friction. Identifying penetration depths that maximize excavation rates while minimizing forces, this study enhanced excavation efficiency and tool longevity.

Similar content being viewed by others

Introduction

TBMs are recognized as some of the most advanced and efficient tools in the tunneling industry. A key component of these machines is the disc cutter, which plays a crucial role in the success of tunneling operations. The use of disc cutters in TBM operations significantly increases excavation speed, enabling these tools to operate continuously and at high speeds, thereby reducing project completion time. Increased excavation speed translates into higher productivity and lower operational costs. High-performance and durable disc cutters minimize the need for frequent replacements and repairs, leading to lower maintenance costs and reduced TBM downtime1,2. The application of disc cutters in TBMs is highly significant due to their precision and quality in excavation, enhanced productivity and speed, cost efficiency, improved worker safety, reduced waste, and environmental preservation. These advantages have made disc cutters a vital and indispensable component of tunneling operations3,4,5. Cuttability is a critical property of rocks in mechanical excavation, representing the resistance of rock to penetration by excavation tools such as point-attack and rolling cutters. This property can be determined in the laboratory using full-scale rock cutting tests (FSRCT) or small-scale rock cutting tests (SSRCT). Laboratory rock cutting tests have proven reliable and effective for observing the interaction between tools and rock. These tests are also instrumental in estimating cutting forces and specific energy. The cutting forces derived from FSRCT and SSRCT are used for TBM design, cutter selection, optimal cutter geometry determination, cost estimation, and performance prediction of mechanical excavation6,7,8,9. In recent years, small-scale testing has gained popularity over full-scale testing due to the ease of preparing smaller specimens, reduced complexity, and lower costs. Numerous studies have modeled the rock cutting process with disc cutters using numerical methods such as the Finite Difference Method (FDM), Finite Element Method (FEM), and Discrete Element Method (DEM). Given the relative novelty and advanced capabilities of FEM, this study primarily focuses on FEM-based investigations. FEM is an advanced analytical technique widely used in engineering and sciences to solve complex problems in various domains, including structural mechanics, fluid dynamics, heat transfer, and electromagnetism. It is particularly effective for analyzing systems with complex geometries, nonlinear loading, and variable boundary conditions.

Recent advancements in the modeling and analysis of disc cutters have significantly contributed to the understanding and optimization of TBM operations. Key studies include the development of FEM models to analyze cutter forces and wear, such as Zhang et al. (2014) and Zhu et al. (2016), which investigated cutter design, lifespan, and failure mechanisms10,11. Han et al. (2017) and Xiao et al. (2017) focused on the impact of rock UCS (Uniaxial Compressive Strength) and penetration rates on TBM performance using FEM and SPH (Smoothed Particle Hydrodynamics) techniques12,13. Geng et al. (2017) and Li et al. (2018) compared cutting strategies and simulated rock and soil cutting, while Guiju and Caiyuan (2018) and Zhao et al. (2019) highlighted the importance of cutter arrangement. Studies by Guo et al. (2020) and X. Zhang et al. (2021) emphasized the effects of cutterhead configuration and varying cutting parameters on rock-breaking efficiency14,15,16,17,18,19. Further, Xu et al. (2022) and X. Jing Li et al. (2022) examined factors affecting cutter efficiency, including FEM-based simulations of rock crushing20,21. Zhao et al. (2022) and Ling et al. (2022) identified cutter failure modes and designed VCS (Variable Cross-Section) ring cutters for enhanced performance22,23. Xia et al. (2023) and Sabri et al. (2023) demonstrated the impact of heat generation and wear on cutter lifespan and TBM parameters24,25. Lastly, studies by Khoshzaher et al. (2023) and Chakeri et al. (2024) explored predictive models and experimental investigations to improve TBM cutter performance and wear mechanisms, employing advanced optimization algorithms and laboratory simulators26.

In this study, a small-scale Linear Cutting Machine (LCM) was developed, and the results from small-scale linear cutting tests were compared with numerical simulations of a V-shaped disc cutter using FEM. A key innovation in this research is maintaining the continuity of excavation during laboratory and numerical tests, addressing a common limitation in previous studies where cutters interacted with intact rock at varying depths. This continuity significantly impacts cutting parameters such as vertical and rolling forces, specific energy, penetration, cutting coefficient, and cutter wear. Experimental tests were conducted on nine rock types with diverse geological origins, and similar boundary conditions were implemented in the numerical simulations. Although cutting continuity is a known factor in cutting tests, this study introduces an integrated experimental-numerical methodology that rigorously maintains excavation continuity through systematic penetration increments and repeated cutting over closely spaced excavation lines in a 1:10 scale linear cutting machine. This setup realistically replicates continuous excavation conditions in a controlled laboratory environment, surpassing simplifications common in many small-scale tests. The experimental results are validated and supplemented by detailed finite element simulations under matching conditions, providing comprehensive insights into the influence of cutting continuity on forces, energy consumption, and cutter wear. This combined approach advances the precision and applicability of small-scale cutting tests for TBM cutter performance evaluation.

Specifications of specimens in laboratory rock linear cutting tests

In the process of rock cutting using discs, various forms of wear occur, leading to the deformation of the discs, particularly their cutting rings. In mechanical excavation, cutting tools (blades or bits) are classified into two main categories: scraping cutters and rolling cutters. The selection of these tools depends on specific ground conditions, rock properties, and the type of machine employed. Thus, understanding the relationship between rock characteristics and the optimal selection of cutting tools is critical. Virgin rock properties significantly influence the choice of bits or cutters. These properties include rock strength (compressive and tensile), abrasiveness or hardness of the rock and its constituent minerals, texture, grain size and shape, and its ductile or plastic behavior. In this study, to better evaluate the wear of disc cutters, specimens from various geological origins were used. The prepared specimens (Fig. 1) include: Travertine-1 and Travertine-2, Onyx Marble, and Fossiliferous Limestone (chemical sedimentary rocks), Andesite-1 and Andesite-2 (intermediate extrusive igneous rocks), Basalt-1 and Basalt-2 (mafic extrusive igneous rocks) and Quartz Syenite (felsic intrusive igneous rock). The dimensions of the rock specimens in this study were 200 mm × 150 mm × 80 mm. For certain specimens, including Travertine-1, Onyx Marble, Fossiliferous Limestone, Basalt-1, and Basalt-2, the thickness was 40 mm. To assess the mechanical properties of the rocks and their influence on wear, tests were conducted to measure uniaxial compressive strength (UCS), tensile strength, and elastic modulus. The equivalent quartz parameter, recognized as a key indicator in assessing rock abrasiveness, was also evaluated. Rock abrasiveness is significantly affected by the quartz content within the specimens. Consequently, each mineral in a rock specimen can influence its overall abrasiveness differently, depending on its hardness on the Mohs scale. The results obtained are detailed in Table 1.

Introduction to the designed and constructed small-scale linear cutting machine (LCM)

Rock specimens located along tunnel lines can be collected during the exploration or pre-construction phase of tunnel branches and then transferred to the laboratory. In the laboratory, a series of cutting tests is performed on these specimens using full-scale linear or rotary cutting machines to assess rock cuttability. Linear Cutting Machine (LCM) and RCM (Rotary Cutting Machine) tests can provide valuable guidance for the design of Tunnel Boring Machines (Tunnel Boring Machine (TBM)) and simulate a wide range of cutting forces and settings, thereby eliminating the effects of variable factors. These tests also reduce uncertainties arising from the unusual behavior of rocks. In other words, Linear Cutting Machine (LCM) and RCM tests are reliable.

The rock specimens were securely fixed within a dedicated specimen placement box designed to integrate with the linear cutting machine. This box includes mechanical clamps and hydraulic jacks that firmly hold the specimens in place, preventing any movement or vibration during cutting. The setup also incorporates vibration-damping elements to ensure a stable cutting environment. Continuous monitoring of cutting forces via a high-frequency data logger was conducted to detect any instability, and no abnormal force fluctuations indicative of specimen movement were observed. These measures ensure that the cutting tests were conducted under stable and controlled conditions, providing reliable and reproducible results.

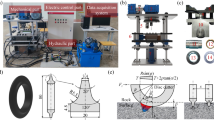

The results of these tests can be directly used to assess the performance of Tunnel Boring Machine (TBM)s under real-world conditions. As a result, many research studies have been based on the results of these tests. The small-scale Linear Cutting Machine (LCM) machine designed and constructed includes several key components: 1- Depth penetration adjustment cylinder, 2- Rock displacement jack cylinder for simulating the excavation process, 3- Rock sample placement box, 4- Compressed air compressor, 5- Manual hydraulic pump, 6- Compressed air control system, 7-Dynamometer for recording cutting forces, 8-Data logger device, 9-Linear cutting machine software. For this machine, a dedicated data logger and specialized software have been designed and constructed to record cutting forces. The features of this machine include its small-scale design, the ability to conduct Linear Cutting Machine (LCM) tests on a wide variety of rocks with different geological origins, a simple operational system, and easy maintenance. The machine also includes safety systems to protect the operator during operation and an advanced data processing system with high sampling capabilities. Figure 2 shows a full view of the constructed small-scale linear cutting machine.

In this study, the term shear disk refers to a conventional disc cutter mounted on the Tunnel Boring Machine (TBM) cutterhead. Specifically, the shear disk modeled and tested is positioned 3.5 m from the center of the cutterhead, representing a mid-radius cutter that experiences characteristic wear and loading conditions distinct from cutters located nearer the center or the periphery. This positioning was selected because it typifies the forces and wear profiles common in operational TBMs. The geometric specifications of the shear disk are consistent with standard TBM disc cutters, including an edge angle of 40°, width of 32 mm, and thickness of 56 mm, as detailed in Table 2.

In the studies conducted, the shear disk has interacted with the undisturbed rock at various depths. In these cases, vertical forces, rolling force, specific energy, etc., were measured for the rock in sections that were not yet excavated. This led to the elimination of the impact of excavation continuity. Excavation continuity is of great importance in Tunnel Boring Machines (Tunnel Boring Machine (TBM)), where initially the shear disks penetrate a few centimeters into the rock. As the Tunnel Boring Machine (TBM) cutterhead rotates, it generates chips in the rock, allowing the excavation process to proceed gradually, with the shear disks continuing to penetrate. The experimental setup simulates a TBM cutterhead with a diameter of 7 m. Based on this diameter, the shear disk travels 22 m per revolution in full scale. Accordingly, the 1:10 scale model in the laboratory travels 2.2 m. Therefore, in this study, the effect of excavation continuity was also considered. For this purpose, in the laboratory tests performed, the shear disk first penetrated 1 mm into the rock, and after 2.2 m of excavation, the depth of penetration was increased by 0.5 millimeters. As a result, the penetration depth was determined in three stages: 1 mm, 1.5 millimeters, and 2 millimeters. In all these stages, the shear disk passed over the previously cut area. Thus, excavation continuity was maintained for 9 different rock specimens. Since the Tunnel Boring Machine (TBM) cutterhead consists of numerous shear disks, these disks undergo different types of wear based on their distance from the center of the cutterhead and their angles, this study focused on a middle shear disk and analyzed its wear. The shear disk studied in this research is located 3.5 m from the center of the cutterhead (Fig. 3). This shear disk travels a distance of 22 m with each rotation of the Tunnel Boring Machine (TBM) cutterhead, considering the circumference of the circle. Based on the 1:10 scale conversion applied in this study, the constructed shear disk should also travel 2.2 m across the rock. The prepared rock specimens for the Linear Cutting Machine (LCM) test are 20 centimeters long, so the constructed shear disk must travel 11 lines, each 1 centimeter apart, at each penetration depth. Figure 4 illustrates the procedure of both laboratory and numerical tests conducted in this study. Typically, several cutting components are analyzed in linear cutting tests, including vertical forces (FN), rolling forces (FR), specific energy (SE), specific vertical penetration (SPN), rolling penetration (SPR), cutting coefficient (CC), and disk wear. These components are used to describe the type of rock and its potential behavior during excavation and failure. To make a successful tool choice, measuring certain properties of these components is essential.

Numerical simulation of rock-tool interaction using a small-scale linear cutting device

Numerical simulation using the Finite Element Method (FEM) is one of the most widely used techniques in the analysis of engineering and physical systems. This method is employed to solve partial differential equations (PDEs) that describe the behavior of complex systems such as structures, fluids, and heat transfer. FEM enhances the accuracy of system behavior analysis by dividing the system into smaller elements and solving equations for each element. It is especially widely used for stress analysis, deformation, and stability of structures. Therefore, in this study, FEM was used with the Abaqus Finite Element Analysis (FEA) software (version number: Abaqus 2022)27 to model the fracture mechanism and rock cutting behavior under shear forces applied by a disc cutter. This FEM code can simulate nonlinear and dynamic fracture sections. The selected material behavior model for this numerical simulation is the modified Drucker-Prager plasticity model. This model is extensively used in finite element analysis for various geotechnical engineering applications. It is employed for modeling frictional and cohesive geologic materials, including soils and rocks. The model allows for the consideration of stress history, stress path, expansion, and the effect of intermediate principal stresses. Additionally, it is useful for modeling composite and polymeric materials where the yield strength in compression exceeds that in tension. This model also enables the simulation of both hardening and softening behaviors in isotropic materials.

Due to the use of a 1:10 scale model in laboratory linear cutting tests, scale effects on fracture propagation mechanisms and rock-tool interactions are acknowledged. The scale model is geometrically and mechanically designed to replicate key conditions of full-scale TBM cutters, including scaled penetration depths and travel distances, ensuring similitude in cutting forces and energy parameters. To mitigate scale limitations, numerical simulations using finite element methods were carried out under matching boundary conditions and material properties, providing a validated link between small-scale tests and full-scale cutter behavior. This combined experimental-numerical approach allows for reliable extrapolation of results to real-world TBM operations, despite recognized differences in fracture process scale. Future work may include further refinement of scaling laws and validation in larger-scale tests.

Geometry design of disk cutting blade and rock specimen modeling

Currently, the use of large-diameter disc cutters has increased in mechanized tunneling projects using Tunnel Boring Machine (TBM) (Tunnel Boring Machines) due to their high load-bearing capacity. The geometric specifications of the designed disc cutters are provided in Table 2. These specifications include the dimensions, cross-sectional shape of the cutters, and other relevant characteristics used for the design and manufacturing of the cutters.

To enhance simulation accuracy, mesh refinement was applied in the contact zone between the disc cutter and the rock specimen. Specifically, a denser mesh with smaller element sizes was used around the contact surface to capture localized stress concentrations and deformation patterns. This mesh gradation ensures accurate modeling of rock-tool interactions while balancing computational cost.

The rock used for modeling has dimensions of 40 × 120 × 200 mm. In the meshing of the rock block, to ensure the results are independent of the mesh; after evaluating various element types in Abaqus, 3D brick elements with 8 nodes (C3D8R) were ultimately chosen. Figure 5 shows the real rock specimen and the 3D element model designed in Abaqus. After evaluating various contact types, general contact was selected for modeling the interaction between the disc cutter and the rock. The contact properties are defined as interaction properties and can be assigned to multiple interactions. In this model, the interaction property is defined based on the selected contact type. The contact properties are defined as tangential behavior properties, and penalty-based methods were used to define the frictional behavior.

Assembly, boundary conditions, and FEM numerical simulations

The numerical model in this study is exactly simulated with boundary conditions that match the laboratory environment. In the laboratory setting, the cutting disc remains stationary while the rock moves towards the disc, and the excavation process occurs. Therefore, for high alignment in numerical simulations, the disc is kept stationary, and the rock is moved toward the disc. The thickness of all rock specimens is considered to be 40 mm. Due to the displacements occurring in the model, boundary conditions for the rock are selected such that one face of the model is fixed, and all faces are constrained in the twisting direction. For the cutting disc, movement is constrained in two directions, but for the disc’s rotation during excavation, twisting along the X-axis is not constrained, as shown in Fig. 6.

In this model, the boundary conditions are set such that the disc is initially adjusted to a penetration depth of 1 mm automatically and then remains at that penetration depth while the rock starts to move towards the disc, and the excavation process takes place. After the disc drills 20 cm of rock, it moves upwards and returns to its initial position before excavation. This process is illustrated in Fig. 7. Then, a linear change of 1 cm is applied, and the disc is positioned on the second 20 cm line at a penetration depth of 1 mm and starts excavation again. This continues until the disc has drilled 220 cm, after which it returns to its initial zero position, and the penetration depth is set to 1.5 mm. The process starts again from all lines where 1 mm penetration occurred. This procedure is repeated for a penetration depth of 2 mm in the same manner, and at the end, the disc returns to its central zero position. This mirrors exactly what happens in the laboratory environment.

In this simulation, the cutting disc begins to rotate based on the frictional interaction between the rock and the disc. With these specifications, Abaqus enables us to set up a model that closely mirrors the experimental conditions, allowing us to compare the modeling results with laboratory tests. Figure 8 illustrates the excavation process of the cutting disc in the rock and the normal forces in the numerical simulations. Table 3 outlines the physical and mechanical properties of the 9 rock specimens used for numerical simulation.

Specific energy (SE) of the cutting disc

The specific energy of the cutting disc refers to the amount of energy required to cut a unit mass of material by the cutting disc within a unit time. It is considered the most critical factor in the cutting disc’s efficiency for rock excavation, holding significant importance. The value of this parameter depends on the type of rock, the design of the cutting disc, and the disc’s rotational speed. By calculating the weight of the produced chips, the cutting geometry, the rolling force, and the sample’s density, the specific energy is determined using Eq. (1)28:

In this equation, SE is specific energy (MJ/m³), FR is rolling force (N), L is cutting length(m), ρ is rock specimen density (kg/m³) and m is mass of the produced chips (kg). Figure 9 illustrates the specific energy diagram for the rocks under investigation. Based on the obtained results, it can be concluded that the weaker the rock, the lower the specific energy required for excavation. According to the diagram in Fig. 9(a), the Travertine-1 rock, due to its softness and crystallized texture, requires greater penetration depth for excavation to reduce specific energy. At a penetration depth of 1 mm, the cutting disc has very low excavation capability in Basalt-1, as this rock has a porous texture, and the depth of these voids and cavities exceeds 1 mm. As a result, the specific energy increases at a 1 mm penetration depth. Additionally, due to the hardness and high resistance of Quartz Syenite and its hypidiomorphic granular texture, the cutting disc has difficulty penetrating the rock, resulting in very little chip production. According to the specific energy diagram for Quartz Syenite, it is evident that specific energy decreases at a 1.5 mm penetration depth. This result strongly indicates that pre-cracking in rocks with high strength can significantly affect the specific energy during excavation. In general, for rocks like Travertine-1, Basalt-1, and Quartz Syenite, as the penetration depth increases from 1.5 mm to 2 mm, the cutting disc produces more chips, leading to a significant reduction in specific energy. As shown in the diagram in Fig. 9(b), the highest specific energy values for Basalt-2 and Fossiliferous Limestone occur at a 1 mm penetration depth. In Basalt-2, due to fewer voids than Basalt-1, the specific energy is lower, indicating the impact of porosity on specific energy. In Fossiliferous Limestone, due to high strength and a crystallized fine-grained texture, the cutting disc has difficulty penetrating the rock, resulting in less chip production and higher specific energy at a 1 mm penetration depth. Furthermore, the diagram for Basalt-2 and Fossiliferous Limestone shows that specific energy decreases at a 1.5 mm penetration depth, but increases at 2 mm, which signifies the end of cracks and micro-cracks in the rock. Once these cracks are exhausted, the cutting disc encounters an intact surface, reducing chip production and increasing specific energy. As indicated in Fig. 9(c), the trend of specific energy values for Pyroxene Andesite and Onyx Marble decreases with increasing penetration depth. Similarly, Fig. 9(d) shows that the trend of specific energy changes for Travertine-2 and Hornblende Andesite is increasing between penetration depths of 1 to 1.5 mm, and decreasing between 1.5 and 2 mm. Analyzing the data for Travertine-2 and Hornblende Andesite, it can be concluded that the optimal specific energy for the cutting disc should be at a 1.5 mm penetration depth, where enough cracks and micro-cracks are generated in both rocks, increasing chip production and consequently reducing specific energy. Figure 10(a) shows the validation diagram for numerical simulations of specific energy. Both experimental and numerical diagrams overlap well with each other. Figure 10(b) shows the average specific energy values. From this Figure, it is clear that the highest experimental (6232 MJ/m³) and numerical (7256 MJ/m³) specific energy values correspond to Basalt-1, due to its high fracturing and porosity. The lowest experimental (675 MJ/m³) and numerical (879 MJ/m³) specific energy values are for Travertine-1, due to its softness.

Specific penetration

The specific penetration, defined as the amount of force required for penetration per unit depth in rock, is obtained in two directions: vertical force and rolling force. The Eq. (2) gives the values28, :

where \(\:{SP}_{N}\) is specific penetration in the vertical force direction (N/m), \(\:{SP}_{R}\) is specific penetration in the rolling force direction (N/m) and P is Penetration depth (m). Since rolling forces are always less than vertical forces and are also considered shear forces in the rock, it is crucial to find the penetration depth at which the vertical force values approach the rolling force values. The goal in determining specific penetration is to find a depth that not only increases the excavation rate in the rock but also minimizes the shear forces. Accurate determination of specific penetration improves excavation efficiency and extends the lifespan of cutting tools. Figures 11 and 12 present the vertical and rolling specific penetration diagrams for the rock specimens under study, categorized into different groups.

Figures (13-a) and (14-a) show the validation diagrams for the numerical simulations of vertical and rolling specific penetration, respectively. Both experimental and numerical diagrams show a good overlap. Figures (13-b) and (14-b) present the overall average vertical and rolling specific penetration diagrams. From these Figures, it can be observed that the highest values for vertical specific penetration are experimental (1464 N/m) and numerical (1654 N/m), as well as the highest values for rolling specific penetration, experimental (220 N/m) and numerical (286 N/m), correspond to Quartz Syenite due to its high hardness. Conversely, the lowest values for vertical specific penetration are experimental (495 N/m) and numerical (520 N/m), as well as the lowest values for rolling specific penetration, experimental (71 N/m) and numerical (80 N/m), correspond to Travertine-1 due to its softness.

Cutting coefficient

The ratio of rolling force to vertical force is called the cutting coefficient (Eq. 3). Studies conducted by Rostami and Ozdemir (1993) show that this coefficient increases with increasing penetration depth29. The cutting coefficient, considering different penetration depths, has been calculated for this study.

Which FN and FR represent the vertical and rolling forces, respectively. By analyzing the cutting coefficient results, it can be observed that as penetration depth increases, the cutting coefficient values increase for all the rocks. The main reason is that with increasing penetration depth, the contact area between the cutting disk and the rock also increases. This increase in contact area results in higher friction and consequently higher vertical and rolling forces. The cutting coefficient is a controlling parameter, indicating that the bearing system of the cutting disk is functioning optimally. Additionally, the results of the cutting coefficient show that the cutting disk is experiencing uniform wear. Since it is impossible to calculate cutting coefficients for the available experimental specimens, only the numerical cutting coefficient results are provided. Upon reviewing the cutting coefficient results, it can be concluded that there is a very small difference between the values for the 9 rock specimens. In the diagram in Figure (15-a), the cutting coefficients of the 9 rock specimens studied are detailed. Figures (15-b) presents the overall average cutting coefficients. From this Figure, the highest numerical cutting coefficient value (0.189) corresponds to Fossiliferous Limestone, due to its fine crystalline structure and the high friction it creates with the cutting disk. Conversely, the lowest numerical cutting coefficient value (0.173) corresponds to Basalt-1, due to its high fracturing and porosity, and the low friction it generates with the cutting disk.

Cutter disc wear

Disc cutter wear refers to the gradual deterioration and degradation of the cutting disc surface due to repeated use. This wear can occur for various reasons and has a significant impact on the efficiency of the disc cutter in the tunnel excavation process. Cutter wear can reduce the efficiency of the Tunnel Boring Machine (TBM) and, consequently, increase excavation costs and time. To extend the useful life of the cutter disc and improve its efficiency, regular maintenance, timely repairs, and the use of high-quality discs are crucial. The results of disc cutter wear show that as penetration depth increases, the wear values for the cutter disc also increase for all types of rock. The primary reason is that as the penetration depth increases, the contact area between the cutter disc and the rock increases. This increase leads to higher friction, heat generation, and interference between the cutter disc and the rock’s cavities and fractures.

Figure 16 illustrates the wear diagrams for the rocks studied. As shown in Figure (17-a), the laboratory and numerical diagrams overlap well. Figures (17-b) presents the overall average disc cutter wear. Based on this Figure, the highest disc cutter wear value (1.88 mm for laboratory tests and 2.02 mm for numerical simulations) is observed for Fossiliferous Limestone, due to its fine crystalline texture and high hardness. Conversely, the lowest disc cutter wear value (0.35 mm for laboratory tests and 0.37 mm for numerical simulations) is observed for Travertine-1, due to its low hardness and friability. Figure 18 presents images of all the worn disc cutters from the laboratory environment along with the numerical simulations results. From this Figure, one can observe the deformation on the cross-sectional surface of both the laboratory and numerical disc cutters.

Conclusions

This study highlights the critical importance of laboratory and numerical simulations in optimizing the design and operation of Tunnel Boring Machine (TBM) cutting tools. Evaluating the impact of cutting tool wear and comparing laboratory results with numerical simulations of V-shaped cutting disks in ABAQUS, several significant insights were gained:

-

1.

Innovative continuity modeling: Unlike prior research that overlooked continuous cutting, this study incorporated continuous and cyclic loading in laboratory tests and numerical simulations, ensuring realistic modeling of TBM operations.

-

2.

Comprehensive rock variety: Linear cutting tests were conducted on nine distinct rock types, covering a wide range of geological origins, providing broader applicability of the results.

-

3.

Force dynamics and material properties: Experimental and numerical analyses revealed significant variations in vertical and rolling forces based on rock hardness. Quartz syenite exhibited the highest forces due to its hardness, while softer rocks like travertine-1 required significantly lower forces.

-

4.

Bearing selection for efficiency: Rolling force data was a critical input for selecting bearings to ensure uniform cutter wear and extended tool life.

-

5.

Specific energy and excavation efficiency: Numerical simulations provided valuable insights into specific energy requirements, aiding in optimizing cutting disc geometry for higher excavation rates and reduced wear. Basalt-1, due to its high porosity, required the highest specific energy, while softer rocks like travertine-1 exhibited the lowest.

-

6.

Specific penetration optimization: Identifying penetration depths that maximize excavation rates while minimizing forces, this study enhanced excavation efficiency and tool longevity. Quartz syenite showed the highest penetration values, reflecting its hardness.

-

7.

Cutting coefficient as a performance indicator: The cutting coefficient increased with penetration depth, emphasizing its role in controlling friction and optimizing disc bearing performance. Fossiliferous limestone demonstrated the highest cutting coefficient due to its fine-grained structure and high friction.

-

8.

Wear Analysis: The study confirmed increased penetration depth correlates with higher cutter wear. Fossiliferous limestone caused the highest wear due to its hardness, while travertine-1 resulted in the lowest wear, reflecting its softness.

This research underscores the importance of integrating experimental and numerical approaches to evaluate cutting forces, specific energy, penetration efficiency, and tool wear. These findings offer valuable guidelines for optimizing TBM cutter design, enhancing operational efficiency, and reducing overall tunneling costs. Future work can expand on this by incorporating more advanced numerical techniques and broader rock typologies to refine predictive capabilities further.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Nickjouye Tabrizi, A. H., Chakeri, H., Darbor, M., Amoun, S. & Shakeri, H. Evaluating the effect of tool wear in soft soil using new TBM tunneling simulator device. J. Test. Eval. 51(6), 3917–3932 (2023).

Xue, Y. et al. Prediction of optimum Tunnel Boring Machine (TBM) penetration strategy with minimum energy consumption in hard rocks. Comput. Geotech. 148, 104844 (2022).

Roxborough, F. F. & Phillips, H. R. Rock excavation by disc cutter. Int. J. Rock. Mech. Min. Sci. And 12(12), 361–366 (1975).

Chakeri, H., Darbor, M., Shakeri, H., Mousapour, H. & Mohajeri, V. Experimental and numerical investigation of the TBM disc cutter wear using a new tunnel boring machine laboratory simulator. Heliyon 10(17), (2024).

Mousapour, H., Chakeri, H., Darbor, M. & Hekmatnejad, A. Evaluating the wear of cutting tools using a tunnel boring machine laboratory simulator. Min. Mineral. Deposits 17(2), 28–34 (2023).

Tumac, D. & Balci, C. Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations. Tunn. Undergr. Space Technol. 45, 84–98 (2015).

Bilgin, N. Investigations into the mechanical cutting characteristics of some medium and high strength rocks (Newcastle University, 1977).

Li, B. et al. Full-scale linear cutting tests to study the influence of pre-groove depth on rock-cutting performance by Tunnel Boring Machine (TBM) disc cutter 122 (Tunnelling and Underground Space Technology, 2022).

Luo, X., Zhang, J., Yang, F., He, F. & Xia, Y. Research on the hard rock cutting characteristics of disc cutter under front-mounted water jet precutting kerf conditions. Eng. Fract. Mech. 287, 109330 (2023).

Zhang, Y., Wang, X. W. & Liu, H. F. Numerical simulation of rock-breaking process by disc cutter in tunnel boring machine. Appl. Mech. Mater. 487, 513–516 (2014).

Zhu, L., Wei, T., Liu, B. & Yu, T. Simulacijska analiza Mehanizma Loma Stijena Stroja Za Bušenje Tunela. Tehnicki Vjesn. 23(6), 1585–1590 (2016).

Han, M. D., Cai, Z. X., Qu, C. Y. & Jin, L. S. Dynamic numerical simulation of Cutterhead loads in tunnel boring machine (TBM) tunnelling. Tunn. Undergr. Space Technol. 70, 286–298 (2017).

Xiao, N., Zhou, X. P. & Gong, Q. M. The modelling of rock breakage process by tunnel boring machine (TBM) rolling cutters using 3D FEM-SPH coupled method. Tunn. Undergr. Space Technol. 61, 90–103 (2017).

Geng, Q., Wei, Z. & Ren, J. New rock material definition strategy for FEM simulation of the rock cutting process by tunnel boring machine (TBM) disc cutters. Tunn. Undergr. Space Technol. 65, 179–186 (2017).

Li, G. et al. Mechanism and numerical analysis of cutting rock and soil by tunnel boring machine (TBM) cutting tools. Tunn. Undergr. Space Technol. 81, 428–437 (2018).

Guiju, Z. & Caiyuan, X. Analysis of thermal stress distribution of tunnel boring machine (TBM) disc cutter. Australian J. Mech. Eng. 16(sup1), 43–48 (2018).

Zhou, P., Guo, J., Sun, J. & Zou, D. Theoretical research and simulation analysis on the cutter spacing of double disc cutters breaking rock. KSCE J. Civ. Eng. 23(7), 3218–3227 (2019).

Guo, Z., Wang, J., Lv, S., Yu, D. & Zhang, X. Rock breaking performance of two disc cutters of tunnel boring machine for safe tunneling in unstable coal rock stratum. Int. J. Saf. Secur. Eng. 10(5), 639–646 (2020).

Zhang, X. et al. Coal rock breaking simulation and cutting performance analysis of disc cutters. Tehnicki Vjesn. 28 (5), 1755–1761 (2021).

Xu, C. et al. Spacing Optimization of the Tunnel Boring Machine (TBM) Disc Cutter Rock Fragmentation, Based on the Energy Entropy Method. Sustain. (Switzerland) 14(20), 13226 (2022).

Li, X., jing, Zhang, H., ken, Bai, Y. & Zhang, X. Factor analysis and numerical simulation of rock breaking efficiency of Tunnel Boring Machine (TBM) deep rock mass based on orthogonal design. Journal of Central South University 29(4), 1345–1362 (2022).

Zhao, J., Yong, X., Hou, Z., Liu, C. & Yang, S. Simulation Modelling Practice and Theory Design and finite element analysis of a variable cross-section cutter ring (Simulation Modelling Practice and Theory, 2022).

Ling, X., Kong, X., Tang, L., Cong, S. & Tang, W. Preliminary identification of potential failure modes of a disc cutter in soil-rock compound strata: Interaction analysis and case verification. Eng. Fail. Anal. 131, 105907 (2022).

Xia, Y. et al. Study on the distribution and variation of temperature field in the rock breaking process of Tunnel Boring Machine (TBM) disc cutter. Int. J. Therm. Sci. 186, 108086 (2023).

Sabri, M., Goshtasbi, K., Nejati, H. R. & Taheri, E. A Numerical Investigation of the Effect of Disc Cutter Wear on Rock-Cutting Forces in Mechanized Tunnel Boring Machines. Int. J. Geomech. 23(5), 04023050 (2023).

Khoshzaher, E., Chakeri, H., Bazargan, S. & Mousapour, H. The prediction of EPB-Tunnel boring machine (TBM) performance using firefly algorithms and particle swarm optimization. Rudarsko-geološko-naftni Zbornik 38(5), 79–86 (2023).

https://www.3ds.com/products-services/simulia/products/abaqus/

Gertsch, R. & Gertsch, L. Rock Toughness and Disc Cutting (University of Missouri-Rolla, 2000).

Rostami, J. & Ozdemir, L. New model for performance production of hard rock Tunnel Boring Machine (TBM)s. Proceedings - Rapid Excavation and Tunneling Conference, 793–809. (1993).

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

H.Ch. conducted Writing – original draft, Supervision, Conceptualization, Software and Formal analysis. A.M. conducted Writing – review & editing, Software, Validation and Resources. H.Sh. conducted Methodology, Investigation and Data curation. M.D. conducted Writing – original draft, review & editing, Conceptualization, Supervision and Data curation. H.M. conducted Writing – original draft, review & editing, Resources. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Review and/or approval by an ethics committee was not needed for this study because it does not include any human or animal participation.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chakeri, H., Maleki, A., Shakeri, H. et al. Laboratory and numerical investigation of cutting tool performance using a new small-scale linear cutting machine. Sci Rep 15, 22337 (2025). https://doi.org/10.1038/s41598-025-08401-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08401-8

Keywords

This article is cited by

-

Simulation of Cutter Wear in Gravel Using a Discrete Element Method Approach

Geotechnical and Geological Engineering (2026)

-

Optimal selection of a metro tunnel excavation method using AHP and TOPSIS: a case study of Tehran metro

Scientific Reports (2025)

-

Mechanical properties of rock cutting by disc cutters and feasibility analysis of mechanical mining in Jinchuan No. 3 Mine with hard rock

Scientific Reports (2025)