Abstract

Urban Heat Island (UHI) effects and stormwater pollution are pressing challenges confronting modern urban environments. Permeable clay bricks (PCBs) have emerged as a promising sustainable solution to address these issues simultaneously. Despite their potential, significant knowledge gaps remain regarding the dual functionality of PCBs in mitigating UHI effects and improving stormwater quality through pollutant removal. This study aims to evaluate the effectiveness of PCBs in reducing UHI impacts and enhancing stormwater treatment, contributing to a deeper understanding of their role in sustainable urban design. Porous PCBs were manufactured using locally sourced clay soil and sawdust from Saudi Arabia. Heat absorption tests of the PCBs were conducted under natural conditions and compared with those of conventional concrete bricks, while pollutant removal from stormwater was evaluated through laboratory-scale filtration experiments. PCBs manufactured with 10% sawdust yielded sufficient compressive strength (20.1 MPa), bulk density (2.48 g/cm3), porosity (40.5%), water absorption (18.3%), and permeability coefficient (0.042 cm/s) for use as pedestrian and light traffic paving bricks. In thermal performance tests, PCBs exhibited the lowest near-surface temperatures, with a 1.2–2.2 °C reduction compared to conventional concrete bricks. The relative cooling performance index (CPI) of PCB ranged from 0.33 to 5.0, indicating superior thermal efficiency and reduced heat retention. Laboratory-scale filtration tests revealed that PCBs effectively removed over 99% of suspended solids (SS) and turbidity, more than 65% of chemical oxygen demand (COD) and biological oxygen demand (BOD), 30% of total nitrogen (TN) and total phosphorus (TP), and 56–100% of various metal pollutants from stormwater runoff. PCBs provide a dual-function solution by reducing urban heat and enhancing stormwater quality, making them a promising and sustainable material for urban development.

Similar content being viewed by others

Introduction

Saudi Arabia and other arid and semi-arid countries are facing significant climatic challenges, including extreme heat, prolonged droughts, and unpredictable weather patterns1. Besides, rapid urbanization has transformed land surfaces, causing water pollution and reduced surface runoff infiltration2,3. The drainage systems in these areas were designed for low-intensity, short-duration rainfall; yet, the frequency of flash floods has increased in recent years due to global climate change, resulting in economic and environmental disasters4. Contemporary methods like rainwater harvesting and low-impact development (LID) are more efficient and can replace the typical stormwater drainage system5.

Studies indicate that LID is sustainable for stormwater management due to its natural and engineered infiltration and storage techniques6,7,8. Through its physical, biological, and chemical filtration process, LID can improve water quality and promote stormwater infiltration in urban areas9,10. LID techniques that are mostly in practice include permeable pavements, sand filters, infiltration trenches, bio-retention ponds, bio-swales, rain barrels, green roofs, and stormwater wetlands9. The unique ability to infiltrate stormwater without covering urban spaces has made permeable pavement systems (PPSs) an alternative in stormwater management among the LID technologies11. PPS consists of multiple layers of a few sub-base and base layers along with a top layer of a permeable surface12. PPS has shown incredible prospects in flash flood control by reducing runoff volume through infiltration and minimizing peak flow discharge13. Moreover, PPS enhances stormwater quality by filtering out various pollutants during infiltration14. Previous studies have shown that PPSs are particularly effective in retaining total suspended solids (TSS) and removing a range of contaminants, including heavy metals, nitrogen (N), phosphorus (P), and hydrocarbons from stormwater runoff15,16.

Urban Heat Island (UHI) effects and stormwater pollution are one of the environmental challenges in modern cities caused by urbanization and population growth, eventually increasing the impermeable surfaces, heat-absorbing materials, and runoff pollutants that are unfiltered17,18,19. The rural areas surrounding the urban areas are several degrees cooler than the urban areas, as UHI is transforming the microclimate and creating a unique urban environment20. In urban areas, the near-surface temperature or the surface temperature is higher than the land in rural areas19, which may add extra warming to the already warmed temperature caused by climate change20. The use of heat absorbing materials like concrete, asphalt, and low-albedo surface increases urban temperature through the UHI effect, which can be greatly reduced by permeable surfaces, vegetation, bare surface, and water17,18,19. Using permeable materials in mitigating these challenges provides two benefits: reduction of urban heat retention and improvement of urban water and air quality. The porous structure and pollutant absorption quality of permeable clay bricks (PCBs) show huge potential in urban areas.

A permeable clay brick pavement can be a sustainable alternative to concrete and asphalt-based PPS for managing UHI and urban stormwater. The simple yet effective mechanism of PCBs aligns well with the objectives of low-cost Low Impact Development (LID) strategies. These bricks can be readily manufactured by incorporating pore-forming waste materials into clay soil, as demonstrated in previous studies21,22,23,24. Recently, a novel low-cost and environmentally sustainable PCB was developed using a mixture of clay soil and sawdust25. The structural and mechanical properties of the PCBs were examined for possible application for light traffic and pedestrians in urban areas of arid regions. The PCBs composed with a 90:10 ratio of clay soil to sawdust showed promising results in terms of compressive strength, bulk density, apparent porosity, water absorption capacity, and permeability coefficient25. Additionally, the stormwater treatment efficiency of permeable clay bricks (PCBs) was evaluated by analyzing key pollutants such as biological oxygen demand (BOD), total suspended solids (TSS), turbidity, nitrogen, and phosphorus25. However, critical knowledge gaps remain regarding the capability of PCBs to mitigate UHI effects and their effectiveness in removing heavy metals and other emerging pollutants from stormwater.

To the best of our knowledge, no previous study has simultaneously investigated both the UHI mitigation potential and stormwater treatment performance of PCBs. Therefore, the present study aims to provide a comprehensive assessment of PCBs in addressing these two critical urban environmental challenges. The specific objectives are: (a) to assess the thermal properties of PCBs, including heat adsorption and cooling performance, to evaluate their effectiveness in mitigating the UHI effect, and (b) to investigate the pollutant removal efficiency of PCBs for stormwater treatment, focusing on particulate matter, heavy metals, and organic compounds.

Materials and methods

Materials collection, processing, and fabrication of permeable clay bricks (PCB)

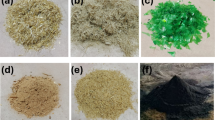

The fabrication of permeable clay bricks was carried out using locally sourced materials in Saudi Arabia. The details of the manufacturing process can be found in a previous study25. Najd Clay Brick Factory Company, located in Unaizah district, AlQassim, Saudi Arabia, supplied clay soil. Whereas the local carpenter shop in Unaizah, Al-Qassim, was the source of Sawdust. After collection, both soil samples and sawdust underwent rigorous screening to remove straw, shells, and other impurities, followed by grounded and sieving through a 0.5-mm sieve for uniform particle size. Sawdust was selected as easily available locally and acted as a good pore-forming agent for the permeable clay brick.

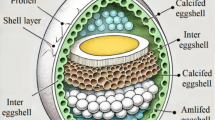

Detailed morphological and chemical characterizations were conducted for both soil and sawdust samples to evaluate their suitability for producing permeable clay bricks. The analyses included sieve analysis, X-ray Fluorescence (XRF), X-ray Diffraction (XRD), and Fourier Transform Infrared (FTIR) spectroscopy. Comprehensive results of these analyses are available in the authors’ previous study25. Briefly, the sieve analysis revealed that the soil samples consisted of 18.8% medium sand, 63.7% fine sand, and 17.5% clay/silt, classifying the soil as sandy clay. The uniformity coefficient (Cu) of 3.67 and the coefficient of curvature (Cc) of 1.48 indicate that the soil is a well-graded medium to fine mix, which is favorable for uniform compaction and molding during brick production25. XRF analysis showed that the soil sample contained 50.47% SiO2 and 19.14% Al2O3, aligning well with the typical composition suitable for clay brick manufacturing26. In contrast, the sawdust sample exhibited 33.11% SiO2, 16.38% Al2O3, 9.56% Fe2O3, and a relatively high CaO content of 28.08%. The elevated CaO content suggests that the sawdust is highly calcareous, which enhances its refractory properties and makes it an effective pore-forming agent25. XRD and FTIR analyses confirmed that the soil samples are rich in quartz (Q), dolomite (D), kaolinite (K), calcite (C), feldspar (F), illite (I), and chlorite (Ch). The sawdust samples, on the other hand, contain both amorphous and crystalline cellulose, contributing to their organic structure25.

A conventional brick-making method was followed to fabricate the permeable clay bricks. Figure 1 shows the step-by-step manufacturing process. The manufacturing process was initiated by mixing clay soil and sawdust at a ratio of 90: 10% by weight. This ratio was selected based on findings from previous studies indicating 10% sawdust as optimal for the permeable clay bricks25. After thoroughly mixing the clay and sawdust, a sufficient amount of tap water was added to form a workable dough. Care was taken to add an appropriate amount of water to ensure adequate plasticity and workability for effective molding. The prepared dough was then placed into standard wooden molds measuring 70 cm × 70 cm × 50 cm, following the method described by Xu et al.27. The mixture was pressed manually into the molds to ensure homogeneity and proper compaction, which is critical for improving brick strength. The molded bricks were then left to dry at room temperature for 24 h to remove the initial moisture. Subsequently, they were oven-dried at 110 °C for 24 h. Finally, the dried bricks were fired in a furnace at 900 °C, with the temperature increasing gradually at a rate of 10 °C per minute over 2.5 h.

Characterizing the structural, mechanical, and hydrological properties of permeable clay bricks

To evaluate the feasibility of permeable clay bricks for use in permeable pavements, the permeable clay bricks were tested for apparent porosity, water absorption, bulk density, compressive strength, and permeability coefficient. The apparent porosity, water absorption, and bulk density of the bricks were determined using the water boiling method28. Briefly, brick samples were oven-dried at 110 °C for 24 h to ensure complete moisture removal. After drying, the dry mass (D) was measured using a precise digital balance. The volume (V) of brick samples was also measured. The dried samples were submerged in distilled water and boiled for 2 h to ensure complete saturation of the pore spaces. After boiling, the samples were removed and allowed to cool to room temperature. Once cooled, the saturated mass (W) of the samples was recorded. Porosity, water absorption, and bulk density were calculated using the following equations.

Where W is the wet mass of the brick sample (g), D is the dry mass of the brick sample (g), and V is the volume of the brick sample (cm3).

The compressive strength test of the bricks was conducted using a Universal Testing Machine (UTM) as per ASTM C67-0529. For the test, the brick specimens were placed in a Universal Testing Machine (UTM) and subjected to force until failure. Compressive strengths were then calculated using the following equation.

The permeability test was conducted by the standard falling head method described by ASTM D2434-6830. The test involved installing the brick in a permeability test setup, allowing water to flow through the brick, and monitoring the drop in water level over time. The permeability coefficient was then calculated using the following equation.

Where k is permeability coefficient (cm/s), a is the cross-sectional area of the water column (cm2), A is the cross-sectional area of the brick samples (cm2), l is specimen thickness (cm) and h1 and h2 are the initial and final height of water level (cm), respectively.

Measurement of near-surface temperature of the bricks

This study aims to evaluate the potential of permeable clay bricks as an alternative pavement material for mitigating urban heat island (UHI) effects by comparing their heat adsorption capacity with two conventional concrete bricks (red and white). Three types of pavement bricks were used for the study, two of which are commonly used. These bricks are made of concrete, one of which is red concrete bricks (RCBs) and another of white concrete bricks (WCBs). The other brick used in this study is permeable clay bricks (PCBs), proposed as an alternative to the currently used pavement bricks. To measure the near-surface temperature on these pavement bricks, the Benetech infrared thermometer was used. To ensure an accurate reading, the emissive was adjusted according to the material of each brick, based on the guidelines provided by Benetech. As the white and red pavement bricks are concrete, the unit’s emissivity was adjusted to 0.95. As for the permeable brick, which is made of clay emissivity was adjusted to 0.90. These bricks were placed under direct sunlight to simulate real-world exposure conditions. The surface near-surface temperature of sample pavements was collected and recorded for a week (Fig. 2). The study was conducted in Unizah City, Al-Qassim region, Saudi Arabia. This region is characterized by an arid climate with high temperatures and intense solar radiation, especially during daytime. Temperature readings were recorded three times during the daytime at 10:00 am, 3:00 pm, and 6:00 pm, and three times during the nighttime at 7:00 pm, 12:00 am, and 4:00 am, for five consecutive days. These measurements were conducted to evaluate the diurnal and nocturnal thermal behavior of the materials. On-site ambient weather temperatures were recorded alongside brick temperatures. The collected data was analyzed to determine whether the permeable clay bricks exhibit lower heat absorption compared to conventional concrete bricks. The cooling performance index (CPI) of permeable clay bricks was calculated using the following formula (Eq. 5).

Where, MTCBs is mean temperature of concrete bricks and MTPBs is the Mean temperature of permeable Bricks.

Stormwater samples collection and filtration experiments

Stormwater samples were collected from two rainwater storage ponds located at the Qassim University (QU) campus and in Buraidah City, Al-Qassim, Saudi Arabia. Figure 3 shows the detailed locations of the storage ponds. Two distinct stormwater samples, designated as SW1 and SW2, were obtained from these sites. SW1 was collected from the pond located within the Qassim University campus (26°21’12.40"N, 43°46’36.51"E), while SW2 was collected from a pond situated in Buraidah City (26°22’32.59"N, 43°56’16.27"E). The SW1 pond receives stormwater runoff from the campus catchment area, which includes academic and administrative buildings, a hospital, parking lots, staff residential buildings, and landscaped areas. In contrast, the SW2 pond receives stormwater runoff from various urban sources, including roadside washouts, supermarket parking lots, city plantations, residential buildings, and other impervious surfaces. This runoff typically contains a mixture of sediments, hydrocarbons, heavy metals, nutrients, and other urban pollutants. Sampling was conducted at three different locations within each pond, with triplicate samples collected at each site to ensure representativeness. The samples were collected and stored in pre-washed high-density polyethylene (HDPE) jars to prevent contamination during collection and transportation. After collection, the water samples were transported to the laboratory and stored at 4 °C to minimize biological or chemical changes before analysis. pH, dissolved oxygen (DO), alkalinity, biochemical oxygen demand over 5 days (BOD5), chemical oxygen demand (COD), total nitrogen (TN), total ammonium nitrogen (TAN), nitrate nitrogen (NO3-N), nitrite nitrogen (NO2-N) were analyzed within 48 h of sampling. For heavy metals, water samples were acidified with HCl solution and preserved in acid-washed glass bottles. Additionally, 200 L of stormwater was collected in HDPE jars to conduct filtration tests.

Stormwater sampling locations of (a) SW1 at Qassim University campus (left image) and (b) SW2 at Buraidah City, Al-Qassim, Saudi Arabia (right image). (image: google earth pro URL : https://www.google.com/earth/about/versions/#download-pro)

Figure 4 presents a schematic diagram of the filtration process conducted in this study. The filtration process consists of a stormwater storage tank followed by an acrylic glass filtration tank. The bottom layer of the filtration tank comprises 10 cm thick gravel with a size range of 5.0–20.0 mm. A permeable clay brick was placed and fixed on the top of the gravel layer. An effluent pipe was set at the bottom of the filtration tank to collect the filtered stormwater. A bulk amount of stormwater was stored in the storage tank and a mixer was employed to maintain homogeneity, preventing sedimentation and ensuring consistent influent quality (Fig. 4). A parasitic pump was used to feed the stormwater to the filtration tank at a flow rate of 8.5 L/h. This flow rate was chosen based on the calculated permeability coefficient of the clay brick used in the study. The stormwater filtration process involved allowing water to pass through a permeable clay brick layer by gravity. The filtered water was then collected in a designated filtered water tank. The filtration experiments were conducted in batch mode over three consecutive days, with each batch running for six hours per day. To assess the performance of the system, two separate sets of filtration experiments were carried out with SW-1 and SW-2. Both influent (raw stormwater) and effluent (filtered water) were collected daily and analyzed for pH, SS, alkalinity, dissolved oxygen (DO), electrical conductivity (EC), chloride ( Cl−) turbidity, bio-chemical oxygen demand (BOD5), Chemical Oxygen demand (COD), total organic carbon (TOC), total nitrogen (TN), ammonia nitrogen ( NH3-N), nitrate nitrogen ( NO3-N), nitrate nitrogen (NO2-N), total phosphorous (TP) and heavy metals including iron (Fe), manganese (Mn), boron (B), Barium (Ba), Chromium (Cr), cupper (Cu), lead (Pb) and zinc(Zn). The water quality of both raw stormwater and filtered water was analyzed following the standard methods defined by the American Public Health Association (APHA)31.

Results and discussions

Structural, mechanical, and hydrological characteristics of the permeable clay bricks

Table 1 outlines the structural, mechanical, and hydrological properties of the permeable clay bricks, including compressive strength, bulk density, porosity, water absorption, and permeability coefficient. Among these, compressive strength is a critical parameter for assessing the suitability of permeable bricks for application in permeable pavements. In this study, permeable bricks composed of 90% clay and 10% sawdust achieved a compressive strength of 20.1 MPa, significantly higher than the standard requirement of 17 MPa for pedestrian and light traffic paving bricks. The corresponding bulk density, porosity, and water absorption of the permeable bricks were measured at 2.48 g/cm³, 40.5%, and 18.3%, respectively. Typically, when sawdust is mixed with soil, the interparticle bonds between the soil particles weaken, leading to a significant reduction in compressive strength compared to conventional clay bricks25. However, the organic matter present in the sawdust was completely burned off during the firing process, creating pores in the bricks. This increases both porosity and water absorption capacity, thereby enhancing permeability. Therefore, it is crucial to select an appropriate ratio of sawdust to ensure the desired properties of permeable clay bricks. This study demonstrated that bricks made with 10% sawdust achieved a compressive strength of 20.1 MPa, water absorption of 18.3%, and porosity of 40.5%, meeting the ASTM C 902 standards for pedestrian and light traffic paving bricks32. Another important parameter for assessing the feasibility of permeable clay bricks is the permeability coefficient, as it directly influences the stormwater runoff infiltration capacity of the bricks. The permeable clay bricks in this study achieved a permeability coefficient of 0.042 cm/s, which is significantly higher than the typical threshold of 0.01 cm/s for fully pervious pavements. Overall, the bricks containing 10% sawdust provide sufficient compressive strength, porosity, and permeability to meet standards for pedestrian and light traffic applications. The combination of structural and hydrological properties makes these bricks suitable for use in permeable pavements, aiding in effective stormwater infiltration.

Comparison of near-surface temperature and cooling performance index (CPI) of permeable clay brick

Figure 5 presents the ambient air temperature and the near-surface temperatures of various pavement materials. Throughout the daytime measurement period, near-surface temperatures consistently exceeded ambient air temperatures, while at night, ambient air temperatures were higher than the near-surface values. This diurnal temperature fluctuation contributes significantly to thermal discomfort near pavement surfaces and exacerbates the urban heat island (UHI) effect. The data indicate that red concrete bricks (RCBs) and white concrete bricks (WCBs) exhibit considerably higher near-surface temperatures compared to the proposed permeable clay bricks (PCBs), especially during peak sun exposure at 10:00 am and 3:00 pm. However, by 6:00 pm, the near-surface temperatures of all pavement types converge, with negligible differences observed. At 10:00 am, the average ambient air temperature was recorded at 31.30C. The corresponding near-surface temperatures were 41.60C for RCBs, 40.60C for WCBs, and 39.40C for PCBs. This demonstrates that PCBs maintained the lowest surface temperature, being 2.20C cooler than RCBs and 1.20C cooler than WCBs, indicating better thermal performance and reduced heat retention. At 3:00 pm, PCBs showed superior cooling performance, maintaining surface temperatures at approximately 2.140C lower than both RCBs and WCBs. By 6:00 pm, the surface temperatures of all brick types aligned closely, ranging between 31.4 °C and 31.6 °C. During nighttime measurements, temperature differences were observed 1.5–1.6 °C at 7:00 pm, 0.8–0.90 C at 12:00 am, and 0.3–0.8 °C at 4:00 am. Notably, at 7:00 pm, PCBs still outperformed, maintaining lower surface temperatures, although the differences gradually diminished throughout the night. These results suggest that PCBs exhibit lower heat absorption due to their increased porosity, which minimizes the amount of solid material exposed to solar radiation. Permeable clay bricks demonstrate superior thermal performance compared to traditional concrete pavements by maintaining lower near-surface temperatures during peak heat periods. Their reduced heat retention capacity helps to mitigate the urban heat island effect and improve thermal comfort in urban settings, making them a promising and sustainable alternative for pavement construction in hot climates.

To quantitatively assess the thermal advantage of PCBs over conventional concrete bricks, the Cooling Performance Index (CPI) was calculated relative to RCBs and CBs. The CPI values, summarized in Table 2, reveal the superior heat reduction capabilities of PCBs during both daytime and nighttime. During the daytime, the CPI values were recorded as 5.0 and 3.0 at 10:00 AM, 4.1 and 4.2 at 3:00 PM, and 0.33 and 0.44 at 6:00 PM for RCBS and WCBs, respectively. At nighttime, the CPI values were 4.8 and 4.4 at 7:00 PM, 3.1 and 2.8 at 12:00 AM, and 1.3 and 3.6 at 4:00 AM, again for RCBS and WCBs, respectively. The CPI values highlight the ability of PCBs to significantly reduce surface heat retention compared to conventional concrete bricks. The heat reduction performance of PCBs is especially critical in arid and semi-arid climates, where daytime temperatures are typically extreme. Elevated temperatures in urban areas of arid and semi-arid regions such as Saudi Arabia, driven by the UHI effect, disrupt the microclimate, reducing environmental quality and negatively affecting human comfort and health33,34,35. By reducing surface heat, permeable clay bricks positively impact urban microclimates, offering better air quality, reduced cooling energy demands, and enhanced comfort, particularly during critical daytime periods. Therefore, permeable clay bricks support sustainable urban planning by lowering near-surface temperatures, enhancing thermal comfort for residents, and reducing heat-related stress.

Stormwater treatment performance of the permeable clay bricks

Two different stormwater samples, SW1 and SW2, were used to evaluate the stormwater treatment efficiency of permeable clay bricks. Among the two, SW1 exhibited higher levels of pollution compared to SW2. Key water quality parameters for both samples were analyzed before and after filtration, as summarized in Table 3. Additionally, the removal efficiency of various pollutants is visually presented in Fig. 6 (a-d). The results revealed a notable difference in the initial pH levels of the samples, with SW1 showing a slightly alkaline pH of 8.45, while SW2 had a pH of 7.61. The pH of both samples remained unchanged after filtration. Alkalinity levels were consistent with the pH values, measured at 102 mg/L for SW1 and 28 mg/L for SW2. A slight reduction in alkalinity was observed for SW1 after filtration, whereas SW2 exhibited a marginal increase. The observed increase in alkalinity for SW2 following clay brick filtration may be attributed to its slightly lower buffering capacity, which likely facilitated the dissolution of alkaline minerals such as calcium carbonate from the clay matrix. In contrast, the relatively stable pH and higher buffering capacity of SW1 may have limited mineral dissolution. Furthermore, the clay bricks may have absorbed certain alkaline species from SW1, contributing to the slight reduction in their alkalinity. Dissolved oxygen (DO) levels were similar for both SW1 and SW2, ranging from 7.6 to 7.8 mg/L, and remained unchanged after filtration. This suggests that no significant biological or chemical oxidation-reduction reactions occurred during the filtration process. A high concentration of suspended solids (SS) was measured in SW1 (881 mg/L) and SW2 (345 mg/L), indicating that both stormwater samples were heavily polluted by solids washed out during runoff. The permeable clay bricks demonstrated high removal efficiency for suspended solids, reducing SS levels to 10 mg/L for SW1 and 2.6 mg/L for SW2 after filtration. The inclusion of sawdust in the permeable clay bricks created sufficient pores (porosity of 40.4%, as shown in Table 1), which effectively trapped most of the suspended solids in the stormwater, thereby making the bricks highly suitable for stormwater treatment. Turbidity levels were measured at 51 NTU for SW1 and 13.8 NTU for SW2, both of which were significantly reduced to 0.7 NTU and 0.4 NTU, respectively, following filtration. These results indicate that the permeable clay bricks are also effective in removing colloidal particles from stormwater. The removal of suspended and colloidal particles by the PCBs was primarily attributed to the interference and absorption facilitated by the internal micro-pores in the brick surface layer25,36. Although elevated levels of electrical conductivity (EC), chloride (Cl⁻), and total dissolved solids (TDS) were observed in both SW1 and SW2, these parameters were not significantly reduced by filtration. This suggests that PCBs are ineffective in removing dissolved solids as their porous matrix primarily targets particulate and colloidal contaminants rather than dissolved ions.

The organic removal performance was assessed, and the results are presented in Fig. 6b; Table 3. Higher concentrations of BOD₅ and COD were measured in SW1, at 54 mg/L and 115 mg/L, respectively, compared to SW2, which had concentrations of 21.4 mg/L and 45.7 mg/L, respectively. Efficient removal of both BOD₅ and COD was observed for both stormwater samples. After filtration, the BOD₅ and COD concentrations were reduced to 12 mg/L and 26.9 mg/L for SW1 and 7.4 mg/L and 15.7 mg/L for SW2. The results indicate that permeable clay bricks can effectively remove organic matter from a wide range of polluted stormwater. Generally, organic removal occurs through biological oxidation and physicochemical absorption processes. Among these, the physical interception provided by the surface layer’s structure and absorption played a significant role in BOD5 and COD removal, particularly over shorter durations37,38. The higher TSS levels in the studied stormwater samples appear to include substantial particulate organic matter. As a result, the particulate fraction of the organics were primarily removed through physical straining by the micro-porous clay brick layer. In contrast, a portion of dissolved organics was removed via absorption onto the porous layers of the natural clay bricks. A previous study by Ogunmodede et al.39, similarly reported that natural clay exhibits sorption capabilities for organics in wastewater.

Nutrient removal performance was assessed, and the results are presented in Table 3; Fig. 6c. SW1 contained 12 mg/L of total nitrogen (TN), comprising 6.8 mg/L of ammonia nitrogen (NH₃-N), 0.05 mg/L of nitrite nitrogen (NO₂-N), and 4.9 mg/L of nitrate nitrogen (NO₃-N). In comparison, SW2 contained 2.1 mg/L of TN, with 0.89 mg/L, 0.25 mg/L, and 0.5 mg/L of NH₃-N, NO₂-N, and NO₃-N, respectively. The removal of TN was 9.8% and 31.4% for SW1 and SW2, respectively. Significant reductions in NH₃-N and NO₃-N concentrations were observed in both stormwater samples. However, NO₂-N removal was insignificant for the SW1 sample, while a notable removal percentage was achieved for SW2. Total nitrogen (TN) removal from stormwater largely depends on absorption within the filtration matrix, as well as biological nitrification and denitrification processes42,43. In this study, the biological processes were unlikely to occur due to the short filtration duration (6 h per day), limiting the activity of nitrifying and denitrifying bacteria. Therefore, it is evident that absorption mechanisms primarily contributed to TN removal, particularly for NH3 and NO3 compounds, via the clay brick layer. Previous studies have reported that natural clay minerals can adsorb NH3 and NO342. Additionally, cation exchange reactions may have contributed to NH₃–N removal, as clay bricks typically contain monovalent cations such as Na⁺ and K⁺36,44,45.

The initial total phosphorus (TP) concentrations in SW1 and SW2 were 2.1 mg/L and 1.8 mg/L, respectively, and were reduced to 1.7 mg/L and 1.1 mg/L after filtration. This corresponds to a TP removal efficiency of approximately 25–30%. Phosphorus removal by clay bricks can occur via chemical precipitation, absorption, and/or physical interception of particulate phosphorus within the pore structure of the bricks36. However, chemical precipitation typically occurs at pH levels above 9.046, whereas the pH values of SW1 and SW2 were 8.4 and 7.6, respectively, below the threshold for effective precipitation. Therefore, the observed phosphorus removal is attributed primarily to absorption into the clay minerals. Recent studies have confirmed that burnt clay bricks can effectively remove phosphorus from aqueous solutions through absorption mechanisms47.

The removal performance of various heavy metals by permeable clay bricks is presented in Table 3; Fig. 6d. A moderate to high range of heavy metal removal was observed. Although the levels of heavy metals in both SW samples were below the standard limits, the removals further reduced the concentrations, making the stormwater suitable for reuse. Among the heavy metals, Fe was reduced from 190 µg/L and 50 µg/L to 30 µg/L and 10 µg/L, respectively, for SW1 and SW2, corresponding to removal rates of 80–84%. Mn was also removed, decreasing from 80 µg/L to 14 µg/L for SW1 and from 39 µg/L to 17 µg/L for SW2. Significant removal of B (14.9%), Ba (68%), and Cr (40%) was observed from SW1, while these elements were not removed from SW2. This could be attributed to the differing physio-chemical characteristics of the collected stormwater samples. Cu, Pb, and Zn were also efficiently removed from both SW samples, with removal rates of 71.3% and 59.6% for Cu, 97% and 100% for Pb, and 31% and 74% for Zn from SW1 and SW2, respectively. pH is a critical parameter for the oxidation and precipitation of heavy metals during the infiltration process of stormwater. In this study, both SW1 and SW2 had average pH values of 8.4 and 7.6, respectively, which remained the same at 8.3 and 7.6 after infiltration through the clay bricks. Most metals can form precipitates within this pH range48, facilitating their removal by the micro-porous clay bricks. Additionally, some heavy metals, such as Cu and Zn, can be removed through nonspecific electrostatic absorption onto the clay-based bricks49. The heavy metal removal performance of the clay bricks indicates that clay bricks are a suitable alternative for removing pollutants from stormwater.

Table 4 shows the effectiveness of PCBs for removing various pollutants from rainwater runoff compared to other commonly used permeable pavement materials like ceramic bricks, porous asphalt, interlocking concrete pavers, and pervious concrete. Permeable Clay Bricks (PCBs) developed in our study exhibit superior or comparable performance across most key pollutants compared to existing materials. Their exceptional removal of heavy metals and suspended solids (SS), in particular, highlights their strong potential for sustainable urban stormwater management. While nutrient removal (TN, TP) is moderate, the overall treatment efficiency makes PCBs a highly promising alternative to conventional permeable pavements.

Practical implications of permeable clay bricks

Urban Heat Island (UHI) effects and stormwater pollution are interconnected challenges in modern cities, exacerbated by impervious surfaces, heat-absorbing materials, and unfiltered pollutant runoff. Urban Heat Island (UHI) effects are particularly pronounced in arid regions due to unique environmental and urbanization factors, including high solar radiation, sparse vegetation, extensive impervious surfaces, and low humidity. These factors amplify the UHI phenomenon, leading to several adverse impacts such as increased energy demand, heightened thermal discomfort, and exacerbated water stress. This study demonstrates that the heat absorption capacity and cooling performance index of permeable clay bricks make them superior to conventional concrete bricks in mitigating UHI effects by reducing surface heat through enhanced water infiltration and evaporation, contributing to a more sustainable urban environment in arid regions. Notably, approximately two-thirds of urban and semi-urban areas are currently covered by impervious pavement surfaces, highlighting the pressing need for sustainable alternatives like permeable clay bricks. Furthermore, filtration experiments in this study revealed that permeable clay bricks efficiently treat a wide range of pollutants in stormwater. Replacing impervious surfaces with permeable pavements offers multiple benefits, including improved water quality, enhanced groundwater recharge, and reduced load on existing storm drainage systems. In many urban areas of arid regions, including Saudi Arabia, the existing drainage infrastructure was originally designed for rainfall events of low intensity and short duration. The adoption of permeable pavements could address the limitations of these systems, offering a sustainable solution to modern urban challenges. Therefore, preamble clay bricks, characterized by their porous structure, provide a sustainable solution by mitigating urban temperatures and improving stormwater quality. Their dual functionality as heat moderators and pollutant absorbers offers a multifaceted approach to urban sustainability. These bricks are well-suited and meet the standards in terms of compressive strength, porosity, water absorption, and permeability coefficient for pavements designed for a wide range of potential applications, such as house lawns, driveways, walkways, parking lots, sidewalks, and even city streets with very light traffic, including small cars, motorbikes, bicycles.

The permeable clay bricks used in the present study have significant potential as a cost-effective and sustainable solution within Low Impact Development (LID) technologies. The raw materials used for manufacturing were locally available, with sawdust—a typical waste material—proving to be a valuable recycled component. Additionally, the manufacturing process for these bricks was simple, making them a low-cost solution due to the incorporation of recycled sawdust. With an estimated manufacturing cost of approximately $0.05 per brick, these permeable clay bricks are considerably more affordable than commercial concrete bricks in Saudi Arabia, priced between $0.50 and $0.75 per brick. Their affordability, coupled with minimal production energy requirements, positions these bricks as an economically and environmentally sustainable choice for permeable pavement systems. Unlike many existing LID technologies that depend on continuous runoff to function effectively, the proposed system can be designed for intermittent operation, making it particularly suitable for arid and semi-arid regions with low annual rainfall. Additionally, the permeable clay brick system requires minimal maintenance, further reducing its long-term operational costs compared to traditional LID solutions. Overall, permeable clay bricks offer a promising alternative for sustainable urban drainage systems, particularly in regions with challenging climatic conditions and limited water resources.

Conclusion and recommendations

This study demonstrated the superior performance of permeable clay bricks (PCBs) compared to conventional concrete bricks in mitigating urban heat island (UHI) effects and treating stormwater pollutants. PCBs fabricated with 10% sawdust exhibited favorable mechanical and hydrological properties suitable for pedestrian and light traffic applications. Key characteristics included a compressive strength of 20.1 MPa, bulk density of 2.48 g/cm³, porosity of 40.5%, water absorption of 18.3%, and a permeability coefficient of 0.042 cm/s. The porous structure of PCBs contributes significantly to both thermal regulation and pollutant removal, positioning them as a sustainable solution to contemporary urban environmental challenges. Thermal performance tests revealed that PCBs reduced near-surface temperatures by up to 2 °C and improved the Cooling Performance Index (CPI) by 5%, indicating effective heat dissipation and reduced thermal retention. In terms of stormwater treatment, PCBs achieved high removal efficiencies: up to 99% for SS, 77% for COD), 31–32% for total nitrogen (TN) and total phosphorus (TP), and 40–100% for various heavy metals. The infiltration experiments were conducted for a short duration (6 h per day over three days), which does not adequately reflect long-term operational performance. This limited testing period is insufficient to assess the effects of pore clogging on the permeability of the clay bricks. Furthermore, field-scale infiltration experiments are necessary to better understand clogging behavior, infiltration capacity, and the consistency of pollutant removal under real-world conditions. Therefore, a long-term field study, incorporating a properly designed permeable pavement system using clay bricks, is recommended for future research to evaluate their sustainability and effectiveness over time.

Data availability

Data will be made available on request from corresponding author.

References

Ghumman, A. R., Ghazaw, Y. M., Alodah, A., Shafiquzzaman, M. & Haider, H. Identification of parameters of evaporation equations using an optimization technique based on Pan evaporation. Water 12 (1), 228 (2020).

Brabec, E., Schulte, S. & Richards, P. L. Impervious surfaces and water quality: a review of current literature and its implications for watershed planning. J. Plan. Lit. 16 (4), 499–514 (2002).

Newman, A. P., Aitken, D. & Antizar-Ladislao, B. Stormwater quality performance of a macro-pervious pavement car park installation equipped with channel drain based oil and silt retention devices. Water Res. 47 (20), 7327–7336 (2013).

Haider, H., Ghumman, A. R., Al-Salamah, I. S., Ghazaw, Y. & Abdel-Maguid, R. H. Sustainability evaluation of rainwater harvesting based flood risk management strategies: A multilevel decision-making framework for arid environments. Arab. J. Sci. Eng. 10 (44), 8465–8488 (2019).

Mugume, S. N., Gomez, D. E., Fu, G., Farmani, R. & Butler, D. A global analysis approach for investigating structural resilience in urban drainage systems. Water Res. 81, 15–26 (2015).

Bhatt, A., Bradford, A. & Abbassi, B. E. Cradle-to-grave life cycle assessment (LCA) of low-impact development (LID) technologies in Southern Ontario. J. Environ. Manage. 231, 98–109 (2019).

Qin, Y. Urban flooding mitigation techniques: A systematic review and future studies. Water 12 (12), 3579 (2020).

Zhang, P. et al. Detailed quantification of the reduction effect of roof runoff by low impact development practices. Water 12, 1–19 (2020).

Hunt, W. F. et al. Low Impact Development Practices: Designing To Infiltrate in Urban Environments. Effects of Urbanization on Groundwater: an Engineering Case-Based Approach for Sustainable Development308–343 (American Society of Civil Engineers (ASCE), 2010).

Locatelli, L. et al. Hydrologic impact of urbanization with extensive storm water infiltration. J. Hydrol. 544, 524–537 (2017).

USEPA, Green Infrastructure in the Semi-Arid West, Low-Impact Development and Green Infrastructure in the Semi-Arid West. https://www.epa.gov/green-infrastructure/green-infrastructure-semi-arid-west#6, accessed on 18 January 2025.

Antunes, L. N., Ghisi, E. & Thives, L. P. Permeable pavements life cycle assessment: a literature review. Water 10 (11), 1575 (2018).

Mullaney, J. & Lucke, T. Practical review of pervious pavement designs. CLEAN- Soil. Air Water. 42 (2), 111–124 (2013).

Zhang, K., Yong, F., McCarthy, D. T. & Deletic, A. Predicting long term removal of heavy metals from porous pavements for stormwater treatment. Water Res. 142, 236–245 (2018a).

Zan, R., Stirling, R., Blackburn, A., Walsh, C. & Werner, D. Activated carbon amendment of sand in the base of a permeable pavement reduces total nitrogen and nitrate leaching. Sci. Tot Environ. 931 (2024), 172831 (2024).

Sun, Y. et al. Understanding the removal of heavy metals from stormwater runoff in permeable pavement system. Sci. Tot Environ. 930 (2024), 172642 (2024).

Wang, J. et al. Performance synergism of pervious pavement on stormwater management and urban heat Island mitigation: A review of its benefits, key parameters, and co-benefits approach. Water Res. 221, 118755 (2022).

Adresi, N., Yamani, A. R. & Tabarestani, M. K. Evaluating the effectiveness of innovative pervious concrete pavement system for mitigating urban heat Island effects, de-icing, and de-clogging. Constr. Build. Mater. 449, 138361 (2024).

Tu, L. et al. Surface urban heat Island effect and its relationship with urban expansion in nanjing, China. J. Appl. Remote Sens. 10, 026037 (2016).

Huang, K., Li, X., Liu, X. & Seto, K. C. Projecting global urban land expansion and heat Island intensification through 2050. Environ. Res. Lett. 14, 114037 (2019).

Bories, C., Borredon, M. E., Vedrenne, E. & Vilarem, G. Development of eco-friendly porous fired clay bricks using pore-forming agents: a review. J. Environ. Manage. 143, 186–196 (2014).

Thalmaiera, G. et al. Influence of sawdust particle size on fired clay brick properties. Mater. Constr. 70, 338 (2020).

Beal, B. et al. A comparison of thermal and mechanical properties of clay bricks prepared with three different pore-forming additives: vermiculite, wood ash, and sawdust. Environ. Prog Sustain. Energy. 38 (6), 13150 (2019).

Maza-Ignacio, O. T., Jiménez-Quero, V. G., Guerrero-Paz, J. & Montes-García, P. Recycling untreated sugarcane Bagasse Ash and industrial wastes for the Preparation of resistant, lightweight and ecological fired bricks. Constr. Build. Mater. 234, 117314 (2020).

Shafiquzzaman, M. et al. Sawdust recycling in the development of permeable clay paving bricks: optimizing mixing ratio and particle size. Sustainability 14, 11115 (2022).

Muñoz Velasco, P., Morales Ortíz, M. P., Mendívil Giró, M. A. & Muñoz Velasco, L. Fired clay bricks manufactured by adding wastes as sustainable construction material—a review. Constr. Build. Mater. 63, 97–107 (2014).

Xu, Y., Yan, C., Xu, B., Ruan, X. & Wei, Z. The use of urban river sediments as a primary Raw material in the production of highly insulating brick. Ceram. Int. 40, 8833–8840 (2014).

ASTM C20-00. Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water (ASTM International, 2000).

ASTM C67-05. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile (ASTM International, 2005). www.astm.org

ASTM D2434-68. Standard Test Method for Permeability of Granular Soils (Constant Head) (ASTM International, 2006).

American Public Health Association (APHA). Standard methods for the examination of water and wastewater. 21st edition, American Public Health Association, Washington, DC. (2005).

ASTM C902-15. Standard Specification for Pedestrian and Light Traffic Paving Brick. ASTM International, West Conshohocken, PA, 2015. (2015).

Li, H., Harvey, J. T., Holland, T. J. & Kayhanian, M. Corrigendum. The use of reflective and permeable pavements as a potential practice for heat Island mitigation and stormwater management. Environ. Res. Lett. 8, 049501 (2013).

Rehan, R. M. Cool City as a sustainable example of heat Island management case study of the coolest City in the world. HBRC J. 12, 191–204 (2016).

Mohajerani, A., Bakaric, J. & Jeffrey-Bailey, T. The urban heat Island effect, its causes, and mitigation, with reference to the thermal properties of asphalt concrete. J. Environ. Manag. 197, 522–538 (2017).

Yu, Z. et al. Performance of permeable pavement systems on stormwater permeability and pollutant removal. Environ. Sci. Pollut Res. 28, 28571–28584 (2021).

Zhang, Z. et al. Systematically investigated the influences of permeable pavement materials on the water quality of runoff: batch and column experiments. Water Air Soil. Pollut. 229, 155 (2018b).

Han, S., Yang, Y., Liu, S. & Lu, M. Decontamination performance and cleaning characteristics of three common used paved permeable bricks. Environ. Sci. Pollut Res. 28, 15114–15122 (2020).

Ogunmodede, O. T., Adebayo, O. L. & Ojo, A. A. Enhancing absorption capacity of clay and application in dye removal from wastewater. Int. Lett. Chem. Physi Astron. 39, 35–51 (2014).

MWE. Technical Guidelines for the Use of Treated Sanitary Wastewater in Irrigation for Landscaping and Agricultural Irrigation (Ministry of Water and Electricity, Kingdom of Saudi Arabia, 2006).

World Health Organization (WHO). Guidelines for the Safe Use of Wastewater. Excreta and Greywater, Volume 4: Excreta and Greywater Use in Agriculture (WHO, 2006).

Zhou, X. et al. Enhancing nitrogen removal in subsurface wastewater infiltration system with natural clay minerals. J. Water Proc. Eng. 69, 106878 (2025).

Song, R., Gong, Y., Li, J. & Li, X. Progress in controlling urban nonpoint source pollution by permeable pavement. Environ. Sci. Technol. 37 (05), 57–63 (2014).

Chen, T. et al. Advanced ammonia nitrogen removal and recovery technology using electrokinetic and stripping process towards a sustainable nitrogen cycle: A review. J. Clean. Prod. 309, 127369 (2021).

Abusultan, A. A. M., Wood, J. A., Sainio, T., Kemperman, A. J. B. & van der Meer, W. G. J. Ion exchange resin – Bipolar membrane electrodialysis hybrid process for reverse osmosis permeate remineralization: cation exchange resins equilibria and kinetics. Sep. Purific Technol. 317, 123798 (2023).

García, D. et al. Enhanced carbon, nitrogen and phosphorus removal from domestic wastewater in a novel anoxic-aerobic photobioreactor coupled with biogas upgrading. Chem. Eng. J. 313, 424–434 (2017).

Kulasooriya, T. P. K., Priyantha, N., Navaratne, A. N., Bandaranayake, A. & Lim, L. B. L. Efficient removal of phosphate from aqueous solution by burnt brick clay: static conditions. Desal Water Treat. 227, 177–187 (2021).

Uddin, M. K. A review on the absorption of heavy metals by clay minerals, with special focus on the past decade. Chem. Eng. J. 308, 438–462 (2017).

Veli, S. & Alyüz, B. Absorption of copper and zinc from aqueous solutions by using natural clay. J. Hazard. Mater. 2007,149 (1), 226–233. (2007).

Niu, Z. G., Lv, Z. W., Zhang, Y. & Cui, Z. Stormwater infiltration and surface runoff pollution reduction performance of permeable pavement layers. Environ. Sci. Pollut Res. 23, 2576–2587 (2016).

Liu, W., Feng, Q., Chen, W. & Deo, R. C. Stormwater runoff and pollution retention performances of permeable pavements and the effects of structural factors. Environ. Sci. Pollut Res. 27, 30831–30843 (2020).

Selbig, W. R., Buer, N. & Danz, M. E. Stormwater-quality performance of lined permeable pavement systems. J. Environ. Manage. 251, 109510 (2019).

Roseen, R. M., Ballestero, T. P., Houle, J. J., Briggs, J. F. & Houle, K. M. Water quality and hydrologic performance of a porous asphalt pavement as a storm-water treatment strategy in a cold climate. J. Environ. Eng. 138 (1), 81–89 (2012).

Acknowledgements

The researchers would like to thank the Deanship of Graduate Studies and Scientific Research at Qassim University for financial support (QU-APC-2025).

Author information

Authors and Affiliations

Contributions

Md. Shafiquzzaman: Conceptualization, Methodology, Investigation, Formal analysis, Supervision, Writing - original draft. Borhan Uddin: Formal analysis, data curation, Visualization, Writing - original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors declare no conflict of interest.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shafiquzzaman, M., Uddin, B. Evaluating preamble clay bricks for mitigating urban heat Island effects and stormwater pollution. Sci Rep 15, 23450 (2025). https://doi.org/10.1038/s41598-025-08603-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08603-0