Abstract

Self-lubricating rolling linear guides are high value-added, maintenance-free rolling functional components. In this article, a porous media with a directional pore structure is prepared by PTFE and pore forming agent naphthalene, the design of the slider end structure is optimized, and the oil film thickness of the rolling linear guide under different operating speeds, loads, and operating mileage are tested and tracked by a spectrometer to provide a comprehensive analysis of the self-lubricating performance of the rolling linear guide. The research results indicate that the oil film thickness is directly proportional to the slider operating speed, while the effects of load and operating mileage on the oil film thickness are not significant. The oil storage rate shows an inverse relationship with the operating mileage. The interconnected pores within the porous media demonstrate good directionality, and the porous oil storage media can achieve full film elastohydrodynamic lubrication of the rolling linear guide under different operating conditions, enabling self-lubrication and maintenance-free operation of the rolling linear guide. This research aims to provide a reference basis for the preparation and use of self-lubricating rolling linear guides.

Similar content being viewed by others

Introduction

Self-lubricating rolling linear guides are a type of high value-added1,2,3maintenance-free rolling linear guide that can be used in working environments requiring high cleanliness and where lubrication is inconvenient for high-altitude operations4,5,6. The porous media utilizes capillary action in its pores to achieve a continuous micro-output of lubricating oil, enabling the self-lubrication of the rolling linear guide, and thus it is gradually being applied to self-lubricating rolling linear guides7,8,9,10.

Self-lubricating rolling linear guides achieve self-lubrication by allowing lubricating oil to seep out from the porous oil storage media to the surfaces of the friction pairs11,12,13. After a period of operation, the surface of the porous oil storage media and its loading mechanism become covered with lubricating oil that has leaked from its pores, which does not participate in the lubrication process14,15,16resulting in the waste of the limited lubricating oil stored in the porous oil storage media, reducing the utilization rate of the lubricating oil in the porous oil storage media, and shortening the lifespan of the porous oil storage media17,18,19. On the other hand, the surplus leaking lubricating oil also causes pollution to the working environment to some extent20,21which is not conducive to environmentally friendly lubrication in the working conditions.

In the actual lubrication of the rolling linear guide, it is not that the more lubricating oil the better, but when the thickness of the lubricating oil film reaches the minimum oil film thickness, the surface of the friction pair can realize elastic hydrodynamic lubrication22,23,24. According to the theory of elastohydrodynamic lubrication (EHL), the lubrication state can be divided into three types: fully film elastohydrodynamic, partially film elastohydrodynamic, and boundary lubricationthe. The lubrication state of the rolling linear guide is not only determined by the thickness of the oil film, but also affected by the surface roughness of the friction pair, and the lubrication state can be comprehensively characterized and determined by the oil film parameters.

The good lubrication state of the friction pair surface of the rolling linear guide can not only improve the contact conditions between the rolling element and the track surface, avoid the occurrence of dry friction, on the one hand, reduce the motion friction of the slider, and cool the temperature rise of the contact pair to control the slider25,26,27. On the other hand, the lubricating oil film will change when the external working conditions change, which will affect the stiffness and dynamic characteristics of the rolling linear guide pair. However, at present, the change of oil film and its lubrication mechanism of self-lubricating rolling linear guide based on porous oil storage media under different working conditions are still unclear.

Therefore, this article proposes a novel porous media with directional pores, utilizing interconnected pore micro channels within the porous media to directionally deliver lubricating oil to the friction pair interface, thereby achieving self-lubrication of rolling linear guides and enhancing their self-lubrication performance. This article aims to provide a reference basis for the preparation of self-lubricating rolling linear guides using novel porous media.

Structural design and experiment

Structural design

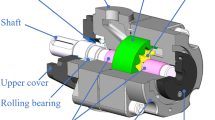

The directional lubrication structure involves the installation of a porous oil storage media with directional pores between the end of the slider reverser and the slider housing, as shown in Fig. 1. The porous oil storage media is prepared using a directional mold, with its directional opening facing downward towards the upper surface of the linear guide, and its shape reasonably adapted to the internal shape of the slider housing and the external structure of the slider reverser. When installed in the end cap of a rolling linear guide, the porous media of PTFE is supported by the end cap and does not have direct contact with the guide rail surface; it is positioned approximately 0.5 mm away from the guide rail surface.

By utilizing the directional porous oil storage media, lubricating oil is directed to seep out onto the friction surfaces of the slider and the rolling linear guide, achieving directional self-lubrication of the rolling linear guide. The axial thickness of the directional porous oil storage media in this structure can be reasonably adjusted according to the design requirements of the axial length of the slider housing; the axial thickness of the porous media determines its oil storage capacity, with a greater axial thickness allowing for a larger oil storage volume. In this experiment, the specification model of the slider is MSA30, and the thickness of the prepared porous media is 10 mm.

The steel ball used in the test is manufactured by Jiangsu Lixing General Steel Ball Co., Ltd., with a diameter of 4.7625 mm, a material of GCr15, a surface roughness value of 0.02 μm, and a surface roughness of 0.3 μm of the guide. The slider has four columns of rolling tracks, each containing about 13 steel balls.

Preparation of directional porous media experiment

The internal directional pores of porous oil storage media can allow lubricating oil to be directed towards the friction pair surface, which helps to improve the efficiency of lubricating oil use and reduce the impact of lubricating oil on the cleanliness of working conditions. The internal pores in porous media are mainly formed by the volatilization of pore forming agents at high temperatures inside the substrate.

To prepare directional pores, it is necessary to make the pore forming agent evaporate in a predetermined direction. According to this idea, when preparing porous media, a layer of high-temperature sealant is applied around the mixed molding blank, and an open surface without sealant is retained, which is the directional output surface of lubricating oil in the porous oil storage media. In a vacuum negative pressure atmosphere, the pore forming agent evaporates at high temperatures and escapes towards the directional opening surface, allowing the internal pores of the porous media to penetrate from the inside towards the directional opening surface, forming a porous media with directional pores. The preparation principle of directional porous oil storage media is shown in Fig. 2.

The experiment used Japanese Daikin PTFE powder as the substrate, which is a fine powder suspension resin with an average particle size of 0.025 mm. Naphthalene is selected as the pore forming agent, and the auxiliary material is mainly high-temperature sealant, which is used for the preparation of directional pores. The high-temperature sealant selected for the experiment is a red single component room temperature cured silicone sealant manufactured by Dongguan Jiu Glue Industry Co., Ltd., with the brand name JD9788MF. This sealant has good high-temperature aging resistance, with a long-term working temperature range of -60 ~ 400 ℃ and an instantaneous temperature resistance of up to 500 ℃. Before curing, it appears as a red paste with a relative density of 1.2 ~ 1.3 g/cm3. Mobil DTE32 lubricating oil is employed in the experiment. The testing conditions are at room temperature.

Self-lubrication test

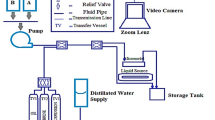

The evaluation of the self-lubricating performance of rolling linear guides mainly involves using an ultra-precision oil film tester to test the oil film thickness state of the slider when running on the ZDS-50 rolling linear guide life testing machine after the in-spallation of the self-lubricating structure of the rolling linear guide. It consists of 4 columns and 2 sets of rolling linear guide pairs, with the upper and lower sets of rolling linear guide pairs composed of load application devices. The theoretical running length of a single stroke of the rolling linear guide is 1.6 m (the actual round-trip mileage is 1.2 m), and the operating speed range of the slider is 0 ~ 1.5 m/s. The effects of operating speed, load, and operating mileage on the self-lubricating performance of rolling linear guides are tested in the experiment separately.

The oil film thickness is an important indicator for evaluating the self-lubricating performance of rolling linear guides. The oil film thickness test is conducted using spectral interferometry, and the PSD-200 W visible light oil film thickness tester from Hangzhou Yangtao Technology Co., Ltd. is used for in situ offline testing of the oil film thick-ness of rolling linear guides, as shown in Fig. 3.

The thickness measurement range of this device is 15 ~ 100 μm, with a refractive index of 100 nm and an accuracy of 2 nm or 0.5%. The measurement accuracy is 0.2 nm and the measurement speed is less than 20 s. The device is equipped with three standard test blocks of different thickness sizes (which should be certified by the national metrology department) for calibration and testing. The testing equipment adopts the single beam interference method for testing, and the beam is visible light with a wavelength of 380~1000 nm.

The main components include computer, data cable, spectrometer box, optical fiber and probe, probe fixture combination, etc. The probe fixture can be used to adjust the position of the probe above the guide for easy focusing of visible light in the probe. The spectrometer box integrates a spectrometer and a signal acquisition and reception device, mainly used for the emission and feedback signals of the light source. The probe is the main device for visible light emission and reception. The collected signals are processed and analyzed by the computer using Apris Spectra Sys software (Version number: Apris Server VISRef v3, https://max.book118.com/html/2022/0815/6132151000004224.shtm). The spectrometer is the Ocean Insight A3-SR-100 high-sensitivity spectrometer (380 ~ 1000 nm) from the United States, and the tungsten halogen light source (wavelength range 380 ~ 2000 nm) is produced by Ocean Insight from the United States. Meanwhile, the Y.CT-Precision industrial micro focus computed tomography (CT) system was used to perform tomography analysis of the internal pore structure of porous media.

Principle of optical interference tests for oil film thickness

When light is incident on the interior of lubricating oil, multiple reflection phenomena occur. The multiple reflections light will be enhanced or weakened due to the phase difference between them, and the phase difference depends on the refractive index and optical path of the lubricating oil. Therefore, the reflection spectrum of the lubricating oil is directly related to its thickness as shown in Fig. 4. The spectral interference method is to utilize this unique spectrum to analyze the thickness of the sample.

The spectrometer measures the oil film with absolute and refractive indexes, which reflect the percentage of visible light reflected/transmitted from the lubricant to the incident light. So a sample with a known refractive index must be used as a reference. For transmitted light, just use air as a reference because air transmittance is 100%. For reflected light, silicon wafers can be used as a reference.

The optical properties of a material can be described by two related physical quantities: the complex refractive index and the complex permittivity. The complex refractive index describes the propagation characteristics of light in a material, the real part of the refractive index describes the propagation speed of light in different media and the refractive properties in different media, and the imaginary part of the refractive index describes the attenuation characteristics of light in a media. The complex dielectric constant ε = ε1 + iε2 describes the microscopic response of a material to an electric field. The relationship between the refractive index and the dielectric constant is given by: ε = n². The Cauchy-Urbach optical model is employed in oil film thickness measurement of the experiment, which can be characterized by:

The calculated reflectance/transmittance can be compared with the measured reflectance or transmittance. For known materials, the thickness can be adjusted by computer or hand until the reflection/transmission spectrum is consistent with the measured results. Mean square deviation (MSE) is used to characterize the difference between the measured reflectance/transmittance curve and the calculated and fitted reflectance/transmittance curve.

Rmodel and Rexp are the calculated and measured reflectance respectively. N is the number of wavelengths, M is the number of parameters fitted, and σ(λk) refers to the uncertainty measured at a particular wavelength. The film thickness and refractive index of the oil film layer can be automatically fitted by software. Combined with the test conditions, the wavelength band selected for the fitting of the oil film thickness test was 800 ~ 900 nm, the integration time was 8 ms, the average number was 50, the smoothness was 2, the MSE was 0.0001, and the fitting method was Analysis.

Results

Oil film thickness

Figure 5 shows the spectral analysis of the oil film thickness on the surface of the tested rolling linear guide. It is obtained by collecting, analyzing, and fitting the signals tested by the spectrometer. The horizontal axis in the figure represents the oil film thickness, and it can be seen that the fitted curve shows a sinusoidal trend. The peak value is the tested oil film thickness value, and the selected test point in the figure has an oil film thickness value of 3396.197 nm. Therefore, after running a certain distance on the rolling linear guide, a spectrometer was used to conduct multi-point oil film thickness testing on the friction surface of the rolling linear guide. Thirty different positions on the surface of the rolling linear guide were selected to test the oil film thickness, and then the average value and variance analysis were taken.

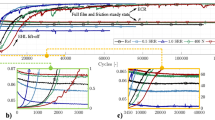

The influence of operating speed on the thickness of lubricating oil film

The oil film thickness of the directional lubrication rolling linear guide is shown in Fig. 6 with operating load is 2.938 kN and operating mileage is 2 km. It can be seen from the figure that the oil film thickness of the directional lubrication rolling linear guide shows a linear increasing trend with the change of speed. Linear fitting of this trend can obtain the fitting equation h = 1863.05v + 3413.01, and the fitted autocorrelation coefficient (Adj. R2) reaches 0.9962, showing a good linear fitting relationship. Furthermore, as shown in the figure, the error bar values of oil film thickness at different speeds are slightly smaller than those without directional lubrication, but still exhibit significant variability. From this, it can be seen that directional porous oil storage media can continuously leak lubricating oil onto the surface of the rolling linear guide pair, and the thickness of the lubricating oil film shows a linear positive effect relationship with the velocity.

The influence of operating load on the thickness of lubricating oil film

The relationship between the oil film thickness and the load variation of the directional lubrication rolling linear guide is shown in Fig. 7 with operating speed is 1 m/s and operating mileage is 2 km. It can be seen that the effect of load variation on the oil film thickness is not significant, and the oil film thickness fluctuates within a certain range (5452 ~ 6232 nm). In addition, compared with the error bar value of the oil film thickness of the non-directional lubrication rolling linear guide, the error bar value of the directional lubrication oil film is relatively small, which also indicates that under directional lubrication, the directional porous oil storage media can stably leak lubricating oil to the surface of the friction pair. The experimental result is consistent with the conclusions drawn in the literature28.

The influence of operating mileage on the thickness of lubricating oil film

The influence of operating mileage on the thickness of lubricating oil film and oil storage rate is shown in Fig. 8 with operating speed is 1 m/s and operating load is 2.938 kN. It can be seen that the operating mileage has no significant effect on the oil film thickness of the directional lubrication rolling linear guide as shown in Fig. 8-a. The oil film thickness fluctuates between 5486 ~ 5855 nm, and the standard deviation of the oil film thickness is smaller than that of the non-directional lubrication oil film thickness, indicating that the degree of dispersion of the oil film thickness is relatively small.

The analysis of the oil storage rate variation of the rolling linear guide during operation can be seen in Fig. 8-b. As shown in the figure, with the increase in the operating mileage of the rolling linear guide, the oil storage rate exhibits a slow linear decreasing trend. The linear fitting relationship between the oil storage rate ψ and the operating mileage d is ψ = -0.00572d + 58.361, with the fitted Adj. R2 reaching 0.9968 which indicating a good linear fitting relationship.

From the experimental results above, it can be observed that under the experimental conditions, the porous oil reservoir media is capable of continuously seeping out sufficient lubricating oil to ensure that there is an adequate lubricating oil film on the friction surfaces, and the impact of operating mileage on the thickness of the lubricating oil film is not significant.

Discussion

Minimum oil film thickness for self-lubricating rolling linear guide

The contact form between the ball and the guide in the rolling linear guide pair is point contact, and the Hamrock-Dowson formula can be used to analyze the oil film thickness in isothermal contact elastic lubrication. The Hamrock-Dowson formula can be expressed as:

Where hmin is the minimum oil film thickness, k is the ellipticity, k = a/b = 1.03(Ry/Rx)0.64, Rx is the equivalent curvature radius of the two surfaces in the xoz plane, and Ry is the equivalent curvature radius of the two surfaces in the yoz plane, which is described as:

R1x and R2x is the radius of curvature of the two surfaces in the xoz plane respectively, and R1y and R2y are the radius of curvature of the two surfaces in the yoz plane respectively. G, W and U are dimensionless parameters, which are respectively expressed as:

Material parameter G = αE, γ1 and γ2 are Poisson’s ratios. U is velocity parameter, U′ is the average surface velocity, U′ = 0.5(U1 + U2), U1 and U2 are the tangential velocities of the contact points of the two surfaces, respectively. W is load parameter. The lubrication state of the rolling linear guide is affected by the combined effect of the oil film thickness and the surface roughness of the friction pair. The lubrication state of the rolling linear guide can be characterized by the oil film parameter Λ:

σ1 and σ2 are the root mean square deviations of the surface roughness of the two friction pairs of the linear guide and the steel ball, respectively (σ = 1.25Ra). Therefore, according to the elastic flow lubrication theory, the lubrication state of the rolling linear guide can be characterized and analyzed by the oil film parameters as shown in Table 1. Thus, the minimum oil film thickness hmin can be calculated by experimental material values into the above formula as shown in Table 2.

Combined with the above testing results (Figs. 6, 7 and 8), it can be seen that the thickness of the lubricating oil film of the directional lubrication rolling linear guide prepared by the test is greater than 1.128 μm, which indicates that the prepared self-lubricating rolling linear guide is in the state of full membrane elastic flow lubrication during operation, and can achieve good lubrication of the friction pair of the rolling linear guide.

Cross-sectional scan images of porous media

To analyze the directional characteristics of the pore structure within the porous media, the oriented opening surface is used as the initial surface for the tomography scan. A layered scan is conducted every 0.36 mm along the central direction of the porous media, allowing for the acquisition of the pore structure characteristics at different layered cross-sections within the porous media, as shown in Fig. 9.

To track and analyze the directional features of the pores, typical pores from the tomography images are selected for analysis, with the pores indicated by the boxes in the figure. The cross-sectional shape of the pores near the oriented opening is relatively irregular (Fig. 9-a), and there is good connectivity between the pores, as one moves closer to the center of the porous media, the cross-sectional shape of the pore openings gradually diminishes (Fig. 9-b). The pores exhibit good consistency along the direction of the oriented opening surface (Fig. 9-c). As one approach the center of the porous media, the cross-sectional shape of the pores becomes more elongated (Fig. 9-d) and gradually connects with surrounding pores (Fig. 9-e). Thus, it can be observed that the internal pores of the porous media exhibit varying cross-sectional shapes and pore diameters, with the internal pores dispersing and converging, while maintaining a good directional characteristic towards the oriented opening surface.

The internal pore shapes and sizes of the oriented porous media vary, and the internal pores exhibit good orientation along the direction of the oriented openings. The internal pores are interconnected, with pore diameters randomly varying along the direction of the pores, presenting an “ink bottle” structure. This internal structure of the oriented pores facilitates oil storage and control under different operating conditions of the rolling linear guide.

Microscopic topography of porous media

The scanning electron micrographs of porous media are shown in Fig. 10. It can be seen that the surface of the porous media has numerous interconnected pores, which vary in shape and size, ranging from 149 micrometers (Fig. 10-a) to a few micrometers (8.91 μm, Fig. 10-b). The pores exhibit characteristics of cave type shapes, which assist in the storage of lubricating oil. Additionally, a fibrous structural organization is observed surrounding the pores, which aids in locking in the lubricating oil stored within.

Combining Figs. 9 and 10, it can be seen that the operating load is directly applied to the slider housing and indirectly affects the steel balls and the raceway, but does not directly act on the surface of the porous oil storage media. Although an increase in load will change the Hertzian contact pressure, under the premise that the porous oil storage media continuously seeps lubricating oil to the surface of the friction pair and considering the relatively limited mileage conditions in this experiment, the thickness of the lubricating oil film will not be significantly affected.

Conclusions

The impact of operating speed on the oil film thickness of the rolling linear guide is significant, and the relationship between the lubricating oil film and operating speed is essentially linear and positive. The effects of operating load and operating mileage on the oil film thickness are not significant. With the increase of operating mileage, the oil storage rate shows a basic linear negative effect relationship with operating mileage.

By optimizing the design of the slider structure, the prepared directional porous oil storage media can achieve full film elastohydrodynamic lubrication for the rolling linear guide friction pair under different operating conditions. This will also provide a reference basis for achieving self-lubrication and maintenance-free operation of the linear rolling guides.

The internal pore shapes and diameters of the porous media vary, with the interconnected pores exhibiting ink bottle shaped connection structure and cave type shape with fibrous structural organization. The internal pore structure is demonstrated favorable directional characteristics which help to achieve oil storage and oil seepage for porous oil storage media.

Data availability

The datasets generated during and/or analysed during the current study are not publicly available due to [the research data in the article is voluminous and not easy to upload, and the data involves industry secrets not to be disclosed] but are available from the corresponding author on reasonable request.

References

Wu, H. et al. Performance evaluation of directional porous oil storage media fabricated by PTFE and naphthalene. Mechanika 30, 438–443 (2024).

Musabbir Rahman, R. et al. A novel microfluidic approach to quantify porescale mineral dissolution in porous media. Sci. Rep. 15, 6342 (2025).

Shi, K., Jin, G., Yan, W. & Xing, H. Permeability Estimation for deformable porous media with convolutional neural network. Int. J. Num. Meth. Heat. Fluid Flow. 34, 2943–2962 (2024).

Xie, Q. et al. Reconstruction of porous media pore structure and simulation effect analysis of multi-index based on SNESIM algorithm. Sci. Rep. 15, 4856 (2025).

Wu, H. Wear characteristics of single diamond grit scratching on Sapphire with different contact forms. Ceram. Int. 47, 8840–8848 (2021).

Zou, Y., Deng, G. & Duan, Y. Investigation of combustion characteristics of critical quenching hydrogen mixing ratios in the presence of ordered porous media. Sci. Rep. 14, 32061 (2024).

Ren, L., Su, Y. & Zhan, S. Fully coupled fluid-solid numerical simulation of stimulated reservoir volume (SRV)-fractured horizontal well with multi-porosity media in tight oil reservoirs. Petr. Sci. Eng. 174, 757–775 (2019).

Xu, S. et al. Analysis and application of low frequency shadows based on the asymptotic theory for porous media. Sci. Rep. 14, 25773 (2024).

Wu, H., Huang, H., Jiang, F. & Xu, X. Mechanical wear of different crystallographic orientations for single abrasive diamond scratching on Ta12W. Int. J. Refract. Met. Hard Mat. 54, 260–269 (2016).

Bahrami, H. R. & Sharifi, A. E. Application of multilayered porous media for heat transfer optimization in double pipe heat exchangers using neural network and NSGA II. Sci. Rep. 14, 31509 (2024).

Sabet, S., Mobedi, M., Barisik, M. & Nakayama, A. Numerical determination of interfacial heat transfer coefficient for an aligned dual scale porous medium. Int. J. Num. Meth. Heat. Fluid Flow. 28, 2716–2733 (2018).

Yang, L., Teng, Q. & He, X. Super-dimension-based three-dimensional nonstationary porous media reconstruction from single two-dimensional image. J. Petr. Sci. Eng. 174, 968–983 (2019).

Wang, C., Zheng, X., Zhang, T., Chen, H. & Mobedi, M. The effect of porosity and number of unit cell on applicability of volume average approach in closed cell porous media. Int. J. Numer. Method Heat. Fluid Flow. 32, 2778–2798 (2022).

Eder, S., Bianchi, D. & Neacsu, I. An experimental and signal analysis workflow for detecting cold-induced noise emissions (cold squealing) from porous journal bearings. Mech. Syst. Signal. Pr. 115, 60–69 (2019).

Wu, H., Huang, H. & Xu, X. The influence of crystallographic orientation on wear characteristics during single abrasive diamond grit scratching on Sapphire. Ind. Lubr. Tribol. 70 (8), 1414–1421 (2019).

Mousapour, M. S. et al. Dynamics of HPAM flow and injectivity in sandstone porous media. Sci. Rep. 14, 28720 (2024).

Younes, M., Ali, C. & Ahmed, A. Nanofluid transport in porous media: a review. Spec. Top. Rev. Porous Med. Int. J. 10, 46–64 (2019).

Liu, C., Guo, R. & Su, Y. A deep learning based prediction model for effective elastic properties of porous materials. Sci. Rep. 15, 6707 (2025).

Li, L. & Yang, J. Surface roughness effects on point contact elastohydrodynamic lubrication in linear rolling guide with fractal surface topographies. Ind. Lubr. Tribol. 70, 589–598 (2018).

Ye, W., Jingyi, W. & Guang, Y. Numerical simulation of heat and momentum transport at the coupled interface between a rectangular channel and porous media. J. Therm. Sci. 31, 332–343 (2022).

Wu, H. & Huang, H. Influence of contact form on mechanical wear characteristics of single diamond scratching on Ta12W. Ind. Lubr. Tri. 72, 1311–1316 (2020).

Xu, X. et al. Black phosphorus nanosheet dotted with Fe3O4-PDA nanoparticles: A novel lubricant additive for tribological applications. Tribol. Int. 110607 (2025).

Xu, Z. et al. Electrochemically assisted laser surface microtexture Preparation and tribological properties research. J. Manuf. Pro. 122, 54–64 (2024).

Xu, Z. et al. A study on the fretting wear characteristic of inconcel 718 alloys formed by selective laser melting (SLM). Wear. 205858 (2025).

Long, R. et al. From experimentation to optimization: surface micro-texturing for low-friction and durable PTFE–Steel interfaces under full film lubrication. Polymers 16, 3505 (2024).

Long, R. et al. Influence of Monstera riedrichsthalii bionic textures on the tribological and vibration behavior of rolling bearings. Friction 13, 9440949 (2025).

Long, R. et al. Parameter optimization for the improvement of tribological behavior of textured tapered roller bearings. Lubricants 13, 165 (2025).

Zhang, C. & Sun, J. Elastic flow lubrication analysis of rolling linear guides (in Chinese). Mech. Des. 9, 27–29 (1997).

Acknowledgements

The authors would like to acknowledge the support of Natural Science Foundation of Fujian Province (Grant No. 2023J01248), Teacher Research and Innovation Team of Zhangzhou Institute of Technology (Grant No. zzyt23002), Fund of “Star of Innovation and Entrepreneurship” of Zhangzhou City (Grant No. ZhangWeiRenCai〔2021〕18#), Fund of the Institute of Manufacturing Engineering of Huaqiao University (Grant No. 2018IME-001), Education and Research Project for Middle and Young Teachers in Fujian Province (Grant No. JAT220684) and Doctoral Research Startup Funding of ZhangZhou Intitute of Techonlogy (Grant No. ZZYB2406 and No. ZZYB2407).

Author information

Authors and Affiliations

Contributions

H.W., N.L. and Y.C. designed the tests, and the experiment and data acquisition was performed by L.L., B.S. and Q.C.; H.W., G.X. and E.L. did the data analysis and figure generation; H.W. wrote the manuscript. The manuscript draft was revised by H.W. and N.L. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, H., Lin, N., Chen, Y. et al. Research on the self-lubricating performance of rolling linear guide based on directional porous media. Sci Rep 15, 20371 (2025). https://doi.org/10.1038/s41598-025-09055-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-09055-2