Abstract

During the mining process of deep coal mines, the coal thickness variation zone is highly prone to coal-rock-gas dynamic disasters. In order to promote the sustainable development of coal resource exploitation and utilization, the numerical simulation was carried out based on COMSOL software. The dynamic disaster mechanism of coal rock gas in the coal thickness variation area was revealed and corresponding prevention and control measures were given. Research shows that the stress concentration degree in the coal thickness variation area is higher. Compared with the non-variation area, the peak stress concentration coefficient increases by 29.4%, with the maximum value being 2.29. There is a temporary increase zone of gas pressure in front of the working face, with the maximum gas pressure reaching 0.82 MPa. The plastic zone in the coal thickness variation area is unevenly distributed, and the plastic deformation of the coal body in the thick coal zone is relatively large. The coal thickness variation zone and the thick coal zone accumulate a large amount of gas expansion energy. The gas expansion energy contained in the unit volume of coal obtained from the simulation is more than six times the elastic energy of the unit volume of coal and rock mass. The gas expansion energy plays a dominant role in disasters. When the coal seam is excavated from thin to thick in the coal thickness variation zone and thick coal zone, the peak energy criterion in the area near the working face is greater than 1 and keeps increasing, indicating that dynamic disasters occur and the degree of harm gradually increases. Comprehensive analysis shows that excavation from thick to thin is more likely to induce rock burst than excavation from thin to thick. Excavation from thin to thick is more likely to cause coal and gas outbursts than excavation from thick to thin. Practice shows that when using the high-pressure water jet slit drilling technology to prevent and control dynamic disasters in the coal thickness variation area, the reasonable slit spacing of coal seam drilling should be set at 3 m, and the average pure amount of gas extracted per hole is 2.6 times that of the ordinary drilling without slits. The hole spacing for drilling in coal seams of equal thickness and coal thickness variation areas should be set at 6 m and 8 m respectively. The stress peak is transferred to the deep part, which can effectively reduce the gas expansion energy and weaken the concentrated stress of the coal seam, and at the same time achieve the purpose of preventing outburst and eliminating protrusions.

Similar content being viewed by others

Introduction

With the increasing depth of coal mining year by year, affected by mining disturbances, the probability of coal-rock gas dynamic disasters in coal seams with deep high ground stress, high gas pressure and coal thickness variation zones has significantly increased, seriously affecting the safe mining of coal mines1,2,3. The in-situ stress of coal seams, gas pressure, lithology of roof and floor, and geological structure all play a controlling role in the occurrence of coal and rock gas dynamic disasters4,5,6. Ground stress and gas pressure act as power sources7. The release of the elastic energy of the roof rock can accelerate the failure of the coal body and increase the intensity of the disaster8,9. Geological structure can affect the distribution of local in-situ stress, causing changes in the thickness of coal seams and forming a coal thickness variation area. In this area, both gas pressure and in-situ stress present an uneven distribution, which is highly likely to induce coal-rock gas dynamic disasters10,11,12. For instance, the locations where coal and gas outbursts occurred in Guanglong Coal Mine in Qiannan13, Guizhou Province, No. 13 Mine in Pingdingshan14, Henan Province, Hancheng Mining Area in Shaanxi Province15 and Xiangshui Coal Mine in Guizhou Province16 are mostly located in the coal thickness variation zone.

For the coal, rock and gas dynamic disaster accidents in the coal thickness variation area induced by geological structures, domestic and foreign experts have conducted rich research in numerical simulation. Shu et al.17 studied the distribution laws of the advanced support pressure and elastic strain energy in the thickness and length variations of different coal thickness variation zones. Zhao et al.18,19 used the FLAC numerical simulation software to explore the dynamic disaster accidents occurring in the coal thickness variation zone from the mechanical perspective. The research shows that the excavation of the working face from thick to thin is more likely to cause rock burst compared with the excavation from thin to thick. Cao et al.20 clarified the dynamic disaster-causing mechanism of coal and gas outbursts from the mechanical mechanism level. Ma et al.21 systematically studied the disaster-causing mechanism of coal and gas outbursts in the coal thickness variation region by using the Comsol multi-physics field coupling simulation method. Hodott22 was the first to propose the energy criterion for the outburst of coal and gas. An23, Zhao et al.24 revealed the key control role of gas expansion energy on coal and rock gas dynamic disasters. Wang25, Kan et al.26 revealed the dynamic disaster-causing mechanism of coal and gas outbursts through multi-field coupling analysis of the stress field - damage field - gas flow field of the coal body. Xu et al.27 systematically characterized the heterogeneous distribution law of coal seam permeability. Chen et al.28 adopted the multi-field coupled numerical simulation method to systematically reveal the spatiotemporal evolution laws of the coal-rock stress field and the gas pressure field under mining conditions. Zhou et al.29 conducted A systematic study on the dynamic evolution law of coal seam pore pressure under mining disturbance conditions. Ma et al.30 studied the control mechanism of coal thickness variation on the mechanical properties of coal and rock (stress-strain relationship, strength parameters and energy accumulation law). Soleimani31, Lei et al.32 systematically clarified the disaster-causing mechanism of dynamic disasters in coal-rock-gas multiphase media based on the principle of energy conservation.

In the existing studies, some scholars, based on the FLAC numerical simulation software, only revealed the disaster-causing mechanism of rock burst in the coal thickness variation zone from the perspectives of stress field evolution and the accumulation of elastic energy in the coal body. In view of the actual situation of deep roadway engineering, the synergistic effect between coal seam gas and the ground stress field was not systematically considered. Although the gas flow process was simulated by Comsol software in part, the stress field, damage field, gas flow field and energy evolution law in the coal thickness variation area were not analyzed in depth. In a deep environment with high ground stress, the roof rock can accumulate a large amount of elastic energy. The release of the roof elastic energy can accelerate the failure of the coal body. Therefore, when studying the excavation of the coal thickness variation zone in deep roadways, the influence of the release of the roof elastic energy on the degree of disaster should be considered. In this paper, based on the Comsol software, a gas-solid coupling model of the dual-hole-fracture gas-bearing coal-rock structure was constructed. The energy equation of the coal-rock gas dynamic disaster considering the influence of the elastic energy of the roof was established and the energy criterion was proposed. From the perspective of excavation from thin to thick and from thick to thin at the working face, An in-depth study was conducted on the stress field, gas flow field, plastic failure zone and energy evolution law in the coal thickness variation zone. The mechanism of coal rock gas dynamic disaster in the coal thickness variation zone was explored. Technical measures for the prevention and control of dynamic disasters in the coal thickness variation zone by using high-pressure water jet slit drilling technology were proposed. The parameters of slit spacing and drilling spacing were optimized, and the prevention and control effects were applied and investigated. It provides methods and basis for the prevention and control of coal, rock and gas dynamic disasters in deep coal thickness variation areas.

Theoretical model construction

The constitutive relation equation of gas-containing coal body

The deformation control equation of gas-containing coal body is33,34,35:

Style, G, Fi respectively represent the shear modulus of coal and the volumetric stress in the i direction, MPa. ν represents Poisson’s ratio. pm, pf represents the gas pressure in the matrix and the fissure respectively. αf, αm represents the effective stress coefficient of fractures and matrix. K represents the volumetric modulus of the coal body. \(\:{\epsilon\:}_{\text{b}\text{m}\text{a}\text{x}}^{\text{s}}\) represents the maximum volume strain of adsorption. pc represents the adsorption deformation pressure.

Criterion equation of coal seam yield failure

The yield criterion of gas-containing coal body adopts the Drucker–Prager criterion:

Style, σ1, σ2, σ3 represents the three effective in-situ stresses of the coal body, MPa.

Equation of control for gas transportation in coal seams

The migration of gas can be divided into three parts: desorption, diffusion and seepage. The diffusion of gas conforms to Fick’s diffusion law, and the seepage of gas conforms to Darcy’s seepage law36,37,38.

The state of gas accumulation in coal seams

The gas in coal seams is mainly composed of free gas in fractures, free gas in matrix pores and adsorbed gas in the matrix.

The total mass of gas per unit volume of coal matrix is39:

Style, Mc represents the molar mass of methane, kg/mol; R represents the ideal gas constant, j/(mol K). T expressed temperature, K. VL represents the maximum adsorption capacity of the monolayer, kg. PL represents the adsorption equilibrium pressure when the adsorption capacity is half of the maximum adsorption capacity, MPa. ρa represents the apparent density of coal, kg/m3. ρs represents the gas density in the standard state, kg/m3. VM is the molar volume of methane in the standard state, m3/mol. φm represents the porosity of the matrix. φf represents the fracture rate.

Gas diffusion control equation

The pressure control equation of matrix gas can be expressed as40,41:

Style, L represents the fracture spacing, m.

Gas seepage control equation

The gas flow in the coal seam fractures is slow, and the gas seepage conforms to Darcy’s law. Its equation of conservation of mass is:

Style, υ represents the gas seepage velocity in the fissure, m/s. ke stands for the effective permeability of coal seams, Md. µ is the dynamic viscosity coefficient of the gas, Pa∙s.

The relationship equation between fracture gas pressure and time is42,43:

Energy equation and criterion of coal, rock and gas disaster

Essentially, the process of coal and gas outburst is actually a process of energy accumulation first, then transfer, and finally release. The disaster process can be understood from the perspective of energy accumulation and energy dissipation44.

Considering the influence of the elastic energy of the roof, the elastic energy accumulated in the coal body and the roof, as well as the gas expansion energy in the coal body, are defined as the disaster kinetic energy. The crushing work, ejection work, thermal energy, kinetic energy, and roof plastic deformation energy, etc. are defined as disaster energy dissipation45,46. Therefore, the energy balance equation of dynamic disaster of coal, rock and gas considering the elastic energy of the roof is:

Style, Wcoal represents the elastic property of coal body. Wrock represents the rock mass elasticity. N represents the gas expansion energy. W1 represents the crushing power. W2 represents the throwing function. W3 represents thermal energy, roof plastic deformation energy, etc.

For the sake of simplicity in analysis and calculation, the energy consumption of this disaster only considers the crushing energy. When the kinetic energy of the disaster is greater than the energy consumption of the disaster, the coal body will be at risk of instability. Therefore, in this paper, the ratio of catastrophe kinetic energy to catastrophe energy consumption is defined as the energy criterion, and the kinetic catastrophe energy criterion E of coal, rock and gas can be expressed as:

Elastic energy of the coal body

The elastic strain energy of coal body is approximately expressed as::

Style, Ecoal represents the elastic modulus of coal, MPa. νcoal represents the Poisson’s ratio of coal. Vp represents the volume of the plastic failure zone, m3.

Elastic energy of the rock mass

The derivation process of the elastic energy of the roof rock is as follows.

Suppose the elastic energy of coal per unit volume:

Then the elastic properties of the coal and rock mass are:

Style, σz represents the strength of coal and rock mass, MPa.

When considering the impact of gas, Ecoal is substituted by ΠEcoal, σ by τσ, and n by n/Π, where 0 < τ < 1 and 0 < Π < 1; Let σz = τAσ, so that A ≥ 1.

The elastic modulus Ez of the coal and rock mass and the elastic modulus Ecoal of the coal body are satisfied:

Style, 0 < Π < 1. m represents the thickness ratio of rock to coal. n is the ratio of the elastic modulus of rock coal.

The contribution rate of the roof elastic energy is:

By combining formula (10) ~ (13), we can get:

It can be concluded that:

To sum up, the roof rock makes the elastic energy of the system increase by at least Πm/n times that of pure coal.

Therefore, the elastic energy of the roof can be approximately expressed as:

Gas expansion energy

The gas stored in coal seams mainly includes free gas and adsorbed gas47.

The expansion energy of free gas

The expansion energy of free gas in a unit volume of coal is calculated by the following formula:

Style, patm represents atmospheric pressure, take a value of 0.1MPa. n retrieve a value1.25.

Adsorbed gas expansion energy

The adsorption gas expansion energy of a unit volume of coal is expressed as:

So the total gas expansion can be expressed as:

Work of crushing coal

The equation of coal body crushing work can be expressed as:

Style, s represents the newly added surface area of the coal body, m2. f represents the robustness coefficient.

By substituting Eqs. (9), (16), (19), (20) into Eq. (8), the formula E for obtaining the energy criterion of coal and gas outburst considering the elastic energy of the roof is:

When the energy criterion E > 1, the coal body in front of the roadway protrudes, and the larger E is, the greater the degree of protrusion hazard. When the energy criterion E < 1, the coal body in front of the roadway does not protrude. When the energy criterion E = 1, the coal body in front of the roadway is in an extreme equilibrium state and the coal body is about to protrude.

Numerical simulation analysis

Engineering background

The Duanshi Coal Mine is located about 20 km east of Qinshui County, Shanxi Province, China, near Jiafeng Industrial Zone. It is a protruding mine. Coal and gas outburst accidents mostly occur in the coal thickness variation area. Among them, in the 3110 working face, the coal seam thickness is 2.64 ~ 6.25 m. The gas content is 6.8 m3/t to 8.2 m3/t. The gas pressure value is 0.65 ~ 0.92 MPa. The average inclination Angle of the coal seam is 17°. The burial depth at the protrusion occurrence site is approximately 650 m. The compressive strength of the coal body is 12.5 MPa, the tensile strength of the coal body is 0.8 MPa, and there is about 8.5 m thick sandy mudstone above the coal seam.

Numerical simulation establishment

This numerical simulation simplifies the modeling of the coal seam in the 3110 working face of Duanshi Coal Mine at a certain scale. The Comsol software is used to conduct numerical simulation studies on the advanced support pressure, gas pressure, plastic zone distribution and energy evolution law during the coal seam mining process in the coal thickness variation zone. Among them, the control equation adopts the relevant equation shown in the second part.

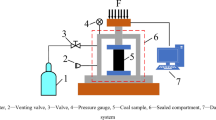

Among them, the solid mechanics module and the PDE module can respectively solve the stress-strain relationship, gas seepage and gas diffusion in the gas-bearing coal rock structure. The volume fraction of the damage variable greater than zero is taken as the plastic deformation volume of coal. A monitoring line is set up respectively in the center of the thin coal seam and in the rock 1 m away from the upper part of the coal seam to obtain the distribution curves of elastic energy, gas expansion energy and energy criterion. The entire solution process adopts steady state. The geometric model and boundary conditions are shown in Fig. 1. The model parameters were determined specifically based on reference 42 in combination with the engineering site, as detailed in Table 1.

Geometric feature

The dimensions of the geometric model are: x = 60 m, y = 22 m, z = 22 m. Among them, the top of the model is 8 m thick rock, the bottom of the model is rock with variable thickness ranging from 8 to 11.5 m, the middle is coal seam with variable thickness ranging from 2.5 to 6 m, the height of the mining and excavation roadway is 2.5 m, the width is 3 m, and the horizontal circulation excavation advance is 5 m.

Initial and boundary conditions

Solid module: a stress of 15 MPa (approximately 600 m) is applied at the top of the model. The bottom boundary is a fixed boundary, and the left, right, front and rear boundaries are all roller boundaries.

PDE module: the upper and lower as well as the right boundaries of the coal seam are the zero flow boundaries, and the roadway within the coal seam is the pressure boundary. The absolute pressure is 0.1 MPa of atmospheric pressure, and the initial gas pressure in the coal seam is 0.74 MPa.

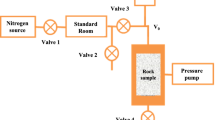

Simulation scenario

This simulation has formulated two excavation scenarios: from thin to thick and from thick to thin. The excavation modes of the two different scenarios are shown in Fig. 2.

Numerical simulation results

The pressure distribution of advanced support during the coal seam mining process

As can be seen from Fig. 3a–h, excavation will cause a stress concentration area to appear in a small section in front of the mining face. The advanced support pressure in this area is 15 MPa greater than the original rock stress. Before the stress concentration area appears, it will first pass through a pressure relief area. The advanced support pressure in the pressure relief area is less than the original rock stress. After the stress concentration area, the stress approaches the original rock stress.

It can be further seen from the two-dimensional line graph of Fig. 3g–h that when the coal seam is excavated from thin to thick to 5 m and 10 m, the working face is relatively far from the coal thickness variation zone, and there is a certain stress concentration area in the area of the coal thickness variation zone close to the thin coal seam. However, as the working face gradually excavates towards the coal thickness variation zone and the thick coal zone, the advanced support pressure is distributed in the form of a “single peak”. When the coal seam is excavated from thick to thin, stress concentration areas will be formed near the working face and in areas close to the thin coal seam, and the advanced support pressure is distributed in the form of “double peaks”.

Figure 4 presents the distribution of peak stress concentration coefficients at the seams of 5 m, 10 m, 20 m, 30 m, and 40 m during excavation. It can be seen that the peak stress concentration coefficients of the seams during excavation from thick to thin, from thin to thick, and excavation at the same thickness of 2.5 m all show an overall trend of increasing first and then decreasing. Compared with the uniform thickness excavation, the increase in the peak stress concentration coefficient from thin to thick and from thick to thin is greater at 20 m and 30 m. The peak stress concentration coefficients at 20 m and 30 m are 2.07, 2.29 and 2.28, 2.20 respectively, and the maximum value is 2.29.

The distribution of gas pressure during coal seam mining

For the gas pressure distribution of fractures and matrices, the calculation results of the two models have little difference. However, the gas pressure of the matrix is slightly higher than that of the fractures. Due to the limited space, only the cloud map of the gas pressure distribution of the matrix as shown in Fig. 5 is presented. It can be analyzed from Figs. 5(a) to (f) that the distribution of coal seam gas pressure in front of the working face is similar to the stress distribution, and it is also divided into the pressure relief area, the concentration area and the original area. Due to the fragmentation of the coal body, gas seeped out from the matrix and fractures, resulting in the gas pressure at the coal wall of the working face being much lower than the initial gas pressure. With the increase of the distance between the coal body and the working face, the gas pressure rises and reaches a peak of 0.82 MPa, which exceeds the initial gas pressure value of 0.74 MPa set in the simulation. It falls within the measured gas pressure range at the site. Moreover, the area above the 0.74 MPa gas pressure region becomes larger as the coal thickness variation zone approaches and as the thick coal seam excavation progresses.

The distribution of plastic failure areas during coal seam mining

The plastic deformation volume of coal was obtained by calculating the volume fraction of the damage variable greater than zero through numerical simulation. Figure 6 shows the distribution of the plastic failure zone at different excavation positions. The results show that the plastic zone in the coal thickness variation area is unevenly distributed. The plastic deformation of the coal body excavated from thin to thick keeps increasing, from 2.54 m3 to 17.91 m3. The plastic deformation of the coal body excavated from thick to thin generally shows a downward trend, from 18.34 m3 to 3.65 m3. The plastic deformation of the coal body in the thick coal zone is relatively large.

The energy evolution characteristics are prominent during the coal seam mining process

The elastic energy of coal body, the elastic energy of rock mass and the expansion energy of gas are all the main energies contributing to the dynamic disasters of coal, rock and gas. The control equations of the elastic energy of the coal body, the elastic energy of the roof and the gas expansion energy were imported into the Comsol software to simulate and obtain the evolution characteristics of the outburst energy of the excavated coal seam from thin to thick and from thick to thin.

It can be known from Figs. 7(a) to (f) that the elastic energy contained in the rock mass is approximately one-third of that contained in the coal body. The elastic energy contained in the rock mass is relatively large, and the influence of the elastic energy of the roof rock on disasters cannot be ignored. Elastic energy accumulation occurs near thin coal seams. If the dynamic disaster of coal rock gas is dominated by stress, when the coal seam is excavated from thick to thin, the formation of a high-energy area in the thinning area of the coal seam will hinder the transfer of energy to the deep part of the coal wall and easily induce rock burst, which is consistent with the research conclusion of Zhao Tongbin et al.19. The gas expansion energy per unit volume of coal obtained through simulation is more than six times the elastic energy of the coal-rock mass per unit volume. The gas expansion energy plays a leading role in disasters.

The distribution of dynamic disaster areas during the coal seam mining process

The energy criterion couples multiple physical fields such as the advanced support pressure, gas pressure, and plastic failure zone. The disaster energy criterion considering the influence of the elastic energy of the top plate (Eq. 21) is imported into the Comsol software. Through numerical simulation, the variation curves of the energy criterion for coal seam excavation from thin to thick and from thick to thin are obtained, and the possibility and danger of disaster occurrence are analyzed.

Figure 8 presents the schematic diagrams of the energy criteria for two excavation situations: from thin to thick and from thick to thin when advancing to different positions. It can be known from Fig. 8 that when the coal seam is excavated from thin to thick to the positions of 10 m and 20 m, the peak value of the energy criterion in the area near the working face is less than 1. When the coal seam is excavated from thin to thick to the positions of 30 m and 40 m, the peak value of the energy criterion in the area near the excavation working face is greater than 1, and the higher the coal seam is excavated, the greater the peak value of the energy criterion. When the coal seam is excavated from thick to thin to 10 m, 20 m, and 30 m, the peak value of the energy criterion in the area near the excavation working face is all greater than 1. When the coal seam is excavated from thick to thin to 40 m, the peak value of the energy criterion in the area near the excavation working face is less than 1. With continuous excavation towards thinner coal seams, the peak value of the energy criterion gradually decreases.

Analysis of coal rock gas dynamics disaster mechanism in coal thickness variation area

Analysis of the catastrophe process in the coal thickness variation area

Clarifying each stage of coal, rock and gas dynamic disasters and understanding the characteristics of each stage is the key to further recognizing the mechanism of disasters. The dynamic disaster of coal, rock and gas can be divided into four stages: gestation, activation, development and termination, as well as the causes, conditions and processes of the disaster47. The schematic diagram of the stage division of the disaster in the coal thickness variation area is shown in Fig. 9.

During the gestation stage of disaster, the coal seam forms a small structural coal seam thickness variation zone under the action of geological tectonic movement. Under the influence of mining and excavation operations, the original stress balance will be disrupted, causing the coal and rock mass to fail. A stress concentration area will be formed in front of the coal wall. This quasi-static deformation failure provides mechanical failure conditions for the subsequent disaster excitation in the coal thickness variation area.

In the disaster activation stage, under the action of ground stress and gas pressure, a large amount of coal and rock mass is broken and thrown out. The failure of coal provides a channel for the release of the elastic energy of the roof and the internal energy of gas. When the coal and rock mass in the coal thickness variation area are difficult to resist the combined effect of the elastic energy of coal and rock and the internal energy of gas, the coal body in the coal thickness variation area becomes unstable, and the elastic energy of the roof accelerates the failure of the coal body. The elastic energy effect of the roof cannot be ignored.

During the development stage of the disaster, the protruding holes further expand, and the coal and rock masses undergo failure forms such as roof fracture, layer fracture failure, and pulverization failure. In the middle, there will be pauses and re-triggers of the disaster.

During the termination stage of a disaster, the disaster stops when the energy released by the disaster is less than the energy dissipated by the disaster.

Analysis of the catastrophe mechanism in the coal thickness variation area

In the coal thickness variation zone, stress, plastic zone, gas and energy all show uneven distribution. Combined with the numerical simulation results and Fig. 10, the coal-rock gas dynamic disaster accidents occurring in the coal thickness variation zone can be analyzed from two situations.

Situation One: Stress plays a dominant role in disasters, and the gas content and gas pressure in coal seams are relatively small. According to the distribution laws of the advanced support pressure and elastic energy in Figs. 3g, 7a–c, it can be known that when the coal seam is excavated from thin to thick to the 30 m and 40 m coal thickness variation zones and thick coal zones, only near the excavation working face exist the stress concentration area and the high elastic energy area, which are distributed in the form of a “single peak”. The pressure and elastic energy of the advanced support can be normally transferred from the thin coal area to the thick coal area. It can be known from Figs. 3h, 7d–f that when the coal seam is excavated from thick to thin, there are two stress concentration areas and a high elastic energy area in front of the excavation working face, distributed in a “double peak” form. Among them, the high elastic energy area formed 40 m near the thin coal seam will hinder the transfer of elastic energy to the deep part of the coal seam. Therefore, excavation of coal seams from thick to thin is more likely to induce rock burst than excavation of coal seams from thin to thick48.

Situation Two: Gas expansion can play a dominant role in disasters. As can be seen from Fig. 3, the area close to the thin coal seam in the coal thickness variation zone will form a stress concentration area with a relatively high peak stress, resulting in a decrease in permeability in this area and the formation of a low-permeability zone. The low-permeability zone will block the gas migration in the thick coal zone. It can be seen from Figs. 5, 6 and 7 that the plastic deformation of the coal body in the thick coal zone is relatively large. The deeper the thick coal seam is excavated, the larger the area of the gas pressure higher than 0.74 MPa becomes. The coal body is soft and prone to form an abnormally rich gas area, and the gas expansion energy increases accordingly. It can be known from Fig. 10 that when the coal seam is gradually mined from the thin coal zone to the coal thickness variation zone and the thick coal zone, the peak energy criterion in the area near the 30 m and 40 m working faces during mining will exceed 1 and become larger and larger, indicating that the outburst occurs and the degree of harm is also increasing. When the coal seam is excavated from thick to thin, the peak value of the energy criterion in the area near the mining face becomes smaller and smaller. The closer to the thin coal area, the smaller the risk of outburst. Only in the coal thickness variation areas of 10 m, 20 m, and 30 m and the thick coal zone, the peak value of the energy criterion is greater than 1 and outburst occurs. When the excavation reaches 40 m, the peak value of the energy criterion near the mining face is less than 1 and outburst does not occur. Therefore, from the perspective of energy, a comprehensive analysis shows that excavation from thin to thick is more likely to cause coal and gas outbursts than excavation from thick to thin.

As can be seen from Fig. 7, in this study, gas expansion can play a dominant role in disasters, which conforms to the second situation in the above analysis.

Prevention and control of coal, rock and gas dynamic disasters in coal thickness variation areas

Protective measures

Based on the numerical analysis of the coal rock gas dynamic catastrophe mechanism in the coal thickness variation zone, the gas expansion can play a dominant role in the catastrophe. When the coal seam is gradually mined from the thin coal zone to the coal thickness variation zone and the thick coal zone, the peak value of the energy criterion near the working face at 30 m and 40 m will exceed 1 and keep increasing, indicating that outbursts will occur and the degree of hazard will also increase. Therefore, the focus of prevention and control is to reduce the gas expansion energy in the coal thickness variation zone and the thick coal seam, secondly by reducing the elastic energy of coal and rock masses. Based on this, the subsequent prevention and control work will be carried out.

This paper mainly adopts the high-pressure water jet slit drilling technology for disaster prevention and control49,50,51. It can be specifically divided into two parts: regional and local. Regional prevention and control: For the roof, uniformly drill holes through the roof from the mining coal seam upwards to unload and dissipate energy. For coal seams of equal thickness, drill holes along the transverse layer of the mined coal seam for pressure relief and permeability enhancement. Local prevention and control: When excavating to the coal thickness variation zone and thick coal seams, increase the number of construction holes diagonally downward from the mined coal seam, thereby effectively reducing the gas expansion energy in the coal thickness variation zone and thick coal seams. The prevention and control measures for dynamic disasters in the coal thickness variation area are shown in Fig. 11.

Optimization of drilling parameters and prevention and control effects

Drilling tests were conducted at the 3110 working face of Duanshi Coal Mine. The specific working condition information is shown in Part Three. Some drilling parameters were determined through relevant tests and are as follows.

Roof drilling

The rotation speed of the drill pipe is 80 r/min, the single-blade slit time is 9 min, the slit pressure is 100 MPa, the slit spacing is 2 m, and the final hole position of the drilling is at 2/3 of the roof thickness. There are 3 holes in each group. According to the engineering geological conditions and test experience of the test site, the hole spacing of the roof drilling is set at 10 m. Front-layer drilling: The rotation speed of the drill pipe is 80 r/min, the single-blade cutting time is 7 min, the average single-hole cutting time is 2.5 h, the cutting pressure is 80 MPa, and the depth of the front-layer drilling hole is 80 m. Denser drilling in the coal thickness variation area: The rotation speed of the drill pipe is 80 r/min, the single-blade slit time is 7 min, the slit pressure is 80 MPa, the final hole position of the drilling is at 2/3 of the thick coal seam, and there are 3 drilling holes in each group. The specific optimization design of the slit spacing and borehole spacing parameters is as follows.

Slit spacing

Four groups of boreholes were constructed in the coal seam of the 3110 working face, with a slit spacing of 2 m (M1), a slit spacing of 3 m (M2), a slit spacing of 4 m (M3), and no slit spacing (M4). Each group was set with 30 boreholes, with a spacing of 60 m, as shown in Fig. 12.

The purity of gas extracted from a single hole within 30 days in 4 groups was statistically compared. It can be seen from Fig. 13 that when the slit spacing was 2 m, the average purity of gas extracted from a single hole was 0.044 m3/min. When the slit spacing is 3 m, the average purity extracted from a single hole is 0.072 m3/min. When the slit spacing is 4 m, the average purity extracted from a single hole is 0.057 m3/min. When no slit was cut, the average purity extracted from a single well was 0.028 m3/min. When the slit spacing was 3 m, the average pure extraction volume of a single hole was the largest among the four groups, which was 2.6 times that of the ordinary boreholes without slits. The reasonable slit spacing of the coal seam boreholes in the test area was set at 3 m.

Drilling spacing

Based on the engineering geological conditions and test experience of the test site, the pressure relief effects of three groups of boreholes with original stress, borehole spacing of 6 m, and borehole spacing of 8 m in the coal seam along the layer were compared, as shown in Fig. 14. The pressure relief effects of three groups of boreholes with original stress, hole spacing of 8 m, and hole spacing of 10 m in the coal thickness variation area were compared, as shown in Fig. 15.

It can be seen from Fig. 14 that the peak stress concentration coefficients after high-pressure water jet slit pressure relief at the original stress, hole distance of 8 m, and hole distance of 6 m are 2.2, 1.8, and 1.4 respectively. The peak stress concentration coefficient at the hole distance of 8 m decreases by approximately 18.2%, and that at the hole distance of 6 m decreases by approximately 36.4%. The distances from the working face corresponding to the peak stress are 5 m, 7 m and 10 m respectively, and the stress peak shifts to the deep part. The best pressure relief effect is achieved when the borehole spacing of the coal seam is 6 m along the layer.

It can be seen from Fig. 15 that the peak stress concentration coefficients after high-pressure water jet slit pressure relief at the original stress, hole distance of 10 m, and hole distance of 8 m are 2.3, 2.0, and 1.5 respectively. The peak stress concentration coefficient at the hole distance of 10 m decreases by approximately 13.1%, and that at the hole distance of 8 m decreases by approximately 34.8%. The distances from the working face corresponding to the peak stress are 4 m, 7 m and 11 m respectively, and the stress peak shifts to the deep part. The pressure relief effect is the best when the hole spacing of the densified boreholes in the coal thickness variation area is 8 m.

Conclusion

The variation of coal seam thickness has significant influences on the advanced support pressure, gas pressure, plastic failure zone and the distribution of various energies of the coal body in front of the tunneling face. The gas dynamic disaster of coal rock in the coal thickness variation zone is caused by the superposition and combination of multiple factors. Based on the Comsol software, a gas-solid coupling model of the dual-pore - fracture gas-bearing coal-rock structure was constructed. From the perspective of excavation from thin to thick and from thick to thin in the working face, the occurrence mechanism of gas-bearing dynamic disasters in the coal-rock thickness variation area was discussed. The main conclusions obtained are as follows:

-

(1)

The peak stress concentration coefficient in the coal thickness variation zone is relatively large, with the maximum value reaching 2.29. When considering the coal-rock gas dynamic disaster dominated by stress, when the coal seam is excavated from thick to thin, the advanced support pressure shows a “double peak” distribution. The high elastic energy area formed in the thinning area of the coal seam will hinder the energy transfer to the deep part of the coal wall and is more likely to induce rock burst. When gas expansion can play a dominant role in disasters, the excavation of coal seams from thin to thick is more likely to cause coal and gas outbursts than that from thick to thin.

-

(2)

The coal thickness variation zone and the plastic zone within the thick coal zone are unevenly distributed, and the plastic deformation of the coal body in the thick coal zone is relatively large. The roof rock can accumulate a relatively large amount of elastic energy. The elastic energy of the rock mass obtained through simulation is approximately one-third of that of the coal body. Therefore, the influence of the elastic energy of the roof rock on disasters cannot be ignored. The coal thickness variation zone and the thick coal zone are prone to form abnormally rich areas of gas, accumulating a large amount of gas expansion energy. Simulations show that the gas expansion energy stored in a unit volume of coal is more than six times the elastic energy of a unit volume of coal and rock mass, and the gas expansion energy plays a dominant role in dynamic disasters.

-

(3)

The energy equation of coal and gas outburst considering the influence of roof elastic energy was established, and the disaster energy criterion considering the influence of roof elastic energy was derived. Studies show that when the coal seam is excavated from thin to thick to the 30 m and 40 m coal thickness variation zones and thick coal zones, the peak energy criterion in the area near the working face is greater than 1 and shows a gradually increasing trend, indicating that dynamic disasters occur and the degree of harm gradually increases.

-

(4)

The application of high-pressure water jet slit drilling technology for disaster prevention and control can effectively reduce the gas expansion energy in the coal thickness variation zone and the concentrated stress in coal and rock masses. Practice shows that the reasonable slit spacing of coal seam boreholes should be set at 3 m, and the average pure amount of gas extracted per hole is 2.6 times that of ordinary boreholes without seams. The pressure relief effect is the best when the hole spacing of the coal seam with equal thickness and the coal thickness variation area is 6 m and 8 m respectively, and the stress peak shifts to the deep part.

Data availability

The data that support the findings of this study are available from the corresponding author T.C.L.

References

Zhang, C. et al. Prediction of rockbursts in a typical Island working face of a coal mine through microseismic monitoring technology. Tunn. Undergr. Space Technol. 113, 103972 (2021).

Li, G. et al. A new determination method of hydraulic support resistance in deep coal pillar working face. Sci. Rep. 15 (1), 1–17 (2025).

Liu, T. et al. Crack instability in deep coal seam induced by the coupling of mining unloading and gas driving and transformation of failure mode. Int. J. Rock Mech. Min. Sci. 170, 105526 (2023).

Zhou, B. et al. Influence of Geo-stress on dynamic response characteristics of coal and gas outburst. Rock Mech. Rock Eng. 53, 4819–4837 (2020).

Xu, P. et al. Effect of polymeric aluminum chloride waste residue and citric acid on the properties of magnesium oxychloride cement. J. Building Eng. 101, 111864 (2025).

Zhang, X., Tang, J., Pan, Y. & Yu, H. Experimental study on intensity and energy evolution of deep coal and gas outburst. Fuel 324, 124484 (2022).

Wang, B., Xu, H., Zhang, Q., Shen, Z. & Jin, Y. Experimental study on the mechanism of rockburst in tunnel construction by drilling and blasting construction in high ground stress stratum. Sci. Rep. 15, 8914 (2025).

Xie, Z., Zhang, N., Yuan, Y., Xu, G. & Wei, Q. Study on safety control of composite roof in deep roadway based on energy balance theory. Sustainability 11 (2019).

Hao, Y., Li, M., Wang, W., Zhang, Z. & Li, Z. Study on the stress distribution and stability control of surrounding rock of reserved roadway with hard roof. Sustainability 15 (2023).

Tu, Q. et al. Experimental study on the guiding effect of tectonic coal for coal and gas outburst. Fuel 309, 122087 (2022).

Cao, Z. et al. Disaster-causing mechanism of spalling rock burst based on folding catastrophe model in coal mine. In Rock Mechanics and Rock Engineering 1–14 (2025).

Srivastava, M. K., Kishor, K., Singh, A. K., Mukherjee, S. & Bharti, S. K. Tectonically deformed coal: focus on microstructures & implications for basin evolution. Mar. Pet. Geol. 172, 107223 (2025).

Shi, X. & Song, D. Study of the solid–gas–stress coupling model and its application. Sci. Rep. 13, 5135 (2023).

Yang, M. et al. Coal pore structure changes in upper protective seam after mining: Pingdingshan Shenma group, Henan province, China. J. Petrol. Sci. Eng. 218, 111045 (2022).

Liu, H., Yang, Y., Jiao, W., Wang, S. & Cheng, F. A new assessment method for the redevelopment of closed coal Mine—A case study in Shanxi Province in China. Sustainability 14 (2022).

Kong, B., Cao, Z., Sun, T., Qi, C. & Zhang, Y. Safety hazards in coal mines of Guizhou China during 2011–2020. Saf. Sci. 145, 105493 (2022).

Liu, Z., Shu, L., Huo, Z. & Fan, Y. Numerical study on the mechanism of coal and gas outburst in the coal seam thickening area during mining. Energies 16 (2023).

Guo, W. Y. et al. Mechanical behavior of rock-coal-rock specimens with different coal thicknesses. Geomech. Eng. 15, 1017–1027 (2018).

Tong-bin, Z., Wei-yao, G. U. O., Yun-liang, T. A. N. & Ze, Z. & Kang-kang, C. Mechanics mechanism of rock burst caused by mining in the variable region of coal thickness. J. China Coal Soc. (2016).

Cao, Z. et al. Disaster-Causing Mechanism of Spalling Rock Burst Based on Folding Catastrophe Model in Coal Mine (Rock Mechanics and Rock Engineering, 2025).

Ma, X., Zhou, A., Cheng, X., Cheng, C. & Zhao, W. Multi-Field coupling models of coal and gas and their engineering applications to CBM in deep seams. Rev. Energies 17 (2024).

Zhu, J. et al. Multiscale pore structure characteristics and crack propagation behavior of coal samples from high gas seam. Materials 15 (2022).

An, F., Yuan, Y., Chen, X., Li, Z. & Li, L. Expansion energy of coal gas for the initiation of coal and gas outbursts. Fuel 235, 551–557 (2019).

Zhao, Y. & Niu, X. Experimental study on work of adsorption gas expansion after coal and gas outburst excitation. Front. Earth Sci. 10 (2022).

Wang, K. et al. Mechanisms of Energy Release in Fracture and Gas Expansion-Driven Instabilities of Coal–Rock Composite Structure: Theoretical Modeling and Experimental Validation (Rock Mechanics and Rock Engineering, 2025).

Kan, Z. et al. Advances and trends in multi-field coupling induced disaster similarity theory within deep ground engineering. Geomech. Geophys. Geo-Energy Geo-Resources. 10, 187 (2024).

Xu, C., Yang, G., Wang, K. & Fu, Q. Uneven stress and permeability variation of mining-disturbed coal seam for targeted CBM drainage: A case study in Baode coal mine, Eastern Ordos basin, China. Fuel 289, 119911 (2021).

Chen, Y., Chu, T., Chen, X. & Chen, P. Coupling of stress and gas pressure in dual porosity medium during coal seam mining. Powder Technol. 367, 390–398 (2020).

Zhou, A., Hu, J., Wang, K. & Du, C. Analysis of fault orientation and gas migration characteristics in front of coal mining face: implications for coal-gas outbursts. Process Saf. Environ. Prot. 177, 232–245 (2023).

Ma, Q., Tan, Y., Liu, X., Gu, Q. & Li, X. Effect of coal thicknesses on energy evolution characteristics of roof rock-coal-floor rock sandwich composite structure and its damage constitutive model. Compos. Part. B: Eng. 198, 108086 (2020).

Soleimani, F., Si, G., Roshan, H. & Zhang, Z. Numerical modelling of coal and gas outburst initiation using energy balance principles. Fuel 334, 126687 (2023).

Lei, Y., Cheng, Y., Wang, L., Ren, T. & Tu, Q. Mechanisms of coal and gas outburst experiments: implications for the energy principle of natural outbursts. Rock Mech. Rock Eng. 56, 363–377 (2023).

Hosking, L. J., Chen, M. & Thomas, H. R. Numerical analysis of dual porosity coupled thermo-hydro-mechanical behaviour during CO2 sequestration in coal. Int. J. Rock Mech. Min. Sci. 135, 104473 (2020).

Wu, Y. et al. Dual poroelastic response of a coal seam to CO2 injection. Int. J. Greenhouse Gas Control. 4, 668–678 (2010).

Li, W. et al. A fully coupled multidomain and multiphysics model considering stimulation patterns and thermal effects for evaluation of coalbed methane (CBM) extraction. J. Petrol. Sci. Eng. 214, 110506 (2022).

Si, L., Li, Z., Yang, Y. & Gao, R. The stage evolution characteristics of gas transport during mine gas extraction: its application in borehole layout for improving gas production. Fuel 241, 164–175 (2019).

Xu, C., Qin, L., Wang, K., Sun, H. & Cao, M. Gas seepage laws based on dual porosity and dual permeability: numerical simulation and coalbed methane extraction practice. Energy Sci. Eng. 9, 509–519 (2021).

Zhang, B., Wang, H., Wang, P., Yu, G. & Gu, S. Experimental and theoretical study on the dynamic effective stress of loaded gassy coal during gas release. Int. J. Min. Sci. Technol. 33, 339–349 (2023).

Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 40, 1361–1403 (1918).

Fan, Y., Shu, L., Huo, Z., Hao, J. & Li, Y. Numerical simulation of sectional hydraulic reaming for methane extraction from coal seams. J. Nat. Gas Sci. Eng. 95, 104180 (2021).

Lim, K. T. & Aziz, K. Matrix-fracture transfer shape factors for dual-porosity simulators. J. Petrol. Sci. Eng. 13, 169–178 (1995).

Lu, S. et al. Numerical assessment of the energy instability of gas outburst of deformed and normal coal combinations during mining. Process Saf. Environ. Prot. 132, 351–366 (2019).

Cui, G., Liu, J., Wei, M., Shi, R. & Elsworth, D. Why shale permeability changes under variable effective stresses: new insights. Fuel 213, 55–71 (2018).

Wu, K., Chen, F., Lin, J., Zhao, J. & Zheng, H. Experimental study on the interfacial bond strength and energy dissipation capacity of steel and steel fibre reinforced concrete (SSFRC) structures. Eng. Struct. 235, 112094 (2021).

He, H. et al. Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 114, 30–39 (2019).

Tu, Q., Cheng, Y., Xue, S., Ren, T. & Cheng, X. Energy-limiting factor for coal and gas outburst occurrence in intact coal seam. Int. J. Min. Sci. Technol. 31, 729–742 (2021).

Lu, S. et al. Damage-induced permeability model of coal and its application to gas predrainage in combination of soft coal and hard coal. Energy Sci. Eng. 7, 1352–1367 (2019).

Shu, L. et al. A novel physical model of coal and gas outbursts mechanism: insights into the process and initiation criterion of outbursts. Fuel 323, 124305 (2022).

Sun, Z., Liu, Y., Qi, Q., Chai, J. & Gu, B. The influence of High-Pressure water jet cutting parameters on the relief of pressure around the coal slot. Processes 11 (2023).

Tian, C. et al. Numerical simulation analysis and prevention measures of dynamic disaster risk in coal seam variation areas during deep mining. Sustainability 17 (3), 810 (2025).

Wang, X. et al. Study on influencing factors and prevention measures of coal-rock-gas compound dynamic disaster in deep coal mine mining. Sci. Rep. 15, 2080 (2025).

Acknowledgements

The authors would like to thank the Shandong postdoctoral innovation project (SDCX-ZG-202400203), Qingdao postdoctoral funding program (QDBSH20230202074), National natural science foundation of China (NSFC) (52278359), and Project funded by open fund of state key laboratory of coal mine disaster dynamics and control (2011DA105287-FW202203) for funding provided to this work.

Author information

Authors and Affiliations

Contributions

J.Y.R.: Conceptualization, Investigation, Resources. T.C.L.: Supervision, Project administration. W. X.: Methodology, Writing - Original Draft, Writing - Review & Editing, Visualization. S.Y.: Supervision, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jian, Y., Tian, C., Wang, X. et al. Numerical analysis of coal rock gas dynamics disaster risk in coal thickness variation area and research on prevention and control. Sci Rep 15, 24545 (2025). https://doi.org/10.1038/s41598-025-09121-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-09121-9