Abstract

Natural fibers are increasingly being explored as sustainable alternatives to synthetic materials in biocomposites, textiles, and biomedical applications. This study aims to extract and characterize natural fibers from Muntingia calabura twigs, evaluating their structural, mechanical, and biological properties for sustainable use. X-ray Diffraction (XRD) analysis revealed a 32.9% crystallinity index, confirming a cellulose structure. Fourier Transform Infrared Spectroscopy (FTIR) identified key functional groups at 3332 cm−1 (O-H stretching) and 2901 cm−1 (C-H stretching), indicating the presence of cellulose and lignin. Tensile testing demonstrated an ultimate tensile strength of 16.40 MPa, an elastic modulus of 5.9 GPa, and an elongation at break of 3.7%, suggesting suitability for reinforcement applications. Scanning Electron Microscopy (SEM) revealed a fibrillar morphology with surface roughness conducive to improved adhesion. Antibacterial testing against Haemophilus bacteria showed inhibition zones of 8 mm (25 µg) and 11 mm (75 µg), compared to 12 mm for Erythromycin (5 µg). Biofilm analysis demonstrated significant bacterial reduction, with fluorescence microscopy confirming increased bacterial death in fiber-treated samples. These findings highlight the potential of Muntingia calabura fibers for use in biocomposites, antimicrobial textiles, and biomedical applications. Their mechanical strength and antibacterial properties position them as a sustainable alternative for textile and automotive industries, with further modifications enhancing their functionality.

Similar content being viewed by others

Introduction

Sustainable development in materials is essential to address the growing environmental concerns associated with resource depletion, pollution, and waste accumulation. The increasing reliance on synthetic and non-biodegradable materials has led to significant ecological challenges, including carbon emissions, microplastic contamination, and landfill overflow1. By adopting sustainable materials such as plant-based fibers, biodegradable polymers, and recycled composites industries can reduce their carbon footprint, minimize waste generation, and promote circular economy principles2. Additionally, sustainable materials play a crucial role in biomedical applications, where biocompatibility, non-toxicity, and eco-friendly disposal are critical factors. The demand for greener alternatives is further driven by regulatory policies, consumer awareness, and the need for long-term resource conservation3. Advancing sustainable material development not only ensures environmental protection but also fosters innovation in medical, construction, and industrial sectors, paving the way for a healthier and more sustainable future4. Plant fibers have gained significant attention as eco-friendly reinforcement materials in biomedical applications, aligning with the principles of sustainable development. Derived from renewable sources such as bamboo, flax, hemp, jute, and Musa fibers, these natural fibers offer excellent biocompatibility, biodegradability, and mechanical strength, making them ideal for use in wound dressings, scaffolds for tissue engineering, and drug delivery systems5. Their ability to enhance composite materials while reducing environmental impact has driven research into their functionalization and integration into biomedical polymers. Additionally, plant fibers exhibit inherent antimicrobial properties and promote cell adhesion, further supporting their role in advanced healthcare solutions6. As the demand for green and biodegradable materials rises, plant fiber-reinforced biomaterials present a promising alternative to synthetic counterparts, fostering sustainability in medical device development7. Kenaf (Hibiscus cannabinus) fibers have emerged as a promising reinforcement material in biomedical applications due to their excellent mechanical properties, biodegradability, and biocompatibility. With a tensile strength ranging from 240 to 930 MPa and a Young’s modulus between 14 and 53 GPa, kenaf fibers provide significant structural reinforcement in polymer-based composites used for tissue engineering, wound healing, and drug delivery systems8. Their high cellulose content (60–65%) enhances their hydrophilicity, making them suitable for biomedical scaffolds that support cell adhesion and proliferation. Additionally, their low density (1.2–1.4 g/cm3) and high aspect ratio contribute to their ability to improve composite strength while maintaining lightweight properties9. Studies have shown that kenaf fiber-reinforced biopolymers exhibit improved degradation rates, making them a sustainable alternative to synthetic materials in medical applications10. Neem (Azadirachta indica) twig fibers have gained attention as a sustainable reinforcement material in biomedical applications due to their inherent antimicrobial properties, biocompatibility, and biodegradability. With a tensile strength ranging from 15 to 24 MPa and a Young’s modulus between 5 and 12 GPa, neem fibers provide moderate mechanical reinforcement in polymeric composites used for wound healing, dental hygiene products, and tissue engineering scaffolds11. Their high cellulose content (50–60%) enhances their hydrophilicity, supporting cell adhesion and proliferation. Neem fibers also contain bioactive compounds such as azadirachtin and nimbidin, which exhibit antibacterial and antifungal properties, making them ideal for applications in infection-resistant biomaterials12. Their low density (1.2–1.3 g/cm3) ensures lightweight composite structures, while their biodegradability facilitates eco-friendly disposal. These properties position neem twig fibers as a promising alternative to synthetic reinforcements in biomedical applications, particularly in antimicrobial coatings, sutures, and dental care products13.

Muntingia calabura plant fibers, derived from the bark of the Muntingia calabura tree, exhibit promising properties for reinforcement in structural applications due to their lightweight nature, good mechanical strength, and biodegradability14. These fibers have a density ranging from 0.9 to 1.3 g/cm3, making them comparable to other natural fibers while ensuring lightweight composite structures. The fibers contain 50–65% cellulose, which contributes to their hydrophilic nature and ability to support cell adhesion in biomedical applications. Additionally, their lignin content of 15–25% provides structural stability, while the hemicellulose composition (10–20%) influences their biodegradability. These properties make Muntingia calabura fibers a viable alternative for eco-friendly reinforcements in sustainable materials, particularly in biomedical, packaging, and structural applications15. The extraction of natural plant fibers involves various methods, depending on the plant source and intended application. The primary techniques include retting, mechanical, chemical, and enzymatic extraction. Retting is the most common method, where microbial or chemical action is used to break down the binding components (such as pectin and lignin) to release fibers. This can be water retting, where fibers are soaked in water for microbial decomposition, or dew retting, where they are left in the field to degrade naturally16. Mechanical extraction involves physically separating fibers from plant stems, leaves, or husks using decorticators, hammer mills, or rollers. This method is commonly used for fibers like banana, jute, and sisal. Chemical extraction uses alkalis, acids, or solvents to break down plant cell walls, improving fiber purity and yield but often posing environmental concerns17. Enzymatic extraction is a sustainable alternative, using specific enzymes to selectively degrade non-cellulose components while preserving fiber quality. Each method has advantages and limitations, with the choice depending on fiber type, desired properties, and sustainability considerations18. Natural plant fibers exhibit varying degrees of antibacterial activity, primarily due to their inherent bioactive compounds, surface properties, and ability to disrupt bacterial adhesion and biofilm formation. Fibers from plants such as neem, coconut, kenaf, and bamboo contain antimicrobial agents like polyphenols, flavonoids, alkaloids, and lignin, which inhibit bacterial growth19. Neem fibers, for example, release compounds such as azadirachtin and nimbidin, effectively preventing biofilm formation by Gram-positive and Gram-negative bacteria. Bamboo fibers exhibit antibacterial effects due to bamboo kun, a natural antimicrobial agent that disrupts bacterial cell membranes20. Biofilm analysis of plant fibers is conducted using techniques such as crystal violet staining, confocal laser scanning microscopy, and scanning electron microscopy to evaluate bacterial adhesion, colony morphology, and biofilm thickness. Studies show that fibers with high surface roughness and hydrophobicity can hinder biofilm development by preventing microbial attachment. These antibacterial and anti-biofilm properties make natural plant fibers valuable for biomedical applications, including wound dressings, sutures, and antimicrobial textiles21.

Through an extensive literature survey, a novel natural fiber was successfully extracted from the twigs of the Muntingia calabura plant. This study aimed to evaluate its distinctive properties and potential as an eco-friendly material. Tensile testing, X-ray Diffraction (XRD), and Fourier Transform Infrared Spectroscopy (FTIR) were conducted to assess its mechanical strength, structural integrity, and chemical composition, confirming the presence of key functional groups associated with cellulose, hemicellulose, and lignin. Scanning Electron Microscopy (SEM) was employed to analyse the fiber’s surface morphology and elemental composition, providing detailed insights into its texture and compatibility with composite materials. Additionally, antibacterial testing and biofilm analysis demonstrated the fiber’s effectiveness against pathogens, including Haemophilus bacteria, highlighting its potential for antimicrobial applications.

Materials and methods

Fiber extraction process

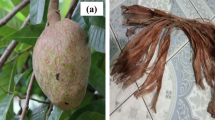

This study complies with relevant institutional, national, and international guidelines and legislation. This work utilized Muntingia calabura fibers, and the plant materials were purchased from Sri Sai Forestry, Bangalore, Karnataka, India. The fiber extraction process from Muntingia calabura plant twigs using the water retting method is an effective and environmentally friendly technique to obtain high-quality fibers for structural applications. Water retting relies on the natural microbial degradation of the binding components, such as pectin, hemicellulose, and lignin, which hold the fibers together within the plant structure. The process begins with the collection of mature twigs, ensuring that they are free from excessive moisture or damage. These twigs are then submerged in water, typically in a pond, tank, where microbial activity initiates the breakdown of the non-fibrous components. The duration of retting varies depending on factors such as temperature, microbial concentration, and water quality, but it generally takes 7 days for optimal fiber separation22. The optimal retting time of 7 days was determined based on preliminary observations. Twigs were immersed in water for different periods (5, 7, and 10 days), and the 7-day immersion period provided fibers that could be easily separated without significant degradation or loss of strength. Fibers retted for less than 7 days were difficult to extract, while fibers retted beyond 7 days showed signs of surface deterioration. During the retting process, anaerobic and facultative bacteria, along with fungi, break down the pectin and other matrix materials, facilitating the loosening of fibers from the woody core. The fermentation process releases gases, and the water may develop an odor due to the decomposition of organic matter. To ensure uniform retting, the twigs are periodically checked by gently pulling the bark to assess fiber separation. If the fibers easily detach without significant resistance, the retting process is complete23. At this stage, the twigs are removed from the water and subjected to thorough washing to eliminate residual pectic substances, microbial debris, and unwanted plant matter. Once cleaned, the fibers undergo a mechanical scraping process to remove any remaining woody portions or impurities. The extracted fibers are then sun-dried in a well-ventilated area to prevent fungal growth and degradation. Proper drying is crucial as excess moisture content can lead to fiber weakening and microbial contamination. The dried fibers are further combed and sorted based on their length, fineness, and strength to ensure consistency in quality. Water retting of Muntingia calabura fibers offers a sustainable and cost-effective method for fiber extraction, producing fibers with good mechanical properties, high cellulose content, and minimal chemical alteration. However, the process requires careful water management to prevent excessive pollution from the decayed organic matter. Implementing controlled retting conditions, periodic water replacement, and wastewater treatment strategies can help mitigate environmental concerns while ensuring high fiber yield. These fibers, once processed, can be utilized in biomedical applications, including biodegradable composites, wound dressings, and natural reinforcements in eco-friendly materials. Figure 1 shows the extraction process of Muntingia calabura fibers.

Experimental process

The experimental characterization of Muntingia calabura fibers involves multiple analytical techniques to assess their structural, mechanical, and biological properties, ensuring their suitability for biomedical and composite applications. Various tests, including X-ray Diffraction (XRD), Fourier Transform Infrared Spectroscopy (FTIR), Scanning Electron Microscopy (SEM), Tensile Testing, Antibacterial Assay, and Biofilm Analysis, are conducted following ASTM standards. These analyses help to determine the fiber’s crystallinity, chemical composition, surface morphology, mechanical strength, antimicrobial activity, and resistance to biofilm formation.

X-ray diffraction

XRD analysis is performed to determine the crystallinity and phase structure of Muntingia calabura fibers. Higher crystallinity generally enhances mechanical strength and durability. The experiment follows ASTM D502 using an X-ray diffractometer equipped with a Cu-Kα radiation source (λ = 1.5406 Å), operating at 40 kV and 30 mA. The diffraction pattern is recorded in the 2θ range of 5° to 50° with a step size of 0.02°. The crystallinity index (CI) is calculated using Segal’s method, which helps in evaluating the proportion of crystalline cellulose within the fibers24.

Fourier Transform Infrared Spectroscopy

FTIR analysis is conducted to identify functional groups and confirm the removal of non-cellulosic components, ensuring fiber purity for biomedical applications. The analysis follows ASTM E1252 and is performed using an FTIR spectrometer in the wavenumber range of 4000–400 cm−1 with a resolution of 4 cm−1. Characteristic peaks corresponding to cellulose (–OH stretching at ~ 3400 cm−1), hemicellulose (C = O stretching at ~ 1730 cm−1), and lignin (C–H deformation at ~ 1245 cm−1) are analyzed to understand the fiber’s chemical composition and potential biocompatibility25.

Scanning electron microscopy

The SEM analysis is used to examine the surface morphology, fiber structure, and porosity, which influence mechanical performance and bacterial attachment. The analysis follows ASTM E766, and the fibers are gold-coated using a sputter coater to enhance conductivity. Imaging is performed using an SEM instrument operating at 10–20 kV, capturing high-magnification images to assess fiber roughness, fibrillation, and surface defects. The SEM samples were prepared by mounting small pieces of the dried fibers onto aluminum stubs using conductive carbon tape. The samples were then sputter-coated with a thin layer of gold to improve conductivity. The thickness of the sputter coating was around 10 nm. This analysis helps evaluate the suitability of the fibers for applications such as wound healing and antimicrobial textiles26.

Tensile test

Tensile testing is conducted to measure the mechanical strength, elasticity, and durability of Muntingia calabura fibers, ensuring their effectiveness as reinforcement materials. The experiment follows ASTM D3822 using a universal testing machine (UTM). Fibers are conditioned at 23 °C and 50% relative humidity for 24 h before testing. The gauge length is set at 20 mm, and the testing speed is maintained at 5 mm/min. Parameters such as tensile strength, Young’s modulus, and elongation at break are recorded to assess fiber reliability for biomedical applications27.

Antibacterial activity

The antibacterial assay is performed to evaluate the antimicrobial potential of Muntingia calabura fibers against Haemophilus bacteria, which are associated with respiratory and oral infections. The test follows ASTM E2149 using the disk diffusion method. Fiber samples are placed on nutrient agar plates inoculated with Haemophilus species and incubated at 37 °C for 24 h. The zone of inhibition (in mm) is measured and compared with the standard antibiotic erythromycin (5 µg). A significant inhibition zone around the fiber sample indicates antimicrobial effectiveness, suggesting potential applications in antibacterial coatings and wound dressings28.

Biofilm analysis

Biofilm analysis is conducted to examine bacterial adhesion and biofilm formation on the fiber surface, as biofilms contribute to persistent infections and material degradation. Sterilization was carried out by exposing the fibers to ultraviolet (UV) light for 30 min on each side under aseptic conditions to prevent microbial contamination during antibacterial and biofilm assays. The study follows ASTM E2562 using the crystal violet staining method. Fiber samples are incubated with bacterial cultures in tryptic soy broth supplemented with 0.5% glucose at 37 °C for 24 h. After incubation, non-adherent cells are washed off, and adherent biofilms are stained with 0.1% crystal violet dye. The optical density (OD) at 570 nm is measured using a microplate reader to quantify biofilm formation. Additional imaging using confocal laser scanning microscopy (CLSM) and scanning electron microscopy (SEM) provides insights into biofilm architecture and bacterial attachment patterns. These experimental analyses comprehensively characterize the structural, mechanical, and biological properties of Muntingia calabura fibers, supporting their potential use in biomedical applications such as antimicrobial textiles, wound dressings, and biodegradable composite materials29. Each test was conducted in triplicate, and the mean value was considered as the final result, with error bars representing the standard deviation.

Results and discussion

XRD analysis of Muntingia calabura fibers

Figure 2 shows the XRD analysis of Muntingia calabura fibers. The XRD analysis is a technique for determining the crystalline structure and phase composition of Muntingia calabura fibers. The degree of crystallinity significantly influences the mechanical strength, thermal stability, and biodegradability of natural fibers, making it an essential parameter for biomedical and composite applications. The XRD pattern obtained for Muntingia calabura fibers exhibits distinct diffraction peaks at 2θ values of 19.97° and 26.14°, indicating the presence of crystalline cellulose along with amorphous regions. The peak at 19,97° is the most intense, suggesting a high degree of cellulose crystallinity, which enhances the fiber’s mechanical properties. The diffraction peaks at 26.14° correspond to the typical reflections of cellulose I, indicating that the fiber retains its natural cellulose structure. The crystallinity index (CI) of the fiber is calculated using Segal’s method, expressed as:

CI=(I002 −Iam)/ (I002)×100.

where I002 represents the maximum intensity of the crystalline peak (at 19.97°), and Iam is the intensity of the amorphous phase (determined around 2θ = 18°). Segal’s method was selected due to its simplicity, wide acceptance in natural fiber research, and suitability for semi-crystalline materials such as lignocellulosic fibers. While more advanced methods such as peak deconvolution and Rietveld refinement provide detailed phase analysis, they require extensive modelling and higher-resolution data. As the aim of this study was to provide a comparative assessment of Muntingia calabura fibers within the context of existing natural fibers, Segal’s method was considered appropriate. Based on the observed diffraction data, the estimated crystallinity index of Muntingia calabura fibers falls 32.9%, indicating a relatively high crystalline nature. This high crystallinity suggests that the fiber possesses good tensile strength and thermal resistance, making it a suitable candidate for reinforcing biomaterials. The mechanism of cellulose crystallization in plant fibers is governed by hydrogen bonding and Van der Waals interactions among cellulose microfibrils. The ordered arrangement of cellulose chains in the crystalline regions is stabilized by strong intra- and intermolecular hydrogen bonds between hydroxyl groups30. This results in compact, well-aligned structures that enhance the mechanical strength and resistance to moisture absorption. In contrast, amorphous regions contain randomly oriented cellulose chains with weaker bonding interactions, making them more susceptible to chemical degradation and water uptake. The broad baseline between 10° and 35° in the XRD pattern suggests the presence of amorphous hemicellulose and lignin, which influence fiber flexibility and biodegradability. The sharper and well-defined crystalline peaks indicate that the alkali treatment or retting process effectively removed a portion of the amorphous components, improving fiber purity. The removal of hemicellulose and lignin disrupts hydrogen bonding networks in amorphous regions, leading to increased crystallinity and enhanced mechanical properties31. Therefore, the XRD analysis confirms that Muntingia calabura fibers exhibit semi-crystalline behavior with a dominant cellulose phase, making them suitable for biomedical applications such as wound dressings, drug delivery systems, and biodegradable composites. The balance between crystalline and amorphous regions allows for optimized mechanical performance and controlled degradation, crucial for bio-based materials.

FTIR spectroscopic analysis of Muntingia calabura fibers

Figure 3 shows the FTIR spectrum of Muntingia calabura fibers. The FTIR spectroscopy is a analytical technique for identifying the chemical composition and functional groups present in Muntingia calabura fibers. This analysis provides valuable insights into the structural integrity and molecular interactions within the fiber, influencing its mechanical, thermal, and biological properties. The FTIR spectrum helps determine the presence of cellulose, hemicellulose, and lignin, which play significant roles in the fiber’s biodegradability and applicability in biomedical and composite materials. The FTIR spectrum of Muntingia calabura fibers exhibits a broad absorption peak in the range of 3330–3400 cm−1, attributed to the stretching vibrations of hydroxyl (-OH) groups present in cellulose and hemicellulose. These hydroxyl groups participate in extensive hydrogen bonding, which contributes to the fiber’s hydrophilic nature and mechanical strength32. The presence of C-H stretching vibrations of aliphatic chains is observed around 2900–2950 cm−1, a characteristic feature of cellulose and lignin components, indicating the presence of structural polysaccharides and aromatic compounds. A prominent peak is detected in the range of 1730–1750 cm−1, corresponding to the carbonyl (C = O) stretching vibrations of ester and carboxyl functional groups found primarily in hemicellulose and lignin. The intensity of this peak is often reduced after chemical treatments such as alkali retting, signifying the partial removal of hemicellulose. The presence of aromatic skeletal vibrations from lignin is confirmed by bands appearing around 1510–1600 cm−1, which correspond to the C = C stretching of aromatic rings in lignin macromolecules. This peak intensity decreases if lignin content is reduced through chemical processing, improving fiber purity and flexibility. Further analysis reveals absorption bands in the region of 1230–1260 cm−1, which are associated with C-O stretching vibrations of acetyl and ether groups from hemicellulose and lignin. The peaks in the range of 1020–1100 cm−1 correspond to the C-O-C asymmetric stretching of β-glycosidic linkages in cellulose, indicating the ordered structure of cellulose microfibrils. Additionally, a peak observed near 895 cm−1 is attributed to the C-H deformation of cellulose, which is characteristic of its crystalline nature. The structural modifications detected in the FTIR spectrum are primarily attributed to molecular interactions at the atomic level. Infrared radiation excites specific vibrational modes of molecular bonds, causing absorption at characteristic wavelengths33. The hydroxyl (-OH) and carbonyl (C = O) functional groups play a critical role in intermolecular interactions, influencing fiber strength, water absorption, and biodegradability. The removal of hemicellulose and lignin during fiber processing leads to noticeable spectral changes, such as reduced intensities in the 1730–1750 cm−1 and 1510–1600 cm−1 regions, which correlate with increased cellulose purity and improved mechanical properties. The FTIR analysis confirms that Muntingia calabura fibers primarily consist of cellulose, with varying amounts of hemicellulose and lignin depending on the processing conditions. The chemical composition revealed by FTIR spectroscopy highlights the fiber’s potential as an environmentally friendly and biodegradable reinforcement material. These properties make the fiber suitable for biomedical applications, including wound dressings, drug delivery systems, and antibacterial composites, where controlled degradation and mechanical stability are essential. The ability to modify the fiber’s composition through chemical treatments further enhances its potential for use in sustainable materials and high-performance biocompatible products. Table 1 reveals the chemical composition of Muntingia calabura fibers and comparison with other natural fibers.

Tensile strength of Muntingia calabura fibers

Tensile strength and tensile modulus are critical mechanical properties that define the structural performance and load-bearing capacity of Muntingia calabura fibers. These properties are essential for determining the fiber’s suitability for reinforcement in composite materials, biomedical applications, and sustainable engineering products. The tensile strength of Muntingia calabura fibers has been determined to be 16.4 MPa, while the tensile modulus is measured at 5.9 GPa, indicating a balance between flexibility and rigidity.

Figure 4 shows the stress vs. strain curve of Muntingia calabura fibers. The stress-strain curve obtained from the tensile test shows a linear elastic region at lower strain values, followed by a gradual increase in stress, indicating the fiber’s ability to withstand deformation before failure. The initial linear portion of the curve corresponds to the fiber’s elastic modulus, calculated as 5.9 GPa, which represents the fiber’s stiffness and brittle nature. The slope of this region suggests a relatively high modulus compared to other natural fibers, making Muntingia calabura fibers suitable for applications requiring high stiffness. As the applied load increases, the fiber reaches its ultimate tensile strength at 16.4 MPa, after which failure occurs. This value indicates the maximum stress the fiber can endure before breaking, reflecting its mechanical robustness. The high strength-to-weight ratio of Muntingia calabura fibers makes them competitive with other lignocellulosic fibers such as jute and kenaf, which exhibit tensile strengths in the range of 15–25 MPa. The fracture behavior observed in the stress-strain curve suggests that fiber failure occurs due to microfibril slippage and cellulose chain breakage, a common mechanism in natural fibers34. The tensile properties of Muntingia calabura fibers are largely influenced by their internal composition, particularly the cellulose content and the alignment of microfibrils. A high cellulose content enhances tensile strength, while the presence of hemicellulose and lignin affects the fiber’s flexibility and toughness35. The moderate tensile strength and relatively high modulus of these fibers indicate their potential as reinforcement in polymer composites, where stiffness and moderate load-bearing capabilities are required. Additionally, their biodegradable nature makes them promising material for biomedical applications such as sutures, tissue scaffolds, and biopolymer reinforcements. Therefore, the tensile strength of 16.4 MPa and the tensile modulus of 5.9 GPa confirm the structural integrity of Muntingia calabura fibers, making them viable for sustainable applications in both engineering and biomedical fields. Further surface modification techniques, such as alkali treatment, could enhance these properties by improving fiber-matrix adhesion in composite applications, extending their usability in eco-friendly material innovations.

SEM analysis of Muntingia calabura fibers

The SEM analysis of Muntingia calabura fibers provides a detailed insight into their microstructural characteristics, which are essential for understanding their mechanical performance, surface morphology, and potential applications in composite materials. One of the significant features observed in the SEM image is the presence of longitudinal striations and microfibrillar orientation, which indicate a high degree of structural integrity. These striations correspond to the aligned cellulose microfibrils, which play a crucial role in the fiber’s tensile properties. The presence of voids and microgrooves along the fiber surface suggests a natural roughness that can enhance adhesion with polymer matrices, making these fibers suitable for reinforcement applications. Additionally, the SEM analysis reveals the presence of surface cracks and partial fibrillation, which might be attributed to the fiber extraction process, particularly water retting. The fibrillation of fibers, where individual fibrils are partially separated, can enhance surface area and improve mechanical interlocking with matrix materials36. However, excessive fibrillation could reduce mechanical strength due to increased fiber fragmentation. The observed voids and pores within the fiber structure suggest a high degree of porosity, which could influence water absorption properties and biodegradability, making them suitable for biomedical applications such as scaffolds or drug delivery systems. The interface between the fiber and the surrounding matrix in a composite application is highly dependent on surface roughness. The SEM micrograph suggests that Muntingia calabura fibers possess an inherent surface roughness that could facilitate better mechanical interlocking with polymer or biopolymer matrices. However, for improved adhesion, surface modifications such as alkali treatment or silane coupling agent treatment may be necessary to reduce non-cellulosic impurities like lignin and waxes, thereby increasing fiber-matrix compatibility37. Furthermore, the presence of lignocellulosic deposits in the microstructure suggests that the fibers retain a certain amount of hemicellulose and lignin, which contribute to their stiffness and impact resistance. These components may also affect the fiber’s hydrophilicity, leading to moisture absorption. The removal or modification of these constituents through chemical treatments can further enhance their performance in engineering applications. Therefore, the SEM microstructural analysis confirms that Muntingia calabura fibers exhibit a natural hierarchical structure with longitudinal alignment, moderate fibrillation, and a rough surface topology, all of which contribute to their mechanical reinforcement potential. These features make them viable candidates for use in biodegradable composites, biomedical applications, and lightweight structural materials, aligning with sustainable material development strategies. Figure S1 shows the SEM microstructure of Muntingia calabura fibers.

Antibacterial activity of Muntingia calabura fibers

Figure 5 shows the antibacterial activity of Muntingia calabura fibers. The antibacterial activity of Muntingia calabura fibers against Haemophilus bacteria was assessed through the disc diffusion method, with inhibition zones measured at varying concentrations of fiber extracts. The effectiveness of the fiber extracts was compared to a standard antibiotic, Erythromycin, which served as a positive control. The inhibition zone for Erythromycin at a concentration of 5 µg was recorded at 12 mm, establishing a benchmark for evaluating the antimicrobial efficacy of Muntingia calabura fibers. The fiber samples demonstrated considerable antibacterial potential, with the low-concentration sample at 25 µg producing an inhibition zone of 8 mm, indicating moderate suppression of bacterial growth. As the concentration of the fiber extract increased to 75 µg, the inhibition zone expanded to 11 mm, suggesting a dose-dependent enhancement of antibacterial activity. The near equivalence of the inhibition zone of the high-concentration fiber extract to that of Erythromycin highlights the strong antibacterial effects of the bioactive compounds present in Muntingia calabura fibers. The antibacterial mechanism of action can be attributed to the presence of various phytochemicals such as phenolic compounds, flavonoids, tannins, and alkaloids38. These bioactive molecules are known to disrupt bacterial cell membranes, interfere with essential enzymatic pathways, and inhibit protein synthesis, ultimately leading to bacterial cell death. The increase in inhibition zone diameter with higher fiber concentrations suggests that the antibacterial agents within the fibers become more effective as their availability increases. The comparative analysis with Erythromycin suggests that Muntingia calabura fibers have promising antibacterial properties that could be harnessed for biomedical and healthcare applications. Although the inhibition zone of the fiber extract at 75 µg was slightly lower than that of Erythromycin, the strong bacterial suppression indicates the potential of these natural fibers as a sustainable alternative to synthetic antimicrobial agents. The use of plant-based antibacterial compounds offers advantages such as reduced antibiotic resistance, biodegradability, and biocompatibility, making them suitable for applications in antimicrobial coatings, wound dressings, oral hygiene products, and other healthcare solutions39. The percentage reduction in bacterial activity was estimated by comparing the inhibition zone diameters of the fiber-treated samples to the standard antibiotic control (Erythromycin, 5 µg). The MCF Sample LC (25 µg) showed a 33.3% reduction in antibacterial effectiveness, while the MCF Sample HC (75 µg) showed an 8.3% reduction relative to the control. The ability of Muntingia calabura fibers to exhibit significant antibacterial effects against Haemophilus bacteria at relatively low concentrations underscores their relevance in the development of eco-friendly and effective antimicrobial treatments. Further investigations into the extraction, purification, and optimization of these bioactive compounds could enhance their practical applications in clinical and industrial sectors. This study supports the potential integration of plant-based antibacterial agents in alternative therapeutic approaches, offering a sustainable solution to combat bacterial infections while minimizing the risks associated with conventional antibiotics.

Biofilm analysis of Muntingia calabura fibers

The biofilm analysis of Muntingia calabura fibers was conducted using fluorescence microscopy, incorporating dual staining with Acridine Orange and Propidium Iodide to evaluate bacterial viability and the structural integrity of biofilms. Acridine Orange, a nucleic acid-binding dye, fluoresces green when bound to bacterial cells, indicating the presence of both live and dead bacteria, while Propidium Iodide selectively stains bacteria with compromised membranes, emitting a red fluorescence signal that marks cell death. This dual-staining approach provides critical insight into the impact of Muntingia calabura fibers on biofilm structure and bacterial viability40. In the control group, fluorescence microscopy images (a1, a2, and a3) reveal a dense and intact biofilm, as indicated by the strong green fluorescence in the Acridine Orange-stained image (a1). The absence of red fluorescence in the Propidium Iodide-stained image (a2) suggests that the majority of bacteria within the biofilm remain viable, signifying robust bacterial colonization and biofilm formation. The overlaid image (a3) further confirms this observation, demonstrating an overwhelming presence of live bacterial populations without significant disruption. In contrast, the Muntingia calabura fiber (MCF)-treated group exhibited a marked reduction in biofilm density and bacterial viability, as observed in images (b1, b2, and b3). The Acridine Orange staining in (b1) shows a disrupted biofilm with less dense bacterial colonization, suggesting that treatment with Muntingia calabura fibers interfered with biofilm formation. The Propidium Iodide-stained image (b2) exhibits a strong red fluorescence signal, indicating a significant number of bacterial cells with compromised membranes, highlighting the potent antibacterial effect of the fiber treatment. The overlaid image (b3) presents a blend of green and red fluorescence, demonstrating a substantial bacterial kill rate and confirming the antibiofilm activity of Muntingia calabura fibers. These findings strongly suggest that the bioactive compounds present in Muntingia calabura fibers, including flavonoids, tannins, saponins, and phenolic compounds, contribute to their antimicrobial and antibiofilm properties41. The observed reduction in bacterial viability and biofilm integrity implies that these fibers can effectively inhibit bacterial adhesion and colonization, crucial steps in biofilm development. The disruption of the biofilm matrix further suggests that Muntingia calabura fibers may interfere with extracellular polymeric substance (EPS) production, a key component of biofilm stability. Biofilms pose significant challenges in clinical and industrial settings, as they provide bacterial communities with enhanced resistance to antibiotics and host immune responses. The ability of Muntingia calabura fibers to weaken and disrupt biofilms suggests their potential application in healthcare and hygiene products. In dentistry, these fibers could be integrated into oral care products such as mouth rinses, toothpaste, or toothbrush bristles to prevent dental plaque and periodontal infections. In wound care, the incorporation of Muntingia calabura fibers into wound dressings or antiseptic coatings could help prevent biofilm-associated infections that hinder wound healing. Furthermore, their use in medical device coatings, such as catheters and implants, could reduce the risk of biofilm-mediated infections, a critical concern in hospital scenario. The mechanism underlying the antibiofilm activity of Muntingia calabura fibers may involve the disruption of bacterial cell membranes, inhibition of quorum sensing pathways, and suppression of biofilm-associated gene expression42. Further research is necessary to elucidate the precise molecular interactions between the fiber extract and bacterial biofilms. Additionally, investigating the synergistic effects of Muntingia calabura fibers with conventional antibiotics could provide valuable insights into developing novel combinational strategies to combat antibiotic-resistant biofilm infections. Therefore, the fluorescence microscopy analysis clearly demonstrates that Muntingia calabura fibers possess significant antibiofilm and antibacterial properties43. The notable decrease in biofilm density, combined with increased bacterial cell death in treated samples, highlights the potential of these fibers as a natural antimicrobial agent. Their broad-spectrum applicability across dental, medical, and industrial fields underscores the need for further exploration and development of Muntingia calabura fiber-based antimicrobial products. Future studies should focus on optimizing extraction techniques, assessing long-term efficacy, and conducting in vivo evaluations to validate their clinical and commercial potential. that future studies will be necessary to assess sterilization compatibility (e.g., autoclaving, gamma irradiation), in vivo biocompatibility, and regulatory compliance (e.g., ISO 10993, FDA approval pathways) before any clinical application can be considered. Figure 6 shows the biofilm analysis of Muntingia calabura fiber.

Conclusion

The characterization of natural fibers extracted from Muntingia calabura twigs highlights their potential as a sustainable alternative to synthetic materials. The study confirmed their structural integrity, mechanical strength, and antibacterial properties, suggesting suitability for applications in textiles and automobile interiors. These fibers also demonstrated antimicrobial efficacy, effectively inhibiting bacterial colonization and biofilm formation an advantage for biomedical and hygienic uses. Their natural origin and biodegradability further support their role in reducing environmental pollution and promoting eco-friendly alternatives. However, several limitations must be acknowledged. Long-term fiber stability under various environmental conditions has not yet been evaluated. Additionally, variability due to the age and growth conditions of source plants, as well as reproducibility across different extraction batches, may influence material consistency and performance. Future research should address these challenges by focusing on stability testing, standardizing extraction protocols, and evaluating batch-to-batch uniformity. Further studies could also explore chemical modifications, hybridization with other bio-based materials, and integration into advanced biocomposites to expand their functional range, particularly in structural and biomedical applications. With continued development, Muntingia calabura fibers could contribute meaningfully to sustainable innovation across multiple industries.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Luo, P., Feng, X., Liu, S., & Jiang, Y. Traditional Uses, Phytochemistry, Pharmacology and Toxicology of Ruta graveolens L.: A Critical Review and Future Perspectives. Drug Design, Development and Therapy, 18, 6459–6485. https://doi.org/10.2147/DDDT.S494417 (2024).

Rebec, K. M., Turk, J. & Kunaver, M. Quantifying the environmental implication of cotton-Fiber-based nanocrystalline cellulose: A life-cycle assessment. Sustainable Prod. Consum. 45, 192–202 (2024).

Adekomaya, O., Jamiru, T., Sadiku, R. & Huan, Z. A review on the sustainability of natural fiber in matrix reinforcement–A practical perspective. J. Reinf. Plast. Compos. 35 (1), 3–7 (2016).

Espinach, F. X. Advances in natural fibers and polymers. Materials 14 (10), 2607 (2021).

Murugadoss, P., Verma, A., Ballal, S., Upadhye, V. J., Shukla, K. K., Das, P. Kenaf/basalt fiber-reinforced epoxy matrix hybrid composites: Current trends, challenges, and future prospects in advanced material development. Results in Engineering, 26, 104816. https://doi.org/10.1016/j.rineng.2025.104816 (2025).

Vijay, R., Vinod, A., Kathiravan, R., Siengchin, S. & Singaravelu, D. L. Evaluation of Azadirachta indica seed/spent Camellia sinensis bio-filler based jute fabrics–epoxy composites: experimental and numerical studies. J. Ind. Text. 49 (9), 1252–1277 (2020).

Vinod, A. et al. Extraction and characterization of natural fiber from stem of cardiospermum Halicababum. J. Nat. Fibers. 18 (6), 898–908 (2021).

Palaniappan, S. K., Singh, M. K., Rangappa, S. M. & Siengchin, S. Eco-friendly biocomposites: A step towards achieving sustainable development goals. Composites 7 (12), 1–3 (2023).

Debnath, S. Natural fibres for sustainable development in fashion industry. In Sustainable Fibres for Fashion Industry: Volume 1 (89–108). Singapore: Springer Singapore. (2016).

Bhuyan, S. & Gogoi, N. Natural fibers: Innovative sustainable and eco-friendly. Int. J. Curr. Microbiol. Appl. Sci. 9 (7), 1004–1011 (2020).

Jagadeesh, P. et al. Recent developments and challenges in natural fiber composites: a review. Polym. Compos. 43 (5), 2545–2561 (2022).

Raja, T. et al. S. A., Studies on mechanical and morphological behaviors of banyan/kevlar fibers reinforced MgO particulates hybrid aliphatic epoxy composite. The Int. J. Adv. Manuf. Technology, 1–8. (2023).

Zhou, J. et al. Research on the mechanism of natural antibacterial properties of Calotropis gigantea fiber. Ind. Crops Prod. 221, 119447 (2024).

Raja, T. & Devarajan, Y. Visco-elastic properties and thermal analysis of corchorus/elastane yarn–reinforced biocomposites. Biomass Convers. Biorefinery. 14 (14), 15363–15372 (2024).

Vinod, A. et al. Effect of alkali treatment on performance characterization of Ziziphus mauritiana fiber and its epoxy composites. J. Ind. Text. 51 (2_suppl), 2444S–2466S (2022).

Karthik, K., Rekha, M. M., Juneja, B., Jena, S. P., Patel, G. M., Srivastava, N. Effect of SiC Filler in Luffa Cylindrica Fiber-Reinforced Epoxy Matrix Composites: A Novel Material for Advanced Structural Applications. Chemistry Africa, 8(4), 1647–1660. https://doi.org/10.1007/s42250-025-01228-w (2025).

Mohammadi, M., Ishak, M. R. & Sultan, M. T. H. Exploring chemical and physical advancements in surface modification techniques of natural fiber reinforced composite: A comprehensive review. J. Nat. Fibers. 21 (1), 2408633 (2024).

Gapsari, F. et al. Isolation and characterization of Muntingia calabura cellulose nanofibers. J. Nat. Fibers. 20 (1), 2156018 (2023).

Raja, T. et al. V., An in-depth investigation into the utilization of nettle fiber-reinforced epoxy composites with embedded MgO nanoparticles. Journal Reinforced Plast. Composites, 07316844241266650. (2024).

Wijaya, H. et al. Characterization of Muntingia calabura fiber as a composite reinforcement with bleaching variation. In International Symposium on Lightweight and Sustainable Polymeric Materials (pp. 119–130). Singapore: Springer Nature Singapore. (2023), February.

Indumathi, T. R., Divya, R., Kumar, B. S. & Selvakumar, A. Antimicrobial study on surface-coated Hibiscus sabdariffa L. fiber reinforcement. Biomass Convers. Biorefinery. 14 (20), 25239–25250 (2024).

Murugadoss, P., Reddy M, S., Das, S. N., Bareja, L., R, G., Mishra, R. Thermal properties and stability of Carica papaya fiber-reinforced MgO particulate epoxy composites for advanced thermal applications. Case Studies in Thermal Engineering, 68, 105921. https://doi.org/10.1016/j.csite.2025.105921 (2025)

Song, Y. et al. Separation process of plant fibers for textile and composite application: A review of recent advances. J. Nat. Fibers. 21 (1), 2406460 (2024).

Lima Lopes Junior, J. et al. Characterization of the natural fibers extracted from the aninga’s stem and development of a unidirectional polymeric sheet. Sci. Rep. 14 (1), 24780 (2024).

Raja, T. & Devarajan, Y. Thermal evaluation of porcelain filler particles in basalt fibre-reinforced polymer composites for thermal applications. J. Therm. Anal. Calorim. 149 (10), 4529–4541 (2024).

Raghunathan, V. et al. Sustainable characterization of brake pads using raw/silane-treated Mimosa pudica fibers for automobile applications. Polym. Compos. 45 (11), 10204–10219 (2024).

Khan, A. et al. Extraction and characterization of vetiver grass (Chrysopogon zizanioides) and Kenaf fiber (Hibiscus cannabinus) as reinforcement materials for epoxy based composite structures. J. Mater. Res. Technol. 9 (1), 773–778 (2020).

Thandavamoorthy, R., Devarajan, Y., & Kaliappan, N. Antimicrobial, function, and crystalline analysis on the cellulose fibre extracted from the banana tree trunks. Scientific Reports, 13(1). https://doi.org/10.1038/s41598-023-42160-8. (2023).

Mylsamy, B. et al. A review on natural fiber composites: Polymer matrices, fiber surface treatments, fabrication methods, properties, and applications. Polym. Eng. Sci. 64 (6), 2345–2373 (2024).

Jahan, M. S., Hossain, S., Das, S. C., Rahman, M. L. & Khan, M. A. Extraction and characterization of cellulose nanocrystals (CNCs) from jute fibers and other by-products towards a circular economy approach. Mater. Circular Econ. 6 (1), 57 (2024).

Raghunathan, V. et al. Effective utilization of surface-processed/untreated Cardiospermum Halicababum agro-waste fiber for automobile brake pads and its tribological performance. Tribol. Int. 197, 109776 (2024).

Bismarck, A. et al. Surface characterization of natural fibers; surface properties and the water up-take behavior of modified Sisal and Coir fibers. Green Chem. 3 (2), 100–107 (2001).

Khan, M. M. et al. Enhancing the performance of lignocellulosic textile fabrics by chemical treatment and filler modification. J. Nat. Fibers. 22 (1), 2457507 (2025).

Ali, A. et al. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. Text. 47 (8), 2153–2183 (2018).

Thandavamoorthy, R., Devarajan, Y. & Thanappan, S. Analysis of the characterization of NaOH-treated natural cellulose fibre extracted from Banyan aerial roots. Sci. Rep. 13 (1), 12579 (2023).

Bakri, M. B. et al. Fundamental study on the effect of alkaline treatment on natural fibers structures and behaviors. J. Eng. Appl. Sci. 11, 8759–8763 (2016).

Thandavamoorthy, R., Devarajan, Y. & Kaliappan, N. Antimicrobial, function, and crystalline analysis on the cellulose fibre extracted from the banana tree trunks. Sci. Rep. 13 (1), 15301 (2023).

de Queiroz, H. F. M., dos Santos, N. V., Neto, J. S. S. & Banea, M. D. Mechanical characterization of novel natural fibre-reinforced composites via a three-dimensional fibre architecture. Compos. Sci. Technol. 261, 110996 (2025).

Mudi, C. & Shaw, A. Natural fiber reinforcement-investigating Ramie in cementitious composites with emphasis on fiber surface modifications. J. Building Eng. 100, 111705 (2025).

Raja, T. Characterization of a novel natural fiber extracted from Albizia julibrissin plant stem: advancing sustainable product development. Results Eng. 25, 103737 (2025).

Logesh, K., R, M., Tutej., Behera. Characterization and applications of Croton bonplandianus fiber for sustainable biomaterials. Results in Engineering,26, 104765. https://doi.org/10.1016/j.rineng.2025.104765 (2025).

Low, W. P. et al. Development of microbial biofilms on cellulosic fibers for organic matter removal in river water treatment. Desalination Water Treat. 224, 144–153 (2021).

Chanakya, H. N. & Khuntia, H. K. Treatment of Gray water using anaerobic biofilms created on synthetic and natural fibers. Process Saf. Environ. Prot. 92 (2), 186–192 (2014).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors have equally contributed to the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

This study complies with relevant institutional, national, and international guidelines and legislation. No Animals were used/handled in the study.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kaliappan, N., Nayak, P.P., Thulasiram, R. et al. Extraction and characterization of natural fibers from Muntingia calabura twigs for sustainable applications. Sci Rep 15, 29060 (2025). https://doi.org/10.1038/s41598-025-09172-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-09172-y