Abstract

Organic contamination is a major problem in the space industry, particularly for satellite optical devices. Although the standards governing this problem are extremely strict, there is no efficient method to measure the in situ, real-time deposition of organic contaminants. An original method based on thickness measurement is reported and tested in this paper. The use of microwave transduction allows to estimate the thickness of paraffin oil and silicone oil deposits from a few nanometers to several hundred nanometers in a low-pressure (mbar) environment. A linear response of the microwave sensor as a function of contaminant layer thickness is thus evidenced for both silicone and paraffin oils, paving the way for the integration of this method as an on-board contamination detection device.

Similar content being viewed by others

Introduction

In a fast-growing field such as space, controlling organic contamination of satellites and optical devices is mandatory, at every stage of their development and assembly, but also during flight. Indeed, contaminating layers can lead to equipment dysfunction or render measurements irrelevant. Standards for monitoring contamination are increasingly strict (ECSS-Q-ST-70-05 C, ESA Standard) aiming for tolerance levels in the nanometer range1,2. Current monitoring methods based on FTIR measurements allow the punctual and ex situ estimation of contamination levels. No dedicated methods allow to measure in situ and in real-time the contamination deposition3. The current technique lacks reliability and the ability to provide real-time characterization, leading to limitations in assessing the contamination of flight hardware during their lifetime.

Newly developed and future instruments display more and more sensitivity to molecular contamination. Typical detrimental effects are, among other, signal transmission loss, laser-induced contamination or damage on optics due to the absorption of the contamination layer depending on its chemical composition.

In this framework, this paper reports an ambitious project carried out in collaboration with the European Space Agency (ESA) concerning the use of microwave transduction to characterize a contaminant layer. This technique allows the development of a sensor, easily integrated, and miniaturized, able to characterize the thickness of contamination layers in situ and in real time. Consequently, this work represents a multidisciplinary challenge. The pollutants to be detected are hydrocarbons and silicones such as paraffin oil and silicone oil. At this stage, this paper constitutes a proof of concept, but does not comply with the strict standards governing the space industry. All this work has been designed to take a step forward regarding constraints ESA has to face. The hardware was selected on the basis of its on-board suitability and stability, while the protocols put in place included measurements in a low-pressure environment (a few mBar) with the aim of approximating flight conditions.

One key point is the determination of the amount of pollution, achievable through the evaluation of the thickness of contaminants in presence. To do so, a large number of thickness characterization techniques are available4. What differentiates these techniques from one another is mainly the different thickness ranges and the type of layers to be characterized (physical state, homogeneity, conductivity). Besides, these are “laboratory” techniques and are not suitable for on-board equipment. These laboratory thickness characterization techniques and their specificities are summarized in Table 1.

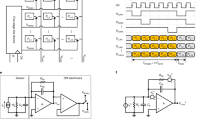

Among all techniques available for detecting or characterizing physico-chemical processes, microwave transduction is relatively recent and has been particularly developed since the last 20 years13,14,15,16,17,18,19,20. Among other, it offers advantages highly complementary to conventional transduction techniques. The principle of microwave transduction is based on changes in the dielectric permittivity of a sensitive material deposited on the surface of a sensor21. In the presence of the target, variations in permittivity result in changes of the resonant frequency measured by a device interrogating the sensor. Figure 1 illustrates the principle of microwave transduction. One of the advantages of microwave transduction is its ability to provide quantitative results22,23. Indeed, the theory of small dielectric perturbations predicts that frequency variations are proportional to the variation in permittivity, and therefore to the quantity of target adsorbed on the sensor surface24,25. In addition to the quantitative aspect, electronics required for microwave transduction are compatible and adapted to all IoT and 5G-related issues26,27.

Microwave transduction principle (a) microwave transduction principle: measurement of microwave parameters (via incident/reflected waves) of a resonant circuit covered with a layer of sensitive material and the target to be detected. (b) Theory of small dielectric perturbations: the circuit has its own resonant frequency (fraw, in black), frequency shift towards low frequencies after deposition of the sensitive material (fmaterial, in blue), new frequency shift towards low frequencies after absorption of the target (fmaterial+target, in red)

To develop the use of microwave transduction for contamination measurements, three major steps are mandatory and will be described in the Methods section, together with the used material. The first step is the generation of nanometric and inhomogeneous contaminant layers on the surface of microwave sensors. These layers have to present characteristics close to those of the undesirable deposits identified by ESA on space equipment. The second step concerns the thickness of the deposits which we must be able to estimate. Finally, the last step is the sensor response, through the measurement of the frequency shift induced by the presence of the deposit. Ideally, the characterization of the thickness of these layers by microwave transduction will be considered effective and relevant when a straight line is obtained linking the microwave variations (step 3) to the estimated thickness of the layer (step 2).

Results

In accordance with the methods described in the dedicated section, the first step is calibration. To do so, the sensor is covered with a layer of sensitive material, conditioned, weighed a first time and then the initial microwave response is measured. After which a layer of contaminant is deposited, and the new microwave response is measured. Finally, a second weighing is performed. Figure 2a,b presents the calibration kit and the reflectometer used in this work to measure the microwave parameters. Additionally, Fig. 2 also shows the raw sensor (c), the sensor covered with a sensitive material layer (d), and the corresponding sensor response (e).

Embedded microwave equipment used and sensor response. (a) Calibration kit used KitCal 3.5 mm 50 Ω. (b) Reflectometer used to measure microwave parameter R180 CopperMountain. (c) Microwave resonator without sensitive material. (d) Microwave resonator with a patch of TiO2 (doctor blade deposition technique). (e) Sensor response after deposition of sensitive material obtained by simulation (red) and measurement (black)

The results presented in Figs. 3 and 4 were obtained at the resonance frequency centered around 4.12 GHz. The evolution of frequency shifts as a function of estimated contaminant (paraffin oil) thickness is thus reported on Fig. 3, where each point is obtained from a single sensor.

According to these results, a linear evolution is observed between measured frequency variations and the thickness of the contaminant layer (R2 = 0.88). This demonstrates the quantitative aspect of microwave characterization of deposited layers. The deviation from linearity is largely explained by the experimental point at 380 nm thickness, which appears to be an outlier. It has been determined that this outlier originated from a defect in one of the sensor’s electronic connector solder joints.

Same experiments have been performed with silicone oil as contaminant. Related results are reported on Fig. 4.

The results for this contaminant also show linearity between measured microwave variations and contaminant layer thickness (R2 = 0.95), confirming the relevance of our method.

To obtain the estimated thicknesses of the contaminant layers, a calculation was performed taking into account the mass of contaminant deposited on the sensor, the density of the contaminant, and the surface area of the sensor. Tables 2 and 3 below provide details of this correspondence.

Methods

The description of the experimental part can be divided into several categories, taking into account both the equipment used to carry out this work (microwave sensor, hermetic cell, reflectometer) and the various protocols developed to obtain reproducible results. These protocols need to be robust, since in this work, each experimental point is obtained from a single sensor. In other words, to obtain the results presented here, several dozen different sensors had to be used. So, to avoid any loss of precision, each step, from sensor design and packaging, through deposition of the sensitive material on its surface, to characterization of the thickness of the contaminant layer, must be meticulously controlled.

Microwave sensor: trapezoidal multiresonator

The microwave sensor used is a trapezoidal multi-resonator with resonant frequencies evenly distributed from 1 to 8 GHz28. The advantages of this resonator are manifold. Firstly, the device offers the possibility of broadband measurement to increase the probability of observing the phenomenon of interest, namely the frequency dependency. In addition, the theory of small dielectric perturbations predicts that the higher the resonant frequency, the greater the frequency variations due to adsorptions (or desorptions) at the sensor surface. As a result, the sensor can be used to select the highest resonance frequency where the phenomena are observed, in order to measure the greatest frequency variations. The final advantage of the multi-resonator is the possibility of multiple data for a single measurement. Depending on the analysis frequency range, the measured phenomenon can be observed at the “optimal” resonance frequency (presenting the greatest variations), but also at the sensor’s other resonance frequencies (particularly useful for AI data processing, dataset construction).

The sensors used in this work were produced by industrial processes in order to minimize the differences in raw response between each resonator and thus increase reproducibility.

Sensitive material: TiO2 P25 patch

To maximize measured frequency variations, a layer (or patch) of P25 titanium dioxide is deposited on the surface of the microwave sensor29. Deposition is carried out by dropcasting (drop volume = 70 µL) on the resonant part only (spiral, using a deposition mask), while the rest of the sensor is protected. Following deposition, the sensors are conditioned for 18 h in an oven (60 °C) to induce maximum desorption of water (water due to deposition, but also atmospheric water). The great influence of variations in the amount of water on the sensor surface on microwave measurements has already been demonstrated in other works23.

Environment: reflectometer and cell

Experiments are carried out in a hermetically sealed, circular stainless steel cell of 20 cm diameter. The hermeticity of the cell guarantees freedom from external interference such as ambient air, humidity or other gaseous interferents. Microwave measurements are carried out by a Copper Mountain R-180 reflectometer (1 port, 10 MHz − 18 GHz, 14.2 × 12.6 cm). The advantage of this instrument is that it offers good performance while being small enough to be portable. A calibration step is necessary before each measurement campaign30. This calibration was carried out under the same experimental conditions as the in situ sensor at P = 30mbar (see next section).

As the aim of this work is to determine the microwave modifications (dielectric permittivity, frequency shift) due to the presence of a contaminant layer, it is necessary to carry out a “before/after” measurement of the resonator’s microwave parameters. To achieve this, these measurements must be carried out directly in situ, taking care to maintain the same experimental conditions in both cases.

A first measurement (“before” measurement) of the sensor’s microwave parameters is taken at the end of the 18 h conditioning period after deposition of the sensitive material, while a second measurement (“after” measurement) is taken just after contamination of the sensor. In both cases, microwave measurements are taken at a pressure of P = 30 mbar.

Sensor contamination protocol

Two different contaminants are studied in this work: a paraffin oil (medicated solution, COOPER) and a silicone oil (low viscosity silicone oil, 10cst, Sigma Aldrich). The technique chosen for the submicron deposits was evaporation-redeposition of the two oils. A crucible containing the contaminant is placed inside the closed cell housing the sensor, which is fixed in one position and whose surface is protected except for the resonant part (already covered with the sensitive material). A hot source is brought into contact with the crucible to raise its temperature locally, and a vacuum is drawn. This protocol induces evaporation of the contaminant. Once evaporated, the contaminant is redeposited inside the cell, particularly on the sensor coil (resonant part).

This protocol was optimized in the course of our work, and several parameters were studied: the positioning and orientation of the crucible in the cell with respect to the sensor, the pressure value, the temperature of the hot source and the initial quantity of contaminant to be introduced into the crucible. In particular, we determined that a minimum pressure was required to ensure minimum convection of the contaminant in the closed cell, otherwise the deposit would not be achieved. This pressure was estimated at 30 mbar. The variation in deposition time results in a variation in the thickness of the deposited contaminant layer.

For paraffin oil, the following experimental conditions were defined: P = 30 mbar, initial mass in the crucible m = 3.20 mg, hot-source temperature T = 350 °C, variable deposition time t = 15 s to 300 s.

For silicone oil, the following experimental conditions were defined: P = 30 mbar, initial mass in the crucible m = 3.00 mg, hot-source temperature T = 300 °C, variable deposition time t = 15 s to 300 s.

Protocol for estimating the thickness of the deposited contaminant layer

Among the various thickness estimation techniques tested (ellipsometry, mechanical profilometer, atomic force microscopy), mass difference estimation was chosen. The principle is simple: a sensor mass measurement is taken before the contaminant layer is deposited (and after conditioning in the oven), then a second mass measurement is taken after deposition of the contaminant layer. Knowing the density of the deposited material and the surface area of the contaminant layer, it is possible to estimate its thickness.

This value corresponds to an “average” thickness over the entire surface, while optical microscopy images demonstrate that the contaminant layer is inhomogeneous on the surface of the sensor (alternating between islands of large drops of contaminant and uncovered surfaces).

The balance used must meet a number of criteria: it must be as accurate as possible, while still being able to measure an object the size of the sensor (2 × 3 cm). In our case, a KERN ABT 220-5DNM balance accurate to 0.01 mg was used. Mass measurements are taken after a vacuum of 30 mbar for 2 min.

Conclusion

Organic contamination is a major problem in the space industry, particularly affecting the performance of instruments such as satellites. Despite strict standards, there is currently no method for in situ, real-time measurement of these deposits. Against this background, this work explored an innovative approach based on microwave transduction to characterize molecular contamination.

The results obtained demonstrate linearity between the thickness of the contaminating layers (paraffin and silicone oils) and the frequency variations measured. Although the thicknesses estimated in this work are higher than the characterization expectations laid down in the standards, the results validate the approach and the effectiveness of the method.

This proof-of-concept represents a significant advance towards reliable, in situ, real-time quantification of contaminant deposits in conditions representative of the space environment, using on-board equipment. Ultimately, this technology could improve the cleanliness control of sensitive devices and optimize their durability on mission.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due to non-disclosure clause from ESA but are available from the corresponding author on reasonable request.

References

Mandrile, L. et al. Direct detection and quantification of molecular surface contaminants by infrared and Raman spectroscopy. Anal. Methods. 7, 2813–2821 (2015).

Pandi, A., Locantore, I., Giuliani, M. & Saverino, A. Molecular contamination control for exomars 2022 mission. IOP Conf. Ser. Mater. Sci. Eng. 1287, 012033 (2023).

Vanhove, E., Tondu, T., Roussel, J. F., Faye, D. & Guigue, P. In situ real-time quantitative and qualitative monitoring of molecular contamination. J. Spacecr. Rockets. 53, 1166–1171 (2016).

Lin, L., Feng, C., Lopez, R. & Coronell, O. Identifying facile and accurate methods to measure the thickness of the active layers of thin-film composite membranes – A comparison of seven characterization techniques. J. Memb. Sci. 498, 167–179 (2016).

Frammelsberger, W., Benstetter, G., Kiely, J. & Stamp, R. Thickness determination of thin and ultra-thin SiO2 films by C-AFM IV-spectroscopy. Appl. Surf. Sci. 252, 2375–2388 (2006).

Handbook of Thin-Film Technology. (Springer Berlin Heidelberg, Berlin, Heidelberg, 2015). https://doi.org/10.1007/978-3-642-05430-3

Quinten, M. A Practical Guide To Optical Metrology for Thin Films (Wiley, 2012). https://doi.org/10.1002/9783527664344

Tompkins, H. & McGahan, W. Spectroscopic Ellipsometry and Reflectometry: A User’s Guide. (1999).

Harrington, G. F. & Santiso, J. Back-to-Basics tutorial: X-ray diffraction of thin films. J. Electroceram. 47, 141–163 (2021).

Yasaka, M. X-ray thin-film measurement techniques. Rigaku J. 26, 1–9 (2010).

Walton, J., Alexander, M. R., Fairley, N., Roach, P. & Shard, A. G. Film thickness measurement and contamination layer correction for quantitative XPS. Surf. Interface Anal. 48, 164–172 (2016).

Cumpson, P. J. The thickogram: A method for easy film thickness measurement in XPS. Surf. Interface Anal. 29, 403–406 (2000).

de Fonseca, B., Rossignol, J., Stuerga, D. & Pribetich, P. Microwave signature for gas sensing: 2005 to present. Urban Clim. 14, 502–515 (2015).

Li, F., Zheng, Y., Hua, C. & Jian, J. Gas sensing by microwave transduction: Review of progress and challenges. Front. Mater. 6, 2–4 (2019).

Piekarz, I. et al. Additively manufactured microwave sensor for glucose level detection in saliva. Sci. Rep. 14, 28235 (2024).

Hamza, M. N., Koziel, S. & Pietrenko-Dabrowska, A. Design and experimental validation of a metamaterial-based sensor for microwave imaging in breast, lung, and brain cancer detection. Sci. Rep. 14, 16177 (2024).

Zaarour, Y. et al. The quality monitoring of Paracetamol medicament using a noninvasive microwave sensor. Sci. Rep. 13, 17443 (2023).

Narang, R. et al. Sensitive, real-time and Non-Intrusive detection of concentration and growth of pathogenic bacteria using microfluidic-microwave ring resonator biosensor. Sci. Rep. 8, 15807 (2018).

Hasar, U. C. et al. Simple and inexpensive microwave setup for industrial based applications: Quantification of flower honey adulteration as a case study. Sci. Rep. 14, 8847 (2024).

Kandwal, A. et al. Highly sensitive closed loop enclosed split ring biosensor with high field confinement for aqueous and Blood-Glucose measurements. Sci. Rep. 10, 4081 (2020).

Barochi, G., Rossignol, J. & Bouvet, M. Development of microwave gas sensors. Sens. Actuators B Chem. 157, 374–379 (2011).

Lasserre, A. et al. From microwave gas sensor conditioning to ammonia concentration prediction by machine learning. Sens. Actuators B Chem. 367, 132138 (2022).

Lasserre, A., Simon, L., Grzelak, L., Rossignol, J. & Stuerga, D. Influence of water on the response of a microwave sensor for Ammonia detection at room temperature. IEEE Sens. J. 24, 22371–22376 (2024).

Balmus, S. B., Pascariu, G. N., Creanga, F., Dumitru, I. & Sandu, D. D. The cavity perturbation method for the measurement of the relative dielectric permitivity in the microwave range. J. Optoelectron. Adv. Mater. 8, 971–977 (2006).

Ahn, J., Youn, Y. & Hong, W. A. Concise and Time-efficient method for characterizing the permittivity of unknown materials. J. Electromagn. Eng. Sci. 23, 385–389 (2023).

Kishore, N. & Senapati, A. 5G smart antenna for IoT application: A review. Int. J. Commun. Syst. 35, 2–6 (2022).

Boric-Lubecke, O. et al. Microwave and wearable technologies for 5G. in 12th International Conference on Telecommunication in Modern Satellite, Cable and Broadcasting Services (TELSIKS) 183–188 (IEEE, 2015). https://doi.org/10.1109/TELSKS.2015.7357765

Bailly, G. et al. Microstrip spiral resonator for microwave-based gas sensing. IEEE Sens. Lett. 1, 1–4 (2017).

Ohtani, B., Prieto-Mahaney, O. O., Li, D. & Abe, R. What is Degussa (Evonik) P25? Crystalline composition analysis, reconstruction from isolated pure particles and photocatalytic activity test. J. Photochem. Photobiol Chem. 216, 179–182 (2010).

Rehnmark, S. On the calibration process of automatic network analyzer systems (Short Papers). IEEE Trans. Microw. Theory Tech. 22, 457–458 (1974).

Acknowledgements

This work was financed through an “Early Technology Development” program, following a public call for projects issued by the European Space Agency, with the aim of defining a technique for characterizing the thickness of organic contaminant layers. Funding for this project enabled the allocation of human resources to the project and covered part of the purchase of equipment needed to produce this work. We warmly thank the European Space Agency for its collaboration and trust.

Author information

Authors and Affiliations

Contributions

1- Conceptualisation : L.A; S.L; R.J; D.C; S.D2- Data Curation : L.A; S.L3- Formal Analysis : L.A; S.L; D.C4- Funding Acquisition : R.J; S.D; E.J5- Investigation : L.A; S.L; R.J; D.C; S.D6- Methodology : L.A; S.L; D.C; R.J; S.D; E.J7- Project Administration : E.J; R.J8- Supervision : E.J; R.J; S.D9- Validation : L.A; S.L; D.C; R.J; S.D; E.J10- Writing - Original Draft : L.A; S.L; R.J; E.J; D.C11- Writing - Review & Editing : L.A; S.L; R.J; E.J; D.CAll authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

All authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alexis, L., Léo, S., Julien, E. et al. Development of in situ real-time sensor for molecular contamination. Sci Rep 15, 25018 (2025). https://doi.org/10.1038/s41598-025-09312-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-09312-4