Abstract

The collimating lens has a diagonal full field angle of 65°. The aperture stop is positioned on the first surface of the lens, with an aperture stop size of 10 mm and F-number of 2.046. The angular resolution is 45 PPD, and the spatial frequency is 60 cycles/mm. This design uses a 1.03-inch microdisplay with an equal aspect ratio. The active area of the microdisplay is 18.432 mm ´ 18.432 mm. The Seidel aberrations are zero for the lightguide, independent of the material index and thickness of the lightguide. The light-emitting surface of the microdisplay is located at the object focal plane of the collimating lens. The function of the collimating lens is to collimate and project the microdisplay image into the lightguide, eventually reaching the eye for viewing. The collimating lens in the AR system can be regarded as a magnifier, with an angular magnification of 12.22. The virtual image size is 225 mm ´ 225 mm at the distance of 250 mm ahead of the viewing eye. Two metrics are developed, the line resolution and the lateral color resolution, to evaluate the amount of line warping and lateral color. The line resolution and the lateral color resolution of the collimating lens design described in this paper are 0.407 arcmin and 0.675 arcmin, respectively, both of which are less than the human eye’s angular resolution of 1 arcmin.

Similar content being viewed by others

Introduction

There are four types of optical waveguide structures used in all Augmented Reality (AR) and Mixed Reality (MR) glasses: geometrical waveguide structures1,2,3, surface relief grating waveguides4,5, volume hologram grating waveguides6,7, and polarization volume grating waveguides8,9.

Currently, both government and the private sector are striving to develop and actively promoting AR glasses applications and products like Google Glasses10. Efforts have been made to combine geometrical waveguide structure with displays by companies like Lumus11, Espon12, and Optinent13. Surface relief grating waveguide structures have been applied in displays by companies such as Microsoft14 and Magic Leap15.

The collimating lens is an important optical component of AR glasses. If the lens resolution is poor, it will affect the optical quality of the entire system, such as light source, lighting, color, and the image. In 2003, Hua and Ha proposed that the system includes a pair of micro-projection lenses16, using an LCD micro-panel with a pixel size of 41.25 μm, pixel number of 640 × 480, and the panel area of 26.4 mm×19.8 mm, diagonal length of 33 mm (approximately 1.3 inches). The optical system including beam splitter, diffractive optical elements (DOE), plastic components and aspherical surfaces is used to increase lens MTF and reduce lens size, while the focal length of the lens is 35 mm and the entrance pupil aperture is 12 mm. The optical performance includes that the field of view (FOV) is 52.4°; the maximum RMS spot value in all FOVs of the light spot diagram is 0.03 mm, which is smaller than the LCD pixel size; the distortion value is less than 2.5% and the MTF > 45% at 25 lp/mm. Pan17 uses OLED as the light source in the geometric lightguide glasses system. The pixel size is 15 μm, the number of pixels is 800 × 600, the light-emitting area is 12.75 mm×9 mm, and the diagonal length is 15.61 mm (approximately 0.61 inches). The collimating lens consists of four lenses, two of which are cemented lenses designed to correct chromatic aberration. The lens focal length is 29.3 mm, F/# is 3.66, the entrance pupil diameter is 8 mm. The optical performance includes that the system FOV is 30°; MTF > 40% at 30 cycles/mm; optical distortion < 2.73%. Hua and Gao proposed a design of a polarized head-mounted projection display (p-HMPD)18. Compared with the existing HMPD design, the image brightness of the p-HMPD system reaches three times better, this will improve the display’s performance in low lighting conditions. Using an LCD panel with the pixel size is 41.25 μm, the number of pixels is 640 × 480, the panel area is 26.4 mm×19.8 mm, the diagonal length is 33 mm (approximately 1.3inches), Hua and Gao design a lens set with 4 pieces of lens, the focal length of the lens is 31.5 mm, the entrance pupil diameter is 12 mm, and the FOV is 52.4°. The optical performance includes that the distortion value is less than 3.8%; the MTF > 30% at 20 cycles/mm, and > 50% at 12.5 cycles/mm. Zhang and Hua proposed a design of a see-through polarization-type head-mounted projection display (p-HMPD)19 that can improve the luminous efficiency of the system. An FLCoS panel was used, where the pixel size is 13.6 μm, the number of pixels is 1280 × 1024, the sensor area is 17.43 mm×13.95 mm, and the diagonal length is 22.3 mm (approximately 0.88inches). The focal length of the lens is 21.1 mm and the FOV is 55°. In the design, plastic material was used instead of glass to reduce the weight. In order to correct the residual chromatic aberration, a DOE was be used on the surface of the component. The DOE’s Abbe number is about − 3.5, so the DOE is attached on the last surface. Then Zhang and Hua’s final lens design has a collimating lens length of 34 mm, a total mass of 8.2 g, a RMS spot of 16 μm, in all fields of view, and a distortion value of less than 4.0%. MTF > 40% at the full frequency (Nyquist frequency) of 37 cycles/mm.

Sun (2024) designed a collimating lens with a 30° FOV for a 0.35-inch LCoS panel20. The entrance pupil diameter of the lens is 14 mm and the lens has an effective focal length of 16.443 mm with an F-number of 1.175. The design has four key issues: optical collimating lens design, lens manufacturing and assembly tolerance analysis, collimating lens resolution testing, and resolution testing of the AR glasses system. The fabricated lens was tested, achieving a central field image quality of 57 cycles/mm, an angular resolution of 33 pixels per degree (PPD), a 0.7 field image quality of 40.3 cycles/mm, and an angular resolution of 23 in PPD. Imaging performance testing based on a diffraction-type waveguide shows a resolution of 57 cycles/mm in the center area and an angular resolution of 33 in PPD.

The collimating lens design discussed in this paper is to reach an FOV of 65°, and it is suitable for use in AR/MR glasses incorporating any of these four types of waveguides.

Theory

Description of the AR glasses architecture, flat glass Seidel aberrations, entrance pupil position shift, magnifier principle, line resolution, and lateral color resolution.

AR glasses architecture

The structure of the collimating lens is shown in Fig. 1. The light-emitting surface of the microdisplay is positioned at the focal plane of the collimating lens. The function of the collimating lens is to collimate the image from the panel and project it through the lens onto a VHOE 1. The VHOE then directs the light through total internal reflection within the lightguide to the next VHOE 2, and finally, the image is projected onto the eye.

Tunnel diagram

The transmitted and reflected light paths within the lightguide are shown in Fig. 1. According to the prism tunnel diagram method21, the path of the chief ray at a 0° field angle within the lightguide can be considered as being traced through a flat glass, with the thickness t of the flat glass representing the path length of the chief ray within the lightguide. Assume the thickness of the lightguide is 1 mm and the center distance between the two VHOEs is 40 mm. When the 0° field angle chief ray is perpendicularly incident on VHOE 1 with a deflection angle of 55°, the light is totally reflected approximately 28 times in the lightguide, and is finally reflected to the human eye through VHOE 2. The 0° field angle chief ray travels approximately 50 mm in the lightguide, that is, t = 50 mm. Since the collimating lens design is reversible, if the lightguide position is taken as the object side and the microdisplay position is taken as the image side, then the object is at infinity and the light is collimated and incident on the collimating lens, and finally focused on the microdisplay position. The optical path of the collimating lens is shown in Fig. 2. The light paths within the lightguide for this collimating lens design are analyzed as if they were tracing through a flat glass in the object space.

Pupil position translation

When light enters the flat glass obliquely, it will experience a parallel displacement D upon exiting, as shown in Fig. 3. Here, n represents the refractive index of the flat glass (lightguide index), t represents the thickness of the flat glass, θ is the angle of incidence, \({{\theta}^{{\prime\:}}}\) is the angle of refraction, and D is the parallel displacement.

When a light ray (paraxial ray) enters the flat glass from the air at a small angle of incidence q, according to Snell’s law, sinq = nsinq\(^{{\prime\:}}\), thus q = nq\(^{{\prime\:}}\). sin(90°-q) = cosq= D/x2»1, thus D»x2. Furthermore, tan q»q =(x1 + x2)/t, tanq\(^{{\prime\:}}\)»q\(^{{\prime\:}}\)=x1/t. Substituting θ and θ′ into the equations, we get q = q\(^{{\prime\:}}\)+x2/t = q/n + x2/t. Therefore, the formula for the parallel displacement D is

Taking the collimating lens shown in Fig. 4 as an example, the aperture stop is in front of the lens.

When no flat glass is placed in the object space, the aperture stop coincides with the entrance pupil; they are both in the same position. The size of the aperture stop is equal to the size of the entrance pupil.

If a flat glass plate is placed in front of the aperture stop of the collimating lens, as shown in Fig. 5, the entrance pupil will move to a distance d in front of the aperture stop. Since the incident angle θ of the chief ray entering the flat glass plate is equal to the exit angle, the incident and refracted rays will experience a parallel displacement D, as illustrated in Fig. 5a. The relationship between d and D is given by

When a flat glass is placed in front of the collimating lens, the entrance pupil shifts forward by a distance , but the size of the entrance pupil remains unchanged, as shown in Fig. 5(b). The size and position of the entrance pupil, as seen from the object space, represent the size and position of the virtual image of the aperture stop. However, if the distance between the lens and the flat glass is too large, the clear aperture of the light source projected onto the surface of the flat glass will increase significantly, thereby increasing the clear aperture at the incident surface of the flat glass (i.e., increasing the clear aperture at the lightguide’s incident surface).

When a flat glass plate is placed in front of the aperture of the collimating lens: (a) the chief ray tracing showing a diagram of the maximum field angle relationship between position of the entrance pupil and aperture stop; (b) the marginal ray tracing of the maximum field angle, demonstrating that the size of the entrance pupil remains unchanged despite the change in its position.

Lagrange invariant and refraction invariant

Before calculating the Seidel aberrations, it is necessary to define the Lagrange invariant and the refraction invariant22, as shown in Fig. 6. The parameters are defined as follows: B is the center of curvature of the surface; n is the refractive index of the object space, and \(\:{n}^{{\prime\:}}\)is the refractive index of the image space; R is the radius of curvature of the surface, which has a positive value if the center of curvature is to the right of the surface and a negative value if it is to the left. The angle is positive if the ray is rotated clockwise to reach the normal line on the surface; the angle is negative for the counterclockwise direction. In additional, i and \(\:\overline{i}\) are the incident angles of the marginal ray and the chief ray, respectively; u and u′ are the angles between the marginal ray and the optical axis on the surface of the object space and the image space; \(\:\stackrel{-}{u}\) is the angle between the chief ray and the optical axis on the surface of the object space. The height is positive if upwards and negative if downwards; h and \(\:\stackrel{-}{h}\) are the heights on the surface of the marginal ray and the chief ray, respectively; h is the object height; h′is the image height.

The incident angle i of the marginal ray, as well as the exterior angle between the marginal ray and its normal line, are determined by the following formula:

where c is the curvature, c = 1/R; \(\:\overline{i}\) is the chief ray incident angle, which is also the exterior angle between the chief ray and its normal line. This can be formulated as follows:

.

The formula for the marginal ray refraction invariant (A)

The formula for the chief ray refraction invariant (\(\:\stackrel{-}{A}\))

The formula for the Lagrange invariant (H) is.

Seidel aberrations of flat glass

The Seidel aberration is related to the height and angle of the chief ray at the maximum half field angle of 32.5° and the marginal ray at the 0° field angle, as shown in Fig. 7.

Here, n1 and n3 represent the refractive indices of the air medium, with n1 = n3 = 1, and n2 is the refractive index of the lightguide medium, with n2 = n; i1 and i1′ are the incident and refracted angles of the marginal ray on the first surface, respectively; i2 and i2′ are the incident and refracted angles of the marginal ray on the second surface, respectively;\(\:\overline{i}\)1 and \(\:\overline{i}\)1′ are the incident and refracted angles of the chief ray on the first surface, respectively;\(\:\overline{i}\)2 and \(\:\overline{i}\)2′ are the incident and refracted angles of the chief ray on the second surface, respectively.

There are seven types of Seidel aberrations: spherical aberration SI, coma SII, astigmatism SIII, field curvature SIV, optical distortion SV, axial color CI, and lateral color CII.

The Seidel aberrations of the flat glass are the sum of the Seidel aberrations on the first and second surfaces, as in Eq. (8) to (14) below22. Thus,

where \(\:{A}_{1}\)and \(\:{A}_{2}\)are the refraction invariants of the marginal ray on the first and second surfaces, respectively; h1 and h2 are the heights of the marginal ray on the first and second surfaces, respectively; \(\:{\left(\frac{u}{n}\right)}_{1}=\frac{{u}_{1}^{}}{{n}_{2}}-\frac{{u}_{1}}{{n}_{1}}=\frac{{u}_{2}}{n}-{u}_{1}\), \(\:{\left(\frac{u}{n}\right)}_{2}=\frac{{u}_{2}^{}}{{n}_{3}}-\frac{{u}_{2}}{{n}_{2}}={u}_{2}^{}-\frac{{u}_{2}}{n}\), \(\:{u}_{1}^{}={u}_{2}\); \(\:{u}_{1}\)and \(\:{u}_{1}^{}\) are the angles between the marginal ray and the optical axis on the first surface for the object and the image spaces, respectively;\(\:{u}_{2}\) and \(\:{u}_{2}^{}\)are the angles between the marginal ray and the optical axis on the second surface of the object and image spaces, respectively.

where \(\:{\overline{A}}_{1}\)and \(\:{\overline{A}}_{2}\)are the refraction invariants of the chief ray on the first and second surfaces, respectively.

where \(\:{\left(\frac{1}{n}\right)}_{1}=\frac{1}{{n}_{2}}-\frac{1}{{n}_{1}}=\frac{1}{n}-1\), \(\:{\left(\frac{1}{n}\right)}_{2}=\frac{1}{{n}_{3}}-\frac{1}{{n}_{2}}=1-\frac{1}{n}\);c1, c2 are the curvatures on the first and second surfaces, respectively.

.

In this design, the light source has a wavelength range from 0.4861 μm(F-line) to 0.6563 μm(C-line), with a central wavelength of 0.5876 μm(d-line). In addition,\(\:{n}_{1}\) and \(\:{n}_{3}\) represent the refractive index of air at the d-line wavelength, with \(\:{n}_{1}={n}_{3}=1\); \(\:{n}_{1}\)and \(\:{n}_{3}\) represent the change in the refractive index of air from the F-line to the C-line, with \(\:{n}_{1}={n}_{3}=0\); \(\:{n}_{2}\)represents the refractive index of the lightguide at the d-line wavelength, with \(\:{n}_{2}={n}_{d}\); and \(\:{n}_{2}\) represents the change in the refractive index of the lightguide from the F-line to the C-line, with \(\:{n}_{2}={n}_{F}-{n}_{C}\); \(\:{V}_{d}\) represents the Abbe number of the lightguide, defined as \(\:{V}_{d}\)=\(\:\frac{{n}_{d}-1}{{n}_{F}-{n}_{C}}\).

.

As shown in Fig. 7, when the object is at infinity, the marginal rays are perpendicularly incident on the first and second surfaces of the flat glass, so the angles of incidence are both zero, i.e., \(\:{i}_{1}={i}_{2}=0\). According to the refraction invariant, we can obtain \(\:{A}_{1}=\) \(\:{A}_{2}=0\). Based on the Seidel aberration expressed in Eqs. (8), (9), and (13), we can deduce that the \(\:{S}_{I}\), \(\:{S}_{II}\), and \(\:{C}_{I}\)are all zero.

Given that the curvatures of the first surface c1 and the second surface c2 of the flat glass are both zero, from Eq. (3) we have i1 = u1, i1′=u1′; i2 = u2, i2′=u2′. Therefore, the angles between the marginal rays and the optical axis are \(\:{u}_{1}={u}_{1}^{{\prime\:}}={u}_{2}={u}_{2}^{{\prime\:}}=0\). Substituting this into Eq. (10), where \(\:{\updelta\:}{\left(\frac{u}{n}\right)}_{1}=(\frac{{u}_{1}}{{n}_{2}}-\frac{{u}_{1}}{{n}_{1}})\)、\(\:{\updelta\:}{\left(\frac{u}{n}\right)}_{2}=(\frac{{u}_{2}}{{n}_{3}}-\frac{{u}_{2}}{{n}_{2}})\), we get \(\:{\updelta\:}{\left(\frac{u}{n}\right)}_{1}={\updelta\:}{\left(\frac{u}{n}\right)}_{2}=0\). Therefore, the astigmatism \(\:{S}_{III}\)of the flat glass is zero.

Given c1 = c2 = 0, from Eq. (11), we can deduce that the field curvature \(\:{\text{S}}_{\text{I}\text{V}}\)for the flat glass is zero.

According to Eq. (12), when c1 = c2 = 0, then \(\:{S}_{V}\)= − \(\:\frac{{\overline{A}}_{1}^{3}}{{A}_{1}}{h}_{1}{\left(\frac{u}{n}\right)}_{1}-\frac{{\overline{A}}_{2}^{3}}{{A}_{2}}{h}_{2}{\left(\frac{u}{n}\right)}_{2}.\) When the chief ray enters the flat glass, the \(\:\overline{{i}_{1}}\) incident angle on the first surface and the \(\:{\overline{i}}_{2}^{}\) refractive angle on the second surfaceare both equal, i.e., \(\:{\overline{i}}_{1}={\overline{i}}_{2}^{}\), and n1 = n3 = 1, so we have \(\:{\overline{A}}_{1}\)= n1\(\:{\overline{i}}_{1}\)= n3\(\:{\overline{i}}_{2}^{}={\overline{A}}_{2}\). The refraction invariant of for the marginal ray on the first surface is A1=n1i1= n1u1= n2i1′= n2u1′(c1 = 0), and similarly, A2= n2u2= n3u2′(c2 = 0). Therefore, the formulation for optical distortion can be derived from Eq. (12) as follows:

The lightguide material used is BK7 glass, with nd = 1.5168 and Vd = 64.1191. The refraction invariant on the first surface of the flat glass is \(\:{\stackrel{-}{A}}_{1}={n}_{0}{\overline{i}}_{1}\) = 1´tan32.5° = 0.63707 = \(\:{\stackrel{-}{A}}_{2}\), \(\:{h}_{1}\) = \(\:{h}_{2}=\)5 mm and n=nd = 1.5168; the optical distortion of the first surface of the flat glass is SV1 = 0.73088; and the optical distortion on the second surface is SV2=-0.73088. Therefore, the total optical distortion of the flat glass is zero.

Similarly, the lateral color equation, Eq. (14) can be rewritten as follows:

.

The first surface lateral color of the flat glass is \(\:{C}_{II1}=-\text{0.016926}\), and the second surface lateral color is \(\:{C}_{II2}=\text{0.016926}\). Therefore, the lateral color of the flat glass is zero. The Seidel aberration values of flat glass is shown in Table 1.

Since all Seidel aberrations of the flat glass are zero, the collimating lens can be designed independently without consideration of the lightguide23.

Microdisplay and collimating lens specifications

This design of a collimating lens with a 65-degree full field angle uses a 1.03-inch microplay manufactured, the pixel number 2560 × 2560. The effective area of the microdisplay is 18.432 mm × 18.432 mm, and the diagonal length is 26.066 mm.

The specifications for the collimating lens are as follows: diagonal object height of 13.033 mm, focal length of 20.458 mm, diagonal full field angle of 65°, horizontal full field angle of 48.50°, aperture stop located on the first surface of lens, entrance pupil diameter of 10 mm, F/# = 2.046, spatial frequency of 60 cycles/mm, and angular resolution of 45 PPD.

Principle of the magnifying glass

When an object with a height \(\:{y}_{o}\)is placed at the distance of distinct vision \(\:{d}_{o}\)(\(\:{d}_{o}\)=-250 mm), the angle a(a < 0) is between the chief ray of the object and the optical axis. At this time, an inverted reduced real image will appear on the retina, as shown in Fig. 8.

Then the relationship between the angle a, object height yo and distance of distinct vision do is formulated as follows:

.

When a magnifying glass is placed between an object and the human eye, and the object is located at the object focal point or within the object focal point of the magnifying glass, an upright magnified virtual image of the object will form. The angle between the chief ray of the image height yi of this virtual image and the optical axis is b (b < 0) as shown in Fig. 9.

Here F is the object focal point; \(({{f}^{{\prime\:}}})\) is the image focal point; So is the object distance (So < 0); Si is the image distance (Si < 0); f is the object focal length (f < 0); \({{f}^{{\prime\:}}}\) is the image focal length (\({{f}^{{\prime\:}}}\) = -f).

If the object is located at the object focus point (F), then the object distance So=f and the image distance Si=-¥, then the relationship between b, yo and f (or \({{f}^{{\prime\:}}}\) ) is

.

The angular magnification (\(\:{M}_{p}\)) of the magnifying glass24 can be obtained by taking the ratio of tanto\(\:\text{t}\text{a}\text{n}\), as follows:

.

In the design described in this paper, the collimating lens functions like a magnifying glass. As a result, the image is magnified after passing through the collimating lens. Let do be the distance of distinct vision, do=-250 mm, \({{f}^{{\prime\:}}}\)=20.458 mm, and MP=12.22.

The active area of the microdisplay is 18.432 mm ´ 18.432 mm, the horizontal object height yo÷÷ and vertical object height yo^ on the microdisplay are 9.216 mm and 9.216 mm, respectively. If the AR glasses do not have a collimating lens, then the horizontal half angle and vertical half angle of the microdisplay seen by the human eye be a÷÷ and a^, respectively. From Eq. (17), we can obtain a÷÷ =-2.111° and a^=-2.111°. Assume that the horizontal half angle and vertical half angle of the microdisplay as seen by the human eye through the collimating lens are b÷÷ and b^, respectively. By using Eq. (18), we can obtain b÷÷ =-24.251° and b^. The horizontal image height (yi÷÷) and the vertical image height (yi^) of the virtual image when the eyes can see at the distance of 250 mm can be calculated 112.622 mm and 112.622 mm. Then the full dimensions of the virtual image are 225.244 mm´225.244 mm.

Optical distortion, TV distortion and line resolution

Optical distortion is a phenomenon that occurs when the magnification varies with the height of different object points under fixed object distance conditions. The definition of optical distortion is

.

The size of the projection microdisplay used in this study is 1.03 inches, with an aspect ratio of 1:1. The microdisplay position is defined as the image plane, with the object located in the direction of the lightguide and at infinity. The collimating lens is designed with a half field angle of 32.5°, producing an image area of 18.432 mm × 18.432 mm and a diagonal image height of 13.033 mm, which is defined as the 1.0 field. The vertical image height of 9.216 mm is defined as the 0.707 field. In Fig. 10, the dashed line indicates the position of the paraxial image, and the solid line indicates the position of the real image. The horizontal line warping (D) is the same as the vertical line warping, and is defined as the absolute difference between the maximum vertical real height (h^max) and the minimum vertical real height (h^min) within the field of view from 0.707 to 1.0, as described

.

TV distortion is mainly used to describe the degree of warping of lines in the screen image. Since the image is square, the horizontal TV distortion is equal to the vertical TV distortion. Taking horizontal TV distortion as an example, we set the paraxial vertical image height to be 0.707 of the field paraxial image height (h0.707P). The horizontal TV distortion \(\:\text{TV}{\text{D}}_{\text{H}}\) is defined as the ratio of horizontal line warping \(\:\left(\right)\) to the paraxial vertical image height\(\:\left({\text{h}}_{0.707\text{p}}\right)\). It is also the absolute value of the difference between the maximum (ODa) and minimum (ODb) optical distortion values within the 0.707 to 1.0 field range, as follows25:

.

The object-space horizontal line resolution () is related to the horizontal line warping (D) and the distance of distinct vision (do) of the human eye. The unit of is arc min. The definition of object-space horizontal line resolution () is given by

.

Multiplying by the angular magnification of the collimating lens, the image-space horizontal line resolution (′) can be obtained by

.

To ensure that the observer does not perceive any warping at the edges of the image, the horizontal line resolution of the image-space needs to be smaller than the angular resolution (1′) of the human eye.

Definition of lateral color and lateral color resolution

The white light emitted from a point off-axis of the object is imaged by the lens. On the image plane at the central wavelength image position, for different wavelengths of the light source, the real image height is different. The lateral color (\(\:{{\Delta\:}}_{{\uplambda\:}}\)) is defined as the absolute value of the difference between the maximum and minimum values of the real image height, from short wavelength to long-wavelength light, as shown in Fig. 11.

Lateral color causes image dispersion. Assume that the position of the microdisplay is the position of the object. The object will be affected by the lateral color of the collimating lens. The object-space lateral color resolution (Ql) is described

.

The collimating lens in this article functions as a magnifying glass. When the microdisplay image passes through the collimating lens, the image will be magnified by the collimating lens, and the lateral color of the image will also be magnified together. The angular resolution of the human eye is 1’. In order to prevent the human eye from detecting chromatic aberration in the image. The image-space lateral color resolution (\(\:{{\Theta\:}}_{}^{{\prime\:}}\)), after magnification by the collimating lens, needs to be less than 1’. The image-space lateral color resolution (\(\:{{\Theta\:}}_{}^{{\prime\:}}\))25 is

.

Optimization of collimating lens design

Lens design data and lens diagram

The design of the 65-degree full field angle collimating lens comprises of four spherical glass lenses, three plastic aspherical lenses, and a flat protective glass plate. The four glass lenses include triplet achromatic lenses to correct chromatic aberration. The effective focal length of the lens is 20.458 mm. The lens design data and aspherical lens data are shown in Tables 2 and 3, respectively.

Analysis of lens image quality

The analysis of lens image quality included the Modulation Transfer Function (MTF), distortion, lateral color, and relative illumination. The MTF imaging quality results are shown in Fig. 12. In the figure, the horizontal axis represents the spatial frequency, with units in cycles/mm, and the vertical axis represents the MTF values; ‘T’ denotes the tangential direction and is represented by solid lines, while ‘S’ denotes the sagittal direction and is represented by dashed lines. Each curve in the figure represents the MTF values for different half field angles. The design’s maximum spatial frequency is set at 60 cycles/mm. The lowest MTF value for this lens design is 0.504 in the tangential direction at a half field angle of 28°.

The relative illumination curve is shown in Fig. 13. In this figure, the horizontal axis represents the half field angle, and the vertical axis represents the relative illumination (%). The red curve shows the relative illumination values at different half field angles. In this design, the relative illumination is greater than 50%.

The results for optical distortion are shown in Fig. 14.

In Fig. 14a, the horizontal axis represents optical distortion (%) and the vertical axis represents the half field angle. The green curve illustrates the variation in optical distortion across different half field angles. The maximum and minimum optical distortions, ODa and ODb, within the 0.707 to 1.0 field range are 0.82132% and 0.79483%, respectively. The horizontal television distortion TVDH is 0.02631%, and the paraxial image height at the 0.707 field is 9.216 mm. The horizontal line warping D = 2.425 × 10− 3 mm, the object-space line horizontal resolution Q is 0.0333 arcmin, and the angular magnification MP is 12.22. This results in an image-space horizontal line resolution Q′ of 0.407 ′, which is much smaller than the human eye’s resolution of 1 arcmin, making the line warping indiscernible to the naked eye. Figure 14b shows the grid chart of the optical distortion. The horizontal axis represents the image height at the horizontal half field angle, and the vertical axis represents the image height at the vertical half field angle. The black curve indicates the variation in paraxial image height, while the red curve represents the real image height. Although the height of the red curve is greater than that of the black curve at the same half field angle position, the red curve is a straight line, indicating that the human eye cannot perceive the line warping.

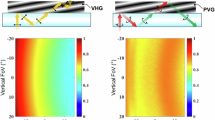

The lens design presented in this paper is based on three wavelengths: short wavelength (F-line, 0.4861 μm), reference wavelength (d-line, 0.5876 μm), and long wavelength (C-line, 0.6563 μm). The design values for lateral color are shown in Fig. 15. In this figure, the horizontal axis represents lateral color in mm, and the vertical axis represents the half field angle in degrees. The red curve represents the lateral color values for the short wavelength and the long wavelength across different field angles. The maximum value of the red curve occurs at a half field angle of 30.875°, with a value of − 2.383 μm. The green curve represents the lateral color values for the short wavelength and the reference wavelength. The maximum value of the green curve occurs at a half field angle of 32.5°, with a value of 3.266 μm. Since the Code V optical software does not display the lateral color between the reference and long wavelengths, we can deduce these values by subtracting the green curve values from the red curve values. From Fig. 15, it is evident that the maximum lateral color between the reference and long wavelengths occurs at a half field angle of 30.875°. At this angle, the lateral color values of the red and green curves are − 2.383 μm and 1.629 μm, respectively, resulting in a lateral color difference of -4.012 μm. Therefore, the lateral color for this collimating lens design, \(\:{{\Delta\:}}_{{\uplambda\:}}\)is 4.012 μm, substituting this into Eq. (25), we can obtain the object-space lateral color resolution \(\:{}_{{\uplambda\:}}\) which is 0.0552′. The image-space lateral color resolution \(\:{{\Theta\:}}_{}^{{\prime\:}}is{\text{M}}_{P}\times\:{{\Theta\:}}_{}\)=12.22 × 0.0552′=0.675′. This value is less than the human eye’s angular resolution of 1′, making the lateral color imperceptible to the naked eye.

Analysis of the seidel aberrations of the collimating lens systems

The collimating lens, without an object-side flat glass, consists of a total of 15 surfaces. Since the Seidel aberrations are determined by the marginal ray at 0° field angle and the chief ray at the 32.5° half field angle, we use six rays including the upper marginal rays, chief rays, and lower marginal rays at 0° field angle (red curves) and the 32.5° half field angle (blue curves) as shown in Fig. 16. The Seidel aberrations of the collimating lens are listed in Table 4.

When the object is at infinity, the incoming light is a collimating beam. The Seidel aberrations of the object-side flat glass are independent of its refractive index and thickness. Assuming the flat glass has a thickness of 50 mm and is made of BK7 material, as shown in Fig. 17.

The Seidel aberrations of the collimating lens system are listed in Table 5. Since the aperture stop is located on the first surface of the collimating lens, the collimating beam remains collimated after passing through the flat glass. The marginal ray enters at the edge of the aperture stop, while the chief ray enters at its center. The height and angle at which the marginal ray at 0° field angle and the chief ray at the 32.5° half field angle enter the aperture stop are the same as in Fig. 16. Therefore, the Seidel aberrations of each surface in the collimating lens remain the same as in Table 4, and the Seidel aberration of the flat glass is zero. As a result, the Seidel aberrations of the collimating lens remain unchanged regardless of whether the object-side flat glass is present.

Given that the object distance is at infinity, the image plane is located at the focal plane of the collimating lens, which corresponds to the microdisplay position. In this case, the image distance equals the focal length of the collimating lens, which is 20.458 mm. If the emitting surface is not at the focal plane, the object-side light beam will no longer be collimated. Consequently, the Seidel aberrations of the object-side flat glass will no longer be zero, and the Seidel aberrations of the collimating lens will change from their optimized values, leading to a degradation in optical quality. For example, if the object distance is 3032 mm, the image distance becomes 20.597 mm. If the microdisplay is shifted 0.139 mm behind the focal plane of the collimating lens (resulting in an image distance of 20.597 mm), the light emerging from the collimating lens will no longer be collimated but will instead converge at approximately 3032 mm in front of the collimating lens. The Seidel aberrations of this collimating system are listed in Table 6.

By comparing Table 6 with Table 5, when non-collimated light enters the object-side flat glass, it introduces aberrations such as astigmatism (SIII), distortion (SV), and lateral color (CII). If the thickness of the flat glass is thicker, these aberrations become more obvious. Additionally, this affects the aberrations of the collimating lens, altering the optimization results of the collimating lens. Manufacturing tolerances exist in collimating lens, such as lens thickness, lens refractive index, surface curvature radius, and air gaps between lenses. As a result, the focal length and back focal length of each collimating lens may deviate from the design values. If the microdisplay light source is placed outside the focal plane, the light exiting the collimating lens will be convergent. Conversely, if the microdisplay light source is placed inside the focal plane, the exiting light will be divergent. Both cases introduce aberrations in the lightguide and alter the aberrations of each surface in the collimating lens, affecting its overall optimization. This issue is unavoidable. Therefore, during assembly, a focusing adjustment must be performed to ensure that the microdisplay light source, after passing through the collimating system, produces a well-collimated beam.

Lens manufacturing and assembly tolerance analysis

Based on the tolerance range for lens manufacturing and lens assembly, the image quality produced by the lens can be simulated. The tolerances include the radius of curvature (DLF), the cylinder irregularity (CYD, CYN), the thickness (DLT), the refractive index (DLN), the V-number (DLV), the wedge (TRX, TRY), the tilt (BTX, BTY), the displacement (DSX, DSY), and the roll (RLX, RLY). The range of tolerance parameters set for this lens design is shown in Table 7.

The cumulative distribution probability curve for tolerance analysis is found by combining the effects of all tolerance items. The vertical axis represents the cumulative distribution probability, and the horizontal axis represents the MTF. Tan stands for tangential direction, and rad stands for sagittal direction. At a cumulative probability of 97.7%, the lowest MTF value for the tolerances at the 1.00 field tan position is 0.1499, as shown in Fig. 18.

Comparison with existing collimating lens designs

To demonstrate the performance advantages of the proposed 65-degree collimating lens, a comparative analysis was conducted with several representative designs reported in the literature, including reference16,17,18,19,20. These studies focus on different collimator designs based on various system architectures and design constraints. The comparison, summarized in Table 8, includes key performance metrics such as field of view (FOV), modulation transfer function (MTF), angular resolution (PPD), and optical distortion.

As shown in Table 8, the design in this study achieves a wider field of view (65°) than most existing systems16,17,18,19,20, while maintaining high angular resolution (45 PPD and 60 cycles/mm), and extremely low optical distortion (1.0%). These values are below the human eye’s detection threshold of 1 arcmin, indicating that the proposed collimating lens offers superior optical performance and is well-suited for lightguide-based AR applications.

Conclusion

Since all Seidel aberrations for the lightguide are zero, the collimating lens can be optimized independently without considering the influence of the lightguide.

The function of the collimating lens is a magnifying glass. Given that the focal length of the collimating lens is 20.458 mm, the angular magnification MP is 12.22.

To minimize television distortion, the difference between the maximum and minimum optical distortion within the 0.707 to 1.0 field range must be as small as possible. In this study, the horizontal television distortion of the collimating lens is 0.02631%, resulting in an image-space line resolution of 0.412 arcmin, which is less than the human eye’s resolution of 1 arcmin. Therefore, in the MR glasses system, the human eye cannot perceive any line warping. The maximum lateral color aberration occurs at a half field angle of 30.875° between the reference wavelength and the long wavelength, with a value of 4.012 μm. This corresponds to an image-spaces lateral color resolution of 0.675 arcmin, which is less than the angular resolution of 1′ perceived by the human eye rendering the lateral color of the collimating lens imperceptible to the eye.

Compared with the representative collimator optics in reference16,17,18,19,20, the proposed design offers the widest field of view, highest angular resolution, and lowest optical distortion. These results substantiate the effectiveness and practical advantage of the proposed collimating lens for lightguide-based AR display systems.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Yang, J. M., Gerard, P. & Fontaine, J. Design of a large field-of-view see-through near to eye display with two geometrical waveguides. Opt. Lett. 41, 5426–5429 (2016).

Hung, H. C. & Pan, J. W. Optical design of a compact see-through head mounted display with light guide plate. In SID Symposium Digest of Technical Papers 45, 293–296 (2014).

Zhao, K. W. & Pan, J. W. Optical design for a see-through head-mounted display with high visibility. Opt. Express. 24, 4749–4760 (2016).

Xiao, J., Liu, J., Han, J. & Wang, Y. Design of achromatic surface microstructure for near-eye display with diffractive waveguide. Opt. Commun. 452, 411–416 (2019).

Liu, Z. Y., Pan, C., Pang, Y. & Huang, Z. A full-color near-eye augmented reality display using a Tilted waveguide and diffraction gratings. Opt. Commun. 431, 45–50 (2019).

Kasai, I., Tanijiri, Y., Endo, T. & Ueda, H. A forgettable near eye display. In International Symposium on Wearable Computers (2000).

Mirza, K. & Sarayeddine, K. Key challenges to affordable see through wearable displays: The missing link for mobile AR mass deployment. In Internal technical paper-OPTINVENT SA (2012).

Weng, Y., Xu, D., Zhang, Y., Li, X. & Wu, S. T. Polarization volume grating with high efficiency and large diffraction angle. Opt. Express. 24, 17746–17759 (2016).

Weng, Y. et al. Liquid-crystal-based polarization volume grating applied for full-color waveguide displays. Opt. Lett. 43, 57735776 (2018).

He, J., Choi, W., McCarley, J. S., Chaparro, B. S. & Wang, C. Texting while driving using Google glasstm: promising but not distraction-free. Accid. Anal. Prev. 81, 218–229 (2015).

Lumus & Geometrical Waveguide Type Glasses. https://lumusvision.com/how-it-works/

Epson & Geometrical Waveguide Type Glasses. https://phys.org/news/2016-02-world-lightest-oled-binocular-see-through.html

Optinvent & Geometrical Waveguide Type Glasses. http://www.optinvent.com/our_products/ora-2/

Microsoft, SRG. https://www.microsoft.com/zh-tw/hololens

Magic Leap, SRG. https://www.magicleap.com/magic-leap-2

Hua, H., Ha, Y. & Rolland, J. P. Design of an ultralight and compact projection lens. Appl. Opt. 42, 97–107 (2003).

Pan, J. W. & Hung, H. C. Optical design of a compact See-through head mounted display with light guide plate. J. Disp. Technol. 11, 223 (2015).

Hua, H. & Gao, C. Design of a bright polarized head-mounted projection display. Appl. Opt. 46, 2600–2610 (2007).

Zhang, R. & Hua, H. Design of a polarized head-mounted projection display using ferroelectric liquid-crystal-on-silicon microdisplays. Appl. Opt. 47, 2888–2896 (2008).

Sun, W. S. et al. Design and manufacture of 30-degree projection lens for augmented reality waveguide. Micromachines 15, 1198 (2024).

MIL-HDBK-141. Optical Design, 13–38. (Defense Supply Agency, 1987).

Welford, W. T. Aberrations of the Symmetrical Optical System (Academic, 1974).

Mahajan, V. N. Aberration Theory Made Simple, Chap. 3, 2nd ed. (SPIE, 2011).

Hecht, E. Optics, Chap. 6, 4th ed. (Addison-Wesley, 2001).

Sun, W. S., Huang, C. M. & Lin, J. S. Discussion of temperature, TV distortion, and lateral color of a 4-meagpixel DLP project lens. OSA Continuum 2, 3188–3203 (2019).

Acknowledgements

This study was supported in part by the Ministry of Science and Technology, under project numbers, Taiwan MOST 113-2218-E−008-011-MBK and MOST 113-2221-E−008-048. The authors would like tahnk Synopsys for providing Code V.

Author information

Authors and Affiliations

Contributions

WSS proposed the design concept, mastered the design process and wrote the manuscript; YSH and GWH designed the lens and joined the technical discussion; designed the lens; YLS and WKL searched for information; WCS, SHL, TXL, and YWY provided opinions and ideas on the paper topic; CCS was the team leader, proposed the idea, and polished the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, WS., Hsu, YS., Su, YL. et al. Design of a 65-degree collimating lens for lightguide-based AR glasses. Sci Rep 15, 24861 (2025). https://doi.org/10.1038/s41598-025-09331-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-09331-1