Abstract

Bimetallic Au@Pt dendritic core–shell nanoparticles were synthesized via co-reduction with ultrasonication, and their nanostructures were characterized to gain insights into the formation mechanism of the Pt shell on the Au core. Two types of nanoparticles, one with ultrasonication and another without, were prepared and examined by scanning transmission electron microscopy to understand the role of ultrasonication. With or without ultrasonication, a thin layer of Pt shell was present on the Au core. The ultrasonication resulted in the Pt cluster formation from precursors, the Pt cluster dispersion, the Pt granule formation, and the Pt granule collision with the Au core. Consequently, Au@Pt nanoparticles were synthesized with the Pt dendritic shell consisting of Pt granules. These findings highlight the potential of ultrasonication in the controlled synthesis of nanoparticles with unique nanostructures.

Similar content being viewed by others

Introduction

Nanoparticles (NPs) with tailored structures and compositions have attracted significant attention for their versatile applications in catalysis1,2,3,4, optics5,6,7, and biomedical fields8,9,10. Platinum (Pt) NPs are well-known for their exceptional catalytic properties, making them ideal for reduction reactions1,2, and hydrogen production3. However, their high cost and limited durability11 of Pt during catalytic processes poses challenges to their widespread application. Bimetallization, combining Pt with another element, is a highly effective approach that reduces Pt usage, enhances durability, and improves catalytic efficiency12,13,14,15,16,17. Among various bimetallic NPs, Au-Pt NPs have been designed to optimize the Pt usage while improving the catalytic performance18,19,20,21,22, with various microstructures including core–shell23,24,25, solid solution alloys26, intermetallic alloys27,28, phase-segregated structures29,30,31,32,33,34,35,36,37, and others, as schematically illustrated in Fig. 1.

Among these structures, Au@Pt NPs have emerged as promising alternatives to monometallic Pt NPs by combining the unique properties of both Au and Pt. Au, known for its excellent chemical stability38 and tunable plasmon resonance properties39, provides a robust core that enhances the durability of the bimetallic Au@Pt NPs. In addition, the plasmonic properties of Au enable enhanced light absorption and localized heating, making Au@Pt NPs suitable for applications in photothermal therapy5,7 and surface-enhanced Raman scattering (SERS)40.

The Pt shell, grown on the Au core, retains its superior catalytic activity, providing a high specific surface area and abundant active sites for chemical reactions41. The synergetic effects between Au and Pt not only enhance the catalytic performance but also enhance stability and efficiency, making these NPs highly attractive for advanced applications in electrocatalysis4, environmental remediation42, and biosensing 9.

Seed-mediated methods are commonly applied to synthesize Au@Pt NPs, enabling precise control over the core and shell morphology and size through a two-step synthesis43,44. More recently, a simpler one-step synthesis has been developed4, based on the difference in reduction potentials between PtCl62− and AuCl4−4,45,46. The reduction reactions of these ions and their standard reduction potentials are presented in equations, Eqs. (1)–(3)4.

Yamauchi et al. successfully synthesized Au@Pt dendritic core–shell NPs in a one-step synthesis using Pluronic F127 as a capping agent47,48. Wang et al. demonstrated the formation of dendritic Pt granules at high molar concentrations of Pt precursors47, suggesting that the critical role of Pt supersaturation in their formation. Ataee-Esfahani et al. reported that ultrasonication increased the Pt nucleation rate and refined granule structures48. They also proposed ultrasonication as an effective route for synthesizing dendritic Pt shells at low Pt precursor concentrations.

Ultrasonication accelerates and promotes chemical reactions in solution, including the reduction of Pt ions through ultrasonic cavitation. Cavitation involves the formation and collapse of microscopic bubbles, generating high-pressure and high-temperature conditions that facilitate Pt ion reduction and NP formation49,50. Sonochemical synthesis offers several advantages, including rapid reaction rates, precise control over size and morphology, short reaction periods, low reaction temperatures, high yields, and uniform size distribution51.

In this study, Au@Pt dendritic core–shell NPs were synthesized at low Pt precursor concentrations using Pluronic F127 as a structural-directing agent, combined with co-reduction and ultrasonication. For comparison, Au@Pt NPs were also synthesized without ultrasonication. Their microstructures were characterized by (scanning) transmission electron microscopy ((S)TEM) to investigate the role of ultrasonication and its effect on the growth mechanism of Pt shells on the Au core.

Materials and methods

Materials

Gold (III) chloride trihydrate (HAuCl4·3H2O, ≥ 99.9% trace metals basis, Sigma-Aldrich), chloroplatinic acid solution 8 wt% (H2PtCl6, Sigma-Aldrich), Pluronic F127 (molecular weight ~ 12,600 g/mol, Sigma-Aldrich), and L(+)-Ascorbic acid (≥ 99.6% , FUJIFILM Wako Pure Chemical Corporation) were purchased and used without further purification. Deionized water (18.2 MΩ) was used for all reactions.

Synthesis of Au@Pt nanoparticles

Samples were synthesized in aqueous media by a one-pot reaction, following previous reports52,53 with modifications. Aqueous solutions of HAuCl4 (5.0 μmol) and H2PtCl6 (5.0 μmol) were mixed with ascorbic acid (AA), followed by the addition of Pluronic F127 as a structure-directing agent (molecular structure of F127, Fig. S1). The mixture underwent ultrasonication for 20 min using a Bransonic 2510J-MTH (42 kHz, 25 °C), then was continuously stirred for 2, 4, and 24 h to investigate the growth behavior of NPs.

For comparison, a precursor solution mixed with AA was stirred with a magnetic stirrer without ultrasonication, with synthesis durations of 2, 4, and 24 h. The resulting NPs were purified via two cycles of centrifugation (10,000 rpm, 30 min) and redispersed in water. For (S)TEM observation, samples were ultrasonically dispersed for 10 min, deposited onto a support grid, and dried for 24 h.

TEM/STEM observation

JEM-2100HC at an acceleration voltage of 200 kV was used to study the microstructure of NPs, including size and morphology, at different reaction periods. High-angle annular dark-field (HAADF) images by STEM (JEM-ARM200F, equipped with CEOS Cs-corrector) were obtained at an acceleration voltage of 200 kV to investigate the morphology of NPs. Energy dispersive X-ray spectroscopy (EDS) analysis was also performed to obtain two-dimensional (2D) elemental distribution maps of Au–L edges and Pt-L edges for each element.

Calculation of the yield of synthesized Au@Pt nanoparticles

To evaluate the influence of ultrasonication on the synthesis of Au@Pt NPs, the yields of Au and Pt were calculated at different reaction periods, for both reactions with and without ultrasonication. The yield for each element was determined using Eq. (4):

This approach incorporates elemental composition data from EDS measurements to ensure precise yield calculations.

Results and discussion

Nanostructure analyses of NPs obtained without ultrasonication

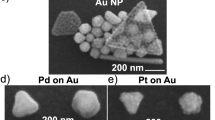

Bright-field (BF) TEM images of Au@Pt NPs synthesized without ultrasonication, shown in Fig. 2a–c, reveal a diverse range of sizes and morphologies, including plate-like (triangle and trapezoid) and polyhedral structures, observed across all reaction periods. The average particle sizes remain nearly constant across different reaction periods, as shown in Fig. 2d. Without ultrasonication, Pt atoms tend to form continuous layers on the Au core, resulting in a smooth Pt shell. In addition, small NPs observed on the TEM grid likely represent residual Pt NPs that failed to integrate into the shell structure due to incomplete attachment or insufficient surface diffusion of Pt atoms. The presence of residual Pt NPs suggests that Pt reduction and deposition occur in a more controlled manner without ultrasonication, resulting in a uniform shell rather than dendritic structures.

Figure 3a presents a high-resolution HAADF-STEM image of the representative NPs synthesized during the shortest reaction period of 2 h. Due to the similar atomic numbers of Pt and Au, their atomic number contrast in the HAADF-STEM image is indistinguishable. The NP surface exhibits the polyhedral nature of the Au core, formed through Au(III) reduction54. Elemental distribution maps of Au and Pt, acquired by STEM-EDS, are shown in Fig. 3b,c, respectively. The overlay image in Fig. 3d confirms the formation of Au@Pt NPs, consisting of an Au core and thin Pt layer (~ 1 nm thick).

Nanostructure analyses of NPs synthesized with ultrasonication

Figure 4a–c present BF-TEM images of NPs synthesized with ultrasonication at different reaction periods. Compared to those synthesized without ultrasonication, these NPs consist of a single core NP surrounded by numerous fine granules. The morphology and size of the ultrasonically treated core NPs were similar to those of the non-ultrasonically treated core NPs, as shown in Fig. 2, exhibiting plate-like (triangular, trapezoidal) and polyhedral shapes formed in all reaction periods. This observation suggests that ultrasonication influenced the shell part of the Au@Pt, which is composed of fine Pt granules. Figure 4d summarizes the sizes of the synthesized NPs and their corresponding Au cores at each reaction period. While the average size of the Au core remained constant at approximately 15 nm, the average size of Au@Pt NPs increased with longer reaction period, indicating a progressive increase in shell thickness, from 2 nm at 2 h to 4 nm at 24 h. These findings strongly suggest that the number of granules forming on the core increased over the reaction period, resulting in the development of a dendritic Pt shell.

Figure 5 shows HAADF-STEM and STEM-EDS images of representative Au@Pt NPs synthesized with ultrasonication for 2 h. The high-resolution HAADF-STEM image reveals both rough and smooth surface regions on the core. Au-L and Pt-L elemental distribution maps of this NP are displayed in Figs. 5b,c, respectively. Similar to Au@Pt NPs synthesized without ultrasonication, a Pt shell layer is observed surrounding the Au core. Furthermore, the rough surface region, composed of the fine granules, is confirmed to consist of Pt. The overlay image further verifies the formation of dendritic Au@Pt core–shell NPs. Moreover, a thin Pt layer is evident on the surface of the Au core and also at the interface between the Pt granules and the Au core.

Figure 6 shows high-resolution TEM images of the interface between Pt granules located on the Au core of NPs synthesized with a reaction period of 2 h. Figure 6b–d confirm epitaxial growth between the core and shell, as evidenced by the continuous atomic arrangement between the {111} lattices extending from the Au core to the Pt shell and subsequently to the Pt granules.

Growth mechanism of Au@Pt dendritic core–shell NPs

In general, the growth model of core–shell NPs is influenced by a complex interplay of factors, including lattice mismatch between the core and shell, the ratio of reducing agents to capping agents, and the molar ratio of metal ions43.

Figure 7 schematically illustrates four distinct growth models for the epitaxial deposition of two different elements. Figure 7a–c illustrate three representative models: heteroepitaxial layered growth, known as the F-M mode (Frank-van der Merwe)55; island-like growth, referred to as the V-W mode (Volmer-Weber)56; and an intermediate process incorporating both F-M and V-W modes, termed the S-K mode (Stranski–Krastanov)57.

For Au@Pt NP synthesis without ultrasonication, as seen in Fig. 8a, a thin Pt layer was observed on the Au core, suggesting that Pt growth followed the F-M mode. In contrast, for Au@Pt NPs synthesis with ultrasonication, as seen in Fig. 8b, fine Pt granules formed on the thin Pt layer surrounding the Au core. This indicates that the Pt granules developed like the S-K mode. However, instead of forming typical islandic structures characteristic of the V-W or S-K modes, Pt atoms aggregated into fine granules, as shown in Fig. 7d.

Although these models were originally developed for thin-film growth, they provide valuable insights into Pt deposition behavior on the Au core. There is a possibility that dendritic structures form through the deposition of homogeneously synthesized Pt granules, a process that deviates from classical growth models. This deviation reflects the complex growth environment caused by ultrasonication, which probably promotes non-classical nucleation and aggregation mechanisms.

Figure 7a–c illustrate three classical growth models for comparison, while the proposed model highlights the distinct nature of dendritic formation. A key distinction between the classical S-K mode (Fig. 7c) and the proposed model (Fig. 7d) lies in the deposition behavior of Pt atoms. In the S-K mode, an initial layer forms on the substrate, followed by the nucleation of discrete islands due to accumulated strain energy57. In contrast, the proposed model suggests that ultrasonication alters nucleation and growth dynamics, leading to the formation of uniformly distributed Pt granules rather than islands. This indicates that ultrasonication enhances nucleation rates while simultaneously inhibiting excessive aggregation, ultimately resulting in a dendritic Pt shell morphology rather than discrete island structures.

Discussions

Nanostructural characterizations by (S)TEM revealed the growth behavior of the thin Pt layer on the Au core during the synthesis without ultrasonication, while Pt granules were found present on the Pt layer with ultrasonication. High-resolution STEM analysis revealed that the surface of NPs was covered entirely by epitaxially grown Pt layer on the Au core, while misfit dislocations were occasionally observed. Moreover, the epitaxial growth of Pt granules on top of the Pt layer was confirmed by HRTEM, where the number of Pt granules was found to be increased with the reaction period. The Pt granules further linked to form a dendritic Pt shell. Although the synthesis of Au@Pt dendritic core–shell NPs was previously reported by Ataee-Esfahani et al.4,48, the dendritic Pt shells were hardly observed in the sample without ultrasonication, probably due to the low molar ratio of Pt precursor. The formation of dendritic Pt shells through ultrasonication, even at the low molar ratio of the Pt precursor in this study, suggests that ultrasonication enhances the effective molar ratio of the Pt precursor by accelerating reduction kinetics. The yields of Au and Pt were measured for samples with and without ultrasonication at various reaction periods to understand the effective molar ratio of the Pt precursor, as shown in Fig. 9. In the case of NPs synthesized without ultrasonication, the reduction yields remained constant regardless of the reaction periods, with Au at 55% and Pt at 31%, suggesting that the Au@Pt NPs formation was completed within 2 h. In the case of NPs with ultrasonication, the yield of Au maintained consistently at 55%, while the Pt yield increased with the reaction period, reaching 38%, 45%, and 67% at 2, 4, and 24 h, respectively. This indicates that ultrasonication promotes Pt deposition and facilitates the formation of dendritic Pt shells.

Two mechanisms have been proposed for the growth mechanism of metal@Pt dendritic core–shell NPs in the past. One is the growth of Pt granules on the metal core by heterogeneous nucleation44,48, and another one is the growth of Pt clusters nucleated homogeneously by attachment58,59,60. Through the current study, Pt granules were commonly observed on the Au@Pt NPs, which support the latter mechanism strongly. The area where Pt could heterogeneously nucleate on the Au core was insufficient when the Pt precursor was reduced.

Ultrasonication induces acoustic cavitation in liquid media, which involves the rapid formation, growth, and implosive collapse of microbubbles. This collapse generates localized hot spots with extremely high temperatures (up to ~ 5000 K), pressures (~ 1000 atm), and rapid cooling rates (> 109 K/s), accompanied by shock waves and high shear forces61. These extreme conditions promote the dissociation of solvent molecules and enhance the reduction of metal precursors near the cavitation sites. Ultrasonication with frequency increasing in the range of 20.0–100.0 kHz can decrease the nanoparticle diameter61, mainly due to the increasing of nucleation rate and thus reducing the effective crystal growth. In the case of Pt dendritic shells, the shell is composed of many small Pt granules which have final size and morphology heavily guided by the long chain of Pluronic F127, while the thickness of the shell can be strongly influenced by increasing the molar ratio of Pt precursor62.

The influence of ultrasonication has disrupted loosely bound small clusters, as shown in Fig. 10. At the same time, the ultrasonication enhance particle collisions, which facilitate the selective attachment of fragments or nuclei onto the surface of the primary Au core particles49,50. As a result, the Au core was formed first due to its lower reduction potential, then formed Pt layers on the previously formed Au core with the aid of a reducing agent and a surfactant, as schematically shown in Fig. 11. In the case of the sample without ultrasonication, the smooth Pt layer grew via the F-M mode, while in the sample with ultrasonication, the dendritic Pt shell grew similarly to the S-K mode due to the mechanical effects.

Conclusion

Au@Pt NPs with/without ultrasonication were synthesized by co-reduction and their nanostructures were characterized by (S)TEM and HRTEM. For the case of NPs without ultrasonication, smooth thin Pt layers were formed on the Au core, while Pt granules are present on the Pt layers for the case of NPs with ultrasonication. The successful synthesis of Au@Pt NPs with dendritic Pt shells was confirmed from the NPs with ultrasonication.

Moreover, HR-TEM characterization confirmed the epitaxial growth of Pt granules on thin Pt layer under ultrasonication, which resulted in the formation of the dendritic Pt shell. This study highlights the critical role of ultrasonication in directing nanostructure evolution by accelerating reduction kinetics and promoting selective particle collisions, even at low precursor concentrations. The findings provide mechanistic insights into how ultrasonication enhances the effective utilization of metal precursors and enables the controlled synthesis of complex core–shell nanostructures. These insights open new possibilities for the rational design of advanced nanomaterials in catalysis, electronics, and biomedical applications.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Ren, X. et al. Current progress of Pt and Pt-based electrocatalysts used for fuel cells. Sustain. Energy Fuels 4, 15–30. https://doi.org/10.1039/c9se00460b (2019).

Huang, L. et al. Advanced platinum-based oxygen reduction electrocatalysts for fuel cells. Acc. Chem. Res. 54, 311–322. https://doi.org/10.1021/acs.accounts.0c00488 (2021).

Huff, C., Biehler, E., Quach, Q., Long, J. M. & Abdel-Fattah, T. M. Synthesis of highly dispersive platinum nanoparticles and their application in a hydrogen generation reaction. Colloids Surf. A Physicochem. Eng. Asp. https://doi.org/10.1016/j.colsurfa.2020.125734 (2021).

Ataee-Esfahani, H., Wang, L., Nemoto, Y. & Yamauchi, Y. Synthesis of bimetallic Au@Pt nanoparticles with Au core and nanostructured Pt shell toward highly active electrocatalysts. Chem. Mater. 22, 6310–6318. https://doi.org/10.1021/cm102074w (2010).

Wang, L., Hasanzadeh Kafshgari, M. & Meunier, M. Optical properties and applications of plasmonic-metal nanoparticles. Adv. Funct. Mater. 2005400, 1–28. https://doi.org/10.1002/adfm.202005400 (2020).

Leary, R. K. et al. Structural and optical properties of discrete dendritic Pt nanoparticles on colloidal Au nanoprisms. J. Phys. Chem. C 120, 20843–20851. https://doi.org/10.1021/acs.jpcc.6b02103 (2016).

Sun, H. et al. Cancer cell membrane-coated gold nanocages with hyperthermia-triggered drug release and homotypic target inhibit growth and metastasis of breast cancer. Adv. Funct. Mater. https://doi.org/10.1002/adfm.201604300 (2017).

Feng, Y. et al. Electron compensation effect suppressed silver ion release and contributed safety of Au@Ag core–shell nanoparticles. Nano Lett. 19, 4478–4489. https://doi.org/10.1021/acs.nanolett.9b01293 (2019).

Wang, Y. & Xianyu, Y. Tuning the plasmonic and catalytic signals of Au@Pt nanoparticles for dual-mode biosensing. Biosens. Bioelectron https://doi.org/10.1016/j.bios.2023.115553 (2023).

Yang, S. et al. Au-Pt nanoparticle formulation as a radiosensitizer for radiotherapy with dual effects. Int. J. Nanomed. 16, 239–248. https://doi.org/10.2147/IJN.S287523 (2021).

Sarma, P. J., Gardner, C. L., Chugh, S., Sharma, A. & Kjeang, E. Strategic implementation of pulsed oxidation for mitigation of CO poisoning in polymer electrolyte fuel cells. J. Power Sources https://doi.org/10.1016/j.jpowsour.2020.228352 (2020).

Tian, N., Zhou, Z.-Y., Sun, S.-G., Ding, Y. & Wang, Z. L. Synthesis of tetrahexahedral platinum nanocrystals with high-index facets and high electro-oxidation activity. Science 316(2007), 732–735. https://doi.org/10.1126/science.1140484 (1979).

Mahmoud, M. A., Tabor, C. E., El-Sayed, M. A., Ding, Y. & Zhong, L. W. A new catalytically active colloidal platinum nanocatalyst: The multiarmed nanostar single crystal. J. Am. Chem. Soc. 130, 4590–4591. https://doi.org/10.1021/ja710646t (2008).

Chen, J., Herricks, T. & Xia, Y. Polyol synthesis of platinum nanostructures: Control of morphology through the manipulation of reduction kinetics. Angew. Chem. Int. Edition 44, 2589–2592. https://doi.org/10.1002/anie.200462668 (2005).

Lim, B. et al. Facile synthesis of highly faceted multioctahedral Pt nanocrystals through controlled overgrowth. Nano Lett. 8, 4043–4047. https://doi.org/10.1021/nl802959b (2008).

Teng, X., Liang, X., Maksimuk, S. & Yang, H. Synthesis of porous platinum nanoparticles. Small 2, 249–253. https://doi.org/10.1002/smll.200500244 (2006).

Schmidt, T. J., Gasteiger, H. A. & Behm, R. J. Rotating disk electrode measurements on the CO tolerance of a high-surface area Pt/Vulcan carbon fuel cell catalyst. J. Electrochem. Soc. 146, 1296. https://doi.org/10.1149/1.1391761 (1999).

Liu, M., Lu, Y. & Chen, W. PdAg nanorings supported on graphene nanosheets: Highly methanol-tolerant cathode electrocatalyst for alkaline fuel cells. Adv. Funct. Mater. 23, 1289–1296. https://doi.org/10.1002/adfm.201202225 (2013).

Wang, D. & Li, Y. Bimetallic nanocrystals: Liquid-phase synthesis and catalytic applications. Adv. Mater. 23, 1044–1060. https://doi.org/10.1002/adma.201003695 (2011).

Gawande, M. B. et al. Core–shell nanoparticles: Synthesis and applications in catalysis and electrocatalysis. Chem. Soc. Rev. 44, 7540–7590. https://doi.org/10.1039/c5cs00343a (2015).

Liu, H. L., Nosheen, F. & Wang, X. Noble metal alloy complex nanostructures: Controllable synthesis and their electrochemical property. Chem. Soc. Rev. 44, 3056–3078. https://doi.org/10.1039/c4cs00478g (2015).

Stephens, I. E. L., Bondarenko, A. S., Grønbjerg, U., Rossmeisl, J. & Chorkendorff, I. Understanding the electrocatalysis of oxygen reduction on platinum and its alloys. Energy Environ. Sci. 5, 6744–6762. https://doi.org/10.1039/c2ee03590a (2012).

Mazumder, V., Chi, M., More, K. L. & Sun, S. Core/shell Pd/FePt nanoparticles as an active and durable catalyst for the oxygen reduction reaction. J. Am. Chem. Soc. 132, 7848–7849. https://doi.org/10.1021/ja1024436 (2010).

Guo, S., Zhang, S., Su, D. & Sun, S. Seed-mediated synthesis of core/shell FePtM/FePt (M = Pd, Au) nanowires and their electrocatalysis for oxygen reduction reaction. J. Am. Chem. Soc. 135, 13879–13884. https://doi.org/10.1021/ja406091p (2013).

Sun, X. et al. Core/shell Au/CuPt nanoparticles and their dual electrocatalysis for both reduction and oxidation reactions. J. Am. Chem. Soc. 136, 5745–5749. https://doi.org/10.1021/ja500590n (2014).

Zhu, M., Nguyen, M. T., Chau, Y. T. R., Deng, L. & Yonezawa, T. Pt/Ag solid solution alloy nanoparticles in miscibility gaps synthesized by cosputtering onto liquid polymers. Langmuir 37, 6096–6105. https://doi.org/10.1021/acs.langmuir.1c00916 (2021).

He, L. L. et al. Facile synthesis of platinum-gold alloyed string-bead nanochain networks with the assistance of allantoin and their enhanced electrocatalytic performance for oxygen reduction and methanol oxidation reactions. J. Power Sources 276, 357–364. https://doi.org/10.1016/j.jpowsour.2014.11.119 (2015).

Mourdikoudis, S. et al. Governing the morphology of Pt-Au heteronanocrystals with improved electrocatalytic performance. Nanoscale 7, 8739–8747. https://doi.org/10.1039/c4nr07481e (2015).

Kim, Y. et al. Synthesis of AuPt heteronanostructures with enhanced electrocatalytic activity toward oxygen reduction. Angew. Chem. 122, 10395–10399. https://doi.org/10.1002/ange.201005839 (2010).

Luo, J. et al. Core/shell nanoparticles as electrocatalysts for fuel cell reactions. Adv. Mater. 20, 4342–4347. https://doi.org/10.1002/adma.200703009 (2008).

Wang, D. et al. Structurally ordered intermetallic platinum–cobalt core-shell nanoparticles with enhanced activity and stability as oxygen reduction electrocatalysts. Nat. Mater. 12, 81–87. https://doi.org/10.1038/nmat3458 (2013).

Luo, J. et al. Phase properties of carbon-supported gold-platinum nanoparticles with different bimetallic compositions. Chem. Mater. 17, 3086–3091. https://doi.org/10.1021/cm050052t (2005).

Ahmadi, M., Behafarid, F., Cui, C., Strasser, P. & Cuenya, B. R. Long-range segregation phenomena in shape-selected bimetallic nanoparticles: Chemical state effects. ACS Nano 7, 9195–9204. https://doi.org/10.1021/nn403793a (2013).

Liao, H., Fisher, A. & Xu, Z. J. Surface segregation in bimetallic nanoparticles: A critical issue in electrocatalyst engineering. Small 11, 3221–3246. https://doi.org/10.1002/smll.201403380 (2015).

Lapp, A. S. et al. Experimental and theoretical structural investigation of AuPt nanoparticles synthesized using a direct electrochemical method. J. Am. Chem. Soc. 140, 6249–6259. https://doi.org/10.1021/jacs.7b12306 (2018).

Cui, C., Gan, L., Heggen, M., Rudi, S. & Strasser, P. Compositional segregation in shaped Pt alloy nanoparticles and their structural behaviour during electrocatalysis. Nat. Mater. 12, 765–771. https://doi.org/10.1038/nmat3668 (2013).

Oezaslan, M., Heggen, M. & Strasser, P. Size-dependent morphology of dealloyed bimetallic catalysts: Linking the nano to the macro scale. J. Am. Chem. Soc. 134, 514–524. https://doi.org/10.1021/ja2088162 (2012).

Thi Ngoc Anh, D., Singh, P., Shankar, C., Mott, D. & Maenosono, S. Charge-transfer-induced suppression of galvanic replacement and synthesis of (Au@Ag)@Au double shell nanoparticles for highly uniform, robust and sensitive bioprobes. Appl. Phys. Lett. 99, 1–4. https://doi.org/10.1063/1.3626031 (2011).

Chapagain, P. et al. Tuning the surface plasmon resonance of gold dumbbell nanorods. ACS Omega 6, 6871–6880. https://doi.org/10.1021/acsomega.0c06062 (2021).

Kartashova, A. D. et al. Surface-enhanced Raman scattering-active gold-decorated silicon nanowire substrates for label-free detection of bilirubin. ACS Biomater. Sci. Eng. 8, 4175–4184. https://doi.org/10.1021/acsbiomaterials.1c00728 (2022).

Liu, H. et al. Stellated Ag-Pt bimetallic nanoparticles: An effective platform for catalytic activity tuning. Sci. Rep. https://doi.org/10.1038/srep03969 (2014).

Sharma, V., Sinha, N., Dutt, S., Chawla, M. & Siril, P. F. Tuning the surface enhanced Raman scattering and catalytic activities of gold nanorods by controlled coating of platinum. J. Colloid Interface Sci. 463, 180–187. https://doi.org/10.1016/j.jcis.2015.10.036 (2016).

Fan, F. R. et al. Epitaxial growth of heterogeneous metal nanocrystals: From gold nano-octahedra to palladium and silver nanocubes. J. Am. Chem. Soc. 130, 6949–6951. https://doi.org/10.1021/ja801566d (2008).

Lim, B. et al. Pd-Pt bimetallic nanodendrites with high activity for oxygen reduction. Science 324(2009), 1302–1305. https://doi.org/10.1126/science.1170377 (1979).

Lee, Y. W., Kim, M., Kim, Z. H. & Han, S. W. One-step synthesis of Au@Pd core-shell nanooctahedron. J. Am. Chem. Soc. 131, 17036–17037. https://doi.org/10.1021/ja905603p (2009).

Huang, X. et al. One-step room-temperature synthesis of Au@Pd core–shell nanoparticles with tunable structure using plant tannin as reductant and stabilizer. Green Chem. 13, 950–957. https://doi.org/10.1039/c0gc00724b (2011).

Wang, L. & Yamauchi, Y. Block copolymer mediated synthesis of dendritic platinum nanoparticles. J. Am. Chem. Soc. 131, 9152–9153. https://doi.org/10.1021/ja902485x (2009).

Ataee-Esfahani, H., Wang, L. & Yamauchi, Y. Block copolymer assisted synthesis of bimetallic colloids with Au core and nanodendritic Pt shell. Chem. Commun. 46, 3684–3686. https://doi.org/10.1039/c001516d (2010).

Sumitomo, S., Koizumi, H., Uddin, M. A. & Kato, Y. Comparison of dispersion behavior of agglomerated particles in liquid between ultrasonic irradiation and mechanical stirring. Ultrason. Sonochem. 40, 822–831. https://doi.org/10.1016/j.ultsonch.2017.08.023 (2018).

Hansen, H. E., Seland, F., Sunde, S., Burheim, O. S. & Pollet, B. G. Frequency controlled agglomeration of pt-nanoparticles in sonochemical synthesis. Ultrason. Sonochem. https://doi.org/10.1016/j.ultsonch.2022.105991 (2022).

Ramli, N. H. et al. Platinum-based nanoparticles: A review of synthesis methods, surface functionalization, and their applications. Microchem. J. https://doi.org/10.1016/j.microc.2024.110280 (2024).

Takeuchi, Y. et al. Formation of multishell Au@Ag@Pt nanoparticles by coreduction method: A microscopic study. Mater. Today Chem. 21, 100515. https://doi.org/10.1016/J.MTCHEM.2021.100515 (2021).

Lee, H. J. et al. Controlling the composition and nanostructure of Au@Ag–Pt core@multi-shell nanoparticles prepared by co-reduction method. Mater. Today Chem. https://doi.org/10.1016/j.mtchem.2024.102132 (2024).

Personick, M. L. & Mirkin, C. A. Making sense of the mayhem behind shape control in the synthesis of gold nanoparticles. J. Am. Chem. Soc. 135, 18238–18247. https://doi.org/10.1021/ja408645b (2013).

Frank, F. C. The influence of dislocations on crystal growth. Discuss Faraday Soc. 5, 48–54. https://doi.org/10.1039/DF9490500048 (1949).

Levi, A. C. & Kotrla, M. Theory and simulation of crystal growth. J. Phys. Condens. Matter 9, 299. https://doi.org/10.1088/0953-8984/9/2/001 (1997).

Volmer, M. & Schultze, W. Kondensation an Kristallen. Z. Phys. Chem. 156A, 1–22. https://doi.org/10.1515/zpch-1931-15602 (1931).

Lim, B., Jiang, M., Yu, T., Camargo, P. H. C. & Xia, Y. Nucleation and growth mechanisms for Pd-Pt bimetallic nanodendrites and their electrocatalytic properties. Nano Res. 3, 69–80. https://doi.org/10.1007/s12274-010-1010-8 (2010).

Xu, J. et al. Synthesis and catalytic properties of Au-Pd nanoflowers. ACS Nano 5, 6119–6127. https://doi.org/10.1021/nn201161m (2011).

Jungjohann, K. L., Bliznakov, S., Sutter, P. W., Stach, E. A. & Sutter, E. A. In situ liquid cell electron microscopy of the solution growth of Au-Pd core-shell nanostructures. Nano Lett. 13, 2964–2970. https://doi.org/10.1021/nl4014277 (2013).

Li, Z. et al. Sonochemical catalysis as a unique strategy for the fabrication of nano-/micro-structured inorganics. Nanoscale Adv. 3, 41–72. https://doi.org/10.1039/d0na00753f (2021).

Shim, K. et al. Rationally designed bimetallic Au@Pt nanoparticles for glucose oxidation. Sci. Rep. https://doi.org/10.1038/s41598-018-36759-5 (2019).

Acknowledgements

This work was partially supported by JSPS KAKENHI (Grant Numbers JP 22K14742 to A.T.N.D.). The authors would like to acknowledge the Ultramicroscopy Research Center (URC) of Kyushu University for providing facilities and scientific and technical assistance for electron microscopy measurements.

Funding

JSPS KAKENHI, JP 22K14742, JP 22K14742.

Author information

Authors and Affiliations

Contributions

Hu-Jun LEE: Investigation, Data curation, Formal analysis, Writing—original draft. Daisuke HANYU: Investigation, Data curation, Formal analysis, Writing—review and editing. Anh Thi Ngoc DAO and Kenji KANEKO: Conceptualization, Methodology, Data curation, Formal analysis, Resources, Funding acquisition, Writing—review and editing, Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lee, HJ., Hanyu, D., Dao, A.T.N. et al. Insights into the formation of Au@Pt dendritic core–shell nanoparticles with the aid of ultrasonication. Sci Rep 15, 29474 (2025). https://doi.org/10.1038/s41598-025-09572-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-09572-0