Abstract

Sampling inspection plan is a valuable tool used across industries to ensure product quality, comply with regulatory standards, and maintain cost efficiency in quality control processes. To check for defects in the products during production, a batch of goods produced may be inspected through sampling to decide whether to accept or reject the entire batch based on the quality level of the sample. In this study we develop acceptance sampling plans based on truncated life tests utilizing the Lomax distribution. The study analyzes different parameters of the Lomax distribution to determine the minimum sample sizes necessary for evaluating the quality of lots or production processes. Additionally, we calculate the operating characteristic function values and establish the minimum ratio of the true mean life to the specified mean life of the product, taking into account the risks faced by both consumers and producers with our proposed sampling method. The effectiveness of these sampling plans is demonstrated through their application to real-world data, assessing their practical utility in quality evaluation.

Similar content being viewed by others

Introduction

Decision-making regarding product quality stands as a foundational element within the realm of statistical quality control. At its core, the objective is to ensure both consumer and producer satisfaction by delivering products that meet predefined standards. Acceptance sampling plan (ASP) is an important tool for ensuring such decision-making and enhancing quality in the field of statistical quality control. It is extensively employed in scenarios where testing is inherently destructive, and conducting comprehensive inspections is prohibitively expensive or time-consuming. In ASP a random sample is drawn from the lot, and based on the findings from this sample, a decision is reached regarding whether to accept or reject the entire lot. If the number of defective units in the sample surpasses a predetermined threshold known as the acceptance number usually denoted as \(c\), the lot is rejected. Conversely, if the number of defective units falls below the acceptance number, the lot is accepted. In the realm of manufacturing, there is a fundamental expectation for products to exhibit a prolonged lifespan. Yet, relying solely on natural failures during testing can lead to significant time and financial investments. So, manufacturers often decide to conclude life tests at a predetermined time, denoted as \(t_{0}\), thereby effectively conserving resources. Such life-tests are known as truncated lifetime tests.

The Lomax distribution is widely used in reliability analysis, survival studies and quality control due to its heavy-tailed nature, making it suitable for modeling lifetimes of products and failure rates. In quality control, it effectively captures extreme values and outliers in data, providing more accurate assessments of reliability and risk. Compared to the Frechet, Lindley and Rayleigh distributions, the Lomax distribution offers greater flexibility due to its shape parameter, which adjusts tail behavior. Its ability to model both decreasing and constant hazard rates makes it superior in situations where failure risks decline over time. The Lomax distribution is particularly advantageous in modeling warranty claims and lifetime predictions of manufactured products. It ensures better estimation of mean residual life and failure probabilities, improving decision-making in production processes. Its tail heaviness helps in identifying defective components that may significantly impact quality assurance. Unlike the gamma and lognormal distributions, the Lomax distribution allows for a better fit of data with high variability. The simplicity of its closed-form expressions for moments and hazard functions makes it computationally efficient in statistical applications. Overall, its adaptability and precision in extreme value modeling make it a valuable tool in quality control.

The field of ASP derived from truncated life tests has been extensively investigated by various researchers. Sobel and Tischendrof1 studied acceptance sampling plans for the exponential distribution. Gupta and Groll2 extended this exploration to sampling plans for gamma distribution, while Gupta3 focused on the lognormal distribution. Kantam et al.4 contributed by examining acceptance sampling based on life tests using the log-logistic model. Rosaiah and Kantam5 proposed an acceptance sampling plan based on the inverse Rayleigh distribution. Tsai and Wu6 further expanded this field by characterizing acceptance sampling based on truncated life tests for the generalized Rayleigh distribution. Balakrishnan et al.7 discussed acceptance sampling plans derived from truncated life tests, specifically based on the generalized Birnbaum-Saunders distribution. Rao and Kantam8 developed acceptance sampling plans from truncated life tests based on the log logistic distribution for Percentile. Aslam et al.9 focused on time-truncated acceptance sampling plans for the generalized exponential distribution. Lio et al.10 considered acceptance sampling plans derived from truncated life tests based on the Birnbaum–Saunders distribution for Percentiles. Al-Nasser and Al-Omari11 contributed by developing an acceptance sampling plan based on truncated life tests for the exponentiated Frechet distribution. Sriramachandran and Palanivel12 introduced an acceptance sampling plan derived from truncated life tests based on the exponentiated inverse Rayleigh distribution. Gui and Aslam13 proposed acceptance sampling plans for weighted exponential distributions based on truncated lifetime tests. Al-Masri14 worked on acceptance sampling plans based on truncated life tests derived from inverse-gamma model. Al-Omari et al.15 proposed acceptance sampling plans derived from truncated life tests for the Rama distribution. Abdullah et al.16 developed Group acceptance sampling plan using Marshall–Olkin Kumaraswamy exponential distribution. Ahmed and Yousof17 established a new group acceptance sampling plans based on percentiles for the Weibull Frechet distribution. Gui & Aslam18 developed acceptance sampling plans for weighted exponential distribution. Kanichukattu et al.19 discussed on Marshall Olkin exponential power distribution. Recently, Ameeq et al.20 explored the group acceptance sampling plan truncated life test on the alpha power transformation inverted perks distribution.

Lomax probability distribution

The probability density function (PDF) of Lomax distribution21 is given by

with shape parameter \(\alpha > 0\) and scale parameter \(\beta > 0\). The cumulative distribution function (CDF) of the Lomax distribution is

The PDF and CDF plots of Lomax distribution are presented below in Figs. 1 and 2 respectively.

Statistical properties of Lomax distribution

Reliability analysis

The survival and the hazard functions respectively of Lomax distribution are

and

The graphical plots of survival and hazard functions of Lomax distribution for different parameters values are respectively given below in Figs. 3 and 4:

Moments

The \(r^{th}\) raw moment about origin of the Lomax distribution is given by

After simplification we get

Putting \(r = 1, 2, 3, 4\) we get

The variance and coefficient of variation of distribution respectively are given by

\(\sigma^{2} = \frac{{ \beta^{2} \alpha }}{{(\alpha - 1)^{2} (\alpha - 2)}}\) and \({\text{coefficient}} {\text{of}} {\text{Variation}} = \sqrt {\frac{\alpha }{(\alpha - 2)}} \times 100\).

Parameter estimation

The likelihood function of a random sample of size \(n\) drawn from given distribution is

Taking log on both sides and after simplification we get

Differentiating partially with respect to αand β respectively and equating to zero we get

and

Solving Eqs. (5) and (6) simultaneously, we obtain the maximum likelihood estimators (MLEs)of the given parameters \(\alpha\) and \(\beta\). However, the above algebraic expressions are in a non-linear form and cannot be evaluated directly, so to obtain MLEs of the parameters we use statistical softwares such R, Mathematica and Newton–Raphson method. We have used R-software22 to compute the parameter values of the given distribution based on a real-life dataset.

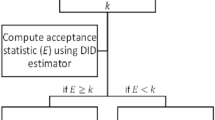

Design of the ASP

In reliability and quality control studies, truncating life tests at a predetermined time significantly impacts the determination of minimum sample sizes and the calculation of the operating characteristic function values in acceptance sampling plans. An ASP based on truncated life tests consists of the following parameters:

-

(1)

The number of units \(n\) on test.

-

(2)

An acceptance number \(c\),

-

(3)

The maximum test duration time \(t_{0}\).

-

(4)

The ratio \(\xi = \frac{{t_{0} }}{{\mu_{0} }}\), where \(\mu_{0}\) is the specified average life of the product.

According to ASP based on truncated life tests, a lot is accepted if it experiences \(c\) or fewer failures within the test duration \(t_{0}\); otherwise, the lot is rejected. These tests serve to establish a confidence limit on the average product lifespan and defined a specified mean life \(\mu_{0}\) with a probability of at least \(P^{*}\)(say) which is the consumer’s confidence level. The ASP suggests that the lot is deemed satisfactory if the actual average life of items or products in a lot \(\mu\) meets or exceeds \(\mu_{0}\), that is if \(\mu \ge \mu_{0}\). Conversely, it is deemed unsatisfactory if \(\mu < \mu_{0}\).

Determine minimum sample size for given Consumer’s risk under ASP

When a life test is truncated at a predetermined time \(t_{0}\), only failures occurring within this time frame are observed. The sample size must be chosen such that it provides sufficient statistical evidence to accept or reject a given lot based on the number of observed failures. The factors affecting the minimum sample size include:

Specified Producer’s and Consumer’s Risks: These risks influence the required confidence level for decision-making.

Truncation Time Relative to the Distribution Parameters: If the truncation time is too short compared to the product’s lifetime distribution, fewer failures may be observed, requiring a larger sample to obtain reliable statistical inferences.

Choice of Lifetime Distribution (Lomax Distribution): The parameters of the assumed lifetime distribution (shape and scale) influence the probability of observing failures within \(t_{0}\).

To determine the minimum sample size \((n)\), we typically solve an equation involving the CDF of the assumed lifetime model. Given a truncation time \(t_{0}\), the probability of failure for a single unit within this time is computed and then binomial approximations are used to estimate the required sample size.

Suppose that the life time of the product follow the Lomax distribution. In this context, a life test is conducted, concluding at a predetermined time \(t_{0}\). Within this time frame, the number of failures (\(d\))occurring between the start and \(t_{0}\)is recorded. The lot is accepted if, by the end of \(t_{0}\) the observed failures do not exceed a predetermined acceptance threshold \(c\). Essentially, this decision reflects the acceptance or rejection of the hypothesis \(H_{0} : \mu \ge \mu_{0}\) against \(H_{1} : \mu < \mu_{0}\).

Throughout the inspection period, it is assumed that the lot size is effectively infinite. Consequently, the number of defective products in the lot is expected to follow a binomial distribution. Therefore, under the assumption of binomial distribution for large lot size, the probability of accepting a lot of quality \(p\) is given by

where, \(n\) is the number of products selected from the lot in order to assess its quality and \(p\) is the probability of failure of the product before maximum test duration time \(t_{0}\) if the true mean life of the product is \(\mu\) and it is calculated from given Lomax distribution as

Here,\(\zeta = \frac{\mu }{{\mu_{0} }}\) is the ratio between the true mean lifetime and the specified mean lifetime of the product.

Generally, the consumer is always willing to accept a lot of good quality. Consumer’s risk refers to the probability that a sampling or decision-making process fails to detect and reject a product, batch, or service that does not meet required quality standards or performance criteria, thereby leading to its unintended acceptance. This type of risk is critical in quality assurance, manufacturing, pharmaceuticals, service delivery, and other industries where consumer safety, satisfaction, and trust are at stake. It is commonly associated with acceptance sampling and statistical quality control, where decisions are made based on a sample rather than inspecting 100% of the product. When a defective or subpar item passes through this filter due to sampling error, the consumer ultimately bears the consequence—hence the term “consumer’s risk”. So, the probability that a sampling plan accepts a lot given that the lot is of bad quality is known as consumer’s risk and can be mathematically expressed as:

In this paper, consumer’s risk as defined above is denoted by \(\lambda_{1}.\) That is

On the other hand, the probability that a sampling plan rejects a lot given that the lot is of bad quality is known as consumer’s confidence level. Here, it is denoted by \(P^{*}\) and can be mathematically expressed as:

\({\text{P}}^{*} = {\text{Consumer's}}\,\,{\text{confidence level}} = P({\text{Rejecting}} {\text{the}} {\text{ lot of bad quality}})\)

\({\text{P}}^{*} = 1 - P({\text{Accepting}} {\text{the}} {\text{ lot of bad quality}})\)

\({\text{P}}^{*} = 1 - \lambda_{1}\)

So, \(\lambda_{1} = 1 - P^{*}\).

Here we assume that consumer’s risk is fixed. Now, our aim is to find the minimum sample size \(n\) such that the probability of accepting a lot of quality \(p\) not exceeds the consumer’s risk \(\lambda_{1}\). Therefore, the minimum sample size needed to draw from lot in order to inspect the lot quality for ASP \((n, c, \xi = \frac{{t_{0} }}{{\mu_{0} }})\) based on Lomax distribution is obtained subject to the condition

Substituting the value of \(p = 1 - \left( {1 + \frac{\xi }{(\alpha - 1)(\zeta )}} \right)^{( - \alpha )}\) in (8), we obtain

The minimum values of \(\,n\) satisfying inequality (9) have been obtained for \(P* = 0.75, 0.90, 0.95, 0.99\) and \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 0.628,\, 0.974, \,1.368\), \(1.571,\,\,2.356,\,\,3.586,\,\,4.817,\,\,5.913\). These values are presented in Tables 1, 2, and 3 for \(\alpha = 5, 9, {\text{and}} 12\) respectively. Comparative analysis has been done in Tables 1, 2, and 3 to obtain the variation in minimum sample size for different levels of consumer’s confidence level, \(\xi = \frac{{t_{0} }}{{\mu_{0} }}\), and parameter of the distribution. It can be observed that as we increase the consumer’s confidence level from 0.75 to 0.99 (i.e., decrease consumer’s risk from 0.25 to 0.01), the minimum sample size also increases, required to arrive at a decision whether to accept or reject the given lot keeping acceptance number and test duration constant. On the other hand, for a fixed consumer’s confidence level and acceptance number, the minimum sample size required to accept or reject the lot, decreases as we increase test duration. Similarly, as we increase acceptance number \(c\) from 0 to 10, the minimum sample also increases for given consumer’s confidence level and test duration.

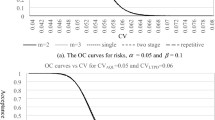

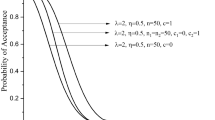

Operating characteristics (OC) function

The acceptance number \(c\) and maximum test duration \(t_{0}\) are critical parameters in an ASP that directly influence the OC curve, which represents the probability of lot acceptance for different quality levels. The effect of each of them on the OC function is explained as:

Effect of acceptance number (\(c\))

A higher \(c\) increases the probability of accepting lots, making the plan more lenient. This benefits producers but increases the risk of defective items reaching consumers. On the other hand, a lower \(c\) makes the plan stricter, reducing the acceptance probability for lots with moderate defect rates, thus favouring consumers but increasing the producer’s rejection risk. The choice of \(c\) must balance producer’s risk (probability of rejecting a good lot) and consumer’s risk (probability of accepting a bad lot) to ensure fairness.

Effect of maximum test duration (\(t_{0}\))

A shorter \(t_{0}\) leads to fewer observed failures, increasing the likelihood of lot acceptance. This may increase the risk to consumers if defective items have longer lifetimes. A longer \(t_{0}\) allows more failures to be observed, leading to a more stringent plan and a lower acceptance probability for marginal-quality lots. This benefits consumers but raises the producer’s rejection rate. Thus, the values of \(c\) and \(t_{0}\) were chosen to ensure an appropriate trade-off between producer’s and consumer’s risks.

The OC function of the given ASP \((n, c, \xi = \frac{{t_{0} }}{{\mu_{0} }})\) based on Lomax distribution is given by

On substituting Eq. (7) in Eq. (10) we obtain

The OC function values are calculated for the ASP \((n, c, \xi = \frac{{t_{0} }}{{\mu_{0} }})\) for \(P* = 0.75, 0.90, 0.95, 0.99\), \(c = 4\) and \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 0.628,\, 0.974, \,1.368\), \(1.571,\,\,2.356,\,\,3.586,\,\,4.817,\,\,5.913\). These values are presented in Tables 4, 5, and 6 for \(\alpha = 5, 9, {\text{and}} 12\) respectively.

Minimum ratio of the true mean life to specified mean life of the product for given producer’s risk

The producer’s risk is the probability of rejection of the lot when it is good. In other words producer’s risk is the probability of rejecting a lot such that the true mean life of product in lot \(\mu\) is more than the specified mean life of product \(\mu_{0}\). Under the assumption of binomial distribution, it can be mathematically expressed as

For the given ASP \((n, c, \xi = \frac{{t_{0} }}{{\mu_{0} }})\) based on Lomax distribution, with consumer’s confidence level \(P*\), the main purpose is obtaining the minimum value of ratio \(\zeta = \frac{\mu }{{\mu_{0} }}\) such that the producer’s risk to be at most \(\lambda_{2}\). So \(\zeta = \frac{\mu }{{\mu_{0} }}\) is the smallest value such that the following inequality is satisfied:

Substituting the value of \(p = 1 - \left( {1 + \frac{\xi }{(\alpha - 1)(\zeta )}} \right)^{( - \alpha )}\) in (12), we get

The minimum value of the ratio \(\zeta = \frac{\mu }{{\mu_{0} }}\) for ASP \((n, c, \xi = \frac{{t_{0} }}{{\mu_{0} }})\) based on Lomax distribution satisfying above inequality (13) are presented in Tables 7, 8, and 9 for different values of parameter \(\alpha = 5, 9, {\text{and}}\,\,12\) respectively. These tables are presented for producer’s risk \(\lambda_{2} = 0.05\) and consumer’s confidence level \(P* = 0.75, 0.90, 0.95, 0.99\).

Discussion

In constructing our ASP, we proceeded with the assumption that the product’s lifespan follows a Lomax distribution. To accommodate various parameter values within this distribution, we meticulously developed our plan. Tables 1 through 9 outline the pivotal parameters of our sampling inspection plan, including minimum sample size \(n\), operating characteristics function \({\text{OC}}(p)\), and the minimum ratio of true mean life to specified mean life \(\zeta = \frac{\mu }{{\mu_{0} }}\).

Let us consider a situation where the parameter \(\alpha = 5\) for the given assumed distribution and the researcher aims to confirm that the mean lifespan is at least \(\mu_{0} = 1000\) hours with a probability of \(P* = 0.99\) (corresponding consumer’s risk is 0.01). Additionally, assume that the life testing of the lot will be concluded at \(t_{0} = 974\) hours. Given these parameters, Table 1 offers the minimum sample size to be drawn from a lot in order to assess its quality, that is, for \(P* = 0.99\), with \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 0.974\) and \(c = 5\) the corresponding entry in Table 1 indicates a sample size of \(n = 15\) units. This means that the researcher has to draw at least 15 products at random from the lot to assure that average life of items or products in a lot is equal to or exceeds \(\mu_{0} = 1000\) hours. Now, the researcher needs to test these 15 products. If out of these 15 products, no more than 5 fail within 974 h, the researcher can confidently confirm that the true mean life \(\mu\) of the product is at least 1000 h, with a confidence level of 0.99 and hence, the lot is accepted.

The proposed ASP, utilizing the Lomax distribution, yields operating characteristic function values showed in Tables 4, 5, 6 across various values of \(P*\), \(\xi = \frac{{t_{0} }}{{\mu_{0} }}\), \(\zeta = \frac{\mu }{{\mu_{0} }}\) and \(c.\) As an example, consider the scenario where \(P* = 0.99\), \(c = 4\), \(n = 13\), \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 0.974\), and \(\zeta = \frac{\mu }{{\mu_{0} }} = 5\). In this case, the corresponding entry in Table 4 is 0.87967. Interpreting this result, under the specified ASP, 13 products are selected from a lot under inspection. If out of 13 products, 4 or fewer items fail before reaching time point \(t_{0} = 974\) hours, then the lot is accepted with probability of at least 0.87967. Moreover, this result can also be interpreted as if the true mean life \(\mu \ge 5 \times \frac{{t_{0} }}{0.974}\) that is \(\mu \ge 5000\) hours, then the lot will be accepted with a probability of at least 0.87967.

Tables 7, 8, and 9 provides the minimum required ratio between the true mean lifetime and the specified one needed to meet the proposed acceptance criteria, ensuring a producer’s risk of 0.05 or lower. For instance, for the given ASP, if we consider \(P* = 0.99\),\(c = 4\), and ratio \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 0.974\), the Table 7 indicates that the minimum acceptable ratio is \(\zeta = \frac{\mu }{{\mu_{0} }} = 6.602\). This signifies that if the true mean lifetime \(\mu \ge 6.602 \times \frac{{t_{0} }}{0.974}\) that is \(\mu \ge 6602\) hours, then, with \(c = 4\) and a sample size of \(n = 13\), the lot will be rejected with a probability at most 0.05. In simpler terms, the lot will be accepted with a probability of at least 0.95. Similar, we can explain minimum sample size \(n\), OC function \({\text{OC}}(p)\) and minimum ratio \(\zeta = \frac{\mu }{{\mu_{0} }}\) tables also for \(\alpha = 9\, {\text{and}}\, 12.\)

Application

This section provides a comprehensive evaluation of the Lomax distribution in modelling real-world scenarios, highlighting its applicability and significance. Furthermore, the effectiveness of the proposed acceptance sampling plan based on the Lomax distribution is analyzed using a real-life dataset, as presented in Table 10. To assess its relative performance, the Lomax distribution is compared with several well-established probability distributions from existing literature, including the Weibull, Frechet, Lindley and Rayleigh distributions. This comparative analysis aims to determine the strengths and limitations of each distribution in accurately representing real-world data. To do so, we examine several criteria including the Kolmogorov–Smirnov test, maximized log-likelihood (\(- 2\ln (L)\)), Akaike Information criterion (AIC), Bayesian Information criterion (BIC), Corrected Akaike Information criterion (CAIC), and Hannan-Quinn Information criterion (HQIC), where

where \(m\) is the number of parameters in the given distribution and \(n\) is the size of the data set. The results are presented in Table 11.

Data set

This dataset is related to failure times (in weeks) of 50 components. This dataset was considered by Jose and Paul23, and the failure times of the components are presented in the Table 10.

According to the Kolmogorov–Smirnov test, the p-value for the fitted model is 0.7094, and the maximum distance between the data and the fitted distribution is 0.099153. This shows that the Lomax distribution provides better fit to given data set than Weibull, Frechet, Lindley and Rayleigh distributions. Furthermore, from Figs. 5, 6, 7, 8, and 9, we observe a more accurate representation of the data through various graphical plots. These include histograms depicting the distribution alongside estimated probability density functions (PDFs), estimated (or empirical) and theoretical cumulative distribution function (CDF) plot, estimated (or empirical) and theoretical survival function plot, quantile–quantile (Q–Q) plots and probability–probability (P–P) plots. Therefore, the Lomax distribution demonstrates an excellent fit as compared to Weibull, Frechet, Lindley and Rayleigh distributions. Now, we will use the estimated parameters of the Lomax distribution and develop the acceptance sampling inspection plan for assessing lot quality in the production process based on given data set as follows:

Since the maximum likelihood estimates of \(\alpha\) and \(\beta\) are respectively given by

\(\hat{\alpha } = 5.6992\) and \(\hat{\beta } = 35.0408\). Then,

So, the specified mean lifetime of the product is \(\mu_{0} = 7.4568\) weeks.

Suppose the researcher has predefined termination ratio equal to \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 1.325\) and consumer’s risk be \(\lambda_{1} = 0.05\), then the maximum test duration time is \(t_{0} = 9.8803\) weeks. Given all these parameters of the ASP, the acceptance number and the corresponding minimum sample sizes for given data set are displayed in Table 12 as below:

From the above Table 12, the acceptance number for given data set is \(c = 32\). Since, the specified mean lifetime of the product is \(\mu_{0} = 7.4568\) weeks and the researcher has predefined termination ratio \(\xi = \frac{{t_{0} }}{{\mu_{0} }} = 1.325\), and the maximum test duration time is \(t_{0} = 9.8803\) weeks. So, if the number of defectives (failed components) before time \(t_{0} = 9.8803\) weeks is less than or equal to \(c = 32\), then the lot will be accepted on the basis of given sample with specified mean life \(\mu_{0} = 7.4568\) weeks. Therefore, the required ASP for the given data set is ASP \((n = 50, \,c = 32, \xi = \frac{{t_{0} }}{{\mu_{0} }} = 1.325)\).

Since, from the given data set, there are 37 components whose failure times is less than 9.8803 weeks, this implies that the number of defectives (or failures) are greater than \(c = 32\). Therefore, the given lot is rejected. Now the OC function and the minimum required ratio between the true mean lifetime and the specified one corresponding to the producer’s risk of \(\lambda_{2} = 0.05\) are presented in Tables 13 and 14 respectively as below:

Conclusion

In this paper, new ASP based on truncated life test has been developed under the assumption that the lifetime of the product follows Lomax distribution. The minimum sample sizes needed to draw from a lot in order to assess its quality are obtained and presented in Tables 1, 2, and 3. The operating characteristic function values based on given ASP are also calculated to measure the performance of the ASP by determining the probability of accepting or rejecting a lot based on certain criteria’s such as number of failures (defectives) or mean life of product. These values are given in Tables 4, 5, and 6. In this paper we also calculate minimum ratio between the true mean lifetime and the specified lifetime of the product to specify certain quality level of the tested lot. These values are presented in Tables 7, 8, and 9. Finally, we used the developed ASP based on Lomax distribution to real-life data set and has found that the proposed sampling plan is effective and useful for assessing lot quality in the production process.

Data availability

The data that supports the findings of this study are available within the article.

References

Sobel, M. & Tischendrof, J. Acceptance sampling with new life test objectives. In Proceedings of 5th National Symposium on Reliability and Quality Control, 108–118 (1959).

Gupta, S. S. & Groll, P. A. Gamma distribution in acceptance sampling based on life tests. J. Am. Stat. Assoc. 56(296), 942–970 (1961).

Gupta, S. S. Life test sampling plans for normal and lognormal distributions. Technometrics 4(2), 151–175 (1962).

Kantam, R., Rosaiah, K. & Rao, G. S. Acceptance sampling based on life tests: log-logistic model. J. Appl. Stat. 28(1), 121–128 (2001).

Rosaiah, K. & Kantam, R. Acceptance sampling based on the inverse Rayleigh distribution. Econ. Qual. Control 20(2), 277–286 (2005).

Tsai, T.-R. & Wu, S.-J. Acceptance sampling based on truncated life tests for generalized Rayleigh distribution. J. Appl. Stat. 33(6), 595–600 (2006).

Balakrishnan, N., Leiva, V. & Lopez, J. Acceptance sampling plans from truncated life tests based on the generalized Birnbaum-Saunders distribution. Commun. Stat. Simul. Comput. 36(3), 643–656 (2007).

Rao, G. S. & Kantam, R. R. L. Acceptance sampling plans from truncated life tests based on the log-logistic distribution for percentiles. Econ. Qual. Control 25, 153–167 (2010).

Aslam, M., Kundu, D. & Ahmad, M. Time truncated acceptance sampling plans for generalized exponential distribution. J. Appl. Stat. 37(4), 555–566 (2010).

Lio, Y. L., Tsai, T.-R. & Wu, S.-J. Acceptance sampling plans from truncated life tests based on the Birnbaum-Saunders distribution for percentiles. Commun. Stat. Simul. Comput. 39, 119–136 (2010).

Al-Nasser, A. D. & Al-Omari, A. I. Acceptance sampling plan based on truncated life tests for exponentiated frechet ´ distribution. J. Stat. Manag. Syst. 16(1), 13–24 (2013).

Sriramachandran, G. V. & Palanivel, M. ‘Acceptance sampling plan from truncated life tests based on exponentiated inverse Rayleigh distribution’. Am. J. Math. Manage. Sci. 33(1), 20–35 (2014).

Gui, W. & Aslam, M. ‘Acceptance sampling plans based on truncated life tests for weighted exponential distribution’. Commun. Stat. Simul. Comput. 46(3), 2138–2151 (2017).

Al-Masri, A. Acceptance sampling plans based on truncated life tests in the inverse-gamma model. Electron. J. Appl. Stat. Anal. 11(1), 397–404 (2018).

Al-Omari, A., Al-Nasser, A. & Ciavolino, E. Acceptance sampling plans based on truncated life tests for Rama distribution. Int. J. Qual. Reliab. Manage. 36(7), 1181–1191 (2019).

Almarashi, A., Khan, K., Chesneau, C. & Jamal, F. Group acceptance sampling plan using Marshall–OlkinKumaraswamy exponential distribution. Processes 9(6), 1066 (2021).

Ahmed, B. & Yousof, H. A new group acceptance sampling plans based on percentiles for the Weibull Frechet model. Stat. Optim. Inf. Comput. 11(2), 409–421 (2022).

Gui, W. & Aslam, M. Acceptance sampling plans based on truncated life tests for weighted exponential distribution. Commun. Stat. Simul. Comput. 46(3), 2138–2151. https://doi.org/10.1080/03610918.2015.1037593 (2016).

Jose, K. & Paul, A. Marshall Olkin exponential power distribution and its generalization: theory and applications. IAPQR Trans. 43, 1–29. https://doi.org/10.32381/IAPQRT.2018.43.01.1 (2018).

Ameeq, M. et al. A group acceptance sampling plan truncated life test for alpha power transformation inverted perks distribution based on quality control reliability. Cogent Eng. 10(1), 2224137 (2023).

Lomax, K. S. Business failures: Another example of the analysis of failure data. J. Am. Stat. Assoc. 49, 847–852 (1954).

R Core Team, R. A Language and Environment for Statistical Computing, R Foundation for Statistical Computing, Vienna, Austria (2023). https://www.R-project.org/

Jose, K. K. & Paul, A. Marshall-Olkin exponential power distribution and its generalization: Theory and application. IAPQR Trans. 43(1), 1–29 (2018).

Funding

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2501).

Author information

Authors and Affiliations

Contributions

Authors have worked equally to write and review the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rather, A.A., El-Saeed, A.R., Qayoom, D. et al. Quality assurance through truncated life tests under the Lomax distribution. Sci Rep 15, 24822 (2025). https://doi.org/10.1038/s41598-025-10164-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-10164-1