Abstract

Sinusoidal buckling of drill strings will be easily caused during drilling process of extended-reach horizontal wells due to the factors such as excessive well length and larger friction torque, which will cause measurement errors of well depth and vertical depth and furthermore influence the accurate calculation of ECD. We have corrected the traditional ECD calculation model, considered the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings, and established a set of equivalent circulating density (ECD) calculation model suitable for extended-reach horizontal wells to meet the requirements for fine ECD control during the drilling operation. We have combined the data from an extended-reach horizontal well in the East China Sea and compared the ECD data obtained from the recorded stand pipe pressure with the prediction results from Landmark commercial software、the model in this work and the conventional model. Results show that the prediction results by the model in this work are closest to the recorded values when drill string sinusoidal buckling occurs. Besides, the ECD value predicted by the model considering the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings is smaller due to the factor that the length of drill strings with sinusoidal buckling is larger than the actual well depth. With the identical case well data, the larger the sinusoidal buckling degree of downhole drill strings, the smaller the predicted ECD value. The model can reduce risks for drilling operations of extended-reach horizontal wells and provide more accurate reference data for their well control operations.

Similar content being viewed by others

Introduction

Extended-reach horizontal well technology is widely used in the high-efficiency development of low-permeability, unconventional, deepwater, deep-layer, and other complex oil and gas reservoirs1,2. The accurate prediction technology of ECD (equivalent circulating density of drilling fluid) is an important method to guarantee wellbore stability3. Because extended-reach horizontal wells have the common characteristics such as wellbore instability in long horizontal section as well as small pressure density windows and abnormal high pressure in some operation formations, accurate ECD prediction technology is indispensable for risk control of extended-reach horizontal wells.

Many scholars have studied the distribution of temperature and pressure in downhole wellbores4,5,6 and explored the functional relationship between the drilling fluid performance parameters such as density and flow index and temperature and pressure7,8,9,10,11 to predict ECD accurately. Meanwhile, for the ECD prediction of extended-reach horizontal wells, the influence of annular pressure loss and rock cuttings must be considered, and many scholars have conducted corresponding research12,13.

Due to the large well depth of extended-reach horizontal wells, the downhole drilling tools are prone to buckling. Due to various factors such as the presence of build-up sections and the placement of centralizers, the buckling state of downhole drill strings often presents as sinusoidal buckling14. Regarding the impact of drill string buckling on ECD prediction, the current studies mostly focus on the impact of the eccentricity effect caused by drill string buckling on drilling fluid pressure loss15,16,17, while the factor of measurement errors in well depth and vertical depth caused by drill string buckling has not appeared in ECD prediction models.

Therefore, to achieve precise ECD control target during drilling operations of extended-reach horizontal wells, it is necessary to consider the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings into the traditional ECD calculation models corresponding to the characteristics of extended-reach horizontal wells. Therefore, to achieve precise ECD control target during drilling operations of extended-reach horizontal wells, it is necessary to consider the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings into the traditional ECD calculation models corresponding to the characteristics of extended-reach horizontal wells. First, we established a set of ECD calculation model considering the effect of drill strings sinusoidal buckling. Second, according to the data from an extended-reach horizontal well in the East China Sea, the ECD data obtained from the recorded stand pipe pressure were compared with the prediction values from Landmark commercial software、the model in this work and the conventional model to verify the accuracy of our work. Third, the effect of sinusoidal buckling severity on the ECD prediction value are analyzed. At present, this model has been applied to the ECD prediction of multiple extended-reach horizontal wells in the East China Sea. The model can reduce risks for drilling operations of extended-reach horizontal wells and provide more accurate reference data for their well control operations.

Model assumption

The following assumptions are made to establish an ECD prediction model suitable for extended-reach horizontal wells:

(1) The wellbore trajectory of an extended-reach horizontal well consists of a vertical section, several build-up and drop-off sections, and several stable-inclination sections. Of which, the build-up and drop-off sections are designed with the circular arc method.

(2) For a well section with drill string buckling, the drill string contacts with the inner wall of the wellbore in the well section. The cross-section at any position within the drill string buckling section is shown in Fig. 4 (b).

(3) The buckling form of the downhole drill string is sinusoidal buckling.

(4) The H-B model can be used to describe the flow characteristics of drilling fluid under high temperature and high pressure.

(5) The presence of sinusoidal buckling of drill strings will not affect the distribution of wellbore temperature field.

ECD prediction model of Extended-reach horizontal well

Wellbore temperature field model

As shown in Fig. 1, the temperature field system of an extended-reach horizontal well during drilling fluid circulation can be divided into five subsystems18: drill string fluid system, drill string wall system, annular fluid system, formation system, and drill bit system. The temperature distribution of each temperature field subsystem satisfies the energy conservation equation, as shown in Formula (1). The temperature distribution of extended-reach wells can be solved by substituting boundary conditions and initial conditions and in combination with numerical methods4,5,6.

Of which, \(\rho\) is drilling fluid density, g/cm3; C is specific heat, J/(kg·℃); v is speed vector, m/s; \(\lambda\) is thermal conductivity, W/(m·℃); T is temperature, ℃; \(\Delta\) is additional heat source, J; t is time, s.

Equivalent static density model

As for high-temperature and high-pressure wells, many scholars have studied the relationship between drilling fluid density and temperature and pressure7,8,9,10,11. The commonly used formula for the relationship between drilling fluid density and pressure and temperature is as follows:

Of which,

Of which, p0 is surface pressure, Pa; T0 is surface temperature, K; ρ(T, p) is the drilling fluid density when temperature is T (K) and pressure is p (Pa), kg/m3; \({\zeta _p}\),\({\zeta _T}\),\({\zeta _{pp}}\),\({\zeta _{TT}}\),\({\zeta _pT}\), are characteristic constants of drilling fluid, which can be determined by multiple nonlinear regression method.

During the drilling process, the drilling fluid may experience expansion or contraction due to the influence of temperature and pressure, so its density is not constant. Therefore, the concept of equivalent static density (ESD) is proposed to represent the changes of the static hydraulic column pressure in wellbore more accurately. Equivalent static density is the equivalent density value that represents the liquid column pressure exerted to drilling fluid at any point on the wellbore cross-section. It is a function of drilling fluid density and hydraulic column height, expressed by the formula as follows:

Of which, P0 is wellbore pressure, MPa; g is gravity acceleration, 9.81 m/s2; H is vertical depth, m.

An ESD model during drilling fluid circulation is established with the iterative numerical calculation method, which supposes the static hydraulic column height of drilling fluid of a well is H, divides the drilling fluid in the wellbore into n calculation nodes evenly along the static hydraulic column height H, and selects the iterative calculation step size Δh= H/n. Firstly, we use the wellbore temperature field model established in Sect. 2.1 to calculate the change of drilling fluid temperature with well depth during the circulation as follows:

Assuming that the temperature, pressure, and density of the drilling fluid are uniform within a wellbore fluid unit of length Δh, the iterative equation for the bottomhole static hydraulic column pressure is:

With the boundary conditions as follows:

The bottomhole static hydraulic column pressure in the annulus can be obtained after n times of iterations of calculation with the above iterative equations and boundary conditions, which is as follows:

With the ESD calculation model of drilling fluid obtained therefrom as follows:

However, in the actual ESD calculation model, for a wellbore in a vertical section, the measurement of vertical depth (H) value depends on the length of the drill string lowered in the section. In build-up, drop-off, and stable-inclination sections, the H value can be converted from the length of the drill string lowered according to geometric formulas19. During the drilling process, if the drill string experiences no buckling, the length of the drill string lowered in the vertical section can be equivalent to the vertical depth (H) value of wellbore. In build-up, drop-off, and stable-inclination sections, the vertical depth (H) value of wellbore can also be directly converted through geometric formulas. However, the drill string of an extended-reach well is prone to sinusoidal buckling during the drilling process due to the excessive depth. The drill string length after sinusoidal buckling differs greatly from that ignoring sinusoidal buckling, which can bring significant difference between the calculated H and the actual vertical depth value of wellbore if it is not corrected.

As shown in Fig. 2, within well sections of the same length, the drill string length after sinusoidal buckling is longer. Since the vertical depth (H) is calculated based on the length of the drill string lowered in the wellbore, and the ESD is calculated therefrom, consequently, the sinusoidal buckling of drill strings may bring inaccurate ESD value. Therefore, Formula (9) shall be corrected.

As shown in Fig. 3, it is assumed that the drill string experiences sinusoidal buckling in a vertical section, the wellbore in the vertical section contains two independent plates of drill strings, namely, the drill string ignoring sinusoidal buckling and the drill string considering sinusoidal buckling. Of which, the length of the drill string ignoring sinusoidal buckling is L0, whose value is the same as that of the well section length. The drill string section considering sinusoidal buckling can be divided into u sections according to different sinusoidal amplitudes. Assuming that the sinusoidal amplitude of each section is Ai (i = 1….u), the unit cycle line length \({L^{\prime}_{{\text{si}}}}\) corresponding to the drill string section considering sinusoidal buckling is as follows:

Then, in the vertical section, the well depth of the vertical section \(\Delta {S_i}\) corresponding to the drill string section considering sinusoidal buckling with sinusoidal amplitude of Ai is as follows:

Of which, \(\Delta {S^{\prime}_i}\) is screw pitch of the drill string section with sinusoidal amplitude of Ai, m; \({L^{\prime}_{{\text{si}}}}\) is unit cycle line length of the drill string section with sinusoidal amplitude of Ai, m. Screw pitch \(\Delta {S^{\prime}_i}\) and unit cycle line length \({L^{\prime}_{{\text{si}}}}\) can be calculated by the model derived by Gao and Miska19. Gao and Miska derived the relationship between the axial load of drill string and the sinusoidal buckling drill string geometric parameters. \({L_{si}}\) is total length of the drill string section with sinusoidal amplitude of Ai, m.

Then, the total length of the wellbore in the vertical section corresponding to the drill string considering sinusoidal buckling with different sinusoidal amplitudes Ai (i = 1…. u) is as follows:

As shown in Fig. 3, the wellbore length \({L_v}\) of the vertical section is as follows:

According to the supposed conditions, the build-up and drop-off sections are designed with the circular arc method. According to the calculation results of the pipe string mechanics model and the actual on-site safety analysis, the downhole drill string will not buckle in the build-up and drop-off sections due to the geometric constraints of wellbore trajectory14. Therefore, it is unnecessary for the ESD calculation models for the build-up and drop-off sections to consider the length measurement errors caused by drill string buckling.

The spatial shape of the stable-inclination section is a spatial oblique line, with its inclination angle of a fixed value. Of which, the inclination angle of a horizontal well is 90°. The mechanical properties of the drill string in a stable-inclination wellbore are different from those in a vertical wellbore, and its critical load value for sinusoidal buckling is different from that in a vertical Sect14. If the drill string in a stable-inclination wellbore occurs sinusoidal buckling, the depth increment Linc in the stable-inclination section is the same as the depth increment Lv in the vertical section, consisting of two parts: the length of the drill string ignoring sinusoidal buckling and the length of the drill string considering sinusoidal buckling. The calculation method for the vertical depth increment \(\Delta {H_{inc}}\)of the stable-inclination section is:

Of which, \({\alpha _{{\text{inc}}}}\) is the inclination angle of the stable-inclination section, °; \(L_{0}^{{inc}}\) is the well depth corresponding to the length of the drill string without sinusoidal buckling lowered in the stable-inclination section, m; \(L_{s}^{{inc}}\) is the well depth corresponding to the length of the drill string with sinusoidal buckling lowered in the stable-inclination section, m. Of which, \(L_{s}^{{inc}}\) is calculated with the method same as that of vertical section.

Assuming the extended-reach well has totally ‘a’ arc sections and ‘b’ stable-inclination sections, the vertical depth (H) in Formula (9) can be modified to Hb:

Of which, \(\Delta {H_{{\text{arc}}}}\) is vertical depth of spatial arc. Please refer to the Reference18 for calculation method.

The calculation process for the vertical depth \({H_{\text{b}}}\)of an extended-reach well considering the error caused by sinusoidal buckling of drill string is: substituting the wellbore structure, wellbore trajectory, and downhole drilling tool parameters into the pipe string mechanics model21 for calculation to determine whether and where sinusoidal buckling occurs in the downhole drill string. If the drill string has no sinusoidal buckling, the drill string length lowered is the well depth, with \({L_s}\)= 0 in Formula (13) and \(L_{s}^{{inc}}\)= 0 in Formula (14). If the drill string has sinusoidal buckling, the axial load of the drill string can be calculated with the pipe string mechanics model, and then, the geometric characteristic parameters of the drill string section after sinusoidal buckling can be calculated separately, which are substituted into Formulas (12) and (13) to calculate the corresponding vertical section depth, and the vertical depth of the stable-inclination section can be calculated with the same method, and finally, together with the vertical depths of the build-up and drop-off sections, are substituted into Formula (15) for length statistics, so as to obtain the vertical depth at the current drill bit position.

The ESD calculation model of drilling fluid after the vertical depth error is corrected is as follows:

Of which, the \(\vartriangle {h_i}\) in Formula (16) represents the length of the well depth L that is evenly divided into n sections corresponding to the drill bit position.

However, just like the relationship between vertical depth H and Hb, if we ignore the measurement error of well depth caused by the sinusoidal buckling of drill strings, and directly use the length of the drill strings lowered into the wellbore to be equivalent to the well depth, it will cause the well depth value to be too large and the ESD value to be inaccurate. Therefore, it is also necessary to make corrections to the well depth L. The corrected well depth at the drill bit position is Lb. The correction result is as follows:

If the drill string has no buckling, the length of the drill string lowered is the well depth. The value of \({L_s}\) and \(L_{{sl}}^{{inc}}\) in Formula (18) is zero.

Finally, the ESD calculation model of drilling fluid by considering the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings is as follows:

Calculation model of equivalent circulating density (ECD)

The equivalent circulating density (ECD) of drilling fluid can be defined as the sum of the equivalent static density (ESD), the equivalent density from annular pressure loss, and the equivalent density for rock debris affects. The expression formula for equivalent circulating density is as follows:

Of which, \({P_f}\) is annular pressure loss, Pa; \({P_d}\) is the bottomhole pressure from rock cuttings, Pa; H is static hydraulic column height of drilling fluid, m.

It is also necessary to establish a calculation model for the annular pressure loss during the drilling fluid circulating period after the ESD prediction model is established. The frictional pressure drop depends on the rheological properties of drilling fluid, the geometric size of wellbore, and the flow rate of drilling fluid.

The frictional pressure drop is the pressure loss caused by the contact between drilling fluid and flowing pipe wall during the flowing period. A boundary layer can be formed on the surface of the flowing pipe wall that transports drilling fluid. The viscosity characteristics of drilling fluid can cause changes in the flowing velocity perpendicular to the flowing direction. The change in flowing velocity of drilling fluid will bring momentum loss and flowing resistance. The pressure drop caused by this is directly proportional to the length of the flowing pipe wall, the drilling fluid density, and the square of the flowing velocity of drilling fluid, and inversely proportional to the diameter of pipe wall.

The calculation formula for the annular pressure loss by ignoring the influence of drill string buckling is as follows:

Of which, f is friction coefficient, dimensionless; \(\:\rho\:\) is drilling fluid density, g/cm3; L is well depth, m; v is flowing velocity of drilling fluid, m/s; \({D_H}\) is annulus OD, mm; \({D_{\text{p}}}\) is annulus ID, mm. The calculation methods for friction coefficient f shall be classified according to flowing states. Please refer to the References16,17 for the classification methods and calculation methods of friction coefficient.

Formula (21) is feasible for calculating the turbulent annular pressure loss without drill string buckling. However, once the drill string inside the wellbore has sinusoidal buckling, it will bring two effects as follows:

1) The (\({D_H} - {D_{\text{p}}}\)) term in Formula (21) assumes that the drill string is located at the center of the wellbore, which is the situation that the drill string has no sinusoidal buckling. However, as shown in Fig. 4(b), once the drill string has buckling, the drill string will not be centered in the wellbore, and the influence of eccentricity shall be considered.

2) The measurement of well depth (H) in Formula (21) depends on the drill string length lowered in the section. During the drilling process, if the drill string has no sinusoidal buckling, the length of the drill string lowered can be equivalent to the well depth, which is H. However, due to the excessive well depth of the extended-reach well, the drill string is prone to sinusoidal buckling during the drilling process, and the length of the drill string after sinusoidal buckling cannot be equated with the length of the wellbore trajectory. As shown in Fig. 4(a), within the well sections with the same length, the length of the drill string after sinusoidal buckling is longer. After the drill string occurs sinusoidal buckling, the calculation of the annular pressure loss by assuming the length of the drill string lowered in the wellbore equivalent to the well depth can result in inaccurate value of the annular pressure loss.

Therefore, it is necessary to correct Formula (21), adding eccentricity coefficient R in Formula (21), which is the calculation formula for the annular pressure loss of H-B fluid considering the eccentricity of drill string:

Please refer to the References16,17 for the calculation method of eccentricity coefficient R.

Although the influence of drill string eccentricity caused by drill string buckling on annular pressure loss is considered in Formula (22), the phenomenon that the drill string length after sinusoidal buckling is unequal to the actual well length is ignored. Based on the analysis of the drill string length change after sinusoidal buckling in Sect. 3.2, we can correct the well depth value L in Formula (22). The corrected formula for calculating the annular pressure loss is as follows:

Therefore, by substituting Formulas (19) and (23) into Formula (20), we can obtain a ECD calculation model of drilling fluid by considering the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings:

During the normal pressure-controlled drilling process, the actual fluid in the wellbore annulus is the solid-liquid two-phase flow. The rock cuttings in the annular fluid bring additional bottomhole pressure, which is closely related to the concentration of rock cuttings. The calculation method of \({P_d}\) is as follows:

Based on the theory of solid-liquid two-phase flow and the relationship between the concentration of rock cuttings in the annulus and the annular return velocity of drilling fluid, the concentration of rock cuttings in the annulus can be obtained as follows:

Of which, \({\rho _c}\)is the density of rock cuttings, kg/m3; \({C_a}\) is the concentration of rock cuttings; R is the rate of penetration, m/s; \({D_1}\) is the wellbore diameter, m; \({D_2}\) is the diameter of drill pipe, m; \({D_3}\) is the diameter of drill bit, m; \({v_1}\) is the annular return velocity of drilling fluid, m/s; \({v_2}\) is the average sliding speed of rock cuttings, m/s.

In sum, the corrected ECD prediction model for extended-reach horizontal wells can be ultimately obtained as follows:

The calculation process for ECD prediction model based on sinusoidal buckling of drill strings is shown in Fig. 5.

As shown in Fig. 5, the drill string status can be obtained by references19,20,21,22 based on the data of wellbore trajectory parameters、downhole drilling tools parameters and so on. If sinusoidal buckling absents, the well depth and vertical depth measurement error is 0 (with \({L_s}\)= 0 in Formula (13) and \(L_{s}^{{inc}}\)= 0 in Formula (14)), otherwise, the well vertical depth Hb and well depth Lb considering the measurement error due to sinusoidal buckling can be calculated by Formula (15) and (18). Then the ESD, annular pressure loss Pf and the additional bottom hole pressure Pd considering the sinusoidal buckling effect can be calculated by Formula (19),(23) and (25). Finally, the ECD can be deduced by Formula (27).

Case study

As shown in Fig. 6, in this section, we selected Well X in the Pinghu Oil and Gas Field, East China Sea, which is an extended-reach horizontal well. The axial friction coefficient is set to 0.1, and the circumferential friction coefficient is set to 0.25. The drilling parameters for the well’s 3rd spudding include drilling pressure of 90 KN, average rate of penetration of 9 m/h, and rotation speed of 90 r/min. The other fundamental data for calculating downhole string buckling (such as drill pipe OD and ID) and ECD (such as wellhead temperature and booster pump displacement) is shown in Table 1.

It can be known from the calculation results of the pipe string mechanics model20 that the drill string at 3280–3589 m in this well is in a sinusoidal buckling state, while the drill strings at other depths have no buckling. It can be known that, by substituting the error caused by the sinusoidal buckling of the drill strings at 3280–3589 m into the correction model for vertical depth and well depth, the well depth L is 6,412 m and the vertical depth H is 4,393 m if the error caused by the buckling of the drill strings is ignored, and the well depth Lb is 6,127 m and the vertical depth Hb is 4,273 m if the error caused by the buckling of the drill strings is considered.

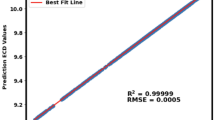

The accuracy of the model

The accuracy of the model should be verified. During the drilling process of the case well, the stand pipe pressure will be recorded, and based on the recorded stand pipe pressure, the ECD can be obtained23, which can be considered as the closest value to the true. Meanwhile, the ECD can also be calculated by commercial software Landmark, which requires four data series to compute ECD: ①Drilling fluid performance parameters, such as density, temperature, and pressure; ②Parameters of wellbore rock debris, such as rock debris density; ③Drilling engineering parameters, such as pump flow rate; ④Structural parameters of the wellbore, such as annular cross-sectional area. From the four input parameters type, it can be seen that Landmark’s model for calculating ECD does not consider the well depth and vertical depth errors caused by sinusoidal buckling.

The calculation results of Landmark commercial software、the model in this paper、conventional model in Eq. (20), and the data obtained from the recorded stand pipe pressure were compared in Fig. 7.

As shown in Fig. 7, the values calculated from the ECD prediction model in this work is closest to the ECD from detected stand pipe pressure. Meanwhile, compared with ECD calculated by Formula (20), the ECD from Landmark is more close to the ECD from detected stand pipe pressure owing to the more input parameters for calculating ECD in Landmark than in Formula (20). Furthermore, due to the influence of the vertical depth and well depth measurement errors caused by the sinusoidal buckling of drill strings, the predicted ECD value for the horizontal section of the case well is smaller. This is caused by the lower circulating pressure loss since the length of the actually drilled wellbore trajectory is smaller than the length of the downhole drill string. The sinusoidal buckling of the drill string can affect the accuracy of the ECD value, causing the calculated ECD value to be greater than the actual situation. The work in this paper can eliminate the effect of drill string sinusoidal buckling to ECD calculation.

The severity of drill string buckling to ECD calculation

Assuming that the drill string at 3280–3589 m in the well is still in a sinusoidal buckling state, the measurement error values of vertical depth and well depth are shown in Table 2 respectively, the measurement error of vertical depth is the \({L_{\text{s}}}+\sum\limits_{{l=1}}^{b} {\left( {L_{{0l}}^{{inc}}+L_{{sl}}^{{inc}}} \right)\cos {\alpha _l}}\) term in Formula (15), and the measurement error of well depth is the \({L_{\text{s}}}+\sum\limits_{{l=1}}^{b} {\left( {L_{{0l}}^{{inc}}+L_{{sl}}^{{inc}}} \right)}\) term in Formula (18). From state A to state E, the sinusoidal buckling deformation of the drill string at 3280–3589 m becomes increasingly severe. The measurement error values of vertical depth and well depth under five different states are substituted into the ECD calculation process for calculation, with the calculation results shown in Fig. 8.

According to Table 2, the sinusoidal buckling degree of downhole drill strings is the smallest in state A and the largest in state E. As can be seen in Fig. 8 that the sinusoidal buckling degree can directly affect the predicted ECD value. The larger the sinusoidal buckling degree, the smaller the predicted ECD value. This is because the length of the actually drilled wellbore trajectory is smaller than the length of the downhole drill strings with the presence of sinusoidal buckling. The larger the sinusoidal buckling degree, the larger the measurement errors of vertical depth and well depth, and the smaller the predicted ECD value.

Conclusion

(1) An ECD prediction model suitable for extended-reach horizontal wells in combination with the environmental and operation characteristics of extended-reach wells has been established. The model considers the measurement errors of well depth and vertical depth caused by the sinusoidal buckling of drill strings. Case study demonstrates that during the third spud section of the subject well, downhole drill string buckling occurred. Neglecting this sinusoidal buckling effect would result in a 4.65% well depth error rate and a 2.8% true vertical depth measurement error rate. Thus, for extended-reach wells, the sinusoidal buckling effect of drill strings cannot be neglected.

(2) It can be known from comparison among the ECD calculation results of Landmark commercial software, the model in this paper, conventional model in Eq. (20), and the data obtained from the recorded stand pipe pressure that, if the sinusoidal buckling of drill strings occurs, the ECD prediction value by this work is closer to the ECD from detected stand pipe pressure. Furthermore, due to the influence of the vertical depth and well depth measurement errors caused by the sinusoidal buckling of drill strings, the predicted ECD value for the horizontal section of the case well is smaller. This is caused by the lower circulating pressure loss since the length of the actually drilled wellbore trajectory is smaller than the length of the downhole drill string. The sinusoidal buckling of the drill string can affect the accuracy of the ECD value, causing the calculated ECD value to be greater than the actual situation.

(3) By comparing the ECD prediction values under different sinusoidal buckling degrees, it can be found that the more severe the sinusoidal buckling of downhole drill strings, the larger the measurement errors of vertical depth and well depth, and the smaller the ECD prediction values. This is because the length of the actually drilled wellbore trajectory is smaller than the length of the downhole drill strings with the presence of sinusoidal buckling. The influence of the sinusoidal buckling factor of downhole drill strings on ECD shall not be ignored for extended-reach horizontal wells.

(4)The computational program developed based on this model has been applied to the prediction of ECD in multiple extended-reach horizontal wells in the East China Sea. Compared to neighboring wells, the complex situation during the drilling process of the application case well reduced the average time by 4.5 days.

Data availability

The datasets used and/or during the current study available from the corresponding author on reasonable request.

References

Jin Guangrong, P. et al. Enhancement of gas production from low-permeability hydrate by radially branched horizontal well: Shenhu area, South China Sea[J]. Energy 253, 124129 (2022).

Tan Mingjian, L. et al. A novel multi-path sand-control screen and its application in gravel packing of deepwater horizontal gas wells[J]. Nat. Gas Ind. B. 9 (4), 376–382 (2022).

Badrouchi, F., Rasouli, V. & Badrouchi, N. Impact of hole cleaning and drilling performance on the equivalent Circulating density[J]. J. Petrol. Sci. Eng. 211, 110150 (2022).

Ramey, H. J. Wellbore heat transmission [J]. J. Petrol. Technol. 14 (4), 427–435 (1962).

Hasan, A. R. & Kabir, C. S. Aspects of Wellbore Heat Transfer during Two-Phase Flow (including Associated Papers 30226 and 30970) [J]9211–216 (SPE Production & Facilities, 1994). 03.

Jiajia Gao, D. et al. Porothermoelastic effect on wellbore stability in transversely isotropic medium subjected to local thermal non-equilibrium[J]. Int. J. Rock Mech. Min. Sci. 96, 66–84 (2017).

Hoberock, L. L. Bottomhole Mud Pressure Variations due to Compressibility and Thermal Effects [C], paper presented at the 1982 IADC Drilling Technology Conference, Houston, : 9–11. (1982).

Peters, E. J., Chenevert, M. E. & Zhang, C. A model for predicting the density of Oil-Base muds at high pressures and temperatures [J]. SPE Drill. Eng. 5 (02), 141–148 (1990).

Quitian-Ardila, L. H., Andrade, D. E. V. & Franco, A. T. A proposal for a constitutive equation fitting methodology for the rheological behavior of drilling fluids at different temperatures and high-pressure conditions[J]. Geoenergy Sci. Eng. 233, 212570 (2024).

Osisanya, S. & Harris, O. Evaluation of Equivalent Circulating Density of Drilling Fluids Under High-Pressure/High-Temperature Conditions [C], SPE Annual Technical Conference and Exhibition, (2005).

Syah, R. et al. Implementation of artificial intelligence and support vector machine learning to estimate the drilling fluid density in high-pressure high-temperature wells[J]. Energy Rep. 7, 4106–4113 (2021).

El Sabeh, K. et al. Extended-reach drilling (ERD)—the main problems and current achievements[J]. Appl. Sci. 13 (7), 4112 (2023).

Hongbin, L. et al. Prediction Method for Equivalent Circulating Density of Deepwater Drilling when Subsea Pressurization Is Considered [J]3772–75 (Oil Drilling & Production Technology, 2015). 01.

Huang, W. J., Gao, D. L. & LIU, Y. A study of mechanical extending limits for Three-Section directional wells [J]. J. Nat. Gas Sci. Eng. 54, 163–174 (2018).

Dokhani, V. et al. Effects of drill string eccentricity on frictional pressure losses in annuli[J]. J. Petrol. Sci. Eng. ,2020,187,106853.

Sorgun, M. Computational fluid dynamics modeling of pipe eccentricity effect on flow characteristics of newtonian and non-Newtonian fluids[J]. Energy Sour. Part A Recover. Utilization Environ. Eff. 33 (12), 1196–1208 (2011).

Erge, O. et al. Frictional pressure loss of drilling fluids in a fully eccentric annulus[J]. J. Nat. Gas Sci. Eng. 26, 1119–1129 (2015).

Yin, Q., Yang, J. & Zhou, B. Operational Designs and Applications of MPD in Offshore Ultra-HTHP Exploration Wells [R], SPE 191060, (2018).

Han & Zhiyong Design and Calculation of Directional Drilling [M] (China University of Petroleum, 2007).

Gao, G. H. & Stefan, M. Effects of friction on Post-Buckling behavior and axial load transfer in a horizontal well. SPE J. [J]. 15 (04), 1, 104–101 (2010).

Lubinski, A. & Althouse, W. S. Helical buckling of tubing sealed in Packers [J]. J. Petrol. Technol. 14 (06), 655–670 (2013).

Huang & Wenjun Study on Pipe String Mechanics and Mechanical Extension Limit of Extended-reach Well [D] (Tsinghua University, 2018).

Chen Mingzhu. Design and application of bottom hole pressure monitoring system based on stand pipe pressure measurement [D]. Southwest petroleum university, 2018. https://doi.org/10.27420/d.cnki.gxsyc.2018.000494

Funding

The authors gratefully acknowledge the financial support from the National Natural Science Youth Fund Project: Research on Coupling Dynamics and Bearing Capacity Evolution Mechanism of Deepwater Subsea Wellhead System (Grant Number: 52204017). This research is also supported by National Key R&D Plan Project (Grant Number: 2022YFC2806100).

Author information

Authors and Affiliations

Contributions

Zhao Huang: Conceived the original idea for the research, led the project, and contributed to the experimental design and data analysis. Yanfei Li: Played a pivotal role in the theoretical development of the hydraulic energy storage drilling rig concept, participated in the mathematical modeling, and assisted in the simulation process.Kun Jiang : Performed the computational simulations, analyzed the results, and contributed to the interpretation of data. Junrui Ge, Yue Gu, Zhiqiang Hu: Managed the field tests, collected empirical data, and provided critical insights into the practical applications and implications of the research findings.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huang, Z., Li, Y., Jiang, K. et al. An equivalent circulating density prediction model for extended-reach horizontal wells considering drill strings sinusoidal buckling. Sci Rep 15, 26598 (2025). https://doi.org/10.1038/s41598-025-10357-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-10357-8

Keywords

This article is cited by

-

Metaheuristic-trained adaptive activation neural networks for reliable buckling resistance prediction of high strength steel columns

Asian Journal of Civil Engineering (2025)