Abstract

This study investigates overburden deformation and surface subsidence mechanisms in fully mechanized top-coal caving (FMTC) mining of “three-soft” (soft coal seam, soft roof, and soft floor) thick coal seams through physical similarity modeling, addressing aquifer disruption and intense surface responses. The experimental results were validated through field monitoring data, achieving a maximum subsidence discrepancy of 2.9%, which confirmed the model’s reliability. Key findings include: compaction of the mining-induced overburden exhibited distinct stratigraphic heterogeneity, with lower strata exhibited greater fragmentation-induced expansion with bulking coefficients of 1.039, contrasting with upper strata coefficients of 1.003–1.008. However, the high compressibility and low strength of lower soft strata reduced the bulking coefficient compared to conventional geological conditions. Overburden fracture patterns evolved progressively from “simply supported beam” structures during initial failure to “cantilever beam” configurations during periodic weighting. While macroscopic deformation aligned with classical theories, the combined effects of the large 11.3 m mining height and high compressibility in lower soft strata destabilized the overburden structure, accelerating upper strata failure. This increased the water-conducting fracture zone height-to-seam ratio to 12.33, representing a 48.7% enhancement compared to the regional average of 8.29 under similar weak overburden conditions; Surface subsidence basins arose from underground goaf volume expansion driven by high mining height and soft rock compressibility, culminating in a maximum subsidence factor of 0.956, exceeding the empirical value of 0.85 for thick-seam mining by 12.5%. This study elucidates the overburden-surface interaction mechanisms in FMTC mining under “three-soft” conditions, offering actionable theoretical insights for subsidence hazard mitigation.

Similar content being viewed by others

Introduction

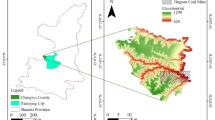

Large-scale coal mining has been a crucial driver for global economic development1,2,3 while simultaneously triggering worldwide environmental challenges including aquifer depletion, surface subsidence, and ecological degradation4,5,6,7. As the world’s largest coal producer, China maintains coal as its dominant energy source, a status projected to persist in the foreseeable future. Advancements in fully mechanized mining technologies for thick seams (e.g., top-coal caving or large-cutting-height mining) have substantially improved operational efficiency and production capacity8. However, these technological advances have paradoxically intensified strata failure and surface subsidence rates in geologically vulnerable regions, exacerbating conflicts between land degradation and the critical need for agricultural productivity enhancement9,10. This conflict is particularly acute in China’s Henan Province, a region fulfilling a vital dual role as a strategic coal base and a key grain production area11. Within Henan, Zhengzhou stands out as the primary coal production hub, encompassing four major coalfields (Xinmi, Dengfeng, Xinggong, and Yanlong). Critically, Zhengzhou exhibits significant geological vulnerability owing to its distinctive “three-soft” thick coal seams. These seams feature a soft floor (typically composed of mudstone, siltstone, and sandy mudstone with poorly developed joints and fissures and an average collapse step distance of approximately 20 m), soft coal seams (with uniaxial compressive strength ≤ 10 MPa, containing various geological structures and joints that make them highly prone to fracturing), and a soft roof (generally consisting of mudstone or sandy mudstone, with a reference uniaxial compressive strength ≤ 25 MPa). These unique geological conditions are known to induce particularly severe and rapid surface deformation during extraction, posing a disproportionate threat to the region’s precious farmland and critical surface infrastructure12. Consequently, while the generic mechanisms of mining subsidence are understood, insufficient research has been conducted on the precise processes governing overburden failure and surface movement under Zhengzhou’s complex and challenging “three-soft” geological conditions. Addressing this critical research gap is essential to develop effective, location-specific mitigation strategies. Targeted investigation is urgently needed to ensure both sustainable resource extraction and the protection of vital agricultural land and infrastructure within this key coal-agriculture overlap zone.

Coal mining induces stress redistribution in the surrounding rock strata, leading to overburden failure when stresses surpass the bearing capacity of the rock mass, with fractured surrounding rocks gravitationally migrating into free spaces (goaf)13,14. This process generates subsidence basins significantly larger than the mined-out areas, accompanied by surface fractures and collapse pits. The associated surface deformations are quantitatively described using parameters including vertical subsidence, horizontal displacement, tilt, curvature, horizontal strain, and distortion15. The formation mechanisms and geometric configurations of subsidence basins, along with extremum values of deformation parameters, exhibit substantial variations under different geo-mining conditions16,17,18,19 necessitating systematic understanding of surface movement patterns for optimal damage mitigation strategies. As a predominant predictive approach, the probability integral method has been extensively implemented in engineering applications20,21 with theoretical derivations demonstrating positive correlations between maximum subsidence magnitude and extremum values of deformation parameters22. Consequently, accurate determination of maximum surface subsidence (Smax) proves critical for evaluating deformation-induced damage severity and guiding preventive measures in coal mining operations.

Coal seam mining thickness is a primary factor influencing maximum surface subsidence (Smax). Previous studies based on field monitoring data have demonstrated an approximately linear relationship between extraction thickness and Smax16,23. Further investigations combining field measurements, laboratory experiments, and theoretical analyses have revealed the mechanism of overburden failure and movement during mining, elucidating how coal thickness governs surface deformation24,25,26,27,28. For thinner seams, fractured roof strata can promptly fill the goaf through bulking effects, resulting in limited strata movement, reduced dynamic load coefficients during initial and periodic roof weighting, and consequently milder Smax29,30. As extraction thickness increases, however, the overburden fails to form stable voussoir beam structures, triggering intense roof movement and pronounced strata pressure. The expanded goaf requires greater bulking volumes from fractured strata, leading to enhanced overburden failure and extended influence zones that amplify surface responses10,31,32,33,34. From a volumetric conservation perspective, increased extraction thickness inherently elevates surface subsidence due to both enlarged mined-out spaces and expanded overburden failure zones30,35. Consequently, increased coal thickness during mining emerges as a critical factor exacerbating surface subsidence severity.

Overburden lithology serves as another critical determinant of Smax, with harder rock strata exhibiting reduced Smax due to their distinct fracturing characteristics and compaction behaviors that govern overburden movement patterns36,37. Consequently, rock bulking and compaction properties must be rigorously considered in analyzing mining-induced Smax. The disturbed overburden stratifies into three zones: the caved zone (comprising variably shaped rock fragments), fractured zone, and continuous deformation zone38,39. Laboratory and numerical studies demonstrate that larger rock fragments from stronger lithologies yield higher bulking coefficients due to inefficient void infilling40,41while complementary research on fragment compaction reveals stiffer lithologies exhibit lower compressibility. Theoretical models further elucidate the micro-macro mechanisms governing fragment compaction and lithology-dependent compaction behavior42,43,44. Although predominantly laboratory-based, field validations confirm bulking-compaction dynamics critically influence overburden failure propagation and practical hazard mitigation38,45,46. These findings mandate explicit incorporation of soft roof compaction behavior when evaluating surface subsidence in “three-soft” thick coal seam conditions.

In summary, top-coal caving mining in “three-soft” thick coal seams exhibits distinct overburden failure and surface subsidence patterns compared with conventional thick-seam mining, primarily due to enhanced compressibility of fragmented rocks in goaf under soft near-field surrounding strata conditions. Similarity simulation experiments - a validated methodology for investigating mining-induced strata pressure, deformation, and surface movement47,48,49,50,51- were adopted in this study. This technique employs scaled physical models using analog materials matching prototype rock mechanical properties, enabling observation of displacement and stress evolution during simulated mining operations to predict field-scale responses52. Focused on soft roof and thick-seam characteristics inherent to “three-soft” conditions, the experimental program specifically examines overburden compaction behavior and Smax development.

This study established a physical model based on similarity simulation principles incorporating actual mining geological conditions. Subsequently, the reliability of experimental results was validated through comparative analysis between simulation outputs and in-situ measurements from working faces. The failure-movement-compaction processes of overburden strata were systematically characterized, with particular focus on stress evolution patterns in goaf. Quantitative analysis of overburden compaction behavior based on stress measurements and bulking coefficients ultimately revealed the fundamental mechanism underlying heightened subsidence coefficients in “three-soft” thick coal seam mining. These findings provide crucial technical support for implementing low-damage extraction strategies and advancing sustainable development in coal mining under challenging geological conditions.

Materials and methods

Engineering context

This study adopts the mining-geological conditions of Longwall Face 12,203 in Zhengzhou mining area as the engineering context. The target No.21 coal seam has an average extraction thickness of 11.3 m and overburden depth of 277.76 m, mined via strike-oriented longwall fully mechanized top-coal caving method (FMTC) with full caving roof management. The face spans 560 m in strike length and 220 m in dip length within a sub-horizontal seam (8° average inclination). Prior to mining at Longwall Face 12,203, the up-dip Longwall Face 12,205 and 12,207, with strike lengths of 200 m and 132 m respectively, had been fully extracted.

The overburden strata predominantly comprise fine-grained sandstone, sandy mudstone, coal seams, mudstone, clay, and gravel, as shown in Fig. 1. The roof structure features a pseudo roof of fine-grained sandstone and direct roof of sandy mudstone, while the floor consists of sandy mudstone and fine-grained sandstone. Both immediate and pseudo roof strata exhibit well-developed fractures with friable characteristics. The comprehensive lithology evaluation coefficient method was applied to assess overburden competency, yielding a composite coefficient P of 0.80 for Face 12,203. According to the correlation table between P and lithology influence coefficient D in Guidelines for Coal Pillar Retention and Coal Mining in Buildings, Water Bodies, Railways, and Main Tunnels53the corresponding D value of 2.2 categorizes the overburden as soft rock strata.

Physical similarity modeling

Model similarity coefficients

In simulating mining pressure phenomena through similarity experiments, the mechanical similarity system governs both rock mass behavior and model responses. When characterizing mechanical processes via similarity principles, three fundamental measurement units can be arbitrarily selected. Adopting the absolute unit system with mass, length, and time as fundamental dimensions enables deterministic derivation of other characteristic variables. Consequently, the similarity simulation experiment must satisfy the following criteria: geometric similarity (scaling ratio CL), kinematic similarity (time scaling Ct), and dynamic similarity (force scaling CF).

Geometric similarity, defined by the proportionality between model and prototype spatial dimensions through the geometric similarity coefficient CL=Lm/Lp, was primarily determined by prototype dimensions and simulation platform constraints. Based on the stratigraphic column analysis, the prototype mining height (H = 277.76 m), seam thickness (11.3 m), floor thickness (5.05 m), and panel length (560 m) satisfy fully developed subsidence conditions. A minimum simulated face advance distance of 388.864 m (1.4×H) was implemented to capture periodic overburden failure patterns post-subsidence stabilization15. Boundary effects were mitigated using 0.8 m-wide coal pillars beyond the setup room and stoppage line in the 4 m×0.3 m×2 m planar simulation system. With CL=1/200, the scaled model height reached 1.38 m, accommodating 2.4 m face advance within boundary-compliant geometry. Temporal similarity coefficient Ct=tm/tp=CL1/2=1/14 was derived under equivalent gravitational acceleration. The analog materials - river sand and wood chips as aggregates, calcium carbonate and gypsum as cementing agents - achieved bulk density similarity Cγ = γm/γp = 0.652. Strength similarity Cσ = σm/σp = CL*Cγ=0.003 and external load similarity CP=Pm/Pp=CL3×Cγ=7.5*10− 8 were mathematically established to maintain dimensional consistency across geometric, kinematic, and dynamic similarity domains.

Experimental design

To comprehensively investigate strata movement mechanics induced by coal extraction, achieving fully developed surface subsidence conditions was prioritized. Based on the mining-geological conditions of the longwall face, the critical face advance distance for achieving fully developed surface subsidence was determined as 388.864 m (1.4H, where H = 277.6 m). A 480-m face advance length was ultimately implemented in the physical model to satisfy both subsidence development criteria and field-specific geological representativeness.

The process from coal extraction to surface subsidence constitutes a systematic mining-induced effect chain. Previous studies have demonstrated that strata movement during overburden migration is predominantly governed by competent rock strata. Accordingly, seven vertical displacement monitoring lines were arranged from the immediate roof to the surface. Each monitoring line contained displacement measurement points spaced at 20 cm intervals. For stress evolution monitoring, four pressure cells were embedded at the No.21 coal seam floor during model construction to capture stress redistribution patterns. The design of the similarity simulation experiment is presented in Fig. 2.

Preparation of similitude materials

The model materials were composed of aggregates, cementing materials, and admixtures blended in predetermined ratios to achieve lithological similarity. For bedrock simulation, river sand was selected as the aggregate bonded with calcium carbonate and gypsum cementing agents. The unconsolidated layer simulation utilized river sand and sawdust as aggregates, while maintaining identical cementing materials (calcium carbonate and gypsum) to replicate weathering-induced geomechanical degradation.

Similitude materials were engineered by modulating constituent ratios to achieve desired mechanical properties. The material formulations were codified using an ABC notation system, where A denotes the weight proportion of aggregates as A/(A + 1), B represents gypsum proportion as(B×0.1)/(A + 1); and C signifies calcium carbonate proportion as (C×0.1)/(A + 1).

The similitude modeling experiments prioritized compressive strength calibration, where the required strength parameters for lithologically varied materials were derived via strength similitude scaling based on in-situ rock properties. Systematic uniaxial compression tests were conducted on specimen groups with distinct mix codes (Fig. 3), enabling determination of optimal material formulations through interpolation analysis of strength-proportion relationships.

The lithology-specific mechanical parameters presented in Table 1 were derived from laboratory testing of rock specimens retrieved during borehole exploration campaigns conducted by the mining operation.

The lithology-specific formulation codes for overburden strata were determined by correlating the uniaxial compressive strength of engineering rock masses (Table 1) with experimental proportioning test results, yielding optimized parameters: coal seam (973), mudstone (837), sandy mudstone (773), and fine-grained sandstone (673), while the unconsolidated stratum formulation (873) incorporated sawdust constituting 10% of the total aggregate mass.

Experimental procedure

Material formulations for each lithology were established in accordance with the mix ratio determination protocol detailed in Section “Preparation of similitude materials”, followed by stratified material quantity estimations calculated through dimensional analysis of model geometry and stratum thickness using the following computational protocol:

Where Qi denotes the total material requirement for stratum i (kg); L represents model frame length (m); b indicates model frame width (m); mi corresponds to modeled stratum thickness (m);ri signifies material unit weight (kg/m³); k accounts for material loss coefficient empirically set at 1.3.

The construction of the physical similarity simulation model commenced with the installation of smooth and rigid retaining plates on the experimental platform. Precisely weighed analog materials for each stratigraphic layer were thoroughly mixed, sequentially poured into the mold frame, evenly spread, and compacted layer-by-layer, with interlayer mica powder application to demarcate strata interfaces. The laying process is illustrated in Fig. 4. This iterative layering process continued until achieving the designed model elevation, followed by retaining plate removal after initial consolidation of the analog materials. Subsequent excavation and monitoring operations were initiated following sufficient drying of the stabilized model.

During the analog model construction, four pressure cells were uniformly positioned within the floor strata of the No. 21 coal seam, with non-coded monitoring points arranged orthogonally at 20 cm intervals.

Excavation and monitoring

Face weighting manifests as strata fracture-induced instability. To prevent strata response inconsistency with field conditions due to excessive single excavation step sizes causing delayed failure, and to avoid inefficient excavation from minimal step sizes that induce no overlying strata movement, the critical initial weighting step size was calculated based on established analytical frameworks for strata behavior, with the governing equation expressed as:

Where h denotes the immediate roof thickness (m); σt represents the tensile strength of the silty mudstone immediate roof (MPa); and q corresponds to the stratigraphically imposed load acting upon the immediate roof (MPa).

The immediate roof, with a thickness of 6.1 m and tensile strength of 2.19 MPa, was subjected to gravitational loading of 0.15 MPa as calculated through the key stratum theory. Based on these parameters, the initial weighting step size of the working face was computationally derived as 26.9 m. The experimental excavation protocol adopted incremental steps of 10 cm per cycle, totaling 24 cycles to achieve a 240 cm mining span, with operations immediately suspended upon observed roof caving and resumed post-stabilization of the strata.

Displacement monitoring during excavation was implemented using the XTDP photogrammetric system (Fig. 6), which established a coordinate system through fixed coded targets with non-coded points serving as measurement markers. High-resolution DSLR cameras captured sequential images of overlying strata under varying excavation stages, and the acquired photographs were reconstructed into 3D coordinates via XTDP software to extract multi-state displacement data from monitoring points. Integrated data processing generated comprehensive displacement-subsidence curves and displacement vector fields. Initial coordinates of observation points were determined by averaging five pre-excavation measurements using high-performance cameras. Strata failure characteristics were documented through pre- and post-excavation observations during each cycle, with a final stabilization observation conducted 24 h after the last excavation to ensure complete stabilization of the model. Deformation patterns of strata and surface were rigorously recorded throughout the monitoring process.

The overburden stress evolution was monitored using an integrated system (Fig. 7), comprising miniature pressure cells, strain gauges, and a data acquisition system. The entire system was calibrated prior to simulated excavation. Continuous data collection was maintained throughout the simulated extraction process, with real-time validation protocols ensuring measurement integrity. Post-experiment analysis involved temporal synchronization of recorded stress-strain histories with phased excavation sequences through timestamp cross-referencing, enabling systematic reconstruction of overburden stress redistribution patterns corresponding to progressive face advancement and strata response stages.

Similarity simulation model calibration

Field monitoring of surface movement and deformation

Surface subsidence monitoring station

The surface subsidence monitoring stations were established above Panel 12,203, comprising two orthogonal survey lines: Line A aligned along the strike direction and Line B oriented in the dip direction of the working face. Both lines were strategically positioned on the primary subsidence profiles and designed to cover the entire primary subsidence zone, with their outermost monitoring points extending beyond the predicted influence boundary of the subsidence basin. Despite topographic constraints causing minor deviations from theoretical layouts during field implementation, all monitoring points were positioned as close as practicable to the main subsidence profile. As illustrated in Fig. 8, the final configuration included 22 monitoring stations (a1-a22) along Line A and 38 stations (b1-b38) along Line B, maintaining essential geometric relationships required for subsidence parameter inversion.

Surface subsidence monitoring instrumentation

Surface subsidence monitoring was conducted using Global Navigation Satellite System Real-Time Kinematic (GNSS-RTK) technology to quantify mining-induced displacements during extraction at Longwall Face 12,203. Concurrent documentation of surface ancillary deformations, including subsidence-induced ground fissures, was systematically implemented. The field measurement operations is presented in Fig. 9. Following initial baseline establishment during station commissioning, iterative measurements were conducted using the baseline dataset as reference, commencing prior to detectable subsidence initiation and continuing until achieving subsidence stabilization criterion (< 30 mm/6 months). Enhanced monitoring frequency was implemented during active deformation phases, systematically recording spatiotemporal displacement patterns until reaching terminal equilibrium states.

Analysis of surface subsidence monitoring results

The investigation primarily focused on displacement characteristics along the face advance direction, and consequently, the surface deformation analysis was predominantly conducted along Survey Line A.

Surface deformation characteristics in similarity simulation

Following the completion of panel extraction in the similarity simulation test, the surface subsidence curve was derived utilizing displacement monitoring line 7 embedded in the physical model (Fig. 5), with the final experimental results graphically presented in Fig. 10.

The two curves in Fig. 10 represent surface subsidence measured after 480 m of panel extraction and 12-h post-excavation stabilization, respectively. The stabilized Smax is determined as 10,396 mm with a subsidence factor (q) of 0.92 derived from the plotted data.

Field monitoring results of surface subsidence

Continuous monitoring of surface movement was conducted during panel advance, with the subsidence curves from 26 Apr. 2024 to 05 Nov. 2024 illustrated in Fig. 11. Field measurements reveal that monitoring station a18 (maximum subsidence location) recorded subsidence magnitudes of 10,688 mm on 26 Apr. 2024 and 10,702 mm on 05 Nov. 2024, resulting in a cumulative subsidence of 14 mm over this > 6-month stabilization period. Consequently, the Smax is determined as 10,702 mm, with a subsidence factor (q) of 0.956 calculated by incorporating the influence of coal seam dip angle. This indicates that coal seam mining thickness directly affects surface subsidence. According to the probability integral method, an increase in the subsidence factor directly amplifies the maximum surface tilt and deformation values15. Under the specific mining and geological conditions of this working face, calculations yield a maximum surface tilt of 70.6 mm/m and a maximum tensile deformation of 27.6 mm/m. Comparison with relevant evaluation standards reveals that such deformation induces extremely intense ground fissures and has caused severe structural damage, rendering surface structures unfit for normal use53.

Comparative analysis of similarity simulated and field monitoring results

The similarity simulation yields a maximum surface subsidence of 10,396 mm with q of 0.92, while field measurements reveal a maximum subsidence magnitude of 10,702 mm and q of 0.956. Given the panel extraction height of 11,300 mm, the physical simulation exhibits a discrepancy of 306 mm in maximum subsidence and 0.036 in subsidence factor compared to field-measured results, as illustrated in Fig. 12.

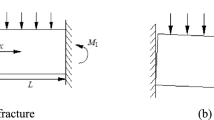

Mining-induced overburden failure generates three characteristic zones: the caved zone, fractured zone, and continuous bending zone13,14,38as illustrated in Fig. 13. The caved zone exhibits irregular collapse of strata into small, heteromorphic rock fragments with extensive voids and high bulk factors, while the fractured zone contains larger, regularly shaped blocks forming stable voussoir beam structures with minimal inter-block gaps that induce inter-strata voids. The combined mechanical effects of fragmented rock accumulation in the caved zone and voussoir beam formation in the fractured zone (collectively termed the " Water conduction fracture zone”) restrict permissible subsidence space in the overlying strata, forcing integrated continuous deformation to develop into the continuous bending zone. Consequently, the compaction state of the disturbed overburden directly governs the maximum surface subsidence magnitude.

The analysis demonstrates that the compaction efficiency of mining-induced overburden directly dictates the Smax. The similarity simulation results (Smax=10,396 mm) align with field measurements (Smax=10,702 mm), with a relative error of 2.9%. This agreement validates the methodology’s efficacy for analyzing subsidence induced by mining in “three-soft” thick coal seams, particularly from an overburden compaction perspective. However, comparative analysis of field-measured and simulated subsidence profiles shows notable discrepancies in deformation patterns, particularly in subsidence basin extent and peak subsidence location offset. These deviations are primarily attributed to the simulation materials’ inability to replicate plastic deformation in unconsolidated layer under actual geological conditions, as evidenced by the wider field-observed subsidence basin.

Results

The coal seam was excavated sequentially to investigate roof caving characteristics and mining-induced stress evolution at varying extraction distances.

Movement and failure mechanisms of Mining-induced overburden

The coal seam was excavated following the experimental design protocol, with photographic documentation of the physical model systematically conducted upon strata collapse accompanied by significant fracture development, and the movement and failure characteristics of overburden strata at different excavation distances are illustrated in Fig. 14.

As shown in Fig. 14a, when the longwall face advanced to 20 m, a large goaf formed behind the working face with the immediate roof remaining suspended and no significant failure observed in overlying strata. At 60 m excavation distance (Fig. 14b), the immediate roof reached its maximum unsupported span, exhibiting initial fracture followed by complete collapse into the goaf, while the main roof remained suspended above the newly created void space. As mining progressed to 80 m (Fig. 14c), the immediate roof demonstrated periodic fracturing with collapse events occurring at approximately 20 m intervals, corresponding to the periodic weighting interval. When advancing to 100 m (Fig. 14d), subsequent periodic fracture and collapse of the immediate roof increased the unsupported span of the main roof, ultimately triggering fracture and immediate collapse of both the main roof and its controlled strata. At 120 m excavation distance (Fig. 14e), collapse of main roof strata reduced overburden pressure above the working face, altering the typical 20 m periodic weighting pattern and forming a distinctive cantilever beam structure through sequential fracturing of immediate and main roof strata. During 140–200 m advancement (Fig. 14f), three periodic weighting events occurred with an average interval of 33 m, characterized by sequential fracturing where the immediate roof initially failed followed by progressive failure of the main roof strata.

When the face advanced to 220 m (Fig. 14g), the failure range of overlying strata expanded significantly, with inferior key strata beyond 20 m behind the face fracturing and collapsing, while bed separation developed between upper strata layers. The strata within 20 m behind the face formed stable cantilever structures, exhibiting increased periodic weighting intervals similar to those observed during main roof collapse. Stress reduction in overburden caused by inferior key strata failure continued until advancing to 246 m (Fig. 14h), where low-position hard strata including immediate and main roofs completely collapsed. The main key stratum fractured without immediate collapse, forming an articulated structure through interlocking with rock masses, while bed separation propagated upward to the interface between unconsolidated layers and bedrock.

When advancing to 260 m (Fig. 14i), the immediate roof remained intact with increased periodic weighting intervals. At 280 m excavation distance (Fig. 14j), lower hard strata fractured and collapsed, inducing periodic fracture of the main key stratum while bed separation propagated upward significantly. Upon reaching 300 m (Fig. 14k), bed separation at the bedrock-unconsolidated layer interface closed, achieving maximum development height with fracturing and compaction of lower unconsolidated layer. During 300–420 m advancement (Fig. 14l), periodic bedrock fracture occurred in lower strata accompanied by immediate collapse, while the composite structure formed by sub-key and main key strata rotated and compressed into articulated structures with closure of uppermost bed separation. At final excavation distance of 480 m (Fig. 14m), periodic fracture and collapse persisted in lower bedrock strata, while upper strata formed horizontal articulated structures through rotational movement, with maximum fracture density near the bedrock-unconsolidated interface and continuous deformation observed in upper unconsolidated layers.

The overburden movement pattern revealed that in “three-soft” thick coal seam mining, the overlying roof strata failed to form stable voussoir beam structures due to large extraction thickness, predominantly experiencing direct caving into goaf. Moreover, the fragmented rock mass formed by caving exhibited significantly higher compressibility influenced by the soft roof characteristics of three-soft coal seams.

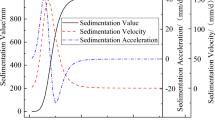

Mining-induced overburden movement and surface subsidence

The XTDP photogrammetric system was employed to investigate displacement evolution and compaction characteristics of overburden strata during coal extraction, with strata-specific displacement patterns at varying face advancement distances illustrated in Fig. 15.

As shown in Fig. 15, distinct behavioral patterns were observed in overlying strata at different horizons during face advance. Monitoring Line 1 exhibited steeper curves with discontinuous and periodic characteristics near the setup entry and longwall face areas, while other monitoring lines demonstrated stronger continuity throughout the advancement. The abrupt curve steepness of Line 1 on the goaf side correlates with the immediate roof strata’s direct collapse mechanism. Line 2, positioned within the main key stratum, displayed articulated structural features characterized by gradual subsidence rather than immediate collapse after fracturing. The fractured strata gradually rotated toward the goaf with face progression, manifesting continuous deformation attributes. Strata above the key horizon exhibited synchronized continuity governed by the main key stratum’s movement. Line 1 further revealed significant compaction settlement (Smax is 11,045 mm) in the immediate roof strata during progressive face advance, a phenomenon consistently observed across all monitoring lines. Quantitative maximum subsidence values post-collapse and compaction for each line are tabulated in Table 3.

Figure 16 was developed by analyzing the subsidence values of monitoring points at varying depths along the vertical profile through the maximum surface subsidence point during panel advancement.

The analysis of Fig. 16 revealed that strata subsidence at varying depths underwent three distinct phases: developmental, abrupt-increase, and stable phases, corresponding to the initial deformation, failure-induced collapse, and compaction stabilization stages of mining-induced overburden. Lower-position strata exhibited loose and dilated states post-collapse due to mining impacts, subsequently undergoing compaction under continuous loading from overlying high-position strata failures, with the compaction process primarily involving recompression of internal pores within fractured rocks, resulting in minimal total compression as evidenced by consistently low curve slopes. In contrast, high-position strata compaction was predominantly attributed to progressive bed separation closure accompanying face advance, demonstrating greater compressibility and dynamically manifested as gradually decreasing curve slopes during the compaction phase.

Mining-induced stress results in the Goaf

Analysis of overlying strata deformation revealed concentrated compaction in the central goaf. To investigate the dynamic evolution from fracturing to progressive compaction and stabilization, two pressure cells embedded in the central floor strata were analyzed. Their stress variations effectively characterize the coupled failure-compaction behavior of collapsed strata and demonstrate phased compaction patterns, providing critical data support for understanding strata compaction behavior during goaf maturation.

Figure 17 illustrates mining-induced stress variations, where negative and positive values represent compressive and tensile stresses, respectively. The monitoring points exhibited stress evolution comprising loading-unloading-reloading cycles with stepwise fluctuations accompanying strata failure. At Monitoring Point PC-1, mining-induced stress peaked at 1.6 MPa (0.30 times in-situ stress), initiating 120 m ahead of the face, peaking at 30 m ahead, then decreasing rapidly upon face passage followed by gob compaction. Monitoring Point PC-2 near the panel boundary showed delayed response (activation at 140 m ahead) with higher peak stress of 1.9 MPa (0.32 times in-situ stress) peaking at 25 m ahead. Both monitoring points’ stresses did not fully recover to their original states post-compaction due to persistent fractures in overburden strata and stress concentrations from manual compaction during modeling.

Discussion

Compaction behavior of mining-induced overburden

The compaction behavior of mining-disturbed overburden is characterized by the bulking coefficients, defined as the ratio of post-failure rock height (Hi’) to intact rock height (Hi), which quantifies volumetric expansion-contraction transitions during strata failure and subsequent compaction processes.

Where K is bulking coefficients of mining-induced overburden; Hi’ is he post-failure height of mining-induced overburden (m); Hi is intact rock height (m);Smax_i is the maximum subsidence value (m) at survey line i; Smax_i+1 is the maximum subsidence value (m) at survey line i + 1.

Figure 18 demonstrates the spatial distribution of overburden bulking coefficients calculated from Table 3 data and monitoring line spacing, where higher values indicate greater void ratios and lower compaction efficiency within mining-induced strata. The fitted relationship between bulking coefficients and their distance to the coal seam reveals a rapid decrease in the first 70 m (the range of the caved zone), with peak values occurring in lower strata near coal seam roofs of fully mined-out areas. This trend progressively reduces with increasing stratigraphic elevation and stabilizes beyond 70 m (the range of rock strata above the caved zone), forming a vertical zoning pattern consistent with gravitational compaction mechanisms documented in longwall mining studies30,45.

The experimental damage coefficients aligned with the equilibrium mining concept35where the summation of damage coefficients across distinct zones equaled unity, validating simulation accuracy. Comparative analysis with existing studies30,38,40,46demonstrated lower bulking coefficients in lower strata of “three-soft” coal seams compared to hard rock conditions, primarily attributed to the soft lithology of immediate roof strata. Bulking mechanisms predominantly originated from inter-block dislocation voids formed during roof collapse into goafs (Fig. 19a), supplemented by fractured rock expansion. Progressive face advancement induced upper strata failure, where gravitational loading promoted fracture closure (Fig. 19b) through enhanced particle rearrangement and plastic deformation in soft strata, resulting in elevated compaction efficiency due to stress-driven fragment alignment and low compaction resistance inherent to soft lithologies.

Failure characteristics of mining-induced overburden

Figure 14 demonstrates that lower strata predominantly behaved as simply-supported beams prior to initial fracturing, transitioning to cantilever beam patterns during periodic fracturing post-initial failure, with post-fracture manifestations (direct caving or articulated interlocking) governed by subsurface void height, while upper strata exhibited continuous deformation patterns despite sustaining damage. Figure 17 reveals three-stage stress evolution in goaf floor: (1) stress escalation phase where abutment stress ahead of the working face progressively intensified to peak values under beam-end effects; (2) stress reduction phase marked by stress release through strata failure until roof caving completed after face passage; (3) stress recovery phase where gravitational compaction re-established stress equilibrium as mining advanced. These overburden failure mechanisms and stress redistribution patterns under “three-soft” thick coal seam conditions aligned with classical theories proposed by Peng and Qian et al.14,38.

In conventional longwall mining, overburden failure mechanisms are stratified into three zones: the caved zone (disordered rock blocks with high void ratios), fractured zone (regular blocks forming voussoir beams), and continuous bending zone (integral deformation). Mining-induced overburden failure characteristics were extracted using MATLAB software (Fig. 20), with three distinct zones delineated based on failure patterns: the caved zone (78.7 m thickness), fractured zone (60.7 m thickness, equivalent to 139.4 m water conduction fracture zone height), and continuous bending zone (138.2 m thickness). These measurements confirmed that “three-soft” coal seams maintained conventional zonal failure patterns18,38,39aligning with classical theories of strata movement and stress redistribution during longwall extraction.

Mining-induced overburden failure adhered to conventional zonal partitioning, whereas the water-conducting fractures height-to-seam ratio (HSR = water-conducting fractures height/ coal seam extraction thickness) under “three-soft” conditions reached 12.33. This value aligns closely with the in-situ measured HSR of 12 and represents a significant increase compared to the reported average HSR of 8.29 in soft rock strata of Henan coal mines31,53. This phenomenon was attributed to the combined effects of large mining height and substantial compression in proximal soft rock strata. Fracture characteristic analysis and previous studies24,26,38,39 demonstrate that beam models effectively describe strata failure mechanisms, revealing that intact strata develop a maximum subsidence deformation (wmax) prior to fracturing, as shown in Fig. 21.

Strata fracture criteria were determined by comparing free subsurface space height (h) with the maximum deformation limit (wmax): when h < wmax, intact strata developed upward counterforce from underlying strata accumulation to resist deformation; otherwise, failure occurred. This fracture criterion was formulated as expressed in Eq. (2).

Large mining heights in “three-soft” thick coal seams, combined with the high compressibility of soft proximal strata, significantly increase subsidence space in underlying strata. This synergistic effect inevitably induces extensive strata failure propagation beyond conventional failure extents observed in competent geological conditions, demonstrated the compounding influence of thick-seam extraction mechanics and lithological weakness on overburden destabilization patterns.

Maximum surface subsidence

The analysis of mining-induced overburden compaction characteristics and strata movement patterns demonstrated that large mining-induced voids combined with substantial soft roof fragmentation compression in “three-soft” thick coal seams predominantly caused direct caving of lower strata post-fracture, resulting in significantly greater overburden failure heights compared to analogous geological conditions. This strata failure mechanism ultimately formed surface subsidence basins, with maximum surface subsidence values served as critical indicators for surface deformation analysis, thereby necessitating focused evaluation of these peak subsidence parameters.

Physical similarity modeling and field monitoring results demonstrated that “three-soft” thick coal seam extraction induced significantly greater maximum surface subsidence (Smax) compared to thin-seam operations30consistent with established thickness-dependent subsidence relationships16,23. This phenomenon reflected the direct correlation between mined-out void geometry and Smax magnitudes. Comparative analysis with subsidence factors from thick-seam studies10 and empirical thresholds53 (e.g., 0.85) revealed elevated subsidence factors under “three-soft” conditions, representing a relative increase of approximately 12.5% ( calculated as (0.956 − 0.85)/0.85 × 100%), attributable to enhanced void propagation through soft overburden. Subsidence initiates as gravitational stress redistribution drives strata collapse from mined voids upward, culminating in surface basin formation. Under full subsidence conditions, the recompacted zone along the face advance direction exhibits minimal bed separation voids (Fig. 22), thereby hosting Smax. Stratigraphic compaction analysis revealed lower strata’s reduced compaction efficiency versus upper strata’s improved reconsolidation. Consequently, void compensation primarily occurs through lower strata bulking – an effect diminished in “three-soft” seams due to thorough lower-strata fragmentation and efficient compaction. This limited void compensation capacity directly translates mined void dimensions to surface deformation, explained why Smax approximate mined seam thickness in such geological settings.

Lateral zonation of mining-induced overburden14.

The integrated analysis revealed that large mining heights and high compressibility of lower soft strata synergistically amplified Smax in “three-soft” thick coal seam mining. The synergistic effect of these factors induced intensified failure in underlying strata and expanded mining-induced damage zones in overburden, ultimately amplifying surface subsidence maxima through bottom-up damage propagation mechanisms. Mining-induced void dimensions directly reflected mining damage intensity, with greater damage exhibited proportional relationships to surface subsidence magnitudes. “three-soft” thick coal seam mining significantly enlarged these voids, underscoring this geological particularity as a critical factor in exacerbated surface subsidence.

Limitations

The widespread application of physical similarity modeling in studying mining-induced overburden deformation and surface subsidence must be contextualized within its inherent limitations. First, planar physical modeling systems inherently neglect three-dimensional effects perpendicular to the face-advance direction. However, in longwall mining systems where face-advance dimensions dominate over face-width parameters, the planar approach remains valid for capturing principal deformation mechanisms, as evidenced by its extensive adoption in fundamental studies24,30,47,49,50. Second, conventional analog materials effectively simulate competent rock strata mechanics but struggle to replicate unconsolidated layer’s high-deformation, low-strength behavior. To address this, wood fibers were incorporated into unconsolidated layer simulations following established protocols48. The fibrous network enhances material ductility, suppresses brittle fracture propagation, and improves strain accommodation capacity – critical attributes for approximating unconsolidated layer’s nonlinear deformation characteristics. While imperfect, this refinement expands the methodology extends applicability to unconsolidated layer systems through fiber-reinforced analog materials (Section “Preparation of similitude materials”).

Conclusions

Through physical similarity modeling tests of stope planar geometry, this study thoroughly investigated the overlying strata behavior and surface subsidence patterns under fully-mechanized top coal caving mining conditions in “three-soft” thick coal seams. Quantitative analysis of compaction characteristics in different overburden zones, failure modes, and maximum surface subsidence values yielded three key findings:

-

(1)

The compaction process of overburden in “three-soft” thick coal seam mining exhibited marked stratigraphic heterogeneity, with lower strata (0–34.6 m above goaf) demonstrating higher bulking capacity (bulking coefficients: 1.039) compared to upper strata (> 34.6 m above goaf, coefficients: 1.003–1.008). This phenomenon is attributed to greater stress relief and void space availability near the mining void, which intensified fragmentation-expansion in proximal strata. The characteristic soft-rock lithology in “three-soft” coal seams reduced post-compaction bulking coefficients compared to conventional mining conditions, resulting from more pronounced void infilling and volumetric compression between fragmented blocks during soft-rock compaction.

-

(2)

The strata failure modes during “three-soft” thick coal seam mining exhibited phased evolutionary characteristics with intensified mining disturbance: initial breakage manifested as a simply-supported beam structure, progressively evolving into cantilever beam configuration during periodic weighting. While the ultimate deformation patterns of overburden strata remained aligned with the conventional three-zone (caved, fractured, and continuous bending zones) and partition theory framework, the combined effects of large-mining-height operation and high compressibility of lower soft rock strata significantly reduced structural stability. This instability exacerbated upper strata failure, resulting in the HSR of 12.33 under “three-soft” conditions − 48.7% higher than the regional average (8.29) in similar soft overburden environments.

-

(3)

Surface subsidence basin formation fundamentally manifests as the macroscopic expression of goaf geometry evolution, where large mining heights and high compressibility of soft lower strata in “three-soft” thick coal seams synergistically enhance underground void volumes. This void-space amplification mechanism elevates the subsidence factor to approximately 0.956 under such conditions – 12.5% higher than the empirical threshold (0.85) for thick-seam operations in comparable geological settings – confirming soft strata’s pivotal role in translating subsurface void dynamics into amplified surface deformation through reduced void-compensation capacities.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Kim, H. & Yoo, S. Coal consumption and economic growth in Indonesia. Energ. Source Part. B. 11, 547–552 (2016).

Wolde-Rufael, Y. Coal consumption and economic growth revisited. Appl. Energy. 87, 160–167 (2010).

Xu, J., Zhou, M. & Li, H. The drag effect of coal consumption on economic growth in China during 1953–2013. Resour. Conserv. Recycl. 129, 326–332 (2018).

Grzovic, M. & Ghulam, A. Evaluation of land subsidence from underground coal mining using timesar (SBAS and PSI) in springfield, Illinois, USA. Nat. Hazards. 79, 1739–1751 (2015).

Salmi, E., Nazem, M. & Karakus, M. Numerical analysis of a large landslide induced by coal mining subsidence. Eng. Geol. 217, 141–152 (2017).

Stojiljkovic, E., Grozdanovic, M. & Marjanovic, D. Impact of the undergroud coal mining on the environment. Acta Montan Slovaca. 19, 6–14 (2014).

Yan, H., Mu, G., Yang, Y. & Qiu, C. Study on the damage evolution and water loss of aquifer under coal mining. Therm. Sci. 28, 1061–1066 (2024).

Wang, G. et al. Research and practice of intelligent coal mine technology systems in China. Int. J. Coal Sci. Technol. 9, 17 (2022).

Bai, E., Guo, W. & Tan, Y. Negative externalities of high-intensity mining and disaster prevention technology in China. Bull. Eng. Geol. Environ. 78, 5219–5235 (2019).

Li, J., Li, X., Liu, C. & Wu, X. Dynamic changes in surface damage induced by high-intensity mining of shallow, thick coal seams in gully areas. Adv. Civ. Eng. 5151246 (2020).

Bai, E. et al. Degradation mechanism of cultivated land and its protection technology in the central coal-grain overlapped area of China. J. Clean. Prod. 468, 143075 (2024).

Guo, W. Subsidence Laws and Applications of three-soft Coal Seam Mining (Science, 2013).

Palchik, V. Formation of fractured zones in overburden due to Longwall mining. Environ. Geol. 44, 28–38 (2003).

Qian, M. & Xu, J. Behaviors of strata movement in coal mining. J. China Coal Soc. 44, 973–984 (2019).

Peng, S. Surface Subsidence Engineering: Theory and Practice (CRC, 2020).

Liu, S. et al. Analysis of mining subsidence characteristics and deformation prediction considering size parameters and mechanical parameters. Geofluids 16 (2022).

Kowalski, A. Polanin PAnalysis of the impact of the coal bed inclination and the direction of exploitation on surface deformation. Arch. Min. Sci. 60, 997–1012 (2015).

Tang, J. & Zhang, Y. Analysis of the influence of the Pressure-shear fault upon the mountain surface movement and deformation. Disaster. Adv. 4, 98–102 (2011).

Scigala, R. & Szafulera, K. Linear discontinuous deformations created on the surface as an effect of underground mining and local geological conditions-case study. Bull. Eng. Geol. Environ. 79, 2059–2068 (2020).

Yang, Z. et al. M an extension of the InSAR-Based probability integral method and its application for predicting 3-D Mining-Induced displacements under different extraction conditions. IEEE Trans. Geosci. Electron. 55, 3835–3845 (2017).

Zhu, C. et al. Retrieval and prediction of three-dimensional displacements by combining the DInSAR and probability integral method in a mining area. IEEE J-STARS. 13, 1206–1217 (2020).

Liu, G. Fundamental Laws of Ground Movement in Coal Mining (China Industry, 1965).

Zhang, X., Liu, Z., Wang, D., Dong, J. & Wang, X. Research PIV-based model on subsidence caused by coal mining. Sci. Rep. 14, 26269 (2024).

Huang, W. et al. Analysis of the movement pattern of overburden and the form of Spatial development of separation after mining in a fully mechanized caving face. Front. Earth Sci. 11, 15 (2023).

Wang, X., Xie, J., Zhu, W. & Xu, J. The field monitoring experiment of the high-level key stratum movement in coal mining based on collaborative DOFS and MPBX. Sci. Rep. 12, 13 (2022).

Sun, Y., Zuo, J., Karakus, M. & Wang, J. Investigation of movement and damage of integral overburden during shallow coal seam mining. Int. J. Rock. Mech. Min. Sci. 117, 63–75 (2019).

Do, T., Wu, J. & Lin, H. Investigation of sloped surface subsidence during inclined seam extraction in a jointed rock mass using discontinuous deformation analysis. Int. J. Geomech. 17, 14 (2017).

Ma, X. et al. Study on surface subsidence characteristics based on three-dimensional test device for simulating rock strata and surface movement. Energies 15, 16 (2022).

Fu, B., Fang, E., Tu, M. & Deng, R. Study on load-transfer mechanism and strata behavior characteristics in deep-buried weak-caking roof. J. Min. Saf. Eng. 36, 24–29 (2019).

Zhang, J. et al. Wu. X. Similar model study on the principle of balanced mining and overlying strata movement law in shallow and thin coal seam based on N00 mining method. Eng. Fail. Anal. 152, 107457 (2023).

Zhang, Y., Shen, C., Zhang, Z. & Li, Y. Regional distribution law of water-conducting fractured zone height in high-strength mining of Thick and extra-thick coal seams in China. Coal Sci. Technol. 50, 38–48 (2022).

Lan, Y., Gao, R., Yu, B. & Meng, X. Situ studies on the characteristics of strata structures and behaviors in mining of a thick coal seam with hard roofs. Energies 11, 2470 (2018).

Chang, Z. et al. Safety and high-recovery mechanisms and application research for initial mining of thick-coal-seam with complex structure and thick-hard roof. Sci. Rep. 14, 19638 (2024).

Lan, T. et al. Study on the linkage mechanism between key strata fracture in overburden and surface subsidence during caving mining in extra-thick coal seams. Sci. Rep. 15, 16 (2025).

He, M., Wang, Q. & Wu, Q. Innovation and future of mining rock mechanics. J. Rock. Mech. Geotech. Eng. 13, 1–21 (2021).

Yan, Y., Yan, W., Liu, J. & Guo, J. The prediction model of super large subsidence in high water table coal mining areas covered with thick unconsolidated layer. Geofluids 15 (2021).

Zhang, Y., He, F., Kong, J., Zhu, Y. & Wang, L. Relationship between surface subsidence range and geological mining conditions using numerical simulation and machine learning. Sci. Program. 8720831 (2022).

Peng, S. Longwall Mining 3nd edn (CRC, 2006).

Qian, M. A. Study of the behaviour of overlying strata in longwall mining and its application to strata control. Developments in Geotechnical Engineering, Elsevier (1981).

Su, C., Gu, M., Tang, X. & Guo, W. Experiment study of compaction characteristics of crushed stones from coal seam roof. Chin. J. Rock. Mech. Eng. 31, 18–26 (2012).

Korman, T., Bedekovic, G., Kujundzic, T. & Kuhinek, D. Impact of physical and mechanical properties of rocks on energy consumption of jaw crusher. Physicochem Probl. Min. Process. 51, 461–475 (2015).

Yuan, F., Tang, J., Wang, Y., Li, C. & Kong, L. Numerical simulation of mechanical characteristics in Longwall Goaf materials. Min. Metall. Explor. 39, 557–571 (2022).

Li, M., Meng, G., Zhang, J., Huang, P. & Germain, D. Sensitivity analysis of key factors influencing compression-induced deformation of waste rocks for backfilling to reduce environmental pollution. Environ. Sci. Pollut Res. 27, 16707–16717 (2020).

Xu, Y. et al. Study on compaction characteristics and mechanical model of dry crushing filling material under lateral confinement condition. Sci. Rep. 14, 16 (2024).

Xu, J. et al. Influencing factors of accumulative effect of overburden strata expansion induced by stress relief. J. China Coal Soc. 47, 115–127 (2022).

Ming, C., He, M., Wang, J., Liu, J. & Coli, M. Control technology of surrounding rock stability based on compensation theory in gob-side entry retaining with composite hard roof. J. Mt. Sci. 22, 1029–1047 (2025).

Yang, J., Yu, X., Yang, Y. & Yang, Z. Physical simulation and theoretical evolution for ground fissures triggered by underground coal mining. Plos One. 13, e0192886 (2018).

Meng, X. et al. Migration evolution laws of overburden structure with deep-lying Thick surface soil and disaster mechanism induced by high stress mutation. J. China Coal Soc. 48, 1919–1931 (2023).

Li, L., Kong, D., Liu, Q., Cai, H. & Chen, L. Study on law and prediction of surface movement and deformation in mountain area under repeated mining of shallow coal seam. Bull. Eng. Geol. Environ. 82, 76 (2023).

Li, X., He, W. & Xu, Z. Study on law of overlying strata breakage and migration in downward mining of extremely close coal seams by physical similarity simulation. Adv. Civ. Eng. 2898971 (2020).

Lu, J. et al. Three-dimensional physical model experiment of mining-induced deformation and failure characteristics of roof and floor in deep underground coal seams. Process. Saf. Environ. Prot. 150, 400–415 (2021).

Li, H. Physical Similarity Modeling Test of Ground Pressure (China University of Mining and Technology, 1988).

Hu, B. Guidelines for Coal Pillar Retention and Coal Mining in Buildings, Water Bodies, Railways, and Main Tunnels (China Coal Industry Publishing House, 2018).

Acknowledgements

The study was funded by the National Natural Science Foundation of China (U21A20108, U22A20620) and the Henan Provincial Key Research and Development Special Project (251111521200). The authors wish to acknowledge these financial contributions and their appreciation of the organizations for supporting this basic research.

Author information

Authors and Affiliations

Contributions

Wenbing Guo: Writing-review and editing, formal analysis, funding acquisition. Weiqiang Yang: Conceptualization, Writing-original draft, Data curation. Zhibo Ge and Bibi Wang: methodology, Data curation. Longxiang Li: formal analysis. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note 出版商说明

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Guo, W., Yang, W., Ge, Z. et al. Investigation on overburden failure and subsurface subsidence characteristics in fully mechanized top-coal caving of “Three-Soft” Thick coal seams. Sci Rep 15, 24833 (2025). https://doi.org/10.1038/s41598-025-10480-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-10480-6