Abstract

Abnormal gas emissions at the mining face under intricate geological conditions pose significant challenges to coal mine safety and operational efficiency. To explore the impact of fault structures on gas migration in mining areas, a two-dimensional geological framework incorporating fault features was established using COMSOL Multiphysics software. Simulations were conducted to analyze gas movement at different proximities to the fault, identifying key factors that affect gas dispersion in mining environments with complex geological characteristics. A predictive model was subsequently developed by integrating fault-induced gas migration effects. The findings reveal that as the mining face advances to nearly 100 m from the fault, the surrounding stress intensifies to about 21 MPa, creating a pronounced stress concentration. At a distance of approximately 50 m from the fault, the stress concentration becomes even more severe than at 100 m, with stress levels reaching nearly 39 MPa, approximately double that at 100 m. Additionally, within the initial 10 m of the mining face, a region of high gas concentration is observed. At 50 m from the fault, gas pressure is about 20% higher than at 100 m, while gas migration velocity is approximately 2.4 times greater. As the coal seam near the fault exhibits increased gas occurrence, the coal structure becomes more fractured with proximity to the fault, further intensifying gas outflow at the mining face. A comparative assessment of the KPCA-WOA-BP neural network model against the BP, ACO-BP, and FA-BP models demonstrated their respective average relative errors as 22.46%, 9.66%, 5.64%, and 2.84%. The proposed model exhibited superior predictive accuracy and computational efficiency, making it a reliable tool for forecasting gas emissions at the mining face under complex geological conditions.

Similar content being viewed by others

Introduction

As a non-renewable energy resource, coal remains a crucial component of China’s energy framework1,2. In 2023, the country’s raw coal output reached 4.71 billion tons, reflecting a 3.4% rise compared to the previous year3. Between 2011 and 2024, China recorded 107 gas-related mining accidents, resulting in 700 fatalities. Among all regions, Guizhou Province had the highest incidence, with 29 accidents and 261 deaths, representing 27% and 38% of the national totals, respectively4. The frequent occurrence of gas-related incidents poses a serious threat to coal mine safety and hinders the industry’s growth. Gas outbursts in mining faces are often abrupt and highly hazardous5. Consequently, analyzing gas migration patterns in coal mine working faces and developing precise gas emission prediction models are essential for improving mine safety and effectively managing gas-related risks during extraction operations6.

During coal mining operations, gas accidents are a common occurrence. Prior research has indicated an increase in gas accidents that can be attributed to structural issues7,8over 80% of gas incidents happen in or are caused by structural areas9. The geological conditions of the mining face in Longfeng Coal Mine are complex, often leading to gas overrun issues when operations approach structural areas. Accurately predicting gas outflow in the working face can significantly mitigate gas accidents10,11. Field measurements by scholars have demonstrated that gas outflow in faulted areas is markedly higher compared to that in conventional mining zones. These findings underscore the significant influence of faults on abnormal gas emissions12; Utilizing fractal dimension for quantitative analysis of the distribution of fracture fields induced by coal seam mining, it has been verified that gas tends to accumulate near fault structures13; small fault exerts a significant influence on gas outbursts14; Stress concentrations near faults facilitate channels for gas flow15,16; The stress distribution and gas content near the fault was simulated using FLAC3D software, revealing a significant impact of the fault on the rate of gas release17; Previous studies have examined the influence of faults on gas outflows. However, there is a paucity of research investigating the extent of significant impact zones.

Complexity, nonlinearity, and stochastic uncertainty are present in the movement and appearance of gases during the extraction process. This dynamic process involves multidimensional influencing factors and overlapping information18,19,20 especially when faults are present ahead of the workings, the influx of gas can be significantly affected21,22. As a result, taking faults into account when constructing the gas prediction model for the goaf is essential to achieving accurate predictions. Researchers have recently put proposed a number of prediction techniques that combine several fields, such as combining prediction networks and genetic algorithms to create a novel gas outflow prediction system. The system leverages the strengths of genetic algorithms to optimize prediction models, specifically to establish a gas outflow prediction model for the mining face during return operations23; Utilizing the minimum absolute value convergence and selection operator in conjunction with the whale algorithm addresses challenges in optimizing prediction model parameters. This approach also mitigates data loss during downscaling, facilitating the establishment of a multi-method coupled gas prediction model24; The convergence speed of the BP (Back Propagation) neural network and its tendency to become trapped in local optima are significant limitations to its predictive performance. To address these shortcomings, genetic algorithms and improved rough set theory can be employed for optimization. This enhances the adaptive optimization of the BP neural network, leading to the development of the RS-GA-BP neural network coupling algorithm prediction model25. The aforementioned scholars have studied the gas outflow prediction model, and their research results provide valuable guidance for managing gas emissions in coal mine working faces. However, the models have certain limitations. For example, the selected influencing factors do not account for the effects of faults and other tectonic structures on gas outflow. Consequently, the accuracy of gas outflow predictions in tectonic zones requires further improvement.

In view of the aforementioned research, the main tool used in this study to create a two-dimensional geological model of the Longfeng coal mine is COMSOL Multiphysics numerical simulation software. By simulating and analyzing the mining face containing faults at various distances, we examine the changes in stress, gas pressure, and gas transport speed to assess the impact of faults on gas outflow. A predictive model is constructed to forecast gas emissions in the mining face under complex geological conditions by considering the effect of faults on gas outflow. Unlike existing prediction models, the proposed model incorporates the effects of hidden faults on the coal body’s microstructure and permeability variations more comprehensively. Traditional models are primarily designed for standard geological conditions, often lacking the accuracy needed for complex environments. As a result, their predictions may not provide adequate guidance for practical mining operations. In this study, the predictive framework is developed by integrating real-world gas outflow data with numerical simulation results, addressing the limitations of conventional models in complex geological settings and significantly improving prediction accuracy. Accurately predicting gas outflow and implementing prevention and control measures in areas prone to abnormal emissions can effectively mitigate the risk of gas accidents in the mining face.

Mathematical model

It is crucial to consider both gas pressure and gas transport rate throughout the back-mining process in order to rationally select the influencing parameters for the gas outflow prediction model in the study area. Coal seam gas transport involves a complex fluid-solid coupling process. This section utilizes the solid deformation equation and the fluid flow equation to construct a mathematical model for the flow-solid coupling in the back-mining face. Additionally, it introduces two optimization methods for prediction models, detailing their mathematical functions, basic principles, and the steps and processes involved in implementing these prediction models.

Gas outflow model

Coal rock formations can be considered as porous mediums with surface-adsorbed gas26 the volume fraction of the porous medium and gas adsorption/desorption vary with external load changes27and excavation of coal bodies involves a complex process of fluid-solid coupling. The equation defining solid deformation control is given as follows28:

where G = E/2(1 + v), K = E/3(1-2v); K is the bulk modulus, Pa; G is the shear modulus, Pa; E is the Young’s modulus, Pa; v is the Poisson’s ratio; α is the Biot coefficient; p is the gas pressure, Pa; fi denotes the interaction force between the components; \(\:{\epsilon\:}_{S}\) is the adsorptive strain; ρ denotes the density of the coal rock mass, kg/m3; and g denotes the gravitational acceleration, m/ s².

The following formula represents the flow equation in a coal rock body based on the conservation of mass principle29:

where ρg is the density of the free-phase gas, kg/m3; \(\:\stackrel{⃑}{\mu\:}\) is the Darcy velocity vector, m/s; Qs is the gas source, kg/(m3·s); and is the gas content, including adsorbed and free gas, kg/m3.

A combination of compressive, adsorption, and volumetric strains significantly influence porosity30:

where φ is the porosity of the coal rock, %; φ0 is the initial porosity of the coal rock, %; and φv is the volumetric strain of the coal rock.

The adsorption strain was regulated using the Langmuir Eq. 31:

where \(\:{\epsilon\:}_{L}\) is the bulk strain constant at infinite pore pressure and \(\:{p}_{L}\) is the Langmuir pressure constant.

Permeability and porosity are quantified using the cubic law32:

where k is the permeability of coal rock, m2; k0 is the initial permeability of coal rock, m2;

The dynamics of the coal seam are significantly impacted by mining activities, which alter the coal rock body’s deformation and stress. These alterations also affect the pore structure and permeability of the coal rock, subsequently influencing the path and velocity of gas migration. In turn, gas migration alters the deformation of the coal rock body, illustrating a complex, multi-physical field characterized by dynamic, multi-scale interactions in achieving solid-gas coupling. Equation (1) is implemented using the Solid Mechanics module in COMSOL simulation software, while Eq. (2) employs the Darcy’s Law module to achieve the fluid-solid coupling process.

Predictive modelling

Principles of the nuclear principal component analysis method

Kernel Principal Component Analysis (KPCA) is a dimensionality reduction method derived from the nonlinear extension of the traditional linear technique, Principal Component Analysis (PCA). The traditional method of illustrating nonlinear relationships is prone to inefficiencies in data processing and can easily lead to data loss. The extended kernel principal component analysis, as indicated by its name, distinguishes itself through the incorporation of a ‘kernel’33,34. The purpose of employing kernel functions is to facilitate the processing of data by constructing complex nonlinear classifiers.

The primary objective of the method is to transform the input 2D data points into a feature space through mapping, facilitating easier processing and analysis of data samples within this feature space.

Let Xi ∈ Rd (i = 1, 2,. . ., p) be a d-dimensional sample point in the input space, and map Rd to the feature space F by a nonlinear mapping Φ, as:

The data becomes linearly separable when mapped into a higher-dimensional space, a process typically facilitated by a Kernel Function. This function transforms the data from its original sample space into a higher-dimensional space, enhancing its discriminative properties. Commonly used kernel functions include:

Sigmoid kernel function:

where α and c are constants.

Polynomial kernel functions:

where r represents a constant term and d denotes the order of the polynomial. These parameters determine the shape of the polynomial kernel function.

Gaussian kernel function:

where γ is a hyperparameter in the Gaussian kernel function, regulating the dispersion of data points within the high-dimensional space. A higher γ value results in a more concentrated distribution, making the downscaled data easier to distinguish.

Compared to other kernel functions in kernel principal component analysis (KPCA), the Gaussian kernel function exhibits a superior nonlinear mapping capability, making it particularly effective for handling complex nonlinear data. Projecting data into a high-dimensional feature space enhances the ability to uncover hidden feature relationships. This characteristic is especially advantageous for identifying intricate geological conditions in the mining sector, where nonlinear data patterns are prevalent.

The kernel function can apply various transformations to the data to influence the effectiveness of dimensionality reduction. The complexity and robustness of the model can be further improved in KPCA by varying the settings of the kernel function. Detailed steps of the kernel principal component analysis method are outlined in the referenced literature35.

The Whale optimization algorithm

In 2016, a new optimization technique was proposed by Australian researcher Mirjalili36 and the approach uses an intelligent meta-heuristic algorithm named the Whale Optimization Algorithm (WOA). The algorithm draws inspiration from the predation techniques of humpback whales, categorized primarily into three strategies: encircling prey, bubble-net attacking, and searching for prey.

BP neural network

The neural network that was selected is a conventional multi-layer feed-forward network. Figure 1 shows the topology of the model, which is composed of an input layer, hidden layers, and an output layer. The fundamental principle of the BP neural network involves using error backpropagation to iteratively adjust weights and thresholds during the computational process. This ensures that the neural network minimizes the sum of squared errors in its output under specified parameter conditions37,38,39.

The number of nodes in the hidden layer of the BP neural network is determined by Kolmogorov’s theorem can be obtained:

where: m is the number of nodes in the implicit layer; n is the number of nodes in the input layer; l is the number of nodes in the output layer; and α is a conditioning constant from 1 to 10.

Predictive model implementation steps

Step 1 involves performing a normalization operation on the input dataset;

Step 2 involves the application of the Gaussian kernel function in the kernel principal component analysis for dimensionality reduction;

Step 3 involves setting the computational parameters of the model and determining the topology of the neural network.;

Step 4 generating the initial whale population;

Step 5 involves calculating the fitness value of the optimization model, identifying the individual optimal and global optimal positions of the population in the initial scenario.;

Step 6 involves calculating the new control parameter a, updating the coefficient vector A, and the random numbers p and 1;

Step 7 evaluates the magnitude relationship between a random number p and 0.5, as well as between the coefficient vector |A| and 1, different strategies are selected to update individual positions based on these comparisons, simultaneously, compute the fitness value of the new position and update the optimal position of the individual during this updating process.;

Step 8 involves determining whether the maximum number of iterations has been reached during the iteration process. If the maximum number of iterations is reached, the optimal weights and thresholds are outputted. If not, steps (5) to (7) are repeated;

Step 9 involves incorporating the optimal weights and thresholds derived from iterative computation into the constructed neural network;

Step 10 involves determining whether the output error meets the pre-set accuracy or maximum number of training iterations. If either condition is met, the model can output the predicted value. Otherwise, the weights and thresholds require updating, followed by repeating steps (9) and (10);

The flowchart depicting gas influx prediction for back mining faces using KPCA-WOA-BP is illustrated in Fig. 2. The implementation steps for constructing the optimized prediction model involve enhancing the gas outflow prediction. This is achieved by optimizing the coupled BP neural network using kernel principal component and WOA algorithms. These enhancements address several shortcomings of the prediction network, including slow convergence, susceptibility to local optima, and model instability. Consequently, this approach significantly improves the accuracy and stability of the gas outflow prediction mode.

In conclusion, the coupled flow-solid mathematical model provides a theoretical foundation and methodological guidance for subsequent numerical simulations by accurately describing the gas transport mechanism in the coal seam and its interaction with the coal rock body. The optimization method selected addresses the existing shortcomings of the BP neural network, as illustrated in the flowchart of the prediction model. This approach enhances the learning rate and improves the accuracy of the prediction model.

Numerical simulation results

Mathematical models can systematically describe the transport and outflow processes of gas in coal seams and the mechanical response of coal and rock bodies, but it is difficult to comprehensively reveal the dynamic behavior of the interaction between gas and coal and rock bodies. Therefore, numerical simulation was used to solve and analyze the mathematical model proposed in the previous section to further reveal the evolution of stress distribution, gas pressure, and transport velocity when the face was mined back to 100 m and 50 m from the fault.

Geometric model

The numerical simulation model in this paper takes Longfeng coal mine as the engineering background. The location of the mine is shown in Fig. 3, the coal-bearing stratum of Longfeng Coal Mine is the Permian Upper Longtan Formation, the main coal seam is the No. 9 coal seam, and the current stage of the mining face is the 120,910 working face, which is located in the transition area of the Yangzi Massif, the Jiangnan and the Right River Orogenic Belt, and a large number of hidden faults have been developed because of the long-term influence of tectonic effects, according to the statistics, more than 120 hidden faults have been developed in the mined areas of the mine, and more than 40 faults have been developed in the square kilometers. According to statistics, there are more than 120 hidden faults in the mined area, with an average of more than 40 faults per square kilometer, and the mine belongs to the category of high-rupture mines, which are characterized by high gas content and complex geological conditions during the mining process, and a series of engineering problems such as gas overloading and protruding occur frequently.

adapted from Jia et al.40

Geological map of Longfeng Coal Mine area.

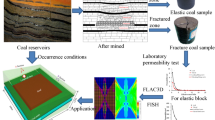

The geometric model of numerical simulation was constructed according to the drill hole 5 –3 of the 120,910 back-mining face in Longfeng Mine, as shown in Fig. 4. From the rose diagram of fault strike in the mine area, we can get, as shown in Fig. 5, that the faults are most developed in the WWN direction, and the secondary development in the near N direction, reflecting that the area is subjected to east-west extrusive tectonic stress; in the rose diagram of the tendency inclination angle, the angle of inclination concentrates in 60~80°, and the direction of the laminations is in a high angle of intersection. In the inclination-dip rose diagram, the dip angle is concentrated at 60~80°, which is intersected with the lamination direction at a high angle, indicating that the mining area as a whole has experienced strong tectonic activities, and the development of WWN-directed faults is remarkable.

Assignment of model parameters

According to the actual geological profile of Longfeng Coal Mine, the mechanical parameters of the coal rock body are detailed in Table 1.

The fluid parameters were set according to Table 2:

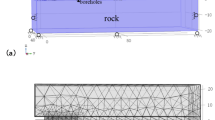

To facilitate modeling, the study area at Longfeng Mine was simplified into a 2D planar model measuring approximately 200 m in length and 240 m in height. The model consisted of 10,375 cells, including 1,638 boundary cells in the grid. Steady-state and transient solvers in COMSOL were predominantly utilized to simulate the influence of faults on the gas outflow from coal seams under conditions of 50 m of back mining (approximately 100 m from the fault) and 100 m of back mining (approximately 50 m from the fault). The simulations aimed to assess the impact of faults on gas outflow from the coal seam. The effects of the fault on the gas outflow from the coal seam are simulated. In the case of the unmined Longfeng coal face 120,910, the primary concern revolves around the self-gravitational stress of the coal rock body.

Validation of numerical simulation models

The accuracy of the numerical simulation model was verified using actual measurements of gas outflow from various coal mining faces in Longfeng Mine during the mining retreat process. Gas outflow from two workings advancing 100 m and 50 m from the fault was monitored, and the measurements are depicted in Fig. 6. The data indicate that gas outflow at 50 m from the fault is approximately twice that at 100 m, consistent with the results of the model simulation.

Analysis of numerical simulation results

Stress changes in the mining face

Figure 7 illustrates the stress distribution at advancements of 50 m and 100 m of the backing face, utilizing the final ground stress distribution after the face has progressed to the specified locations. Figure 7a illustrates that when the working face advances to approximately 100 m from the fault, significant stress concentration occurs. The stress in the working face peaks at approximately 21 MPa, while the stress in the floor ahead of the working face shows a slight increase, accompanied by the appearance of a tensile stress zone in certain areas. Figure 7b illustrates that as the workface advances to approximately 50 m from the fault, stress concentration becomes more pronounced compared to locations 100 m away from the fault. Concurrently, stress concentration in the top and bottom plates ahead of the workface intensifies, with stress reaching about 39 MPa in the workface—approximately double that observed when the distance from the fault is 100 m. In conclusion, faults significantly influence stress distribution on the mining face, with closer proximity to faults correlating with greater stress escalation in the face.

Workface gas pressure distribution pattern

The distribution of gas pressure along the advancing face between 50 and 100 m is shown in Fig. 8. Through a comparative study of gas pressure changes at varying distances from the advancing face, it is evident that gas pressure closer to the fault (50 m distance) exceeds that at 100 m distance from the fault. This phenomenon is attributed to the higher gas content enriched near faults, tectonic effects causing increased coal body fissures, and consequently greater gas outflow closer to the fault. Specifically, gas pressure is notably elevated within 10 m preceding the face’s open-off cut, with pressures at 50 m from the fault approximately 20% higher compared to those at 100 m.

A high-stress concentration region was observed 10 m ahead of the workpiece. Figure 9 presents the gas pressure versus time curve, derived from data collected in the high gas pressure concentration zone under different conditions. Analysis of this curve indicates that at a distance of 50 m from the fault, gas pressure rises sharply within a short period, reaching a peak before gradually declining. In contrast, at 100 m from the fault, the pressure drops more rapidly and stabilizes in a shorter time compared to the 50 m distance. This indicates that proximity to the fault during mining operations results in higher and more sustained gas pressures ahead of the workpiece, leading to increased gas outflow and heightened operational risks.

Gas outflow law of working face

Before coal seam excavation, the internal stress within the seam remains stable, resulting in low gas flow. However, after excavation, the migration rate plays a crucial role in determining the velocity and volume of gas escaping from the working face. Analyzing migration rates at different mining distances provides insight into the influence of faults on the speed and intensity of gas outflow from the mining face.

Figure 10a illustrates that as the workface advances to 100 m from the fault, the gas flow rate increases sharply due to mining disturbance. The gas migration rate ahead of the workface reaches 1.1 × 10− 3 mm/s and remains stable in subsequent days. The direction of gas flow in the coal seam stabilizes post-excavation, predominantly towards the workface. Comparison between gas flow near the fault and the workface shows minimal difference, indicating the fault’s insignificant influence on gas migration within the first 100 m.

Figure 10b illustrates the gas migration velocity over time at a distance of 50 m from the fault in the mining face. Initially, as the mining face advances to its designated location, the gas flow velocity measures 2.59 × 10− 3 mm/s, approximately 2.4 times higher than that observed 100 m from the fault. Over time, this migration velocity gradually decreases, yet remains greater at 50 m compared to 100 m from the fault. This disparity is attributed to the tectonic stresses on the coal rock layer, resulting in increased fracturing and enhanced fissure development within the coal body41,42. These factors contribute to higher coal seam permeability, thereby accelerating gas migration rates and subsequently increasing both the rate and total volume of gas emanating from the mining face.

In summary, by simulating the gas pressure, stress distribution, and gas transport speed of the mining face at different distances from the fault, and combining the monitoring of gas outflow at different faces, we can get that the gas outflow of the face is significantly larger at 50 m from the fault compared to 100 m from the fault, which indicates that the existence of a fault 50 m in front of the face has a significant effect on the size of gas outflow at the face, and this factor can be used as one of the key factors to construct a prediction model of gas outflow under complex geological conditions. This factor can be one of the key factors in constructing the prediction model of gas outflow under complex geological conditions.

Predictive modelling results

A numerical simulation analysis revealed that the primary factor influencing the magnitude of gas outflow is the presence of faults within 50 m in front of the mining workings, and the conclusion provides an important theoretical basis and practical reference for the accurate prediction of gas outflow. On this basis, this key finding and other important influencing factors will be further utilized in this section in conjunction with the chosen optimization method to construct a gas outflow prediction model suitable for complex geological conditions.

Data monitoring and collection

Numerous factors influence the magnitude of gas outflows from mine workings, with geological and mining factors emerging as pivotal contributors to these emissions43,44,45. Analysis of the geological situation of the 120,910 back-mining faces in Longfeng Coal Mine reveals that there is little change in the influencing factors such as the gas content of the neighboring seams, the spacing of the seams, the inclination angle of the present coal seam, and the lithology of the seams. The more obvious factors affecting the amount of gas outflow from the 120,910 coal mining face, as well as the key research results in the previous paper, are selected, such as coal seam gas content X1, whether there is a fault 50 m in front of the mining face X2, the thickness of the coal seam X3, depth of burial of the coal seam X4, length of the working face X5, daily work progress X6, the intensity of mining X7, and amount of gas outflow from the coal seam Y. By monitoring the gas outflow at each measurement point of the working face and the coal mining situation of the working face on that day, the gas outflow data of the mining face was collected as the sample data of this study, and the sample data was obtained after processing the outliers and so on, which is shown in Table 3:

Principal component analysis of impact factors

The data from the previously described 35 sample sets were subjected to factor analysis applying the maximum variance method using SPSS software. Principal component analysis was conducted to obtain Kaiser-Meyer-Olkin (KMO) and Bartlett’s test results, as presented in Table 4. The KMO test assesses the correlation and partial correlation among influencing factors, yielding a test value between 0 and 1. A value closer to 1 indicates stronger correlations and weaker partial correlations, suggesting a more effective factor analysis46. Conversely, a lower value indicates poorer effects. Bartlett’s test of sphericity evaluates the distribution of sample data and the independence among influencing factors.

From Table 4, it is evident that the KMO test value meets the necessary criteria (KMO > 0.5), and the Bartlett sphericity test yields a significance of less than 0.05. These results indicate that the collected sample data are suitable for kernel principal component analysis.

Predictive model parameter selection

ACO-BP, FA-BP, KPCA-WOA-BP, and BP are the four prediction models that were developed with the MATLAB software platform. The optimal number of nodes in the hidden layer, determined based on the mean square error of the training set samples is 6. Consequently, the neural network topology is established as 7-11-1. The internal optimal parameters of the prediction model were fine-tuned through iterative debugging. Specifically, the model’s maximum training iterations were set to 1000, with a learning rate of 0.01 and a minimum target training error of 0.000001. For training purposes, the initial 30 datasets were utilized, while the remaining 5 datasets were reserved for model prediction.

The parameters chosen for the whale algorithm are as follows: an initial population size of 30, a maximum number of evolutions set to 50, a learning rate of 0.01, and 200 training sessions.

The evolution curve illustrates the model’s stability. Figure 11 depicts the evolution curve of WOA, revealing that the model stabilizes its adaptation value after approximately 20 iterations. This suggests that the enhanced prediction model requires only a relatively small number of iterations to determine the optimal initial weights and thresholds for BP neural networks.

Analysis of the results of the prediction model

A variety of advanced methods from machine learning were utilized in this study to develop a high-precision prediction model. Figure 12 presents a comparison and analysis diagram between the KPCA-WOA-BP gas outflow prediction model and the actual gas outflow from the working face. The results indicate that the constructed model effectively predicts gas outflow, aligning closely with measured values from the working face. This demonstrates high accuracy and reliability in the model’s predictions. The application of this model for predicting coal mining and gas outflow can effectively guide the development of retreat mining plans and gas control measures.

Discussion and analysis

This section explores the impact of faults on gas outflows from the back-mining face, along with a predictive model for estimating gas outflows under complex geological conditions based on fault influence ranges.

Effect of faults on gas outflows

Coal and rock bodies near the fault undergo rock fragmentation and re-development of fissures under tectonic action, which gives the area a larger storage space and channel, resulting in a higher gas content in this area than in the area away from the fault. During the mining process, the stress near the fault will change due to the impact of mining, which will cause the fault zone and the nearby coal and rock bodies to continue to rupture and deform, forming new fissures or expanding the existing fissures, especially when the working face is closer to the fault, the effect of stress concentration will be significantly enhanced, which will lead to more gas desorption and release. By simulating and analyzing the stress distribution, gas pressure distribution, and gas migration speed at different distances from the fault, it can be seen that at a 50 m distance from the fault, the gas outflow is more significantly affected by the fault than at 100 m distance from the fault. Compared with the existing research results, the model can play an important role in guiding coal mines to lay out the plan for mining back to the face as well as predicting the amount of gas influx.

Comparative analysis of forecasting models

To effectively demonstrate the optimization of the BP neural network using kernel principal component analysis and the whale optimization algorithm, this study compares and analyzes the prediction results of four models: BP prediction model, ACO-BP prediction model, FA-BP prediction model, and KPCA-WOA-BP prediction model. The comparison focuses on gas prediction results and their respective relative error values, presented in Table 5. Additionally, Fig. 13 illustrates the measured and predicted values, while Fig. 14 depicts the relative error comparison curves for the four models.

According to Table 5; Figs. 13 and 14, we can get that the prediction effect of the KPCA-WOA-BP prediction model is significantly better than that of the BP prediction model, the ACO-BP model, and the FA-BP prediction model, and the average errors of the three comparative models are 22.46%, 9.66% and 5.64%, which are all higher than that of the KPCA-WOA-BP prediction model, which is 2.84%. models all have a great difference in prediction error, and the prediction models show unstable characteristics, and the comparison with the three models shows that the KPCA-WOA-BP model has higher stability and accuracy.

Through the prediction error analysis of the four models, the results show that: the BP neural network shows unstable characteristics, the prediction model is easy to falls into the local optimum when calculating, thus affecting the prediction accuracy of the whole model, the WOA algorithm optimizes the BP neural network to make up for the existing shortcomings of the model that is easy to fall into the local optimum resulting in low prediction accuracy, and then through the nonlinear dimension reduction (KPCA) method to improve the prediction rate and stability of the neural network, while ensuring that the data will not be lost and the global are converged. Then the prediction rate and stability of the neural network are improved by the method of nonlinear dimensionality reduction (KPCA), which ensures that the data will not be lost and is globally convergent while reducing the dimensionality. Therefore, the KPCA-WOA-BP prediction model improves the prediction rate while the overall error is smaller.

Evaluation of forecasting models

The accuracy of the prediction of the optimized model is evaluated by selecting three indicators as quantitative indicators, namely, the mean absolute error (EMAE), the mean relative error (EMRE), and the mean squared error (EMSE), with the smaller of the three values representing the more accurate prediction, with the following expression47:

where \(\:{\widehat{\text{y}}}_{\text{i}}\) is the predicted value of gas influx and \(\:{\text{y}}_{\text{i}}\) is the measured value of gas influx, the errors of different models are compared and analyzed in Table 6:

Combined with the comprehensive analysis of Figs. 12 and 13 and the data in Tables 5 and 6, the results show that the constructed prediction model performs better in terms of error value and prediction accuracy, and can provide a theoretical basis for the prediction of gas outflow from the back-mining face under complex geological conditions.

Conclusion

This study investigates gas migration and outflow in the back-mining face of the Longfeng coal mine. COMSOL software was employed to simulate gas behavior in the presence of faults ahead of the back-mining face. Based on these simulations, a predictive model was developed to estimate gas outflow under complex geological conditions. This approach not only improves gas control strategies in coal mines but also contributes to the advancement of machine learning techniques, as demonstrated by the following findings:

-

(1)

Numerical simulations indicate that at a distance of 100 m from the fault, stress levels rise to approximately four times their initial state. As the mining face advances to 50 m from the fault, this stress increases to nearly seven times the initial level. Furthermore, the stress at 50 m from the fault is double that observed at 100 m. Closer proximity to the fault leads to greater stress concentration at the mining face, which in turn amplifies gas outflow. Analysis of gas transport velocity patterns reveals that velocities at 50 m from the fault are significantly higher than at 100 m, with the former reaching approximately 2.4 times the latter. This increased velocity results in a steeper pressure gradient, accelerating gas molecule movement and ultimately enhancing gas outflow from the mining face.

-

(2)

To overcome the limitations of the BP neural network, this study integrates Kernel Principal Component Analysis (KPCA) and the Whale Optimization Algorithm (WOA) to develop a KPCA-WOA-BP neural network prediction model. The analysis identifies faults located 50 m ahead of the working face as a key factor influencing gas outflow. The model was validated through real-world engineering applications, showing a high degree of consistency between predicted and observed values. This validation highlights the effectiveness of the developed model in accurately forecasting gas outflow under complex geological conditions.

-

(3)

The numerical simulation results provide valuable guidance for optimizing the mining plan of the back-mining face. When compared to three other prediction models, the KPCA-WOA-BP neural network model demonstrates a smaller error margin, highlighting its enhanced accuracy, efficiency, and ease of operation. This predictive model establishes a theoretical basis for gas prevention and control in back-mining faces under complex geological conditions, contributing to improved mine disaster prevention and mitigation strategies.

Data availability

All data, models, and code generated or used in the course of the research appear in the submitted article. As some of the data in this article will be used in the research team’s next research program, the datasets generated and/or analyzed in this study are not publicly available but can be obtained from the corresponding authors upon reasonable request.

References

Jia, Z. & Lin, B. How to achieve the first step of the carbon-neutrality 2060 target in china: The coal substitution perspective. Energy 233, 121179 (2021).

Liu, Y. et al. Research status and development trend of coal spontaneous combustion fire and prevention technology in china: A review. ACS Omega. 9, 21727–21750 (2024).

Qiu et al. Experimental study on resistivity evolution law and precursory signals in the damage process of gas-bearing coal. Fuel 362, 130798 (2024).

You, M., Li, S., Li, D. & Xu, S. Applications of artificial intelligence for coal mine gas risk assessment. Saf. Sci. 143, 105420 (2021).

Zhang, M., Cao, X., Li, B. & Zhou, A. Quantitative study on the role of desorption gas on coal-gas outbursts: Energy contribution and dynamic characteristics. Process. Saf. Environ. Prot. 171, 437–446 (2023).

Wang, L., Jia, B. & Su, G. Risk identification of coal and gas outburst based on improved CUOWGA weighting TOPSIS model. Sci. Rep 15, (2025).

Li, H. et al. Characteristics and distribution of tectonic fracture networks in low permeability conglomerate reservoirs. Sci. Rep. 15, 5914 (2025).

Li, J. et al. Shale pore characteristics and their impact on the gas-bearing properties of the longmaxi formation in the Luzhou area. Sci. Rep. 14, 16896 (2024).

Wang, D., Cheng, Y., Yuan, L., Wang, C. & Wang, L. Implications of geological conditions on gas contents: A case study in the Pingdingshan coalfield. Energy Fuels. 37, 6465–6478 (2023).

Bi, S., Shao, L., Qi, Z., Wang, Y. & Lai, W. Prediction of coal mine gas emission based on hybrid machine learning model. Earth Sci. Inf. 16, 501–513 (2023).

Ting, W., Lin-qin, C., Yao, F., Tingcheng, Z. A. & Wavelet-based robust relevance vector machine based on sensor data scheduling control for modeling mine gas gushing forecasting on virtual environment. Math. Probl. Eng. 1–4 (2013). (2013).

Zhou, A., Hu, J., Wang, K. & Du, C. Analysis of fault orientation and gas migration characteristics in front of coal mining face: implications for coal-gas outbursts. Process. Saf. Environ. Prot. 177, 232–245 (2023).

Kang, X. et al. Study on gas migration law of mining coal seam under the influence of normal fault. Geofluids 2022, 1–17 (2022).

Lin, J. et al. Coal and gas outburst affected by law of small fault instability during working face advance. Geofluids 2020, 1–12 (2020).

Gao, K. et al. Coal–rock damage characteristics caused by blasting within a reverse fault and its resultant effects on coal and gas outburst. Sci. Rep. 11, 19158 (2021).

Ma, Y. et al. Quantification of Natural CO 2 Emission Through Faults and Fracture Zones in Coal Basins. Geophys. Res. Lett. 48, eGL092693 (2021). (2021).

Feng, S., Chen, X., Dong, X., Wang, L. & Li, G. Study on the effect of small faults on the gas content in 3 coal seam of the Changping mine field. ACS Omega. 8, 16800–16808 (2023).

Xu, G., Hou, Y., Jin, H. & Wang, Z. Study on source identification of mixed gas emission and law of gas emission based on isotope method. Energies 16, 1225 (2023).

Zeng, J. et al. The research of coal seam gas pressure and initial gas emission characteristics of borehole. Energy Sci. Eng. 7, 1961–1969 (2019).

Zhang, B., Zhang, D., Yang, Y. & Wen, D. Test and study on transfusion law of gas in mining coal. Energy Sci. Eng. 7, 179–193 (2019).

Chen, Y., Liu, R. & Xuan, P. A calculation method of gas emission zone in a coal mine considering main controlling factors. Sci. Rep. 11, 23597 (2021).

Shi, Y. et al. Study on the influence of stress constraint conditions on multi-scale gas emission characteristics in in-situ coal. Energy 290, 130160 (2024).

Ji, P., Shi, S. & Shi, X. Research on gas emission quantity prediction model based on EDA-IGA. Heliyon 9, e17624 (2023).

Song, W., Han, X. & Qi, J. Prediction of gas emission in the working face based on LASSO-WOA-XGBoost. Atmosphere 14, 1628 (2023).

Zhu, J. et al. Evaluation of deep coal and gas outburst based on RS-GA-BP. Nat. Hazards. 115, 2531–2551 (2023).

Ren, J. et al. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel 283, 119292 (2021).

Zhou, A. et al. Experimental study on coal deformation induced by gas adsorption-instantaneous pressure relief under unconstrained stress state with different pore structures. Energy 276, 127480 (2023).

Liu, J., Chen, Z., Elsworth, D., Miao, X. & Mao, X. Evaluation of stress-controlled coal swelling processes. Int. J. Coal Geol. 83, 446–455 (2010).

Zhang, H., Liu, J. & Elsworth, D. How sorption-induced matrix deformation affects gas flow in coal seams: A new FE model. Int. J. Rock. Mech. Min. Sci. 45, 1226–1236 (2008).

Cheng, W. et al. A multi-layer nanocased model to explain the U-shaped evolution of shale gas permeability at constant confining pressure. Fuel 359, 130478 (2024).

Cui, X. & Bustin, R. M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 89, 1181–1202 (2005).

Chilingar, G. V. Elsevier, Relationship Between Porosity, Permeability, and Grain-Size Distribution of Sands and Sandstones. in Developments in Sedimentology (ed. van Straaten, L. M. J. U.) vol. 1 71–75 (1964).

Souza Filho, J. B. O., Diniz, P. S. R. & Improving KPCA online extraction by orthonormalization in the feature space. IEEE Trans. Neural Netw. Learn. Syst. 29, 1382–1387 (2018).

Jiang, Q. & Yan, X. Parallel PCA–KPCA for nonlinear process monitoring. Control Eng. Pract. 80, 17–25 (2018).

Wang, H. & Hu, Z. An unified EM algorithm for PCA and KPCA. Neurocomputing 71, 459–462 (2007).

Mirjalili, S. & Lewis, A. The Whale optimization algorithm. Adv. Eng. Softw. 95, 51–67 (2016).

Wang, Y., Lu, C. & Zuo, C. Coal mine safety production forewarning based on improved BP neural network. Int. J. Min. Sci. Technol. 25, 319–324 (2015).

Wang, Y. et al. Triaxial compression strength prediction of fissured rocks in deep-buried coal mines based on an improved back propagation neural network model. Processes 11, 2414 (2023).

Wu, Y., Gao, R. & Yang, J. Prediction of coal and gas outburst: A method based on the BP neural network optimized by GASA. Process. Saf. Environ. Prot. 133, 64–72 (2020).

Jia, Y., Jia, S. & Pang, R. Measurement and impact analysis of social vulnerability to geological disasters in Guizhou province, China. Sci. Rep. 14, 25098 (2024).

Lin, C. Effects of tectonic stress environment on tectonophysical features of deformed coal. Int. J. Green. Energy. 16, 185–199 (2019).

Liu, C. et al. Deformation and permeability evolution of coals considering the effect of beddings. Int. J. Rock. Mech. Min. Sci. 117, 49–62 (2019).

Lei, D., Li, H. & Meng, H. Geological division of gas in the Pingdingshan mine area based on its tectonic dynamics characteristics. Int. J. Min. Sci. Technol. 25, 827–833 (2015).

Xu, L. et al. Elimination mechanism of coal and gas outburst based on geo-dynamic system with stress–damage–seepage interactions. Int. J. Coal Sci. Technol. 10, 74 (2023).

Xu, Y., Lin, B., Liu, T., Cao, J. & Liu, T. Influence law and control mechanism of overburden isolated Grout injection on methane emission in the working face. J. Clean. Prod. 430, 139612 (2023).

Mostafaeipour, A., Zarezade, M., Goudarzi, H., Rezaei-Shouroki, M. & Qolipour, M. Investigating the factors on using the solar water heaters for dry arid regions: A case study. Renew. Sustain. Energy Rev. 78, 157–166 (2017).

Wang, W., Liang, R., Qi, Y., Cui, X. & Liu, J. Prediction model of spontaneous combustion risk of extraction borehole based on PSO-BPNN and its application. Sci. Rep. 14, 5 (2024).

Acknowledgements

The authors appreciate the support provided by the funders.

Funding

Guizhou Provincial of Social Funding Projects (LDLFJSFW2024-9).

Author information

Authors and Affiliations

Contributions

Funding acquisition: L.Z. Methodology: Y.S., H.L., X.Y. Software: Y.S., J.W., B.W Investigation: B.L., F.Y. Writing—original draft: Y.S. Writing—final d raft: Y.S., H.L., W.J., B.L. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

We declare that we have no financial or personal relationships with other persons or organizations that could unduly influence our work and that we have no professional or other personal interests of any nature or kind in any product, service, and/or company that could be perceived as influencing the position set out in the manuscript titled Study of Gas Outflow Patterns and Prediction Models for Outflows from Mining Backfaces under Complex Geological Conditions or the review of that manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, Y., Zheng, L., Lan, H. et al. Study on the gas outflow pattern and outflow prediction model of the return mining face under complex geological conditions. Sci Rep 15, 25601 (2025). https://doi.org/10.1038/s41598-025-10634-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-10634-6