Abstract

In this study, the improvement effect of fiber-reinforced EPS (expanded polystyrene) granular lightweight soil was systematically investigated to address roadbed issues caused by severe cold climatic conditions, specifically, extremely low temperature of -20 °C and an average freezing depth of 92 cm—in Chaoyang City. The test results demonstrate that the use of lime as a curing agent significantly enhances the material’s performance while reducing overall cost. Standard compaction tests revealed a negative correlation between the dry density of the lightweight soil and the EPS content, with values ranging from 1.53 to 1.90 g/cm³. Unconfined compressive strength tests showed a decrease in strength with increasing EPS content; however, the incorporation of polypropylene fibers effectively compensated for this strength loss, achieving a peak compressive strength of 1.93 MPa. Freeze-thaw cycle tests (-18℃ to 20℃) confirmed the material’s excellent frost resistance, with significantly reduced strength loss and stabilized mass loss after multiple cycles. SEM analysis revealed a three–phase synergistic reinforcement mechanism characterized by “particle dispersion - fiber homogeneity - cementation reinforcement”. In this mechanism, the closed pore structure formed by EPS particles, the fiber network, and lime cementation products collectively enhances the internal stability of the material. Based on these findings, optimizing the mix proportions achieves a synergistic balance of lightweight, high strength, and frost resistance, providing an effective solution for roadbed engineering in cold regions.

Similar content being viewed by others

Introduction

EPS pellets (Expandable Polystyrene) are lightweight, corrosion-resistant and frost-resistant. In this study, a lightweight soil was prepared using natural soil, EPS particles, lime as a curing agent, and fibers, achieving a compressive strength of 0.5-2.0 MPa, which significantly reduces the self-weight of the roadbed. Fiber reinforcement technology increased the compressive strength by 30-50% and improved the residual stress1,2. This approach not only promotes the resourceful reuse of EPS waste helping to address the issue of “white pollution”but also offers an innovative material solution for roadbed construction in cold regions, with significant practical application value3,4.

EPS granular lightweight soils have demonstrated significant technical advantages in the field of engineering5,6,7,8,9. In soft ground treatment, Tang10 verified the feasibility of a lightweight soil replacement scheme (settlement ≤ 10 cm) in shallow, medium-thickness soft ground through experimental testing, and proposed a simplified calculation method for additional stress and anti-floating checks. In retaining wall projects, modeling tests by Hou11 showed that the cushioning properties of EPS particles can reduce earth pressure by 30–40% while maintaining excellent self-supporting characteristics. In terms of engineering applications, Yao12 confirmed through a bridgehead settlement treatment program that lightweight soil can control post-construction settlement differences within 3 mm. Similarly, Li13, through comparative road widening tests, demonstrated that lightweight soil backfill reduces settlement by 60–70% compared to conventional fill, while also improving shear strength. These studies collectively show that lightweight soils offer unique advantages in load distribution and settlement control for roadbed applications. At present, although there is increasing research and engineering application of fiber-reinforced EPS granular lightweight soils, there remains a lack of data specific to cold regions. In particular, studies on the internal working mechanisms of the three-phase material system, as well as investigations into performance variations under freeze-thaw cycles, are still limited.

Scholars both domestically and internationally have conducted systematic research on the key factors influencing the engineering performance of roadbed soils. In terms of compaction characteristics, Yang et al.14 confirmed through red soil compaction tests that the water content corresponding to the maximum CBR value ensures optimal bearing capacity, with a CBR enhancement of 15–20%. This provides a theoretical basis for controlling water content and compaction during roadbed filling. Sha et al.15 found that the shear strength of EPS lightweight soil prepared from engineered silt was positively correlated with confining pressure and cohesion increased with the higher cement content but decreased as EPS content increased. Mei16 further demonstrated that the compressive strength of lightweight soil is primarily governed by cement and EPS content.For example increases with more cement and decreases with higher EPS particle content. In terms of frost resistance, Gu’s study17 showed that the rate of shear strength loss (15–20%) of lightweight soils was only half that of ordinary materials, confirming the frost heave mitigation effect of EPS particles. Recent research also found that the strength retention rate of lightweight soils after freeze-thaw cycles can exceed 90% through improved curing agent formulations, providing an important technical reference for the treatment of special soil roadbeds18.

Scanning electron microscopy (SEM)19,20,21,22,23 is a key research tool for revealing the interaction mechanism within the three-phase system of polypropylene fibers, EPS particles, and limestone soil. High-resolution micro-morphological characterization allows for the visualization of the distribution of fibers and EPS particles within the soil, as well as observation of their internal bonding states. Based on microstructural information obtained through SEM, the synergistic mechanism of fiber reinforcement, particle dispersion, and cementation product formation can be thoroughly investigated, providing a theoretical basis for optimizing the properties of lightweight soil.

Most existing studies focus on the evolution of mechanical properties of in situ and improved soils in cold regions after freeze–thaw cycles, while relatively few have examined the properties of EPS granular lightweight soils under such conditions24,25,26. Addressing the problems of frost heave and poor bearing capacity in roadbed engineering in cold areas, systematic research on the mechanical properties and frost resistance of fiber-reinforced EPS granular lightweight soil has significant theoretical and engineering value. In this study, standard compaction tests, unconfined compression tests, and freeze-thaw cycle test were conducted in combination with SEM microscopic characterization. A preparation method for lightweight soil was proposed, and its physical, mechanical, and microstructural properties were systematically analyzed. The research focused on key factors influencing the strength of fiber EPS granular lightweight soil, the correlation between the lightweight soil with EPS particles and frost resistance, and the internal interaction mechanism among fibers, particles and the soil matrix. The results provide a theoretical foundation and technical reference for the design and construction of roadbed engineering in cold regions.

Materials and methodology

Experimental material

The soil used in this experiment was sourced from the construction site of Lingsui Expressway in Kazuo County, Chaoyang City, Liaoning Province. To reduce project costs and meet local material availability, the soil was locally obtained, as shown in Fig. 1(A). The soil used for the experiment is a remodeled sample prepared by drying, crushing, and sieving. Its physical properties were tested through laboratory experiments. The soil is classified as silty clay, and its physical property indices are presented in Table 1.

The lightweight material used in this experiment is EPS particles or waste foam. This material is corrosion-resistant but causes serious environmental pollution when discarded. Considering its lightweight characteristics, EPS foam particles were selected as the filler material for this test, with the aim of turning waste into a valuable resource, reducing environmental pollution, and producing a lightweight, high-strength composite materials. As shown in Fig. 1(B), EPS particles with a diameter of 2–3 mm and a particle density of 0.013 g/cm³ were used for sample preparation.

The curing agent used in this experiment is construction-grade lime powder. Using lime as a curing agent can reduce economic costs while ensuring sufficient strength27,28. Additionally, the exothermic reaction of lime hydration accelerates the initial setting time and improves construction efficiency, as shown in Fig. 1.(C).

The fiber reinforcement material chosen for this experiment is polypropylene fiber, which has the characteristics of high strength, good stability, corrosion and alkali resistance, and low cost. Applying this kind of fiber to the roadbed soil can significantly improve its compressive strength and integrity, as well as enhance resistance to cracking and seepage29, as shown in Fig. 1(D). The specific parameters are presented in Table 2.

Experimental methodology

Liquid and plastic limit combined test

Before conducting the unconfined compressive test, it is necessary to determine the liquid limit and plasticity index of the raw soil material. This method can help us evaluate the soil’s properties, predict the specimen’s strength, and provide a theoretical basis for optimizing the lightweight soil experimental program.

In this study, the combined liquid-plastic limit determination method (based on the “Specification for Highway Soil Test” JTG3430-2020)30 was used to determine the liquid limit, the plastic limit, plasticity index of the soil samples. The method is applies to the soil with particle size less than 0.5 mm and an organic matter content not exceeding 5% of the dry soil mass. The specific device and equipment parameters are shown in Fig. 2; Table 3. The test results classified the soil sample as plastic silty clay.

Compaction experiment

Because EPS particles have the characteristics of strong filling ability and light weight, they greatly affect the density and strength of lightweight soil specimens.Therefore, it is necessary to determine the optimal moisture content and maximum dry density in advance. This provides a theoretical basis for assessing specimen quality, determining the degree of compaction, and avoiding strength fluctuations caused by the moisture content deviation.

The maximum dry density and optimum moisture content of the soil samples were determined using the standard compaction test (based on the Test Procedure for Inorganic Binder Stabilizing Materials for Highway Engineering, JTG E51-2009)31.

The Marshall electric compactor was selected as the test equipment, and the specific device and equipment parameters are shown in Fig. 3; Table 4. The specific test procedures are as follows: first, according to the proposed mix ratio, EPS particles, polypropylene fibers, and lime were added to the soil sample, thoroughly mixed, and sealed for 24 h to ensure uniform distribution. Subsequently, the mixture was layered into the compacting cylinders and each layer was compacted according to the standards specified in the regulation. By determining the dry density of the specimens at different moisture contents and plotting the compaction curves, the maximum dry density and the corresponding optimal moisture content were determined. The test results provide key parameter support for subsequent specimen preparation.

The calculation of wet density and dry density of the specimen is based on the Test Procedure for Stabilized Material of Inorganic Binding Material for Highway Engineering (JTG E51-2009)30. The compaction curve was plotted with moisture content as the horizontal axis and dry density as the vertical axis, with the peaks corresponding to the optimum moisture content and maximum dry density. The test results show that the dry density decreases with increasing EPS particle content (1.55–1.90 g/cm³), while the optimal moisture content remains stable in the range of 28.5-29.2%. Therefore, the specimens were prepared with 29% moisture content, and the compaction results are shown in Fig. 4.

Unconfined compressive strength test

In order to obtain a set of reasonable mixing ratios, this experiment was based on previous engineering experience, considering the EPS content and polypropylene fiber mixing content as the main factors affecting the deformation and strength of the specimen.

In Northeast China, traditional roadbed construction usually involves adding 6% lime for curing treatment. A 6% lime content is generally sufficient to meet the requirements for roadbed strength and stability. Increasing the lime content beyond this level can lead to difficulties in mixing during construction, as well as reduced compaction quality and other problems.

In this test, considering that EPS particles are light weight and have low strength, their addition to the soil may weaken the strength of the roadbed. Therefore, using only 6% lime might not be sufficient to compensate for the strength loss caused by the incorporation of EPS particles. It is thus necessary to increase the lime content to enhance the cementation. The reference results are shown in Fig. 5. The unconfined compressive strength of lightweight soils meets the specification requirements when the lime content is increased to 9%. Therefore, 9% lime was selected as the curing agent for this test.

The optimal moisture content was determined through standard compaction tests. The experimental variables included: EPS content (0%, 0.2%, 0.5%, 0.8%), polypropylene fiber content (0%, 0.5%, 1%, 2%), and lime content (9%). Table 5 presents the complete mix proportions of raw soil, EPS particles, polypropylene fibers, water, and lime.

In this study, the specimens were prepared strictly in accordance with the “Test Methods of Soils for Highway Engineering” (JTG 3430 − 2020). The specific procedure was as follows: after drying, crushing, and sieving the raw soil at 105℃, the soil was dry-mixed with the designed amount of lime for 3 min until uniform, and then the optimal moisture content was added. An optimized “fiber priority - progressive dispersion” process was used: polypropylene fibers were added in three batches, each batch ≤ 1/3 of the total amount, mixed three times at intervals, followed by EPS particles, also in three batches (at 2-minute intervals). This method effectively reduces EPS segregation and ensures material homogeneity through a combination of viscous matrix enhancement and mechanical interlocking.

The specimens were compacted using a layered compaction method, placing the mixed soil into a standard mold (50 mm × 50 mm) in three equal layers. Each layer was pre-compacted and then roughened to ensure optimal interlayer bonding. The molding process applied 2 MPa pressure for 2 min, and the mold was removed using an electro-hydraulic mold release machine after a 4-hour (as shown in Fig. 6; Table 6). Finally, all specimens were sealed and cured in a standard environment (temperature 20 ± 2℃, relative humidity 95%) for 7 and 28 days, respectively.

This indoor test used the unconfined compressive test to compare the performance between traditional lime-stabilized soil and fiber–EPS particle lightweight soil, specifically the specimen’s ultimate strength under axial loading without confinement. The test was conducted using a microcomputer-controlled electronic universal testing machine (model WDW-100E) located at Heilongjiang University, as shown in Fig. 7; Table 7. During the test, the loading rate was set to 1 mm/min, and the total test time was controlled within 10 min.

Freeze-thaw cycle test

In the construction of subgrade in cold regions, due to the low temperature, some road subgrades often freeze, causing the water in soil pores to freeze and expand the soil volume, which in turn affects the normal performance of the subgrade. The indoor freeze-thaw cycle test can simulate this freezing-thawing process and intuitively explore the improvement effect of fiber–EPS particle lightweight soil on highways in cold regions. The purpose of this experiment is to investigate the working mechanism of polypropylene fibers and EPS particles during freeze-thaw cycles, as well as to analyze the impact of these freeze-thaw cycles, and the quality and strength of the specimens.

In the unconfined compression test, based on a comparative analysis of compressive strength data, when the EPS particle content reached 0.8%, the strength of the specimens—whether cured for 7 days or 28 days—fell below the standard requirements. Therefore, this content was excluded from the freeze-thaw cycle experiments. When the polypropylene fiber content was increased to 2%, the strength of the specimens was approximately the same as that with 1% fiber content, exhibiting a slight decrease rather than an improvement. This indicates that adding more fibers does not necessarily result in better performance. Consequently, the 2% fiber content was also excluded from the freeze-thaw cycle experiments.

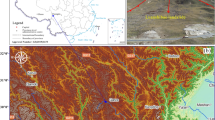

This freeze-thaw cycle test was conducted under the climatic conditions of winter in the Chaoyang area, Liaoning Province, based on the field investigation data. According to climate records, the average winter temperature in the region can reach − 18 °C, and the average depth of permafrost is approximately 92 cm. The purpose of this test is to simulate the actual freezing and thawing environment of highway roadbed soil in cold regions, systematically study the inhibitory effects of polypropylene fiber and EPS particles on freeze–thaw damage in lightweight soils and their mechanism, and analyze the relationship between the number of freeze–thaw cycles, specimen mass loss, and strength attenuation rate.

The specimen preparation strictly followed the established proportion scheme, using a standard cylindrical mold with specifications of 50 × 50 mm to make samples. The molded specimens were sealed, packaged, and placed in a standard curing room (temperature of 20 ± 2℃, relative humidity of 95%) for a period of 28 days. At the end of the curing cycle, all specimens were saturated by immersion in a water bath, and their mass was measured before and after saturation to determine the change in mass. Four freeze-thaw cycle gradients, such as 0, 1, 3, and 5 cycles—were set for the control group. The specific cycle program was as follows: the saturated specimen was frozen at −18℃ for 16 h and then transferred to a constant temperature and humidity environment at 20 °C (relative humidity 90–95%) for 8 h. The specific cycle procedure was as follows: the saturated specimen was placed in a −18℃ low- temperature environment frozen for 16 h, then transferred to a constant temperature and humidity environment at 20℃ (relative humidity 90–95%) and thawed for 8 h. This 24-hour period is defined as one complete freeze-thaw cycle. The temperature and humidity settings for the freeze thaw cycles align with the actual winter soil temperature changes in the local environment.

SEM scanning electron microscope test

The above tests examined the mechanical properties of fiber-reinforced EPS particles in lightweight soil from a macro perspective. To observe the structural characteristics of polypropylene fibers within EPS particle lightweight soil on a microscopic level, a Hitachi S-3400 scanning electron microscope (SEM) was used. This SEM test analyzed three types of specimens: lime soil, fiber soil and fiber EPS particle lightweight soil.

The specimens cured for 28 days underwent stress testing. After failure, samples were taken from the fractured sections, keeping them as intact as possible, with each approximately the size of a thumb. These samples were then placed in a well-ventilated environment for a 7-day drying treatment. After drying, the samples were subjected to air pumping and gold coating. Once these treatments were completed, the resulting samples were used as the definitive scanning specimens for the SEM analysis.

Results and discussion

Results

Effect of EPS particles on the density of lightweight soils

In the preliminary test conducted before the unconfined compression test, it was observed that the influence of polypropylene fiber and lime on the density of EPS lightweight soil specimens could be neglected. As a lightweight filler, EPS particles occupy a significantly larger unit volume than lime and polypropylene fibers at the same mass, making them the primary factor influencing specimen density.

As shown in Fig. 8, the density of the lightweight soil specimens decreased significantly with increasing EPS content, decreasing from 1.94 g/cm³ at 0% EPS to 1.53 g/cm³ at 0.8% content, clearly demonstrating the effective weight-reducing capability of EPS particles. However, this increase in EPS content also led to a notable decline in compressive strength, which dropped from 1.93 MPa to 0.41 MPa, as shown in Fig. 9.

Effect of fibers on the compressive strength of lightweight soils

When conventional non-reinforced foundation soil is subjected to overloading, it typically exhibits pronounced cracking and sudden bearing capacity failure. Upon reaching the peak load, the soil undergoes immediate structural collapse. As a result, plain soil lacks ductility and structural continuity. Experimental investigations have shown that incorporating an optimal fiber content greatly enhances the geotechnical properties of embankment soil. Laboratory analyses indicate that uniformly distributed fibers within the soil matrix create frictional resistance, and mechanical interlocking under load, effectively restricting soil displacement and improving load-bearing capacity. As the fiber dosage increases to a critical threshold, polypropylene fibers form a three-dimensional network that densifies particle-to-particle contacts, thereby enhancing the structural integrity of the composite. These mechanisms collectively lead to significant soil improvement, as demonstrated by the comparative performance data of plain and fiber-reinforced EPS lightweight soils in Table 8 (unconfined compressive strength and failure strain).

The stress-strain relationship curves of lightweight soil specimens with varying polypropylene fiber contents are shown in Fig. 10. Under curing durations of 7 days and 28 days, the initial portions of the stress-strain curves are nearly identical; however, as strain increases, the strength gap between the two gradually expands. When the EPS particle content is 0.2% and the lime content is 9%, the addition of polypropylene fiber significantly enhances the unconfined compressive strength of the specimens. After 28 days of curing, the peak stress reached 1.73 MPa, an increase of 40% compared to the 7 days value. Following specimen failure, the reinforcing effect of the fibers becomes more apparent, restricting soil deformation and improving specimen ductility. As shown in Fig. 10 (a) and (b), polypropylene fiber has a notable effect on both the compressive strength and ductility of lightweight soil specimens. is significant. However, when the fiber content exceeds 1%, the improvement in strength becomes negligible. This is because, at 2% fiber content, most fibers in the lime soil overlap and fail to contribute to strength and toughness enhancement. Instead, they form weak zones within the specimen, which not only raise construction costs but also introduce potential safety hazards. Therefore, experimental analysis indicates that a fiber content of 1% yields the highest specimen strength while meeting the highway subgrade strength requirements specified in current regulations. Therefore, based on comprehensive experimental analysis, it is evident that a fiber content of exactly 1% yields the maximum specimen strength. Moreover, this strength level fully meets the requirements for highway subgrade filling as specified in the relevant standards.

Effect of EPS particles on the compressive strength of lightweight soils

Traditional subgrade backfill materials are characterized by substantial self-weight and inherently limited bearing capacity, which pose significant drawbacks. In real-world engineering applications, these issues often lead to subgrade settlement. Furthermore, road widening projects, differential settlement a persistent challenge that engineers must frequently address. With the continuous development of engineering technology, and considering significant advantages of EPS particles, such as their light weight and strong durability, a reasonable amount of EPS particles was introduced in the experiment as a lightweight filling material, aiming to reduce the adverse effects caused by the self-weight of subgrade soil. However, there is a limit to the amount of EPS particles that can be added; it cannot be increased indefinitely. As the proportion of EPS particles in the soil gradually increases, the mechanical properties of the soil change significantly, most notably, the soil becomes more brittle, and its overall integrity and stability are reduced.

Figure 11 depicts the stress–strain relationship curves of lightweight soil specimens containing varying EPS particle contents. Using curing times of 7 days and 28 days as representative cases, this paper explores the correlation between EPS particle content and the compressive strength of the specimens. When the content of polypropylene fiber and lime are held constant, the stress-strain relationship of the specimen exhibits a linear trend, and the unconfined compressive strength decreases with increasing EPS particle content. From Fig. 11(A), it can be observed that at a curing time of 7 days, the strength of lime-stabilized soil without EPS particles is not significantly different from that containing 0.2% EPS particles. When both reach their ultimate stress, the post-failure plastic deformation is minimal, and the residual stress declines rapidly, resulting in an insufficient safety margin for practical engineering applications. After 28 days of curing, lime generates capillary pressure within the soil matrix, which the densifies the specimen by reducing voids and enhancing homogeneity, thereby leading to significantly increased strength. However, when the EPS particles content reaches 0.5%, the strength of the specimen shows a significant downward trend. This phenomenon is attributed to the increased replacement of lime and polypropylene fiber, both of which contribute to strength enhancement, by EPS particles. This substitution results in a significant decrease in interparticle bonding, making it difficult for the remaining lime soil and polypropylene fibers to fully exert their intended enhancement effect.

As is evident from Table 8, as the content of polypropylene fiber increases incrementally, the unconfined compressive strength of the specimen shows a gradual upward trend. However, when the fiber content exceeds 1%, the reinforcement effect becomes negligible and may even slightly reduce strength. This phenomenon is neither economical nor aligned with the practical engineering application requirements. For fiber-reinforced soil containing EPS particles, the specimen’s strength decreases as the EPS content increases. When the EPS particle content reaches 0.8%, a substantial portion of the lime soil, which originally served a reinforcing function, is replaced by numerous EPS particles. The excessive presence of EPS particles increases the capillary voids within the soil matrix. As a result, even with higher fiber content, the specimen strength fails to meet the filling strength requirements specified in the relevant standards.

The influence of freeze-thaw cycles on the quality of lightweight soil

Figure 12 illustrates the relationship between mass loss and freeze-thaw cycles for fiber EPS particle lightweight soil. As shown in the figure, when the fiber content is fixed, the mass of the specimens subjected to freeze-thaw cycles gradually decreases with increasing EPS particle content. When the EPS particle content is 0, the specimen’s mass decreases from 188.1 g to 168.5 g as the number of freeze-thaw cycles increases. On average, each freeze-thaw cycle results in a mass loss rate of 2.1%. Mass loss rate was calculated in strict accordance with the specifications outlined in the Test Procedures for Inorganic Binder Stabilized Materials in Highway Engineering (JTG E51-2009). When the EPS particle content is increased to 0.2%, the specimens mass decreases to 173.1 g. Following five freeze-thaw cycles, the average mass loss rate reduces from 2% to 1.58%. At an EPS particle content of 0.5%, the mass loss reaches its minimum value, with the specimen decreasing from 163.3 g to 153.2 g, and the average mass loss rate dropping to 1.23%. Compared with plain soil specimens, under the same freeze-thaw conditions, the fiber-reinforced EPS particle specimens show a significantly lower mass loss rate, only 41.4% observed in the plain soil specimens.

Based on a comprehensive analysis of the aforementioned test data, it is evident that the addition of EPS particles plays a pivotal role in mitigating soil damage. During the initial phase of the freeze-thaw cycle, the free water dispersed within the specimens undergoes physical freezing under low-temperature conditions. This freezing process causes volumetric expansion, ultimately leading to frost heave within the specimen. When the frost heaving force exceeds the cohesive force between soil particles, the interparticle gaps widen, resulting in deformation of the soil structure and increased mass loss. As the volume of ice crystals formed from frozen pore water continues to expand, the degree of soil damage gradually intensifies. After several freeze-thaw cycles, the repeated formation and thawing of ice lead to the development of preferential pathways within the soil structure.

As the freeze-thaw cycles continue, the repeated formation and melting of ice cause the soil to develop enlarged voids that can accommodate an increasing volume of ice crystals formed during freezing. Over time, the pore gradually establishes unobstructed pathways within the soil structure. As repeated freeze-thaw cycles continue, the soil develops enlarged voids capable of accommodating the increasing volume of ice crystals formed during the freezing phase. Consequently, the detrimental impact of frost heave on the soil gradually diminishes. The internal connectivity of soil particles becomes more robust and stable, leading to a steady reduction in mass loss. This transformation reflects the soil’s microstructure adaptation to the mechanical stresses imposed by the freeze-thaw cycles, leading to improved resilience and reduced material degradation over time.

The influence of freeze-thaw cycles on the strength of lightweight soil

In accordance with the previously described experimental procedure for freeze-thaw cycle tests, the unconfined compressive strength values of fiber-reinforced, EPS particle lightweight soil after undergoing 1, 3, and 5 freeze-thaw cycles are presented in Table 9 and illustrated in Fig. 13.

From Fig. 13 (A), it can be observed that after five freeze-thaw cycles, the unconfined compressive strength of the specimen without EPS particles decreased significantly from 1.6 MPa to 0.55 MPa, resulting in a strength of up to 65%. Although the addition of fibers improves the compressive strength and helps inhibit failure deformation, it cannot effectively mitigate the adverse effects of temperature fluctuations during freeze-thaw cycles. As shown in Fig. 13(B), when the EPS particle content is 0.2%, the strength loss of the specimen is slightly reduced to 44%, and the strength tends to stabilize as the number of freeze-thaw cycles increases. Figure 13(C) illustrates that with increasing EPS content, when the content reaches 0.5%, the strength of the specimen decreases from 0.88 MPa to 0.5 MPa, but the rate of strength loss is significantly reduced. After five freeze-thaw cycles, the specimen exhibits only a 10% reduction in strength. However, increasing the EPS content beyond an optimal level does not necessarily lead to better performance Excessive amounts can compromise the original strength of the stabilized soil, as a high concentration of EPS introduces numerous pores into the specimen, which is more likely to reduce its strength. Therefore, incorporating an appropriate quantity of EPS particles can significantly enhance the soil’s frost resistance. This improvement is attributed to the excellent durability and frost-resistant properties of EPS particles, which help the soil maintain its structural integrity even after multiple freeze-thaw cycles. These characteristics highlight the beneficial role of EPS particles in mitigating the damaging effects of freezing and thawing on soil structure.

Analysis of failure pattern

The failure modes of the specimens at different time points during the unconfined compressive strength test of the EPS particle lightweight soil are illustrated in Fig. 14. During the compression test, a fine oblique crack initially appears in the upper-middle part of the fiber-reinforced EPS lightweight soil specimen, and the reinforcing effect of the fibers is not yet evident.As the loading continued, the cracks gradually propagated downward. The middle section of the specimen begins to bulge and shows visible signs of cracking, with the crack width increasing until the specimen ultimately fails. After unloading, the overall integrity of the specimen is maintained, clearly demonstrating the fibers’ role in enhancing toughness and improving residual strength. It is evident that the reinforcing effect of the fibers becomes fully apparent only once the specimen reaches its ultimate strength.

The failure process of the EPS granular lightweight soil without polypropylene fiber is depicted in Fig. 15. The inclusion of EPS particles not only reduces the density and weight of the specimen but also decreases the strength of the lightweight soil and increases the extent of damage. At a loading time of 100 s, cracks initiate at the base of the specimen and propagate irregularly upward at a slow rate. The brittleness of the EPS particles is not yet evident, and the specimen remains intact without failure. At a loading time of 400 s, the specimen experiences partial failure, with cracks widening and extending. Simultaneously, large soil fragments break away quickly, indicating the specimen’s pronounced brittle behavior. After continuous loading for 600 s, the specimen is completely destroyed, with severe damage visible. The poor adhesion between the EPS particles and the soil becomes apparent, resulting in a crumbling effect.

As can be seen from Figs. 14 and 15, there is a distinct contrast between the fiber-reinforced EPS particle lightweight soil and the EPS particle lightweight soil without fiber addition when subjected to longitudinal loads. Initially, both types of soil exhibit small cracks, and at this stage, the reinforcement effect of the polypropylene fibers has not yet manifested. As the pressure continues to increase, the crack propagation rate in the specimens without fiber addition is faster, and the number of cracks is greater than in the fiber-reinforces specimens. With increased test duration, the lightweight soil without fiber addition shows signs of failure earlier. Its strength drops sharply, accompanied by flaking and debris detachment. In contrast, for the specimens mixed with fibers, only crack extension and bulging in the middle section are observed. The fibers in the soil bear part of the tensile stress and help limit soil failure. After the test, the specimens without fiber addition completely lose their bearing capacity and exhibit more severe damage than the fiber-reinforced specimens. Meanwhile, the fiber-reinforced EPS particle lightweight soil maintains good integrity and toughness. The specimens crack but do not disintegrate. Through comparative analysis of the tests, it is evident that the reinforcement effect of polypropylene fibers is only fully realized when the soil is subjected to relatively large external forces. As cracks and deformations occur, the fibers effectively restrict cracks propagation and prevent sudden failure. Since the polypropylene fibers are uniformly distributed throughout the soil, they provide strong bonding at the fracture surface, mitigating the brittle failure commonly observed in fiber-free specimens. As a result, the addition of polypropylene fibers significantly enhances both the strength and structural integrity of the lightweight soil.

SEM scanning electron microscope test result

Figure 16 shows SEM images of lime-stabilized soil. The soil is primarily composed of remolded soil, lime, and water mixed in a specific proportion. The soil used in this test is the remolded soil that has been dried, rolled, and sieved. When magnified 300 times under a scanning electron microscope, the soil sample reveals numerous particle pores. The presence of these pores makes the sample vulnerable to damage under external loads, compromising its structural integrity. When magnified 300 times under a scanning electron microscope, the soil sample displays numerous particle pores, which make it vulnerable to damage under external loads and compromise its structural integrity. Upon the addition of lime, the soil undergoes a of lime, the soil undergoes a ripening process, during which the lime effectively fills initially packed voids within the soil matrix. The results in a more compact and denser soil structure, significantly enhancing its overall strength. Figure 16(B) presents a scanning electron microscope image magnified 5000 times. The image shows that, after lime is added to the remolded soil, it reacts with water through an exothermic hydration process. As the lime ripens, it becomes embedded in the soil and forms crystalline structures. At higher magnification, distinct gaps between the solidified soil particles become clearly visible.

It can be seen from Fig. 17 (A) that the polypropylene fiber is firmly embedded in the solidified soil, and the solidified soil acts to anchor the fibers dispersed within it. At the same time, the fibers distributed throughout the soil matrix form an irregular network structure. This structure effectively bears part of the tensile stress in the soil, thereby significantly enhancing its compactness. Through the combined effect of the firmly anchored fibers and this unique network structure, the goals of improving soil strength and limiting deformation are achieved.

However, excessive fiber content leads to overlapping distribution. Such overlapping may create weak zones in the soil matrix. Consequently, these weak zones prevent the fibers from functioning optimally and introduce uncertainties regarding the soil’s vulnerability to damage, as the structural integrity and uniformity are compromised. Therefore, to achieve the intended effect, the amount of fiber content should be carefully selected.

The photo in Fig. 17 (B) shows the distribution of EPS particles and fibers within the soil. The addition of EPS particles imparts lightweight properties to the soil. However, as the number of EPS particles increases, their presence within the limited space displaces the lime soil, which originally played a crucial role in the curing process. This substitution reduces the soil’s strength of the soil and results in a tendency for easy dispersion. The incorporation of polypropylene fiber effectively counteracts this negative effect. The fibers are enveloped by the lime-solidified soil, forming a capillary network structure within the pores of the lightweight soil.

This network significantly increases the frictional resistance and cohesion between the EPS particles and the soil matrix, thereby enhancing the soil’s stability and strength. This mechanism prevents slip dislocation and deformation failure of the lightweight soil under stress. As a result, it not only improves the overall strength of the lightweight soil but also significantly restricts the initiation and spread of cracks, thereby enhancing its structural integrity and durability.

Discussion

In this study, the road performance and synergistic mechanism of fiber-EPS granular lightweight soil were systematically analyzed and revealed using various experimental and theoretical methods. The main innovations of this study are reflected in:

-

(1)

The mixing process for fiber-EPS particle lightweight soil was proposed, with control over mixing sequence, duration, and moisture adjustment. This process ensures uniform fiber distribution and prevents segregation of the EPS particles, providing reliable technical support for the application of EPS lightweight soil in roadbed engineering.

-

(2)

The research addressed the multi-objective synergistic optimization of strength, density, and frost resistance in the design of lightweight soil materials. By controlling the dosage of each component, an optimized balance among strength weight and durability was achieved. This mix design not only reduced construction costs but also overcame limitations in frost resistance and durability of traditional roadbed materials in cold regions, offering a new solution to roadbed issues in such environments.

-

(3)

The synergistic working mechanism of fiber, EPS particles, and lime was clarified. The stabilized system formed by the three components was examined through microscopic analysis, breaking the limitation of conventional single-reinforcement methods.

-

(4)

To better highlight the innovation of this study, Table 10 summarizes the main findings of existing related research and contrasts with the methods and findings of this work. However, some limitations remain in the research on fiber EPS granular lightweight soil, such as limited number of real-world construction cases and the absence of verification through full-scale roadbed test sections. The adaptability of fiber-EPS granular lightweight soil in different environments also requires further investigation, as its performance may be significantly affected under special conditions such as high humidity or high salinity.

Conclusion

This study investigated the properties and preparation process of fiber EPS particles in lightweight soil. The experimental results show that the compressive strength of the material decreased from 1.93 MPa to 0.41 MPa and the density decreased from 1.94 g/cm³ to 1.53 g/cm³ with increasing EPS particle content (within the test range), and the brittle damage will be caused by excessive doping. Based on this, the proposed “fiber priority - progressive dispersion” process improves the fiber dispersion through the viscous matrix, effectively controlling the segregation phenomenon of EPS particles. However, it should be noted that the current study only examined the short-term mechanical properties; all the experiments were done under laboratory conditions, and the applicability in real engineering environments has not yet been verified. These findings provide material solutions for roadbed engineering in cold regions, but their practical application still needs to be further verified.

Studies have shown that the traditional lime dosage of 6% struggles to meet the strength requirements of EPS lightweight soils (measured strength is only 65-75% of the specification value). When the lime dosage is increased to 9%, the strength of specimens meets the design requirements and retains a certain amount of stress reserve; when the dosage is further increased to 12%, problems such as mixing difficulties, reduced compaction and increased costs occur. Moderately increasing the lime dosage can effectively alleviate the adverse effects of EPS on soil properties, and this conclusion provides a theoretical basis for the optimization of the mixing ratio of EPS lightweight soils in cold zone projects.

The results of this study show that polypropylene fiber improves the mechanical properties of lightweight soil. The compressive strength of the material reaches the maximum value when the fiber dosage is 1% and maintains a certain residual stress after damage; however, when the dosage is more than 1%, the fiber stacking leads to a decrease in strength instead of an increase. The study showed that the fibers were constructed to the reinforcement mechanism alongside lime hydration products by enhancing the frictional resistance between the EPS particles and the lime soil and limiting the displacement of the EPS particles. The strength and performance of the lightweight soils were optimized at 0.2% of EPS particles and 1% of fibers, which can be adjusted according to the needs of the project. It should be noted that the current conclusions are based on the standard laboratory conditions, and the effects of variables such as loading and environmental humidity have yet to be verified in the actual project.

The lightweight soil containing EPS particles exhibited improved frost resistance after multiple freeze-thaw cycles, with a strength reduction of approximately 10% and a mass loss rate of 1.23%. The study suggests that the closed-pore structure of EPS particles contributes to modifying the soil’s pore distribution, reducing density, and working in combination with polypropylene fibers to enhance frost resistance. SEM observations indicated that the EPS particles closed-pore structure facilitated fiber distribution, while the fibers formed a network between EPS particles and lime-treated soil, increasing frictional resistance and restricting particle displacement. The binding products from lime hydration, along with the fiber network, contributes to a reinforcing mechanism involving particle dispersion, fiber distribution, and cementation, which help mitigate strength loss and improve frost resistance and stability. These findings could offer a design approach for lightweight roadbed construction in cold regions.It should be noted, however, that the current results are based on standard laboratory freeze-thaw conditions, with a limited number of freeze-thaw cycles, and do not take into account the effects of temperature gradients, freeze-thaw rates, and other variables in actual projects, and lack an assessment of the long-term durability of the materials. These findings provide a reference for the construction of roadbeds in cold regions, but the practical application needs to be verified in the context of the engineering environment.

Data availability

The data that support the findings of this study are available from the corresponding author, [F.J. Zu], upon reasonable request.

References

Mei Lifang. Research on Physical and Mechanical Properties of Lightweight Soil with fiber EPS particles[D] (China University of Geosciences, 2017).

Mei et al. Preparation and Mechanical Properties of Lightweight Soil with fiber Polystyrene Foam particles[J] (Journal of Composite Materials, 2016).

Jiang, J. et al. (ed Mingxue) Comparative study on mechanical properties of different roadbed materials under freeze-thaw cycle. J. Hebei Univ. Archit. Eng. 42 01 50–57 (2024).

Zhang et al. Application of Polystyrene Foam Particle Lightweight Soil in Road engineering[J] (Transportation World, 2018).

Fu et al. Application of fiber-foam Lightweight Soil in Roadbed Engineering in Soft Soil Area [J] (Construction Technology Development, 2023).

Zhang, Y. Research and engineering application of lightweight roadbed materials for overlay hub roads on subway projects [D]. Southeast University,2019.004648.

Summer, Duan Hongtao. Research on the application of lightweight soil technology in highway construction.Transportation world(construction and maintenance. Machinery), (2015).

Wang et al. Technological promotion and application of EPS granular mixed lightweight soil in high grade highway[J]. Sci. Technol. Perspect. ,2013,(19):183 .https://doi.org/10.19694/j.cnki.issn2095-2457.2013.19.140

Chongmin Liu. Application of EPS granular mixed lightweight soil technology in the Southern connection project of Qianjiang channel[J]. Transp. Stand. 42 (09), 82–85. https://doi.org/10.16503/j.cnki.2095-9931.2014.09.029 (2014).

TANG Yongbin. Analysis on the treatment of shallow buried medium-thickness soft ground for highway with foam lightweight soil replacement[J]. Roadbed Eng. 2023 (04):108–112 .https://doi.org/10.13379/j.issn.1003-8825.202210031

Tianshun, H. O. U. et al. Modeling experimental study on static Earth pressure characteristics of EPS particles mixed with lightweight soil fill behind retaining wall[J]. Geotechnics,2021,42(12):3249–3259 .https://doi.org/10.16285/j.rsm.2020.1598

Yao, X. Application of foam lightweight hybrid soil in the treatment of Bridge head jumping problem[J]. China New. Technol. New. Prod. (23), 119–121. https://doi.org/10.13612/j.cnki.cntp.2021.23.037 (2021).

Li, Y. Application of foam lightweight soil in roadbed widening.Shandong Transp. Sci. Technol. (2022).

Jianhua, Y. A. N. G. et al. Research on the method of improving the properties of red clay with high liquid limit as backfill fill.Groundw., 36(03): 153–155. (2014).

Ling, S. H. A. et al. Experimental study on strength characteristics of silt recycled mixed lightweight soil.J. Nanjing Univ. Sci. Technol., 37(03): 441–446. (2013)

Lifang, M. E. I. et al. Preparation and mechanical properties of lightweight soil with fiber polystyrene foam particles.J. Compos. Mater, (2016).

Hao-Yu, G. U. et al. Experimental study on mechanical properties of EPS lightweight soil under freeze-thaw cycle.J. Hubei Univ. Technol.,38(05): 110–114 . (2023)

Lifang et al. Physical and mechanical properties of expanded polystyrene (EPS) particle lightweight soil under Freeze – Thaw. Cycles ACS Omega. 8, 31365–31372 (2023).

von Ardenne, M. The scanning electron microscope. Theoretical fundamentals. Z. Phys. 109, 553 (1938).

Oatley, C. The Scanning electron Microscope: Part 1, the Instrument (Cambridge University Press, 1972).

Hayat, M. A. Principles and Techniques of Scanning electron Microscopyvol. 6 (Litton Educational Publishing, Inc, 1978).

Muhmed, A. & Wanatowski, D. Effect of lime stabilisation on the strength and microstructure of clay. IOSR J. Mech. Civ. Eng. (IOSR-JMCE). 6 (3), 87–94 (2013).

Onitsuka, K., Modmoltin, C. & Kouno, M. Investigation on Microstructure and Strength of Lime and Cement Stabilized Ariake Clayvol. 30p. 49–63 (Reports of the Faculty of Engineering, Saga University;, 2001).

Caixia, F. et al. Mechanical behaviors of frozen clay under dynamic Cyclic loadings with freeze-thaw cycles.Cold Reg. Sci. Technol.,181, 103184, ISSN 0165-232X (2021).

Ekaterina, K., Jiankun, L., Weiwei, N., Shujuan, Z,. Performance of clay soil reinforced with fibers subjected to freeze-thaw cycles.Cold Reg. Sci. Technol.,https://doi.org/10.1016/j.coldregions.2018.05.002153, 18-24, ISSN 01, (2018)

Dianzhi, F., Yong, W., Jiaxu, J., Xingxing, H., Bing, L., Qiang, X,. The effects of wetting-drying and freezing-thawing cycles on mechanical properties of biopolymer-fiber treated soil.Developments in the Built Environment,https://doi.org/10.1016/j.dibe.2025.10066622, 100666, ISSN 2666-1659, (2025)

Jia et al. Experimental investigation on strength development of lime stabilized loess.RSC Advances, (2019).

Mariana Tonini de Araújo. et al, Mechanical and Environmental Performance of Eggshell Lime for Expansive Soils Improvement,Transportation Geotechnics.Volume 31,2021,100681,ISSN 2214–3912.

Cheng, H. et al. Performance of polypropylene Fiber-Reinforced solidified soil,advance in Civil Engineering;2021.

Specification for Highway Soil Test (JTG 3430 – 2020).

Test Specification for. Inorganic Binder Stabilized Materials for Highway Engineering (JTG E51- (2009).

Qizhi, H. et al. Experimental study on physical and mechanical properties of lightweight soil with polypropylene fiber.Journal of Henan University of Technology (Natural Science Edition),1–10 (2025).

You qiang Pei,et al,study on the microstructure of foam lightweight soil and its strength properties[J]. J. China Foreign Highway. 39 (1), 215–217 (2019).

Gou et al. Strength formation mechanism of mycelium-bran-sand composite lightweight soil[J]. J. Geotech. Eng. https://doi.org/10.11779/CJGE20240753

Ying, L. I. U. et al. Experimental study on the performance of foam lightweight soil material with powdered clay[J]. Highway Transp. Sci. Technol. 2024, 41(5):20–26. https://doi.org/10.3969/j.issn.1002-0268.2024.05.003

Author information

Authors and Affiliations

Contributions

Fajin Zu: Investigation, Methodology, Visualization, Supervision.Hechao Dou: Writing – original draft, Validation, Formal analysis, Conceptualization. Bo Xu: Data curation, Investigation. Fuxing Li: Methodology, Visualization. YaNan Li: Material supply,on-site guidance.Hongbo Liu: Supervision, Funding acquisition, Project administration, Writing – review & editing, Resources. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dou, H., Xu, B., Li, F. et al. Research and application of fiber-reinforced EPS particle lightweight soil in highway engineering in cold regions. Sci Rep 15, 25264 (2025). https://doi.org/10.1038/s41598-025-10866-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-10866-6