Abstract

To investigate the effects of magnesium oxysulfates adhesives with varying performance characteristics on the shear strength and bending resistance of bonded bamboo, eight types of these adhesives were prepared and applied to bamboo specimens of size 2150 mm × 22 mm × 5.5 mm for testing. The flowability, flexural strength, and compressive strength of the adhesives were measured to analyze their impact on the performance of bonded bamboo. The experimental results showed that the magnesium oxysulfates adhesive with the number H exhibited the highest adhesive shear strength under 7-day and 28 day curing conditions, at 1.05 MPa and 1.46 MPa, respectively, while the adhesive with the numbers B and A had lower strength. Magnesium oxysulfates adhesives with varying performance characteristics also had a significant impact on the bending resistance of glued bamboo. The adhesive with the number H showed the highest bending strength at 79.02 MPa under 28 day curing conditions, while the adhesive with the number B had the lowest bending strength at 39.96 MPa. The study also found that the thickness of bamboo curtains had a relatively small effect on the bending resistance of magnesium oxysulfates cementitious materials, but temperature and water immersion conditions had significant impacts on the mechanical properties of magnesium oxysulfates adhesives. After treatment at 250 °C, the peak load of magnesium oxysulfates adhesive significantly decreased, showing more pronounced performance degradation. After one year of immersion in clean water, the bending strength of magnesium oxysulfates adhesive decreased from 69 to 58 MPa, and the softening coefficient decreased from 1.0 to 0.79. From this, magnesium oxysulfates adhesivess with varying performance characteristics have significant impacts on the adhesive shear strength and bending resistance of glued bamboo. By optimizing the formula and process of magnesium oxysulfates adhesive, its application performance in glued bamboo can be significantly improved, providing scientific basis and technical support for promoting the widespread application of bamboo in construction and engineering fields.

Similar content being viewed by others

Introduction

Driven by sustainable development, the application of green and environmentally friendly materials in the fields of construction, decoration, and engineering is becoming increasingly widespread1. Glued bamboo has characteristics such as renewability, high strength, lightweight, and environmental friendliness, making it an ideal substitute material for traditional wood2. Magnesium Oxysulfates (MOS) is a new inorganic cementitious material that has shown great potential in the field of glued bamboo due to its excellent bonding performance, environmental friendliness, and weather resistance3. In recent years, researchers have conducted extensive research on the performance optimization of MOS adhesive agents. For example, R. Tian et al. analyzed the effect of titanium carbide on the microstructure and mechanical properties of MOS adhesive. An appropriate amount of titanium carbide could significantly improve the bending strength and compressive strength of materials, while also improving their crack resistance4. Y. Sun et al. significantly improved the setting rate and compressive strength of MOS adhesive through highly active magnesium oxide powder5. Yan et al. applied MOS adhesive to geothermal drilling. It was found that MOS adhesive had good temporary sealing performance6. The performance of MOS adhesive is influenced by various factors, including its fluidity, bending strength, compressive strength, and curing conditions, which directly affect its adhesion effect and mechanical properties in glued bamboo7. Related studies have shown that MOS adhesives with different properties have significant differences in the adhesive shear strength and bending resistance of glued bamboo8. The structural performance of glued bamboo not only depends on the performance of the adhesive, but is also closely related to the thickness, maintenance conditions, and environmental factors of the bamboo9. In the study of hydration mechanism and durability of magnesium-based cementitious materials, J. Hu et al. found that MOS adhesive still maintained certain mechanical properties under long-term immersion, but its bending strength and softening coefficient significantly decreased10. Liu et al. improved the crack resistance of MOS adhesive coatings by adding metallurgical waste, further expanding their application scope11. The relevant research summary table is shown in Table 1.

It can be known from Table 1, at present, research on MOS binders mostly focuses on the improvement of the material’s own properties. For instance, the reinforcing effect of titanium carbide on MOS cement is mainly achieved by refining the grain structure and improving the internal stress distribution. In a dry and temperature-stable environment, an appropriate amount of titanium carbide can significantly enhance the flexural strength and compressive strength of the material, as well as improve its crack resistance. However, when in an environment with high humidity or strong acid and alkali erosion, a chemical reaction occurs at the interface between titanium carbide and the hydration products of MOS cement, weakening the enhancement effect. Although previous studies have initially confirmed that MOS adhesives with different properties have a significant impact on the mechanical properties of glued bamboo materials, in the actual building environment, the performance evolution law of them under the coupled action of multiple factors such as temperature, humidity and load has not yet been clarified. Based on the above background, this study aims to experimentally analyze the influence of MOS adhesives with different properties on the bonding shear strength and bending resistance of glued bamboo materials, and to explore the performance variation laws under different curing conditions and environmental factors. The research results will directly contribute to achieving breakthroughs in two aspects. On the one hand, by optimizing the formula and process of MOS adhesives, the mechanical properties and durability of bonded bamboo structures can be enhanced, the service life of bamboo structure buildings can be prolonged, and the replacement frequency of building materials and resource consumption can be reduced. On the other hand, it is necessary to clarify the types of adhesives with strong environmental adaptability, guide the standardized construction of bamboo structures under complex climatic conditions, promote the expansion of bamboo materials from traditional simple buildings to modern building systems such as high-rise buildings and large-span buildings, and reduce the reliance on non-renewable building materials.

Methods and materials

Preparation and determination of MOS adhesive

The study selects lightly burned magnesium oxide prepared by Lixin Magnesium Industry Co., Ltd. to prepare MOS adhesive. Light-burned magnesium is obtained by calcining magnesite, brucite and magnesium hydroxide extracted from seawater at around 800 to 1000 degrees Celsius, causing them to decompose and release CO2 or H2O12. Before preparation, the hydration method is used to determine the activity of magnesium oxide, as active magnesium oxide easily reacts with water to form magnesium hydroxide. The activity is evaluated by measuring the reaction weight gain or the amount of magnesium hydroxide produced13. Firstly, the magnesium oxide sample is weighed and placed in a constant temperature and humidity environment. According to the standard method of “Magnesium Oxide for Magnesium-based Cementitious Materials Products”, the prepared samples were placed in a forced convection drying oven and continuously dried at a constant temperature of 105 ± 2 ℃14. During this period, the samples were taken out every 2 h, cooled to room temperature in a desiccator, and then accurately weighed. When the mass difference between two consecutive weighings does not exceed 0.0002 g, it is determined that the sample has reached a constant weight state. Based on the mass change data before and after drying, combined with the stoichiometric relationship of chemical reactions, the content of active magnesium oxide was calculated by the incineration reduction method15. The activity of magnesium oxide is shown in Eq. (1).

In Eq. (1), \(w_{a}\) represents the initial weight. \(w_{b}\) represents the mass after adding water and drying. The MOS preparation process is shown in Fig. 1.

From Fig. 1, the prepared light burned MgO and magnesium sulfate have a molar ratio of 4:1, and the mass ratio of water to magnesium oxide is 0.6:1. From the perspective of the chemical reaction mechanism, the theoretical molar ratio of the main hydration product of magnesium oxysulfide cement, 5 Mg (OH)2·MgSO4·7H2O (5·1·7 phase), is MgO:MgSO4 = 6:1. However, in the actual preparation process, an excess of MgO can promote the stable generation of the 5·1·7 phase. To enhance the alkaline environment of the system and suppress the generation of adverse by-products, when the molar ratio of MgO to MgSO4 is controlled between 4 and 5, the early strength and later stability of the cementitious material can achieve an optimal balance. Therefore, a molar ratio of 4:1 is selected. The mass ratio of water to magnesium oxide is 0.6:1, taking into account the balance between the water required for the hydration reaction and the working performance of the system comprehensively. An appropriate amount of water can not only meet the full hydration requirements of MgO and MgSO4, but also ensure that the slurry has suitable fluidity, facilitating subsequent impregnation and bonding operations with bamboo materials. Magnesium sulfate is dissolved in water to prepare a solution of a certain concentration. The magnesium oxide powder is mixed with magnesium sulfate solution. The mixture is then placed in a magnetic stirrer and thoroughly stirred to ensure uniformity at a stirring speed of 300 rpm for 2–3 min16. During the mixing process, the modifier sodium citrate (C6H5Na3O7·2H2O) was added to adjust the reaction rate and the performance of the product. The carboxyl group (-COO-) and hydroxyl group (-OH) in the C6H5Na3O7·2H2O molecule can form stable chelates with Mg2+, reducing the concentration of free Mg2+ in the solution and delaying the hydration reaction rate of MgO with MgSO4·7H2O. The mixing time is 5 min to ensure the uniformity of the slurry. The mixed slurry is injected into the specimen molding mold for molding. The physical images of the magnetic stirrer and the specimen forming mold are shown in Fig. 2.

The slurry is left to stand in the test piece molding mold for 24–48 h.According to the requirements of the "Standard Test Methods for Basic Properties of Building Mortar" (JGJ/T 70–2009), the curing temperature is strictly controlled within the range of 20–30℃. This temperature range can not only ensure the full hydration reaction of magnesium oxysulfide cementitious materials, but also avoid the rapid early hydration caused by excessive temperature, resulting in internal structural defects. At the same time, it avoids the problems of a significant slowdown in reaction rate and insufficient crystallization of hydration products in low-temperature (below 5 ℃) environments17. Maintenance is a key stage in the development of MOS adhesive properties, mainly including initial and post maintenance. The initial maintenance is to ensure the initial curing of MOS adhesive and prevent surface cracking, with a duration of 0–24 h. Post maintenance is to promote the full hydration of MOS adhesive, improve strength and durability, and lasts for 1–28 days. The strength of MOS adhesive is tested according to the “Test method for strength of hydraulic cement mortar (ISO method)” (GB/T 17,671–1999)18. The testing equipment is the YAW-300C microcomputer controlled fully automatic cement compression and bending testing machine. The maximum test force of the YAW-300C microcomputer controlled fully automatic cement compression and bending testing machine is 300kN for compression and 10kN for bending, with a test force accuracy of ± 1%, a test force resolution of 1/300,000, a compression loading rate range of 0.1kN/s-10kN/s, and a bending loading rate range of 0.01kN/s-1kN/s19. Bending strength, namely flexural strength, refers to the ability of a material to resist damage under bending force. The bending strength is shown in Eq. (2).

In Eq. (2), \(P\) represents the failure load. \(L\) represents the spacing between the supporting rollers. \(b\) represents the specimen width. \(h\) represents the specimen height. Compressive strength signifies the ability of a material to resist damage under compressive force, usually expressed in terms of the maximum pressure it can withstand per unit area. The compressive strength is shown in Eq. (3).

In Eq. (3), \(P_{\max }\) represents the maximum load at which the specimen fails. \(A\) represents the compressive area of the specimen. The fluidity of MOS adhesive material reflects the fluidity and operability of MOS slurry during the construction process, directly affecting its construction performance and the quality of the final product20. The flow performance of adhesives refers to the flow performance of adhesives on surfaces under certain conditions. Adhesives with good fluidity can form a uniform coating on the bonding surface, thereby enhancing the bonding strength, sealing performance and water resistance. The fluidity of MOS adhesive materials is determined using the cement mortar fluidity measurement method (GB/T 2419-2005). The X-ray diffractometer is applied to determine the mineral composition of MOS adhesive materials21. The equipment adopts the D8 ADVANCE X-ray diffractometer of the D8 diffractometer series platform to test and analyze MOS adhesive powder samples. Energy Dispersive Spectroscopy (EDS) is a type of microbeam analysis that determines the types and contents of elements in a sample by measuring the X-ray energy generated by the interaction between an electron beam and the sample. The study uses EDS to quickly analyze the main elements and other possible impurity elements in MOS adhesive materials. The EDS analysis chart of MOS adhesive materials is shown in Fig. 3.

In Fig. 3, by detecting the characteristic X-rays emitted by the material after excitation, EDS can accurately identify and determine various elements present in the adhesive, including O, Mg, Si, S, Ca, and Fe. Thermogravimetric analysis explores the thermal stability and compositional changes of materials. By conducting thermogravimetric analysis on MOS adhesive materials, the mass changes at different temperatures can be analyzed, revealing the hydration products, decomposition processes, and thermal stability of the materials22. The MOS adhesive material is ground into fine powder, and 10 mg of the sample is taken and placed in the sample tray of the thermogravimetric analyzer. The heating rate is set to 10 ℃/min and the temperature is adjusted to room temperature -1000 ℃. The thermogravimetric analysis instrument is started and the curve of sample mass variation with temperature is recorded. The thermogravimetric diagram of the MOS adhesive material are shown in Fig. 4.

In Fig. 4, the TG curve decreases in a stepped manner, with each step corresponding to a quality loss stage. The peak of the DTG curve corresponds to the maximum quality loss rate of each stage. After heating to 1000 ℃, the total mass of MOS adhesive material decreases by 25.36%, and the remaining mass accounts for 74.61% of the total mass. The excellent high-temperature quality retention characteristics of MOS adhesives stem from their unique chemical composition and thermal decomposition mechanism. Its main hydration products, phases 5·1·7, exhibit phased changes during the heating process: crystalline water is lost in the range of 100–200 ℃, and decomposes into MgO and MgSO4 at 300–500 ℃, with significant mass loss occurring at this stage. However, the residual MgO after decomposition and the incompletely decomposed MgSO4 interact with the light-burned MgO and inert mineral admixtures that do not participate in the hydration reaction in the system to form a high-temperature resistant framework structure with Mg–O and S–O chemical bonds as the core. This high-temperature resistant skeleton structure interweaves with each other at high temperatures, eventually forming a dense MgSO4 composite ceramicized residue, effectively resisting high-temperature impacts. Compared with the mass loss of over 50% of traditional silicate adhesives at 800 ℃, MOS adhesives can still retain 74.61% of the initial mass after a high temperature of 1000 ℃. X-ray diffraction analysis confirmed that the residual substances were composite ceramic phases with strong heat resistance. It fully demonstrates the outstanding thermal stability advantage of this material in maintaining structural integrity under extreme high temperatures.

Adhesive shear strength of glued bamboo based on MOS adhesive

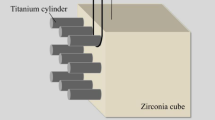

When MOS adhesive is used to bond glued bamboo, its adhesive shear strength is an important indicator for evaluating the bonding resistance. Therefore, the study analyzes the adhesive shear strength of MOS adhesive glued bamboo. Shear strength is the ability to resist damage under shear force, reflecting its ability to resist shear deformation and failure23. The adhesive shear strength of MOS adhesive glued bamboo refers to the GB/T 7124-2008 standard, which specifies the method for determining the tensile shear strength of adhesives and is suitable for testing the adhesion of rigid materials to rigid materials24. Cut the bamboo into standard specimens of 100 mm × 22 mm × 5.5 mm and carry out surface treatment. The surface treatment is carried out by a three-step method of mechanical grinding, chemical cleaning and interface activation. The bonding surface of bamboo was mechanically ground using 240-mesh sandpaper to remove the dense waxy layer and oxide film on the surface, forming a microscopic groove structure conducive to the penetration of the adhesive. The specimens were immersed in a 5% sodium hydroxide solution for ultrasonic cleaning for 15 min to dissolve weak interface layer substances such as lignin and hemicellulose, and at the same time neutralize the surface acidic groups to make the surface potential more suitable for the alkaline environment of MOS adhesives. Rinse repeatedly with deionized water and dry in a 60℃ drying oven for 2 h. After the surface moisture content drops to 8%-12%, immediately apply MOS adhesive. The prepared MOS adhesive was applied to the surface of the bamboo, overlapped by 20 mm, pressed and fixed, and cured for 28 days. The size and shear strength test of glued bamboo specimens based on MOS adhesive is shown in Fig. 5.

As shown in Fig. 5, during testing, the glued specimen is installed in the fixture of the testing machine to ensure uniform force distribution. The shear force is applied at a constant loading rate of 2 mm/min until the specimen fails. Finally, the failure load is recorded and the shear strength is calculated. The adhesive shear strength \(\chi\) of glued bamboo based on MOS adhesive is shown in Eq. (4).

In Eq. (4), \(F_{\max }\) represents the failure load. \(l\) represents the length of the bonding surface. In order to obtain more reliable experimental results, the average shear strength of multiple glued bamboo specimens based on MOS adhesive is adopted, as shown in Eq. (5).

In Eq. (5), \(n\) signifies the number of glued bamboo specimens based on MOS adhesive. \(\chi_{i}\) represents the shear strength of the \(i\)-th specimen.

Bending resistance of glued bamboo based on MOS adhesive

Traditional organic adhesives suffer from poor fire resistance and durability in application, while MOS adhesives, as an inorganic cementitious material, have excellent characteristics of green environmental protection, durability, and fire resistance25. This study evaluates the practical performance of MOS adhesive in glued bamboo by examining its bending resistance. The bending resistance directly reflects the stiffness, strength, and toughness of glued bamboo, which is of great significance for its application in fields such as construction, furniture, and decoration26. The bending resistance is usually characterized by bending strength and elastic modulus. Bending strength refers to the maximum bending stress that a material can withstand before bending failure, while elastic modulus refers to the ratio of stress to strain during the elastic deformation. The bending strength is shown in Eq. (6).

The elastic modulus is shown in Eq. (7).

In Eq. (7), \(\Delta \delta\) represents the incremental deflection. The mid span deflection \(\delta\) refers to the maximum vertical displacement that occurs at the mid span position of the specimen under load, as shown in Eq. (8).

In Eq. (8), \(z\) represents uniformly distributed load. \(l\) represents the span of the beam. \(I\) represents the moment of inertia of the cross-section. According to the principle of equivalent bending moment at mid span, the concentrated load \(T\) can be converted into a uniformly distributed load \(z\). The calculation for converting concentrated load into uniformly distributed load is shown in Eq. (9).

The bending stress is based on the normal stress generated along the height direction of the material cross-section of glued bamboo using MOS adhesive under bending load. It reflects the ability to resist bending deformation, as presented in Eq. (10).

In Eq. (10), \(M\) represents the bending moment. \(y\) represents the distance from the neutral axis to the outermost edge of the cross-section. Tensile stress refers to the force per unit cross-sectional area that glued bamboo based on MOS adhesive is subjected to when subjected to tensile force. When MOS adhesive based glued bamboo is subjected to tensile force, internal stress is generated to resist deformation, which is called tensile stress. Tensile stress is the stress of a material in a tensile state, as presented in Eq. (11).

In Eq. (11), \(S\) signifies the cross-sectional area. \(F^{^{\prime\prime}}\) represents tensile force. For specimens controlled by the tensile strength of glued bamboo, the ultimate bearing capacity \(q_{u}\) is shown in Eq. (12).

In Eq. (12), \(f_{m}\) signifies the design value of the bending strength of laminated bamboo. \(f_{n}\) represents the design value of tensile strength for laminated bamboo. For specimens controlled by the shear strength of end connectors, the ultimate bearing capacity \(q_{u}\) is shown in Eq. (13).

In Eq. (13), \(F_{\max }{\prime}\) represents the maximum load-bearing capacity of the connector. \(s\) represents the spacing between connectors. \(a_{c}\) represents the geometric parameters of the connector. \(A_{c}\) represents the cross-sectional area of the connector. \(E_{c}\) represents the elastic modulus of the connecting component. \(\gamma_{c}\) represents the safety factor of the connector. The bending resistance test usually adopts three-point bending or four-point bending test methods, and analyzes its ultimate bearing capacity, bending strength, and elastic modulus through the loading-deflection curve. The bending strength test diagram is shown in Fig. 6.

As shown in Fig. 6, the study places the glued bamboo specimen based on MOS adhesive on the support roller of the testing machine, ensuring that the center of the specimen is aligned with the loading roller. A load at a constant loading rate of 2 mm/min is adopted until the specimen fractures. The destructive load and deflection is recorded, the bending strength and elastic modulus are calculated. To comprehensively assess the mechanical properties of MOS adhesive materials in practical use environments, especially their performance in humid or water environments, water resistance tests are conducted. The water resistance of MOS adhesive materials is usually measured by the softening coefficient, which is the ratio of the unconfined compressive strength in the water saturated state to the unconfined compressive strength in the dry state, as presented in Eq. (14).

In Eq. (14), \(f\) represents the unconfined compressive strength of MOS adhesive material in a water saturated state. \(F{\prime}\) represents the unconfined compressive strength of MOS adhesive material in a dry state. To assess the quality changes of materials in high-temperature environments and their impact on performance, the quality loss analysis is conducted to reveal the mechanism of high-temperature performance degradation, and guide material optimization and application. The quality loss rate of glued bamboo specimens based on MOS adhesive is shown in Eq. (15).

In Eq. (15), \(Q_{1}\) represents the absolute dry mass of glued bamboo specimens based on MOS adhesive before testing. \(Q_{2}\) represents the dry mass of glued bamboo specimens based on MOS adhesive after testing.

Results

Adhesion shear strength testing of glued bamboo based on MOS adhesive

The research selected bamboo materials with a size of 2150 mm × 22 mm × 5.5 mm for the experiment, and carried out mechanical property tests in accordance with "Test Method for Flexural Strength of Wood" (GB/T 1936.1–2009). The flexural strength test adopts the three-point bending method. The span of the specimen is set at 1800 mm, and the specimen is subjected to pure bending load through uniform loading. The compressive strength test adopts the axial compression method. The specimen is vertically placed at the center of the upper and lower pressure plates of the press and uniformly loaded at a rate of 1.5kN/min until obvious failure occurs in the specimen. After testing, the average flexural strength of bamboo is 68 MPa and the compressive strength is 154 MPa. Eight types of MOS adhesive materials are used, as presented in Table 2.

According to Table 2, the performance parameters of MOS adhesives numbered A-H were different, with H having the lowest fluidity and C having the highest fluidity of 220. Under 7-day maintenance, the bending strength and compressive strength of number H were the highest, at 8.0 and 41.9, respectively, while number A was the lowest, at 0.7 and 13.0, respectively. Under 28 days of curing, the bending strength and compressive strength of number H were the highest, at 9.7 and 51.9, respectively, while number A was the lowest, at 1.5 and 17.6, respectively. Compared with traditional wood adhesives and related materials, MOS adhesives demonstrate unique performance advantages. Take the commonly used urea–formaldehyde resin adhesive as an example. Its 28-day flexural strength is usually between 5 and 7 MPa, and the compressive strength is approximately 30 to 35 MPa. The MOS adhesive numbered H significantly outperforms these values in both flexural and compressive strength. Compared with the common epoxy resin adhesives in the construction field, the compressive strength of MOS adhesive numbered H is comparable, and its flexural strength performance is close. Traditional wood adhesives often contain harmful substances such as formaldehyde, while MOS adhesives, as inorganic cementitious materials, have obvious advantages in terms of environmental protection. In the application of bamboo bonding, the high strength characteristics of MOS adhesives not only enhance the mechanical properties of bamboo structures, but also their environmental protection attributes align with the development trend of green buildings, demonstrating excellent application potential and competitiveness. The comparative results of the adhesive shear strength of the above eight MOS adhesive materials are shown in Fig. 7.

Figure 7a shows the adhesive shear strength test of different performance MOS adhesive glued bamboo under 7-day curing. Figure 7a illustrates the adhesive shear strength of different MOS adhesives after 7-day curing. The MOS adhesive labeled H achieved the highest shear strength of 1.05 MPa when bonding bamboo, while adhesive B exhibited the lowest at 0.52 MPa. When using MOS adhesive material numbered B to bond bamboo, the adhesive shear strength of the glued bamboo bonding surface was the lowest, at 0.52 MPa. Figure 7b shows the adhesive shear strength test of different performance MOS adhesive glued bamboo under 28 day curing. From Fig. 7b, during 28 day curing, when using MOS adhesive material with the same number H to bond bamboo, the adhesive shear strength of the glued bamboo bonding surface was the highest, which was 1.46 MPa. When using MOS adhesive material with the number A to bond bamboo, the adhesive shear strength of the glued bamboo bonding surface was the lowest, which was 0.82 MPa. Overall, with the increase of maintenance time, the shear strength of the bonding surface of most MOS cementitious materials to bamboo also increases, except for numbers A and D. The adhesive shear strength of different performance MOS adhesives on laminated wood and laminated bamboo is shown in Fig. 8.

According to Fig. 8, the adhesive shear strength of different performance MOS adhesives on laminated wood ranged from 9.22 to 9.78, with an average value of 9.54. The adhesive shear strength of different performance MOS adhesives on glued bamboo ranged from 9.49 to 9.80, with an average value of 9.64. The average value of glued bamboo is higher than that of glued wood, indicating that glued bamboo has better performance in this performance index. It is suitable for replacing traditional glued wood in certain engineering or construction applications. The high performance of glued bamboo may be related to the optimized MOS adhesive and the mechanical properties of bamboo itself. Overall, glued bamboo has demonstrated excellent performance potential and is worthy of further optimization and promotion. The shear strength of MOS adhesive glued bamboo material under different degrees of damage is shown in Fig. 9.

Figure 9a shows the shear strength variation of MOS adhesive glued bamboo material with minor damage. From Fig. 9a, the maximum load value was about 12,500N when the displacement was 0.7. Figure 9b shows the shear strength of MOS adhesive glued bamboo material with medium damage. From Fig. 9b, the maximum load value was about 3,000N when the displacement was 1.1. Figure 9c shows the shear strength of MOS adhesive glued bamboo material with high damage. From Fig. 9c, the maximum load value was about 5,840N when the displacement was 0.8. Figure 9d shows the shear strength variation of MOS adhesive glued bamboo material with super-high damage. From Fig. 9d, the maximum load value was about 6,900N when the displacement was 2.3. The moderate damage shows a lower load capacity in some cases than high damage. This is because specimens with moderate damage are located in the concentrated area of weak interfaces, leading to rapid expansion of local debonding, while specimens with high damage may activate more crystal fiber interlocking points due to a more dispersed damage distribution.

Bending resistance test of glued bamboo based on MOS adhesive

To test the bending resistance of MOS adhesive glued bamboo, MOS adhesive numbered A-H is used as the experimental object to bond two types of glued bamboo, thin and thick. The thickness of thin-curtain glued laminated bamboo is 1–1.2MM, and that of thick-curtain glued laminated bamboo is 4MM. Glued bamboo specimens were prepared in accordance with "Bamboo Laminated Timber for Structural Use" (GB/T 26,899–2020). The experiment followed a completely random design. For each adhesive, there were 100 thin-curtain and 100 thick-curtain specimens respectively, totaling 1,600 specimens, in order to eliminate the material variability error. The statistics of compressive and tensile strength test data are shown in Table 3.

The effect of different types of MOS adhesive on the bending strength of thin and thick curtain glued bamboo is shown in Fig. 10.

Figure 10a shows the bending strength of thin curtain glued bamboo with different performance MOS adhesives. From Fig. 10a, when using MOS adhesive numbered H to bond thin curtain glued bamboo, its bending strength was the highest, at 79.02 MPa. When using MOS adhesive material numbered B to bond thin curtain glued bamboo, its bending strength was the lowest, at 39.96 MPa. Figure 10b shows the bending strength of thick curtain glued bamboo with different performance MOS adhesives. From Fig. 10b, when the MOS adhesive material numbered H was used to bond bamboo, the bonding shear strength of the glued bamboo bonding surface was the highest, at 63.75 MPa. Therefore, in subsequent testing, the study selects the number H with the best performance for testing. In general, although the bending strength of thick curtain glued bamboo is smaller than that of thin curtain glued bamboo, there is little difference between the two, so the thickness of bamboo curtain has little influence on the bending strength of MOS glued bamboo composite material. To verify the effect of temperature on MOS adhesive glued bamboo materials, bending load tests are conducted at different temperatures of 20 °C, 50 °C, 100 °C, 150 °C, 200 °C, and 250 °C. The test results are shown in Fig. 11.

In Fig. 11, At 20 °C, the flexural load of the bamboo material bonded by the adhesive reaches its peak at a displacement of approximately 5 mm, which is approximately 1400N. At 250 °C, the flexural load of the bamboo material bonded by the adhesive reaches its peak at a displacement of approximately 2.5 mm, which is about 600N. After that, the load decreases rapidly and the curve tends to be stable. After that, the load rapidly decreased and the curve tended to stabilize. Overall, as the temperature increases, the peak load of MOS adhesive glued bamboo material bending specimens gradually decreases. This indicates that temperature has obvious impacts on the mechanical properties, and high-temperature treatment may lead to a decrease in material strength after treatment at 250 °C. The peak load of the specimens is below that of specimens treated at other temperatures, indicating more significant performance degradation. The failure curve of the bending strength test of MOS adhesive glued bamboo is shown in Fig. 12.

Figure 12a shows the bending strength test of MOS adhesive glued bamboo before damage. From Fig. 12a, at a displacement of about 10 mm, the force reached a peak of about 800N. Subsequently, the force rapidly decreased, dropping to approximately 300N at a displacement of about 20 mm. Afterwards, the force remained relatively stable until the displacement reached about 60 mm, and the force maintained at around 400N. At this point, the self-healing ability of micro-cracks of the MOS adhesive and the frictional energy dissipation caused by the tearing of bamboo fibers form a mechanical behavior of cracking but not breaking, reflecting the ductile failure characteristics of the material. Figure 12b shows the bending strength test of MOS adhesive glued bamboo after damage. From Fig. 12b, at a displacement of approximately 8 mm, the force reached about 80N, at which point the MOS adhesive bonded the bamboo was destroyed. It can be known through microstructure analysis that the generation of the lower peak load is mainly attributed to the weak connection characteristics at the interface between the MOS adhesive and the bamboo. During the curing process of MOS adhesive, the hydration products have a relatively weak chemical bond interaction with cellulose and hemicellulose on the surface of bamboo, resulting in insufficient interfacial bonding strength and easy interfacial debonding under load. Meanwhile, the inherent defects of bamboo such as natural knots and uneven textures cause stress to concentrate in local areas, accelerating the initiation and expansion of cracks. When the displacement reaches 8 mm, the rapid penetration of interfacial debonding and internal microcracks in the bamboo material causes the material to lose its load-bearing capacity, resulting in a relatively low peak load. To test the effectiveness of MOS adhesive in glued bamboo, it was soaked in clean water for one year, that is, 360 days. The bending strength change of MOS adhesive glued bamboo under water immersion is shown in Fig. 13.

Figure 13a displays the bending strength of MOS adhesive glued bamboo under water immersion. In Fig. 13a, with the increase of water immersion days, the bending strength of MOS adhesive glued bamboo fluctuated up and down. The bending strength of MOS adhesive glued bamboo without water immersion was about 69 MPa. After soaking in clear water for 360 days, the strength decreased from 69 to 58 MPa. This is because the clear water seeped into the pores of the MOS adhesive bonding bamboo interface, carrying impurity ions that reacted with the MOS hydration products to form low-strength substances, filling the pores and reducing the structural density, thereby weakening the load-bearing capacity. Figure 13b displays the softening coefficient of MOS adhesive glued bamboo under water immersion. From Fig. 13b, the bending softening coefficient of MOS adhesive glued bamboo before immersion was about 1.0. As the days of water immersion increased, the bending softening coefficient of MOS adhesive glued bamboo changed significantly. After soaking in water for one day, the bending softening coefficient of MOS adhesive glued bamboo dropped sharply to 0.82. On the seventh day, the bending softening coefficient of MOS adhesive glued bamboo increased to 0.84. After 360 days of immersion, the bending softening coefficient of MOS adhesive glued bamboo finally reached 0.79.

Discussion and conclusion

Discussion

MOS adhesive glued bamboo is a composite material that combines the natural characteristics of bamboo with the excellent performance of MOS adhesive, which has shown wide application prospects in many fields such as construction and furniture. Adhesive shear strength and bending resistance are key indicators for evaluating the performance of glued bamboo. The study delved into the performance of MOS adhesive glued bamboo in these two aspects, providing theoretical basis for related research fields.

The adhesive shear strength of glued bamboo based on MOS adhesive showed that with the increase of curing time, the adhesive shear strength of most MOS adhesives significantly improved. The increase in shear strength is mainly attributed to the continuous hydration reaction of MOS adhesive during the curing process, which forms more 5·1·7 phase needle like crystals and enhances the interfacial bonding strength. This finding coincides with the research results drawn by H. Du et al., who pointed out that the hydration reaction of MOS adhesive continued to generate stable hydration products during the curing process, thereby improving the mechanical properties27. During the formation process of the hydration products of traditional adhesives, factors such as reaction rate and raw material distribution often lead to internal structural inhomogeneity, such as the presence of numerous pores and weak interfaces. During the growth process of 5·1·7 phase needle-rod crystals, they can interweave and interpenetrate with each other, forming a relatively dense spatial network structure28. When MOS adhesive is used for bamboo bonding, this dense crystal network structure not only enhances the adhesive’s own cohesion but also forms a closer mechanical meshing and chemical adsorption with the bamboo surface, thereby significantly improving the interfacial bonding strength. The adhesion shear strength of MOS adhesives numbered A and D did not significantly improve after 28 days of curing, and even slightly decreased. This is because although excessive water can improve the fluidity of construction, it will dilute the concentration of reactants, slow down the hydration reaction rate of MgO and MgSO4, and result in insufficient generation of the hydration product phase 5·1·7. In addition, after water evaporation, a large number of pores are left in the colloid, which has a serious negative impact on the microstructure and mechanical properties of the adhesive. From the perspective of microstructure, these pores become stress concentration points during the curing process of the adhesive. When subjected to external forces, stress will concentrate around the pores, resulting in local stress being much higher than the average stress level of the material. K. V. Balaji et al. also showed that the fluidity and compressive strength of materials had a significant impact on their interfacial bonding performance. Excessive fluidity or insufficient compressive strength could lead to uneven internal structure of materials, thereby reducing their mechanical properties29. Fluidity is an important performance parameter of MOS adhesive, which directly affects its spreading and permeability on the surface of bamboo. MOS adhesive numbered C and H with moderate fluidity exhibited higher adhesive shear strength. The adhesive shear strength of numbered A with lower fluidity under the same conditions was only 0.82 MPa. From the perspective of the internal structure of the material, adhesives with excessively high fluidity tend to form a large number of interconnected pores and weak areas internally during the curing process due to water evaporation, which intensifies the stress concentration phenomenon. When subjected to bending loads, these pores and weak areas become the starting points for crack initiation and propagation, greatly weakening the bending resistance of the material. However, adhesives with too low fluidity are difficult to fully penetrate into the pores of bamboo materials and cannot form a firm mechanical interlocking and chemical adsorption with bamboo fibers, which reduces the interfacial bonding strength. Under the action of bending stress, they are prone to interfacial peeling failure, which also leads to a decrease in bending strength. The research drawn by W. M. Shi et al. also supports this viewpoint. When optimizing high-temperature resistant surface materials through multi-source data mining, they found that the fluidity of the material had a significant impact on its interfacial bonding performance. Moderate fluidity can optimzie the mechanical properties30. The study also compared the adhesive shear strength of MOS adhesive in glued bamboo and glued wood. The average adhesive shear strength of glued bamboo exceeded that of glued wood, demosntrating that the application of MOS adhesive in glued bamboo has significant advantages, which may be related to the fiber structure and surface characteristics of bamboo31.

The test results of the bending resistance of glued bamboo based on MOS adhesive showed that different performance MOS adhesives had obvious impacts on the bending strength of glued bamboo. The MOS adhesive with the number H exhibited the highest bending strength in thin curtain glued bamboo, while the MOS adhesive with the number B had the lowest bending strength in thin curtain glued bamboo. This difference is mainly attributed to the differences in performance parameters such as fluidity, bending strength, and compressive strength of the MOS adhesive. The MOS adhesive with moderate fluidity, numbered H, can better penetrate the pores of bamboo, form uniform interface bonding, and thus improve bending strength. Boonrit et al. obtained that the morphology and distribution of hydration products in MOS adhesive had a significant impact on its mechanical properties. MOS adhesive with moderate fluidity can promote the uniform distribution of hydration products, improving the bending strength32. The MOS adhesive with high bending and compressive strength, numbered H, has better internal structural stability and can effectively resist bending loads. The study drawn by S. A. N. Alireza et al. also pointed out that the compressive strength of MOS adhesive was closely related to the stability and interfacial bonding ability of its hydration products33. Through the failure curve of the bending strength test, it was found that MOS adhesive glued bamboo exhibited certain ductile failure characteristics. At 20 °C, the specimen reached its peak load at a displacement of approximately 10 mm, followed by a gradual decrease in load and a stabilization at a displacement of approximately 60 mm. This ductile failure mode indicates that MOS adhesive glued bamboo has good energy absorption capacity and bending resistance, making it suitable for engineering applications that require high toughness. The study drawn by Z. Yao et al. also suggested that the ductile failure mode of materials was closely related to their interfacial bonding strength and fiber distribution34.

In summary, significant progress has been made in the performance optimization of MOS adhesive, the influence of fluidity on interface bonding, systematic research on bending resistance, analysis of ductile failure modes, and sustainability of green materials, providing new theoretical support for the research and application of glued bamboo.

Conclusion

The study analyzed and explored the effects of different performance MOS adhesive agents on the adhesive shear strength and bending resistance of glued bamboo through systematic experiments. In the adhesion shear strength test of glued bamboo based on MOS adhesive, MOS adhesive with different properties had obvious impacts on the adhesion shear strength. The adhesion shear strength of MOS adhesive with the number H was the highest at 1.46 MPa after 28 days of curing, while the adhesion shear strength of MOS adhesive with the number A was the lowest at 0.82 MPa, indicating that MOS adhesive with moderate fluidity, high bending strength, and compressive strength could better penetrate bamboo pores, form uniform interface bonding, and thus improve adhesion shear strength. In the bending resistance test of glued bamboo based on MOS adhesive, it was found that MOS adhesive with the number H exhibited the highest bending strength in thin curtain glued bamboo, at 79.02 MPa, while MOS adhesive with the number B had the lowest bending strength, at 39.96 MPa. This indicates that MOS adhesive with high bending and compressive strength has better internal structural stability and can effectively resist bending loads. In conclusion, the MOS adhesive bonded bamboo shows certain ductile failure characteristics, has good energy absorption capacity and bending resistance performance, and has dual value for practical applications. In the field of architecture, high-performance MOS adhesives can significantly enhance the load-bearing capacity and durability of bamboo structures, facilitating the expansion of bamboo from simple components to high-rise and large-span building systems. In decoration and Marine engineering, its environmental protection features and water resistance can effectively replace traditional organic adhesives, reducing environmental risks and maintenance costs. Future research can be deepened and expanded in three aspects. First, by adding functional additives, such as nano-silica and organic polymers, the hydration kinetics and microstructure of MOS binders can be optimized. Secondly, explore the influence of new curing conditions on the performance of adhesives, shorten the curing cycle and improve the internal pore structure; Thirdly, conduct long-term performance research in complex environments, establish a material performance attenuation model, and provide data support for engineering design. The above research directions will promote the standardized application of MOS adhesives in green buildings, Marine infrastructure and other fields, and help achieve the low-carbon transformation and sustainable development goals of the construction industry.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Elmoghazy, Y. et al. Effective mechanical properties evaluation of unidirectional and bidirectional composites using virtual domain approach at microscale. Arch. Adv. Eng. Sci. 1(1), 27–37 (2023).

Zhang, N., Yu, H., Ma, H., Ba, M. & Ma, H. Effects of compound mineral admixtures on the properties of magnesium oxysulfate cement. Adv. Cem. Res. 34(12), 560–573. https://doi.org/10.1680/jadcr.22.00006 (2022).

Zeng, X. & Yu, H. Research on technology of performance improvement of basic magnesium sulfate cement-BMS. Struct. Concr. 24(3), 4313–4321. https://doi.org/10.1002/suco.202000165 (2023).

Tian, R., Sun, Q., Han, X., Jin, C. & Liu, J. Effects of titanium carbide on modified magnesium oxysulfate cement: Microstructure and mechanical properties. Ceram. Int. 51(3), 3320–3342. https://doi.org/10.1016/j.ceramint.2024.11.310 (2025).

Sun, Y. et al. Preparation of magnesium oxysulfate cement with significantly improved setting rate and compressive strength using highly active magnesium oxide powders. Ceram. Int. 50(22), 46440–46451. https://doi.org/10.1016/j.ceramint.2024.08.488 (2024).

Yan, L., Pang, S., Dong, H., Zheng, X. & An, Y. Magnesium oxychloride and magnesium oxysulfate cements as temporary plugging agents in geothermal drilling. ACS Omega 9(2), 2696–2706. https://doi.org/10.1021/acsomega.3c07654 (2023).

Li, W. Y., Zhou, J. B., Zhang, Z. Y. & Zhu, X. X. Study on preparation and properties of red mud magnesium oxysulfate cement foamed concrete. Bull. Environ. Contam. Toxicol. 109(1), 130–134. https://doi.org/10.1007/s00128-022-03521-7 (2022).

Wen, J., Sui, H., Jiang, T., Li, L. & An, X. High-value utilization of boron mud waste: Preparation of magnesium oxysulfate cement after primary blank roasting and secondary (NH4)2SO4 roasting. Process Safe. Environ. Protect. 1(188), 1376–1384. https://doi.org/10.1016/j.psep.2024.05.155 (2024).

Meenakshi, M. Effect of epsom salt concentration and dry-mix composition on bonding properties of magnesium oxysulfate. Asian J Chem 35(4), 869–876. https://doi.org/10.14233/ajchem.2023.26992 (2023).

Hu, J., Wang, Y., Zhang, S., Chang, T. & Sun, L. Preparation, classification, hydration mechanism and durability of magnesium-based cementing material. J. Mining Sci. Technol. 8(6), 856–867 (2023).

Liu, J., Cui, B. & Pang, B. Preparation and properties of magnesium oxysulfide cement based foam board absorbing material. J. Wuhan Univ. Technol. Mater. Sci. Ed. 39(1), 118–125. https://doi.org/10.1007/s11595-024-2862-1 (2024).

Ning, X., Zhang, Y. & Wu, C. Effects of calcium impurities on the properties of magnesium oxychloride cement. Adv. Cement Res. 36(3), 94–104. https://doi.org/10.1680/jadcr.23.00182 (2023).

Wang, N. et al. Hydration and improved properties of magnesium oxysulfate cement modified by phosphoric acid. Adv. Cem. Res. 34(1), 36–44. https://doi.org/10.1680/jadcr.20.00050 (2022).

Bernard, E. et al. MgO-based cements—Current status and opportunities. RILEM Tech. Lett. 16(8), 65–78 (2023).

Wang, L. et al. Introducing reactive magnesia to activate chloride/sulfate in waste incinerator fly ash for immobilization of potentially toxic elements. ACS Sustain. Chem. Eng. 12(26), 9602–9611. https://doi.org/10.1021/acssuschemeng.4c00522 (2024).

Azevedo, A. G. S. et al. Effect of the rehydration method on the physical-mechanical properties of CO2-cured magnesium-based fiber cement boards. CivilEng 5(1), 247–264. https://doi.org/10.3390/civileng5010013 (2024).

Liu, X., Wen, J. & Chang, C. Effects of calcination process of salt lake magnesium slag on the properties of magnesium oxysulfide cement. Adv. Cem. Res. 34(5), 225–234. https://doi.org/10.1680/jadcr.21.00145 (2022).

Chen, M. et al. Corrosion behavior of steel bar in magnesium oxysulfide cement-based materials: The role of chloride and nitrite. J. Mater. Res. Technol. 32, 1577–1588. https://doi.org/10.1016/j.jmrt.2024.08.020 (2024).

Cui, B., Guan, Y. & Bi, W. Non-isothermal kinetic analysis on the thermal decomposition of the phase 517 from hydration product of magnesium sulfide cement. J. Wuhan Univ. Technol. Mater. Sci. 38(2), 374–380 (2023).

Xu, X. et al. Investigation on water resistance of basic magnesium sulfate cement containing weak organic acids. Adv. Cem. Res. 35(10), 466–479. https://doi.org/10.1680/jadcr.22.00192 (2023).

Azevedo, A. G. S. et al. Assessment of the physical-mechanical performance of magnesium oxide-based fiber cement submitted to accelerated carbonation. Cerâmica 69(392), 312–317. https://doi.org/10.1590/0366-69132024703923500 (2024).

Santos, H. S. et al. Effect of ammonium sulfate on the precipitation mechanism of Mg carbonates. Cryst. Growth Des. 24(17), 7044–7058. https://doi.org/10.1021/acs.cgd.4c00700 (2024).

Ke, D. I. & Yanluo, X. I. Adaptability of burgers rheological model and its improved model to the creep properties of glue laminated bamboo. Mechanics. 30(3), 214–220. https://doi.org/10.5755/j02.mech.35600 (2024).

Gao, X. & Li, Q. Carbon dioxide sequestration on magnesium-based binders. Carbon Dioxide Sequestrat. Cementitious Constr. Mater. https://doi.org/10.1016/B978-0-443-13577-4.00014-4 (2024).

Nguyen, V. L. et al. Wafer-scale integration of transition metal dichalcogenide field-effect transistors using adhesion lithography. Nat. Electron. 6(2), 146–153. https://doi.org/10.1038/s41928-022-00890-z (2023).

Zhou, G. & Leung Su, R. K. A review on serviceability of foam concrete. Proc. Inst. Civil Eng. Constr. Mater. 177(6), 381–392. https://doi.org/10.1680/jcoma.24.00004 (2024).

Du, H., Li, J., Ni, W., Hou, C. & Liu, W. The hydration mechanism of magnesium oxysulfate cement prepared by magnesium desulfurization byproducts. J. Mater. Res. Technol. 17, 1211–1220. https://doi.org/10.1016/j.jmrt.2022.01.070 (2022).

Toom, S. R. et al. Nanoscale adhesion and material transfer at 2D MoS2-MoS2 interfaces elucidated by in situ transmission electron microscopy and atomistic simulations. ACS Appl. Mater. Interfaces 16(23), 30506–30520. https://doi.org/10.1021/acsami.4c03208 (2024).

Balaji, K. V. et al. Hybrid heterophasic polypropylene composites with basalt fibers and Magnesium oxysulfate reinforcements for sustainable automotive materials. J. Mater. Res. Technol. 28, 546–559. https://doi.org/10.1016/j.jmrt.2023.12.043 (2024).

Shi, W. M. Research on optimization modeling of high temperature resistant surface materials based on multi-source data mining. Int. Conf. Soc. Comput. Dig. Econ. ICSCDE https://doi.org/10.1109/ICSCDE54196.2021.00068 (2021).

Du, H. et al. Effects of steel slag on the properties and microstructure of magnesium oxysulfate cement prepared by magnesium desulfurization byproducts. J. Mater. Res. Technol. 30, 3200–3212. https://doi.org/10.1016/j.jmrt.2024.04.070 (2024).

Boonrit, T., Yang, M. & Chen, G. Effects of the properties of Mg(OH)₂ precursor on the hydrothermal synthesis of magnesium oxysulfate whiskers. Particuology 92, 13–23. https://doi.org/10.1016/j.partic.2024.04.011 (2024).

Alireza, S. A. N., Negahdar, A., Negahdar, H. & Badakhshan, E. Stabilised sulfate-rich clay with magnesium oxysulfate cement. Geomech. Geoeng. 17(6), 1751–1761. https://doi.org/10.1080/17486025.2021.1975044 (2022).

Yao, Z. et al. Synthesis and characterization of superhydrophobic magnesium oxysulfate whiskers. Particuology 78, 111–121. https://doi.org/10.1016/j.partic.2022.10.001 (2023).

Funding

This work was supported in part by Foreign cooperation project of Fujian Provincial Science and Technology Department, “Study and application of color protection technology of natural safflower yellow pigment” (No.2024I0025).

Author information

Authors and Affiliations

Contributions

X.M.L. processed the numerical attribute linear programming of communication big data, and the mutual information feature quantity of communication big data numerical attribute was extracted by the cloud extended distributed feature fitting method. L.F.Q. and X.M.C. Combined with fuzzy C-means clustering and linear regression analysis, the statistical analysis of big data numerical attribute feature information was carried out, and the associated attribute sample set of communication big data numerical attribute cloud grid distribution was constructed. L.F.Q. and J.F.M. did the experiments, recorded data, and created manuscripts. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, X., Qiu, L., Chen, X. et al. Considering the bonding shear strength and flexural performance of bamboo scrimber bonded with magnesium oxysulfates adhesives of different properties. Sci Rep 15, 25952 (2025). https://doi.org/10.1038/s41598-025-11150-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11150-3