Abstract

This study investigates the machinability of Inconel 718 (IN718) in wire electrical discharge machining (WEDM) using molybdenum wire and demineralized water as the dielectric fluid, aiming to optimize machining efficiency and surface quality. The effects of current, pulse duration (Ton), and pulse interval (Toff) on machining time (MT), material removal rate (MRR), and surface roughness (SR) were analyzed. The overall evaluation criteria (OEC) method was employed to optimize multi-response outputs. Surface morphology was examined through SEM, and elemental analysis was performed using EDS. The results showed that increasing current and Ton enhanced MRR but also led to higher SR due to deeper crater formation. A high Ton combined with insufficient Toff caused process instability, increasing MT and reducing MRR. Conversely, increasing Toff improved surface finish by enhancing debris removal, though excessive Toff slightly reduced MRR. Current was the most influential factor across all responses, as evaluated by ANOVA. Optimal machining conditions, when equal importance was given to efficiency and surface quality in OEC, were identified as 2 A current, 40 µs Ton, and 9 µs Toff. SEM analysis revealed that lower discharge energy produced a uniform recast layer with fewer defects, while higher energy resulted in larger globules, micro-pores, and debris accretion. EDS analysis revealed the presence of carbon, oxygen, and molybdenum on machined surface, indicating element migration and possible formation of secondary phases in the recast layer. These findings offer a practical basis for optimizing machining efficiency and surface quality in WEDM of IN718 for high-performance aerospace and thermal applications.

Similar content being viewed by others

Introduction

Inconel, a nickel-chromium-based super alloy, is extensively utilized in high-performance applications, including jet engine components, gas turbines, heavily loaded rotating components, pumps, nuclear reactors, rocket engines, and high-temperature fasteners and bolts1. Inconel alloys are preferred over titanium-based alloys in high-temperature, high-pressure applications due to their superior strength, corrosion and creep resistance at temperatures up to 1140 °C, and excellent thermomechanical properties2. Inconel alloys like 600, 625, 718, and 825 offer superior strength and work hardening but pose machining challenges due to adhesion to tool materials, work hardening, and retained hardness at high temperatures. The primary challenge with machining Inconel alloys is their low thermal conductivity and high cutting forces, which can lead to elevated cutting temperatures, rapid tool wear, and deterioration of the machined surface characteristics3. Various strategies, such as minimum quantity lubrication (MQL), cryogenic fluids, high-pressure jets, and vegetable oil-based cooling, mitigate conventional machining challenges, while conventional cooling is often avoided due to health risks4. Although MQL, vegetable oils, and cryogenic cooling can mitigate some issues associated with conventional cooling systems, they still lead to increased material hardness and rapid tool wear5. Additionally, when machining Inconel alloys, cutting tools are often replaced before reaching the end of their tool life to avoid surface damage and subsurface deterioration caused by tool wear6. Conventional machining of Inconel is challenging, making non-conventional methods like electrical discharge machining (EDM) and laser cutting preferable for intricate, high-precision parts. These methods prevent direct contact, minimizing tool wear and heat issues, making them ideal for machining Inconel alloys7. While laser cutting improves machining performance, it often creates a heat-affected zone (HAZ), inducing tensile residual stresses that degrade surface integrity and reduce fatigue life8. Laser machining of Inconel alloys typically requires a two-stage process: roughing followed by finishing. A major limitation of laser machining is the depth of the melting zone, which can extend up to 1.4 mm when using a 1000 W laser at a cutting speed of 1000 mm/min9. This significant subsurface damage poses a challenge for the subsequent finishing process, as it can compromise surface integrity.

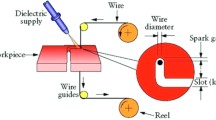

EDM is widely used for high-precision machining of conductive materials, including metals, alloys, composites, and ceramics. Among its techniques, wire electrical discharge machining (WEDM) effectively machines Inconel alloys, ensuring superior performance while considering cost and environmental impact10. Notably, WEDM can cut a wide variety of conductive materials, regardless of hardness, producing intricate shapes11,12. In WEDM, a conductive wire (0.05–0.3 mm diameter) machines tough, electrically conductive materials through thermal erosion13. Similar to die-sinking EDM, WEDM also generates rapid, repetitive electrical sparks between the wire electrode and the workpiece, which locally melt and vaporize both materials. A continuous stream of dielectric fluid, aligned with the wire, cools and clears molten material and debris. Pulsating voltage creates a plasma channel, rapidly melting and vaporizing the tool and work materials14,15. When the power supply stops, the plasma channel collapses, cooling quickly and allowing the fluid to clear debris. The wire, fed under tension without touching the workpiece, maintains a clearance of 0.025–0.05 mm based on machining parameters13. WEDM of Inconel alloys has gained significant attention due to their challenging machinability and critical applications in aerospace and nuclear engineering, necessitating a comprehensive evaluation of process parameters to optimize performance measures such as machining time (MT), material removal rate (MRR), kerf width (KW), and surface roughness (SR). Research indicates that pulse duration (Ton), pulse interval (Toff), current, and spark gap voltage significantly influence WEDM performance, with extensive efforts made to optimize it for MRR, SR, and KW. For instance, Tonday and Tigga16 reported that Ton significantly affects both MT and SR in machining Inconel 718 (IN718). The lowest MT and SR were achieved with the shortest Ton and Toff. Raj et al.17 demonstrated that increasing Ton enhances both MRR and SR, as longer discharge durations facilitate greater material removal per spark due to increased electron activity. However, this often degrades surface quality, as higher energy discharges can create larger craters, which in turn increases SR. In another study on Inconel 603 XL, Manikandan et al.18 found that Ton significantly impacts surface quality. Specifically, as Ton increases from 115 to 130 µs, SR also rises. An optimal Toff of around 50 µs yields better surface characteristics. Furthermore, Newton et al.19 investigated how process parameters affect the formation of recast layers (RL) during the machining of IN718, emphasizing the importance of parameter optimization for improved surface integrity. Burek et al.20 examined the effects of WEDM parameters on IN718 turbine disc slots, achieving a SR of Ra = 0.84 μm and a RL thickness of 5 μm. Optimal parameter control ensured high shape accuracy and minimized defects. Elsewhere, response surface methodology (RSM) has been widely used for parameter optimization, effectively modelling input-output relationships and enabling multi-objective optimization to balance MRR and SR21.

The literature suggests that optimization techniques provide a systematic framework for identifying the most influential WEDM parameters and their interactions, enabling the selection of optimal settings for desired performance in Inconel machining. By carefully balancing process parameters, productivity can be maximized while maintaining high surface integrity. Although a few studies on WEDM of IN718 exist, they primarily focus on maximizing machining efficiency and minimizing SR. However, a comprehensive investigation that correlates machining efficiency with surface quality, while achieving a balance through optimal parameter selection, is lacking. Thus, the present study empirically investigated the machining IN718 to analyze the effects of current, Ton, and Toff on MT, MRR, and SR. Analysis of variance (ANOVA) was employed to assess the significance of the process parameters. The responses were then optimized using a single index called overall evaluation criteria (OEC), with several OECs formulated by assigning different priorities and weightages to the responses. Additionally, the machined surfaces were examined using scanning electron microscopy (SEM) to evaluate their morphological characteristics. This study aims to correlate surface quality (SR and morphology) and machining efficiency (MT and MRR) with process parameters for robust optimization.

Materials and methods

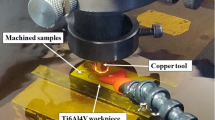

Experiments on machining IN718 were conducted using a WEDM setup (Make: CONCORD Wire EDM; Model: DK7732). A molybdenum wire (ϕ 0.18 mm) was used as the tool electrode and discarded after passing through the workpiece, ensuring fresh wire is introduced for each cut. The workpiece had a thickness of 10 mm, and the length of cut was set at 20 mm to evaluate the parametric effects on the response measures. An image of the workpiece after WEDM experiments is shown in Fig. 1a. The energy dispersive spectroscopy (EDS) spectrum, detailing the weight% and atomic% of the elements, is presented in Fig. 1b. The spectrum reveals peaks corresponding to Ni, Cr, Nb, Ti, and Fe, with weight of 53.12%, 17.97%, 4.49%, 1.79%, and 15.75%, respectively, confirming the material as IN718. Rigorous pilot experiments were conducted to identify suitable ranges for the process parameters. Based on their influence on machining stability and response variation, current, Ton, and Toff were selected as the key parameters. Current was varied at three levels: 2, 3, and 4 A; Ton at four levels: 20, 30, 40, and 50 µs; and Toff at four levels: 9, 10, 11, and 12 µs. The chosen ranges, current (2–4 A), Ton (20–50 µs), and Toff (9–12 µs), ensured stable machining conditions and meaningful response differentiation. Current below 2 A produced weak discharges, insufficient to sustain consistent sparking, resulting in negligible material removal, while values above 4 A led to wire breakage and thermal overloading. Ton below 20 µs caused unstable plasma formation and inconsistent erosion, whereas Ton beyond 50 µs resulted in excessive thermal loading, surface damage, and spark instability. Toff below 9 µs failed to allow proper debris evacuation and dielectric recovery, increasing the risk of short-circuiting and wire rupture; conversely, Toff beyond 12 µs excessively reduced spark frequency, diminishing machining efficiency. The experiments were conducted with straight polarity, using demineralized water as the dielectric medium, which was flushed onto the inter-electrode gap (IEG) during the process. Table 1 lists the experimental conditions, including fixed and process parameters.

MT for each cut was recorded using a stopwatch. After the experiments, the workpiece was examined under an optical microscope (Make: Leica) to measure the KW of each cut. The KW was measured along the length of each cut, and the average value was taken as the final KW. Subsequently, the MRR was calculated as the ratio of the volume of material removed to the MT, as per Eq. (1).

Although MT and MRR are mathematically related, but, both are considered in this study because they capture distinct aspects of WEDM performance. MT reflects the total duration required to complete a cut, which is critical for assessing overall process productivity. In contrast, MRR quantifies the efficiency of material removal per unit time and provides insight into the rate of erosion under specific machining conditions. Evaluating both responses enable a more comprehensive assessment of process behavior, particularly when trade-offs between speed, efficiency, and surface quality must be considered. Subsequently, the machined samples were cut across their cross-section using WEDM for SR analysis and surface characterization. SR was evaluated using a diamond tip stylus profilometer (Make: Tokyo Seimitsu Co. Ltd.) with a radius of 5 μm. The centerline average roughness (Ra) was measured at three random locations on the machined surface, and the average of these Ra values was taken as the final SR. The machined samples were analyzed using SEM for surface characterization.

Results and discussion

In WEDM, current is supplied to the IEG in pulses, where the discharge energy per pulse (DE) is calculated using Eq. (2)22.

where, \(\:{V}_{p}\), \(\:{I}_{p}\), \(\:{T}_{on}\), and \(\:{T}_{off}\) represent the voltage of a single pulse, current of a single pulse, pulse duration, and pulse interval, respectively.

Effect of process parameters on responses

The parametric effects of current, Ton, and Toff on MT, MRR, and SR are shown in Figs. 2 and 3, and 4, respectively. As the current increases from 2 to 4 A, the MT decreases due to the higher DE. This increment in DE intensifies the sparks, which can effectively melt and vaporize larger amounts of the workpiece material in a shorter period, thus, reducing the MT for a given volume of material removal23.

In WEDM, Ton specifies the duration for which the spark is sustained between the two electrodes in each cycle. Short pulses don’t allow the plasma channel to fully develop or stabilize, leading to unstable channels and inconsistent material removal, which increases MT. The DE increases with a rise in Ton, causing intense heat generation within the plasma channel and leading to a localized temperature rise on the machining surface24. Thus, longer pulses (20–50 µs) enable the plasma channel to expand and reach higher energy levels, improving stability and energy density, thereby reducing MT, as displayed in Fig. 2(b–d)25. In WEDM, Toff is the time between successive electrical discharges and is crucial for regulating discharge frequency and the overall machining process26. An increase in Toff reduces the discharge frequency, which leads to longer MT, as illustrated in Fig. 2(a–d). A contrasting characteristic is observed in MT, which increases when using a combination of very high Ton (50 µs) and very low Toff (9 µs), as displayed in Fig. 2a. A longer Ton can cause thermal damage or distortion to the workpiece due to extended heating, requiring slower machining speeds. But a very short Toff may not allow sufficient time to clear debris and molten material from the IEG. This buildup of debris can disrupt the discharge process and affect the servo motion control leading to wire breakage, which ultimately results in lowering machining efficiency and further increasing MT27.

MRR measures the volume of material removed from a workpiece per unit of time, as shown in Eq. (1). In WEDM, evaluating MRR is essential for optimizing efficiency and maintaining process control. According to Eq. (2), DE is directly proportional to the current. As the current increased from 2 to 4 A (Fig. 3(a-d)), MRR also increased due to the higher DE, which resulted in more intense sparks, greater material erosion per pulse, and thus, a higher MRR. Shorter Ton restricts energy transfer, resulting in lower MRR. Extending the Ton from 20 to 50 µs allows more energy per pulse, which enhances material erosion and increases MRR. Additionally, longer Ton cause the plasma channel to expand, leading to larger craters and further increasing MRR. MRR decreases with an increment in Toff (9–12 µs), because the reduced DE leads to a lower discharge frequency, ultimately resulting in lower MRR.

To optimize MRR, the Toff should not be excessively reduced. This interval is crucial for cooling the workpiece and electrode, managing thermal effects, and preventing overheating. It also allows for the removal of eroded material and debris from the IEG, which is essential for maintaining effective discharge conditions. Additionally, the dielectric fluid helps to flush away debris and keep the machining environment clean28. Overall, the Toff plays a key role in thermal management, debris removal, and ensuring the efficiency and stability of the WEDM process. The negative impact of a shorter Toff (9 µs) is evident in Fig. 3a, where MRR decreases as Ton increases from 40 to 50 µs at currents of 2 and 3 A. This is due to unstable discharge conditions caused by ineffective debris flushing from the IEG. Debris accumulation leads to secondary sparking, which increases MT and, ultimately, results in lower MRR. This aligns with the findings of Rajurkar and Wang29and Gostimirovic et al.30who observed that excessive Ton results in energy wastage, thereby reducing machining efficiency.

Evaluating SR after WEDM is essential to ensure part performance, precision, and durability. It helps manufacturers to meet quality standards, reduce post-machining operations, and optimize the part’s service life in demanding applications. The effect of process parameters on SR after WEDM of the Inconel workpiece is shown in Fig. 4a–d. Two sample roughness curves are presented in Fig. 5a, b. The first curve shows the lowest Ra value of 1.36 μm, achieved at the lowest DE setting, while the second curve shows the highest Ra value of 3.91 μm, obtained at the highest DE setting. At a lower current of 2 A, the DE is minimal, resulting in smaller craters and a smoother surface finish with reduced thermal effects and a smaller HAZ25. As the current increases from 2 to 3 A, the DE rises, leading to larger craters and a rougher surface finish due to more aggressive material removal and increased thermal impact31. At a high current of 4 A, the intense discharges create significantly rougher surfaces, with deeper craters and greater surface irregularities. With lower Ton, the craters on the surface are smaller and shallower, which leads to a finer finish32. However, as Ton rises, the craters become larger and deeper, creating a rougher surface. This is because longer Ton allow more heat to melt and remove material, forming broader and deeper craters. Additionally, extended Ton causes more heat to penetrate into the workpiece, increasing the RL thickness and HAZ depth, further deteriorating the surface quality33. Therefore, to achieve better surface finish in WEDM, it is desirable to use shorter Ton, while considering the trade-off with MRR which improves with higher Ton. SR decreases as the Toff increases from 9 to 12 µs. This is due to the extended cooling and flushing at higher Toff, which allows more molten material to be removed from the IEG, leading to a smoother surface finish34.

Analysis of variance

ANOVA is vital for quantifying the impact of factors on a response variable, enabling the identification of significant effects and optimization of process parameters. The ANOVA results at a 95% confidence level for all responses are shown in Table 2. Parameters with a P-value ≤ 0.05 are deemed statistically significant, signifying that these parameters have a substantial effect on the responses35,36. The F-value, which represents the ratio of variance explained by a factor to the variance due to error, indicates the strength of influence. A higher F-value implies that a parameter contributes more dominantly to variations in the response, and thus has greater sensitivity37. The percentage contributions, calculated by dividing the sum of squares (SS) of a factor by the total SS and multiplying by 100, further highlight the relative importance of each parameter in explaining the total variation in the respective responses. This provides a practical basis for prioritizing process control strategies38. For MT, current was the most influential factor, with an F-value of 149.98, a P-value of 0.000, and a contribution of 57.62%, confirming that MT is highly sensitive to variations in current. Similarly, current had the highest F-values for MRR (142.50) and SR (439.60), with corresponding contributions of 51.55% and 80.63%, respectively. Although Ton and Toff were also significant (P ≤ 0.05), their influence was relatively lower, as reflected in their F-values and contributions. The high R2 values across all responses (MT = 92.51%, MRR = 92.95%, and SR = 96.42%) and their respective adjusted R2 values demonstrate strong model fits and predictive accuracy, reinforcing the importance of these parameters in optimizing WEDM process.

Overall evaluation criteria

Roy39 introduced a concept, which involves normalizing individual responses based on their quality characteristics, applying priority weightages, and then aggregating these to derive a single comprehensive index named OEC. The formulated OEC comprising MT, MRR and SR with different priority weightages is represented in Eq. (3).

.

where, \(\:{X}_{i}\), \(\:{Y}_{i}\) and \(\:{Z}_{i}\) represents \(\:{i}^{th}\) experimental values of MT, MRR and SR, respectively. \(\:{W}_{X}\), \(\:{W}_{Y}\) and \(\:{W}_{Z}\) represents weightages assigned to MT, MRR and SR, respectively. \(\:{X}_{max}\), \(\:{Y}_{max}\) and \(\:{Z}_{max}\) denotes the maximum experimental values of MT, MRR and SR, respectively. Similarly, \(\:{X}_{min}\), \(\:{Y}_{min}\) and \(\:{Z}_{min}\) denotes the minimum experimental values of MT, MRR and SR, respectively. The characteristics of the OEC, including the best and worst response values, their quality characteristics, and corresponding weightages, are summarized in Table 3.

In this study, four distinct OEC were developed, as shown in Table 3. OEC 1 assigns equal weightage to all criteria (\(\:{W}_{X}=33\), \(\:{W}_{Y}=33\) and \(\:{W}_{Z}=34\)). OEC 2, however, prioritizes both machining efficiency and surface quality equally. Machining efficiency is indicated by MT and MRR, while surface quality is represented by SR. So, \(\:{W}_{X}=25\), \(\:{W}_{Y}=25\) and \(\:{W}_{Z}=50\) has been taken as the relative weightages of MT, MRR and SR, respectively. As an extension of the optimization framework through OEC 2 where equal emphasis has been laid on machining efficiency and surface quality, OEC 3 and OEC 4 were formulated by assigning equal weightage to MT (\(\:{W}_{X}=50\)) and SR (\(\:{W}_{Z}=50\)) in OEC 3, and to MRR (\(\:{W}_{Y}=50\)) and SR (\(\:{W}_{Z}=50\)) in OEC 4. The rationale behind excluding MRR in OEC 3 and MT in OEC 4 stems from the consideration that both MT and MRR can serve as independent indicators of machining efficiency in WEDM. By focusing exclusively on MT in OEC 3 and on MRR in OEC 4, these criteria aim to balance machining efficiency with surface quality (SR), depending on the priority of the process outcomes. Figure 6a presents the results of OEC obtained using different relative weightages, while Fig. 6b displays the ranking of experimental runs for each OEC. Each OEC demonstrates different trade-offs based on how much weight is assigned to each response, with the best OEC depending on whether the goal is to minimize time, maximize material removal, or improve surface quality.

The mean effect plots for the OEC are displayed in Fig. 7. From these plots, the levels of each process parameter that correspond to the highest OEC are identified as the predicted optimum conditions, based on the mean effects of the parameters. The mean effect plots also demonstrate the influence of each process parameter on the OEC outcomes. Notably, the effect of Toff is particularly prominent, as evidenced by the considerable variation in OEC values with changes in Toff. The optimum condition for OEC 1 was identified as current of 4 A, Ton of 40 µs, and Toff of 9 µs. In contrast, the optimum conditions for OEC 2, 3, and 4 were found to be current of 2 A, Ton of 40 µs, and Toff of 9 µs. The similar outcomes for OEC 2, 3, and 4 can be attributed to the equal emphasis placed on both machining efficiency and surface quality in their respective weightages. The actual optimum conditions for OEC 1, 2, 3, and 4 showed errors of 13.15%, 5.42%, 2.74%, and 0%, respectively, compared to the predicted optimum conditions.

Surface morphology analysis

SEM analysis is performed on samples machined by WEDM to examine surface morphology, identify microstructural changes, detect thermal damage (such as RL, cracks, and pores), and analyze the topography at a high resolution, providing insights into the effects of machining parameters on surface integrity and quality. Figures 8a and b represent SEM images of samples machined at a lower DE setting (current: 2 A, Ton: 20 µs, Toff: 12 µs) and higher DE setting (current: 4 A, Ton: 50 µs, Toff: 10 µs), respectively.

The surface characteristics of IN718 after WEDM are significantly influenced by the DE levels used during machining, which in turn affect the thermal dynamics of the process. At a lower DE setting, features such as smaller globules, a thinner and more uniform RL, and fewer defects like micro-pores and debris clusters occur due to controlled, less aggressive material removal. In WEDM, discharges at around 10,000 °C melt and vaporize conductive materials, but not all molten material is expelled34. Repeated pulses with fixed intervals and a dielectric medium cause molten material to undergo multiple heating and cooling cycles. This results in solidification and forms a RL on the machined surfaces, as shown in Fig. 840. The debris of resolidified material observed on the machined surface can be attributed to the ineffective flushing of material by the dielectric fluid. As the molten material solidifies, air bubbles can get trapped, forming micro-pores on the surface41. The RL produced by the WEDM process can reduce fatigue life, as it serves as a source of crack initiation due to the presence of high residual stresses42. Globules on the surface are formed due to increased surface tension of the molten material, which is a result of the quenching action of the dielectric medium43. Lower energy results in reduced melting, allowing better cooling and preventing excessive thermal damage. The increased flushing action at higher Toff allows ejection of more molten materials and results in less formation of micro-pores and globules. On the other hand, at a higher DE setting, the surface shows debris accretion, a thicker RL, and prominent thermal defects like micro-pores and larger globules. These features arise from increased melting and material ejection due to higher heat input, resulting in unstable molten pool dynamics and rapid solidification. This is further aided by the use of a lower Toff which hinders flushing of molten debris from the IEG. This process can trap gases and lead to the formation of numerous micro-pores, as shown in Fig. 8b. The RL thickens because the molten material resolidifies on the workpiece surface before being fully flushed by the dielectric fluid. The microstructure analysis results are consistent with the SR findings, as illustrated in Fig. 5. The Ra values for the samples at the lowest and highest DE settings are 1.36 μm and 3.91 μm, respectively. Additionally, the Rz parameter, which indicates the mean peak-to-valley height over the assessment length, was 8.07 μm at the lowest DE setting and 18.23 μm at the highest. The increased Rz at higher DE is attributed to the formation of larger and deeper craters compared to those formed at lower DE. These roughness values correlate directly with the surface defects observed in the SEM images, smoother surfaces with lower Ra and Rz correspond to smaller globules, fewer micro-pores, and uniform RL, while rougher surfaces with higher Ra and Rz are associated with larger globules, denser debris clusters, and prominent micro-pores. These observations align with previous studies34,44, which have shown that higher DE increases MRR but at the cost of SR and defect formation. While SEM images in this study qualitatively illustrate the formation and variation of the RL under different DE conditions, quantitative measurement of RL thickness was not performed. Future work will incorporate cross-sectional SEM or optical microscopy techniques to precisely quantify RL thickness and further validate these observations. The EDS analysis of the machined surface at the highest DE is shown in Fig. 9. In addition to the base elements of IN718, the spectrum revealed a significantly high carbon content (33.51 wt%), which was not observed in the unmachined specimen (Fig. 1b). Similar findings have been reported in the literature for Inconel alloys machined using deionized (DI) water as the dielectric. Nguyen et al.45 observed significant surface carbon content (12.62%) during micro-EDM of IN718 using DI water, which they attributed to the redeposition of debris particles on the machined surface. Similarly, Alkahlan et al.46 reported carbon (8.1%) and oxygen (12.1%) enrichment on the machined surface during WEDM of IN718 and linked it to the dielectric decomposition due to electrolysis and environmental exposure during high-energy discharge conditions. Trace amounts of molybdenum, originating from the tool electrode, and oxygen, likely introduced from the ambient environment during the discharge process, were also detected. These observations indicate the migration of elements from both the tool electrode and the dielectric surroundings. Collectively, the presence of carbon, molybdenum, and oxygen suggests the potential for the formation of secondary phases such as carbides and oxides in the recast layer. Although this study does not directly confirm such phase formation, evidence from spark plasma sintering study on IN718 hybrid alloys has shown rapid formation of MC and M7C3 type carbides under brief, high-temperature exposure in carbon-rich environments, supporting the plausibility of similar transformations under WEDM conditions47.

Conclusions

Parametric analysis of WEDM on IN718 was conducted successfully by evaluating the effect of current, Ton, and Toff on MT, MRR, and SR. MT decreased whereas MRR increased with the increment in current, Ton, and Toff. A contrasting feature of MT and MRR were noticed at high Ton and low Toff levels. This can be attributed to the prolong heating at higher Ton and insufficient time for debris removal at lower Toff leading to the disruption of the WEDM process and resulting in higher MT and lower MRR. Elsewhere, SR increased with an increment in current and Ton due to the formation of bigger and deeper craters, while SR reduced with an increase in Toff due to improved flushing. The EDS study demonstrated the transfer of electrode material onto the machined surface. The presence of carbon on the machined surface indicated redeposition of debris particles and dielectric decomposition, whereas the presence of oxygen suggested material transfer from the environment. The responses were optimized by implementing the concept of OEC, wherein weightages were varied as per priority. The four different OEC resulted in varying actual optimum conditions as compared to the predicted ones evaluated from their mean effect plots. The outcome of actual optimum OEC 1 showed highest error (13.15%), followed by OEC 2 (5.42%), OEC 3 (2.74%), and OEC 4 (0%) compared with their predicted optimum outcomes. When machining efficiency and surface quality were given equal priority, the optimal conditions were found to be a current of 2 A, Ton of 40 µs, and Toff of 9 µs. The machined surfaces were characterized by SEM analysis, where uniform RL with smaller globules are formed on surfaces machined at lower DE, whereas non-uniform RL with larger globules are formed at higher DE. Further, higher DE leads to the formation of numerous micro-pores and debris accretion as compared to lower DE. Parametric analysis showed that higher DE improved machining efficiency but degraded surface quality. The OEC results emphasized the need for a trade-off, with varying weightages for MT, MRR, and SR reflecting the WEDM process’s specific goals.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Li, H. Z. & Wang, J. A cutting forces model for milling inconel 718 alloy based on a material constitutive law. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 227, 1761–1775 (2013).

Cinoglu, I. S., Charbal, A. & Vermaak, N. Towards exploiting inelastic design for inconel 625 under short-term Cyclic loading at 600∘C. Mech. Mater. 140, 103219 (2020).

Thirumalai, R., Senthilkumaar, J. S., Selvarani, P. & Ramesh, S. Machining characteristics of inconel 718 under several cutting conditions based on Taguchi method. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 227, 1889–1897 (2013).

Shokoohi, Y., Khosrojerdi, E. & Rassolian Shiadhi, B. H. Machining and ecological effects of a new developed cutting fluid in combination with different cooling techniques on turning operation. J. Clean. Prod. 94, 330–339 (2015).

Marques, A., Paipa Suarez, M. & Falco Sales, W. Rocha machado, Á. Turning of inconel 718 with whisker-reinforced ceramic tools applying vegetable-based cutting fluid mixed with solid lubricants by MQL. J. Mater. Process. Technol. 266, 530–543 (2019).

Bartolomeis, A., De, Newman, S. T., Jawahir, I. S., Biermann, D. & Shokrani, A. Future research directions in the machining of inconel 718. J. Mater. Process. Technol. 297, 117260 (2021).

Seidi, M., Yaghoubi, S. & Rabiei, F. Multi-objective optimization of wire electrical discharge machining process using multi-attribute decision making techniques and regression analysis. Sci. Rep. 14, 10234 (2024).

Xu, D. et al. Investigation of surface integrity in laser-assisted machining of nickel based Superalloy. Mater. Des. 194, 108851 (2020).

Pan, Z. et al. Heat affected zone in the laser-assisted milling of inconel 718. J. Manuf. Process. 30, 141–147 (2017).

Suárez, A. et al. Surface integrity and fatigue of non-conventional machined alloy 718. J. Manuf. Process. 48, 44–50 (2019).

Sahu, A. K., Pattanayak, S. & Panda, S. WEDM microdrilling of 316 L stainless steel orthopedic implant. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 234, 3416–3435 (2020).

Gürbüz, H. Estimation of surface roughness and cutting speed in CNC WEDM by artificial neural network that employed trainable activation function. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 235, 2737–2753 (2021).

Rakshit, R. & Das, A. K. A review on cutting of industrial ceramic materials. Precis Eng. 59, 90–109 (2019).

Diviya, M. et al. Parametric investigation of W-EDM factors for machining AM60B conductive biomaterial. Sci. Rep. 14, 1–17 (2024).

Raj, A., Misra, J. P., Khanduja, D., Saxena, K. K. & Malik, V. Design, modeling and parametric optimization of WEDM of inconel 690 using RSM-GRA approach. Int. J. Interact. Des. Manuf. 18, 2107–2117 (2024).

Tonday, H. R. & Tigga, A. M. An empirical evaluation and optimization of performance parameters of wire electrical discharge machining in cutting of inconel 718. Measurement 140, 185–196 (2019).

Raj, A. et al. Performance analysis of WEDM during the machining of inconel 690 miniature gear using RSM and ANN modeling approaches. Rev Adv. Mater. Sci 62, (2023).

Manikandan, K., Ranjith Kumar, P., Muthukumaran, S. & Suresh Kumar, B. Effect of WEDM process parameters on surface roughness and waviness of inconel 603 XL. J. New. Mater. Electrochem. Syst. 23, 31–35 (2020).

Newton, T. R., Melkote, S. N., Watkins, T. R., Trejo, R. M. & Reister, L. Investigation of the effect of process parameters on the formation and characteristics of recast layer in wire-EDM of inconel 718. Mater. Sci. Eng. A. 513–514, 208–215 (2009).

Burek, J., Babiarz, R., Buk, J., Sułkowicz, P. & Krupa, K. The accuracy of finishing WEDM of inconel 718 turbine disc Fir tree slots. Mater. (Basel). 14, 562 (2021).

Louis, D. M., Manivel, S., Seeniappan, K. & L, N. Multiresponse optimization and network-based prediction modelling for the WEDM of AM60B biomedical material. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. (2024). https://doi.org/10.1177/09544062241264939

Son, S., Lim, H., Kumar, A. S. & Rahman, M. Influences of pulsed power condition on the machining properties in micro EDM. J. Mater. Process. Technol. 190, 73–76 (2007).

Naeim, N., AbouEleaz, M. A. & Elkaseer, A. Experimental investigation of surface roughness and material removal rate in wire EDM of stainless steel 304. Mater. (Basel). 16, 1022 (2023).

Anand, G., Sardar, S., Guha, A. & Das, D. Role of spark energy and frequency on wire-EDM performances of al-2Mg alloy and al-2Mg/20 al 3 Fe composite: a comparative study. Adv. Mater. Process. Technol. 0, 1–28 (2024).

Ikram, A., Mufti, N. A., Saleem, M. Q. & Khan, A. R. Parametric optimization for surface roughness, Kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J. Mech. Sci. Technol. 27, 2133–2141 (2013).

Almeida, S., Mo, J., Bil, C., Ding, S. & Wang, X. Comprehensive servo control strategies for flexible and high-efficient wire electric discharge machining. A systematic review. Precis Eng. 71, 7–28 (2021).

Yan, M. T. & Liao, Y. S. Adaptive control of the WEDM process using the fuzzy control strategy. J. Manuf. Syst. 17, 263–274 (1998).

Chakraborty, S., Dey, V. & Ghosh, S. K. A review on the use of dielectric fluids and their effects in electrical discharge machining characteristics. Precis Eng. 40, 1–6 (2015).

Rajurkar, K. P. & Wang, W. M. Thermal modeling and on-line monitoring of wire-EDM. J. Mater. Process. Technol. 38, 417–430 (1993).

Gostimirovic, M., Kovac, P., Skoric, B. & Sekulic, M. Effect of electrical pulse parameters on the machining performance in EDM. Indian J. Eng. Mater. Sci. 18, 411–415 (2011).

Ishfaq, K. et al. Optimization of WEDM for precise machining of novel developed Al6061-7.5% SiC squeeze-casted composite. Int. J. Adv. Manuf. Technol. 111, 2031–2049 (2020).

Pasam, V. K., Battula, S. B., Valli, M., Swapna, M. & P. & Optimizing surface finish in WEDM using the Taguchi parameter design method. J. Brazilian Soc. Mech. Sci. Eng. 32, 107–113 (2010).

Kumar, S., Singh, R., Singh, T. P. & Sethi, B. L. Surface modification by electrical discharge machining: A review. J. Mater. Process. Technol. 209, 3675–3687 (2009).

Sharma, P., Chakradhar, D. & Narendranath, S. Evaluation of WEDM performance characteristics of inconel 706 for turbine disk application. Mater. Des. 88, 558–566 (2015).

Majumder, H. & Maity, K. Application of GRNN and multivariate hybrid approach to predict and optimize WEDM responses for Ni-Ti shape memory alloy. Appl. Soft Comput. J. 70, 665–679 (2018).

Rath, D. et al. Wedm Process Optimization for Machining Characteristcis of AISI 52100 Grade Alloy Steel. Adv. Mater. Sci. Eng. 1–12 (2022). (2022).

Nguyen, T. T., Phi, B. P., Tran, V. T., Nguyen, V. T. & Nguyen, V. T. T. Three-Stage optimization of surface finish in WEDM of D2 tool steel via Taguchi design and ANOVA analysis. Met. (Basel). 15, 682 (2025).

Karthikeyan, A. G., Prabhu, L., Khan, T. & Sebaey, A. Influence of WEDM input variables on the machinability of Ni–Cu Superalloy. Mater. Manuf. Process. 40, 1–8 (2025).

Roy, R. K. Design of Experiments Using the Taguchi Approach: 16 Steps To Product and Process Improvement (Wiley, 2001).

Reolon, L. W., Laurindo, H., Torres, C. A., Amorim, F. L. & R. D. & WEDM performance and surface integrity of inconel alloy IN718 with coated and uncoated wires. Int. J. Adv. Manuf. Technol. 100, 1981–1991 (2019).

Abhilash, P. M. & Chakradhar, D. Effect of wire material and discharge energy on productivity and surface integrity of WEDM-processed inconel 718. Adv. Mater. Process. Technol. 8, 4698–4719 (2022).

Ayesta, I. et al. Influence of the WEDM process on the fatigue behavior of Inconel® 718. Int. J. Fatigue. 92, 220–233 (2016).

Kou, Z. & Han, F. Machining characteristics and removal mechanisms of moving electric arcs in high-speed EDM milling. J. Manuf. Process. 32, 676–684 (2018).

Sharma, P., Chakradhar, D. & Narendranath, S. Analysis and optimization of WEDM performance characteristics of inconel 706 for aerospace application. Silicon 10, 921–930 (2018).

Nguyen, M. D., Rahman, M. & Wong, Y. S. Simultaneous micro-EDM and micro-ECM in low-resistivity deionized water. Int. J. Mach. Tools Manuf. 54–55, 55–65 (2012).

Alkahlan, B., Tabbakh, T., Kurdi, A., Pramanik, A. & Basak, A. K. Formation and characterization of the recast layer formed on inconel 718 during wire electro discharge machining. Mater. (Basel). 16, 930 (2023).

Ahmed, B. A., Hakeem, A. S., Ogunlakin, N., Tauqir, A. & Ehsan, M. A. M7C3 and MC-Type carbide formation during sintering of inconel 718/ticn/go hybrid alloy: insights from electrolytic extraction. J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-025-11089-6 (2025).

Author information

Authors and Affiliations

Contributions

S. Kar, N. C A, P. N R – Conceptualization, Data Collection and analysis of results. T. Majumder, B. K. Baroi, A.W. Kebede – Draft manuscript preparation, reviewing and editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kar, S., C A, N., N R, P. et al. Experimental investigation and parametric optimization of machinability and surface characteristics in wire EDM of Inconel 718. Sci Rep 15, 33947 (2025). https://doi.org/10.1038/s41598-025-11188-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11188-3

Keywords

This article is cited by

-

Shaping superalloys with sparks: Electric discharge machining for next-generation manufacturing

Journal of the Brazilian Society of Mechanical Sciences and Engineering (2026)