Abstract

The weak anchoring force and poor stability of the anchoring system in fractured surrounding rock roadway often lead to anchor rod slip failure, which seriously affects the safe and efficient mining of the mine. Therefore, this article intends to use theoretical analysis, indoor experiments, numerical simulations, and industrial experiments to study the migration law of wedge-shaped borehole grout and the reinforcement characteristics of surrounding rock grouting, the axial anchoring force reinforcement characteristics of the expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods, and the anchoring reinforcement mechanism of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods. Firstly, The dimensions of the numerical simulation model are 2000 mm × 2000 mm. The study of the migration law of wedge-shaped borehole grout and the reinforcement characteristics of surrounding rock grouting reveals the diffusion law of wedge-shaped borehole grout and the mechanical changes in surrounding rock modification and replacement; Secondly, indoor anchor rod pull-out tests were conducted on three different anchoring forms, and the anchoring force changes of the three anchoring tests were compared and analyzed, as well as the interaction results between the filling body and the surrounding rock interface in the comparison group. The reinforcement characteristics of the expanded bottom filling anchoring using self expanding head anchor rods were obtained; Simultaneously, establish a mechanical model for expanding bottom backfill anchorage through theoretical analysis; Finally, on-site industrial inspections were carried out in Roadway 050001-07, the roadway is a 2.6 m × 2.6 m three arch roadway. It was found that after using self expanding head anchor rods for bottom filling and anchoring support, the roadway surrounding rock deformation shifted from axial-dominant to transverse-dominant. In comparison with the original support scheme, the maximum roof-to-floor displacement of the roadway decreased by 94%, and the maximum displacement of the two sides decreased by 88%. The stable time of the roadway was reduced from the original 300 days to 150 days, with the stable time advanced by 150 days. Further evidence shows that this anchoring support technology can achieve a significant increase in anchoring force with a small increase in engineering investment, effectively ensuring the stability of the roadway.

Similar content being viewed by others

Introduction

In mining engineering, bolt support is one of the most economical and effective methods for rock mass reinforcement in underground engineering construction such as roadways, tunnels and chambers. With the wide application of bolt support technology in coal mine roadway support, the control effect of surrounding rock in coal mine roadways has been significantly improved, which has greatly enhanced the safety level of underground mining of coal resources. At the same time, the bolt support technology has also been comprehensively developed in practice1,2,3,4.

Bolt support is widely used to control the stability of the roadway. The AS consists of three components (bolt, anchoring agent, and surrounding rock) and two interfaces (the bolt anchoring agent interface and the surrounding rock-anchoring agent interface)5,6,7. In the cyclic pull-out test, the crack of the anchored interface propagates from the anchorage head to the anchorage end. Under the action of multiple stress, the roof occurrence, fragmentation of surrounding rocks, and pre-tightening stress are all significant factors that contribute to the failure of AS8,9,10,11.

In the field of mining engineering, considerable research has been conducted on the working mechanism, reaming parameters, reaming construction equipment, and reaming performance of the reaming technology. These studies have effectively promoted the application and development of this technology in various aspects of coal mine production. Regarding the reaming technology, Sun et al.12 have studied the laws of cuttings migration during reaming under different conditions and provided reasonable value ranges for rotational speed and flow rate. Wang et al.13 proposed a new type of large-diameter multi-plate soil anchor and its reaming cavity forming tool. In order to study the influence of the diameter of anchor plate, the number of anchor plates and the spacing of anchor plates on the vertical uplift capacity of the large-diameter multi-plate soil anchor, 25 sets of comparative models were established for simulation analysis. It is verified that the new large-diameter multi-plate soil anchor can be effectively applied to various projects. Zhong et al.14 proposed the multi-stage reaming drilling technology. This technology improves the mining efficiency of coalbed methane resources. The engineering geological model and simulated tests on tectonic coal samples have verified the applicability of this technology to tectonic coal seams. The experimental simulation of multi-stage underreaming drilling has been completed in the laboratory, providing a reference example for field drilling. Zhang et al.15 studied the reaming morphology, cutting size and cuttings removal amount of sandstone, limestone and granite with different reaming and reaming diameter ratios. Then, based on the plastic damage model, a three-dimensional dynamic damage numerical model of button bit-reaming rock was established to study the impact stress distribution, damage evolution characteristics, impact depth and other parameters under the action of reaming impact load. Geng et al.16 proposed a reaming technology to address the problem that drilling in tectonically deformed coal is prone to hole shrinkage or closure due to its poor deformation resistance. This technology can effectively reduce the risks of sticking, blocking, and hole collapse without changing the drilling structure.

Wang et al.17 studied the influence of pressure-relief boreholes on roadway deformation and proposed a segmented reaming pressure-relief scheme. The study further analyzed the effects of parameters such as reaming diameter, depth, and spacing on the fracture evolution characteristics and pressure-relief performance of segmented reaming. Field tests have demonstrated that the optimized segmented reaming technology can significantly improve the deformation control of roadway surrounding rock and enhance construction efficiency. There are also some renowned scholars who have carried out in—depth research on reaming methods, reaming tools, and the mechanical distribution laws after reaming18,19,20.

In the context of reaming anchoring technology, Liu et al.21,22,23,24,25,26 conducted research on the anchoring mechanism of reaming bolts under direct tensile loading, pull-out tests of bolts with different reaming shapes, the influence of reaming dimensions on the anchoring system, and the variation patterns of the stress state of the anchoring system after reaming. A systematic analysis was performed on the variation patterns and characteristics of the pull-out load curves of reaming anchor bolts, thereby validating the feasibility and stability of reaming anchoring. Wang et al.27 addressed the challenges of complex stress conditions and significant deformation in soft surrounding rocks of deep coal mine roadways by proposing an end-expansion anchoring method. Through theoretical modeling and numerical simulations, they analyzed the interfacial stress distribution, propagation of debonding length, and extrusion stress distribution at the end face of the expanded anchor. Additionally, the deformation characteristics and stress concentration patterns of roadway surrounding rocks under different anchoring configurations were investigated. Guo Gang et al.28,29,30 studied the effects of geometric dimensions and burial depth of vertical tension-expanded bolts in homogeneous sand on their bearing characteristics. Nan et al.31,32,33 addressed the problem of resin bolt slippage failure in soft rock roadways by proposing an innovative expanded-base backfill anchoring support technology. The study investigated the anchoring performance under various hole expansion dimensions and validated the reliability of this technique through in-situ field trials.

Based on the above, considerable research has been conducted on the working mechanism, reaming parameters, construction tools and equipment, and reaming performance of reaming anchoring technology for anchor holes. These studies have effectively promoted the application and development of this technology in coal mine roadway support, providing technical support for improving the support effect of bolts (cables) in weak surrounding rock roadways of coal mines. But based on the characteristics of reaming anchoring technology and previous experimental studies, when resin anchor agents are used for bolting (cabling), phenomena such as incomplete curing and insufficient filling of anchor agents were observed in the reamed area. After backfilling high-strength grouting materials to replace the excavated weak surrounding rock in the reamed area, followed by resin anchoring operations, although the anchoring force is enhanced, the anchoring operation time is significantly prolonged. Therefore, to effectively address the issues existing in reamed anchorage holes, this paper adopts a comprehensive approach integrating numerical simulation, laboratory tests, theoretical analysis, and field inspection. The study investigates the strengthening characteristics and mechanism of anchoring in fractured surrounding rock roadways from four aspects: the migration law of grout in wedge-shaped reaming, anchoring strengthening characteristics, strengthening mechanism, and engineering verification. The research findings aim to improve the anchoring effect under reamed anchorage hole conditions and further enhance the control quality of bolt support for roadways.

Study on migration law of grout in hole-enlarged grouting

Experimental scheme

Taking the physical and mechanical properties of the surrounding rock in the 050001-07 stope roadway as a reference, a two-dimensional numerical model for grout diffusion was established to investigate the migration patterns and diffusion characteristics of base-enlarged backfill grouting and conventional grouting under the dual-medium conditions of fractured-porous media. The model size is 2000 mm × 2000 mm, with the maximum reaming diameter of 400 mm and the reaming length of 450 mm. Taking the borehole center line as the reference, a total of nine data acquisition lines are set in the model, on each monitoring line, 11 monitoring points were arranged at distances of 0 mm, 100 mm, 200 mm, 300 mm, 400 mm, 500 mm, 600 mm, 700 mm, 800 mm, 900 mm, and 1000 mm from the borehole center, respectively, and the layout of monitoring points is shown in Fig. 1.

Analysis of grout diffusion results

As shown in the results of Fig. 2, the grout diffusion distance increases with the increase of grouting time, but the increasing amplitude of the diffusion distance gradually decreases as the grouting time prolongs. Fracture intersection degree is a key parameter describing the spatial distribution characteristics of fracture networks in rock masses, referring to the density and complexity of fractures intersecting each other per unit volume or area. In this paper, comparative analysis and simulation tests were carried out with non-intersecting fractures as the baseline. In the region with a higher fracture intersection degree along the radial distribution, the variation of the grout diffusion range is more obvious. Notably, while radial fractures enhance diffusion, axial fractures exhibit contrasting effects. However, for the fractures distributed along the axial direction, the presence of fractures accelerates the decay rate of grout pressure, leading to a reduction in the grout diffusion range.

According to the results presented in Fig. 3, based on the curve variation results of hole reaming and grouting, it can be concluded that monitoring lines 1# and 2# were affected by hole enlargement and fractures, with the maximum grout diffusion range reaching 1000 mm. Monitoring line 2# was significantly influenced by fracture intersections, leading to notable dispersion in the data curves of all monitoring points. Although monitoring line 3# had no directly connected fractures, monitoring point 8 coincided with the end of a long fracture directly interlinked with the bolt hole and was affected by hole enlargement, resulting in a maximum grout diffusion range of 770 mm. Two crossing fractures were directly connected to monitoring line 4#, exerting a direct influence on monitoring points 2, 3, 4, 5, and 6. Thus, the data showed discrete variations, while the grout pressure at Monitoring Point 7 suddenly dropped to 0. The maximum grout diffusion range of monitoring line 4# reached approximately 660 mm. The No. 2 monitoring point of the monitoring line 5# was affected by multiple intersecting fractures, where the grouting pressure reached the maximum. However, due to the fracture propagation direction, the outward extension of grout was constrained, resulting in a reduction in the grout diffusion range. The maximum diffusion range was 330 mm. The No. 2 and No. 3 monitoring points of the monitoring line 6# were affected by multiple intersecting fractures, with the highest grouting pressures at these two points. Similarly, constrained by the fracture propagation direction, the outward extension of grout was restricted, leading to a decrease in the grout diffusion range. The maximum diffusion range was 440 mm. Multiple intersecting fractures were found directly connected to the 7#, 8#, and 9# monitoring lines, all of which directly communicated with bolt holes. This directly influenced all monitoring points on the 7# line, weakening the trend of grout diffusion pressure decreasing with increasing distance. The maximum grout diffusion range of the 7# monitoring line was 1000 mm, while that of the 8# and 9# lines was 880 mm.

As shown in the results of Fig. 3, based on the curve variation results of conventional grouting, it can be concluded that the nine monitoring lines were all affected by fractures to varying degrees. When fractures existed, the data curves exhibited obvious discreteness, and there was almost no case of curve coincidence.

As shown in the results of Fig. 4, after reaming and in the presence of fractures, the diffusion range of grout into the deep surrounding rock of the roadway increased significantly, and it has obviously diffused to the boundary of the surrounding rock.

Research on grouting modification of surrounding rock

Shear test scheme

Laboratory tests were designed to conduct shear tests on ungrouted rock specimens, grouted rock specimens, and grout solid specimens, analyzing the variation patterns of shear strength among the three types of specimens. The ungrouted rock specimens refer to those without grouting modification; the grouted rock specimens were processed from ungrouted specimens after grouting modification; and the grout solid specimens were fabricated by processing solidified grouting materials.

The specimen grouping is shown in Table 1, where 1-1 to 1-4 are rock specimens, 2-1 to 2-4 are grouted rock specimens, and 3-1 to 3-4 are grout solid specimens. The grouting material used is Portland cement of type 42.5, with a particle size of 600 mesh and a water-cement ratio of 1:234. After grouting, when the grout achieved initial setting and certain strength, the specimens were removed, and the adhered grout solids on their surfaces were cleaned off. Then, the specimens were cured in the laboratory for 14 days before fabrication.

Analysis of shear test results

According to the results in Fig. 5, during the shear tests on three groups of specimens, the shear stress curve exhibited a pattern of rapid increase with the increment of shear displacement. After reaching the peak value, the shear stress curve first showed a rapid decline followed by a slow decrease, presenting an overall descending pattern of "fast first, then slow, and finally leveling off". However, in the descending stage of the shear stress curves, the amplitude of the grout solidified specimens was the most drastic, followed by that of the grouted rock mass specimens, and finally the original rock specimens.

According to the results in Table 2, the peak shear stress of grout solidified body specimens was significantly higher than that of original rock specimens and grouted rock mass specimens. Under different normal pressure gradients, the residual shear stress values of grout solidified body specimens were the smallest, while those of the other two groups were relatively close. Thus, after the grout solidified body specimens reached the peak shear stress and underwent shear failure, the decline in shear stress was the most significant. The ratio of peak shear stress to residual shear stress was the largest for grout solidified body specimens, ranging from 2.75 to 4.6, followed by grouted rock mass specimens (1.38–2.01) and original rock specimens (1.52–1.83). The characteristics of brittle failure in grout solidified body specimens were significantly evident.

According to the results of Fig. 6, the normal displacement-shear displacement curves of the three groups of specimens can be mainly divided into the following three stages: the first stage is the stable normal displacement stage, the second stage is the pre-peak abrupt change stage of normal displacement, and the third stage is the post-peak reduction stage of normal displacement. The pre-peak abrupt change stage of normal displacement is more obvious in the experimental results of grouted rock mass specimens and grout solidified body specimens. When the normal stress gradients were 2 MPa, 4 MPa, and 6 MPa, the results of the three groups of specimens all exhibited the law that the greater the normal stress, the smaller the normal displacement under the same shear displacement. However, when the normal stress increased to 8 MPa, compared with the grouted rock mass specimens and original rock specimens, the grout solidified body specimens showed an obvious downward trend in normal displacement after it stabilized with the increase of shear displacement. Comparative analysis with the variation law of original rock specimens reveals that when the shear stress applied to grout solidified body specimens reaches a certain threshold, the normal displacement increases rapidly. However, when the shear displacement exceeds 5 mm, the normal displacement of grout solidified body specimens exhibits a downward trend, especially when the normal stress is 8 MPa, where the decreasing trend is more pronounced. As the normal stress in the shear test scheme increases from 2 to 8 MPa, the variation pattern of normal displacement in grout solidified body specimens generally demonstrates a decreasing trend with the increase of normal stress.

Research on anchoring reinforcement characteristics

This chapter mainly studies the axial pull-out variation laws of conventional anchor rod hole expansion anchoring and self expanding head anchor rod hole expansion anchoring, analyzes the failure characteristics of the anchoring system, the variation laws of acoustic emission, and the variation laws of internal stress in the surrounding rock, and then reveals the reinforcement characteristics of the self expanding head anchor rod with bottom expansion backfill anchoring.

Experimental design

Three sets of indoor experiments were set up, and the design dimensions are shown in Fig. 7. The first group is the conventional anchoring group, which serves as the reference group. The second group is the conventional anchor rod drilling anchoring group, and the third group is the self expanding enlarged head anchor rod drilling anchoring group. To minimize the variability of the pull-out test data as much as possible, three sets of tests were set up for each group, and the average value was taken at the end.

The support technology of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods, as well as the working principle and component schematic diagram of the independently developed self-expanding enlarged head anchor rods, are shown in Fig. 8. The self-expanding head anchor rod includes an anchor rod body equipped with grouting holes. The front end of the anchor rod body features installation holes oriented radially. A pin shaft is threaded through these installation hole, and the extension pieces located on both sides of the rod body are securely connected to both ends of the pin shaft. A torsion spring is mounted on the pin shaft to facilitate its rotation. One end of the torsion spring is inserted into the socket, while the other end presses against the inner wall of the grouting hole of the anchor rod body. There is a deployment switch on the left extension that is located between the outer circle of the anchor rod. This deployment switch includes a convex inclined block fixed to the left expansion piece, and the outer circumference of the anchor rod contains a sloping groove that matches the convex inclined block. The direction from the bottom of the inclined groove to the groove forms an acute angle with the centerline of the anchor rod body. The direction from the bottom of the inclined groove to the groove extends from front to back. When the convex inclined block is assembled in the inclined groove, the pin shaft is positioned at the forefront of the installation hole. Both the left and right extensions exhibit identical structure and are symmetrically arranged around the centerline of the pin axis. These extensions are semi-circular tubes, and their inner diameters are equal to the outer diameter of the anchor rod body.

Structure diagram of self-expanding head anchor rod. Anchor hole; 2. Self-expanding enlarged head anchor rod; 3 grouting holes; 4. Anchor rod body; 5 pin shafts; 6 left extension components; 7 right extension components; 8 torsion springs; 9 convex oblique blocks; 10 inclined slots; 11 installation holes; 12 sockets; 13. Left connecting plate; 14 Right connecting plate; 15 limit cap; Drill rod 16; 17 ordinary drill bits; 18 hole puncher; 19 wedge-shaped hole expansion; 20 pallets; 21 grouting pipe.

Analysis of anchoring force results

The average tensile load and acoustic emission ringing count variation curves of the three sets of experiments are shown in Fig. 9. The maximum load of the first group is 48.7 kN, the second group is 75.9 kN, the third group is 126.2 kN, and the maximum pulling load of the anchor rod in the third group is 2.6 times that of the first group and 1.4 times that of the second group.

The anchor rod pull-out curve is divided into initial stress stage (AB section), elastic–plastic stress stage (BC section), stable equilibrium stage (CD section), and residual failure stage (DF section). With the application of axial load, the AB section anchoring system is initially subjected to force, and the gasket further adheres to the surface of the surrounding rock specimen. The gaps in the anchoring system are compacted, and the growth rate of axial load is slow. At this stage, the acoustic emission probe collects the weakest signal. Subsequently, the tensile load curve of the anchoring system enters an elastic stress state, and the rate of increase in axial load reaches the maximum rate of the entire tensile load curve, as shown in the BC section of the Fig. At this point, as the axial load increases, acoustic emission signals begin to appear, but the activity level of the acoustic emission signals is relatively low. Subsequently, the growth rate of the pulling curve decreases, and the anchoring system transitions from the elastic stress stage to the elastic–plastic stress state, as shown in the CD segment in the Fig. In the early stage of the CD segment, the acoustic emission signal is still inactive, but as the pull-out curve reaches the peak point D, the acoustic emission signal undergoes a sudden change. In the later stage of the CD segment and the early stage of the DE segment, the ringing count of acoustic emission increases sharply, and the cumulative count shows a “nearly vertical” growth pattern. The reason is that the load-bearing structure of the anchoring system is severely damaged, and there is relative motion between the anchor rod and the slurry solid body. The interface between the two is basically completely destroyed, so the pull-out curve rapidly drops from point D to point E, as shown in the DE segment in the Fig. In the early stage of the DE segment, the ringing count of sound emission still belongs to the active peak, but in the later stage of the DE segment, the sound emission signal weakens significantly, and the growth rate of the cumulative count curve of sound emission also decreases. As the pull-out curve develops from the DE stage to the EF stage, the bearing effect of the anchoring system basically disappears. At this time, the load is mainly composed of the frictional force between the anchor rod and the slurry solid, as well as the surrounding rock, which participates in the anchoring force. At this point, the sound emission signal weakens until it disappears, and the cumulative count of sound emissions tends to stabilize.

The failure modes of the first and second groups of anchoring systems were primarily characterized by the debonding at the interface between the grout body and the rock bolt. This failure type manifested as shear failure between the ribbed grout body around the bolt and the surrounding grout matrix, as shown in Fig. 10. Conversely, the third group exhibited a distinct failure mode where the surrounding rock mass failed while the anchoring system remained relatively intact. This was attributed to the gradual propagation and coalescence of internal fractures within the rock mass, ultimately leading to loss of load-bearing capacity and subsequent failure of the anchoring system, as depicted in Fig. 11.

Analysis of interface stress results

The two-dimensional schematic diagram of the layout of three sets of stress boxes on the expansion interface is shown in Fig. 12. The stress variation curve of the stress box at the interface of the conventional anchor rod expansion bottom backfill anchoring and expansion hole is shown in Fig. 13. The maximum stress value of stress box 1 # is 1447.4 kPa, the maximum stress of stress box 1 '# is 1881.7 kPa, the maximum stress of stress box 2 # is 168.1 kPa, the maximum stress of stress box 2’ # is 190.2 kPa, the maximum stress of stress box 3 # is 165.8 kPa, and the maximum stress of stress box 3 '# is 179.1 kPa.

The stress variation curve of the stress box at the interface of the self expanding head anchor rod with bottom expansion, backfill anchoring, and hole expansion is shown in Fig. 14. The maximum stress of 1 # stress box is 3980.4 kPa, the maximum stress of 1 '# stress box is 3996.4 kPa, the maximum stress of 2 # stress box is 375.5 kPa, the maximum stress of 2’ # stress box is 377.19 kPa, the maximum stress of 3 # stress box is 371.8 kPa, and the maximum stress of 3 '# stress box is 373.6 kPa. The stress peak values of the 1 # and 1 '# stress boxes in this group are the highest, much higher than the stress peak values of the other group of stress boxes. The main reason is that 1 # and 1 '# are located at the variable diameter between the expansion section and the conventional anchoring section. When the anchoring system is under stress and stable, there is a significant stress concentration phenomenon here. Compared with the stress changes of the other two groups of stress boxes, the growth rate of 1 # and 1’ # stress boxes is faster, and the stress concentration phenomenon is more obvious.

Study on the mechanism of anchorage strengthening

Drawing on the elastic theoretical analysis methods for cylindrical underreamed bolts in References35,36, and37, this study further extends the approach to the research on wedge-shaped underreamed bottom-backfilled anchoring. Based on the degree of rock mass mobilization in the underreamed section, normal borehole section, and their connection zone, the setting of underreamed section length and normal borehole section length is discussed. On this basis, the anchoring bearing capacity of underreamed bolts is investigated.

A schematic diagram illustrating the mechanical analysis of wedge-shaped reaming anchoring is shown in Fig. 15.

Based on the mechanical schematic diagram in Fig. 15, it is assumed that the reaming length is lx and the reaming angle is θ. The radius Rx of the wedge-shaped reaming is thus a function expression related to the reaming length (lx) and reaming angle (θ).

The surface area calculation formula of the wedge-shaped(S) and length of the wedge-shaped(l) inclined plane is shown as follows.

The mechanical equilibrium equation of the wedge-shaped reamed micro-element is shown as follows.

The above equation is simplified to derive the following equation.

The boundary conditions are as follows.

When x equals 0, the limit value of Rx is the radius r of a conventional anchor bolt hole.

\(\sigma_{x}\) is the axial stress of the backfill material, MPa; \(\sigma_{{}}\) is the stress of the wedge-shaped force-bearing surface, MPa; \(\tau_{{\text{x}}}\) is the axial shear stress of the backfill,MPa;\(\tau\) is the shear stress along the wedge-shaped inclined plane, MPa; Rx s the radius of wedge-shaped reaming at position x, mm;\(\theta\) is Reaming angle,°; r is the radius of the bolt hole, mm; P is the tensile force applied to the bearing capacity unit, kN. Extend inward starting from the position where the conventional anchorage section is adjacent to the free section. "0 < x ≤ l₁" is the conventional section and "l₁ < x ≤ l₂" is the reamed section.

\(\sigma_{{\text{p}}}\) is the acting force of the surrounding rock mass at the mutation point of the anchorage section on the reamed section, which is assumed to be passive surrounding rock pressure, and the expression is as follows.

c is the cohesive force of surrounding rock mass, MPa;\(\phi\) is the internal friction angle of the surrounding rock mass, °;h0 is the burial depth, m;l1 is the reaming length, mm;l2 is the total anchoring length, mm;\(l_{1}^{ - }\), \(l_{1}^{ + }\) respectively refer to the reaming side and the conventional hole side at the position of reaming end l1.

The physical equation expressions for the spatial problems of elasticity in the cylindrical coordinate system are shown as follows.

\(\sigma_{\rho }\) is the radial stress, MPa;\(\sigma_{\phi }\) is the tangential stress, MPa;\(\sigma_{{\text{x}}}\) is the axial stress, MPa;\(\varepsilon_{\rho }\) is the radial strain.

The mechanical models are all based on the premise that the grouting body is fully cured and the influence of the rib patterns of the rock bolts can be ignored. Assuming that the axial force on the cross-section within the anchoring system is uniformly distributed and the stresses subjected are equal, i.e., \(\sigma_{\rho }\) = \(\sigma_{\phi }\) = \(\sigma_{{\text{R}}}\), the following equation can be derived.

\(E_{c}\) is the elastic modulus of the anchor solid, GPa;\(\mu_{{\text{c}}}\) is the Poisson’s ratio of the anchor solid;\(\rho\) is the radial radius of the anchor solid, mm;\(\sigma_{{\text{R}}}\) is the confining pressure, MPa。

According to the elastic theory, for an infinite plane with a circular hole, the expression for the radial displacement under the action of a uniformly distributed radial pressure \(\sigma_{{\text{R}}}\) is as follows.

When \(\rho\) equals R, it is considered that there is no relative displacement in the radial direction between the anchoring system and the surrounding rock, and the following equation can be derived.

Simplifying and arranging the above equation leads to the following equation.

\(E_{{\text{s}}}\) is the elastic modulus of surrounding rock mass, GPa;\(\mu_{{\text{s}}}\) is the Poisson’s ratio of surrounding rock mass. Other symbols have the same meanings as above.

Assuming that the Coulomb failure criterion is satisfied at the interface between the anchored body and the surrounding rock mass, the following expression can be derived.

Substituting the above equation into the calculation yields the following equation.

\(\sigma_{{\text{R}}}\) is the normal stress on the contact interface between the anchor solid and the surrounding rock and soil, MPa. The solution for the axial stress \(\sigma_{{\text{x}}}\) of the grout solidified body is calculated as follows.

The expression for the shear stress \(\tau_{{\text{x}}}\) at the interface between the anchor solid and the surrounding rock mass under the ideal assumed state is obtained as shown in the following equation.

Overall, it can be concluded that the axial stress of the anchoring system and the shear stress between the grout solidified body and the surrounding rock interface along the axial direction of the rock bolt exhibit a segmented negative exponential distribution. The reaming section length, reaming diameter, and mechanical parameters of the rock and soil mass have significant influences on the anchoring bearing effect.

Engineering verification

Support scheme design

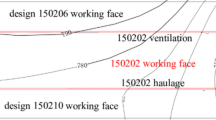

The industrial test section was selected to conduct industrial tests in the roadway of mining area 050001-07 to verify the practicality and reliability of the research results. The roadway is a 2.6 m × 2.6 m three arch roadway. The original support schematic is shown in Fig. 16, with the original support serving as the reference group. The comparison group consists of a combination of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods. In the first row of top plate support in the comparative group, the middle position of the top plate is supported by expanded bottom backfill. Conventional anchoring support is used after an interval of 800 mm on both sides, and expanded bottom backfill support is used after an interval of 1600 mm, as shown in Fig. 17. In the second row of support, the middle position of the top plate is supported by conventional anchor rods. After a spacing of 800 mm on both sides, expanded bottom backfill support is used. After a spacing of 1600 mm, conventional anchor rod support is used. After a spacing of 2400 mm, expanded bottom backfill support is used, as shown in Fig. 18. The third row of support should be consistent with the first row, the fourth row of support should be consistent with the second row, and so on, forming a “diamond” staggered bottom-expansion backfilling arrangement.

Analysis of anchor rod stress results

Optical fiber installation grooves were respectively processed on the rock bolts of different support schemes. The initial optical fiber monitoring point was set at 0.3 m from the tail of the bolt body, and thereafter, points were arranged at 0.2 m intervals. Multiple optical fiber monitoring points were respectively deployed on each bolt body to monitor the stress state at the corresponding positions of the rock bolt. By collecting data from each distributed fiber optic anchor rod, the on-site monitoring results of the anchor rod’s stress are shown in Fig. 19. The data at the monitoring point is negative, indicating that the anchor rod at this location is greatly affected by lateral shear force, while the data at the monitoring point is positive, indicating that the anchor rod at this location is greatly affected by axial tension. As can be seen from 1-1 to 1-6 in Fig. 19, it can be seen that the anchor rod is mainly subjected to axial tension, indicating that the deformation of the surrounding rock of the roadway is mainly along the axial direction of the anchor rod. As can be seen from 2-1 to 2-6 in Fig. 19, it can be seen that compared with the grating monitoring results of the anchor rod body in the original support scheme of the roadway, the stress on the anchor rod body of the roadway bottom expansion backfill anchoring combined support scheme is mainly transverse shear stress. This indicates that the changes in the surrounding rock of the roadway are mainly caused by transverse shear changes, and the effect of controlling the axial deformation of the surrounding rock of the roadway is significant.

Analysis of rock deformation results

The monitoring period for roadway deformation of the two support schemes was both 300 days. The monitoring frequency was once daily from day 1 to day 30, once every three days from day 31 to day 150. From day 151 to day 300, the original support was monitored once every 7 days, and the comparison group was monitored once every 10 days. The monitoring results are shown in Fig. 20 and Table 3. According to the results in Fig. 20 and Table 3, compared with the original support scheme, the combined support scheme integrating expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods significantly reduced the maximum deformation and deformation rate of roadway surrounding rock. In comparison with the original support scheme, the maximum roof-to-floor deformation within 300 days decreased from 451 to 28 mm, representing a 94% reduction in the maximum displacement. The maximum deformation of the roadway sides decreased from 429 to 53 mm, with an 88% reduction in the maximum displacement, effectively controlling the deformation of roadway surrounding rock. During the 300-day monitoring period of the roadway, the surrounding rock displacement of the roadway with the original support scheme continuously changed, so 300 days was taken as the benchmark for the roadway stability time. The combined support scheme integrating expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods significantly shortened the time for the roadway to reach stability, with the roadway stability time advanced by more than 150 days. Additionally, a comparison in terms of economic investment shows that compared with the original support scheme, the application of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods support has reduced the number of roadway repairs within one year from the original 1 time to zero repairs within one year.

In summary, a comparative analysis of the maximum roof-floor deformation, maximum deformation rate, maximum rib deformation, maximum deformation rate, and roadway stability time results of the two roadway support schemes reveals that the combined support scheme using expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods significantly controls the deformation of roadway surrounding rock and achieves better roadway stability control effects.

Conclusion

This paper investigates the grout migration law of wedge-shaped hole enlargement and the strengthening characteristics of surrounding rock grouting, the strengthening characteristics of anchoring force of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods, as well as the anchoring strengthening mechanism. Field industrial tests were conducted to further verify the reliability and practicability of the research results. The main conclusions drawn in this paper are as follows:

-

1.

Numerical simulation of grouting tests revealed that hole expansion increased the diffusion range of grout, and the higher the fracture intersection degree, the larger the grout diffusion range. The intrusion of grout realized the modification of fractured surrounding rock. Meanwhile, results of shear tests on rock mass specimens showed that the shear strength of grout solidified bodies was significantly higher than that of original rock specimens.

-

2.

The results of the bolt pull-out tests indicated that the maximum load for the first group was 48.7 kN, the second group was 75.9 kN, and the third group was 126.2 kN. The maximum load of the third group was 2.6 times that of the first group and 1.4 times that of the second group.

-

3.

Based on the theory of cylindrical hole expansion strengthening, the distribution laws of axial stress in the anchor body and shear stress at the contact interface between the surrounding rock mass were analyzed. A mechanical model was established for the inclined plane stress of wedge-shaped hole expansion anchoring and the shear stress at the contact surface between the anchor body and surrounding rock mass. It is revealed that the strengthening mechanism of bottom-expanded backfilled anchoring lies in that the wedge-shaped hole expansion changes the diameter of part of the bolt hole, directly affecting the comprehensive shear strength and mechanical distribution law of the anchoring system.

-

4.

Through on-site industrial tests, it was found that after the combined support scheme of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods was applied to the roadway, the deformation characteristics of the surrounding rock were effectively improved, and the axial deformation of the roadway was effectively controlled. In comparison with the original support scheme, the maximum roof-to-floor deformation within 300 days decreased from 451 to 28 mm, representing a 94% reduction in the maximum displacement. The maximum deformation of the roadway sides decreased from 429 to 53 mm, with an 88% reduction in the maximum displacement. During the 300-day monitoring period of the roadway, the surrounding rock displacement of the original support roadway continuously changed, so 300 days was taken as the benchmark for roadway stability time. Compared with the original support, the roadway stability time of the comparison group was 150 days, which was advanced by 150 days. It was verified that the combined support of expanded bottom backfill anchoring technology and self-expanding enlarged head anchor rods can significantly improve the deformation of the roadway surrounding rock, with a good control effect.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Shan, R. L. et al. Research progress of coal roadway support technology at home and abroad. Chin. J. Rock Mech. Eng. 38(12), 2377–2403. https://doi.org/10.13722/j.cnki.jrme.2019.0386 (2019).

Kang, H. P. et al. Analysis on anchorage performances and affecting factors of resin bolts. J. China Coal Soc. 39(1), 1–10. https://doi.org/10.13225/j.cnki.jccs.2013.1919 (2014).

Pinazzi, P. C. et al. Mechanical performance of rock bolts under combined load conditions. Int. J. Min. Sci. Technol. 30(2), 167–177. https://doi.org/10.1016/j.ijmst.2020.01.004 (2020).

Xu, P. et al. Effect of polymeric aluminum chloride waste residue and citric acid on the properties of magnesium oxychloride cement. J. Build. Eng. 101, 111864–111864. https://doi.org/10.1016/J.JOBE.2025.111864 (2025).

Belghali, M. et al. Pseudo-static stability analysis of rock slopes reinforced by passive bolts using the generalized Hoek-Brown criterion. J. Rock Mech. Geotech. Eng. 9(4), 659–670. https://doi.org/10.1016/j.jrmge.2016.12.007 (2017).

Feng, X. W. et al. Mechanical response of fully bonded bolts under cyclic load. Int. J. Rock Mech. Min. Sci. 109, 138–154. https://doi.org/10.1016/j.ijrmms.2018.06.018 (2018).

Chen, Y. Experimental study and stress analysis of rock bolt anchorage performance. J. Rock Mech. Geotech. Eng. 6(5), 428–437. https://doi.org/10.1016/j.jrmge.2014.06.002 (2014).

Wang, P. et al. Cumulative damage and bearing capacity attenuation law of anchorage structure interface under cyclic loading and unloading. Geomech. Geophys. Geo-Energy Geo-Resour. https://doi.org/10.1007/S40948-023-00612-5 (2023).

Han, C. L. et al. Multiple and long-term disturbance of gob-side entry retaining by grouped roof collapse and an innovative adaptive technology. Rock Mech. Rock Eng. 52(8), 2761–2773. https://doi.org/10.1007/s00603-018-1612-0 (2018).

Jing, H. W. et al. Deformation and failure characteristics of anchorage structure of surrounding rock in deep roadway. Int. J. Min. Sci. Technol. 30(05), 593–604. https://doi.org/10.1016/j.ijmst.2020.06.003 (2020).

Wang, P. et al. Fiber bragg grating monitoring of full-bolt axial force of the bolt in the deep strong mining roadway. Sensors https://doi.org/10.3390/s20154242 (2020).

Sun, X. F. et al. Evaluating the effectiveness of cleaning tools for enhanced efficiency in reamed wellbore operations. Geoenergy Sci. Eng. 246, 213620–213620. https://doi.org/10.1016/J.GEOEN.2024.213620 (2025).

Wang, J. et al. Study on the influence of anchor plate parameters on the bearing characteristics of the new large-diameter multi-plate soil anchor and creep property of anchor. Sci. Rep. https://doi.org/10.1038/S41598-024-79783-4 (2024).

Zhong, C. Y. et al. Laboratory study on the application of reciprocating multi-stage reaming drilling for horizontal wells in tectonically deformed coal seams. Rock Mech. Rock Eng. 57(3), 2253–2266. https://doi.org/10.1007/S00603-023-03685-6 (2024).

Zhang, C. S. et al. Experimental and numerical analyses of rock damage behavior and fragmentation mechanism under enlarged hole impact conditions. Geoenergy Sci. Eng. 249, 213778–213778. https://doi.org/10.1016/J.GEOEN.2025.213778 (2025).

Geng, J. S. et al. Investigation of dynamic response of drilling parameters and deformation characteristics of coal around borehole during multi-stage reaming in tectonic coal. Int. J. Rock Mech. Min. Sci. https://doi.org/10.1016/J.IJRMMS.2023.105540 (2023).

Wang, W. M. et al. The optimization of segmented reaming parameters and the analysis of the pressure relief effect in impacted coal seams. Processes https://doi.org/10.3390/PR11041235 (2023).

Niu, X. G. et al. Research on the coal seam permeability-increasing technology via high-pressure water jet reaming and its application. Geofluids https://doi.org/10.1155/2021/6647500 (2021).

Liu, C. C. et al. Research on borehole forming characteristics of two-wing polycrystalline diamond compact bit in coal mines. Energy Sources Part A Recov. Util. Environ. Effects 45(14), 1–14. https://doi.org/10.1080/15567036.2020.1787562 (2020).

Zhang, L. et al. Relief mechanism of segmented hole reaming and stress distribution characteristics of drilling holes in deep coal mine. Processes 10(8), 1566–1566. https://doi.org/10.3390/PR10081566 (2022).

Jia, H. S. et al. Development and experimental research of the cable bolt constant resistance device by using composite expansion pipe. J. China Coal Soc. 49(6), 2604–2614. https://doi.org/10.13225/j.cnki.jccs.2023.0944 (2024).

He, D. Y. et al. Anchoring effect guarantee method and experiment for the bottom reaming area of borehole in weak surrounding rock of coal mine roadway. J. China Coal Soc. 49(S1), 108–120. https://doi.org/10.13225/j.cnki.jccs.2023.0295 (2024).

Liu, S. W. et al. Study on the relationship between catalyst-resin mastic ratio and anchoring performance of mineral resin grout. J. China Coal Soc. 46(12), 3819–3832. https://doi.org/10.13225/j.cnki.jccs.2021.0126 (2021).

He, D. Y. et al. Analysis of eccentric resin anchoring characteristics for cable bolts and the design of pushing and limiting device for resin cartridges. Chin. J. Rock Mech. Eng. 42(3), 708–723. https://doi.org/10.13722/j.cnki.jrme.2022.0341 (2023).

Jia, H. S. et al. Experimental study on double cuneiform reamed anchorages for cable bolt boreholes in soft rock. Int. J. Rock Mech. Min. Sci. https://doi.org/10.1016/J.IJRMMS.2022.105198 (2022).

Jia, H. S. et al. Development and testing of a tool to create multiple conical reamed cable bolt anchorages in weak rock. Rock Mech. Rock Eng. 55(12), 7887–7897. https://doi.org/10.1007/S00603-022-03044-X (2022).

Wang, Z. et al. Numerical simulation study on bolting mechanism and support control of soft rock roadway. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 40(3), 35–43. https://doi.org/10.16452/j.cnki.sdkjzk.2021.03.005 (2021).

Guo, G. et al. Model test research on bearing capacity characteristics of underreamed ground anchor in sand. Rock Soil Mech. 33(12), 3645–3652. https://doi.org/10.16285/j.rsm.2012.12.040 (2012).

Guo, G. et al. Model test on mechanical behavior of underreamed ground anchor. In Proceedings of The Fourth International Conference on New Development in Rock Mechanics & Engineering. England: Raton, 217–223 (2012).

Guo, G. et al. Model test research on failure mechanism of underreamed ground anchor. Chin. J. Rock Mech. Eng. 32(8), 1677–1684 (2013).

Wang, S. et al. Experimental study on resin anchoring with reaming bottom and filling in soft rock. ACS Omega 8(9), 8815–8826. https://doi.org/10.1021/ACSOMEGA.3C00095 (2023).

Nan, H. et al. Influence of anchorage body post-expansion on radial pressurization of surrounding rock. Saf. Coal Mines 54(5), 232–239. https://doi.org/10.13347/j.cnki.mkaq.2023.05.033 (2023).

Nan, H. et al. Experimental study on preventing slippage failure of resinbolt in coal roadway by backfilling with enlarged bottom. Saf. Coal Mines 52(2), 54–62. https://doi.org/10.13347/j.cnki.mkaq.2021.02.012 (2021).

Li, G. D. et al. A new determination method of hydraulic support resistance in deep coal pillar working face. Sci. Rep. 15, 19158. https://doi.org/10.1038/s41598-025-04268-x (2025).

Li, W. B. et al. Shearing characteristics of reaming anchorage body in coal mine roadway. J. China Coal Soc. 44(12), 3887–3893. https://doi.org/10.13225/j.cnki.jccs.2018.1686 (2019).

Guo, G. Study on bearing mechanism and ultimate bearing capacity of underreamed anchor. Harbin Inst. Technol. https://doi.org/10.27061/d.cnki.ghgdu.2019.005100 (2019).

Yang, Z. Experiment Study on the anchoring mechanism and Bearing Characteristics of the Capsule-type Expansion Bolt (China University of Mining and Technology, 2016).

Acknowledgements

All authors contributed to this article. I would like to thank Co-author of the thesis Dr. Gang Jing, Prof. Liqiang Ma, A.Prof. Leilei Zhao, Prof. Weiguang Zhang, Hua Nan reviewed and modified the manuscript.

Funding

We acknowledge the financial support for this work provided by the Key Laboratory of Xinjiang Coal Resources Green Mining, Ministry of Education (KLXGY-Z2505), Uygur Autonomous Region Key R&D Program Projects (2024B03017-1), Xinjiang Tian Shan Talent Development Plan Young Top Talent Project (2024TSYCCX0051), Doctoral Start-up Fund of Xinjiang Institute of Engineering (2025XGYBQJ07) and National Key Research and Development Programmes (2023YFC2907501).

Author information

Authors and Affiliations

Contributions

All authors contributed to this article. I would like to thank Co-author of the thesis Dr. Gang Jing, Prof. Liqiang Ma, A. Prof. Leilei Zhao, Prof. Weiguang Zhang, Hua Nan reviewed and modified the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, S., Jing, G., Ma, L. et al. Research on the characteristics and mechanism of bottom expansion backfilling anchoring reinforcement in fractured surrounding rock roadway. Sci Rep 15, 26167 (2025). https://doi.org/10.1038/s41598-025-11417-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11417-9

Keywords

This article is cited by

-

Mechanism and application of reaming anchorage of inverted wedge-shaped hole bottom in argillaceous cemented roadway

Scientific Reports (2026)

-

Research and application on the “multi-layer” filling body with foamed expansion filling material for gob-side entry retaining gateway

Scientific Reports (2025)