Abstract

This study proposes a concrete piezoelectric sensing detection method based on mathematical morphology and fractal theory, which effectively monitors and quantitatively assesses the dynamic evolution process of damage cracks in concrete structures under impact loads. The main contents of this study are as follows: First, it establishes the mapping relationship between the dynamic evolution of damage cracks in concrete under impact loads and the characteristics of piezoelectric time-domain signals for the first time. Through systematic research on the evolution law of peak characteristic parameters of signals in each stage of crack propagation, the intrinsic correlation between the degree of damage and acoustic signals is revealed. Second, it systematically conducts morphological parameter analysis of piezoelectric sensing signals and calculates the morphological fractal dimension (MFD) of piezoelectric signals. Third, it innovatively constructs an intelligent structural damage recognition model integrating morphological fractal theory and artificial neural network (ANN), and conducts a systematic comparative analysis with the traditional wavelet packet transform (WPT) method, verifying the effectiveness of the proposed MFD-ANN intelligent recognition model in this paper. The research results show that the signal corrosion algorithm based on mathematical morphology can significantly enhance the contrast of the steepness characteristics of wave peaks at different damage stages, thereby more effectively capturing the self-similarity characteristics of signal waveforms. Compared with the traditional wavelet packet transform method, the intelligent recognition model established by integrating fractal features and neural networks has a higher recognition accuracy rate for the degree of damage.

Similar content being viewed by others

Introduction

During their service life, transportation infrastructures are subjected to various unexpected dynamic loads, such as terrorist bombings, rockfall impacts, or vehicle collisions. These extreme events, characterized by their abruptness, high randomness, and unpredictability, can readily induce cracking damage in concrete structures. If not promptly addressed, these damages can accumulate and intensify over time during operational phases, severely compromising structural integrity, operational safety, and service functionality. There is therefore an urgent need to develop accurate diagnostic methodologies for detecting concrete cracking damage, which will provide critical technical support for infrastructure condition assessment and maintenance decision-making, ultimately ensuring structural safety and long-term service performance.

Over the past decade, various nondestructive testing (NDT) methods in the field of structural health monitoring have experienced rapid advancements1,2. Among these, the active sensing technique based on lead zirconate titanate (PZT) smart materials with remarkable piezoelectric properties - the Wave Propagation Method (WPM) - has been increasingly demonstrating its significant role in the health monitoring of civil engineering structures. This prominence stems from its distinct advantages, including real-time capabilities, remote accessibility, strong autonomous monitoring capabilities, and cost-effectiveness3.

In the Wave Propagation Method (WPM), at least two sensors must be configured: one serves as an actuator to transmit stress waves, and the other acts as a receiver to capture vibration signals propagated through the medium4. Since the state of the medium is closely related to wave propagation characteristics, structural damage or minor changes in mechanical properties can be characterized by analyzing signal differences between PZT sensors. Due to its sensitivity to micro-damage, active excitation capability, and real-time monitoring advantages, the PZT-based WPM has been widely applied in structural health monitoring. Examples include corrosion monitoring in reinforced concrete structures5, hydration monitoring of concrete6, and damage detection in reinforced concrete structures7,8,9. Zhang et al.10 developed a distributed sensing network using Distributed Fiber-Optic Sensor (DFOS) technology to evaluate the structural integrity of immersed concrete tunnels. Ai et al.11 proposed a novel damage localization method by integrating the Electromechanical Impedance/Admittance (EMI/EMA) technique with a Gaussian distribution-based probability-weighted imaging algorithm.

Lacidogna et al.12 employed acoustic emission (AE), dynamic identification, and piezoelectric sensing techniques to detect stress-induced damage in pre-cracked concrete beams during four-point bending tests. Lakušić et al.13 developed an innovative approach for active health monitoring and damage detection in massive reinforced concrete structures using piezoelectric smart aggregates, establishing a three-dimensional damage index matrix based on wavelet signal decomposition and wave propagation energy. This method demonstrates applicability to various reinforced concrete structures. Xu et al.14 and Chen et al.15 combined PZT-based wave propagation method (WPM) with wavelet packet analysis to actively monitor interfacial debonding damage in concrete-filled steel tubes. Ai et al.16,17 and Nguyen et al.18 integrated one-dimensional and two-dimensional convolutional neural network (CNN) methods with piezoelectric ceramic-based sensing technology, respectively, achieving intelligent monitoring of structural damage. Lacidogna G et al.19 and Accornero F et al.20 enhance the discussion on crack extension monitoring by comparing the proposed piezoelectric method with other NDT techniques such as acoustic emission (AE). Recent advances in acoustic emission-based structural health monitoring techniques have shown high sensitivity to microcrack initiation21.

The aforementioned studies predominantly rely on conventional time-frequency domain analysis methods such as wavelet packet transform or windowed Fourier transform, necessitating manual extraction of dominant signal features accompanied by subjective evaluation. Consequently, signal feature extraction remains constrained by traditional time-frequency analysis frameworks, whose effectiveness is inherently limited by the matching degree of selected basis functions (e.g., mother wavelet functions) or window functions. Moreover, the manual selection of features introduces significant subjectivity and fails to provide effective quantitative characterization for the morphological complexity, irregularity, and evolutionary patterns inherent in piezoelectric signals. To address these limitations, this paper extends the application of the Wavelet Packet Modulation (WPM) method based on PZT sensors to impact damage monitoring. Furthermore, morphological fractal theory is introduced to calculate fractal dimensions as deep-seated damage features that effectively characterize signal waveform complexity. Building upon this foundation, an intelligent recognition model integrating fractal features within a neural network framework is constructed to identify structural damage conditions under impact loading scenarios.

Based on this research foundation, laboratory model tests of steel ball impacts on concrete cube specimens were conducted. The variation patterns of peak characteristics in experimental waveforms corresponding to different crack development stages were systematically investigated using piezoelectric sensing technology. A comprehensive study was performed to examine the influence of different structural morphological operators, operator heights, and lengths on signal morphological analysis. The morphological fractal dimension (MFD) of piezoelectric signals was calculated through fractal theory to quantitatively characterize the complexity variations in signal waveforms. Subsequently, a structural damage identification model based on artificial neural networks (ANN) was developed. Systematic comparative analysis was conducted between the MFD-ANN based damage identification results and traditional wavelet packet transform (WPT) methods, thereby validating the effectiveness of the proposed intelligent identification model utilizing fractal characteristics.

Falling hammer impact specimen model test

Principle of the wave propagation method

The principle of the wave propagation method (WPM) involves applying a transient alternating voltage within a specific frequency range, causing the actuator to undergo harmonic vibration through the inverse piezoelectric effect and generate solid stress waves. Subsequently, these stress waves propagate through the main structure to reach the piezoelectric sensor. The piezoelectric sensor then converts the received stress waves into time-domain voltage signals via the direct piezoelectric effect. Consequently, WPM sensing technology requires at least two surface-mounted or embedded PZT sensors for stress wave transmission and reception. Among the installed piezoelectric sensors, a subset functions as actuators to emit stress waves, while the remainder serve as receivers to capture vibration signals transmitted through the medium. When employing the WPM method to detect impact damage in drop hammer-concrete specimens, both the amplitude and transmission energy of stress waves exhibit gradual attenuation as damage severity increases. Therefore, by analyzing variations in stress waves detected by PZT sensors, it becomes feasible to accurately identify and evaluate impact-induced dynamic damage in concrete structures.

Pilot programme

The impact test system employed a steel frame as the supporting structure, with a 4 kg bearing steel sphere serving as the impactor. The impacted body consisted of C50 concrete specimens. Data acquisition was implemented using National Instruments (NI) data acquisition cards coupled with dedicated computers and connecting cables for waveform recording. The PVC conduit was securely fastened using cable ties to prevent displacement during multiple impacts and sphere rebound processes. Initial alignment between the PVC conduit center and specimen center was ensured using a plumb line prior to impact testing. A 30 cm clearance was maintained between the PVC conduit and specimen top surface to facilitate observation of collision and rebound dynamics. The NI data acquisition system integrated with LabVIEW software formed a comprehensive data collection and analysis platform, comprising four independent acquisition channels. The test utilized swept-sine wave electrical signal inputs with the following parameters: initial frequency 1000 Hz, final frequency 4 × 10⁵ Hz, frequency step of 4 Hz, amplitude 10 V, and duration 1 s. Signal acquisition was performed at 1 × 10⁶ Hz sampling frequency. Median filtering algorithm was applied for noise reduction in piezoelectric sensor signals, effectively eliminating impulse noise and high-frequency interference. PZT patches were precisely positioned at specimen surface centers using plumb lines, rulers, and ink markers for geometric alignment. Detailed specifications and material parameters of the piezoelectric sensors are presented in Table 1.

The drop hammer impact test was conducted on a standard cubic specimen, as illustrated in Fig. 1. A 4 kg iron ball was used as the impactor, released from a height of 1.8 m through a PVC pipe to achieve free-fall motion onto the C50 concrete specimen. The specimen was subjected to repeated impacts until structural failure occurred. Following each impact event, signal variations were monitored and recorded using NI measurement equipment to quantify progressive damage accumulation.

Analysis of impact test results and wave experiment results

The division of impact test stages adopts a classification method based on crack morphology characteristics22. According to Reference22, experimental studies revealed that RC components under punching shear demonstrate distinct phased crack development characteristics, which can be categorized into three stages: Stage I: From initial loading to the emergence of first visible cracks, the component remains primarily in the elastic working stage. Stage II: As cracks progressively develop up to 80% of the ultimate load, a complete annular crack pattern forms, though the component maintains geometric stability without forming a mechanism structure. Stage III: Beyond this point, crack widths increase substantially with significant stiffness degradation until reaching 100% of the ultimate load, at which point the component loses load-bearing capacity.

Therefore, the crack development during the impact test in this section can be described through three stages as analyzed above. The surface crack evolution and piezoelectric time-domain signals during the impact process are presented in Table 2. After the 19th impact, the concrete specimen fractured completely, with the surface crack development during the impact process illustrated in Table 2. Initial indentation stage (Stage I): The first 4 impacts formed distinct impact craters on the specimen surface, creating an indentation diameter of 25.3 mm. The specimen primarily exhibited localized plastic deformation without visible macroscopic cracks. Surface spalling emerged around the impact crater during subsequent impacts (5th-9th). At the 10th impact, the first observable macroscopic crack initiated on the specimen surface, accompanied by crater expansion to 28.6 mm in diameter. Crack propagation stage (Stage II): Subsequent impacts accelerated crack development. A second surface crack appeared after the 11th impact, followed by a third crack after the 13th impact, with the crater diameter further increasing to 30.0 mm. Later impacts (14th-15th) caused continuous widening and significant elongation of existing cracks. The 16th impact marked a critical juncture, with the first penetrating crack appearing across the specimen surface, indicating damage propagation through the primary surface region. Final fracture stage (Stage III): During the 17th and 18th impacts, surface cracks continued to propagate inward and laterally. The specimen completely fractured and lost its load-bearing capacity after the 19th impact. In summary, the test stages are defined as follows: Stage I: 0–10 impacts; Stage II: 11–16 impacts; Stage III: 17–19 impacts.

In this section, the original time-domain signals collected by piezoelectric sensors during impact tests were analyzed using the WPM method. As shown in Table 3, the entire impact process can be divided into three distinct stages based on the evolution of signal amplitude and waveform characteristics. Stage I (1st to 7th impact): The voltage amplitude exhibited minimal fluctuations, remaining stable around 0.2 V. The waveform features remained essentially consistent without noticeable distortion. Stage II (8th to 12th impact): The signal amplitude began to decrease progressively, reaching approximately 0.15 V. A significant waveform alteration was observed during the 10th impact, where the single wave peak transformed into a double wave peak. Stage III (13th to 16th impact): The amplitude experienced substantial reduction, stabilizing at about 0.062 V (representing 31.0% of Stage I amplitude and 41.3% of the Stage I terminal value). Final Stage (17th to 19th impact): The signal amplitude further decreased abruptly to approximately 0.006 V, accompanied by severe waveform distortion characterized by irregular high-frequency oscillations with a sawtooth-shaped pattern.

Morphological fractal theory

Mathematical morphology

Basic theory

Mathematical morphology is a branch of mathematics based on topology and geometry, which is widely used in image processing, computer vision, pattern recognition and other fields, with simple and easy to use, clear physical meaning and other characteristics, only requires simple addition and subtraction operations and comparison process, so the calculation speed is more advantageous compared with wavelet transform and other methods, and can be fast and real-time processing of signals and images. In addition, it examines the interrelationships between various parts of the signal from the characteristics of the object and geometric structure of the research object, and effectively filters out the noise and interference signals in the waveforms through the selection of structural elements in the calculation process. Currently mathematical morphology has been widely used in image processing23, signal noise cancellation24, fault identification25 and many other disciplines and engineering fields.

The basic operations of mathematical morphology are: erosion (Θ), expansion (⊕). A certain signal is f(n) with definition domain Df={0,1,…,N-1}. Define g(n) as a structural element and the domain of definition is Dg={0,1,…,M-1}, N > M. Then the four basic operations corrosion, expansion, open and closed operations are shown in Eq. (1)~(4):

Expansion operation cuts the peaks of the wave by an expansion process, while erosion operation fills the troughs by a contraction process. The open operation, in which the corrosion operation is performed first, followed by the expansion operation, smooths out the signal profile while suppressing peak noise. Closed operations, on the other hand, involve expansion followed by erosion, which fills in the signal troughs and suppresses valley noise.

Comparison of operators with different structures

When applying morphological processing to signals, it is essential to select an appropriate structuring element that moves continuously across the signal to perform dilation and erosion operations. This can be considered as a form of window filtering in the operations, making the choice of structuring element critically important for waveform signal processing. Common structuring elements include circular, linear, curved, triangular, polygonal shapes, or combinations thereof.

This study conducted a comparative analysis of preprocessing piezoelectric signal waveforms (samples 4 and 40) using three types of structuring elements: linear, triangular, and trapezoidal, as illustrated in Figs. 2(a)-(d). The linear structuring element was defined as [0.005, 0.005, 0.005], the triangular as [0, 0.005, 0], and the trapezoidal as [0.005, 0.005, 0]. The linear structuring element demonstrated superior performance in revealing fine-grained details during both erosion and dilation operations: the erosion effectively captured local concave features of the waveform, while the dilation enhanced contour information at abrupt transitions. In contrast, the triangular and trapezoidal structuring elements, due to their geometric constraints, introduced excessive steepness variations in peaks and distortion of signal maxima during processing. It is concluded that linear structuring elements exhibit distinct advantages in waveform signal processing. Consequently, this study ultimately selected the linear structuring element as the core operator for morphological processing.

Parameter analysis of structural operator

This section employs a trial method to analyze the length and height parameters of structuring elements. The length parameters of the structuring elements are selected as 2、 3、 and 4, while the height parameters are set to 0、0.005、and 0.01. Erosion and dilation operations were performed on specific time segments of two sample waveforms: a non-impacted waveform sample 4 and an impacted waveform sample 40, as illustrated in Fig. 3. Both sample groups demonstrate similar collision effects in erosion operations. Figures 3(a)-(d) reveal the erosion and dilation effects of linear structuring elements with different lengths on original waveforms. Small-scale structuring elements (Ln=2) generate filtering windows that effectively capture waveform edge details while preserving high-frequency signal information, though their decomposition performance remains limited. Conversely, large-scale operators (Ln=3 and 4) exhibit more distinct decomposition characteristics, yet produce coarser edge details with notable waveform distortion and significant changes in peak steepness. These phenomena primarily stem from the short intervals between peak data points in the sampled experimental waveforms. Figures 3(e)-(h) demonstrate the erosion and dilation effects of linear structural operators with varying heights on the original waveform. As the operator height Ap increases, the erosion results exhibit intensified peak attenuation with progressively sharpened peak morphology and significantly aggravated waveform distortion. Similarly, the dilation results show substantial distortion phenomena in the trough regions of the derived curves. Therefore, this study adopts the structural parameters of the operator with Ap = 0 and Ln= 2 for optimal performance.

Fractal theory

Basic concepts

The concept of fractal geometry was first introduced in 1975 by the French Mathematician B.B Mandelbort26. Fractals have three important features: infinite recurrence, autocorrelation and fractional dimension. Fractal can be considered as a pattern formed by a certain micrograph after countless recursive iterations, which can be enlarged infinitely in detail, and the structural pattern of this kind has similarity from the point of view of each iteration or at various scales, and the similarity between the local nature of the structure and the overall nature is called autocorrelation. Similar to the Koch curve pattern, the fractal pattern formed by a one-dimensional line through iteration, when the number of iterations is infinite, the one-dimensional line segments gradually fill the two-dimensional space, at this time the dimensionality of the pattern can no longer be defined by the traditional dimensionality, Hausdorff from the object’s self-similarity to define the dimensionality, proposed the Hausdorff dimension, defined as:

Where: N is the percentage of graph reduction, and M is the number needed to reduce the graph to cover the original.

Similarly, the fractal dimension formula can be defined as follows:

Where: ε is the length of the side of the small cube, and N(ε) is the number of this cube required to cover the measured object.

Difference box dimension

In 1986 Gangepain and Roques-Carms proposed the fractal dimension27 based on Box-counting, which calculates the minimum number of boxes covering the surface of an image to describe the fractal dimension of the image. In this section, the fractal dimension of the test waveform is calculated by calculating the minimum number of boxes covering the waveform pattern. The test waveform is considered as a two-dimensional object with the horizontal coordinate as time (length N) and the vertical coordinate as the grey value of the object, which indicates that the grey value of the waveform at moment x is f(x). The waveform image is divided into a number of grid sub-blocks with side length n. Each grid is covered with small boxes of unit length (the unit length can be defined), and the number of small boxes covering the whole waveform can be calculated by Eq. 728:

Where: m is the number of boxes in the ith grid containing the minimum grey value and l is the number of boxes in the ith grid containing the maximum grey value.

The number of boxes Nr that cover the entire waveform curve:

This leads to the fractal dimension DM.

Where: r is n/N, a set of Nr is computed by varying the size of the mesh side length n. A linear regression is performed on the computed points {log(1/r), log(Nr)}, and the slope of this line is the fractal dimension DM.

The fractal dimension of the original waveform sample 4 was estimated and its double logarithmic scatter plot is shown in Fig. 4, presenting the process of applying the box counting method, which was obtained by calculating the number of boxes required to cover the curve at different scales, which was fitted by the least squares method.

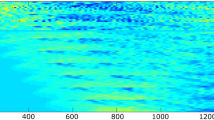

Fractal result analysis

The overall test involved 19 impact applications, with 5 sets of sample data collected after each impact. Additionally, 10 sets of sample data were obtained from non-impacted specimens. This resulted in a total of 105 experimental datasets. Based on the analysis in the preceding section, the test conditions were divided into three stages: conditions 1–60 as Stage I (initial crack emergence), conditions 61–90 as Stage II (complete annular crack formation), and conditions 91–105 as Stage III. Fractal dimension calculations were performed on all 105 piezoelectric sensing signals, with the fractal analysis results shown in Fig. 5. Mathematical morphology operations including dilation, opening operation (erosion followed by dilation), and closing operation (dilation followed by erosion) were applied to the original waveform data, with the calculation results presented in Table 3.

As can be seen in Fig. 5, the fractal dimension of the overall impact test conditions shows a decreasing trend, in which the fractal dimension of the first stage of the conditions is at 1.815 ~ 1.830, the fractal dimension of the second stage is at 1.781 ~ 1.795, and the fractal dimension of the third stage is at 1.697 ~ 1.760. In addition, the fractal dimension of some samples in the second stage (data collected after the 11th and 12th impacts) still fluctuates above and below 1.82, which is due to the fact that the cracks on the surface of the specimen just appeared and did not have a big influence on the stress wave propagation until the third crack appeared, at which time the crack had developed to the centre of the specimen. The fractal dimension still fluctuates up and down at 1.82, which is due to the fact that the cracks on the surface of the specimen just appeared and did not have a large impact on the propagation of the stress wave until the third crack appeared, at which time the cracks had developed to the centre of the specimen and the fractal dimension of the waveform decreased to 1.78.

According to Table 3, the fractal dimensions exhibited the following ranges under different treatments: For post-corrosion samples, Stage I fractal dimensions ranged from 1.806 to 1.826, Stage II from 1.776 to 1.789, and Stage III from 1.681 to 1.751. Expanded samples showed fractal dimensions of 1.809–1.826 in Stage I, 1.775–1.789 in Stage II, and 1.679–1.750 in Stage III. The corrosion-expansion sequential treatment resulted in fractal dimensions of 1.811–1.827 for Stage I, 1.776–1.791 for Stage II, and 1.679–1.749 for Stage III. Conversely, the expansion-corrosion sequential treatment demonstrated Stage I fractal dimensions between 1.812 and 1.828, Stage II values of 1.776–1.791, and Stage III measurements ranging from 1.679 to 1.750.

Parameter analysis of neural network model

According to Sect. “Fractal result analysis”, after morphological processing of experimental waveforms, the differences in fractal dimensions among three-phase samples became more pronounced. This section further extracts features using neural network algorithms and constructs a concrete crack state recognition model combined with Softmax regression. A neural network model was developed through TensorFlow by establishing a Sequential model architecture, where the Adam optimizer was employed for parameter optimization. Hold-out cross-validation (70% samples for training and 30% for testing) was implemented for model refinement. The input matrix (dimension = 5) incorporates fractal dimensions of raw data, eroded data, dilated data, open-operation data, and closed-operation data, while the output consists of three categorical classes.

The study investigated how hidden layer configurations and neuron quantities influence model performance. Initial parameters included 6 hidden layers with 10 neurons per layer, ReLU activation functions, and 20,000 iterations. Models with varying neuron numbers (4, 10, 14, 20) were comparatively analyzed for accuracy and loss function values illustrated in Figs. 6(a)-(h) and detailed in Table 4. From Fig. 6; Table 4, it can be obtained that increasing neuron counts progressively reduced training loss and enhanced training accuracy. However, test accuracy exhibited an initial increase followed by subsequent decline, attributable to overfitting caused by excessive neurons. This validates the necessity for judicious neuron selection, leading to the determination of 10 neurons per layer as the optimal configuration through comprehensive analysis.

The number of hidden layers serves as a critical parameter in neural network construction Iterative training was conducted on models with 2, 6, 10, and 15 hidden layers, with the corresponding model accuracy and loss function values illustrated in Figs. 7(a)-(h) and detailed in Table 5. The results demonstrate that as the number of layers increases, model accuracy initially improves before declining, while the loss function value first decreases and then rises. This phenomenon arises because models exceeding 10 hidden layers exhibit overfitting issues, manifesting oscillations in both sample accuracy and loss function values. Notably, the 15-layer neural network model displays particularly pronounced oscillation characteristics (as shown in Fig. 7. g-h), leading to degraded predictive performance. Consequently, this section adopts a 6-hidden-layer neural network architecture as the optimal configuration.

Therefore, the neural network architecture with 10 neurons and 6 hidden layers was selected as the optimal configuration, and its training performance is demonstrated in Figures c-d. As shown in Fig. 7, as the number of iterations increased, both the loss function values of the testing and training sets progressively decreased, while the prediction accuracy of samples continued to improve until stabilization was achieved at 12,000 iterations. Specifically, the training set attained a loss function value of 0.31 with an accuracy of 85%, whereas the testing set achieved a loss function value of 0.37 and an accuracy of 88.4%. These results confirm that fractal dimension can be effectively used to detect crack damage in concrete structures under impact load.

Contrast verification

Wavelet packet transform and neural network model

To validate the effectiveness of the fractal theory-based feature extraction method, the piezoelectric signal sample 4 was subjected to wavelet packet decomposition using the Bior1.5 wavelet. The sample data were decomposed over three levels, yielding 8 sub-bands of time-domain signals across distinct frequency ranges, as illustrated in Fig. 8. Subsequently, multi-scale spatial energy features were extracted from the wavelet packet decomposition and sequentially arranged into feature vectors to construct the wavelet energy spectrum, shown in Fig. 9(a). Further analysis involved three-level wavelet packet decomposition of 105 sets of piezoelectric sensing signals acquired throughout the impact experiment. This process generated eight frequency sub-bands for each sample, and a comparative analysis was conducted on the energy peaks of 105 samples across three impact stages. Extract the peak energies from the eight frequency sub-bands generated by wavelet packet decomposition of each set of piezoelectric sensor signals, and an energy peak diagram of wavelet decomposition for the total samples was subsequently plotted. as presented in Fig. 9(b).

Figure 9(a) illustrates the band numbering (horizontal axis) and energy distribution proportions (vertical axis) of each frequency band after wavelet packet transform processing. As clearly observed from Fig. 9(b), the energy peak distributions of piezoelectric sensing signals exhibit distinct characteristics following wavelet packet decomposition. The results demonstrate that the fractal energy spectrum of impact test waveforms under complete experimental conditions shows a descending trend. Specifically, the peak energy of wavelet energy spectrum in Stage I falls within the interval [9 × 10−2, 0.23], while that in Stage II ranges between [3.1 × 10−3, 4.7 × 10−2], and Stage III displays fractal energy spectrum peaks within [1.2 × 10−5, 2.8 × 10−5]. Notably, the energy spectrum peak energy of partial specimens in Stage II (data collected after the 16th and 17th impacts) decreased from 5.9 × 10−4 to 1.2 × 10−5. This phenomenon is attributed to the initial formation of surface cracks in the specimen, which exerted minimal influence on stress wave propagation until the emergence of the third crack. At this critical phase where cracks had propagated to the specimen’s core, the waveform fractal energy spectrum declined significantly to 0.118 × 104.

Contrast verification

Adopting the optimal neural network model parameters from Sect. “Parameter analysis of neural network model”, the wavelet energy spectra obtained through wavelet packet transform from piezoelectric signal samples in comprehensive impact tests were utilized as input features, with an input matrix dimension of 8 and 3 output categories. The neural network model comprised 6 hidden layers containing 10 neurons each, employing ReLU activation functions, and underwent 20,000 training iterations. The performance comparison between this model and the fractal dimension-based neural network approach is illustrated in Figs. 10(a)-(d).

As shown in Fig. 10, with the increase in iteration numbers, both the training and testing loss values of the morphological sample and wavelet packet transform (WPT) sample exhibit a decreasing trend, while their prediction accuracies progressively improve until stabilization occurs at 16,000 iterations. Specifically, the morphological sample achieves a training loss value of 0.31 with 85% accuracy, and a testing loss value of 0.37 with 88.4% accuracy. In contrast, the WPT sample attains a training loss value of 0.26 with 82.5% accuracy, and a testing loss value of 0.31 with 80.1% accuracy. These results indicate that the concrete damage identification model based on morphological fractal theory and neural network framework demonstrates superior precision. The mathematical morphology method requires less stringent preprocessing of original piezoelectric signals, and the calculation of fractal dimension as a damage characterization parameter proves relatively straightforward and efficient. In comparison, the effectiveness of WPT depends heavily on wavelet packet selection. Collectively, this study validates that the feature extraction method integrating mathematical morphology and fractal dimension exhibits higher effectiveness for crack damage detection in concrete structures under impact loading conditions.

Conclusion and prospect

This study proposes a concrete structure damage identification model that integrates piezoelectric sensing technology with mathematical morphology analysis. Through steel ball impact tests and piezoelectric sensing techniques, we reveal the evolution pattern of peak characteristics in piezoelectric signal waveforms during different stages of concrete crack propagation. A systematic investigation was conducted on the influence of structural elements (type, length, height) on mathematical morphology analysis effectiveness. Results demonstrate that the erosion algorithm effectively enhances the contrast of damage signal peak characteristics and improves the discernibility of their self-similarity properties. Building on this foundation, the fractal dimension of piezoelectric signals was extracted as a damage feature to construct an artificial neural network-based damage identification model. Compared with traditional wavelet packet transform (WPT) methods, this model achieves significant improvement in damage severity recognition accuracy, reaching 88%. This research provides an effective new solution for damage detection in concrete structures.

This study proposes a concrete structure damage identification model based on fractal dimension features, established through indoor impact test models and piezoelectric sensing technology. However, the model’s effectiveness lacks validation using real-world engineering data, limiting its generalizability for practical applications. Therefore, subsequent research will incorporate data from actual engineering scenarios to verify and optimize the model, which holds significant practical engineering value. Furthermore, unresolved challenges such as environmental noise sensitivity, real-time acquisition of engineering data, and damage characterization in complex environments remain unaddressed. Future work will prioritize the development of adaptive noise suppression algorithms and feature extraction methods incorporating environmental compensation mechanisms. Additionally, establishing quantitative relationships between core fracture mechanics parameters and fractal dimension features is critical to enhancing the physical interpretability of concrete damage identification models, facilitating the characterization of damage states and evolution processes. To further validate and generalize the approach, long-term monitoring tests on critical infrastructure components (e.g., bridge elements) will be conducted to acquire real operational data, optimize iterative algorithm models, and propose practical deployment solutions and application scenarios for this methodology.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Jiao, P. et al. Piezoelectric sensing techniques in structural health monitoring: A State-of-the-Art Review[J]. Sensors 20 (13), 3730 (2020).

Ju, M. et al. Piezoelectric materials and sensors for structural health monitoring: fundamental aspects, current status, and future Perspectives[J]. Sensors 23, 543 (2023).

Gao, W. H. et al. High Spatial resolution imaging for damage detection in concrete based on multiple wavelet decomposition[J]. Constr. Build. Mater. 319, 126057 (2022).

Zhang, C. et al. Real-time monitoring stiffness degradation of hardened cement paste under uniaxial compression loading through piezoceramic-based electromechanical impedance method[J]. Constr. Build. Mater. 256, 119395 (2020).

Jin, C., Jeong, J-A. & Kyoung, E-J. A study on the corrosion monitoring of Multi-functional sensors for reinforced concrete structures: part 1[J]. Corros. Sci. Technol. 11 (6), 270–274 (2012).

Ai, D., Lin, C. X. & Zhu, H. P. Embedded piezoelectric transducers based early-age hydration monitoring of cement concrete added with accelerator/retarder admixtures[J]. J. Intell. Mater. Syst. Struct. 32, 847–866 (2020).

Kocherla, A. & Subramaniam, K. Stress and damage localization monitoring in fiber-reinforced concrete using surface mounted PZT sensors[J]. Meas. Sci. Technol. 31 (2), 024004 (2019).

Tang, Z. S. et al. Development of analytical and numerical models for predicting the mechanical properties of structural adhesives under curing using the PZT-based wave propagation technique[J]. Mech. Syst. Signal Process. 128, 172–190 (2019).

Carpinteri, A. et al. Mechanical and electromagnetic emissions related to stress-induced cracks. Exp. Tech. 36, 53–64 (2012).

Zhang, X. H. et al. Designing a Distributed Sensing Network for Structural Health Monitoring of Concrete Tunnels: A Case Study[J]. Structural Control and Health Monitoring, DOI10.1155/2024/6087901 (2024).

Ai, D., Zhang, D. L. & Zhu, H. P. Damage localization on reinforced concrete slab structure using electromechanical impedance technique and probability-weighted imaging algorithm[J]. Constr. Build. Mater. 424, 135824 (2024).

Lacidogna, G., Piana, G. & Carpinteri, A. Acoustic emission and modal frequency variation in concrete specimens under Four-Point Bending[J]. Appl. Sci. 7, 339. https://doi.org/10.3390/app7040339 (2017).

Lakušić, S. Energy Based three-dimensional Damage Index for Monitoring and Damage Detection of Concrete structures[J] (Journal of the Croatian Association of Civil Engineers, 2022).

Xu, B. et al. Active interface debonding detection of a concrete-filled steel tube with piezoelectric technologies using wavelet packet analysis[J]. Mech. Syst. Signal Process. 36 (1), 7–17 (2013).

Chen, H. B. et al. Debonding detection for rectangular CFST using surface wave measurement: test and multi-physical fields numerical simulation[J]. Mech. Syst. Signal Process. 117, 238–254 (2019).

Ai, D. & Cheng, J. A deep learning approach for electromechanical impedance based concrete structural damage quantification using two-dimensional convolutional neural network[J]. Mech. Syst. Signal Process. 183, 109634 (2023).

Ai, D. et al. Automated identification of compressive stress and damage in concrete specimen using convolutional neural network learned electromechanical admittance[J]. Eng. Struct. 259, 114176 (2022).

Nguyen, T. T. et al. Deep learning-based functional assessment of piezoelectric-based smart interface under various degradations[J]. Smart Struct. Syst. 28, 69 (2021).

Lacidogna, G., Accornero, F. & Carpinteri, A. Influence of Snap-Back instabilities on acoustic emission damage monitoring. Eng. Fract. Mech. 210, 3–12 (2019).

Jiang, Z. et al. Multi-technique analysis of seawater impact on the performance of calcium sulphoaluminate cement mortar. Constr. Build. Mater. 443, 137717 (2024).

Lomazzi, L. et al. On the explainability of convolutional neural networks processing ultrasonic guided waves for damage diagnosis[J]. Mech. Syst. Signal Process. 183, 109642 (2023).

Bazant, Z. P. & Cap, Z. Size effect in punching shear failure of slabs[J]. ACI Struct. J. 84 (1), 44–53 (1987).

Kimori Yoshitaka. Mathematical morphology-based approach to the enhancement of morphological features in medical images. J. | [J] J. Clin. Bioinf. Volume. 1, Issue 1., 33 (2011).

Weilin Huang. Runqiu wang; shaohuan zu; yangkang chen. Low-frequency noise Attenuation in seismic and microseismic data using mathematical morphological filteringJournal[J]. Geophys. J. Int. Volume. 222 (Issue 3 ), 1728–1749 (2020).

Zhong, H. H. et al. Lightning strike identification algorithm of an All-Parallel Auto-Transformer traction power supply system based on morphological fractal Theory[J]. IEEE Trans. Power Delivery, 38 (3), 2119–2132 (2022).

Mandelbrot, B. B. Stochastic models for the Earth’s relief, the shape and the fractal dimension of the coastlines, and the number-area rule for islands[J]. Proceedings of the National Academy of Sciences, 72(10): 3825–3828. (1975).

Tzeng, Y. C., Fan, K. T. & Chen, K. S. A parallel differential Box-Counting algorithm applied to hyperspectral image Classification[J]. IEEE Geosci. Remote Sens. Lett. 9 (2), 272–276 (2012).

Soares, F. et al. 3D lacunarity in multifractal analysis of breast tumor lesions in dynamic Contrast-Enhanced magnetic resonance Imaging[J]. IEEE Trans. Image Process. 22 (11), 4422–4435 (2013).

Acknowledgements

This study is financially supported bythe Transport Technology Project of Jiangxi Province, China (Grant No. 2023H0018), Special Project for Cultivating Early Career Young Talents in Vocational Fields of Jiangxi Province, China (Grant No. 20244BCE52139), Ph.D. Initiation Fund Project (Grant No. 2003423052).

Author information

Authors and Affiliations

Contributions

Hanqing Zhong: Writing-original draft, Software, Data curation, Methodology.Liwei Shuai: Writing– review & editing, Software, Data analysis. Dongmin Deng: Writing– review & editing, Modelling.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhong, H., Shuai, L. & Deng, D. Research on concrete structure damage detection based on piezoelectric sensing technology and morphological fractal method. Sci Rep 15, 26604 (2025). https://doi.org/10.1038/s41598-025-11619-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-11619-1