Abstract

Methylene blue dye contamination poses serious environmental and health risks, necessitating efficient removal methods. Conventional Zinc Oxide (ZnO) nanoparticles synthesized chemically face issues like toxicity, instability, and agglomeration, reducing their effectiveness. This study explores the green synthesis, characterization, and application of teff straw-assisted ZnO nanoparticles, using neem leaf extract as a capping agent, for MBD removal from textile wastewater. Characterization via X-ray diffraction (XRD) and Fourier Transform Infrared Spectroscopy (FTIR) confirmed functionalization, with an average crystalline size of 27.196 nm. Adsorption experiments analyzed the impact of pH, adsorbent dose, contact time, and initial dye concentration, while Response Surface Methodology (RSM) with a Central Composite Design (CCD) optimized conditions, achieving 99.77% removal efficiency at pH 6.9, 68.5 mg/L dye concentration, 0.265 g adsorbent dose, and 77.87 min contact time, fitting the Freundlich isotherm model (R² = 0.99). Real textile wastewater treatment showed 92.5% removal efficiency, proving teff straw-assisted ZnO nanoparticles as a sustainable, eco-friendly alternative for wastewater treatment.

Similar content being viewed by others

Introduction

Water, which makes up two-thirds of the earth’s surface, is the most basic ingredient for all life forms1. Contamination of water resources has increased as a result of wastewater discharged directly into the water without sufficient treatment as industry and urbanization have progressed. Environmental pollution caused by colored effluents is threatening to the world2. Textiles, rubber, paper, plastic, cosmetics, and others produce colored organic effluent3. Textile industries processes are among nearly all industries that discharge colored wastewater including dye which becomes a major environmental alarm4.

As revealed by Oyewo et al., 2020 5, Methylene Blue Dye (MBD) is the most widely used dye in the textile and printing sectors. Methylene Blue (C16H18CIN3S) is a cationic dye that’s commonly used to color cotton, wool, and silk6. In the chemical industry, it’s also utilized as a stabilizer and an indicator. As a result, these companies effluents include a high quantity of MBD, rendering water unsuitable for both industrial and home usage. This is because MBD, even at trace levels, has a considerable impact on aquatic life’s photosynthetic activity. It could potentially cause significant harm to human organs, including the reproductive system, kidneys, central nervous system, brain, and liver7.

The World Health Organization (WHO) recommends that coloring chemicals in drinking water be limited to 1 mg L−18. As a result, effective and functional equipment to extract MBD from wastewater is urgently needed. The textile industry discharges effluents into receiving water might be hazardous to marine life, and sunlight transmission is reduced through colored water. Particularly when even a 1.0 mg L−1 concentration of dye in the water supply could be unsuitable for human intake.

Different procedures, including biological, chemical, and physical processes, could be used to remove MBD from wastewater. Some of these approaches have drawbacks, such as limited performance, MBD non-biodegradability, and secondary waste formation, all of which cause disposal issues5 Because of its simplicity, low cost, and high efficiency in removing color and other impurities, the adsorption method is frequently utilized2. The use of nanoparticles in adsorption techniques is getting attention, and it’s a potential method for removing color from textile wastewater9. Because of their higher surface-to-volume ratio than other adsorbents, nanoparticles have been shown to have a significant potential for adsorbing organic chemicals, particularly colors, from wastewater and sewage tanks2.

Adsorption of hazardous dyes by metal oxide nanoparticles has shown considerable promise10. Because of their great surface area and thermal and chemical stability, a variety of inorganic metal oxides may be useful adsorbents11. Because of their nontoxicity, long-term stability, affordable cost, biocompatibility, and powerful antibacterial properties against microbes often found in water, zinc oxide nanoparticles (ZnO NPS) have gotten a lot of interest in water treatment12. Chemical, physical, and biological techniques, for example, take less time to synthesize vast amounts of metal nanoparticle but they require hazardous compounds as capping agents to ensure stability, resulting in environmental toxicity13. Sol-gel techniques, co-precipitation, laser vaporization, microemulsion, and ball milling are some of the physiochemical approaches that can be used to make ZnO nanoparticles (NPS). The expensive cost of equipment, the wide area required for equipment setup, and the added usage of capping agents, stabilizers, and hazardous chemicals are all common drawbacks of these preparation procedures14.

As a result, there is an increasing need to develop clean, non-toxic, and environmentally friendly nanoparticle synthesis procedures. Some of the distinct advantages that biological synthesis protocols have over traditional physical and chemical methods are as follows15: Because no toxic chemicals are used, the method is clean and environmentally friendly; the active biological component, such as an enzyme, acts as a reducing and capping agent, lowering the overall cost of the synthesis process; even during large-scale production, small nanoparticles can be produced. External experimental conditions such as high energy and pressure are not required, resulting in significant energy savings. For nanoparticle synthesis, a wide variety of biological resources such as microorganisms (bacteria, yeast, fungi, algae, and viruses) and plants can be used. While microbe-based protocols have been developed as a result of the combined research efforts of several authors, plant-mediated biological synthesis of nanoparticles has only recently gained prominence. Plant extracts, as opposed to microbes, reduce metal ions in a shorter time. Nanoparticles can be synthesized in a matter of minutes or hours, depending on the plant type and concentration of phytochemicals, whereas microorganism-based methods take much longer15. The main disadvantage of microbe-mediated nanoparticle synthesis is the requirement for aseptic conditions, which necessitates trained personnel and raises the scaling-up cost. All of these factors, combined with the ease with which plants can be found in nature, make plants preferable biological resources to microbes.

The green technique of synthesis of metal oxide (ZnO) nanoparticles is easier and safer to utilize in the development of nanomaterials, and plant-mediated production of nanoparticles using polyphenol as a reducing agent is still a new approach. Biosynthesis often called green synthesis is a technique for making NPs from plant extracts. This technology produces biocompatible NPs without the use of harmful chemicals, and it is used in the production of pharmaceuticals. Green synthesis is also a more cost-effective alternative to chemical synthesis, which is quite expensive9. Plants that have previously been used to synthesize ZnO NPs include Cassia fistula16Aloe vera17Solanum nigrum, Agathosma18. In Ethiopia, neem (Azadirachta indica) is a cheap and readily available source; hence a researcher used neem leaf extract for ZnO NP production.

Due to their large specific surface area and high reactivity, most of the atoms of Metal oxide nanoparticles (ZnO-NPS) occur on the surface of the NPS (hence, they are unstable). Because the surface atoms are not saturated, they can bind with more atoms, resulting in increased chemical activity19. Metal oxides can be reduced to nanosize to increase surface area, but this increase can also cause instability. The nanoparticles with high reactivity will be susceptible to agglomeration during the synthesis process20. Furthermore, nanoparticles have a high aggregation tendency, which could result in a loss of adsorption efficiency21. To avoid these drawbacks, metal oxides are characteristically incorporated into supports or other bulk adsorbents22.

Various adsorbents such as activated carbon, agricultural wastes, and nanomaterials have been used for methylene blue (MB) removal, each with limitations in capacity, cost, or reusability. Composite materials like chitosan-pectin (Cs-Pc) outperform these alternatives due to their highly porous structure, abundant active sites, and strong electrostatic interactions with MB molecules. Cs-Pc composites achieve higher adsorption capacities (up to 328.02 mg/g), excellent reusability, and cost-effectiveness compared to traditional adsorbents. Thus, their superior performance in the adsorption process makes them promising candidates for efficient and sustainable MB dye removal from wastewater23. Mango seed powder, coconut shell activated carbon, and pineapple peel are highlighted for their high adsorption capacities due to functional groups and porosity. Fish scale-derived mesoporous carbon and ZnCl₂-activated cashew nut peel demonstrate tailored surface chemistry for MB binding24. This study aimed to green synthesize and characterize teff straw-assisted ZnO nanoparticles, enhancing their properties for Methylene Blue Dye (MBD) removal from textile wastewater. The research explored the influence of adsorption parameters and kinetics, with experiments designed using the central composite design method.

Materials and methods

Chemicals and materials

In this study, the fresh leaves of neem for phenol extraction were collected from Jimma, around the Jimma Institute of Technology (JIT) Campus, and Teff straws which were used as porous materials were collected from the agricultural farm field of Wolkite, Gubre, Gurage zone using plastic bags and used as raw materials. This study complies with all relevant institutional, national, and international guidelines and legislation for the collection and use of plant materials. Appropriate permissions were obtained for the collection of plant or seed specimens from the relevant authorities, ensuring adherence to ethical and legal requirements. The identification of plant species was conducted following standard botanical protocols, and voucher specimens were deposited in a recognized herbarium for future reference. The Materials, chemicals, and reagents required for the experimentation were purchased from Merck india pvt ltd, India: Methylene blue (C16H18N3CLS, AR 85%), analytical grade zinc nitrate (99%) used for stock solution preparation, potassium bromide (to form pellet paste), Distilled water, sodium chloride (99.5%) (LOBA Chemie, India) for the analysis of point of zero charges, hydrochloric acid (HCl, 99%, Sigma-Aldrich, Bangalore, India) and sodium hydroxide (99.8%) (ATDM, Turkey) for pH adjustment, distilled water was used for solutions preparations, Potassium dichromate (K2CrO3) and Silver nitrate (AgNO3) for chloride testing, standard sulfuric acid (St. H2SO4) and ferrous ammonium solution for COD testing, Ferroin indicator as an indicator for the color change.

The types of equipment such as XRD (DW-XRD-Y7000, China), UV-Vis Spectrophotometer (UV- 1800, Germany), and FTIR (Perkin Elmer spectrum Two, China) were used to characterize synthesized ZnO-TSA nanoparticles.

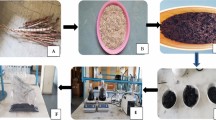

Preparation and modification of the adsorbent

Green synthesis of ZnO nanoparticles

After collection, the straw samples were air-dried, cut into smaller pieces to reduce the size, and then washed five times with distilled water to remove dust particles and other soluble impurities. The samples were ground in an electric mill after drying and allowed to pass through a 0.25 mm. The powdered samples were dried for 24 h in a 105 °C oven until the bulk of the powdered sample was constant25.

According to Razali et al., 202025 with slight modification, the collected neem leaves were washed thoroughly 2–3 times with distilled water before use. The leaves were allowed to dry at room temperature (25°C), and 10 g were taken for synthesis. 10 g of leaves were boiled in 100 mL of distilled water for 20 min at 60 °C. During the boiling process, a light-yellow solution was formed that was cooled at room temperature. The yellow-colored extract was then filtered with filter paper (Whatman No.1) and refrigerated. The resulting extract was used in the synthesis of Zinc oxide and Teff straw-assisted Zinc oxide nanoparticles as neem extract solutions.

A typical procedure was used to synthesize zinc oxide nanoparticles. 10 mL of neem leaf aqueous extract was taken from the stock solution (stored in the refrigerator). Later, 2 g of zinc nitrate hexahydrate [Zn(NO3)2•6H2O] crystal was dissolved in the neem leaf extract solution while using a magnetic stirrer to maintain constant stirring. After the mixture was completely dissolved, the solution was boiled at 60 °C with a magnetic stirrer until a deep yellow-colored paste formed. The paste was transferred to a ceramic crucible cup and placed in a 400oC furnace for 2 h25. Finally, the resultant light yellow powder is used for further characterization of teff straw-assisted zinc oxide of nanoparticles.

Teff straw assisted ZnO nanoparticles

Two grams of Zn (NO3)2.6H2O were dissolved in 100 mL deionized water and added to a 250 mL beaker with 10 mL of neem leaf extract and 0.5 g of ground teff straw powder, then heated for 2 h at 60 °C under mild string using a magnetic stirrer. Then 4 mL of 2 M (8 g) NaOH was added dropwise until the solution changed to a deep yellow color, indicating the formation of Teff straw-assisted ZnO nanoparticles. The solution was left undisturbed, and the deep yellow precipitates accumulated at the flask’s bottom. The solution was left alone, and the yellow precipitates accumulated at the bottom of the flask. After decanting the solution, the precipitates were isolated and washed twice with deionized water. Following that, the solution was centrifuged at 250 rpm for 20 min. The centrifugation and washing procedures were carried out three times each. The precipitates were then carefully transferred to a ceramic crucible and dried in a furnace at 400oC for 2 h. Finally, the Product was kept in the appropriate place for characterization and applicability for the removal of MBD from Textile industry wastewater (adsorption purposes)25,26.

Characterization of adsorbent

The synthesized ZnO NPs characterized by UV–Visible absorption spectroscopy, X-ray Diffractometer spectroscopy, and Fourier Transform Infrared spectroscopy analyses.

The UV-visible spectral analysis confirmed the synthesis of Teff Straw Assisted Zinc oxide Nanoparticle (ZnO-TSA NPS). For the analysis, a small aliquot of the supernatant of the synthesized ZnO or ZnO-TSA nanoparticles was used. As a result, the characteristic absorption peak for the synthesized ZnO-TSA nanoparticles was recorded and analyzed in a spectrophotometer with a resolution of 1 nm using UV–visible absorption spectroscopy in the wavelength range of 200 to 800 nm. X-ray diffraction (DW-XRD-Y7000) was used to study the crystallite size and crystallinity of green synthesized ZnO-TSA NPS. Characterization was performed on the well-dried and powdered samples. It was used with CuK radiation (= 0.154021 nm) at 30 kV and 25 mA. The scanning was done from 10 to 80° in 0.03°s−1 steps to collect 2θ data. Match! Software version 3.10.2.173 was used to analyze the phase and pattern of the XRD data in Eq. (1).

Where D is the mean crystalline size, κ is the Scherer’s constant (shape factor) with the value of 0.9, λ is the X-ray wavelength (0.154021 nm), β is the full width at half maximum (FWHM) in radians, and θ is the Bragg angle.

The surface functionalization of the synthesized ZnO-TSA NPS was characterized using Fourier transform infrared (FT-IR) spectroscopy (Perkins Elmer L1600300). The synthesized adsorbent was dried, ground, and mixed in appropriate ratios with KBr powder to form a pellet for FT-IR spectroscopy analysis. The pelletized sample was then analyzed using FT-IR spectra before the adsorption experiments. These measurements were carried out, and spectra in the 500–4000 cm−1 range were collected.

The pHpzc (point of zero charges) is pH when the charge on the surface is zero. The procedure of the pH drift method could be described as follows: to a series of nine 250 mL conical flasks, 50 mL of 0.01 M NaCl was added. Then, the initial solution pH values (initial pH) were adjusted as 2,3,4,5,6,7,8,9, and 10 using 0.01 M HCl solutions and 0.01 M NaOH. After the constant value of the initial pH had been reached, 0.10 g of ZnO-TSA Nps sample was added into each conical flask and caped immediately. This mixture was kept undisturbed for 12 h till reaching equilibrium. After 12 h, the pH of the solution was measured carefully by using a pH meter and noted as pH final. The pHpzc of the ZnO-TSA Nps sample is the point when initial and final pH same. The plot of the initial pH versus the difference in final pH was constructed and the pH of the point of zero charges (pHpzc) was obtained as the intercept on an x-axis of the plot. Similar reports were stated by27.

Preparation of adsorbate

In this study, MBD powder was used as the adsorbate molecule in adsorption experiments. Preparation of the stock solution of MBD was carried out by dissolving 1 g of MBD in 1000 mL distilled water to get 1000 mg/L. The intermediate solution of 100 mg/L of MBD was prepared from the stock solution of 1000 mg/L by using the dilution law. Additional 10, 30, 50, 70, and 90 mg/L of working standard solutions of MBD were prepared from the intermediate dye solution by dilution. The working standard solution was prepared by adding a real sample solution28.

Adsorption experiments

With a slight modification as stated by28 at room temperature, all adsorption experiments were performed. A stock solution of MBD at a concentration of 1000 mg/L was prepared for the experiments. The various MBD concentrations were prepared by dilution in deionized water (using the C1V1 = C2V2 relationship). On MBD removal, the effects of ZnO-TSA NPS dosage (0.2, 0.3, and 0.4 g/L), contact time (40, 60, and 80 min), pH (5, 8, and 11), and initial MBD concentration (30, 50, and 70 mg/L) will be investigated. 0.1 M HCl or 0.1 M NaOH solutions will be used to adjust the pH of the solution. Each experiment’s solution volume was 100 mL. A mixer at 180 rpm was used to mix the mixture for different contact times. Following the specified contact time, each sample was filtered through the Whatman filter paper and analyzed for MBD residuals. The absorbance of MBD residuals was measured using a UV-visible spectrophotometer at 664 nm, and the concentration of MBD residues was calculated using the calibration curve. The following equation was used to calculate the adsorption capacity of the NPs (qe) given in Eq. (2).

Also, the removal efficiency (%R) was calculated based on Eq. (3)

Where C0 (mg/L) is the initial concentration of MB Ce (mg/L) is the equilibrium liquid phase concentration of MBD, Cf (mg/L) is the final concentration, V is the volume of the solution (L) and M is the amount of ZnO-TSA NPs used (g).

Characterization of textile wastewater

After textile wastewater was collected through a polyethylene bottle, an initial experiment was carried out to determine the character of wastewater in terms of parameters namely COD, TSS, TDS, TS, turbidity, and pH. These experiments were conducted based on procedures that are provided under standard methods for the examination of water and wastewater. To decide the concentration of MBD in the textile wastewater, five series of standard MBD solutions (10, 30, 50, 70, and 90 mg/L) were prepared by diluting the intermediate solution of MBD with distilled water. Blank solution and working standards were run in UV Spectrophotometer at a maximum wavelength of 664 nm and five-point calibration curves were established. Then, textile wastewater sample solutions were taken to the UV spectrophotometer direct readings of the sample absorbance were recorded and the concentration of the sample was calculated from the standard calibrated Eq. (4)28.

Where y is absorbance, m is slope, x is final or equilibrium concentration, and b is interecept.

Adsorption isotherms

The adsorption isotherm is the relationship between the amount of adsorbate adsorbed on the adsorbent and the equilibrium concentrations of adsorbate at constant temperatures. The adsorption isotherm indicates how the adsorption molecules distribute between the liquid phase and the solid phase when the adsorption process reaches an equilibrium state.

The study of equilibrium adsorption data, by fitting them to different isotherm models, is an important step in finding a suitable model that can be used for design purposes. Adsorption isotherm study was carried out on two well-known isotherms, Langmuir and Freundlich. The applicability of the isotherm equation was compared by judging the correlation coefficients, R2.

Langmuir adsorption isotherm

According to the Langmuir model, the adsorbent surface has numerous active interaction sites for the adsorption process. It is concerned with the relationship between adsorbed material and its equilibrium concentration. The linear form of the Langmuir adsorption isotherm model is described in Eq. (5), allowing for the processes of adsorption and desorption of molecules on the surface29,30.

Where qe denotes the mass of adsorbate adsorbed over adsorbent (mg/g); Ce denotes the equilibrium concentration of adsorbate acquired in liquid phase after adsorption (mg/L); max denotes the maximum adsorbate that can be adsorbed (monolayer capacity) (mg/g), and b denotes the Langmuir isotherm constant (L/mg). In another manner, using the equation given by, the separation factor (dimensionless), also known as the RL factor or the equilibrium parameter, was also determined using the Eq. (6) given by31.

The value of RL indicates the adsorbent’s suitability for adsorption, and the affinity between adsorbate and adsorbent.

If 0 < RL<1.0 represents favorable adsorption, RL>1.0 represents unfavorable Adsorption, and RL= 0 Represents Irreversible adsorption31.

Freundlich adsorption isotherm

It is a relationship between the amount of an adsorbate absorbed per unit weight of adsorbent and the adsorbate equilibrium concentration (Ce) in the fluid.

The Freundlich model, unlike the Langmuir model, is based on multilayer adsorption and may be expressed as an Eq. (7).

Where K and n are the Freundlich coefficients, X is the weight of adsorbate adsorbed on M unit weight of adsorbent, and Ce is the adsorbate equilibrium concentration. However, it is possible to express the equilibrium condition as an Eq. (8)32.

Where qe is the mass of adsorbate adsorbed over adsorbent (mg/g); Kf, is the Freundlich capacity factor (units determined by qe); Ce is the equilibrium concentration of adsorbate in liquid phase after adsorption (mg/L); n is Freundlich intensity parameter. The intercept and slope of a plot of log (qe) versus log (Ce) can be used to determine the value of coefficients kf and n.

Adsorption mechanism and kinetics

The adsorption of MBD onto Teff Straw-Assisted ZnO nanoparticles primarily occurs via chemisorption, as supported by the pseudo-second-order kinetic model, indicating strong chemical interactions between MB and the adsorbent surface33. MBD, a cationic dye, interacts with the negatively charged functional groups on Teff straw (such as hydroxyl and carboxyl groups) and the surface of ZnO nanoparticles through electrostatic attraction, hydrogen bonding, and π–π interactions34. Density functional theory (DFT) studies show MBD’s aromatic rings align parallel to the ZnO surface, maximizing contact and facilitating charge transfer, which strengthens adsorption. The process is efficient, with high removal rates (> 90%) at low dye concentrations, and is typically spontaneous and endothermic35. Teff straw enhances adsorption by increasing surface area and providing additional binding sites, making the composite highly effective for MBD removal (Fig. 1).

-

i)

Kinetic model of pseudo-first order.

The Eq. (9) represents the linear form of the generalized pseudo-first-order equation:

where: qe=amount of dyes adsorbed at equilibrium (mg g─ 1), qt=amount of dyes adsorbed at time t (mg g─ 1), and K1 = pseudo-first-order rate constant (min─ 1). Plotting log (qe-qt) versus (t), should see a straight line. It helps to figure out both K1 and qe for the pseudo-first-order model, by simply looking at its slope and where it crosses the y-axis.

-

ii)

Pseudo-second order kinetic model.

The pseudo-second-order Eq. (10) was written as follows:

Plotting (t/qt) versus (t) yields a linear connection, and the slope and intercept may be used to compute the values of the qe and K2 parameters, respectively. Where K2 denotes the second-order rate constant (g mg─1 min─1).

Experimental design and statistical analysis

Data analysis was using Design-Expert version 11.1.2.0 software tool by RSM using Central Composite Design to evaluate the effects of the process variables. CCD is a common and efficient design in RSM; it was selected as a designing tool to investigate the interactive effect of process variables and to build mathematical models to describe the overall MBD adsorption process. To study the process parameters, four major factors: ZnO-TSA NPS dosage (0.1–0.5 g/L), initial MBD concentration (10–90 mg/L), solution pH (2–14), and contact time (20–100 min) were selected.

Design of Experiments (DOE) surpasses the traditional One-Factor-at-a-Time (OFAT) by efficiently exploring interactions between variables and reducing experimental runs. The authors chose Response Surface Methodology (RSM) with Central Composite Design (CCD) because it models nonlinear relationships and quadratic effects, enabling precise optimization. CCD’s structure, including factorial, axial, and center points, captures curvature in responses, which OFAT cannot. It also requires fewer experiments than full factorial designs, saving time and cost. Compared to other methods, CCD offers better flexibility and robustness for process optimization, making it ideal for identifying optimal conditions in complex adsorption studies36,37.

Ranges of factors were selected by considering the earlier related works as shown in Table 1. The response variable was the removal percentage. The design of the experiment helps to optimize and set of combination of process parameters. The significance of the result was set from the analysis of variance (ANOVA)2,38.

The total number of the experiments (N) was estimated using Eq. (11). The experiments were conducted using four independent process variables consisting of 16 factorial points, 8 axial points, and 6 center points2,8

The total of 30 experimental runs were generated from RSM design namely CCD39.

\(24+2*4+6 = 16+8+6 = 30\)

The optimum conditions obtained using the CCD model were validated by conducting laboratory experiments. Statistically, the optimum conditions were obtained by the following model Eq. (12):

Where Y is a response to the process, I stands for linear coefficient and j represents quadratic coefficients, xi, and xj are the independent variables, β0 stands for regression coefficient, k is the number of factors in the design, and ε represents an error2.

Results and discussion

Characterization of synthesized ZnO-TSA nanoparticles

The UV-visible spectra of synthesized ZnO-NPs and ZnO-TSA nanoparticles were analyzed using a spectrophotometer. The presence of surface plasmon resonance (SPR) effects was observed, with absorption peaks detected at approximately 312 nm for ZnO-NPs and 321 nm for ZnO-TSA nanoparticles Because of the surface plasmon resonance (SPR) effect conducting electrons begin to oscillate at a specific wavelength range. This confirmed the successful synthesis of both nanoparticle types, with ZnO-TSA nanoparticles produced via the reduction of Zn(NO3)2•6H2O using neem leaf extract containing polyphenols as reducing and capping agents, as previously reported. The consistent findings from UV-Vis spectra analysis and previous studies validate the formation of Zinc oxide nanoparticles using neem leaf extract (Raj & Lawerence, 2018). The synthesized nanoparticles are shown in the Fig. 2 (A and B).

FTIR spectroscopy characterized functional groups on ZnO-TSA nanoparticles’ surface, crucial for dye binding. Spectra analysis indicated the presence of aliphatic C-H stretching, amide C = O stretching, and aromatic C = C stretching from lignin. Additionally, C-O and C-C bending vibrations were observed. Identified functional groups, including O-H, C = O, and C-O, facilitated MBD adsorption. Intensity reduction of O-H and C = O peaks post-MBD adsorption indicated interaction. New peaks at 1380 and 1591 cm−1, attributed to MBD presence, further confirmed adsorption. These results align with previous studies5,26 validating ZnO-TSA nanoparticle functionality showen in Fig. 3 (A and B).

XRD analysis confirmed the green synthesis of ZnO-NPs, showcasing sharp and narrow diffraction peaks indicating crystallinity. Peaks corresponding to specific crystal planes of ZnO nanoparticles affirmed their structure. Despite slight impurities, the synthesized ZnO-TSA nanoparticles exhibited high crystallinity. Using Scherer’s formula, their average crystalline size was determined to be 27.196 nm, while pure ZnO NPs showed a size of 24.619 nm. These findings highlight the successful synthesis and crystalline nature of the nanoparticles, crucial for their potential applications.

The pH of the point of zero charges (pHpzc) of ZnO-TSA nanoparticles was determined to be approximately 4.35, indicating its surface charge neutrality at this pH (Fig. 4). Below this value, the nanoparticles exhibit a positive charge due to protonation, enhancing anion adsorption, particularly for basic dyes like MBD. Conversely, above pHpzc, the surface becomes negatively charged, inhibiting anion adsorption. The pHpzc findings, spanning pH 2 to 10, illustrate the adsorbent’s pH-dependent surface charge behavior, crucial for understanding its adsorption properties. Additionally, the dye removal efficiency of teff straw-assisted Zinc oxide nanoparticles demonstrates promising results under varying pH conditions, with improved efficiency observed as pH increases, likely due to enhanced chemical precipitation facilitated by higher pH levels.

Influencing parameters

Several factors such as pH, contact time, adsorbent dose, and initial concentration are known to influence significantly the uptake of dyes on adsorbents. The pH of solutions significantly affects MBD removal by ZnO-TSA nanoparticles. Optimal removal occurs at pH 8, with decreased efficiency at both lower and higher pH levels. At low pH, the positively charged ZnO-TSA nanoparticles attract cationic MBD species, leading to effective removal. However, competition arises between MBD and hydrogen ions for binding sites on the nanoparticles, decreasing MBD adsorption at extreme pH values40.

Higher solution pH enhances electrostatic attraction with MBD, reducing adsorption capacity. The study by Sharifi & Shoja (2018)8 finds pH increase from 3 to 11 boosts dye removal from 45–82%.ZnO-TSA’s surface charge changes with pH, affecting MBD removal. Below pHpzc, protonation hinders adsorption; above pHpzc, deprotonation aids it. Aligns with4 (Fig. 2 A).

The contact time significantly impacts MBD removal by ZnO-TSA nanoparticles. Initial rapid adsorption, with around 94.2% removal within 20 min, suggests abundant active sites on the adsorbent surface. Further increasing contact time up to 80 min enhances adsorption efficiency due to the efficient binding of surface functional groups with MBD ions. However, beyond 80 min, there’s negligible improvement in MBD removal, indicating equilibrium between adsorbed and desorbed MBD29. This underscores the importance of active site availability in MBD binding over time (Fig. 2B).

As shown in Fig. 3 A the effect of adsorbent dose on MBD removal was investigated at room temperature. Increasing the dose of ZnO-TSA nanoparticles from 0.1 to 0.4 g led to a rise in MBD elimination from 93.162 to 97.164%, indicating sufficient active sites and surface area. Aggregated adsorbents with low surface area reduce removal effectiveness. Consistent with findings by Gu et al., 202041 increased adsorbent amount enhances contact surface, but further increase saturates adsorption sites, reducing removal efficiency. Aggregation decreases total surface area and increases diffusional path length, as noted by Pirbazari & Saberikhah (2014)26.The impact of initial MBD concentration on removal by ZnO-TSA nanoparticles was studied and shown in Fig. 3B at room temperature. Higher initial concentrations led to lower removal percentages, with maximum and minimum removal at 10 mg/L (99.62%) and 90 mg/L (81.79%), respectively. This suggests that as MBD concentration rises; available active sites become saturated, reducing removal efficiency, in line with findings by12.

Interaction effect of process parameters on MBD removal

As shown in Figs. 5 and 6 the research examines the interaction effects of various process parameters on the removal of MBD. Significant interaction effects were observed between adsorbent dosage, initial concentration, contact time, and pH. Initially, increasing adsorbent dosage and decreasing MBD concentration led to improved removal efficiency, This can be because the increase of the initial adsorbent concentration is a driving force to resolve the resistance of the dye to mass transfer between the aqueous and solid phases8,42. However, this trend reversed at higher adsorbent dosages. Furthermore, higher concentrations of MBD resulted in greater removal efficiency until equilibrium was reached. Increasing both the initial concentration of MBD and contact time enhanced removal percentages, with the adsorption rate being higher initially due to available active sites but decreasing over time as more MBD ions were adsorbed Similar studies8,42. Moreover, MBD removal efficiency increased with decreasing solution pH and increasing contact time, reaching maximum efficiency under specific pH and contact time conditions. However, the efficiency decreased at lower MBD concentrations with increasing pH and beyond optimal pH. the removal efficiency decreases gradually because MBD is a cationic dye43.

Higher initial concentrations of the adsorbent facilitated increased removal efficiency due to enhanced contact between the adsorbate and adsorbent. This can be because the increase of the initial adsorbent concentration is a driving force to resolve the resistance of the dye to mass transfer between the aqueous and solid phases.

(3D plot for the combined effect of adsorbent dosage and initial conc. of MBD (A), Contour plot for the combined effect of pH and adsorbent dosage (B), the 3D plot for the combined effect of contact time and initial conc. of MBD (C), Contour plot for the combined effect of Contact time and Conc. of MBD(D), The 3D plot for the combined effect of contact time and pH on MBD removal, (E), Contour plot for the combined effect of Contact time and pH on MBD removal (F), 3D plot for the combined effect of Initial conc. of MBD and pH (G), and Contour plot for the combined effect of Initial conc. of MBD and pH ) (H), on MBD removal.

Optimization of the adsorption process for MBD removal

The optimization of process parameters such as adsorbent dose, initial dye concentration, pH, and contact time on the performance of percentage removal of MBD was done using CCD.

Optimal points responsible for optimum removal efficiency were indicated on the ramps that connect the values of the process variables. Thus, optimal removal efficiency indicated on-ramps was obtained at optimal parameters where ZnO-TSA is 0.265 g; initial MBD concentration is 68.489 mg/mL; solution pH is 6.904, and contact time is 77.873 min (Table 2).

Model validation

Numerous tests were carried out to check the validity of the model at predicted optimum process parameters. As a result, quadruplicate tests were conducted using the predicted optimum process parameters, and the average removal efficiency of MBD was experimentally found to be 98.940% showing the high reliability of the model. It was found that the predicted and experimental values were near to each other. There was only a slight percentage difference (0.83%) between the predicted and experimental values. So, the validity of the model was confirmed because it is less than 3%, showing that the quadratic models adopted could predict the experimental result well. Similarly, the efficiency of normal Zinc oxide nps using the optimized parameters of teff straw-assisted zinc Oxide Nano Particles Was tested experimentally and was reported as 97.8%. Therefore, As compared both the efficiencies of teff straw-assisted zinc oxide nanoparticles with normal zinc oxide nps, the teff straw-assisted zinc oxide nps was a highly efficient one.

Dye removal from real textile wastewater

As given in the Table 3, next to determine the optimal conditions for the adsorption of MBD from aqueous solutions, teff straw-supported zinc oxide nanoparticles’ capability for the removal of MBD from wastewater of a textile factory, was tested. Two samples (50 mL) of effluent, with 0.265 g adsorbent were contacted in the optimum conditions. 68 mg/L of the dye was manually added to a sample, and another sample without adding any dye was studied at Contact time 78 min, and pH is 6.904. The results indicated that about 92.5% of the dye was removed. In addition to MBD, industrial textiles contain large amounts of other common dyes. Thus, the results of this study show the high performance of teff-assisted Zinc Oxide Nanoparticles for MBD removal from wastewater29. The removal efficiency of Waste water after the treatment of impurities was 75%.

The Table 4 shows various studies have investigated the removal of hazardous dyes from wastewater utilizing various agricultural biomasses such as straw, fiber, husk, stalk, and so on. Teff straw has no commercial value except for its use as animal feed, open-burning fuel, and mud-composite for rural house building. Every year, around two million tons of teff straw are discarded as waste45,46.

Adsorption isotherm studies

The studies of adsorption isotherm were performed by differing initial concentrations of MBD from 10 to 90 mg/L at room temperature using 100 mL of initial MBD solutions with an adsorbent dose of 0.265 g, shaking speed of 180 rpm, the contact time of 77.873 min and pH of 6.904. The adsorption behavior between the ZnO-TSA nanoparticles and MBD ions under different concentrations was interpreted by a Langmuir model and Freundlich isotherms models as shown in Figs. 7 and 8 respectively.The outcomes set in Table 5 show the experimental data were fitted with both Langmuir and Freundlich adsorption isotherm models. However, Fig. 4 describes that the result from experimental data fitted very well with the Freundlich isotherm model than the Langmuir adsorption isotherm model with a good correlation coefficient (R2) of 0.999.Thus, it indicates the adsorption of MBD ions on the surface of ZnO-TSA nanoparticles effectively undergo the monolayer and homogeneous adsorption process of MBD ions rather than the multilayer adsorption process. The values of separation factor RL (0 < RL < 1) given in Table 4, designate the favorability of the adsorption process with a maximum adsorption capacity (qmax) of 2.32 mg*g-1 (Table 4). Furthermore, a value of Langmuir coefficient (b) which is 0.4311 L mg−1 implies strong binding sites exist on the surface of the adsorbent, thus the adsorbents can adsorb dyes effectively. On the other hand, as represented in Table 6, the value of the Freundlich constant (n) which is greater than 1 indicates a Favorable Adsorption condition With a Correlation Coefficient (R2) of 0.999 representing that heterogeneous condition can exist. Generally, in this thesis study, the Freundlich isotherm model gives the best fit for the experimental data in contrast to the language isotherm model with a maximum correlation coefficient as indicated in Table 4 below.

Adsorption kinetics

Out of the two models shown in the Figs. 9 and 10, the pseudo-second-order model helps us understand how quickly substances absorb the material. The chemisorption limits the overall rate of adsorption. In chemisorption, adsorbate molecules chemically bond to the adsorbent’s surface. This model provides valuable insights into chemisorption, which frequently dictates the rate of adsorption. To determine the rate constant (K2), the slope of a graph plotting t/qt against t, where t is the time and qt is the amount of adsorbate taken up at that time of adsorption (Fig. 10). In this study, the K2 value was 6.1 × 10−3. This indicates that the adsorption process is slower when compared to a first-order model. The equilibrium adsorption capacity (qe) calculated using this model was 25.67. This value is quite close to the experimentally observed adsorption capacity of 23.85. Furthermore, the model’s best fit to the experimental data is evident from its high coefficient of determination (R2) of 0.999, as shown in Table 7. This strong R2 value confirms that the pseudo-second-order kinetics accurately describe the adsorption process34.

Conclusion

Teff straw helped create ZnO-TSA nanoparticles through an eco-friendly process. This surface-modified nano-adsorbent proved effective at removing Methylene Blue Dye (MBD) from textile wastewater. Analyses like XRD and FT-IR confirmed the nanoparticles’ successful synthesis and function, with an average crystalline size of 27.196 nm. MBD removal was significantly influenced by pH, contact time, nanoparticle dosage, and initial MBD concentration. Response Surface Methodology (RSM) optimized the process. Optimal conditions for maximum MBD removal were identified as pH 6.904, 68.489 mg/L initial MBD, 0.265 g nanoparticle dosage, and 77.873 min contact time, yielding a remarkable 99.769% removal efficiency. pH and adsorbent dose were the most dominant factors. The experimental removal efficiency of 98.9% closely matched the predicted 99.7694%, validating the model. MBD removal fits the Freundlich isotherm model well, with a correlation coefficient of 0.99. In real textile wastewater, the nanoparticles achieved 92.5% MBD removal. This study showcases green-synthesized Teff straw-assisted ZnO-TSA nanoparticles as an efficient solution for MBD removal, promising for textile wastewater treatment.

Data availability

The data used in this study can be accessed from the authors with reasonable requests.

References

Goutam, S. P., Saxena, G., Roy, D., Yadav, A. K. & Bharagava, R. N. Green synthesis of nanoparticles and their applications in water and wastewater treatment. Bioremediat. Industrial Waste Environ. Saf. https://doi.org/10.1007/978-981-13-1891-7_16 (2020).

Ahmadi, S., Engineering, E. H. & Igwegbe, C. A. Removal of methylene blue on zinc oxide nanoparticles: nonlinear and linear adsorption isotherms and kinetics study. Sigma J. Eng. Nat. Sci. 1, 289–303 (2020).

Gayathri, S., Manjunath, N. T., Nagarajappa, D. P. & Shetty, R. BATCH STUDIES ON COLOUR REMOVAL POTENTIAL BY ZINC OXIDE NANOPARTICLES. 2181–2185 (2019).

Mohammad Razi, M. A., Mohd Hishammudin, M. N. A. & Hamdan, R. Factor Affecting Textile Dye Removal Using Adsorbent from Activated Carbon: A Review. MATEC Web of Conferences 103, 1–17 (2017).

Oyewo, O. A., Adeniyi, A., Sithole, B. B. & Onyango, M. S. Sawdust-Based cellulose nanocrystals incorporated with ZnO nanoparticles as efficient adsorption media in the removal of methylene blue dye. ACS Omega. 5, 18798–18807 (2020).

Moawed, E. A., Hegajy, T. A., Kosbar, T. R. & Eissa, M. S. Removal of methylene blue dye from wastewater using ZnONPs in the dark and light. (2019).

Rajabi, M., Mahanpoor, K. & Moradi, O. Removal of dye molecules from aqueous solution by carbon nanotubes and carbon nanotube functional groups: critical review. RSC Adv. 7, 47083–47090 (2017).

Sharifi, S. H. & Shoja, H. ARTICLE ORIGINAL optimization of process variables by response surface methodology for methylene blue dye removal using Spruce sawdust / MgO nano- biocomposite. J. Water Environ. Nanotechnol. 3, 157–172 (2018).

Yashni, G. et al. A review on green synthesis of ZnO nanoparticles using Coriandrum Sativum leaf extract for degrading dyes in textile wastewater: A prospect towards green chemistry. IOP Conf. Ser. Mater. Sci. Eng 736, (2020).

Rath, P. P., Priyadarshini, B., Behera, S. S., Parhi, P. K. & Panda, S. R. Adsorptive removal of congo red dye from aqueous solution using TiO2 nanoparticles: kinetics, thermodynamics and isothermal insights adsorptive removal of congo red dye from aqueous solution using TiO 2 nanoparticles. Kinetics Thermodyn. Isot. 030115, 2–6 (2019).

Shokry Hassan, H. & Elkady, M. F. 2, 3 A. H. El-Shazly, 2 andHishamS.Bamufleh4 1. Formulation of Synthesized Zinc Oxide Nanopowder into Hybrid Beads for Dye Separation. J Nanomater (2014). (2014).

Gu, M. et al. The selective heavy metal ions adsorption of zinc oxide nanoparticles from dental wastewater. Chem. Phys. 534, 110750 (2020).

Nithya, K. & Kalyanasundharam, S. Effect of chemically synthesis compared to biosynthesized ZnO nanoparticles using aqueous extract of C. halicacabum and their antibacterial activity. OpenNano 4, (2019).

Sankaranarayanan1, N. K. Journal of university of Shanghai for science and technology ISSN: 1007–6735. J. Univ. Shanghai Sci. Technol. 23, 887 (2021).

Herlekar, M., Barve, S. & Kumar, R. Plant-Mediated green synthesis of Iron nanoparticles. J. Nanopart. 2014, 1–9 (2014).

Suresh, D., Nethravathi, P. C., Rajanaika, H., Nagabhushana, H. & Sharma, S. C. Green synthesis of multifunctional zinc oxide (ZnO) nanoparticles using Cassia fistula plant extract and their photodegradative, antioxidant and antibacterial activities materials science in semiconductor processing green synthesis of multifunctional z. Mater. Sci. Semicond. Process. 31, 446–454 (2015).

Sangeetha, G., Rajeshwari, S. & Venckatesh, R. Green synthesis of zinc oxide nanoparticles by aloe barbadensis miller leaf extract: structure and optical properties. Mater. Res. Bull. 46, 2560–2566 (2011).

Thema, F. T., Manikandan, E., Dhlamini, M. S. & Maaza, M. Green synthesis of ZnO nanoparticles via Agathosma betulina natural extract. Mater. Lett. 161, 124–127 (2015).

Mohamad Sukri, S. N. A., Shameli, K. & Mohamed Isa, E. D. Green synthesis of zinc Oxide-Based nanomaterials for photocatalytic studies: A Mini review green synthesis of zinc Oxide-Based nanomaterials for photocatalytic studies : A Mini review. ICATAS-MJJIC 2020 IOP Conf. Series: Mater. Sci. Eng. https://doi.org/10.1088/1757-899X/1051/1/012083 (2021).

Khairunnisa, S., Wonoputri, V. & Samadhi, T. W. Effective deagglomeration in biosynthesized nanoparticles: A Mini review. IOP Conf. Ser. Mater. Sci. Eng. 1143, 012006 (2021).

Homaeigohar, S. The nanosized dye adsorbents for water treatment. MDPI 10, 1–43 (2020).

Dixit, S. & Hering, J. G. Comparison of arsenic (V) and arsenic (III) sorption onto Iron oxide minerals: implications for arsenic mobility. 37, 4182–4189 (2003).

Mohrazi, A. & Ghasemi-Fasaei, R. Removal of methylene blue dye from aqueous solution using an efficient chitosan-pectin bio-adsorbent: kinetics and isotherm studies. Environ. Monit. Assess. 195, 339 (2023).

Garcia, R. V. et al. Materials for methylene blue adsorption. Res. Soc. Dev. 10, e37410918114 (2021).

Razali, S. Z., Aziz, M. Y. & Edinur, H. A. & Razali ishak, A. Adsorption of methylene blue onto Iron oxide magnetic nanoparticles coated with sugarcane Bagasse. IOP Conf. Ser. Earth Environ. Sci 596, (2020).

Pirbazari, A. E. & Saberikhah, E. Fe 3 O 4 – wheat straw: preparation, characterization and its application for methylene blue adsorption. Water Resour. Ind. 7–8, 23–37 (2014).

Swamy, M. M. et al. Fast adsorptive removal of methylene blue dye from aqueous solution onto a wild Carrot flower activated carbon: isotherms and kinetics studies. Desalin. Water Treat. 71, 399–405 (2017).

Mulushewa, Z., Dinbore, W. T. & Ayele, Y. Removal of methylene blue from textile waste water using Kaolin and zeolite-x synthesized from Ethiopian Kaolin. Environ. Anal. Health Toxicol. 36, e2021007 (2021).

Droepenu, E. K., Asare, E. A. & Dampare, S. B. Laboratory and commercial synthesized zinc oxide nanoparticles adsorption onto coconut husk: characterization, isotherm, kinetic, and thermodynamic studies. 11, 7871–7889 (2021).

Chemingui, H. et al. Investigation of methylene blue adsorption from aqueous solution onto ZnO nanoparticles:equilibrium and Box-Behnken optimisation design View supplementary material Investigation o … International Journal of Environmental Analytical Investigation of me. Int J Environ Anal Chem 00, 1–26 (2021).

Zaidi, R., Khan, S. U., Azam, A. & Farooqi, I. H. A study on effective adsorption of lead from an aqueous solution using copper oxide nanoparticles. IOP Conf. Ser. Mater. Sci. Eng. 1058, 012074 (2021).

Kyzas, G. Z. & Kostoglou, M. Green adsorbents for wastewaters: A critical review. Materials 7, 333–364 (2014).

Vallejo, W., Diaz-Uribe, C. E. & Duran, F. Kinetic and thermodynamic study of methylene blue adsorption on TiO2 and ZnO thin films. Materials 16, 4434 (2023).

Alprol, A. E., Eleryan, A., Abouelwafa, A., Gad, A. M. & Hamad, T. M. Green synthesis of zinc oxide nanoparticles using Padina Pavonica extract for efficient photocatalytic removal of methylene blue. Sci. Rep. 14, 32160 (2024).

Choudhary, N. et al. Remediation of methylene blue dye from wastewater by using zinc oxide nanoparticles loaded on nanoclay. Water (Basel). 15, 1427 (2023).

Sarah Lee. Top 6 Advantages of Using Response Surface Methodology in R&D. (2025). https://www.numberanalytics.com/blog/top-6-advantages-response-surface-methodology

Stat-Ease 360. Stat-Ease » se360 » Central Composite Design. (2025). https://www.statease.com/docs/se360/contents/response-surface-designs/central-composite-design/

Saha, B., Gayen, S. & Debnath, A. Sequestration of Paracetamol from aqueous solution using zinc oxide/polypyrrole nanocomposite: cost analysis, Scale-Up design, and optimization of process parameters. J Hazard. Toxic. Radioact Waste 27, (2023).

Afolabi, F. O., Musonge, P. & Bakare, B. F. Evaluation of lead (II) removal from wastewater using banana peels: optimization study. 30, 1–10 (2021).

Nasuha, N., Hameed, B. H. & Din, A. T. M. Rejected tea as a potential low-cost adsorbent for the removal of methylene blue. J. Hazard. Mater. 175, 126–132 (2010).

Ramutshatsha, D., Ngila, J. C., Ndungu, P. G. & Nomngongo, P. N. Application of response surface methodology for simultaneous removal of major cations from seawater using metal oxide nanostructures. 46, 313–321 (2020).

Subramaniam, R. & Kumar, S. Novel adsorbent from agricultural waste (cashew NUT shell) for methylene blue dye removal: optimization by response surface methodology. Water Resour. Ind. 11, 64–70 (2015).

Vahab Ghalehkhondabi, A. F. and K. K. Synthesis and characterization of modi Fi ed activated carbon (MgO/AC) for methylene blue adsorption: optimization, equilibrium isotherm and kinetic studies Vahab ghalehkhondabi, Alireza Fazlali and Keyhan Ketabi. 83, 1548–1565 (2021).

Bageru, A. B. & Srivastava, V. C. Biosilica Preparation from abundantly available African biomass Teff (Eragrostis tef) straw Ash by sol-gel method and its characterization. Biomass Convers. Biorefin. 8, 971–978 (2018).

Saha, B., Shaji, S. & Debnath, A. Fabrication of polyaniline based calcium ferrite nanocomposite and its application in sequestration of Victoria blue dye from wastewater. J. Dispers Sci. Technol. 45, 2602–2616 (2024).

Nharingo, T. & Shoniwa, V. Exploring the biosorption of methylene blue dye onto acid treated sugarcane Bagasse. Int. J. Curr. Res. 5, 2169–2175 (2013).

Sen, T. K., Afroze, S., Ang, H. M. & Equilibrium Kinetics and mechanism of removal of methylene blue from aqueous solution by adsorption onto pine cone biomass of Pinus radiata. Water Air Soil. Pollut. 218, 499–515 (2011).

Danish, M. et al. Use of banana trunk waste as activated carbon in scavenging methylene blue dye: kinetic, thermodynamic, and isotherm studies. Bioresour Technol. Rep. 3, 127–137 (2018).

Amuda, O. S., Olayiwola, A. O., Alade, A. O., Farombi, A. G. & Adebisi, S. A. Adsorption of Methylene Blue from Aqueous Solution Using Steam-Activated Carbon Produced fromLantana camara Stem. J Environ Prot (Irvine, Calif) 05, 1352–1363 (2014).

Acknowledgements

Mattu University and Jimma University are recognized for providing the required lab facilities during the research.

Funding

This research received no specific funding from any agency, public or private.

Author information

Authors and Affiliations

Contributions

The authors of this manuscript have read and approved the published version. Conceptualization, E.A.T. and D.T.M; Methodology, G.L.R.; Formal analysis and investigation, G.L.R. M.A.B, A.R.H; Resources, G.L.R. and Data curation, S.Y.B; Writing, original draft preparation, G.L.R., T.L.R; Writing, review and editing, D.M.R.P, E.A.T. and D.T.M.; supervision, D.T.M., D.M.R.P.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rorissa, G.L., Tesema, E.A., D.M., R.P. et al. Removal of methylene blue dye from textile industry wastewater using green synthesized Teff straw assisted ZnO nanoparticle. Sci Rep 15, 26230 (2025). https://doi.org/10.1038/s41598-025-11746-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-11746-9