Abstract

In sublevel caving without sill pillar, the shape of caving body is an important factor affecting the ore drawing effect. The depth of collapse area is one of the important parameters of collapse body shape, but there was no research on the influence of the depth of collapse area on reducing ore loss and dilution in the past. This paper puts forward the problem of the influence of the depth of the collapse area on ore loss and dilution. A large scale model of end ore drawing is developed, and matching positioning films and coded color marker particles are made. The specific experimental scheme has been determined, and experiments on collapse collapse area at different depths have been carried out. Each group of experiments has carried out ore rock filling, symbolic particle placement, and ore drawing experiments according to the experimental scheme. In the process of ore drawing, the sorted ore and rock data, recovered landmark particles and corresponding codes and drawing time are collected. The following achievements have been made: (1) The depth of the collapse area affects the formation of the draw out body and has a greater impact on the ore loss and dilution. As the depth of the collapse area deepens, the ore loss rate increases and the ore dilution rate changes slightly. When the depth of collapse body collapse area is 0 mm, the ore loss rate is 29.73%, and the dilution rate is 20.60%. The ore loss rate is the smallest, and the dilution rate is relatively low. (2) When the cut-off grade is 20%, the amount of pure ore recovered in each group of experiments is about twice the amount of pure ore in the pure ore stage with the change of the depth of the collapse body collapse area. (3) During end ore drawing, the closer the pole position of the subsidence area is to the flow axis, the faster the pole descending speed, the expansion speed of the waste rock and ore contact surface, and the ore dilution speed are.

Similar content being viewed by others

Introduction

The bottomless pillar segmental collapse method is a new mining method that emerged in the 1960s with the advent of new technology. This method is applied to mines where the ore rock is moderately stable and the return tunnel does not require extensive support. Compared with the original mining method, it is characterized by simpler mining structure, safer mining environment, more mechanized mining equipment, more efficient work efficiency, and cheaper production cost1. Therefore, the rapid promotion of China’s metal mines to become the application of the main mining methods, and in the iron ore mining application is particularly prominent. According to statistical analysis, not only China’s underground iron ore mined about 80% of the amount of ore is used in this mining method2,3,4, and with the extension of the ore, many of the old open-pit mines transformed into underground mines, mining from the ground into the underground, the amount of mining is likely to increase, so that the bottomless column segmented avalanches in the future is still the mainstream of the iron ore mines mining method, so that the study of bottomless column segmented avalanche mining method, optimizing the avalanche body Therefore, it is important to study the bottomless pillar segmented chipping mining method to optimize the chipping body morphology, reduce the depth of chipping body sinking area, reduce the loss of ore depletion, and improve the recovery and utilization of mineral resources5,6.

In the underground quarry mining environment, due to the bottomless pillar segmental chipping mining method routinely adopts the blasting method to drop the ore, the formation of the upper end of the covered loose rock layer7,8, then in the process of mining operations, there will be the upper end of the waste rock in advance to reach the outlet, resulting in the loss of ore depletion increase9,10. In order to reduce the loss of ore depletion, many experts and scholars on the bottomless column segmental chipping method for systematic research, chipping body, release body, loose body is a process of mutual influence. The main requirement of ore release is to release as much as possible after blasting the crumbling ore, and the study of the morphology of the ore crumbling loose body is the basis and premise of the analysis of the problem of ore release, and furthermore from the morphology of the crumbling body analysis of ore release which is a very important understanding of the process11.

With the increase of the depth of the study of the ore release theory, many scholars have created many mathematical formulas based on the ellipsoid theory and the random medium theory12, such as: the calculation formula of the volume of the release body, the calculation equation of the disintegration step distance, the surface equation of the release body, the equation of the velocity field of the disintegrated mineral rock dispersion, the equation of the trajectory line of the disintegrated mineral rock dispersion, the equation of the change of the position of the contact surface of the disintegrated mineral rock dispersion, and the moving funnel equation, etc.13, which provide the data basis for the analysis of the bottomless pillar segmental disintegration method and a reasonable analysis basis14,15. In actual production, in order to reduce the loss of ore depletion, it is necessary to recognize and analyze the fallout trap area, so as to reduce the adverse effects of the fallout trap area on the ore release. The presence or absence of avalanche fallout zone, the size of the response to the actual blasting effect is good or bad. When the shape of the blasting fallout is not good, there is a large fallout zone, in the ore release stage, the waste rock will be mixed in advance, resulting in loss of depletion or reach the cut-off grade earlier, or cause waste rock congestion, resulting in pseudo-no ore phenomenon. In summary, it is of great significance to study the depth of the fallout trap to reduce the loss and depletion of the ore. This paper puts forward the problem of the impact of the depth of the fallout zone on the loss and depletion of ore. A large-scale model of the end ore release was developed, and the matching positioning tablets and colorful iconic particles with codes were produced. Specific experimental plans were determined and experiments were conducted at different depths of the avalanche trap, and each group of experiments was conducted according to the experimental plans for loading the ore rock, placing the iconic particles, and placing the ore in the experiments. In the process of ore release, the data of sorted ore rocks and recovered landmark particles were collected, and the corresponding codes and release times were recorded.

Development of an experimental setup for the depth of the fallout trapping zone

Development of the experimental setup

The bottomless column segmental chipping method is widely used in domestic and foreign underground metal mines, especially in iron ore mines, because of the advantages of high mining efficiency, low mining cost and superior safety. However, the bottomless column segmental chipping method in practice, at the same time, there is a common problem of ore loss and depletion16, most of the depletion rate of 15% to 25%, ore loss rate of about 15% to 20%, resulting in a serious waste of mineral resources, and reduce the economic efficiency.

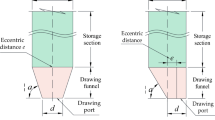

In the bottomless column segmental chipping method, the morphology of the chipping body directly affects the effect of ore release, and many of the causes of ore release cut-off are the large amount of waste rock mixed in the top. In the actual production, there is the phenomenon that mining reaches the cut-off grade, but the recovery of the ore is obviously reduced, and the waste rock is mixed in again when the ore is released. This increases the loss of ore depletion, increasing the difficulty of mining. The morphology of the falling body is studied under the overlying rock layer, which is invisible and untouchable, thus invariably increasing the difficulty of the study. It is also very difficult to study in the actual mine, so we use the laboratory physical model simulation to further analyze the impact of the depth of the fallout zone on the ore loss and depletion.

In mining practice, with the development of machinery and equipment, the structural parameters of the high segment are further optimized and updated. Against the background of such high segment structural parameters, in order to be close to the actual situation, the experimental equipment is equipped with a larger proportion of simulation. The experimental equipment is shown in Fig. 1.

Experiments on different avalanche shapes under large structural parameters. For example: simulating Qianqianshan Iron Mine, with a section height of 18 m;

-

(1)

Experiment on the change of morphological parameters of rockfall body. For example, the height of the avalanche is Hb, the width is Sb, and the thickness is Lb. The single variable method is used to take 1.0, 1.2, 1.4 times of their data for experiments;

-

(2)

For experiments at different depths in the area of avalanche traps.

-

(3)

Experiments on the mixing ratio of bulk particles with different grain sizes. Experiments to study the effect of disintegrants with different looseness on ore loss depletion.

-

(4)

Experiments on the natural grading phenomenon of the ore rock by end release.

-

(5)

Experiments on the relationship between avalanches, releases, and loose bodies for large structural parameters.

Principles of experimental setup design

The research methods of the bottomless pillar segmental disintegration method include physical simulation test research method, mathematical simulation research method and field test research method. After the physical simulation test to master a certain mining method scheme of ore release law, you can prepare mathematical models, using modern computers to do stochastic simulation, processing data large, to achieve a large number of data simulation. However, regardless of the physical simulation test method or mathematical simulation method, the results obtained need to be verified by the field test; the field test can also provide original information for the physical simulation and mathematical simulation.

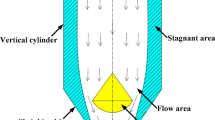

Physical simulation experiments have a single model, a flat model, and a three-dimensional model. This experiment chooses the monomer model, the following is a brief introduction to the monomer model. For the monomer model, the scope of research is a mine outlet, reflecting the nature and laws of ore release relative to this outlet, such as the movement of bulk particles, the development of the end of the release of ore release body range and corresponding to the release of the corresponding stage of the corresponding morphology, the release of the loss of ore depletion causes and so on. This kind of simulation is characterized by the study of the basic theory of ore release and the provision of original data for other simulation tests. Its simulation range is small, so it can be used with larger simulation ratio and repeated tests to obtain more accurate data. In the model box on the transparent glass wall, can be convenient to observe the changes in the discharge of the body of each profile.

The monolithic experimental device for the study of the relationship between the morphology of the crumbling body and the loss of depletion, the actual range is large, the simulation of the ratio must also be relatively matched, the experiments using the simulation ratio of 1:30, with a certain degree of accuracy. After setting the ratio, it is necessary to choose the corresponding size according to the actual reference bottomless column segmental disintegration method parameters. The height of the experimental box in the design is approximately equal to the sum of the height of the crumbling body and the height of the overlying waste rock.

The height of the test section is 600 mm, the height of the covered waste rock is 960 mm, and the height of the avalanche is 640 mm. At the same time, it is required that the width and thickness of the model should meet the requirements of the boundary conditions. For ore drawing at the end, it is required that there is no boundary rock wall away from the ore drawing mouth, which should not limit the development of the loose ellipsoidal hole for ore drawing, that is, it should be greater than the short half axis of the ellipsoidal hole, and the width of the collapse body is about 1.2–1.5 times of the ore collapse step distance. According to the above comprehensive design, the test box is 800 mm long, 600 mm wide and 2000 mm high.

The overlying mining environment of the bottomless pillar segmental chipping method is the overburden waste rock, and the blast chipped waste rock is in contact with the ore. When the collapse of the ore rock appeared in the trap area, the trap area is the combination of ore and rock. When studying the morphology of the collapse body with a trap area, it is necessary to study not only the movement of the collapse ore rock, but also the movement of the overburden rock.

In the underground quarry mining environment, the bottomless pillar segmental chipping mining method using blasting, the upper end of the distribution of loose cover rock layer, in the mining work, will occur in the ore release process waste rock mixed in advance, released in advance, resulting in the loss of ore depletion rate increased. In order to reduce the loss of ore depletion, many experts and scholars on the bottomless column segmental chipping method for systematic research, chipping body, release body, loose body is a process of mutual influence. The object of mine release is the blasting of the ore pile, the study of the morphology of the ore fallout is the theoretical basis and premise of the mine release problem. The blasting parameters of the collapsed ore, the physical and mechanical properties of the overlying rock layers around the blasted ore body, as well as the nature of the blasted ore body itself, the release process and other constraints on the morphology of the collapsed body development17. In mine production, the spacing of the approach, segment height, the collapse step distance, the release step distance, as well as other matching drop ore, ore equipment, blasting parameters of the blasting ore body, the nature of the overlying rock layer, have become the main factors affecting the bottomless pillar segmental collapse method.

Loose overlying rock layer in the quarry, after blasting process by the pressure impact, extrusion, resulting in crushing, the formation of a large number of small-sized rock, with the increase in mining depth, in the overall rock fragmentation, small particles of rock in the rock pile from the top to the bottom of the interspersed, moving fast, so that the rock fragmentation zone formed on the upper side of the rock particles, the lower side of the rock particles are large, the rock particles are small. Small particles of rock settling quickly, resulting in the process of ore release waste rock mixed into the ore in advance, resulting in ore depletion, increasing the difficulty of ore release. In actual mines, such as the immediate mountain iron ore, there is an increase in the depth of mining, small particles of rock subsidence, natural grading phenomenon is obvious, increasing the difficulty of ore release. The natural grading process, the size of the loose overlying rock layer is one of the grading factors18,19.

The morphology of avalanches has an important influence on the loss and depletion in ore release, and the mixing of ore and rock in the trap area, resulting in overburden depletion, is a problem that needs to be solved urgently. It is hoped to find out the mixing law of the overburden rock20,21.when ore is released from the trap area of avalanches through experiments. At present, the study of ore release theory is still dependent on the development of experiments22, if the bulk moving state experiment guides the study of the theory of ore release random medium, then the experiment on the morphology of the released body is an effective method to test the fidelity of the theory. Before introducing the experimental results, the experimental principle and the experimental process are briefly described here.

In the laboratory, the experiments of releasing the body form are divided into two methods, one of which is to preset the electronic marking sphere, in this method, the electronic marking sphere can measure the actual displacement of the experimental release of the mine, and derive the law of movement. However, the sphere is large in size and requires a large scale experimental model, and the actual operation is more complicated, requiring high-precision equipment and instruments. The other one is to determine the approximate volume of the released body, establish the coordinate system in the released bulk particles by matching with the locating piece, count the markers of the released marking particles when releasing the ore, determine the coordinate point of its original space placement, and draw the boundary of the released body.

Experimental setup design and fabrication

The dimensions of the experimental chamber are shown in the table below, which are based on the specific structural parameters of the mine and reduced to a scale of 1:30. At the same time, the development of the loose body is taken into account, and combined with the parameters of the previous experimental model is determined. The three-dimensional design and production of the experimental box is shown in Fig. 2, the experimental box is made of white steel frame, transparent acrylic plate production of the outer surface. The front end of the box is the feeding port, the box using internal welding screws, external fixed white steel beams, the side of the panel can be movable, easy to dismantle the structure. The structural parameters of the test box are: the overall height is 2300 mm, the base height is 300 mm, the external dimensions of the bin are 800 mm long, 600 mm wide, 2000 mm high, the ore drawing mouth is 150 mm × 120 mm, the front discharge mouth is 150 mm × 150 mm, the dimensions of the acrylic plate are 2000 mm × 600 mm for the right side panel, 200 mm × 600 mm for the left side panel (10 pieces), and 2000 mm × 800 mm for the front panel.

The design of the experimental device conforms to the concept of large structural parameters, increases the actual proportional dimensions of the length, width and height of the equipment, and considers the high segmentation, large access distance and relative drawing step distance. The experiment model adopts a similarity ratio of 1:30 to simulate the actual iron ore parameters. The section height adopted is 18 m, the route spacing is 20 m, the ore drawing step spacing is 5 m, and the mining route size is 5 m × 4 m. The size of the experiment model made in proportion is taken as follows: the section height is 600 mm.

Design and fabrication of experimental multi-point localization tablets

The positioning sheet in this experiment is a semicircular sheet made of white steel, as shown in Fig. 3. The total design radius is 240 mm, and a positioning line is made every 22.5°. There are nine positioning lines in total. The radius of the positioning sheet’s aperture is 5 mm, and the spacing between the holes is 40 mm. In order to ensure the accuracy of the hole location, the positioning sheet is made by laser positioning drilling technology.

The experimental locators are placed with the median line at the end as the center point, which serves to locate the landmark particles, and at the same time, each landmark particle is given a separate coordinate point, which forms a complete landmark coordinate system when the placement is completed. The localization tablets are used in conjunction with the landmark particles. The aperture of the locator plate and the iconic particles are matched, there are two options: one is that the aperture of the locator plate is much larger than the aperture of the iconic particles, the iconic particles are placed directly from the aperture; the other is that the aperture of the locator plate is the same as the iconic particles, and the locators are positioned through the center of the locator plate and the outline of the outer diameter. The first solution has the advantage of simple operation, but the disadvantage is that the aperture of the positioning piece must be larger than the iconic particles, which limits the size of the iconic particles, and the iconic particles have different geometries, so it is difficult to locate the iconic particles in the center position when they are placed. The advantage of the second scheme is that it excludes the inaccuracy of the center position of the iconic particles with different geometries, and the selection of different sizes of iconic particles is in line with the randomness of the actual simulation experiment, and in line with the random distribution law of the size of the actual mineral release bulk, but the disadvantage is that it needs to be manually placed in a fine manner, and there is a process of determining the center position of the iconic particles and the positioning holes, which is a cumbersome operation, especially when the amount of iconic particles is large, which is a very complicated operation, and the size of the particles is very large. When the amount of particles is large, the workload is large.

Design and production of experimental iconic pellets

The marker grains are an important part of the experiment, which are placed by the positioning tablets to establish the experimental coordinate system. The iconic particles should be clearly numbered, and in the process of ore release, the marking should not be scratched off or scratched under the pressure and friction of the ore rock, so that the experimenter can misinterpret the marking, and the iconic particles are shown in Fig. 4.

The production of experimental iconic pellets involves three parts: selection, group coloring, and imprinting.

Initial selection, from the point of view of the experimental materials, iron ore and quartz sand are relatively hard things, the choice of other materials instead of the material will show the difference in materials, affecting the results of the experiment. Therefore, we can only consider iron ore and quartz sand for experiments. Group dyeing, experiments with the number of iconic particles need to be considered from the experimental logo level area size, experimental groups to consider the size of the avalanche morphology, the experiments selected 1000 iron ore, because different layers to be dyed in different colors, so the experiments first of all the 1000 ores divided into 10 groups, each group of 100 iron ore, with 9 different colors spray dyeing, the dye required to be clearly distinguishable after spraying, easy to dry, do not lose color, to prevent affecting the results of the recovery of the iconic particles, and to avoid the impact of the experiments. Prevent the impact of the experimental landmark particle recovery results. Engraving, the requirement of clear and recognizable handwriting, engraving marks should be deep, to prevent friction between the particles, grinding off the engraving. Laser engraving, select a certain amount of iron ore and quartz sand samples for the sample, laser engraving iron ore, iron ore engraving effect is clear and recognizable.

Depth experiments and data collection in areas of avalanche traps

Experimental preparation

The experiment on the depth of the fallout zone is to study the effect of different depths of the fallout zone on the depletion of ore loss under certain conditions. The selection of experimental materials, according to the actual simulation of the mine, the simulation of the morphology of the collapse body should be used black iron ore, simulation of the overburden rock layer material should be used white quartz sand. This color is easy to distinguish, and these two materials have a certain degree of strength, in the release, the mineral rock particles in contact with each other extrusion is not broken, can retain the original form. The choice of these two materials must also be good sorting, can use magnetic sorting, simple method is to put the magnet block in a plastic basin or wrapped in a cloth and put into the non-magnetic and magnetic mixed materials pile, magnetic material that is adsorbed on the surface of the plastic basin or on the cloth, and then move out of the heap, take out the magnet block, magnetite that is the natural fall, to achieve the purpose of sorting.

During the experiment, ore and rock need to be loaded to a height of 1600 mm. The manual loading is strong and difficult, and the difficulty coefficient of loading increases with the height. Large workload and poor safety. The steel ladder is used together with the feeding machine, which is convenient, fast and safe. The feeder adopts lifting control and has a slide. It can transport ore and quartz sand of certain particle proportion to the designated position for loading and unloading through remote manual control switch. Realize automation and increase safety factor. The steel ladder can facilitate the manual filling of ore piles. The experiment is based on manual ore drawing shovel. In order to record the rule of ore and rock particle movement zone in the process of ore drawing, the experiment uses high-definition camera fixed on the matching support to shoot the experiment process. The experiment uses an electronic scale to ensure accuracy. See Table 1 for the shape of experimental filling rockfall, and Fig. 5 for the experimental filling map.

-

(1)

The experimental simulation adopts layered filling. The collapse body is 640 mm high, and 8 sections are layered, each 80 mm is a section, and the filling is carried out. Each layer has a different color number of the marking particles. It is easy to distinguish and select when releasing. Starting from the bottom layer, positioning piece is used to place rock marker particles, and the size of ore particles is about 8–10 mm. The upper overburden is a mixture of 3–5 mm, 8–10 mm, 13–15 mm and 23–35 mm in four different particle sizes.

-

(2)

Each 80 mm shall be filled with a layer of marker particles. The position and label of the marker particles are numbered from left to right, from 1 to 60, and from bottom to top, from 1–1 to 8–1. In addition, according to the length of the long and short axis of the avalanche body shape, determine the number of particles to be placed. The marker particles placed at the edge should be placed at or near the pole of the avalanche body shape as far as possible. For example, the first layer is 101, 102 to 160, the second layer is 201, 202 to 260, and so on until the eighth layer. Select the placement position and place it as a semi ellipsoid, because the shape of the avalanche body is close to the ellipsoid, which is wide at the top and narrow at the bottom. The ninth layer of the experiment is to study the mixing rule of the upper ore and rock by placing landmark particles in the rock layer.

-

(3)

Place quartz sand particles at 1600 mm position in the upper overburden.

-

(4)

Make a table and statistics according to the placement of particle layers, and draw a preliminary linear structure connection diagram.

-

(5)

Discharge the ore and start counting, counting the mass of each discharge and the labeling of the marked particles discharged.

-

(6)

When releasing, observe the flow at the end of the experiment.

When loading the avalanches, we need to block the waste rock with a gear plate to prevent the waste rock from mixing in, and collect data for each layer of the experimental loading, photograph the position of the marking particles, and the range of the size of the ore placed in each layer.

Experiments and data collection

A total of 60.040 kg ore was filled in the experiment, and nine layers of symbolic particles were placed. The first layer was placed with labels of 101–142, the second layer was placed with labels of 201–250, the third layer was placed with labels of 301–360, the fourth layer was placed with labels of 401–460, the fifth layer was placed with labels of 501–562, the sixth layer was placed with labels of 601–660, the seventh layer was placed with labels of 701–761, the eighth layer was placed with labels of 801–863, and the ninth layer was placed with labels of 901–964. The filling height is 1600 mm, as shown in Fig. 6.

The morphology of the first group of experiments is shown in Fig. 7, and the different stages of ore release are shown in Fig. 8. Observing the discharge situation, the first stage of ore discharge is pure ore discharge, which can be seen from the photos of the released ore, and there is no waste rock mixed in. The ore released in the third stage has a small amount of waste rock mixed in, and after sieving, it is found that the waste rock mixed in is powder or small particles.

By comparing the experimental statistical Figs. 9a–e and 10a–e, the experimental results show that:

-

(a)

The first group is filled with 70.010 kg ores in total. Waste rock mixing is the 28th time in the third stage of ore drawing. The first stage is pure ore drawing. In the stage of pure ore drawing, the first group of experiments released 24.120 kg of pure ore. With the increase of ore drawing times, the waste rock mixing rate gradually increased. By the end of the 76th ore drawing, 62.937 kg of ore rock was discharged in total, including 49.194 kg of pure ore and 13.743 kg of mixed waste rock, The accumulated waste rock dilution rate of the first group of experiments was 20.60%, and the waste rock mixing rate at the end of the experiment was 58.80%. In the first group of experiments, the pure ore drawing stage, the recovery rate of pure ore is 34.45%. The recovery rate of pure ore was 70.27% at the end of the first group of experimental ore drawing. In the first group of experiments, a total of 540 landmark particles were placed, 219 landmark particles were released by the end of ore drawing, and 102 were in the pure ore stage.

-

(b)

The second group is filled with 60.780 kg ores in total. Waste rock mixing is the 20th time in the second stage of ore drawing. The first time is pure ore drawing. In the pure ore drawing stage, 20.112 kg of pure ore is released. Later, with the increase of ore drawing times, the waste rock mixing rate is gradually increasing, and the ore grade is reduced. By the end of the 48th ore drawing, a total of 51.888 kg of ore rock has been released, including 40.506 kg of pure ore, 11.382 kg of mixed waste rock, and the cumulative waste rock dilution rate is 21.94%, At the end, the mixing rate of secondary waste rock was 61.54%. In the second group of experiments, the recovery rate of pure ore is 33.08% at the stage of pure ore drawing. In the second group of experiments, the recovery rate of pure ore was 66.64% at the end of ore drawing. In the second group of experiments, a total of 514 landmark particles were placed, 210 landmark particles were released by the end of ore drawing, and 95 were in the pure ore stage.

-

(c)

The third group is filled with 60.040 kg ores in total. Waste rock mixing is the 18th time in the second stage of ore drawing. The first time is pure ore drawing. 18.530 kg of pure ore is discharged in the pure ore drawing stage. With the increase of ore drawing times, the waste rock mixing rate is gradually increasing, and the ore grade is reduced. By the end of the 46th ore drawing, a total of 49.133 kg of ore rock has been discharged, including 38.049 kg of pure ore, 11.084 kg of mixed waste rock, and the cumulative waste rock dilution rate is 22.59%, At the end, the mixing rate of secondary waste rock was 55.27%. The third group of experiments is in the stage of pure ore drawing, and the recovery rate of pure ore is 30.86%. In the third group of experiments, the recovery rate of pure ore was 63.37% at the end of ore drawing. It can be seen from the sharp and slow trend of the curve that the pure ore increases rapidly in the drawing stage of pure ore, and the content of discharged pure ore is less later. Later, the waste rock is mixed faster, and the curve trend becomes sharp. From the view of the waste rock mixing rate at that time, the waste rock shows a curve resilience increase, and the mixing rate with low falling point is that large pieces of waste rock are stuck in the ore drawing stage, or the waste rock in the upper collapse area is mixed, resulting in advanced dilution. In the third group of experiments, a total of 512 landmark particles were placed, 184 landmark particles were released by the end of ore drawing, and 90 were in the pure ore stage.

-

(d)

The fourth group is filled with 59.680 kg ores in total. Waste rock mixing is the 16th time in the second stage of ore drawing. The front is pure ore drawing, and 17.804 kg of pure ore is discharged in the pure ore drawing stage. With the increase of ore drawing times, the waste rock mixing rate is gradually increasing, and the ore grade is reduced. By the end of the 42nd ore drawing, a total of 44.758 kg of ore rock has been discharged, including 35.647 kg of pure ore, 9.111 kg of mixed waste rock, and the cumulative waste rock dilution rate is 20.36%, At the end, the mixing rate of secondary waste rock was 61.63%. The fourth group of experiments is in the stage of pure ore drawing, and the recovery rate of pure ore is 29.83%. In the fourth group of experiments, the recovery rate of pure ore was 59.73% at the end of ore drawing. In the fourth group of experiments, a total of 523 landmark particles were placed, 175 landmark particles were released by the end of ore drawing, and 75 were in the pure ore stage.

-

(e)

The fifth group is filled with 57.340 kg ores in total. Waste rock mixing is the 14th time in the second stage of ore drawing, before which is pure ore drawing and ore drawing. In the fifth group of experiments, the total amount of pure ore discharged in the stage of pure ore drawing is 15.293 kg. Later, with the increase of ore drawing times, the waste rock mixing rate gradually increases, and the ore grade is getting lower and lower. By the end of the 36th ore drawing, 38.312 kg of ore rock has been discharged, including 30.980 kg of pure ore and 7.032 kg of mixed waste rock, In the third group, the cumulative waste rock dilution rate is 19.12%, and the waste rock mixing rate at the end of ore drawing is 59.00%. In the fifth group, the recovery rate of pure ore is 26.67% in the stage of pure ore drawing. In the fifth group, the recovery rate of pure ore was 54.04% at the end of ore drawing. It can be seen from the sharp and slow trend of the curve that the pure ore increases rapidly in the drawing stage of pure ore, and the content of pure ore is less when it is released later. Later, the waste rock is mixed faster, and the curve trend becomes sharp, and the waste rock just released presents small particles or powder, which proves the existence of natural classification of ore rock. From the view of the waste rock mixing rate at that time, the waste rock shows a curve resilience increase, and the mixing rate with low falling point is that large pieces of waste rock are stuck in the ore drawing stage, or the waste rock in the upper collapse area is mixed, resulting in advanced dilution. In the fifth group of experiments, a total of 523 landmark particles were placed, 166 landmark particles were released by the end of ore drawing, and the pure ore stage was 70.

The total recovered pure ore volume at the cut-off time of each group of experiments/pure ore volume at the pure ore release stage, the ratio of 2.03, 2.01, 2.05, 2.00, 2.02, respectively, can be obtained: the experimental recovery grade of 20%, the experimental ore release cut-off time of the pure ore recovery rate is the beginning of the experiments when the pure ore release stage of the pure ore recovery rate of about twice, that is, the pure ore recovered in each group of experiments This means that the amount of pure ore recovered in each group of experiments is about twice the amount of pure ore in the pure ore stage.

Study of the depth of the avalanche trap zone on the depletion of ore losses

In the experiment, the total amount of each ore drawing is counted, and the amount of each ore drawing, the amount of waste rock each time, the cumulative amount of ore drawing, and the dilution rate are counted, and the number and sequence of released landmark particles are recorded. The cut-off grade is set at 20%, and the iron ore grade with Fe is set at 50%. Draw the statistical table of ore amount, draw the loss and dilution curve, draw the flow axis curve through the release sequence of the landmark particles, draw the shape diagram of the actual drawing body, and use the formula to fit.

Comparative analysis of experimental data on loss depletion

The recovery metrics of the experimental ores were comparatively analyzed as shown in Table 2.

It can be seen that the ore recovery rate of the avalanche form with trap area is larger than that without trap area. The depth of the trap area is inversely proportional to the ore recovery rate, and the ore recovery rate increases as the depth of the trap area decreases. The upper part of the waste rock is mixed in advance with the avalanche with trap area, which leads to the depletion of the ore loss and reduces the recovery rate.

Relationships between internal flow and loss depletion in avalanche morphology

The release order of the signature particles, to a certain extent, reflects the speed of particle flow in the release layer, and at the same time, reflects the release pattern of the spatial upper body. The flow axis curve, that is, the curve formed by the point of the maximum vertical movement velocity of particles in the corresponding layer. In the experiment is the same height and the same level, the first released mark, that is, the fastest flow. Calculated as follows Eq. 1.

where i—natural angle of repose, radian of ore rock spalling; μ—end wall damping coefficient, value range is 0 to 1; ω—flow parameters of granular materials.

The flow axis actually maps the internal movement law of the particles of the avalanche body, which is the axis of the fastest falling speed. The spatial distribution form of the velocity field is actually reflected. By comparing the sequence of releasing the landmark particles with the previous placement, it is found that 101, 201, 301, 401, 501 released earlier than other landmark particles in the same layer, while the sixth layer is different from the ninth layer. The landmark particles 604, 704, 804, 904 came out earlier than 601, 701, 801, 901, They are the points close to the flow axis in the same longitudinal direction of the X axis on the spatial coordinate O-XYZ with the end wall ore outlet as the coordinate origin. The experiment shows that the closer the granular particles are to the flow axis, the greater the flow velocity is, and the earlier the release time is. The axis curve offset of the first group of experimental flow is shown in Table 3, and the axis curve offset of the second group of experimental flow is shown in Table 4.

The location of the trap area has a great relationship with the depletion of ore loss, and the extreme point of the trap area of the collapsed body refers to the lowest point of the waste rock in the depression area. The downward shift of the pole of the trap means the beginning of waste rock mixing, and the direction of the pole of the trap also indicates the increase of the contact area of the ore-rock contact surface to a certain extent, and the experimental study is conducted to investigate the positional relationship between the pole of the trap and the flow axis in the horizontal direction.

Combining the above Fig. 11 and Tables 3 and 4, it can be concluded that: I. At the same horizontal position, the pole of the trap area is tangent to the flow axis, the pole of the trap area flows fast, the development of the trap area is fast, the contact area of the ore and rock increases, the flow of the waste rock is fast, the waste rock mixes faster, resulting in the increase of the depletion rate of the released ore fast; II. The same horizontal position of the trap zone pole is above the flow axis, the trap zone pole moves relatively slowly, but the bulk of this position is vertically close to the end. III. The same horizontal position of the trap zone pole below the flow axis, the trap zone pole flow is relatively slow, the flow area of the trap zone changes to the intersection with the flow axis of the regional point, after the development of the trap zone, the influence of the depletion rate of the release of the large area becomes a small area of the upper orientation, the waste rock mixing is relatively small. According to the current release landmark particles to return to the current release amount of fitted body, the detailed current release landmark particles. The experimental results show that: the released bulk particles, possessing viscosity, the released amount of small bulk particles and the nearby bulk particles form a certain geometrical shape of large bulk block release; after connecting the coordinates of the current release iconic particles, the phenomenon of simultaneous release of iconic particles at different layers and heights is presented. This is a phenomenon that can be summarized as follows Schedule Statistical table of experimental data.

Morphological analysis of releases

The trajectory of the pole movement in the trap area is shown in Fig. 12, and the end release ore release body and flow zone (vertical direction–horizontal direction) are shown in Fig. 13.

Fitting of exudate morphology, positional reduction of exudate signature particles.

Given by Prof. Ren Fengyu of Northeastern University, the equations for the surface of a body are put as follows.

Fitting to actual values yields the empirical formula.

where α, β, α1, β1 are bulk flow parameters; μ. ω refers to Eq. 1.

In the ore release stage, the ore and rock start to flow, and the waste rock flow mixing is in the ore and rock contact with each other, and integrated into the ore particles. And slowly released ore rock increase, the release body is growing, ore rock mixing is also increasing. When the apex of the release body is just close to the contact surface of the ore and rock, the waste rock funnel just reaches the release outlet, and the previous release stage is the pure ore release stage. After the ore release, the waste rock funnel ruptures, and the waste rock enters into the ore, starting the depleted ore release stage, and as the ore release continues, the section of the waste rock funnel mouth increases, and the mixing of waste rock increases. Comparing the first group and the second group, the waste rock funnel ruptures first in the fallout body with trap area, and the waste rock mixes into the ore in advance, resulting in early loss and depletion of the ore. The morphology of the released ellipsoid was fitted as shown in Table 5, and the development of the end-exposed ore release is shown in Fig. 14.

Figure 15 shows the development of exudates from experiments in groups 1–5, with a total of 166 signature particles released at the end of the experiment and 70 signature particles released during the pure ore recovery phase.This is a phenomenon that can be summarized as follows Schedule Statistical table of experimental data. Figure 16 shows the 3D drawn-out ore body.

Through the physical simulation experiment, the release of iconic particles and the release of the ore rock, to make the change of the release of the body graph, can be seen in the release of the body at the beginning of the ore release, in the vertical direction of the development is faster than in the direction of the development of the approach, after a certain height of release, the development of the development of the vertical direction slows down, the development of the development of the direction of the approach to increase.

Fitted curves of ore loss depletion versus depth of the fallout trap zone

The relationship curves between ore loss, depletion rate and the depth of the fallout zone were fitted by the least-squares method, and based on the five sets of experimental data, the formulas were set up as follows in Eqs. 5–8, as shown in Fig. 17.

Calculate the partial derivatives of F (or 0, or 1, or m) with respect to or i respectively, and obtain m Eq. 6:

Equation 7 is obtained by organizing the equation.

Use the Gaussian elimination method to find the unknown number or a0, or a1, or a2, or a3, or a4 in the formula, and get the formula 9, 10:

Through five groups of experiments at different depths of the collapse area, the results show that under certain other conditions, when the depth of the collapse area is 0 mm, the ore loss rate is 29.73%, and the dilution rate is 20.60%; When the depth of collapse area is 25 mm, the ore loss rate is 33.36%, and the dilution rate is 21.94%; When the depth of collapse area is 50 mm, the ore loss rate is 36.63%, and the dilution rate is 22.59%; When the depth of collapse area is 75 mm, the ore loss rate is 40.27%, and the dilution rate is 20.36%; When the depth of collapse area is 100 mm, the ore loss rate is 45.96% and the dilution rate is 19.12%. The comparison of experimental data shows that when the collapse area is 0 mm, the ore loss is the least, the dilution rate is relatively low, and the recovery rate is the highest. With the deepening of the subsidence area, the ore loss rate increases, and the ore dilution rate is basically about 20%.

Conclusions

-

(1)

A large-scale model was developed for the end ore release, and matching positioning sheets and color-coded landmark particles were produced. Specific experimental programs were determined, and experiments were carried out at different depths in the trap area of the avalanche, and each group of experiments was conducted in accordance with the experimental program for loading the ore rock, placing the iconic particles, and placing the ore experiments. In the process of ore release, the data of sorted ore rocks and recovered landmark particles were collected and the corresponding codes and release times were recorded, and the data of the experimental groups were analyzed and processed separately.

-

(2)

Through the experiments at different depths of the collapse area, the results show that when other conditions are certain, the depth of the collapse area affects the formation of the draw out body, and has a greater impact on the ore loss and dilution. With the deepening of the collapse area, the ore loss rate increases, and the change of the ore dilution rate is small. When the depth of collapse area is 0 mm, the ore loss rate is 29.73%, and the dilution rate is 20.60%; When the depth of collapse area is 25 mm, the ore loss rate is 33.36%, and the dilution rate is 21.94%; When the depth of collapse area is 50 mm, the ore loss rate is 36.63%, and the dilution rate is 22.59%; When the depth of collapse area is 75 mm, the ore loss rate is 40.27%, and the dilution rate is 20.36%; When the depth of collapse area is 100 mm, the ore loss rate is 45.96% and the dilution rate is 19.12%. According to the above experimental data, when the collapse area is 0 mm, the ore loss is the least, the dilution rate is relatively low, and the recovery rate is the highest. With the deepening of the subsidence area, the ore loss rate increases, and the ore dilution rate is basically about 20%.

-

(3)

It was found that, under other conditions, when the cut-off grade was 20%, the amount of pure ore recovered in each group of experiments was about twice the amount of pure ore in the pure ore stage as the depth of the fallout trap varied.

-

(4)

When the end is put into the ore, the closer the position of the pole of the trap area is to the flow axis, the faster the pole falling speed, the expansion speed of the contact surface between the waste rock and the ore, and the depletion speed of the ore.

-

(5)

The relationship between ore loss rate q, ore dilution rate ρ and depth h of collapse body subsidence area is fitted by least square method and Gaussian elimination method as follows:

$$q = - 1 \times 10^{ - 7} h^{4} - 7 \times 10^{ - 6} h^{3} - 0.0002h^{2} + 0.1526h + 29.73$$$$\rho = - 6 \times 10^{ - 7} h^{4} - 0.0001h^{3} + 0.0056h^{2} - 0.0224h + 20.06.$$

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Deng, Y. Y. et al. Investigation on the characteristics of overlying strata caving in the Chengchao Iron Mine, China. Environ. Earth Sci. 77(10), 1 (2018).

Chen, Q., Gan, Q., Wang, H. & Liu, C. A new combined mining method: The stope limit length calculation of considering bulk support boundary. Rock Mech. Rock Eng. 57, 6909–6925 (2024).

Wu, X., Wu, X. & Zhang, N. Analysis of the location of a lower coal seam roadway under multiple stress disturbances in a close coal seam. Sci Rep 15, 22504 https://doi.org/10.1038/s41598-025-05371-9 (2025).

Zagumennyi, I. V. & Dimitrieva, N. F. Optimization research of structural parameters in non-pillar sublevel caving method with large structural parameters. AIP Conf. Proc. 1944(8), 020006 (2018).

Milic, V. & Radovanovic, M. Determination of the main parameters of semi-level induced caving method with lateral loading. J. Min. Sci. 57(1), 76–85 (2021).

Yu, J. & Yang, Z. Study on the prediction of ore dilution and loss rates in side drawing. Jinshu Kuangshan/Met. Mine 10, 70–73 (2009).

Pirogov, G. G. & Kozlova, I. M. Interaction of side rocks and broken ore subjected to shrinkage. Min. Inf. Anal. Bull. 2021(3–2), 118–124 (2021).

Zhang, W., Zhou, B., Han, Y. et al. Study on the migration law of end draw ore and rock based on discrete element. Nonferrous Met. Eng. 11(8), 99–105 (2021).

Chen, Q., Qin, S. & Wu, S. Quantitative study on the contact force and force chain characteristics of ore particle systems during ore drawing from a single drawpoint under the influence of a flexible barrier. Geofluids 2020, 1–13 (2020).

Liu, Z.-D., Tao, G.-Q., Ren, Q.-Y. & Yang, D.-S. Calculation of loss ratio and dilution ratio on end ore drawing based on random medium ore-drawing theory. Meitan Xuebao/J. China Coal Soc. 36(4), 572–576 (2011).

Zatar, O. M., El-Safty, S. A., Galal, A. & Askora, M. M. Uniform flow and stress evolution laws of caved ore and rock particles between multiple drawpoints. J. Northeast. Univ. (Nat. Sci.) 43(5), 724–732 (2022).

Qin, S., Chen, Q., Chen, Q. & Zhao, F. Correlation between ore particle flow pattern and velocity field through multiple drawpoints under the influence of a flexible barrier. Open Geosci. 11(1), 533–541 (2019).

Sun, H., Chen, S., Jin, A., Tang, K., Liu, M. & Wei, L. Evolution characteristics of three dimensional force chain in particle system of caved ore and rock under influence of single coarse particle. J. Central South Univ. (Sci. Technol.) 1930–1941 (2023).

Ke, B. & Li, P. Application of non-pillar sublevel caving method in pillar recovery. Jinshu Kuangshan/Met. Mine. 30(2), 51–52 (2009).

Zhou, C. et al. Numerical simulation of independent advance of ore breaking in the non-pillar sublevel caving method. J. China Univ. Min. Technol. 17(2), 295–300 (2007).

Tang, X., Kou, X. & Cao, W. Analysis on stress characteristics of stope structure in a non-sill-pillared sublevel caving system. Kuangye Yanjiu Yu Kaifa/Min. Res. Dev. 21(4), 16–18 (2001).

Zhang, G.-L., Song, J. & Qiu, J.-P. Optimization of development work for non-pillar sublevel caving with following-vein drift. Nonferrous Met. (China) 58(4), 89–93 (2006).

Du, C.-F., Du, J.-H., Guo, L.-W. & Tang, G.-Y. Mechanism of capping rock collapse by no-pillar sublevel caving. J. Univ. Sci. Technol. Beijing 31(6), 667–673 (2009).

Ming, J. & Hu, N. Research on the deformation failure law of stope drift with pillarless sublevel caving method. Jinshu Kuangshan/Met. Mine. 5, 25–28 (2010).

Fang, S. et al. Microscopic investigation of the effect of uniaxial stress on the structure of pore-fissure system and methane adsorption in lean coal. Energy 288, 129837. https://doi.org/10.1016/j.energy.2023.129837 (2024).

Fang, S. et al. Study on the adsorption characteristics and pore-fissure response mechanism of meagre coal and anthracite under different methane pressures. Energy 332, 137283. https://doi.org/10.1016/j.energy.2025.137283 (2025).

Meng, X. et al. A new insert drawing technique for controlling ore loss and dilution during sublevel caving. Sci. Rep. 15, 23104. https://doi.org/10.1038/s41598-025-07362-2 (2025).

Funding

Funded by Science and Technology Innovation Program of Higher Education Institutions in Shanxi Province (2022L447); Funded by Basic Youth Research Fund of Datong University, Shanxi Province (2022Q17); Funded by the 14th Five-Year Plan of Educational Science Planning of Shanxi Province (GH-220556).

Author information

Authors and Affiliations

Contributions

Xiaoyu Wu and Xiaowei Wu and Nan Zhang wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, X., Zhang, N. & Wu, X. The effect of depth of the trap zone of an end release avalanche on the depletion of ore loss. Sci Rep 15, 26199 (2025). https://doi.org/10.1038/s41598-025-11784-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-11784-3