Abstract

To address the production succession challenges posed by single-wing mining, this study investigates the 5-1081 roadway of the Fenyuan Coal Mine as a representative example. Theoretical analysis and numerical simulation were combined to systematically examine the spatiotemporal relationship between the gob-side roadway and the overlying working face, with a focus on their influence on excavation strategies and surrounding rock deformation. The results indicate that, under a fixed coal pillar width, the adjacent mining and driving scheme significantly enhances surrounding rock stability and reduces succession constraints compared to other methods. Under this scheme, the roadway undergoes pronounced asymmetric deformation, with significant disturbances occurring especially before and after the intersection with the working face. Based on the deformation characteristics, a segmented support strategy was proposed, defining the key reinforcement zone as spanning from 40 m before to 60 m after the intersection. This study provides a theoretical basis and practical guidance for the safe and efficient construction of gob-side roadways under comparable geological and mining conditions.

Similar content being viewed by others

Introduction

Gob-side roadway excavation plays a crucial role in coal mine production, as its effectiveness directly affects safety, operational efficiency, and economic performance1,2,3. However, under complex geological conditions, the surrounding rock often demonstrates poor stability, resulting in stress concentrations and triggering dynamic disasters such as gas outbursts, rockbursts, and water inrushes4,5. These issues pose serious threats not only to construction safety but also to the sustainable and efficient development of coal mines. Therefore, addressing the technical challenges associated with adjacent mining and excavation is of considerable practical importance6,7,8,9.

Unlike conventional gob-side excavation methods, the advancing gob-side roadway excavation technique is commonly employed in single-wing mining districts. During the retreat of the upper working face, the new roadway is excavated within a zone still affected by mining-induced stresses10,11. In this process, the roadway is continuously subjected to abutment pressure and lateral support stress from the working face, leading to severe deformation and substantially increased support challenges12,13,14,15. Consequently, developing effective strategies to manage these issues has become a key research focus in this field.

Numerous scholars have made significant contributions to this field. For example, Bai Jianbiao16,17 analyzed the effects of dynamic pressure during roadway excavation under advancing mining conditions and proposed a support scheme designed to enhance the stability of coal pillars and the roof. His findings revealed asymmetric deformation patterns in the surrounding rock and emphasized the need for reinforcement measures to improve its bearing capacity. Yu Yang, Zhong Deyu, and colleagues18,19,20,21,22 investigated the spatiotemporal effects of overlying strata movement and proposed dynamic, segmented support strategies. Han Changliang23 employed theoretical and physical models to examine support strategies for gob-side entries affected by mining-induced disturbances.

Furthermore, Lian Changjun and Yang Hailou24,25 examined the influence of coal pillar width on plastic zone development and proposed targeted reinforcement strategies. Kang Jizhong26 focused on the spatiotemporal evolution of stress in gob-side entries and developed a zoned support control strategy using high-performance bolt systems. Gou Jin27 utilized numerical simulations to investigate techniques for controlling surrounding rock deformation, while Zhao Yao28 emphasized the importance of early-stage support enhancement as the working face advances. Liu Yang29 examined failure mechanisms in dynamically loaded roadways and optimized support parameters using high-strength torque bolts.

Although significant progress has been made in understanding dynamic deformation mechanisms and in the development of segmented support strategies, existing studies are often constrained to specific geological settings. Systematic investigations into optimal excavation schemes for advancing gob-side roadways under complex stress conditions remain limited. In particular, few studies have addressed the spatiotemporal disturbance effects associated with mining–driving interactions, and even fewer have proposed generalized theoretical models or practical guidelines for optimizing excavation timing and mitigating dynamic stress impacts.

This study aims to fill these gaps by systematically analyzing the spatiotemporal effects of advancing gob-side roadway excavation. A numerical simulation approach is adopted to evaluate various excavation schemes and determine the optimal strategy under mining-induced disturbances. A zoning-based support strategy is subsequently developed to enhance roadway stability in critical zones. The results contribute not only to the theoretical understanding of mining–driving interactions but also to the practical advancement of excavation adaptability and support precision in complex geological conditions.

Project overview

Project background

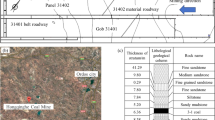

The Fenyuan Coal Mine is located in Dujia Village, Jingle County, Xinzhou City, Shanxi Province, China. It is classified as a typical low-gas mine, with the No. 5 coal seam as the primary mining layer. The No. 5 seam has an average thickness of 13.5 m and a dip angle ranging from 25° to 37°, with an average of 35°, characterizing it as a typical inclined and extra-thick coal seam.

The immediate roof is mainly composed of argillaceous limestone and mud-bearing limestone, with an average thickness of 8.2 m. The floor consists primarily of mudstone and fine sandstone, averaging 2 m in thickness. This complex lithological structure imposes strict requirements on mine design and support technologies.

The columnar lithologic profile (Table 1) visually depicts the thickness and lithological distribution of the No. 5 coal seam, as well as its overlying and underlying strata. This provides essential theoretical support and valuable reference for optimizing mining design and formulating control strategies.

Working face layout and mining sequence

The 5-106 working face is situated in the second mining district of the Fenyuan Coal Mine and primarily extracts the No. 5 coal seam, with an average burial depth of approximately 300 m. To alleviate succession pressure caused by the single-wing mining method, preparations for the 5-108 working face commenced before the 5-106 working face had completed its retreat. This approach ensured operational continuity within the mining district and enhanced production capacity.

However, this arrangement resulted in a unique configuration in which the return airway of the 5-108 working face and the retreat direction of the 5-106 working face move in opposite directions. The specific configuration of the working faces and associated roadways is illustrated in Fig. 1.

Advancing gob-side roadway excavation method considerations

Spatiotemporal distribution of gob-side roadways

Under complex mining conditions, roadways excavated along goafs are frequently situated in zones that are significantly influenced by mining-induced disturbances. This is particularly evident during forward, or face-approaching, excavation, where the stress environment and structural integrity of the surrounding rock undergo continuous changes, leading to distinct staged deformation characteristics.

Using the 5-1081 roadway in the Fenyuan Coal Mine as a case study, and considering the fracturing patterns of the overlying strata above the 5-106 working face as well as the characteristics of mining-induced disturbance, the surrounding rock response during face-approaching excavation can be classified into three distinct stages:

(1) Excavation Stage

In this stage, the 5-1081 roadway is excavated along the original coal seam. Due to the limited influence of dynamic pressure from the adjacent working face, the external mechanical environment remains relatively stable. As a result, the stress distribution within the surrounding rock is relatively uniform, and the roadway deformation progresses slowly and steadily. The overall deformation is minor, and the support requirements are relatively simple—primarily focused on controlling localized displacements to ensure safe and continuous excavation.

(2) Mining Influence Stage from Adjacent Working Face

As the roadway approaches the adjacent 5-106 working face, the surrounding rock gradually comes under the influence of dynamic loading induced by ongoing mining activities. This stage can be further subdivided into two sub-stages:

(i) Advanced Mining-Induced Stress Stage

As the excavation face approaches, but does not yet intersect, the adjacent working face, the area ahead of the roadway is subjected to elevated stress caused by abutmen pressure. This results in a pronounced stress concentration in the surrounding rock.

(ii) Residual Mining-Induced Stress Stage

After the excavation face intersects or passes beyond the active working face, the roadway behind enters the disturbance zone associated with the goaf. Roof collapse and stress redistribution occur, leading to a more complex rock mass structure and significantly increasing the risk of large deformations and structural instability.

These two phases represent critical periods for roadway stability control, characterized by rapidly increasing deformation rates, accelerated expansion of the plastic zone, and localized failures such as roof separation and rib shear damage.

(3) Stress Stabilization Stage in the Goaf Zone

Once the excavation face has fully passed through the adjacent goaf, the surrounding rock structure gradually stabilizes as a result of collapsed material compaction and stress redistribution. Although the overall stress level may remain slightly elevated compared to undisturbed coal seam zones, the resulting structural disturbances are relatively manageable. With appropriate support measures, long-term roadway stability can be effectively maintained.

It is important to note that the above stage classification is derived from theoretical analysis of geological conditions and the mining sequence. The specific evolution of stress and deformation characteristics in the surrounding rock will be quantitatively analyzed and validated through numerical simulations in Sect. “Numerical Simulation of Roadway Excavation”.

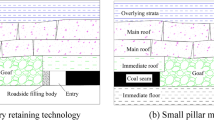

Rationality of roadway excavation methods

Given the staged nature of surrounding rock response, selecting an appropriate excavation strategy is essential to ensuring roadway stability and effectively coordinating mining and tunneling operations. To alleviate production scheduling pressures and address the challenges of dynamic support, three typical strategies are commonly adopted in field practice: “Excavation Near an Inactive Panel,” “Mining Near a Halted Excavation,” and “Concurrent Mining and Excavation.” The following sections present a comparative analysis of these three approaches:

(1) Excavation Near an Inactive Panel

In this approach, mining operations at the working face are temporarily halted before the roadway enters the zone influenced by mining-induced stress. As illustrated in Fig. 2, excavation proceeds through the high-risk zone first, after which coal production resumes. This method effectively reduces the risk of dynamic stress superposition and contributes to maintaining the stability of the surrounding rock.

However, its main drawback is the significant disruption to the normal advancement of the working face, which can result in reduced production capacity and scheduling delays. Consequently, its applicability is limited, particularly in mines with high production requirements.

(2) Mining Near a Halted Excavation

In this approach, roadway excavation is temporarily suspended before entering the zone influenced by dynamic mining-induced stress, allowing mining operations at the working face to take priority. Excavation then resumes once mining has sufficiently advanced. The main advantage of this method is its ability to ensure uninterrupted coal production, making it suitable for mines with tight production schedules.

However, when excavation resumes, the surrounding rock conditions become more complex due to mining-induced disturbances, as shown in Fig. 3. As a result, the support system must be highly adaptable and flexible to accommodate the increasingly complex geological conditions.

(3) Concurrent Mining and Excavation

This approach is currently the preferred strategy employed by most coal mines. By synchronizing excavation and mining operations and incorporating stage-specific responses of the surrounding rock, this method facilitates the use of targeted dynamic support techniques and adaptive construction management. As a result, excavation efficiency is improved while maintaining roadway stability and safety.

Especially under conditions where the distance between the roadway and working face changes dynamically and the stress environment fluctuates frequently, the “Concurrent Mining and Excavation” strategy offers improved adaptability and cost-effectiveness, as illustrated in Fig. 4. This is achieved by flexibly adjusting excavation parameters and support measures in response to evolving geological and stress conditions.

Under the engineering conditions of the Fenyuan Coal Mine, three primary excavation strategies are commonly employed to coordinate the transition between mining and excavation and to ensure roadway stability: “Excavation Near an Inactive Panel,” “Mining Near a Halted Excavation,” and “Concurrent Mining and Excavation.” Each strategy presents distinct advantages and limitations in terms of stress control, construction efficiency, and field adaptability.

The “Excavation Near an Inactive Panel” strategy can significantly optimize the stress environment of the surrounding rock but tends to disrupt the mining schedule, thereby reducing production efficiency. The “Mining Near a Halted Excavation” method effectively avoids mining-induced disturbances and is particularly suitable under conditions involving wide coal pillars and tight production timelines; however, it may still pose stability risks in complex stress environments. The “Concurrent Mining and Excavation” strategy employs dynamic segmented support and optimized construction scheduling, enabling continuous production while effectively controlling surrounding rock deformation. This approach offers relatively strong overall adaptability.

Considering the actual production requirements, mining conditions, and construction timelines at the Fenyuan Coal Mine, the “Mining Near a Halted Excavation” and “Concurrent Mining and Excavation” strategies are considered more reliable. To further evaluate their performance in terms of roadway stability, this study conducts numerical simulations to analyze the surrounding rock response and the adaptability of the associated support systems, with the ultimate goal of determining the optimal excavation strategy.

Numerical simulation of roadway excavation

Numerical simulation model

Based on geological data from the Fenyuan Coal Mine, a numerical model with dimensions of 225 m × 400 m × 180 m was established using FLAC3D software. The model consists of eight stratified layers and employs a hexahedral mesh for numerical calculation. To emphasize key research zones, mesh refinement was applied to the coal and rock mass within a defined range around the stoping face and the approaching roadway.

The mechanical and physical parameters of the surrounding rock used in the numerical model are listed in Table 2, and the initial model configuration is shown in Fig. 5. The Mohr-Coulomb yield criterion was adopted in the simulation.

Numerical Model. Created using FLAC3D (Version 7.0, https://www.itascacg.com/software/flac3d).

Numerical simulation scheme

To investigate the full-process dynamic pressure effects of overlying strata induced by stoping at the adjacent working face on nearby excavated roadways, a spatiotemporal approach is adopted to assess the degree of influence and determine a rational excavation strategy.

In the simulation, both the 5-106 working face and the 5-1081 roadway are excavated using a stepwise cyclic method, with the roadway length set to 300 m. Beginning 60 m ahead of the working face, the stress distribution patterns of the adjacent excavated roadway are analyzed incrementally. The simulation advances in 10 m calculation increments until stoping is completed and roadway excavation stabilizes. Monitoring points are installed at the heading of the 5-1081 roadway to analyze stress evolution at different stages under the influence of the 5-106 working face, thereby identifying an optimal excavation strategy for the 5-1081 roadway.

(1) Analysis process of halting excavation before stoping:

The working face advances 10 m (total excavation: 140 m), and the roadway advances 20 m (total excavation: 80 m, within the 80 m stress influence range of the working face). The excavation of the 5-1081 auxiliary roadway halts. The working face then advances another 10 m (total excavation: 180 m), followed by an equilibrium calculation.

(2) Analysis process of simultaneous mining and excavation:

The working face advances 10 m (total excavation: 100 m), and the roadway advances 20 m (total excavation: 120 m, within the 80 m stress influence range of the working face). The working face then advances another 10 m (total excavation: 110 m), while the roadway advances 10 m (total excavation: 130 m), followed by an equilibrium calculation.

Stress distribution for different excavation methods

During the excavation of the approaching roadway, it is primarily influenced by fluctuating high stresses induced by overlying strata movement caused by adjacent working face stoping. To analyze the impact of adjacent mining on roadway excavation, monitoring lines were arranged at the heading of the 5-1081 roadway in the numerical model. Vertical stress at a cross-section located 1 m behind the excavation heading was analyzed at various advancing distances. In the figures below, “–” denotes that the roadway has advanced beyond the working face.

Based on the analysis of Figs. 6 and 7, the following conclusions are drawn:

-

(1)

As the roadway approaches and then passes the working face, both the lateral abutment pressures on the working face and the roadway initially increase, then decrease, with the peak position gradually shifting inward before stabilizing.

-

(2)

The variation trends of the two schemes are generally similar, with slight differences in peak lateral abutment pressure on the roadway. Due to the dynamic effects of simultaneous mining and excavation, the peak stress in this method is slightly higher, while the peak abutment pressure on the working face remains unchanged. This indicates that the roadway stress environment is primarily influenced by the working face’s lateral abutment pressure, which has minimal impact beyond 30 m. The influence range of lateral stress during excavation is relatively limited, while the mining–excavation overlap effect is clearly observed.

-

(3)

As the 5-1081 roadway advances toward the 5-106 working face, it gradually enters the lateral stress influence zone of the goaf, under the influence of advanced abutment stress from the 5-106 working face. Consequently, the peak stress first increases and then decreases, exhibiting distinct segmentation characteristics.

-

(4)

Compared with the “Mining Near a Halted Excavation” method, the “Concurrent Mining and Excavation” method increases peak stress on both sides of the roadway by approximately 0.85 MPa and 0.59 MPa, respectively. Correspondingly, the stress concentration factors increase from 1.36 to 1.37 to 1.46 and 1.44.

Based on the above analysis, during the advancement of the 5-1081 roadway toward the 5-106 working face with a 30 m coal pillar, the dynamic stress induced by mining–excavation overlap is comparable to that caused by mining alone, resulting in a relatively stable stress environment. Therefore, the “Concurrent Mining and Excavation” strategy is recommended to ensure smooth mining succession.

Stress field evolution in simultaneous mining and excavation

Based on the preceding analysis, the selected excavation method for the roadway is the “Concurrent Mining and Excavation” strategy. To further investigate the stress distribution and deformation characteristics of the roadway under this method, the peak lateral stress, as well as the roof and floor deformation, were analyzed separately. The deformation curve of the surrounding rock under the “Concurrent Mining and Excavation” strategy is illustrated in the figure below.

Stress evolution analysis

To investigate stress variation along the roadway, vertical stress monitoring points were arranged along its longitudinal axis. Simulation results indicate significant spatial variation in stress levels, exhibiting a clear segmentation pattern along the excavation path.

Specifically, when the roadway is far from the adjacent working face, the vertical stress in the surrounding rock remains close to the in-situ stress level, indicating a relatively stable zone. However, as the excavation face approaches within approximately 40 m of the working face, the influence of abutment pressure becomes increasingly pronounced, causing a sharp rise in vertical stress and the formation of a stress concentration zone.

Once the excavation face intersects the working face, the roadway enters the frontal boundary of the goaf. In this stage, the stress distribution within approximately 60 m behind the face continues to fluctuate due to the combined effects of stress redistribution from the goaf and structural disturbances in the surrounding rock. Although peak stress values slightly decrease compared to those in the concentration zone, they remain elevated relative to the original in-situ level. Beyond this range, as the collapsed overlying strata gradually stabilize, the stress field begins to rebalance, and the surrounding rock transitions into a new state of relative stability.

Overall, the stress evolution process follows the pattern: initial stability → sharp increase in the middle section → gradual decline in the later stage (Fig. 8).

Surrounding rock deformation patterns

To further investigate the deformation response of the surrounding rock under simultaneous near-mining and near-excavation conditions, displacement monitoring points were installed at the midpoints of both ribs and the centers of the roof and floor of the test roadway. These monitoring points continuously recorded the displacement evolution of the surrounding rock during stoping of the adjacent working face, as shown in Fig. 9. In the figure, negative values on the horizontal axis indicate positions located behind the adjacent working face.

As shown in the figure, the surrounding rock deformation under the near-mining and near-excavation scheme can be broadly divided into three stages:

Stage 1: From roadway excavation to 40 m before intersecting the adjacent working face, excavation-induced disturbance is minimal, resulting in only slight deformation of the surrounding rock. The deformation curve remains nearly horizontal, with a magnitude of approximately 125 mm.

Stage 2: Between 40 m before and 60 m after the intersection of the 5-106 working face and the 5-1081 roadway, surrounding rock deformation increases rapidly due to the influence of stoping. Beyond 60 m, roof-floor convergence and deformation of the solid coal rib tend to stabilize. However, owing to the softness of the coal seam and intense disturbance on the coal pillar side, significant deformation persists in the coal pillar rib.

Stage 3: Beyond 60 m after the intersection, surrounding rock deformation gradually stabilizes. At this stage, the coal pillar exhibits the largest deformation (386 mm), followed by roof subsidence (257 mm), floor heave (204 mm), and solid coal rib deformation (182 mm).

Comprehensive analysis reveals that deformation mechanisms of the surrounding rock differ significantly before and after the intersection with the working face. Notably, during the second stage, the surrounding rock shows high sensitivity to mining-induced disturbance, with pronounced asymmetry in deformation across different locations. Deformation is most severe in the narrow coal pillar sidewall and roof regions, indicating these areas should be prioritized in subsequent support design. As the excavation face moves away from the mining-affected zone, surrounding rock deformation gradually decreases and stabilizes, confirming the coupling relationship between support timing and deformation evolution.

Dynamic support zoning and optimization of control strategies

Analysis of surrounding rock disturbance characteristics during roadway excavation

During roadway excavation, as the excavation face advances, the stress state and energy release process in the surrounding rock exhibit a distinct spatial lag effect, commonly referred to as the “spatial effect.” The corresponding curves30 are shown in Fig. 10, where the vertical axis represents the displacement release coefficient and the horizontal axis denotes the distance from the excavation face.This spatial effect implies that the rock mass ahead of the excavation face is subjected to stress disturbances in advance, whereas plastic deformation and displacement release behind the face do not occur instantaneously, but instead display a time–space lag.

Previous studies have shown that significant stress disturbance typically initiates within a distance of 2 times the initial deformation control radius of the surrounding rock (2R₀) ahead of the excavation face, whereas deformation release behind the face generally completes and stabilizes within 4R₀.

Based on the numerical model developed in this study and on-site monitoring data, the advance disturbance range in the 5-1081 roadway during excavation is approximately 4.4 m, while the lagging disturbance range is about 8.8 m. Although this disturbed zone is much smaller than the total disturbance zone induced by mining activities (extending approximately 40 m ahead and 60 m behind the working face), it plays a critical role in identifying stress-sensitive segments of the surrounding rock.

In particular, as the roadway approaches the mining-affected zone, the advance disturbance can induce a preloading effect on the support system. If not properly addressed, this may result in early-stage support failures, such as localized anchor loosening or initial structural damage.

Therefore, the spatial effect not only reflects a fundamental characteristic of surrounding rock behavior during excavation but also serves as a theoretical basis for dynamic support design. In subsequent support zoning, it is essential to incorporate the influence radius of advance disturbance and integrate it with zones of mining-induced stress variation. This approach enables precise delineation of support sections and facilitates proactive risk management and control.

Time-Zoned dynamic control technology

Under simultaneous near-mining and near-excavation conditions, the roadway segment located approximately 40 m ahead to 60 m behind the 5-106 working face is identified as a critical mining–excavation stress coupling zone. Within this region, the surrounding rock is simultaneously affected by advance abutment pressure, mining-induced disturbance, and the structural response of the rock mass, resulting in highly nonlinear deformation behavior. This makes it a key zone for roadway stability control.

The disturbance range previously identified based on spatial effect theory (+ 4.4 m to − 8.8 m) further supports the rationale for designating this segment as a support reinforcement zone. To achieve precise control, support strategies should be optimized through zonation, according to the evolution of stress and deformation characteristics in the surrounding rock, as detailed below:

(1) Stable Excavation Zone in Intact Coal (Distance > 40 m ahead of the working face).

This zone remains under the influence of the original in-situ stress field, with relatively intact surrounding rock unaffected by adjacent mining activity. Deformation is primarily elastic, and support demand is minimal. Standard bolt + wire mesh support is sufficient to ensure stability while minimizing cost and construction interference.

(2) Mining-Excavation Coupling Zone (From 40 m ahead to 60 m behind the working face).

This is the most critical segment, subject to both abutment pressure and unloading effects due to coal extraction. It can be further subdivided into:

Face-Approaching Sub-Zone (From 40 m ahead to the intersection point):

Influenced by strong stress gradients, this segment exhibits plastic shear-dilatant deformation, especially in the ribs and roof. Recommended measures include increased bolt density, extended anchorage length, and use of high-strength mesh to fully enclose the cross-section, enhancing initial support capacity.

Mining Disturbance Sub-Zone (From intersection point to 60 m behind):

Affected by roof collapse and goaf-induced stress redistribution, this area is prone to crack propagation and high deformation rates. Active support is essential, including high-strength anchors, prestressed anchor cables, and localized grouting reinforcement to improve adaptability and deformation coordination.

(3) Stress Stabilization Zone (Distance > 60 m behind the working face).

As the overlying strata collapse and compact, the stress field reaches a secondary equilibrium. Although stress remains slightly elevated compared to intact coal, the rock structure becomes relatively stable. Standard support should be resumed, along with monitoring systems to track deformation evolution and ensure long-term reliability.

In summary, the mining–excavation coupling zone represents the core segment for ensuring roadway stability. The support strategy should follow the principle of “zone identification – graded control – dynamic response,” establishing a differentiated and adaptive support system. This approach enables targeted reinforcement in high-risk areas and ensures the full lifecycle stability of the roadway. The proposed zoning scheme is illustrated in Fig. 11.

Conclusions

This study systematically investigated optimal excavation methods and support strategies for gob-side roadways influenced by advancing working faces, by integrating theoretical analysis with numerical simulation. The main conclusions are as follows:

-

(1)

With a fixed coal pillar width, comparative numerical simulations of various excavation methods confirmed the feasibility and effectiveness of the “simultaneous excavation and mining” approach (i.e., adjacent mining and driving) in addressing succession-related challenges.

-

(2)

During adjacent mining and excavation, the surrounding rock of the roadway is significantly affected by the overlying working face, exhibiting asymmetric deformation. Severe disturbances were observed in the coal pillar side and roof, making their stability critical to maintaining overall roadway integrity.

-

(3)

Based on the stress distribution and deformation patterns, a segmented control strategy was proposed. The key reinforcement zone was defined as extending from 40 m before to 60 m after the intersection between the working face and the roadway, effectively mitigating stress concentrations through targeted support.

This study provides both theoretical support and practical guidance for roadway design in comparable geological conditions and offers new insights into the spatiotemporal behavior and adaptive support strategies in deep coal mining.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Shuai, Y., Ma, Z., & Feng,X.Study on transportation and stress distribution of the overburden rock of gob side entry with cutting top and unloading pressure Sci. Rep. 15, 79218 https://doi.org/10.1038/s41598-024-79218-0 (2025).

Li, L. et al. The entry retained along gob side with small coal pillar and its surrounding rock control: a case study. Sci. Rep. 14 (1), 28021–28081 (2024).

Yao, Q. L. et al. Post-mining failure characteristics of rock surrounding coal seam roadway and evaluation of rock integrity: a case study. Bull. Eng. Geol. Environ. 80 (4), 1–17 (2020).

Wu, W., Wang, T., Bai, J., Liu, J., Wang, X., Xu, H., & Feng, G.. Failure Characteristics and Cooperative Control Strategies for Gob‑Side Entry Driving near an Advancing Working Face: A Case Study Processes 12(7), 1398https://doi.org/10.3390/pr12071398 (2024).

Chen, Y., Ma, S. & Yu, Y. Stability control of underground roadways subjected to stresses caused by extraction of a 10-m-thick coal seam: A case study. Rock. Mech. Rock. Eng.50(9), 1–10 (2017).

Kang, H., Wu, L., Gao, F., Lv, H., & Li, J.. Field study on the load transfer mechanics associated with longwall coal retreat mining. International Journal of Rock Mechanics and Mining Sciences. 124, 104141(2019). https://doi.org/10.1016/j.ijrmms.2019.104141

Wang, M. et al. Numerical study on the strength and fracture of rock materials with multiple rough preexisting fissures under uniaxial compression using particle flow code. Comput. Part. Mech. 12 (1), 453–477 (2025).

Wang, M. et al. Peak strength, coalescence and failure processes of rock-like materials containing preexisting joints and circular holes under uniaxial compression: Experimental and numerical study. Theor. Appl. Fract. Mech.125, 103898 (2023).

Huang, W., Zhao, T., Zhang, C., et al. Assessment of pillar stability and its control in a double roadway layout Energy Science & Engineering, 12(10), 4192–4209 https://doi.org/10.1002/ese3.1884 (2024).

Zhang, N., Li, X. H. & Gao, M. S. Pre-tensioned support and engineering application of gob-side entry retaining in mining-affected working face. J. Rock Mech. Eng.23, 2100–2105 (2004).

Zhang, G. C. et al. Ground response of a gob-side entry in a Longwall panel extracting 17m-thick coal seam: a case study. Rock. Mech. Rock. Eng. 53 (2), 497–516 (2020).

Chen, X. X., Wang, Y. L. & Zhang, T. Deformation law and control technology of surrounding rock in gob-side entry retaining of mining-affected face. Saf. Coal Mine.51(76), 66–71 (2020).

Liu, J. H. et al. Study on reasonable width of the isolation coal pillar in deep Thick coal seam gob-side entry retaining under mining influence. J. Rock. Mech. Eng. 34, 4269–4277 (2015).

Wang, M. et al. Experimental and numerical study on peak strength, coalescence and failure of rock-like materials with two folded preexisting fissures. Theor. Appl. Fract. Mech.125, 103830 (2023).

Wang, M., Wan, W. & Zhao, Y. Experimental study on crack propagation and the coalescence of rock-like materials with two preexisting fissures under biaxial compression. Bull. Eng. Geol. Environ. 79 (6), 3121–3144 (2020).

Wang, M. et al. Deformation law and control technology of surrounding rock in gob-side entry retaining under mining influence. J. Min. Saf. Eng. 29, 197–202 (2012).

Bai, J. et al. Roof deformation, failure characteristics, and preventive techniques of gob-side entry driving heading adjacent to the advancing working face. Rock Mech. Rock Eng.48(6), 2447–2458 (2015).

Yu, Y., Bai, J., Wang, X. & Zhang, L. Control of the surrounding rock of a goaf-side entry driving heading mining face. Sustainability12, 2623 (2020).

Yu, Y. et al. Dynamic segmented control technology of surrounding rock in gob-side entry retaining of mining-affected working face. Coal Sci. Technol. 41, 43–46 (2013).

Yu, Y. et al. Study on Spatiotemporal effects and control technology of opposing mining and excavation roadways. Coal Technol. 37, 18–21 (2018).

Wang, M., Wan, W. & Zhao, Y. Prediction of the uniaxial compressive strength of rocks from simple index tests using a random forest predictive model. C. R. Mec.348(1), 3–32 (2020).

Wang, M. & Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock. Mech. Min. Sci. 123, 104094 (2019).

Han, C. L., Zhang, N., Ran, Z., Gao, R. & Yang, H. Q. Superposed disturbance mechanism of sequential overlying strata collapse for gob-side entry retaining and corresponding control strategies. J. Cent. South. Univ.25, 2258–2271 (2018).

Lian, C. J. Study on the width of protective coal pillar and surrounding rock control technology in gob-side entry retaining of Xichuan Coal Mine, (China University. of mining and technology (Xuzhou), (2014).

Yang, H. L., Yu, Y. & Zhu, Q. Q. Study on surrounding rock stability and segmented control technology of opposing mining and excavation roadways. Coal Eng.45, 11–14 (2013).

Kang, J. Z. et al. Deformation law and segmented control technology of surrounding rock in strong dynamic pressure roadway. Min. Saf. Environ. Prot. 44, 74–78 (2017).

Gou, J. Study on surrounding rock control technology of gob-side entry retaining under mining influence. Coal Eng. 50, 43–47 (2018).

Zhao, Y. et al. Research and application of gob-side entry retaining technology in Chensilou mine. Coal Eng. 6, 41–43 (2012).

Liu, Y. Study on deformation instability mechanism and control technology of dynamic pressure roadway in Majialiang Coal Mine (China University. of mining and technology (Xuzhou), (2017).

Zhang, R. et al. Analysis on characteristics of surrounding rocks of roadway and bearing structure based on stress regulation. Adv. Civ. Eng. (2021). (2021).

Acknowledgements

This research is funded by the National Natural Science Foundation of China (No.52274148).

Author information

Authors and Affiliations

Contributions

R.S.L.: Methodology, Resources, Funding acquisition. Z.X.P.: Conceptualization, Methodology, Validation, Investigation, Formal analysis, Writing—original draft. H.J.W.: investigation. L.Y.Z.: investigation. L.D.: investigation. B.H.B.:investigation.W.H.T.: investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shan, R., Zhao, X., Huang, J. et al. Excavation methods and stability control strategies for gob-side roadways based on spatiotemporal evolution. Sci Rep 15, 27092 (2025). https://doi.org/10.1038/s41598-025-11826-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11826-w