Abstract

Mastering the deformation and air leakage patterns of gob-side retained roadway in fully mechanized mining faces, as well as the distribution characteristics of the gas flow field, is of great significance for the comprehensive prevention and control of gas in the goaf. Taking the 20,107 fully mechanized mining face of Qincheng Coal Mine in Shanxi Province as a case study, this paper employs fracture mechanics and plate-beam theory to analyze the impact of the roof fracture position on stress concentration and deformation failure of the roadway wall. It is found that when the fracture line is located outside the wall, the supporting stress can be effectively transferred and pressure can be relieved. Based on this, a calculation method for the critical position of roof-cutting and pressure-relief is proposed. Through field measurements and statistical analysis, the quantitative characteristics of the air leakage flow field and gas concentration distribution in the gob-side retained roadway goaf area were obtained. Consequently, a comprehensive gas prevention and control technology for gob-side retained roadway was proposed, which primarily includes directional drilling with staged hydraulic fracturing for roof cutting and pressure relief, along with enhanced coordinated gas extraction. Additionally, it incorporates auxiliary measures such as silicate composite material spraying for leakage sealing, optimization of ventilation pipe parameters in retained roadway, and airflow regulation for pressure reduction. The proposed approach was validated through field practice. The research results indicate that: (1) The air leakage flow field in the 20,107 goaf is characterized by positive-pressure leakage from the intake airflow of the belt roadway and high-concentration gas accumulation on the retained roadway side, which then enters the return airflow. The positive-pressure air leakage volume in the inclined section of the working face (0–36 m) is 332.84 m3/min, accounting for 58.17% of the total, while the air leakage volume in the retained roadway section (36–108 m along the strike) is 408.45 m3/min, accounting for 87.09%. (2) After optimization, the average pure gas extraction rate of directional drilling boreholes (fracturing and extraction boreholes) in the fractured zone reaches 7.46 m3/min, while the average gas concentration in the gob-side retained roadway gradually decreases from 0.59 to 0.34%. These findings provide a theoretical and practical basis for controlling the deformation of gob-side retained roadway walls, reducing air leakage in the goaf, and improving gas extraction efficiency, thereby guiding the safe and efficient production of fully mechanized mining faces.

Similar content being viewed by others

Introduction

In recent years, with the widespread application of pillarless mining technology in high outburst mines, the deformation and failure of gob-side retained roadway walls have facilitated gas leakage from both adjacent goaf areas into the retained roadway1, leading to excessive gas concentrations in the return airflow and constraining safe mine production. Therefore, investigating the distribution of wall deformation-induced air leakage in gob-side retained roadway of high outburst mines and proposing targeted prevention and control technologies are fundamental to mitigating gas hazards in the goaf.

Gob-side retained roadway offer multiple advantages, including pillarless mining and Y-type ventilation2,3; however, they also increase air leakage in the goaf, exacerbating the challenges of coal spontaneous combustion and gas control4. Yu Yanan5, Zhang Xingrun, et al. utilized fluid simulation software to determine the flow field and gas concentration distribution in the goaf of a fully mechanized mining face under a two-intake, one-return “Y”-type ventilation system6. Ding Houcheng et al. investigated the spatial distribution of the gas flow field inside the goaf in the strike, dip, and vertical directions7. Ji Chuanren et al. introduced the concept of working face air leakage rate8. Li Zongxiang et al. analyzed the gas sources within the goaf and demonstrated that gas emission decay follows a negative exponential function, proposing a method for estimating air leakage volume9,10. Zhao Liang et al. examined the evolution of the air leakage flow field, leakage volume, and oxygen concentration under different wall porosities in gob-side retained roadway11. Gao Guangchao12, Suo Liang, et al. developed a three-dimensional “O”-ring caving non-homogeneous porous media mathematical model13, obtaining the gas flow field and concentration distribution characteristics in the goaf under Y-type ventilation. Wang Jiong14, Luo Zhenmin, et al. conducted numerical simulations to analyze the flow field and air leakage behavior under different ventilation volumes and retained roadway lengths15. Li Zongxiang16 and Zhang Chun17 analyzed the air leakage flow field and oxygen concentration distribution characteristics in the goaf and proposed a method for determining the oxygen consumption rate of residual coal. Guo Yanfei et al. employed the tracer gas method to investigate the air leakage and gas migration patterns in a gob-side retained roadway under a “one-intake, two-return” ventilation system18. Zhang Zhenbin19, He Kaimin, et al. analyzed the air leakage flow field in the goaf and the concentration distribution of various gas components, proposing wind barrier installation and leakage-sealing spraying as mitigation measures20. Li Chenwu21, Luan Hengjie, et al. implemented a comprehensive approach combining enhanced cross-layer borehole extraction and goaf pipeline extraction to effectively intercept gas leakage into the retained roadway return airflow22. Sun Siqing et al. investigated the extraction of gob gas using groups of directional long boreholes drilled into the roof and proposed reasonable borehole layout parameters23,24. Guo Silong proposed an integrated gas control technology involving borehole insertion along gob-side entry retaining and high-level boreholes targeting the fracture zone25. In summary, previous studies on gob-side entry retaining primarily considered hydraulic fracturing boreholes for roof cutting and boreholes for gas extraction in fracture zones as independent approaches, resulting in extensive drilling workloads and prolonged construction periods. Moreover, these studies mostly focused on conventional single-method control technologies, lacking consideration of the temporal sequencing and synergy among multiple techniques.

Taking the 20,107 working face of the outburst-prone coal seam in Qincheng Coal Mine as a case study, this paper employs theoretical modeling and field measurements to reveal the mechanism of pressure-induced deformation and air leakage in gob-side retained roadway, as well as the distribution characteristics of the air leakage flow field in the goaf. Based on these findings, a comprehensive prevention and control strategy is proposed, integrating directional drilling with segmented hydraulic fracturing for roof cutting and pressure relief, along with enhanced preemptive gas extraction. This approach is further supplemented by multi-faceted cooperative measures, including leakage-sealing spraying for existing fractures in the roadway wall and optimized pipeline insertion. The proposed method provides significant guidance for mitigating air leakage in the goaf and preventing excessive gas concentrations in gob-side retained roadway.

Engineering background

Qincheng Coal Mine is located in Longgang Town, Qinshui County, Jincheng, Shanxi Province (Fig. 1), and the minefield is generally characterized by a NW-trending monocline structure. Its gas content ranges from 9.41 to 13.24 m3/t, exhibiting a distribution pattern that is higher in the west and lower in the east. The ventilation system is of the central parallel type, and the mine is classified as a coal and gas outburst mine. The primary mining target is the No. 2 coal seam, with a mining elevation of + 520 m. The fully mechanized longwall mining method is used, extracting the full seam height in one pass, and the coal seam is classified as a Class III non-self-igniting coal seam. In 2023, the mine’s absolute gas outburst rate was 66.85 m3/min, and the relative gas outburst rate was 36.33 m3/min.

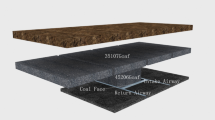

The experimental working face, 20,107, is located in the 201 panel area, where the average thickness of the No. 2 coal seam is 4.8 m, with a dip angle ranging from 2° to 8°. The mining elevation is between + 585 and + 595 m, and the working face dimensions are 1505 m × 231 m. The basic gas parameters of the coal seam are shown in Table 1, and it is classified as a typical high-content, high-adsorption outburst-prone coal seam. The 20,107 working face utilizes gob-side retained roadway mining with pillarless extraction (Fig. 2), where ventilation is provided via the working face transport roadway, intake airway, and auxiliary intake airway, with the return airflow directed through the U-shaped return roadway in the goaf. A gob-side retained roadway is arranged on the side of the auxiliary intake airway. The dimensions of the wall are 1.3 m in width and 3.7 m in height, and a foundation measuring 1.4 m in width and 0.87 m in height is constructed beneath the wall, all made from C40 concrete. Gas extraction in the goaf is primarily conducted through directional long boreholes and the step-type pipe insertion method along the gob-side retained roadway. As of now, 210 m of the working face has been mined, and field observations reveal the upper section of the gob-side retained roadway wall exhibits deformation reaching 192 mm, with distinct fractures observed at the junction with the roof, accompanied by audible hissing sounds indicative of air leakage nearby. The gas concentration in the return airflow ranges from 0.52% to 0.84%, approaching the gas limit threshold. Preliminary analysis suggests that the increased gas outburst due to mining-induced pressure relief, as well as potential air leakage from the working face or the gob-side retained roadway walls, may be contributing factors.

Mechanism of retained roadway wall deformation and distribution of air leakage in the goaf

Mechanism of gob-side retained roadway wall deformation

Under mining conditions, the gob-side retained roadway wall and roof undergo incompatible deformations, or the deformation and failure of the wall itself create fracture channels, allowing CH4 from the goaf to infiltrate, leading to elevated and even excessive gas concentrations in the return airflow of the retained roadway. As the working face advances, periodic breakage of the overlying strata occurs. Under the combined effect of the load of the coal seam roof and the movement of the roof after mining, rotational stress coupling is generated, causing the roof to break, rotate, and subside26. Once the basic roof of the coal seam fractures, the rock mass, under the action of rotational torque, sinks toward the goaf, disrupting the structure and stress state of the roof in the gob-side retained roadway. This results in the formation of a support stress concentration zone near the gob-side roadway, and the extent and size of this affected area are closely related to the location of the key layer (basic roof) breakage in the roof.

There are three possible relative positions between the mining-induced roof fracture line and the gob-side retained roadway: ① When the basic roof fracture of the gob-side retained roadway occurs on the inside (Fig. 3a) or above (Fig. 3b) of the retained roadway, the fractured rock mass rotates and subsides, resulting in a significant differential subsidence between the roof of the 20,107 return airway and the retained roadway wall. This leads to high support stresses, which can induce deformation and the formation of fractures in the retained roadway wall, causing elevated gas concentrations. ② When the basic roof fracture of the gob-side retained roadway occurs on the outside of the retained roadway (Fig. 3c), the roof experiences some subsidence, but the stress is released and weakened. As the distance from the fracture line increases, the stress gradually decreases to the original in-situ stress level.

When the basic roof fractures on the inside or above the retained roadway, the coal mass on the exposed side and the retained roadway wall are subjected to the rotational torque and load of the fractured roof block, leading to compressive torsional and shear deformations, and the formation of fracture channels (Fig. 4). At the same time, the basic roof releases elastic potential energy at the moment of fracture, generating compressive torsional impact forces on the retained roadway wall and the immediate roof rock mass, which increases the deformation rate of the retained roadway wall and surrounding rock. Under the influence of these two factors, the retained roadway wall and roof undergo incompatible deformations and compressive torsional failure during the rotational and subsidence processes, initiating fractures that cause gas leakage from the goaf into the return airway.

Field testing of goaf air leakage and gas flow field using the finite element method

Finite element method testing plan

To accurately obtain the goaf air leakage flow field and gas distribution characteristics of the 20,107 working face, gas emissions from the working face were quantified using the unit method, whereby the face is partitioned into several discrete units along the airflow direction (Fig. 5a). For each unit, both the airflow rate and the gas concentrations at its inlet and outlet cross-sections are measured. Within each unit, three sampling points—at the coal-wall side, within the working-face airflow, and on the goaf side (Points 1, 2, and 3 in Fig. 5b)—are used to collect concentration data. The mean of these three measurements is taken as the unit’s representative gas concentration. By aggregating the contributions of all units, the total gas emission from the various sources across the entire working face can be determined. Therefore, the working face is divided into 14 unit points (G-1# to G-14#, with G-1# being the intersection of the belt roadway and the working face) at 18-m intervals, as shown in Fig. 5c. For each unit, three measurement points are arranged along the mining direction: one near the coal seam, one at the hydraulic support passage, and one at the end of the support. The average values of airflow and gas concentration are taken from the data at these points, to avoid the influence of measurement location and equipment such as the shearer and supports on the accuracy of the measurements.

The airflow (Qin, Qout) and gas concentrations (c1, c2, c3) at each unit’s inlet and outlet sections are measured using a CFJ-10 medium-speed anemometer and a CJG-10 optical gas detector. Considering the impact of operational equipment on the working face, the equivalent cross-sectional area of each section is used to obtain the corresponding airflow and gas concentration data. For each unit, the gas source mass conservation and airflow conservation are quantitatively satisfied according to the system of Eqs. (1).

The layout of the unit measurement points on the gob-side retained roadway is shown in Fig. 6, with a spacing of 18 m between the measurement points. These points are designated as Y-1# to Y-15#, with Y-1# being the intersection of the auxiliary intake airway and the working face.

where, qgoaf is the gas influx (or outflux) in the goaf unit, in m3/min; qface is the gas outflow from the working face of each unit, in m3/min; Q1 is the air leakage flow entering (or exiting) each unit from the goaf, in m3/min; c is the gas concentration in the goaf air leakage flow, in %; Qin and Qout are the airflow entering and exiting the unit, in m3/min; cin and cout are the gas concentrations in the airflow entering and exiting each unit, in %.

Analysis of measurement results

Gas distribution in the working face and retained roadway

The airflow in the working face roadway (from the belt roadway to the auxiliary transport roadway) generally shows a trend of initially decreasing and then increasing (Fig. 7a). Specifically, the airflow drops from 1179.36 m3/min at the G-1# measurement point to 825.42 m3/min at the G-11# point, and finally increases to 1086.26 m3/min at the G-14# point. There are small fluctuations at the G-5# and G-9# points, indicating that the airflow initially leaks into the goaf, and then some of the goaf airflow converges, resulting in significant fluctuations in gas concentration. The gas concentration in the working face roadway increases in a fluctuating pattern along the length of the roadway. It rises from 0.06% at the G-1# point to 0.21% at the G-7# point, peaking at 0.54% at G-12#. The average gas concentration in the first half is 0.13%, while in the latter half, it rises to 0.39%. Throughout the process, two instances of gas flow from the goaf enter the roadway, causing spikes in gas concentrations. Ultimately, when the airflow from the auxiliary intake airway of the working face converges, the gas concentration drops to 0.38%, indicating that the Y-type ventilation system effectively mitigates the accumulation of gas in the upper corner, preventing gas concentrations from exceeding the limit.

The airflow along the gob-side retained roadway (from the working face to the deep part of the goaf) generally shows a trend of initially decreasing and then increasing (Fig. 7b). Specifically, the airflow drops from 2032.52 m3/min at the Y-1# measurement point to 2024.15 m3/min at the Y-2# point, and then increases to 2313.26 m3/min at the Y-13# point. There is a small fluctuation near the G-4# point, indicating that gas from the goaf gradually leaks into the retained roadway, with a peak occurring at the intersection of the goaf and retained roadway at the far end of the goaf. The gas concentration in the retained roadway increases steadily with minimal fluctuation along the length of the roadway. Between the Y-3# and Y-15# measurement points, the gas concentration remains at a high level, reaching 0.59%, and peaking at 0.65% (approaching the critical value for gas concentration exceeding the limit). Throughout this process, two instances of gas flow from the goaf enter the retained roadway, causing fluctuations and increases in the return air gas concentration. This suggests that the leakage of goaf air into the retained roadway is the primary cause of the increased gas concentration, while the coupling effect of the retained roadway pipe extraction and the leakage through wall fissures causes further fluctuations in the gas levels.

Analysis of air leakage patterns in the working face and retained roadway

Based on the airflow variation at each measurement point, a schematic diagram of the air leakage distribution in the working face and retained roadway was constructed. In the working face roadway, the airflow first leaks under positive pressure and then under negative pressure (Fig. 8a). Specifically, the total wind volume leaking from the working face into the goaf is 572.15 m3/min, while the total wind volume from the goaf flowing into the working face is 221.80 m3/min, with 350.35 m3/min of airflow first entering the goaf and eventually flowing towards the retained roadway. In the section of the working face from 0 to 36 m in the dip direction, 332.84 m3/min of airflow leaks into the goaf, accounting for 61.17% of the total airflow leaking into the goaf, and a vortex zone is formed in this region by the inflow from the belt conveyor roadway. In the 72 to 180-m section, 198.76 m3/min leaks into the goaf, accounting for 32.74% of the total airflow leaking into the goaf. In the 36 to 72 and 180 to 216-m sections of the working face, 60.56 m3/min and 161.24 m3/min, respectively, flow into the working face, accounting for 27.31 and 72.69% of the total wind entering the working face. In the 216 to 230-m section, the auxiliary intake air in the retained roadway becomes dominant, forming a vortex zone near the corner, with some airflow leaking into the goaf.

As shown in Fig. 8b, the primary airflow in the retained roadway is the leakage from the goaf into the roadway, with some of the return air from the retained roadway leaking into the goaf. Specifically, the total airflow leaking from the goaf into the retained roadway is 469.01 m3/min, while the total airflow leaking from the retained roadway into the goaf is 87.26 m3/min. In the section from 18 to 180 m along the strike of the retained roadway, there is airflow leaking into the retained roadway, indicating that the entire retained roadway has relatively well-developed wall fractures forming leakage channels, with varying degrees of leakage and a significant total leakage volume. Notably, in the section from 36 to 108 m, 408.45 m3/min of airflow leaks into the retained roadway, accounting for 87.09% of the total airflow leaking into the retained roadway. In the sections from 0 to 18 m, 18 to 36 m, and 108 to 248 m along the dip direction of the working face, 18.78 m3/min, 37.67 m3/min, and 30.81 m3/min leak into the goaf, respectively, accounting for 21.52, 43.17, and 35.31% of the total airflow flowing into the working face, although the volume is relatively small.

Furthermore, under the negative pressure effect of the borehole drainage in the retained roadway, a large amount of gas from the goaf is accelerated toward the vicinity of the retained roadway wall, with some gas flowing into the borehole and some entering the return airflow through wall fractures, leading to elevated gas concentrations. Among them, the gas concentration in the borehole drainage was 2.1%, which is less than 3%. The mixed extraction flow rate was 66.78 m3/min, yielding a pure gas drainage volume of only 1.40 m3/min. This accounted for merely one-eighth of the total gas emission from the goaf, indicating limited effectiveness of the extraction method. The airflow entering the working face via the belt entry is 1259.36 m3/min, which is greater than the 1086 m3/min entering through the auxiliary intake airway, facilitating the leakage of airflow into the goaf. In summary, the primary factors contributing to elevated gas levels in the retained roadway are the leakage airflow, gas volume from the goaf, and the fracture channels in the retained roadway walls, which also limit the safe and efficient production of the working face.

Multi-faceted gas control technology for the goaf

Based on the previous section, further research should focus on four aspects: enhancing gas extraction from fractured zones, controlling the deformation of the retained roadway walls and sealing the wall fractures, managing the pressure differential between the two intake tunnels, and optimizing the installation of pipework in the retained roadway. Targeted multi-faceted gas control technologies for the goaf should be proposed.

The directional drilling segmented fracturing top-cut unloading and enhanced extraction technology

The principle of segmented fracturing top-cut unloading and enhanced extraction technology

Based on the aforementioned mechanism of deformation of the roadway retaining wall, in order to prevent deformation and damage to the retaining wall, it is necessary to control the fracture point of the roof to be on the outer side of the retaining lane. This reduces the rotational stress of the broken roof blocks and the impact force generated by the breaking of the hard roof, which could otherwise cause large deformations in the roof and wall of the retaining lane, as well as decrease and transfer the stress concentration zone in the roof of the retaining lane. At the same time, the surrounding rock mass fractures in the fracturing zone are fully developed and interconnected with the collapse zone, facilitating the extraction of gas from the goaf. Therefore, the segmented fracturing top-cut unloading and enhanced extraction technology for the fracture zone gas is proposed. As shown in Fig. 9, before the mining operation of the 20,107 working face, directional drilling is carried out along the top stress propagation path in the retaining lane for fracturing. The fracturing section is located within the basic roof. Fracturing at this location can partially unload the load transmitted from the overlying rock collapse and transfer it to the deep part of the goaf. Meanwhile, it gradually releases the accumulated elastic potential energy and high bearing stress of the hard roof. Additionally, a fracture development zone is formed within a certain longitudinal range of the fracturing line. This technology can effectively control the compressive deformation and instability of the retaining wall while improving the efficiency of gas extraction from the fracture zone in the goaf.

As shown in Fig. 10, during the coal seam mining process, the horizontal direction can be divided into the compaction zone, delamination zone, coal wall support zone, and original rock stress zone. After segmented fracturing is implemented in the basic roof area, a weak structure is formed. Under the influence of mining-induced stress, the original fractures further expand and connect, causing the key layer fractures to develop further until they break, significantly reducing their bearing capacity and enhancing their plasticity. As a result, the support stress before fracturing is transferred to the deep side of the solid coal. Simultaneously, as the key layer of the fractured section breaks, the accumulated elastic potential energy is released, effectively alleviating the degree of stress concentration and achieving unloading and stress transfer of the retaining lane surrounding rock. Additionally, due to the fracturing-induced seam creation, a triangular-shaped longitudinal through-fracture development zone (star-shaped filling zone) is formed between the fracturing line and the original natural collapse line. The fracturing hole is dual-purpose, efficiently extracting gas from the goaf. This approach integrates the prevention of gas leakage from the goaf from both the energy source and gas source perspectives, achieving a synergistic control of gas leakage in the goaf.

Design of directional drilling segmental fracturing location and parameters

Determination of the position of the roof fracture line for fracturing

Since the position of the fracture line determines the magnitude and range of the pressure on the retained roadway wall, it is necessary to further determine the horizontal distance and the fracture dip angle between the segmented fracturing and the retained roadway wall.

Based on the geological prototype of the 20,107 working face along the retained roadway, a mechanical model of the cantilever beam of the basic roof was established (Fig. 11). Taking the return airway along the retained roadway as the origin, the x-axis and y-axis were established along the horizontal and vertical directions, respectively. Assuming that the basic roof structure is stable and primarily experiences shear deformation, according to the Mohr–Coulomb criterion, it can be determined that when the basic roof fractures26, the horizontal stress σx and vertical stress σy satisfy the following equation:

In the equation, ψ represents the friction angle within the basic roof rock mass (°); C denotes the cohesion of the rock mass.

As shown in Fig. 11, a unit body with a width of dx is selected in the ultimate equilibrium zone on the side of the gob-side entry. The forces in the horizontal and vertical directions on this unit satisfy Eqs. (3) and (4), respectively.

In the equations:τxy—Shear force received by the ultimate equilibrium zone, MPa; hg — Mining height, m;λ— Overlying rock side pressure coefficient; Px—Support resistance of the filling wall at different distances, MPa; c0— Cohesion of the filling wall, MPa.

In the ultimate equilibrium zone, the normal stress σy and shear force τxy satisfy Eq. (5).

By differentiating Eqs. (2) and (5) and substituting Eq. (3), the following can be derived:

Furthermore, by integrating dy and dx, it can be obtained that the normal stress y and the horizontal distance x satisfy Eq. (7).

Substituting Eq. (7) into Eq. (4) gives:

Integrating Eq. (5) and combining it with Eq. (7) yields:

By combining Eqs. (8) and (9), the undetermined coefficient D is solved, and then substituted into Eq. (7) to obtain:

Based on Eq. (9), the expression for the horizontal distance x is derived. When x equals the width of the limit plastic zone x1, the vertical stress y reaches its maximum value ymax = K1λh. Finally, the expression for the predicted location of hydraulic fracturing × 1 is obtained as shown in Eq. (11).

In the equation, K1 is the stress concentration coefficient; λ is the overburden side pressure coefficient; H is the burial depth of the coal seam, in meters.

Based on the actual data from the Qin Cheng coal mine, the following parameter values are derived: the burial depth of the No. 2 coal seam in the working face is between 350 and 410 m, the thickness of the basic roof is 15.7 m, and the side pressure coefficient is 1. The mining height is 4.8 m, the support resistance of the lane wall is 0.3 MPa, the internal friction angle is 29°, the cohesion is 5.8 MPa, and the support stress coefficient is 3.8. The reasonable range for × 1 is determined to be between 8.2 and 8.9 m, with an average value of 8.6 m. Additionally, according to the “Technical Specifications for Protective Layer Mining”27, which provides the range of pressure relief angles for the extraction of underlying protective layers along the dip direction (State Administration of Work Safety. 2008), and considering the average dip angle of the No. 2 coal seam at the 20,107 working face (7°), the pressure relief angle for the overburden along the side of the reserved lane is selected as 77°. Therefore, the dip angle of the fracture line θ must be greater than the pressure relief angle of the overburden collapse along the side of the reserved lane, which is 77°.

Segmented fracturing parameter design

The design of the drilling parameters in this study innovatively adopts a combination of segmented fracturing drilling and large-diameter directional long drilling, aiming to simultaneously achieve control over the deformation of the surrounding rock of the roadway and enhance gas extraction from the goaf. Based on the analysis above, the horizontal distance from the segmented fracturing line of the directional drilling to the surrounding roadway is 8.6 m. Considering the “upper three zones” testing report of the No. 2 coal seam in this mine, the vertical development range of the roof fracture zone is between 17.26 and 49.61 m. It is estimated that the horizontal misalignment distance of the mining fracture development zone should be less than 57.63 m. Preliminary calculations indicate the gas accumulation region in the goaf. Therefore, the overall layout of the directional long drilling in the goaf is along the direction of the retained roadway (Fig. 12), Each group consists of 7 boreholes, of which 3 are fracturing boreholes and 4 are pumping boreholes, with an average length of 400–500 m. The design parameters of each borehole are shown in Table 2.

To ensure the roof of the goaf collapses progressively with mining, reduce the lateral roof suspension on the side of the roadway, and control the deformation and failure of the surrounding rock and fracture development range. In the directional drilling for the roof on the side of the surrounding roadway, three outermost holes are selected for hydraulic fracturing to cut and depressurize the roof. As shown in Fig. 13a, In the directional drilling for the roof on the side of the surrounding roadway, three outermost holes are selected for hydraulic fracturing to cut and depressurize the roof, its horizontal displacement distances of 5#, 6#, and 7# fracturing holes from the return airway are 23.5, 17.5, and 11.5 m, respectively, with distances from the coal seam roof of 32, 22, and 13 m. As shown in Fig. 13b, the length of each fracturing segment corresponds to the length of the packer. The central diverter generates high-pressure water jets that induce coal rupture, forming a fracture network within a defined radius. The effective fracturing radius of each segmented borehole reaches up to 6.2 m. Within the overlapping effective zones of adjacent boreholes, the induced fractures interconnect to form a continuous fracturing zone. This zone effectively severs two key bearing strata—siltstone layers with thicknesses greater than 10 m—located between 6.1 and 42 m above the coal seam, thereby achieving the objective of roof cutting and pressure relief.

Directional drilling and fracturing equipment and technology

Due to the limited effective range of hydraulic fracturing in conventional ordinary drilling and the common occurrence of uneven fracturing effects and insufficient pump flow28, directional long drilling with segmented fracturing is selected to achieve top-cut unloading and control the deformation of the tunnel wall. The key equipment for segmented fracturing (Fig. 14) includes a 250KW intelligent booster pump with a rated pressure of 31.5 MPa and a flow rate of 22m3/h, as well as fracturing tool series which concluding packers, sleeve tools, casing flange installation, multi-stage packer seating, and packer unseating tools29.

As shown in Fig. 14c, process flow of directional long borehole segmented hydraulic fracturing for roof cutting: according to the fracturing borehole design, select the borehole entry location → adjust the drill bit cutting face to ensure accurate execution of the designed borehole trajectory → drill to complete the borehole and install equipment at the borehole opening → lower the hydraulic fracturing tool string to the bottom of the borehole → initiate the fracturing pump, calibrate the equipment, and perform fracturing of the initial segment → pull the tool string to the next designated position and carry out sequential fracturing until completion → withdraw the drill string and seal the borehole. The main fracturing parameters include: a fracturing segment length of 10-15 m, which can be divided into 20 segments according to the effective length of the directional drilling; the initiation fracture pressure is 16.7–27.5 MPa; the fracturing duration is no less than 20 min, and the water injection volume per segment is not less than 130m3.

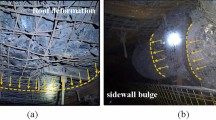

Silicate-based composite material spray sealing for leak plugging

Based on the analysis in the previous section, gas leakage from the goaf was observed in the 18–216 m section of the gob-side entry. On-site investigations revealed swelling deformation of the entry walls deeper than 28 m, fissures caused by the inconsistent deformation between the wall and the roof after compression, and cracks between the pipe and the wall. Near the back, a hissing sound of leaking air was heard. On-site testing with a portable gas detector showed that the gas concentration on the wall side of the entry was higher than on the solid coal side, with a difference of 0.03%. Therefore, a silicate-based composite material was used to spray and seal the fissure development areas on the entry walls. The spraying thickness ranges from 10 to 22 cm, and the full-section spray coating is applied in one pass (Fig. 15). Special attention is given to densely spraying the fissure development areas in the dynamic pressure-bearing zone and the stabilized zone of the goaf-side entry. Before spraying (Fig. 15a), deformation occurred at both the top and bottom ends of the wall, with the deformation at the top particularly causing fractures that easily form air leakage channels. After spraying (Fig. 15b), the entire wall was coated with a silicate-based composite material, effectively sealing the deformation-induced fractures in the wall.

Retained roadway intubation + airflow control and pressure reduction

Optimization of gob-side intubating parameters

Based on the previous section, it is known that gas tends to accumulate easily on the gob-side, especially concentrated in the upper-middle part of the goaf. Therefore, the position of the intubation along the gob-side is raised to 3 m, closer to the roof, and the intubating spacing is reduced to 15 m. Field investigations revealed that the gas concentration near the last three rib supports at the mining face was relatively high, maintaining around 0.68%. The tubing depth at this location was only 0.2 m (Fig. 16), and the intubating openings were easily blocked by fragmented rock. Therefore, the intubating depth at this location was increased to 0.5 m, with metal mesh wrapped around the intubating openings.

Wind control and pressure reduction

The air volume of the main and auxiliary intake air lanes, as well as the pressure difference between the two lanes, significantly affect the amount of leakage air in the goaf30. To ensure normal ventilation for the working face personnel and that the gas concentration in the airflow does not exceed the limit, the air volumes in the main and auxiliary intake air lanes can be adjusted, and wind barriers can be set up to reduce leakage. To this end, a ventilation adjustment experiment was conducted on-site. After implementing the measures, the gas extraction from the goaf increased, allowing for a slight reduction in the air volume of the belt conveyor lane and an increase in the auxiliary intake air volume. The gas concentrations at the working face (15 m from the leave road side) and at the leave road (40 m from the start of the leave road), as well as the pressure differences at the airflow corners of the belt lane and the two ends of the leave road, were used as effectiveness indicators for evaluation and testing. As shown in Fig. 17, the air volume of the 07 belt lane decreased from 1259 m3/min to 929 m3/min, while the auxiliary intake air volume increased from 853 m3/min to 1078 m3/min. Simultaneously, the pressure difference at the corners and the leave road decreased by 18%, and the gas concentration in the leave road gradually decreased and stabilized. As the air volume in the main intake lane decreased, the gas concentration at the working face increased. To ensure safe production and the effective use of ventilation, the final selected air volume for the belt lane was 1072 m3/min, and the auxiliary lane air volume was 945 m3/min.

Implementation effectiveness

Deformation magnitude of the retained roadway wall

After implementing the multi-faceted prevention and control technology proposed in this paper, a follow-up investigation was conducted over a period of 5 months (with the working face advancing approximately 180 m). Three monitoring points, designated as a, b, and c, were arranged at different distances along the gob-side entry in the advancing direction of the working face. Concurrent measurements were conducted to assess the convergence of the roof and floor as well as the horizontal deformation of the entry wall at each point with respect to the working face advance distance (Fig. 18). Prior to and following the implementation of segmented hydraulic fracturing for roof cutting and pressure relief (around 210 m of face advance), the horizontal deformation of the entry wall decreased from a range of 138–218 to 62–86 mm, representing an average reduction factor of 1.41. The convergence of the roof and floor reduced from 231–281 mm to 84–98 mm, corresponding to an average reduction factor of 1.82. Field monitoring indicated that after hydraulic fracturing of the roof, wall bulging deformation was essentially eliminated. No hissing sounds indicative of air leakage were detected at the interface between the wall and the roof, demonstrating effective mitigation of wall deformation and fracture development.

Effectiveness of directional borehole gas extraction

The gas extraction volume and gas concentration of boreholes #1 to #4 at the gob-side directional drilling site were monitored to investigate their variation with working face advance distance (Fig. 19). Before and after implementing multi-method gas control measures (around 210 m of face advance), the single-borehole gas extraction volume increased from 0.81–1.28 m3/min to 1.42–2.09 m3/min, representing an average increase of 72%. Meanwhile, the gas concentration in boreholes #1 to #4 rose from 33–54 to 63–87%, with an average increase of 69%. Among these, borehole #2 exhibited superior extraction performance, achieving a gas extraction volume of 2.09 m3/min and a gas concentration of 87%.

Gas concentration in gob-side retained roadway airflow

A comparative analysis of the gas concentration in the mined-out area before and after the optimization of gas control measures shows that the average gas concentration in the along-strata retention tunnel decreased from 0.59 to 0.34% (Fig. 20), with a maximum value of 0.46%, effectively eliminating the high gas concentration issue in the retention tunnel. The daily advance rate of the working face increased from 0.8 to 1.4 m, achieving efficient production at the working face.

Discussion

To clarify the applicable conditions and combination strategies for multi-method gas control technologies in the goaf with gob-side retained roadway, the advantages and disadvantages of each individual control technique are summarized in Table 3. Additionally, the conditions for synergistic control and corresponding combination methods are provided. When the face abutment pressure is low and the deformation of the entry wall is minimal, the “2 + 3 + 4” technology combination mode listed in Table 3 is preferred. When the face abutment pressure is high and the entry wall deformation is severe, the “1 + 2 + 3” technology combination mode is prioritized. In cases of high face abutment pressure, significant air leakage, and severe wall deformation, the comprehensive “1 + 2 + 3 + 4 + 5” technology combination mode is employed as outlined in Table 3.

Conclusion

-

(1)

It is indicated that when the basic roof fracture line is located outside the gob-side entry, it can effectively redistribute the supporting stress. Additionally, a calculation formula for determining the horizontal position of the fracturing line is provided.

-

(2)

It was concluded that the main source of air leakage into the goaf in the 20,107 woring face is the positive pressure leakage of the intake air from the belt entry, while the return air side primarily experiences high-concentration gas leakage into the air-return roadway. Specifically, in the 0-36 m section of the working face, 332.84m3/min of intake air leaks into the goaf, accounting for 58.17%; in the 54–108 m section along the roadway, 408.45m3/min of goaf air leaks into the air-return roadway, accounting for 87.09%.

-

(3)

The key parameters of multiple control technologies—including segmented hydraulic fracturing for roof cutting, directional drilling in the fracture zone, gob-side entry borehole installation, sealing by spray-applied materials, and airflow control and pressure reduction—were scientifically determined. Field validation demonstrated that the horizontal and vertical deformations of the entry wall decreased by factors of 1.41 and 1.82, respectively, compared to the original conditions. The overall gas extraction rate from directional boreholes increased to 7.46 m3/min, while the gas concentration in the gob-side entry decreased gradually from 0.59 to 0.34%.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Manchao, He. et al. Future of mining - reflections on intelligent 5G N00 mine construction. China Coal 46(11), 1–9 (2020).

Honglin, L. et al. Gas comprehensive control technology based on gob-side entry retaining. Saf. Coal Mines 43(9), 60–62 (2012).

Xiaohong, Yang, Bucai, Ma. & Shaowu, Fan. Analysis on gas control effect based on gateway retained along goaf Y type ventilationld. Coal Sci. Technol. 39(7), 46–49 (2011).

Minggao, Yu. et al. Study on the mechanism of air leakage in goaf of goaf under gas extraction in goaf retaining roadway working face. J. Saf. Environ. 16(2), 108–113 (2016).

Yanan, Yu., Ruxiang, Q. & Yan, C. Numerical simulation of leakage field and gas flow field in Y-shaped ventilation goaf. Coal Mine Saf. 44(02), 25–28 (2013).

Xingrun, Z. Numerical simulation study of gas flow field in goaf of high extraction roadway+Y-shaped ventilation working face. Shanxi Cok. Coal Technol. 47(07), 23–28 (2023).

Houcheng, D., Hao, Q. & Quanlong, D. etc Research on the distribution law of gas seepage in goaf of fully mechanized mining face under Y-shaped ventilation collaborative extraction. Saf. Environ. Eng. 30(06), 146–153 (2023).

Chuanren, Ji., Zongxiang, Li. & Jianxin, Li. Iterative calculation of air leakage distribution along the boundary of goaf ventilation tunnels. J. Liaoning Univ. Eng. Technol. (Nat. Sci. Ed.) 28(02), 165–168 (2009).

Zongxiang, Li., Zhengyi, Ti. & Guochen, Z. Numerical simulation study on gas emission law in goaf of mining face. Chin. J. Geol. Hazards Prev. 04, 46–50 (2005).

Zongxiang, Li. et al. Calculation method for air leakage exchange between working face and goaf. J. Coal Sci. 43(08), 2256–2260 (2018).

Liang, Zhao et al. Study on the effect of side slope porosity of cutting top and leaving roadway on the air leakage law of goaf in working face. China Min. 30(03), 188–192 (2021).

Guangchao, G. et al. Numerical simulation of multi field distribution characteristics in goaf based on three-dimensional “O” rings. J. Saf. Environ. 17(03), 931–936 (2017).

Liang, Suo. Gas Migration Law and its Application in Y-Shaped Ventilation Working Face along Goaf (Xi’an University of Science and Technology, 2014).

Jiong, W. et al. Y-shapedventilation air leakage law of working face of gob-sideentry retaining by cutting roof to release pressure. J. Min. Saf. Eng. 38(3), 625–633 (2021).

Zhenmin, Luo et al. Experiment sand numerical simulation research on gas migration in goaf. J. Xi’an Univ. Sci. Technol. 40(1), 31–39 (2020).

Zongxiang, Li. et al. Characteristics of spontaneous combustion distribution in goaf based on “O” type caving and non-uniform oxygen consumption. J. Coal Sci. 37(03), 484–489 (2012).

Chun, Z., Zhengyi, Ti. & Zongxiang, Li. Three dimensional numerical simulation study on spontaneous combustion of residual coal in fully mechanized goaf. Chin. J. Saf. Sci. 23(05), 15–21 (2013).

Yanfei, G. et al. Study on the air leakage law of goaf under the “one entry and two returns” ventilation method in the working face along the gob. Min. Saf. Environ. Protect. 49(06), 46–51 (2022).

Zhang Zhenbin, Yu. & Congming, Chen Ruiding. Numerical simulation study on the leakage law of goaf with complex ventilation mode in goaf retaining roadway working face. Energy Technol. Manag. 47(04), 50–52+67 (2022).

Kaimin, He. Analysis of air leakage law and ventilation optimization in working faces along gob entry. Automation Application 11, 143–144+147 (2020).

Chenwu, Li. Comprehensive gas control technology for fully mechanized mining face along goaf in outburst coal seam. Coal Sci. Technol. 43(S1), 89–92+123 (2015).

Hengjie, L., Yujing, J. & Huili, L. Application of gas comprehensive treatment technology based on goaf retaining and multi-directional extraction. J. Shandong Univ. Sci. Technol. (Nat. Sci. Ed.) 36(03), 38–44 (2017).

Sun Siqing, L. I. et al. Research progress and development trend of staged hydraulic fracturing technology in long-borehole underground coal mine. Coal Geol. Explor. 50(8), 1–15 (2022).

Sun Siqing, L. I. High-efficiency gas extraction technology of staged fracturing roof with sand of underground broken and soft coal seam. J. Mine Autom. 48(12), 101–107 (2022).

Silong, G. Application of gas comprehensive control technology in fully mechanized caving face of gob-side entry retaining. Jiangxi Coal Sci. Technol. 34(12), 178–181 (2023).

Yukun, L., Jiangwei, L. & Yaoyou, L. The influence of key parts of hydraulic roof cutting and roof fracture behavior in mining roadway. J. Coal Sci. 49(4), 1819–1833 (2024).

AQ 1050-2008, Technical criterion of protective coal seam exploitation. Beijing: State Administration of Work Safety, 11 (2008).

Siqing, S. et al. Research progress and development trend of staged hydraulic fracturing technology in long-borehole underground coal mine. Coal Geol. Explor. 50(8), 1–15 (2022).

Wenbo, Li. Study on Gas Drainage Technology of Long Borehole Staged Hydraulic Fracturing in Underground Roof of Broken and Soft Coal Seam (China Coal Research Institute, 2023).

Peng, Zhou. Study on Gob Permeability Evolution Law With N00 Mining Method and Application in Ningtiaota Coal Mine (China University of Mining & Technology-Beijing, 2023).

Acknowledgements

This study was financially supported by National Natural Science Foundation of China (NSFC) Young Fund no. 52204133, and Hebei Provincial Natural Science Foundation General Project no. E2024508055. This work was supported by the Langfang Municipal Science and Technology Research and Development Program (Project No. 2024011074) and NCIST Research Project (Project No. 3142024001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Luo, X., Chen, L., Wu, B. et al. Air leakage characteristics and comprehensive prevention of goaf side retained roadway of fully mechanized mining faces in Qincheng coal mine. Sci Rep 15, 26342 (2025). https://doi.org/10.1038/s41598-025-11849-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-11849-3