Abstract

The impact of helium ion irradiation on the evolution of microstructure and mechanical properties of a Ni-45%Cr-1.4%Mo (wt%) alloy has been investigated. Analysis via transmission electron microscopy (TEM) of a pristine sample revealed an uneven distribution of alpha-Cr phase precipitates along with a few isolated planar arrangements of dislocations within the fcc γ-Ni matrix phase. A detailed study of irradiated samples established the presence of radiation-induced defect clusters, dislocation loops, network dislocations as perceptible irradiation effects. X-ray diffraction (XRD) and positron annihilation spectroscopy (PAS) studies also confirmed lattice swelling as an effect of irradiation in this alloy, likely caused by helium-stabilized vacancy cluster. A line profile analysis method which takes into account of planar defects, was employed on GIXRD (Grazing Incidence X-ray Diffraction) data to analyze changes in microstructural parameters such as domain size, microstrain, dislocation density and lattice parameter as a function of irradiation dose. All of these irradiation-damage manifestations led to the increase in the hardness of the alloy in nano-indentation experiment. Overall, the findings of this work provide significant insights into the radiation-induced microstructural changes and their effect on the hardening behavior of the studied Ni-Cr-Mo alloy.

Similar content being viewed by others

Introduction

Ni-based alloys and their modifications have emerged as promising structural materials, possessing excellent creep properties at elevated temperatures and adequate swelling resistance1,2,3,4,5. Their potential for use in nuclear reactors is undeniable; however, they are prone to substantial ductility loss under irradiation, which may severely limit their application. Despite this limitation, the invaluable characteristics of Ni-based alloys still position them as potential candidates for structural materials in heat exchangers or core components where the dose of irradiation is limited to a few dpa (displacement per atom) at most. The majority of published studies on Ni-based alloys concern Ni-Cr-Fe-Mo systems such as Inconel 625, Inconel 718, Hastelloy X, Nimonic PE16, etc. and Ni-Cr-Fe systems such as Alloy 600, Alloy 690, Inconel X-750, Alloy 903, Incoloy 800, Nimonic 80 A, etc4,6,7. Notably, a critical concern with Ni-based alloys in nuclear environments is the production of helium due to Ni (n, α) Fe transmutation reaction, which leads to He-embrittlement8,9,10,11.

The recent advancements in the design of Ni-based alloys, particularly NiCrMo compositions, have shown improved swelling resistance and microstructural stability under high-dose irradiation conditions. Gurovich et al. have investigated the structural evolution of the 42XNM (Ni-Cr-Mo) alloy during neutron irradiation up to 12 dpa at ~ 300 °C and brought out the role of He bubble formation in microstructural changes due to irradiation11. This alloy system is being used in nuclear reactors as a control rod shell and is being considered for fuel element shell in Gen IV reactors3,5. We have already reported irradiation response of a modified alloy composition (Ni-42 wt% Cr) against proton irradiation to a very low dose of ~ 0.07 dpa12.

The 42XNM (Ni-41.1%Cr-1.18%Mo) alloy is considered a promising structural material for Generation IV nuclear reactors due to its favorable properties under extreme conditions, where irradiation effects play a critical role. To ensure the safe functioning of reactors, it is crucial to have a comprehensive understanding of the impact of high dose ion irradiation in such materials. In this context, heavy ion irradiation is widely used to effectively simulate the microstructural and mechanical changes induced by neutron irradiation13,14,15,16,17,18,19,20. The damage due to heavy ion irradiation can be effectively evaluated using advance characterization techniques such as grazing incidence X-ray Diffraction (GIXRD), transmission electron microscopy (TEM), positron annihilation spectroscopy (PAS), and nanoindentation, as they can probe the thin irradiated layers and provide critical insights into the material’s response to irradiation21,22,23. The line profile analysis of XRD enables determination of changes in the key microstructural parameters such as domain size, dislocation density, and micro-strain through the broadening of diffraction peaks. On the other hand, PAS is a well-established technique for identifying vacancy-type defects due to the strong affinity of positrons for open-volume sites22,23. These techniques offer critical insight into irradiation-induced microstructural changes through non-destructive analysis. Moreover, to directly observe and confirm the presence of such defects, TEM is often employed, providing high-resolution imaging and detailed compositional characterization. Further, nanoindentation has also proven to be one of the effective tools for evaluating the mechanical properties of irradiated materials with small sample volumes. In nano-indentation, the continuous stiffness measurement (CSM) mode gives the hardness of irradiated materials as a function of depth in the order of nm.

In the current study, we have selected a potential candidate with modified alloy composition Ni-45Cr-1.4Mo (wt%) for investigation. This alloy has been exposed to He ion irradiation at room temperature to achieve a range of irradiation doses up to 17.1 dpa of peak damage. This study aims to provide an in-depth understanding of the microstructural and mechanical responses of Ni-45Cr-1.4Mo alloy subjected to high-dose He ion irradiation by comprehensively elucidating the effects of irradiation-induced damage probed through a variety of advanced depth-resolved characterization techniques such as GIXRD, TEM, PAS, and nanoindentation.

Experimental

A sheet of Ni-45Cr-1.4Mo (wt%) alloy was vacuum-sealed in a quartz tube and subjected to heat treatment at 1150 °C for 10 min, followed by quenching in water. To prepare the samples for irradiation experiments, samples with dimensions of 10 × 10 × 1 mm were cut from the heat-treated sheet. The surfaces of these samples were prepared employing standard metallographic procedures followed by electropolishing with a solution of 10% perchloric acid and 90% methanol (v/v) at 20 V and − 40 oC.

The samples were irradiated using He ion beam from a 6.45 GHz electron cyclotron resonance (ECR) ion source available at Variable Energy Cyclotron Centre, Kolkata. Three samples were exposed to He ion beam of energy 65 keV under 10− 6 mbar vacuum to achieve total doses of 3 × 1016, 2 × 1017, and 7 × 1017 ions/cm2, respectively, at an implantation rate of 3.5 × 1012 ions/cm2-sec at room temperature.

Since the damage due to ion irradiation is limited to few hundreds of nanometers from the exposed surface of the sample, these were characterized by Grazing Incidence X-ray Diffraction (GIXRD) technique with a PANanalytical system employing CuKα X-rays of 1.545 Å wavelength. The diffraction profiles of unirradiated and irradiated samples were obtained in the 2θ range of 40–95̊ with a 0.02̊ step size.

For further insight into microstructural changes, un-irradiated and irradiated samples was examined using a 300 kV JEOL 3010 TEM. TEM samples were prepared by mechanically grinding from the unirradiated side to get thin foil (80–100 μm) and subsequently 3 mm diameter discs were punched from these foils. The discs were then thinned to the point of perforation using the twin jet electropolishing process, in which Lacomit peelable varnish was applied to the irradiated side to prevent its polishing and ensure thinning only from the unirradiated side. This procedure ensured that the irradiated zone of the samples is transparent to electrons. Electropolishing was performed at 20 V and − 45 °C using an electrolyte consisting of 10% perchloric acid in methanol. In addition to the imaging of microstructural features, EDS (energy dispersive spectroscopy) analysis of the composition of second-phase precipitates and that of the matrix phase was also performed.

The samples were also subjected to depth-dependent Doppler broadening measurements using a slow positron beam of variable energy. All the measurements were performed at room temperature using incident positron energies ranging from 0.2 to 17.2 keV with a high purity Ge detector having an energy resolution of 1.4 keV at 514 keV of 85Sr. The Doppler broadening spectrum at different implantation energies or implantation depths (total counts ~ 5 × 105) was characterized by two line-shape parameters, viz., S- and W-parameters. The S-parameter was evaluated by taking the ratio of counts in the low momentum region (511.000 ± 0.684 keV) to the total counts under the annihilation peak, whereas the W-parameter was evaluated by taking the ratio of counts under a 4.564 keV window centered at (511.000 ± 13.692 keV) in the high momentum region to the total area of the annihilation peak.

The hardness of unirradiated and irradiated samples was evaluated using the nanoindentation technique employing a Berkovich diamond indenter (UNHT, CSM, Switzerland). The continuous stiffness measurement method was used to measure the hardness of the irradiated samples as a function of depth. The indentation was carried out up to a depth of 450 nm from the irradiated surface. At least 10 indentations were performed at each depth and the average of these measurements was considered for interpretation. The spacing between two successive indents was kept at 50 μm to prevent interference with plastic zones formed by adjacent indents.

Results

The nominal composition of the Ni-Cr-Mo alloy obtained by chemical analysis is given in Table 1. A widely known Monte-Carlo simulation-based software SRIM-2008 24 has been used to estimate the depth profile of the distribution of implanted He ions and vacancies formed during irradiation and the same is shown in Fig. 1. The irradiation damage has been evaluated in terms of dpa (displacements per atom) using the following formula:

where Φ signifies the irradiation fluence (ions/cm2), No denotes the atom density of the target material (for this alloy 8.72 × 1022 atoms/cm³) and νNRT stands for the number of displaced atoms per Å per ion determined by the method outlined by Stoller et al. using Eq. (2)25.

where \(\:{T}_{dam}\) represents the total damage energy calculated from the phonon contribution to the ions and recoils. The displacement threshold energy, \(\:{E}_{d}\:\)is set to a value of 40 eV26. The estimated peak damage for the samples irradiated with fluences 3 × 1016, 2 × 1017, and 7 × 1017 ions/cm2 is 0.72, 4.85, and 17.1 dpa, respectively. The number density of He atoms implanted during the irradiation experiments for a fluence equivalent to a dose of 7 × 1017 ions/cm2 is 2 × 1022 ions/cm3. Figure 1 shows that irradiation damage is extended up to a depth of ~ 350 nm with a peak at around 200 nm. The peak becomes more pronounced with an increase in irradiation dose.

In order to probe the damage region which is confined up to a depth of 350 nm from the surface using GIXRD, the effective penetration depth (\(\:{x}_{\alpha\:}\)) of an X-ray beam was calculated using Eq. (3).

where ν is the fraction of the incident beam that is absorbed up to a depth of \(\:{x}_{\alpha\:}\), µ is the linear attenuation coefficient of the material,\(\:\:\alpha\:\) is the grazing angle, and 2\(\:\theta\:\) is the diffraction angle. In this study, the fraction of unabsorbed X-rays is taken as 1/e and the diffraction angle of the most intense peak corresponding to the (111) plane is taken as 2\(\:\theta\:\). The mass attenuation coefficient of Ni-45Cr-1.4Mo (wt%) alloy is 110 cm2/g for CuKα X-rays. Based on Eq. (3), the grazing angle of 1.5° was found to be most appropriate to investigate the irradiation-induced microstructural changes up to a depth of 350 nm and therefore GIXRD experiments were carried out at 1.5° angle of incidence.

Microstructure prior to irradiation

The microstructure of the pristine alloy is presented in Fig. 2. An overview of the gross microstructural features of the alloy can be obtained from Fig. 2a. The irregularly shaped precipitates seen in Fig. 2a correspond to alpha-Cr. Similar observations have been reported in previous studies on the similar alloy systems27,28. A non-uniform distribution of such precipitates was noticed within the matrix phase with grain boundaries acting as the preferred site for nucleation. The volume fraction of the precipitates was found to be small with their sizes varying between 100 and 300 nm. The average composition of the precipitates was estimated to be Cr-10.3Ni-3.5Mo (wt%) through EDS analysis. The matrix phase showed an average composition of Ni-43.4Cr-1.1 Mo (wt%). The micrograph shown in Fig. 2b was obtained under two-beam diffracting condition. It depicts the planar arrangement of dislocations within the matrix phase without any sort of dislocation interaction or entanglement.

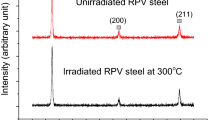

X-Ray diffraction line profile analysis

Figure 3 shows a typical GIXRD profile for the un-irradiated and irradiated NiCrMo alloy samples. The peaks observed in the diffractogram before and after irradiation are indexed to the fcc γ-Ni phase. It can be concluded from these diffractograms that no new phases have formed after irradiation. Figure 4 shows the enlarged view of the strongest intensity (111) peak before and after irradiation. This figure suggests that this peak shifts gradually to a lower 2θ value with an increase of irradiation dose, indicating an increase in the lattice spacing with the increase in the irradiation dose. Indeed, other peaks were also observed to shift to lower diffraction angle with an increase in irradiation dose. Therefore, it could be inferred that the He ion irradiation caused lattice expansion in the irradiated samples.

In addition to the shift in Bragg’s peak, width of the peak also changes with irradiation. The broadening of Bragg peaks is mainly due to a change in domain size and microstrain after accounting for the broadening due to instrumental parameters. Line profile analysis of the diffractograms can bring out important microstructural parameters such as the root mean square microstrain and the average domain size, which help in understanding the irradiation effect on these samples. In this study, Williamson–Hall method based on whole powder pattern fitting technique has been employed.

Modified williamson hall method

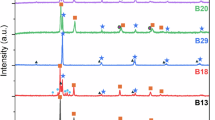

Figure 5 Show the Williamson-Hall plots for both unirradiated and irradiated samples. It is apparent that the data points in the WH plots are scattered and therefore, not suitable for linear fitting with acceptable accuracy. In the WH method, it is assumed that the micro-strain is isotropic along the crystallographic axes. The highly scattered data points in the WH plots reveal the existence of anisotropic broadening in the samples. The scattering tendency of the data points is also observed to increase with the increase in dose, suggesting that the micro-strain anisotropy along the different crystallographic planes increases with dose.

To account for such anisotropies, Ungár et al.29,30 proposed a modified version of the Williamson-Hall (W-H) method, which allows for a more accurate estimation of microstructural parameters in the presence of anisotropic strain. However, if a sample contains planar defects such as stacking faults, twin boundaries, or both, the apparent domain size is smaller than the actual domain size. Therefore, the effects of twinning and stacking faults included in the Modified Williamson-Hall method as given in supplementary materials to analyze the XRD data.

Figure 6 shows linear fitting of data points in the plot of Modified Williamson Hall for all the samples. The domain size and dislocation density were evaluated from these plots using slope and intercept of these liner plots and their variation as a function of irradiation dose is given in Table 2. The domain size decreases significantly from 356 Å to 136 Å when irradiated at highest dose of 17.1 dpa. The domain size is seen to decrease with increase in irradiation dose and the rate of its decrease is ~ 156 Å /dpa, 88 Å /dpa, and 11 Å /dpa at doses of 0.72 dpa, 4.85 dpa, and 17.1 dpa, respectively. This indicates that the maximum reduction in domain size occurred during the initial phase of irradiation and approaches saturation as the dose of irradiation increases.

Transmission electron microscopy of irradiated samples

The irradiated samples were investigated in TEM to reveal the geometric configurations attained by the clusters of point defects generated by irradiation. The extent of the irradiated region which got probed in TEM by virtue of the sample preparation technique is ~ 50 to 100 nm from the irradiated surface. This is in view of the fact that the approximate film thickness required for electron transparency is also of the same order. TEM analysis could bring out extensive dislocation loop formation within this depth. The bright-field TEM micrographs of Fig. 7a–d show the defect microstructures of irradiated samples recorded under two-beam diffraction imaging conditions at doses of 4.85 dpa and 17.1 dpa, respectively. Two different diffraction g-vectors were used to image the defect structure. A network of dislocation loops could be observed in both the irradiated samples very clearly besides small, black dot-like feature which represents defect clusters/small dislocation loops. No discernible difference could be noticed in terms of the density of the loops in the two samples (4.85 vis-à-vis 17.1 dpa) although more of dot-like feature was observed in the 4.85 dpa sample in contrast to 17.1 dpa when imaged with 200 diffraction vector (Fig. 7a vs. c). This suggested towards an increase in the size of the defect clusters/small dislocation loops with irradiation dose, leading to the attainment of a more distinct loop-like character. Although the nature of the loops has not been determined in the present work, it is expected to be similar to that exhibited by the microstructure of any irradiated fcc material with predominance of faulted (Frank) loops (1/3 < 111 > Burgers vector) over perfect loops (1/2 < 110 > Burgers vector) owing to lower stacking fault energy.

It is to be noted that all these defect features are an outcome of the irradiation process alone, as the unirradiated sample imaged under similar diffracting condition did not exhibit any of these features except for a few isolated planar dislocations (Fig. 2b). Another major irradiation effect on the microstructure of the alloy, which became apparent through TEM examination, was the dissolution of the native alpha-Cr precipitates. The alpha-Cr precipitates present in the unirradiated matrix (Fig. 2a) were hardly visible after irradiation; only their leftover vestiges were noticed as shown marked in Fig. 8. The dissolution of alpha-Cr precipitates got accompanied by a corresponding increase in the Cr- and Mo-content of the matrix phase to 44.7 wt% and 1.8 wt%, respectively from that of 43.4 wt% and 1.1 wt% in the unirradiated condition. Elemental analysis carried out on the precipitate remnants showed composition very close to that of the irradiated matrix namely Ni-47Cr-2.3Mo (wt%), thereby proving their dissolution. However, the re-precipitation of alpha-Cr phase was not observed. To support these observations, representative EDS spectra from both the matrix and precipitate for the un-irradiated and 17.1 dpa irradiated samples are provided as supplementary details. It should be noted that pristine samples were heat treated in such a way so as to minimize the precipitate volume fraction during processing. Thus, the dissolution of small fraction of pre-existing precipitate may not be considered detrimental for application purpose.

Positron annihilation spectroscopy study

The variation of S-parameter as a function of mean positron implantation depth (S(Z) profiles) from the sample surface is presented in Fig. 9 for both unirradiated and irradiated samples. The experimental S-Z profiles could be analyzed using the variable energy positron fit (VEPFIT) software31,32,33. The solid line shows the fitting of VEPFIT program. It can be seen that the S-parameter of the unirradiated sample increase sharply close to the surface, before mean implantation depth of 50 nm. This behavior is generally observed in metallic samples and is attributed to the back diffusion of positrons towards the surface, which results in the formation of a positronium-like state that has higher S-parameter values34. The S-parameter values of the irradiated samples are higher than that of unirradiated samples throughout the depth and the S-parameter value increases as the dose increases. The S-W plot is analyzed to identify the defects that have been produced by ion implantation. The typical S-W plots for the unirradiated and highest-dose irradiated sample (17.1 dpa) are shown in Fig. 10a and b, respectively. The S-W plots for the other two irradiated samples are included in the inset of Fig. 10b.

Nano indentation

The hardness H of the samples before and after irradiation were evaluated using nano-indentation. The inset in Fig. 11 shows the average nanoindentation hardness as a function of depth. The hardness of all irradiated samples was observed to be higher than that of the unirradiated sample together with a progressive increase in hardness with irradiation dose. There is a decrease in the hardness of all the samples with increasing indentation depth in irradiated as well in unirradiated samples. This is attributed to the ‘indentation size effect’ (ISE) which can be described by Nix–Gao model based on geometrically necessary dislocations35,36 using Eq. (4).

where H is the measured hardness corresponding to indentation depth h, H0 is the hardness corresponding to infinite depth which is also known as the bulk equivalent hardness or ISE free hardness, \(\:{h}^{*}\) is the characteristic constant of indention depth which depends on the indenter shape and shear modulus. In evaluating the hardness of shallow-depth low-energy ion-irradiated materials, the estimated hardness often turns out to be a convoluted hardness having contributions from both the hard-irradiated surface and the underneath soft unirradiated substrate. An approach developed by Kasada et al.37allows one to evaluate the hardness of irradiated region without interference from the unirradiated substrate.

A fitting of H2 against 1/h of the hardness data was carried out for depths beyond 125 nm and the same is shown in the Fig. 11. For all irradiated samples, the plot of H2 versus 1/h exhibits an inflection at a critical indentation depth (hc) and this inflection point is more pronounced at higher dose of 17.1 dpa and can be seen at around 300 nm. The hardness of the irradiated samples, H0, and h* evaluated by fitting the data in the range of 125 nm < h < hc are given in Table 3. It is observed that the value of H0 increases and h* decreases with increase in irradiation dose.

In order to understand the effect of He ion irradiation on the mechanical properties, the change in the average nanohardness value (∆H), defined as ∆H = Hirradiated - Hunirradiated was evaluated and shown in Table 3. The hardening rates at 0.72 dpa, 4.85 dpa and 17.1 dpa were found to be 722 MPa/dpa, 403 MPa/dpa and 49 MPa/dpa, respectively. This shows that the hardening rate is higher at lower irradiation doses. The irradiation hardening, for simplification purpose (as discussed in the following section), was assumed to be mainly due to a change in dislocation density and, therefore, the defect density (in terms of dislocation density) was estimated using Eq. (5) and presented in Table 3.

where M is the Taylor factor (3.06 for cubic lattice) and α (= 0.5) is defect barrier strength (dependent on dislocation structures)38,39. G represents the shear modulus (87 GPa), and Cʹ represents the Tabor’s factor. For metals Cʹ = 3 can be considered38,39.

Discussion

Different characterization techniques have been used in this study to understand the role of irradiation induced defects on microstructural and mechanical property changes of Ni-Cr alloy owing to He ion irradiation. The SRIM profile (Fig. 1) shows that the damage region extends up to a depth of approximately 350 nm, whereas the S-Z profiles of irradiated samples suggested the damage to be extended beyond 350 nm. This is due to the thermal effects that SRIM ignores. The vacancies introduced by He ion irradiation can easily diffuse beyond the irradiation zone as the vacancies in Ni have been reported to be mobile even at room temperature40. It can be seen from Fig. 10 that the S parameter value is higher in the irradiated samples in the region with positron penetration depth of 100 to 300 nm indicating that the defect density in this region is higher than that in the unirradiated sample or in bulk region (beyond 350 nm) as expected. As per SRIM estimation, peaking in S-Z profile should occur around 200 to 300 nm, but S- parameter is observed to continuously decrease beyond 100 nm. This can be understood considering the following. As per SRIM implantation profile, nearly 87% of He ions stopped in the range of 100 nm to 350 nm. Authors and other researchers have established that He ions have a strong affinity for vacancies, vacancy clusters and can form ion-vacancy complexes which have lower S-parameter values than that of a vacancy or a vacancy cluster41,42,43,44,45. Hence, the damage region having higher deposition of He ions may show lower S-parameter value. This inference is complemented by the S-W plots of the irradiated samples of highest dose 17.1 dpa, which is shown in Fig. 10b, where two different regions prominently appear. For the sake of completeness, the S-W plots of lower doses are shown as inset of same figure. These plots show two different slopes corresponding to the depth below 100 nm (Layer I, higher S- values) and between 100 and 300 nm (Layer II, lower S- values). Different slopes suggest the presence of different types of defects in Layer I and Layer II. In addition, it can be noticed that the slope of the line in layer II is higher compared to the slope of the line in layer I, indicating that layer II might have a smaller size of defect compared to layer I, which can be attributed to the formation of He ion-vacancy complexes in layer II. It should be noted that even though the Layer I will have contribution from the surface defects as well but it will be insignificant and can be ignored due to very short positron diffusion lengths (a few nm) in ion irradiated Ni alloys39. The effect of the size of defects on the slope change in S-W parameter plot has also been brought to notice by other researchers40,46. Authors have shown that these ion-complexes have lower S-parameter values43.

The formation of defect clusters/dislocation loops in the irradiated microstructure has been brought to light by TEM investigation. The indirect corroboration for such observation can be readily obtained if the PAS results corresponding to the region probed by TEM, which is layer I, is put in perspective. According to PAS analysis, Layer I comprised mostly of vacancy clusters and less of He-vacancy complexes whereas layer II has dominating He-vacancy complexes. At the same time, it is also a known fact that He atoms help stabilize a three-dimensional configuration of vacancy clusters by preventing the collapse of them into vacancy loops8,9. Hence, in layer I, which is having a smaller number of He-vacancy complex, vacancy cluster can collapse to form loops. Thus, the lower concentration of He-vacancy complexes in Layer I could clearly corroborate the lower density of vacancy clusters in the 50–100 nm irradiated zone.

Analysis of XRD data of irradiated samples indicated an increase in the lattice parameter of these samples. The lattice parameter expansion (Δa) corresponding to the highest irradiation dose of 17.1 dpa calculated from the peak shift is about 0.14% with respect to the unirradiated sample. In general, the lattice expansion may be attributed to the contribution from beam heating i.e. due to electronic energy loss (ionization, electronic excitation or phonon interaction of target atoms) as well as due to nuclear energy loss (displacement effects) with the later playing major role as the irradiation temperature did not exceed the room temperature47,48. The observed lattice swelling may be partially attributed to the formation of He-stabilized vacancy clusters during irradiation. Hofmann et al. observed lattice swelling in tungsten alloy due to helium-filled vacancy defects after helium implantation49. Wang et al. also showed lattice parameter expansion of about 0.2% in high-entropy carbide after Zr ion irradiation50.

Further, line-profile analysis of XRD data showed a decrease in domain size and an increase in microstrain and dislocation density. A complementary observation is seen in S-parameter values where the broad hump in the S-Z profile of irradiated samples became more prominent as the irradiation dose increased suggesting an increase in the inhomogeneous distribution of irradiation-induced open volume defects along the depth. At lower doses, a large change in these parameters could be noticed from Table 2, whereas the magnitude of the change became smaller with increase in dose suggesting the onset of a saturation-type behavior at higher irradiation doses. The decrease in domain size and increase in dislocation density, microstrain and S-parameter with increase in irradiation dose can be attributed to the formation of point defects, defect clusters, and dislocation loops due to irradiation. Because the damage caused by ion irradiation is primarily confined within 350 nm of the sample surface, a high concentration of defects remains localized within this region, promoting defect migration. Generally, the reactions that the point defects usually encounter while migration are: (1) annihilation by mutual recombination of self-interstitial atoms and vacancies; (2) elimination at pre-existing as well as newly created defect sinks, such as grain boundaries and dislocation loops; (3) accumulation (of similar type) into defect clusters; and (4) collapse to form dislocation loops51. Thus, although the concentration of point defects keeps on increasing with increasing dose, these point defects are also eliminated during irradiation. Consequently, an equilibrium between formation and elimination of point defects sets in at a higher dose of irradiation. Thus, although lower domain size, higher microstrain, higher dislocation density, higher S-parameter and higher hardness values at higher doses indicated an increase in defect density, the decrease in the corresponding rate of change in these parameters with dose suggested the defect density to increase at a slower rate on account of their annihilation by cascade overlap, mutual recombination, and annihilation at sinks.

It is expected that the microstructural changes induced by He ion irradiation would also affect the mechanical properties. A progressive increase could be noticed in the hardness of the alloy with irradiation dose as seen in the inset of Fig. 11. Hardness of a material is generally influenced by multiple factors, such as precipitates, voids, grain size, dislocations, and dislocation loops. In the present study, irradiation did not alter the grain size of the sample but led to a partial dissolution of the native alpha-Cr precipitates along with formation of dislocation loops. In the present work, an attempt was made to estimate the defect density responsible for such hardness increase from the hardness data itself. Further, to simplify the analysis, the defect density was estimated under the assumption that the change in hardness was entirely due to dislocations. Thus, the defect density was estimated in terms of dislocation density from the hardness values using Eq. 5 (Table 3). Notably, such values were observed to be higher than the dislocation density estimated from the XRD analysis (Table 2). As XRD, being sensitive to dislocations/dislocation loops, provides an estimation of dislocation density alone, the observed difference in the density values establishes the contribution of He-stabilized vacancy clusters in irradiation hardening. In addition, the contribution of solid solution hardening in this hardness increment, due to the rise in Cr and Mo content of the matrix phase on account of irradiation induced ‘recoil dissolution’52,53 of native alpha-Cr precipitates, cannot also be ignored as well.

Conclusions

The impact of He ion irradiation on the evolution of microstructure and mechanical properties of a Ni-45%Cr-1.4%Mo (wt%) alloy was studied employing depth sensitive defect characterization techniques. TEM analysis of unirradiated sample showed a non-uniform distribution of irregularly shaped precipitates of alpha-Cr phase (sizes varying between 100 and 300 nm) in fcc γ-Ni matrix with grain boundaries as the preferential nucleation site. A few isolated planar arrangements of dislocations within the matrix phase were also noticed. Examination of irradiated samples brought out the existence of radiation induced defect clusters, dislocation loops, network dislocations, ion-vacancy complexes. In addition, partial dissolution of the native alpha-Cr precipitates accompanied with concomitant increase in Cr and Mo content of the matrix upon irradiation were confirmed through TEM-EDS analysis. An increase in the size of the defect clusters/small dislocation loops with irradiation dose was also noticed. The density of irradiation induced defects showed a tendency of saturation with increase in irradiation dose. SRIM calculation indicated the damage depth to extend up to 350 nm from the irradiated surface which was complemented by nanohardness measurement study which showed a clear increase in hardness up to a depth of ~ 300 nm from the surface. GIXRD and PAS studies also established lattice swelling as an irradiation effect in this alloy probably due to He-stabilized vacancy clusters. Other microstructural parameters such as domain size, microstrain and dislocation density were estimated by performing line profile analysis of GIXRD data and these microstructural observations were used to rationalized the irradiation induced hardening phenomenon.

Data availability

Experimental data will be made available on demand by the corresponding author.

References

Solonin, M. I. et al. XHM-1 alloy as a promising structural material for water-cooled fusion reactor components. J. Nucl. Mater. 233–237, 586–591 (1996).

Gurovich, B. A., Frolov, A. S. & Fedotov, I. V. Improved evaluation of ring tensile test ductility applied to neutron irradiated 42XNM tubes in the temperature range of (500–1100)°C. Nuclear Eng. Technol. 52, 1213–1221 (2020).

Yvon, P. & Carré, F. Structural materials challenges for advanced reactor systems. J. Nucl. Mater. 385, 217–222 (2009).

Bates, J. F. & Powell, R. W. Irradiation-induced swelling in commercial alloys. J. Nucl. Mater. 102, 200–213 (1981).

Abram, T. & Ion, S. Generation-IV nuclear power: A review of the state of the science. Energy Policy. 36, 4323–4330 (2008).

Stopher, M. A. The effects of neutron radiation on nickel-based alloys. The effects of neutron radiation on nickel-based alloys. (2016). https://doi.org/10.1080/02670836.1187334 33, 518–536 (2016).

Boothby, R. M. Radiation effects in nickel-based alloys. Compr. Nucl. Mater. Volume. 1–5, 123–150 (2012).

Fave, L., Pouchon, M. A., Döbeli, M., Schulte-Borchers, M. & Kimura, A. Helium ion irradiation induced swelling and hardening in commercial and experimental ODS steels. J. Nucl. Mater. 445, 235–240 (2014).

Trinkaus, H. & Singh, B. N. Helium accumulation in metals during irradiation–where do we stand? J. Nucl. Mater. 323, 229–242 (2003).

McCoy Jr, H. & Weir Jr, J. Materials development for molten-salt breeder reactors. (1967).

Gurovich, B. A. et al Structural evolution features of the 42XNM alloy during neutron irradiation under VVER conditions. J. Nucl. Mater. 543, 152557 (2021).

Srivastava, A. P. et al Proton irradiation of Ni–Cr alloy: Understanding the evolution of the damage microstructure. J. Alloys Compd. 815, 152408 (2020).

Was, G. S. Challenges to the use of ion irradiation for emulating reactor irradiation. J. Mater. Res. 30, 1158–1182 (2015).

Odette, G. R., Alinger, M. J. & Wirth, B. D. Recent developments in irradiation-resistant steels. (2008). https://doi.org/10.1146/annurev.matsci.38.060407.130315 38, 471–503.

Yamamoto, T. et al The transport and fate of helium in nanostructured ferritic alloys at fusion relevant he/dpa ratios and Dpa rates. J. Nucl. Mater. 367–370, 399–410 (2007).

Duffy, D. M. Fusion power: a challenge for materials science. Philosophical Trans. Royal Soc. A: Math. Phys. Eng. Sci. 368, 3315–3328 (2010).

Mansur, L. K. Theory and experimental background on dimensional changes in irradiated alloys*. J. Nucl. Mater. 216, 97–123 (2008).

Fluss, M. & Hosemann, P. Charged-Particle irradiation for neutron radiation damage studies. Characterization Materials (2012).

Srivastava, A. P. et al Understanding the effect of irradiation temperature on microstructural evolution of 20MnMoNi55 steel. Sci. Rep. 12, 1–17 (2022).

Lu, C. et al Direct Observation of Defect Range and Evolution in Ion-Irradiated Single Crystalline Ni and Ni Binary Alloys. Sci. Rep. 6, 1–10 (2016).

Jin, S. X. et al Microstructural evolution of P92 ferritic/martensitic steel under argon ion irradiation. Mater. Charact. 62, 136–142 (2011).

Neogy, S. et al Proton irradiation of Zr–1 wt.% Nb cladding material: A depth-wise assessment of inhomogeneous microstructural damage using X-ray diffraction line profile analyses. J. Alloys Compd. 640, 175–182 (2015).

Schultz, P. J. & Lynn, K. G. Interaction of positron beams with surfaces, thin films, and interfaces. Rev. Mod. Phys. 60, 701 (1988).

Ziegler, J. F., Ziegler, M. D. & Biersack, J. P. SRIM–The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. B. 268, 1818–1823 (2010).

Stoller, R. E. et al On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. B. 310, 75–80 (2013).

Lu, C. et al Enhanced radiation-tolerant oxide dispersion strengthened steel and its microstructure evolution under helium-implantation and heavy-ion irradiation. Sci. Rep. 7, 1–7 (2017).

Ustinovshikov, Y. Phase transformations in alloys of the Ni–Cr system. J. Alloys Compd. 543, 227–232 (2012).

Solonin, M. I. Radiation-resistant alloys of the nickel-chromium system. Met. Sci. Heat Treat. 47, 328–332 (2005).

Ungár, T. & Borbély, A. The effect of dislocation contrast on x-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 69, 3173 (1998).

Groma, I., Ungár, T. & Wilkens, M. Asymmetric X-ray line broadening of plastically deformed crystals. I. Theory. J. Appl. Crystallography Preprint At. https://doi.org/10.1107/S0021889887009178 (1988).

Veen, A., Van, Schut, H., Vries, J., De, Hakvoort, R. A. & Ijpma, M. R. Analysis of positron profiling data by means of ‘VEPFIT’. AIP Conf. Proc. 218, 171–198 (1991).

van Veen et al VEPFIT applied to depth profiling problems. Appl. Surf. Sci. 85, 216–224 (1995).

Lynn, K. G., Chen, D. M., Nielsen, B., Pareja, R. & Myers, S. Variable-energy positron-beam studies of Ni implanted with he. Phys. Rev. B. 34, 1449–1458 (1986).

Wang, R. et al Proton-irradiation-induced damage in Fe–0.3 wt% cu alloys characterized by positron annihilation and nanoindentation. Nucl. Instrum. Methods Phys. Res. B. 307, 545–551 (2013).

Nix, W. D. & Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids. 46, 411–425 (1998).

Yabuuchi, K., Kuribayashi, Y., Nogami, S., Kasada, R. & Hasegawa, A. Evaluation of irradiation hardening of proton irradiated stainless steels by nanoindentation. J. Nucl. Mater. 446, 142–147 (2014).

Kasada, R., Takayama, Y., Yabuuchi, K. & Kimura, A. A new approach to evaluate irradiation hardening of ion-irradiated ferritic alloys by nano-indentation techniques. Fusion Eng. Des. 86, 2658–2661 (2011).

Changizian, P., Yao, Z., Lu, C., Long, F. & Daymond, M. R. Radiation effect on nano-indentation properties and deformation mechanisms of a Ni-based Superalloy X-750. J. Nucl. Mater. 515, 1–13 (2019).

Gao, J., Yabuuchi, K. & Kimura, A. Ion-irradiation hardening and microstructural evolution in F82H and ferritic alloys. J. Nucl. Mater. 515, 294–302 (2019).

Mantl, S. & Triftshiuser %. Defect annealina stutlies Un metals by pesitrun annihilatiun anti electrical resistivity measurements. 17, (1978).

Ortiz, C. J., Caturla, M. J., Fu, C. C. & Willaime, F. Influence of carbon on the kinetics of he migration and clustering in α-Fe from first principles. Phys. Rev. B Condens. Matter Mater. Phys. 80, 134109 (2009).

Fu, C. C. & Willaime, F. Ab initio study of helium in-Fe: dissolution, migration, and clustering with vacancies. https://doi.org/10.1103/PhysRevB.72.064117

Sharma, S. K., Saini, S., Srivastava, A. P. & Pujari, P. K. Identification of chemical surrounding and type of vacancy defects in the damaged region of ion irradiated Ni–Cr alloy. Mater. (Oxf). 15, 100999 (2021).

Saini, S. et al Ar irradiated cr rich Ni alloy studied using positron annihilation spectroscopy. J. Nucl. Mater. 479, 279–286 (2016).

Tuomisto, F. et al Segregation of Ni at early stages of radiation damage in nicofecr solid solution alloys. Acta Mater. 196, 44–51 (2020).

Muthe, K. P. et al Positron annihilation and thermoluminescence studies of thermally induced defects in α-Al2O3 single crystals. J. Phys. D Appl. Phys. 42, 105405 (2009).

Minagawa, H., Tsuchida, H., Murase, R. & Itoh, A. In situ X-ray diffraction study of irradiation-induced lattice expansion in al foils by MeV-energy heavy ions. Nucl. Instrum. Methods Phys. Res. B. 372, 38–43 (2016).

Yamamoto, Y., Ishikawa, N., Hori, F. & Iwase, A. Analysis of Ion-Irradiation induced lattice expansion and ferromagnetic state in CeO2 by using Poisson distribution function. Quantum Beam Sci.. 4, 26 (2020).

Hofmann, F. et al Helium-Ion-Implantation in tungsten: progress towards a coherent Understanding of the damage formed and its effects on properties. Procedia IUTAM. 21, 78–85 (2017).

Wang, F. et al Irradiation damage in (Zr0.25Ta0.25Nb0.25Ti0.25)C high-entropy carbide ceramics. Acta Mater. 195, 739–749 (2020).

Was, G. S. Fundamentals of radiation materials science: Metals and alloys, second edition. Fundamentals of Radiation Materials Science: Metals and Alloys, Second Edition 1–1002 (2016). https://doi.org/10.1007/978-1-4939-3438-6/COVER

Nelson, R. S., Hudson, J. A. & Mazey, D. J. The stability of precipitates in an irradiation environment. J. Nucl. Mater. 44, 318–330 (1972).

Russell, K. C. Phase instability under cascade damage irradiation. J. Nucl. Mater. 206, 129–138 (1993).

Acknowledgements

The authors extend their sincere gratitude to the Director, Variable Energy Cyclotron Centre (VECC), India, and to Prof. P.Y. Nabhiraj, Head, ECR Ion Source Facilities Section of this centre, for generously providing access to the irradiation facility. The authors also express their sincere appreciation to the Head, Department of Metallurgical Engineering and Materials Science, IIT Bombay for their assistance in facilitating XRD measurements for this study. Furthermore, the authors wish to convey their gratitude to Dr. R. Tewari, Director, Materials Group, Bhabha Atomic Research Centre, India for his unwavering interest and invaluable insights that significantly enriched the progression of this study. This study has been funded by the Department of Atomic Energy, Government of India.

Funding

Open access funding provided by Department of Atomic Energy.

Author information

Authors and Affiliations

Contributions

All the authors contributed equally in designing of the experiments, analysis and preparation of the manucsript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Saini, S., Menon, R., Sharma, S.K. et al. A comprehensive study on the impact of He ion irradiation on the microstructure and mechanical properties of a Ni-Cr-Mo alloy. Sci Rep 15, 28733 (2025). https://doi.org/10.1038/s41598-025-11922-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11922-x