Abstract

This study aimed to optimize the ultrasonic-assisted extraction process of goose fat using response surface methodology (RSM) with a four-factor, three-level experimental design to obtain high-quality goose fat that meets national standards. The optimal extraction conditions were determined as follows: ultrasonic power 558 W, extraction time 20 min 36 s, solid-to-liquid ratio 1:5, and temperature 29 °C, achieving an average extraction yield of 78.78%. Verification experiments under these conditions (n = 3) yielded a goose fat recovery rate of 80.22 ± 0.22% (relative error: 0.98%). Scaling up the process by 100-fold (n = 3) resulted in a recovery rate of 81.12 ± 0.22% (relative error: 2.97%). The extracted goose fat exhibited an acid value of 1.112 ± 0.21 mg/g and a peroxide value of 0.031 ± 0.012 g/100 g, both complying with national standards. Accelerated stability tests (60 °C, 24 days) confirmed the fat’s oxidative stability, with acid value remaining below 2.5 mg/g and peroxide value below 0.20 g/100 g. GC-MS analysis identified 23 fatty acids, with unsaturated fatty acids accounting for 59.17% of the total (including 39.94% monounsaturated fatty acids). The optimized extraction process not only ensured high yield but also produced crude goose fat with excellent color and minimal impurities, demonstrating its potential for industrial-scale production.

Similar content being viewed by others

Introduction

Goose oil (Goose Fat) is a kind of animal fat, mainly composed of triglycerides (TG), and contains a small amount of free fatty acids (Free Fatty Acids, FFA), phospholipids (Phospholipids), cholesterol (Cholesterol), tocopherols (Tocopherols) and other components.) and other components. Its chemical characteristics mainly include fatty acid composition, physical and chemical properties (such as melting point, iodine value, acid value, etc.) and oxidative stability1.

Accordingly, 95.9% of goose meat was produced in Asia, 2.4% in Europe and 1.4% in Africa; the share of the other continents in total goose meat production is an order of magnitude lower2,3. After years of development, China’s goose industry ranks first in the world in terms of raising and market output and plays an indispensable role in the world poultry industry. According to statistics, the total goose production (including guinea fowl) in China was approximately 2.52 million tonnes in 2018 and approximately 95.2% of the total global goose production4.Goose fat is a food obtained during the reprocessing of the demolition parts (sub cutaneous and abdominal fat) via thawing out the raw grease.Goose fat is good for health as it contains oleic, linolenic, linoleic and arachidonic acids, cholesterol and carotenoids5,6,7,8.Goose fat is also rich in minerals and vitamins, it can be therefore considered as a functional food9.

Goose fat biodiesel is a promising biofuel with favorable environmental, economic, and physicochemical properties, making it a viable, sustainable alternative fuel for diesel engines10,The fat is considered to be relatively safe for consumers due to its low level of saturated fatty acids11. Geese are characterized by a longer growth cycle and superior nutrient content compared to chickens and ducks12.

RSM serves as a toolbox of mathematical and statistical methods to enhance responses affected by multiple independent variables. Through careful experimental design and analysis, RSM endeavors to establish the relationship between a response and the diverse levels of input variables or factors affecting it13.The major methods under RSM that are mainly used are central composite design and Box–Behnken design, among others. Central composite design is renowned for its balanced exploration of the experimental space, employing both factorial and axial points to capture the curvature of the response surface14. Box–Behnken design stands out for its efficiency in exploring response surfaces with fewer experimental runs, omitting the need for axial points while maintaining high accuracy, aiming to pinpoint the optimal settings for these variables15. Owing to its positives, the Box–Behnken design has been chosen for this study.

Ultrasound power has a direct impact on cell breakage efficiency and oil stability and needs to be optimized to balance extraction rate with oxidation risk.Ultrasound generates micro-bubbles in the liquid, releasing mechanical energy when the bubbles collapse, disrupting the cell wall and promoting the release of oil16. Too low power Insufficient cavitation, low extraction rate. Too high power excessive cavitation may lead to localized high temperatures, accelerating oxidation of oils and fats17. Minimum effective time in order to balance the extraction rate and energy consumption, longer time can improve the dissolution of fats and oils, but too long time may lead to: thermal degradation: ultrasound continuous action may increase the temperature, leading to oxidation of fats and oils. Increased energy consumption and reduced economics18. Optimization of the material-liquid ratio improves solvent utilization and reduces the proportion of waste solvent affects the diffusion of oils and fats from the solid phase (goose fat tissue) to the liquid phase. Too little solvent high mass transfer resistance, incomplete extraction. Too much solvent dilution effect, increase the cost of subsequent concentration19. Temperature needs to find a balance between promoting extraction and preventing oxidation. Increasing temperature reduces solvent viscosity and increases diffusion rate. At the same time, high temperature promotes the oxidation of fats and oils20.

As a high-value animal fat, goose oil has received widespread attention in the food, pharmaceutical and cosmetic fields in recent years because it is rich in unsaturated fatty acids (especially monounsaturated fatty acids) and its ratio is close to the WHO-recommended balanced ratio of 1:1:1. Currently, the extraction methods of goose oil mainly include the traditional boiling and refining method, vacuum and low-temperature refining, ultrasonic-assisted extraction, and dry partitioning technology. Traditional boiling method is low cost, simple operation, but the yield is not high, the risk of oxidation is high, the quality is not stable, only small-scale production. Vacuum low-temperature refining has higher yield, reduces oxidation, improves stability, but equipment requirements are high. Dry fractionation is environmentally friendly, safe, medium yield, no solvent, but the process is complicated.Solvent extraction Highest yield, but solvent residue. Ultrasonic-assisted method is energy efficient, shortens the time, and has high yield21,22,23.

Currently, there are relatively few studies on goose oil and little utilization of goose oil, this paper extracts goose oil by ultrasonic-assisted extraction method. Single-factor, response surface method to determine the optimal ultrasound-assisted extraction process. Improve the extraction rate of goose oil and lay the foundation for the subsequent utilization of goose oil and through this experiment, we hope to turn goose oil into treasure.

Materials and methods

Main experimental materials

Zhejiang big white goose (Zhedong goose) goose fat purchased from Yangzhou Taoji Co.The extractant is petroleum ether with a boiling range of 60–90 °C, purchased from Chuandong Chemical Co.

Goose oil extraction process flow chart

The whole flow chart of goose oil extraction is shown in Fig. 1.

Ultrasonic extraction method

Taking 50 g of goose fat into a three-necked flask, according to different material-water ratios, add the extraction solvent petroleum ether, use a glass rod to stir the experimental objects well and then placed in the UV ultrasonic extractor, according to the experimental set values set other single factor values, and carry out the experiment. At the end of the experimental treatment, the sample solution was centrifuged, the supernatant was taken, and the extraction solvent was removed from the sample solution by vacuum rotary evaporator to calculate the yield. The single factors were ultrasonic power, time, material-water ratio, and temperature, and the best single-factor conditions were screened and optimized for the experiments by the controlled variable method.

Extraction rate = Crude goose oil mass ÷ Goose fat mass*100%.

One-factor experiment on ultrasonic extraction of Goose oil

Set the single-factor range of 350–750 W in five groups, fixed material-water ratio of 1:5, temperature of 15 ℃, time of 10 min, determine the yield, analyze the effect of different power on this test. Then, set the single-factor range of 10 min to 30 min five groups, fixed material-water ratio of 1:5, temperature 15 ℃, power is the best power obtained in the above single-factor experiments, determination of the yield, analyze the effect of different time on this test. Then, the ultrasonic power and processing time were set as the optimal values obtained in the above experiments, the temperature was 15℃, and the range of material-liquid ratio was adjusted to 1:2 − 1:6, and the yield was measured to study the effect of different material-liquid ratios on the experiment. Finally, the temperature was adjusted to 15℃-55℃ for the test, respectively, to determine the yield of goose oil, and the other factors were the optimal values obtained from the previous experimental operations, in order to discuss the effect of different temperatures on this experiment.

Response surface method optimization

Through the preexperimental selection, the best single-factor conditions were selected, the next two points were chosen, the experimental design (as shown in Table 1), and the yield was used as the design of this experimental index to conduct the test in order to determine the best optimization parameters.

Validation of optimal process conditions for Goose oil

Three experiments were repeated according to the optimal extraction conditions and the predicted values were compared.

Extended experiments

Expand the sample size by a factor of 100 and repeat it 3 times according to the best optimization conditions and compare with the predicted values.

Determination of physicochemical indexes of Goose oil

Determination of acid value

Weigh 1 g of crude oil and grease sample in a clean 250mL conical flask, add 50mL of ether-isopropanol mixture (ratio of 1:1), shake until the sample is fully dissolved, then add 3–4 drops of phenolphthalein indicator and mix well, then titrate with potassium hydroxide standard solution (concentration of 0.1 mol/L). Three parallel experiments were carried out. Then, according to the same method, no crude oil samples as a blank test.

X: acid price of the sample (mg/g).

C: concentration of KOH standard solution (mol/L).

V: volume of potassium hydroxide consumed by the sample (mL).

V0: volume of potassium hydroxide consumed by reagent blank (mL).

m: grease sample (g).

Determination of peroxide value

Weigh 1 g of crude fat sample to be tested, put it in a 250mL iodine measuring flask, add 30mL of trichloromethane glacial acetic acid mixture, make the sample dissolve completely, add 1mL of saturated potassium iodide solution. The bottle was tightly capped and gently shaken for 0.5 min, then placed in the dark for.

3 min, remove and add 100mL of water, shake well. Immediately titrate with 0.002 mol/L sodium thiosulfate standard solution, to light yellow color, add 1 ml starch solution.color, add 1 ml starch indicator, continue titration until the blue color disappears as the end point. Perform 3 parallel tests. Do the reagent blank test according to the same method.

X: peroxide value of the sample (g/100 g).

V1: Volume of sodium thiosulfate standard solution consumed by the sample (mL).

V2: volume of sodium thiosulfate standard solution consumed by reagent blank (mL).

c: Mass concentration of sodium thiosulfate material (mol/L).

m: crude fat sample (g).

Infrared spectroscopic determination of Goose oil

200 mg of potassium bromide was weighed, dried, and pressed into tablets, both sides of the pressed tablets were evenly coated with duck fat, and the results were analyzed by infrared band scanning.The results were analyzed by scanning in the infrared band.

Determination of oxidative stability of Goose oil

150.0 g of goose oil was weighed and placed in a constant temperature oven at 60 ± 1 ℃, and its sensory indexes and acid price were determined every 3d, POV value were determined every 3d, and the results were analyzed for 21d consecutively.

Determination of fatty acids in Goose oil

Pre-treatment: 1000 mg of sample was placed in a 50mL graduated glass tube, and 10mL of 2% sodium hydroxide methanol solution was added to the sample.Add 10mL of 2% sodium hydroxide methanol solution and reflux the sample for 60 min at 80℃±1℃ in a water bath.80℃±1℃ water bath reflux for 60 min, add 5mL of 14% trifluoride solution from the upper end of reflux condenser.Add 10mL of 14% boron trifluoride methanol solution, continue toReflow for 3 min, cool to room temperature. Add 10mL of n-heptane and shake for 2 min.After 2 min, add 10mL of saturated aqueous sodium chloride solution, and leave to stratify.Pipette 5mL of supernatant into a 25mL centrifuge tube, add about3g of anhydrous sodium sulfate, shaking for 2 min, let stand for 5 min, aspirate the upper layer of solution and filter into the injection bottle.Add about 3 g of anhydrous sodium sulfate into a 25mL centrifuge tube, shake for 2 min, let it stand for 5 min, absorb the upper layer of solution and filter it into the injection bottle for measurement.

Gas chromatographic conditions: the method was slightly modified with reference to TANet al.24 Agilent HP-5ms column (30 m×250 μm×0.25 μm).Air flow rate 400 mL/min; hydrogen flow rate 40 mL/min; nitrogen flow rate 25 mL/min.Flow rate of air 400mL/min; flow rate of hydrogen 40mL/min; flow rate of nitrogen 25mL/min; temperature of injection port 270℃; temperature of detector280°C; split ratio 30∶1.

Data analysis

The above experiments were set up in three parallel experiments, and the results obtained from the orthogonal experiments were analyzed by SPSS 27.0, and the graphs were drawn by Design Expert 13 and Origin 2021 software.

Results and discussion

Results of one-factor experiments

It can be seen from Fig. 2-a. In the case of other conditions are the same, the extraction rate of goose oil with the increase of ultrasonic power shows a trend of first increase and then decrease, to 550 W after the extraction rate began to decline. Extraction power is an important factor in the extraction process, as the extraction power increases, the stronger the mechanical effect and cavitation effect produced, the faster the release and diffusion of goose fat, so the extraction rate of goose oil will rise. However, when the extraction power reaches a certain value, the extraction rate of goose oil also tends to stabilize or even decline accordingly, first of all, this is because the osmotic pressure inside and outside the goose oil has already reached equilibrium, and raising the power has little effect on the exudation of goose oil. Secondly, with the increase of power, the temperature of the system will also increase in a certain range, resulting in the volatilization of the solvent, while the extraction power is too large to cause the destruction of the internal structure of duck fat, resulting in a decrease in the extraction rate25. It can be seen from Fig. 2-b. In the case of other conditions are the same, the extraction rate of goose oil with the increase of time shows the trend of first rise and then decline, to 20 min after the extraction rate began to decline, which may be due to the prolongation of the extraction rate of goose oil with the increase of time, a certain amount of time after the tendency to stabilize. This is due to the greater osmotic pressure in the extraction solution at the beginning of the ultrasonic treatment, with the prolongation of time, goose oil in the solvent to get sufficient diffusion, so the extraction rate increased accordingly. After a certain period of time the osmotic pressure in the solution gradually reached equilibrium, the extraction rate also tends to stabilize accordingly26. From Fig. 2-c can be seen, in other conditions the same case, the extraction rate of goose oil with the increase in the material-liquid ratio showed a trend of first increase and then decline to the material-liquid ratio of 1:5 when the beginning of the decline may be due to the increase in the amount of solvent, the extraction rate of the goose oil, which is due to an increase in the solvent, which is conducive to the exudation of fats and oils, and at the same time increase the contact area of the goose fat with the solvent. However, when the liquid to material ratio reaches a certain value after the goose oil extraction rate tends to stabilize, this is because the osmotic pressure in the solution system has tended to equilibrate, most of the goose oil has been exuded, this time the increase in solvent has little effect on the extraction rate27. From Fig. 2-d, it can be seen that, under the same conditions, the extraction rate of goose oil with the increase in temperature showed a trend of first increase and then decrease, to the temperature of 25℃ when the extraction rate began to decline. This may be because the temperature accelerates the molecular movement between the solvent molecules and the raw materials, and the solvent solubility is also increased, which is conducive to the exudation of the oil, but other conditions are the same, the higher the temperature, the faster the solvent volatilization, the greater the loss, resulting in a decrease in the extraction rate of goose oil28.

Results of response surface experiments

The experimental design and results are exhibited in Table 2,The single-factor experiment was designed with three levels for each factor (based on four factors: ultrasonic power, time, material-liquid ratio and temperature), and the yield was used as a reference for further optimization of the above four factors by response surface methodology.The results were analyzed by the response surface software Design expert 13 and the linear regression equation is as follows: Y = -393.86 + 0.96 A + 16.46B − 18.81 C + 2.63D − 0.0098AB + 0.029AC + 0.0012AD + 0.1925BC + 0.025BD + 0.1325CD − 0.000717A2 − 0.2854B2 − 9.3193C2 − 0.0656D2. Response surface analysis was performed on the above response surface test. An analysis of variance (ANOVA) was performed.

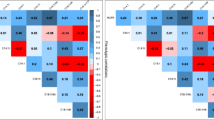

As is shown in Table 3, the analysis of variance showed that this model was significant (p < 0.01),indicating that the regression model as a whole was highly significant, and the model misfit term was not significant; R2 = 0.9435, indicating that the model fit was good, indicating that this experiment has a certain degree of feasibility. In this experiment, the influence of a single factor was material-liquid ratio = ultrasonic temperature > time > ultrasonic power, in which material-liquid ratio and ultrasonic temperature had a highly significant effect on the experiment (P < 0.01), and ultrasonic time and ultrasonic power did not have a significant effect on the experiment. The interaction terms AB (P < 0.01) and AC (P < 0.05) had better significance, indicating that the interaction of ultrasonic power and ultrasonic time, ultrasonic power and material-liquid ratio had a greater effect on crude goose oil extraction rate. The other A2B2C2 and D2 had highly significant effects on the experimental results (P < 0.0001).

Response surface and contour plots of the effect of factors on oil yield of goose oil. Note: a) - extraction time and ultrasound power; b) - material-water ratio and ultrasound power; c) - temperature and ultrasound power; d) - material-water ratio and extraction time; e) - temperature and extraction time; f) - temperature and material-water ratio.

Figure 3 Response surface and contour plots of the effect of each factor on the oil yield of goose oil A total of six groups included a1, a2, b1, b2, c1, c2, d1, d2, e1, e2, f1, f2.The steepness of the response surface reflects the degree of influence of each factor; the steeper the surface and the more curved the curve, the greater the influence of the study factor; the faster the color change of the response surface plot indicates the greater the slope, the more significant influence on the results. In the contour plot, the contour lines are the projections of the response surface 3D map at the bottom, and the contour lines can directly present the interaction of variables, where the oval shape indicates a strong interaction between factors, while the circle indicates a weak interaction. By analyzing the 3D response surface plots of the interaction of the factors, it can be determined that the response surface plots composed of all the factors are in the form of a downward opening and an upward bulge in the center part, indicating that the response values have extreme values.

According to the resultant plots, it can be seen that the effects of all interacting factors on oil yield showed a trend of increasing and then decreasing. The steep slope of the response surface plots of Figures a1 and b1, and the fast color change of the plots indicate that the two interacting factors of ultrasonic power and ultrasonic time, ultrasonic power and material-liquid ratio showed significant effects on crude goose oil extraction rate, of which the slope of Figure a1 is the steepest, indicating that ultrasonic power and ultrasonic time interacted with each other in an extreme way; Figure b1 has a steeper slope, indicating that the interaction effect is significant; in comparison, Figures c1, d1, and e1, f1 response surfaces have flatter slopes, indicating that there is no significant interaction between temperature and ultrasonic power, material-liquid ratio and ultrasonic time, temperature and ultrasonic time, and temperature and material-liquid ratio.

According to the contour shape analysis shown, it can be seen from the figure that the shape of the contour lines of Figures a2 and b2 is close to elliptical, indicating that the response value is somewhat related to the sensitivity to changes in the treatment conditions; in contrast, the contour lines of Figures c2, d2, e2, and f2 all show a distribution of nearly circular shape, which reflects that the four groups of factors, namely, temperature and ultrasonic power, material-liquid ratio and ultrasonic time, temperature and ultrasonic time, and temperature and material-liquid ratio, interact more strongly than the four groups of factors. ratio, temperature and ultrasonic time, temperature and ultrasonic time, temperature and material-liquid ratio, these four groups of factors interacted weakly, and the degree of influence on the extraction rate of crude goose oil was more limited.

Validation of optimal process conditions for Goose oil

The data were processed and analyzed using Design Expert 13 software, and the predicted yield was 79.445% under the optimum conditions, which were time 20min36s, temperature 29 °C, ultrasonic power 558 W, and material-liquid ratio 1:5. The experiment was repeated three times under these conditions, and the oil yield was obtained as 80.22 ± 0.22% with a relative error of 0.98%.The relative error is less than 5%, which further verifies the validity of the optimal results of the response surface experiment.

Extended experiments

The data were processed and analyzed using Design Expert 13 software, and the predicted yield was 79.445% under the optimum conditions (time 20min36s, temperature 29°C, ultrasonic power 558 W, and material-liquid ratio 1:5). Expanding the sample size by 100 times under these conditions for three experiments yielded an oil production rate of 81.12 ± 0.22% with a relative error of 2.97%. The relative error is less than 5%, which further verifies the validity of the optimal results of the response surface experiment.Microwave pretreatment was used in “Microwave-assisted extraction of goose fat: a kinetic and comparative study”by R. Wang et al29. The results showed that the extraction time was reduced by 70% and the extraction rate was increased by 89% using microwave pretreatment. than the higher extraction rate in our experiment. The reason may be the different types of geese selected and the parts of goose fat.

Determination of acid value and peroxide value

The acid value of goose oil extracted under the optimal conditions was 1.112 ± 0.21, which was less than the national requirement of 2.5. The peroxide value was 0.031 ± 0.012, which was less than the national requirement of 0.2.

Infrared spectroscopic determination of Goose oil

Infrared waves are mainly used to study the vibration spectra between atoms connected by chemical bonds in molecules and the rotation of molecules.spectra, which have significant effects on the qualitative analysis of organic and inorganic compounds, and are commonly used for discriminatory analysis. Infrared spectra of oils and fats Each peak and shoulder on the infrared spectra represents, to some extent, molecular structure and functional group information30,31,32

As can be seen from the Fig. 4, goose oil has obvious absorption peaks at 1700 cm− 1 and 2700–3000 cm− 1, in which the absorption peaks in the region of 2700–3650 cm− 1 indicate the presence of OH groups in the oil; there are three absorption peaks in the region of the stretching vibration of the CH group, including the absorption peaks of cis-double-bonded CH group, the absorption peaks of the fat chain in CH2 and the absorption peaks of the end of CH3.The strong absorption peak in the middle of the spectrum represents O-C = O absorption, and the presence of COOH indicates hydrolysis of the fat or the presence of free fatty acids in C = 0-CH2-CH2-CH2.The presence of COOH indicates hydrolysis of the oil or the presence of C = 0-CH2-CH2-CH2 containing free fatty acids, and the absorption region of 1550 –1000 cm− 1 is the fingerprint region of the oil, which is used to identify the type of oil. As shown in the figure above, no strong absorption peaks were seen in this absorption region, indicating that there were no non-conjugated and conjugated trans fatty acids. In order to determine the fatty acid type, the fatty acid composition of goose oil should be determined.Chen & Li33 in FTIR combined with chemometrics for authentication of goose oil. obtained that goose oil showed characteristic absorption peaks in the following wave number regions: 3010 cm-¹ (= C-H stretching vibration, indicative of unsaturated fatty acids) 2925 cm -¹ and 2854 cm-¹ (C-H telescopic vibration, saturated fatty acids) 1745 cm-¹ (ester carbonyl C = O telescopic vibration, triglyceride characteristic) 1165 cm-¹ (C-O telescopic vibration, ester bonding) are the same as those appearing in the present experiment. There is an identity in the position of the absorption peaks.

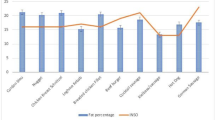

Determination of oxidative stability of Goose oil

Stability determination, can determine whether the fat has a stable acid value and peroxide value during storage. It facilitates the storage of fats and oils34. The goose oil was stored at 60 ℃for 24d and the acid price and peroxide value were determined every 3d. As shown in Fig. 5, the acid price and peroxide value of duck oil stored at 60 ℃ increased for 24 days, but they did not exceed the national standard, indicating that the duck oil was stable under this condition.Although the acid price and peroxide value increased, they did not exceed the national standard, indicating that the duck oil did not oxidize, and the stability of duck oil was good under this condition.

Determination of fatty acids in Goose oil

Fatty acids in oils and fats are mainly categorized into saturated, monounsaturated and polyunsaturated fatty acids. The category of fatty acid composition and the amount of content is one of the important indexes for evaluating the quality of edible oils, and its composition, content and proportion largely determine the nutritional value of fats and oils5. Due to the high boiling point of fatty acids, they are unstable at high temperatures and easy to be cracked, so when fatty acids are analyzed, they are first prepared as fatty acid methyl esters to lower the boiling point and improve the stability. The fatty acid composition of the goose oil was analyzed by GC-MS, and the mass spectra were obtained as shown in Fig. 6.

The mass spectrometry data of the duck oil samples were compared with the NIST mass spectrometry search library, and the fatty acids corresponding to each peak were confirmed.

The relative content of each fatty acid was calculated by peak area normalization, and the results are shown in Table 4.

As shown in the table, a total of 23 fatty acids were detected by GC-MS, and the unsaturated fatty acid content accounted for 59.17%, of which 7 monounsaturated fatty acids accounted for 39.94%.Among them, 7 monounsaturated fatty acids accounted for 39.94%, namely myristoleic acid, palmitoleic acid, (Z)-hexadecenoic acid, methyl ester, Z-13-docosenoic acid, oleic acid, cis-decahydroxyacidAmong them, 7 monounsaturated fatty acids accounted for 39.94%, namely myristoleic acid, palmitoleic acid, (Z)-hexadecenoic acid, (Z)-methyl ester, Z-13-docosenoic acid, oleic acid, cis-9-octadecenoic acid, and erucic acid.octadecadienoic acid, and cis-eicosatrienoic acid.Yan Zhang et al.35 in Fatty Acid Composition of Goose Oil and Its Potential Health Benefits, the unsaturated fatty acid and saturated fatty acid ratios obtained in this paper are in accordance with the ratios obtained in this paper. Indirectly, it can also be obtained that compared with other animal fats (such as lard and tallow), goose oil has a higher proportion of PUFA.

Conclusions

The optimal extraction conditions determined were: ultrasonic power of 558 W, extraction time of 20 min 36 s, solid-liquid ratio of 1:5, temperature of 29 °C, and an average extraction rate of 78.78%. Validation experiments (n = 3) conducted under these conditions yielded a goose fat recovery of 80.22 ± 0.22% (relative error: 0.98%). Scaling up the process 100 times (n = 3) resulted in a recovery of 81.12 ± 0.22% (relative error: 2.97%). The fatty acid value of the extracted goose was 1.112 ± 0.21 mg/g, and the peroxide value was 0.031 ± 0.012 g/100 g, which were in accordance with the national standards. Accelerated stability test (60 °C, 24 days) confirmed the oxidative stability of the fat, with the acid value remaining below 2.5 mg/g and the peroxide value below 0.20 g/100 g. Gas chromatography-mass spectrometry (GC-MS) analysis identified 23 fatty acids, of which 59.17% were unsaturated (including 39.94% monounsaturated). The optimized extraction process not only ensured a high yield, but also produced crude goose fat with excellent color and minimal impurities, showing its potential for industrial production.

Limitations of this experiment were that the interaction effect of solid phase particle size (e.g. 3 mm vs. 5 mm crumbles) on the feed-to-liquid ratio was not investigated; only extended experiments were done without actual industrial extraction; and the chamber data did not take into account the uneven acoustic field distribution of the industrial equipment The effect of the goose breed/feeding method on the fat composition was not controlled for. In addition to the above issues, future research needs to analyze the effect of ultrasound on micronutrients in conjunction with LC-MS/MS to conduct life cycle assessment (LCA) to evaluate the environmental benefits.

Data availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

References

Chen, X., Zhang, Y., Wang, L. & Li, J. Fatty acid composition and oxidative stability of Goose fat: effects of dietary supplementation with linseed oil. Food Chem. 405 (Part A), 134832 (2023).

FAOSTAT. Meat, Poultry Production. Meat, Goose and Guinea Fowl Production (2018) Accessed 22 May 2020. (2020).

Zhang, X., Liu, C., Kong, Y., Li, F. & Yue, X. Effects of intramuscular fat on meat quality and its regulation mechanism in Tan sheep. Front. Nutr. 9, 908355 (2022).

FAO-STAT. Food and Agriculture Organization of the United Nations. Livestock Primary. Accessed Aug. 2020. (2020).

Haraf, G., Woloszyn, J., Okruszek, A., Orkusz, A. & Werenska, M. Fatty acids profile of muscles and abdominal fat in geese of Polish native varieties. Anim. Sci. Papers Rep. 32 (3), 239–249 (2014).

Adamski, M. & Wencek, E. Young Polish oat goose. Carcases and elements of young Polish oat goose. Production principles, pp. 4-22 (Warszawa). (2012).

BEŁKOT, Z. & PYZ-ŁUKASIK, R. Influence of the age of geese on chemical and organoleptic properties of fat. Medycyna Weterynaryjna. 67, 843–846 (2011).

Kozák, J. Goose production and Goose products. Worlds Poult. Sci. J. 77, 403–414 (2021).

Chen, Y. et al. Glycyrrhiza Uralensis Extract Mitigates Mycotoxin Effects in Poultry (Frontiers in Veterinary Science, 2025).

Zakrzewski, M. et al. Study on the rheological properties of biodiesel in the form of Goose fat Methyl ester[J]. Fuel, 386 (2025)

Buza, A. M., Adamski, M. & Janicki, B. Characteristics of performance traits and the qualityof meat and fat in Polish oat geese[J].World\s. Poult. Sci. J. 70 (03), 531–542 (2014).

Huo, W. et al. Effect of muscle fiber characteristics on meat quality in fast- and slow-growing ducks. Poult Sci. 100(8), 101264 (2021).

Vashisth, V., Nigam, K. D. P. & Kumar, V. Nanoparticle de-agglomeration in viscous fluids using different high shear mixer geometries[J]. Chem. Eng. Sci. 248, 117132 (2022).

Machado, A. A., Anusha, Y. G. & Lavanya, M. Adsorption of oil from water using sugarcane bagasse: an analysis using response surface methodology[J]. Monatshefte Für Chemie - Chem. Monthly. 156 (6), 617–630 (2025).

Jérme Morchain, Fox, R. O. et al. The Closure Issue Related To liquid-cell Mass Transfer and Substrate Uptake Dynamics in Biological systems[J] (Biotechnology and Bioengineering, 2021).

Chemat, F. et al. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications540–560 (Ultrasonics Sonochemistry, 2017).

Tian, Y., Xu, Z., Zheng, B. & Lo, Y. M. Optimization of ultrasonic-assisted extraction of pomegranate Peel oil using response surface methodology. Ultrason. Sonochem. *20* (1), 202–208 (2013).

Li, Y., Fabiano-Tixier, A. S. & Chemat, F. Solvent-free microwave extraction of bioactive compounds provides a tool for green analytical chemistry. TRAC Trends Anal. Chem. 47, 1–11 (2013).

Wang, L. & Weller, C. L. Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 17 (6), 300–312 (2018).

Pingret, D., Fabiano-Tixier, A. S. & Chemat, F. Degradation during application of ultrasound in food processing: A review. Food Control. *31* (2), 593–606 (2013).

Rodríguez-Escales, P. et al. Does enhanced mixing improve groundwater quality Evaluating the impact of injection-extraction engineering on redox conditions, contaminants of emerging concern, and antibiotic resistance genes. EGU General Assembly 2025. (2025).

Anonymous Compound Antioxidant on Goose Oil (Zhaodanci Dictionary, 2025).

Cheng, S., Zhang, T., Li, Y., Wang, X. & Song, Y. Use of low-field-NMR and MRI to characterize water mobility and distribution in Pacific oyster (Crassostrea gigas) during drying process. Drying Technology. (2017).

Tan, S. L., Suhaimy, S. H. M., Samad, N. A. A. Evaluation of fresh palm oil adulteration with recycled cooking oil u sing GC-MS and ATR-FTIR spectroscopy: A review [J]. Czech Journal of Food Sciences 40 (1), 1-14. (2022).

Alptekin, E. & Canakci, M. Optimization of pretreatment reaction for Methyl ester production from chicken fat[J]. Fuel 89 (12), 4035–4039 (2010).

Pop, F., & Mihalescu, L. Effects of α-tocopherol and citric acid on the oxidative stability of alimentary poultry fats during storage at low temperatures[J]. International Journal of Food Properties, 20 (5), 1085-1096. (2016).

Zhang, H. & Liu, S. Ultrasonic assisted extraction of Jatropha seed oil and analysis of oil component by HPLC[J]. Asian Journal of Chemistry 26 (13), 3920. (2014).

Saffar Taluri, S., Jafari, S. M. & Bahrami, A. Evaluation of changes in the quality of extracted oil from olive fruits stored under different temperatures and time intervals. Sci. Rep. 9(1), 19688 (2019).

Wang, R., Zhang, L., Li, Y. & Chen, H. Microwave-Assisted extraction of Goose fat: A kinetic and comparative study. Innovative Food Sci. Emerg. Technol. 72, 102567 (2021).

Xu, Y. et al. Physicochemical, functional, thermal and structural properties of isolated Kabuli chickpea proteins as affected by processing approaches[J]. Int. J. Food Sci. Tech. 52(5) (2017).

Fadavi, G. et al. Composition and physicochemical properties of Zedo gum exudates from amygdalus scoparia[J]. Carbohydr. Polym. 101, 1074–1080 (2014).

Ma, X. et al. Monitoring Lipid Oxidation in Edible Oils by FTIR Spectroscopy: A Review162–175 (Trends in Food Science & Technology, 2023).

Chen, X. & Li, Y. FTIR combined with chemometrics for authentication of goose oil. Food Chemistry, 305, 123456. (2020).

Magdalena, M. et al. Oxidative Stab. Sel. Edible Oils[J] Molecules, 23(7):1746 (2018).

Zhang, Y., Wang, L. & Li, X. Fatty acid composition of Goose oil and its potential health benefits. J. Agric. Food Chem. 66 (15), 3925–3933 (2018).

Author information

Authors and Affiliations

Contributions

“Junli Ning, Yan Jiang and Mengqing Xiang conceived the project and wrote the manuscript; Mengqing Xiang andXinyue Li conducted experiments; Junli Ning and Mengqing Xiang analyzed data; Qi Tang , Yan Jiang and Junli Ning provided critical revisions.“The experimental process increased the expansion of the experiment, verification experiments, while the expert’s response to the statement corrections are responsible for Xueli Li.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ning, J., Xiang, M., Li, X. et al. Optimisation of Goose oil extraction process by response surface methodology. Sci Rep 15, 27404 (2025). https://doi.org/10.1038/s41598-025-12616-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-12616-0