Abstract

During shield tunnelling, vertical ground displacement is significantly influenced by deviations in both jacking force and cutterhead torque. This study investigates the effects of deviations in these parameters on ground displacement via numerical simulations. On the basis of measured data from the Zhubai-Longgang Sewage Connecting Pipeline Project in Shanghai, a parametric analysis was conducted with ABAQUS software to simulate the effects of deviations in jacking force and cutterhead torque on vertical ground displacement. The results indicate that a positive deviation in jacking force increases the arch ratio (R) ahead of the shield cutterhead, leading to greater ground heave. Additionally, the positive area of the arch ratio contracts towards the tunnel’s central axis with increasing cutterhead torque deviation, further increasing ground heave. The study also revealed that cutterhead torque deviation has a more pronounced effect on ground heave than does jacking force deviation. The maximum ground heave converges when the cutterhead torque deviation extends over an 8-ring distance, while this result occurs when jacking force deviation extends over a 1-ring distance. When the deviations in both jacking force and cutterhead torque are combined, the maximum ground heave is the linear superposition of the independent effects of each parameter. The relationship between the combined deviation distance and the maximum ground heave can be expressed with a power function.

Similar content being viewed by others

Introduction

Shield tunnelling can cause considerable disruption to urban underground spaces, potentially leading to safety hazards1,2. With increasing urbanization, stricter control over stratum deformation and construction safety has become essential. As a result, studies on stratum disruption control during shield construction are very important.

Research have focused largely on empirical formula predictions, model tests, analysis of measured data, and numerical simulations. In terms of empirical formulas, scholars such as Wei3 proposed a two-dimensional solution to predict soil deformation caused by shield tunnelling, whereas Fang et al.4 used a normal distribution function-based empirical method to estimate surface settlement troughs. Additionally, Wang et al.5 developed an analytical solution based on random medium theory for predicting surface settlement in sandy pebble layers. Moreover, Wang et al.6 proposed a new empirical formula of surface settlement curve, and the slice method is introduced into the calculation of settlement radius.

With respect to model testing, Liu et al.7 designed a novel apparatus to study grouting consolidation mechanisms, while Di et al.8 used a model to simulate tunnel excavation and analysed the effects of tunnel depth?diameter ratios on surface settlement in sandy pebble strata. Similarly, Zhang et al.9 investigated changes in stress around tunnels with a micro shield tunnelling test platform and analysed the influence of pile groups and overloading on surface settlement.

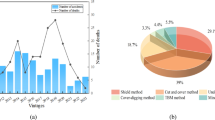

Numerical simulations play essential roles in studies on the control of shield tunnelling-induced ground disturbances. Many scholars have conducted parametric analyses of shield tunnelling. Zhang et al.10 used finite difference methods to study the impact of grouting on surface settlement during the construction of the Honglang-Xingdong section of Shenzhen Metro Line 5. Their findings showed that the grouting volume and pressure could effectively control surface settlement. Xie et al.11 used three-dimensional finite difference methods and measured data from the Yingbin Road tunnel in Shanghai to study the factors that affect surface settlement. Their study emphasized the importance of the grouting pressure. Zheng et al.12 conducted parametric analyses of the friction between the shield machine and the surrounding soil, evaluating its impact on surface settlement and soil stress. Cheng et al.13 studied the multi-parameter response of the lining force of the existing tunnel to the adjacent shield construction, and analyzed the stress changes of the surrounding soil. Zhou et al.14 used numerical simulation method to compare the mechanical response of surrounding rock and supporting structure under different methods, and put forward suggestions for the adoption of methods.

The control of shield jacking force and cutterhead torque is very important in practical engineering. In specific cases, shield tunnelling has led to surface instability. For example, excessive jacking force during the construction of Guangzhou Metro Line 315 caused cutterhead torque to act continuously on the soil, resulting in surface collapse. Moreover, on Shenzhen Metro Line 1416, reduced cutterhead torque, which was used to overcome friction resistance, ultimately led to shield jamming. Many scholars have carried out prediction, optimization analysis and numerical simulation analysis on jacking force and cutterhead torque. Bai et al.17 proposed an effective method to monitor the development of cutterhead blockage based on machine learning. Shen et al.18 established a model of cutterhead-soil interaction to predict tunnel thrust and cutterhead torque, and the prediction results were fitted to the experimental monitoring values. He et al.19 used numerical simulation to optimize the jacking force of the tunnel face when the shield passes through the upper soft and lower hard strata to reduce the stress of the lining segment. Based on the Fuzhou subway tunnel project, Qin et al.20 carried out parametric analysis of jacking force, cutterhead torque and other parameters, and analyzed the surface settlement response.

Because the jacking force and the cutterhead torque are important for the tunneling efficiency, reasonable parameters can effectively cut the front soil and effectively excavate the tunnel. In the actual construction, the parameters often need to be adjusted. At the same time, the jacking force and the cutterhead torque are positively correlated with the tunneling rate21,22. Therefore, this paper focuses on the response of the vertical displacement of the surface when the jacking force and the cutterhead torque deviate during the construction process, so as to achieve the purpose of improving the tunneling rate under the premise of ensuring the construction safety.

This study combines numerical simulations with field data from the Shanghai Zhuyuan-Bailonggang sewage connecting pipeline project to explore the effects of deviations in jacking force and cutterhead torque on surface displacement during shield tunnelling. The aim is to determine the optimal combination of parameters for effectively controlling surface deformation.

Engineering background

This study is based on the Zhuyuan-Bailonggang sewage connecting pipeline project in Pudong, Shanghai, and focuses on the section between Shaft No. 13 and Shaft No. 14, the longitudinal profile of engineering geology is shown in Fig. 1a. An earth pressure balance (EPB) shield machine was used for tunnel construction. The diameter of the shield machine is 4.8 meters, with the outer diameter of the tunnel segments being 4.6 meters and the segment thickness being 0.3 meters. Because the physical and mechanical parameters of borehole Z74 are relatively complete, it can support the modeling of subsequent numerical simulation. Therefore, this position is selected as the research soil layer, and its thickness and physical and mechanical parameters are shown in Fig. 1b. The parameters are obtained by experiment and calculation, such as :

Where M is the stress ratio; \(\phi '\) is the effective internal friction angle of the soil, which is derived from the soil engineering test report.

Shield tunneling parameters

The variations in the jacking force and cutterhead torque of the shield machine with segment mileage are shown in Fig. 2. During the initial stages of tunnelling—prior to reaching approximately 100 metres of segment mileage—there are significant fluctuations in both the jacking force and cutterhead torque as the shield machine penetrates the soil. Beyond 100 meters, these parameters stabilize as they are adjusted in real time on the basis of surface settlement monitoring. Notably, between 170 and 320 meters, the jacking force fluctuations reach up to 1500 kN, after which the jacking force stabilizes between 4100 and 4300 kN. The cutterhead torque fluctuates significantly from 100 kN·m to 350 kN·m as the machine adapts to changes in the soil layers.

Surface monitoring and settlement analysis

The surface settlement monitoring points were set up along the tunnel’s axis, and the results are shown in Fig. 3. Figure 3a shows the changes in the longitudinal settlement curve over time. Data were collected every 10 days, starting on September 13, with a total of 11 observations. The maximum settlement at each monitoring point slightly rebounded after reaching peak levels, likely because of soil unloading following shield passage. Additionally, surface heave was observed up to 300 meters from the start of the tunnel, after which no further heave occurred.

Figure 3b shows the surface response near Shaft No. 14, where slight heave was observed as the shield approached the receiving well. In contrast, the settlement rates near Shaft No. 13 exhibited more uniform growth. Cross-sectional monitoring was performed at two points, DB434 and DB476, with the results displayed in Fig. 4. The surface settlement trough exhibits a ‘V’ shape, but it is asymmetrical due to variations in cutterhead rotation and the presence of surrounding buildings, which is consistent with the findings of Xie et al.11 on settlement troughs in Shanghai soil.

Prediction of transverse settlement trough

Peck’s formula

In 1969, Peck23 proposed a predictive formula for settlement troughs generated by tunnel excavation, assuming that soil deformation occurs under undrained conditions (as shown in the Fig. 5). He posited that the volume of actual soil loss corresponds to the volume of the settlement trough, which approximates a normal distribution. The equation for the settlement trough curvature is as follows:

Where S(x) is the surface settlement at a horizontal distance x from the tunnel centerline; \(S_{\text {max}}\) is the maximum settlement at the tunnel centerline; i is the width of the settlement trough, defined as the distance from the centerline to the inflection point; D is the tunnel diameter; and \(V_l\) represents the rate of ground loss.

Peck’s formula was later refined by O’Reilly and New24, who reported a linear relationship between the settlement trough width (i) and tunnel depth (\(Z_0\)). The expression is as follows:

The coefficient K is determined by the physical and mechanical properties of the stratum where the tunnel is located, and the stratum loss rate \(V_l\) needs to be obtained according to the local construction experience, such as: Ong et al.25 proposed the selection of parameters based on the previous construction experience of Singapore and the physical and mechanical parameters of the stratum when predicting the settlement trough of tunnel construction in Singapore. In this study, due to the rich experience of shield tunnel construction in Shanghai and the relatively uniform engineering geological conditions in the city, based on the soil particle size distribution curve (Fig. 6) and combined with the existing construction data26 and the research of Zhou et al.27, taking into account the most unfavorable conditions, the recommended value of the settlement trough width coefficient \(K = 0.5\), and the ground loss rate \(V_l = 6.9\%\).

Linear regression

On the basis of measured settlement data, the settlement curve for the surface can be approximated by a normal distribution. Using Peck’s formula, a linear regression analysis is performed to establish a relationship between the measured surface settlement data and the predicted values. Taking the natural logarithm of both sides of the equation yields:

Linear regression is then performed with \(\ln S(x)\) and \(-x^2/2\) as the variables. The regression equations for the surface settlement curve are as follows:

The regression constants a and b are determined by the equations:

The regression line is then expressed as:

Three eligible cross-sections were selected within the scope of the project site, namely DB192, DB341 and DB348, and were named as section 1, section 2 and section 3, respectively. There is a difference between the measured data and the formula fitting in Fig. 8. This is because the empirical value is used in the selection of the formula parameters. However, the thickness and strength of the soil in the actual engineering site are not uniform (As shown in Fig. 1a ), and the parameters are deviated. The measured data of the three sections are compared with the regression curve after regression and plotted in Fig. 7. The regression curve fits well with the measured data, indicating that the linear conversion is reasonable.

Peck formula modification

As shown in the Fig. 8, the original Peck formula may not accurately predict the surface settlement for all projects, necessitating modifications. A correction factor is applied to the maximum settlement value \(S_{\text {max}}\) and the width of the settlement trough i via the following modified equation:

where \(\alpha\) is the correction coefficient for the maximum settlement value, and \(\beta\) is the correction coefficient for the settlement trough width. Taking the logarithm of both sides of the equation yields:

From the linear regression results, the expressions for \(\alpha\) and \(\beta\) are as follows:

The correction coefficients obtained for the three monitoring sections are presented in Table 1.

The values indicate that the actual maximum settlement is smaller and that the width of the settlement trough is larger than those predicted by the original Peck formula. Since these coefficients were calculated on the basis of measured data, they are specific to this project and can provide a reference for future shield tunnelling projects under similar soil conditions. The revised Peck formulation effectively predicts the geometric characteristics of the settlement trough, thereby providing a preliminary design basis for shield tunneling parameters under analogous construction conditions. However, achieving fine control of shield tunneling parameters necessitates highly timely parameter adjustments. A significant limitation of the revised Peck formulation is its difficulty in quantifying the potential impact of parameter deviations. Consequently, future work will employ numerical simulation methods to specifically investigate the response of vertical displacement to deviations in key parameters. This approach aims to proactively predict vertical displacement responses arising from potential parameter deviations during construction.

Numerical modelling

Model parameters

A three-dimensional numerical model of shield tunnelling was created with ABAQUS, which incorporates fluid-solid coupling. Diagrammatic drawing of finite element mode is shown in Fig. 9. To minimize boundary effects28, the model dimensions were set as follows: height = 32 m, length = 75 m, and width = 50 m. The jacking force is applied to the node at the tail of the shield machine head, and the cutterhead torque is applied to the soil surface in front of the shield cutterhead. The soil was modelled via the modified Cam-clay constitutive relationship, with values derived from the project’s survey report, as presented in Fig. 1.

The contact between the shield casing and the surrounding soil was modelled using a friction coefficient of 0.2. The number of rings per day is recorded during the construction, and the average tunneling speed is about 5.5 rings/day (5.7 mm/min). Therefore, this speed is selected as the tunneling speed in the numerical simulation. The jacking force and cutterhead torque of shield tunneling are averaged within the fluctuation range of the measured monitoring data. The average value is the average value of the parameters in the whole construction interval from No.13 shaft to No.14 shaft, and the parameters are output once for each construction ring. The working face pressure was set to 180 kPa, which is consistent with the soil chamber pressure during construction, and the grouting pressure was set to 300 kPa. The shield tail gap of the shield machine is 100 mm, which provides a basis for setting the thickness of the grouting body.

Model verification

The results of the numerical simulation of surface settlement were compared with the measured data in the longitudinal and transverse sections, as shown in Fig. 10. The shapes of the settlement curves from the simulation align well with the measured results, although the final measured settlement was slightly larger than the simulated values. First of all, because the thickness and strength of each soil layer in the numerical modeling are constant, the thickness and strength of the actual soil layer are changed. As shown in Fig. 1a, the thickness of the soil layers ③, ②\(_{3-2}\), ①\(_{1-1}\) and ①\(_{1-2}\) above the tunnel are obviously changed, and there is interlayer soil ②\(_{2-1}\). Therefore, it is of great significance to accurately select the parameters in the numerical simulation process25. This paper does not consider the synchronous adjustment of formation strength when the parameters change. We will take this influencing factor into account in the follow-up study for more detailed research. Secondly, because the tunneling parameters in the numerical simulation of Fig.10 are averaged, the parameters will deviate in the actual construction, so the difference mainly comes from the deviation of the parameters. The influence of the deviation of the parameters on the vertical displacement of the surface is discussed later. Furthermore, to model more conservative scenarios, the numerical simulation assumed a water level at the ground surface, whereas the actual level was situated 4 5 meters below. Consequently, the simulated heave values are underestimated. Additionally, similar to the study of Wang et al.29, the construction surrounding environment affects the fitting of the measured data and the numerical simulation results. In this study, the construction site is near the automobile wharf, and its influence on the vertical displacement of the surface caused by the construction is underestimated.

Nevertheless, this study primarily focuses on analyzing trends in strata response under parameter deviations. Therefore, the acceptable discrepancies between numerical predictions and field measurements do not significantly impact the main research conclusions regarding these trends. Overall, the model parameters derived from the project’s measured data were validated by the simulation results, demonstrating the feasibility of the use of the numerical method that was applied in this study.

Study on parameter deviation

Independent parameter multiring deviation

Jacking force multiring deviation Multiring parameter deviation refers to the occurrence of deviations in the shield tunnelling parameter over a continuous sequence of rings. When the cutterhead reaches the DB434 monitoring cross-section, the positive deviation of jacking force is set to 10%.At this time, the cutterhead torque remains unchanged at its average value (420kN\(\cdot\)m). Simulations were conducted for 1, 2, 4, 6, and 8-ring deviations. The deviation defined in this paper is based on the fluctuation of the average value of the tunneling parameters in the construction shown in Fig. 2. For example, the jacking force has a positive deviation of 10%, that is, the jacking force increases by 10% on the basis of the average value, and the cutterhead torque is the same. In addition, except for the construction section with large jacking force fluctuation, the fluctuation range of jacking force in other construction sections is within 10% of the average jacking force (4225kN). Therefore, it is more practical to study the deviation value based on the average jacking force of 10%. In order to ensure a single variable, the deviation of the cutterhead torque is also set to 10% based on the average (420kN\(\cdot\)m).

When the shield machine reached the DB434 section, the vertical displacement of the surface above the tunnel was recorded, as shown in Fig. 11. The data show that a deviation in the jacking force over just one ring significantly increases surface heave, whereas further increasing the number of rings has a relatively smaller effect on heave variation. The maximum surface heave occurs approximately 10.5 meters (7 rings) in front of the cutterhead. The transition point between settlement and heave is located approximately 3 meters (2 rings) in front of the cutterhead, and its position is independent of the jacking force deviation.

Figure 12a shows the surface settlement trough when the shield machine reaches the DB434 monitoring cross-section. The results indicate that the maximum surface settlement increases as the number of rings with jacking force deviations increases. While the effect of a single-ring deviation is minimal, settlement increases significantly when 2 rings and 4 rings deviations occur, accounting for 4.7% and 7.8% of the total settlement, respectively. The settlement converges when the deviation extends over 8 rings. Figure 12b further shows that surface heave in front of the cutterhead converges after a 1 ring deviation.

In summary, multiring deviations in the shield jacking force lead to increased surface settlement directly above the cutterhead. When the number of deviation rings exceeds 8, this settlement growth converges. The surface heave in front of the cutterhead stabilizes after just 1 ring deviation. To further understand this phenomenon, we analyse it from the perspective of vertical stress soil arching.

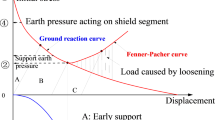

Shield tunnelling disrupts the surrounding soil, redistributing stress and forming a temporary “stress arch” that the stabilizes vertical displacement above it. To quantify the soil arch, Lee et al.30 introduced the concept of the “arch ratio” , which is defined as:

where R is the arch ratio, \(\sigma _z\) is the vertical stress in the soil, and \(\Delta \sigma _z\) is the change in vertical stress. In Fig. 13a , positive R values indicate areas where the vertical stress increases, forming the arch foot, whereas negative values represent areas where the vertical stress decreases. In Fig. 13b , we observe the changes in vertical stress when the deviation in jacking force spans 8 rings with a 15% increase. Owing to the influence of jacking force on the soil contact around the shield shell, the area with values with a positive R value above the cutterhead shrinks toward the shield machine, while area with the negative R area expands outwards, increasing settlement above the shield. Moreover, the vertical stress in front of the cutterhead increases due to the shield jacking force, further exacerbating the degree of soil heave.

Cutterhead torque multiring deviation Similarly, deviations in the cutterhead torque affect the vertical displacement. At this time, the jacking force remains unchanged at its average value (4225kN). Figure 14 shows the surface heave behaviour in the vertical section when multiring deviations in the cutterhead torque occur. As with the jacking force deviation, the torque deviation significantly increases surface heave in front of the cutterhead. However, unlike the jacking force, surface heave increases more substantially with the number of deviation rings, converging at 8 rings.

Figure 15a shows that when the cutterhead torque deviation is limited to 1 ring, the surface settlement curve coincides with the curve for no deviation. As the number of deviation rings increases beyond 2 rings, surface heave intensifies. Maximum settlement occurs when the number of deviation rings reaches 4, after which the settlement curve stabilizes. For surface heave outside the central axis (±7 meters) , heave increases with the number of torque deviation rings, converging at 8 rings. Figure 15b shows the same trend for surface heave 7 rings in front of the cutterhead.

In conclusion, deviations in cutterhead torque primarily suppress surface settlement and exacerbate surface heave. Maximum settlement suppression occurs when the deviation spans 4 rings. For surface heave, the effect increases with the number of deviation rings and converges at 8 rings. Figure 13c shows that when the torque deviation spans 8 rings with a 15% increase, the area with positive R values in front of the cutterhead contracts towards the tunnel’s central axis, causing the soil in front of the shield machine to rise.

Combined parameter multiring deviation

When both the shield jacking force and cutterhead torque increase by 10%, the resulting soil displacement due to multiring parameter deviation can be observed, as shown in Figs. 16 and 17. The location of the maximum heave ahead of the cutterhead remains consistent with that observed when the parameters vary independently, and the settlement behaviour caused by deviations in the number of parameter combination rings follows the same pattern as when only deviation in cutterhead torque occurs. In Fig. 17a , at the point of maximum surface settlement directly above the shield machine’s cutterhead, the settlement is smallest with a 2-ring deviation and largest with a 6-ring deviation. Outside the range of -7 m to 7 m from the central axis, the heave pattern mirrors the surface heave behaviour observed for the 7-ring deviation in front of the cutterhead, as shown in Fig. 17b . This behaviour is consistent with the influence of the cutterhead torque, although the magnitude of the heave shows more variation.

The vertical stress arch that occurs in the surrounding soil when the jacking force and cutterhead torque exhibit an 8-ring, 15% positive deviation simultaneously is shown in Fig. 13d . The vertical stress changes in the soil are essentially a linear combination of the stress variations observed when each parameter deviates independently. Given that shield tunnelling is a continuous process, controlling the tunnelling length during parameter deviation more precisely and in real time is crucial. To this end, the relationship between the deviation length and surface deformation under the combined effect of deviations in both jacking force and cutterhead torque is further investigated.

Figure 18 presents the surface heave response corresponding to different numbers of rings with combined parameter deviations, and a power function is used to model the relationship between surface heave and the magnitude of the parameter deviation. When the parameter deviation is 5%, 10%, and 15%, the coefficient of determination (R\(^2\)) exceeds 0.95, indicating a good fit. From the fitting curve, it is evident that as the distance of the combined thrust and cutterhead torque deviation increases, the surface heave gradually decreases, eventually converging when the deviation reaches approximately 12 m. Therefore, this set of fitting curves enables more precise, real-time control of parameter deviations during shield machine construction, allowing adjustments beyond simply counting the number of deviation rings.

Discussion

On the basis of the numerical simulations, deviations in cutterhead torque have a more pronounced effect on surface heave than do deviations in jacking force deviations. To better quantify the impact of these deviations, the incremental percentage of maximum heave (\(\Delta S\)) is defined as the heave increment due to a 10% positive deviation, divided by the heave value with no parameter deviation. Let S represent the maximum ground heave caused by a 10% positive deviation. Figure 19 shows the response of ground heave to different ring deviations. The combined parameter deviation response is approximately a linear superposition of the independent deviations. As the number of rings increases from 0 to 2, the ground heave response increases sharply. Beyond 2 rings, the increase in ground heave slows, converging at 8 rings, after which the deformation stabilizes. It should be noted that there is no large deformation such as continuous failure in the range of parameter deviation in this study. Therefore, under the premise of small parameter deviation (The deviation is within 10%), the linear superposition of surface uplift response caused by the combined parameter deviation is caused by the independent action of each parameter of the maximum ground heave.

In the existing research, most scholars only analyze the independent deviation of the parameters, and the influence range of the parameter deviation is not discussed in depth. In order to control the tunneling parameters of shield construction more precisely, this paper studies the combined effect of independent deviation of parameters and parameter deviation, analyzes the vertical stress level of strata, and discusses the influence range of parameter deviation. The practical engineering significance of this study includes : (1) When uncertain surface vertical displacement occurs during construction, according to the variation law of surface vertical displacement and the characteristics of field surface response when each parameter deviates, the causes of surface vertical displacement change can be analyzed and the parameters can be adjusted quickly to ensure the safety of construction; (2) When shield construction is carried out near the site with strict control requirements for the range of surface vertical displacement, such as dense urban buildings and key cultural relics protection areas, the parameters can be finely adjusted in advance according to the convergence distance of the vertical displacement of the surface when the parameters deviate, so as to ensure the safety of the key protection areas.

Conclusion

Based on the Zhuyuan-Bailonggang sewage connecting pipeline project in Zhuyuan, Shanghai, this study utilized ABAQUS finite element simulations to analyse soil displacement above and in front of the cutterhead in response to deviations in the jacking force and cutterhead torque during shield tunneling. The following conclusions were drawn:

-

1.

The surface heave due to deviations in the jacking force and cutterhead torque is most pronounced at approximately 10.5 meters (7 rings) in front of the cutterhead. Positive deviations in the jacking force cause the area with positive R value around the shield to shrink and the area with negative R values to expand, increasing settlement above the shield. Conversely, positive deviations in the cutterhead torque decrease the area with positive R values in front of the cutterhead towards the tunnel’s central axis, pushing the soil forwards and causing surface heave.

-

2.

When only jacking force deviations occur, surface heave converges when the deviation distance reaches 1.5 meters (1 ring).However, cutterhead torque deviations have a more significant effect on surface heave, which converges at a deviation distance of 12 meters (8 rings). Cutterhead torque deviations are more sensitive to deviation distance than are jacking force deviations.

-

3.

The maximum surface heave caused by deviations in both jacking force and cutterhead torque is approximately the linear superposition of the heave caused by each parameter independently. The relationship between the deviation distance and maximum surface heave is consistent with the cutterhead torque alone and can be fitted to a power function. This provides practical guidance for real-time control of deviations in jacking force and cutterhead torque to ensure construction safety.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Li, X. Y., Yan, J. Y. & Sun, Y. P. Reasons and countermeasures of accidents happened during the shield tunnel construction. Chin. J. Undergr. Space Eng. 1, 968–971 (2005).

Zhu, Y. M., Zhou, J. J., Zhang, B., Wang, H. C. & Huang, M. Q. Statistical analysis of major tunnel construction accidents in china from 2010 to 2020. Tunn. Undergr. Space Technol. 124, 104460 (2022).

Wei, G. Prediction of ground deformation induced by shield tunneling construction. Chin. J. Rock Mech. Eng. 28, 418–424 (2009).

Fang, Y. S., Wu, C. T., Chen, S. F. & Liu, C. An estimation of subsurface settlement due to shield tunneling. Tunn. Undergr. Space Technol. 44, 121–129 (2014).

Wang, F., Du, X. L. & Li, P. F. Predictions of ground surface settlement for shield tunnels in sandy cobble stratum based on stochastic medium theory and empirical formulas. Undergr. Space 11, 189–203 (2023).

Wang, J., Zhou, P., Song, Z., Li, S. & Zhang, Q. A new calculation method for tunneling-caused stratum settlement. KSCE J. Civ. Eng. 26, 2624–2640 (2022).

Liu, W., Liang, J. X. & Xu, T. Tunnelling-induced ground deformation subjected to the behavior of tail grouting materials. Tunn. Undergr. Space Technol. 140, 105253 (2023).

Di, Q. G., Li, P. F., Zhang, M. J. & Cui, X. P. Investigation of progressive settlement of sandy cobble strata for shield tunnels with different burial depths. Eng. Fail. Anal. 141, 106708 (2022).

Zhang, Z. X., Li, X. C. & Li, J. Y. Stability investigation during shield tunneling in soft soil by model test. J. Civil Environ. Eng. 46, 41–51 (2024).

Zhang, H., Chen, S. & Deng, X. Analysis of the influence of shield driving parameters on ground settlements. Modern Tunnel Technol. 47, 48–53 (2010).

Xie, X. Y., Yang, Y. B. & Ji, M. Analysis of ground surface settlement induced by the construction of a large-diameter shield-driven tunnel in shanghai, china. Tunn. Undergr. Space Technol. 51, 120–132 (2016).

Zheng, G., Lu, P., Jiang, X. T., Cui, Y. J. & Gao, C. Influence of shield shell friction on surrounding soil mass properties. Modern Tunnel Technol. 54, 65–72 (2017).

Cheng, W.-C., Li, G., Ong, D. E., Chen, S.-L. & Ni, J. C. Modelling liner forces response to very close-proximity tunnelling in soft alluvial deposits. Tunn. Undergr. Space Technol. 103, 103455 (2020).

Zhou, P. Y., Wang, J. B., Song, Z. P., Cao, Z. L. & Pei, Z. M. Construction method optimization for transfer section between cross passage and main tunnel of metro station. Front. Earth Sci. 10, 770888 (2022).

Qin, J. S. Analysis of destabilization accident of excavation surface in shield tunnel construction. Zhejiang Construction 59–61 (2005).

Song, T. T., Ma, G. Y., Yao, C. F., Wang, S. M. & Kang, X. Y. Analysis on the cause and treatment methods for dual-mode shield jamming in rock stratum of shenzhen metro line. Railway Standard Design 67, 131–139 (2023).

Bai, X.-D., Cheng, W.-C., Ong, D. E. & Li, G. Evaluation of geological conditions and clogging of tunneling using machine learning. Geomech. Eng. 25, 59–73 (2021).

Shen, X. et al. Model test on cutterhead-soil interaction during shield tunneling and its theoretical model. Undergr. Space 20, 46–68 (2025).

He, X. F., Gao, F., Shen, X. Z. & Wang, F. Optimization study on jacking force of the tunnel face when shield tunnel crossing the upper-soft and lower-hard stratum. Chin. J. Undergr. Space Eng. 14, 1603–1610 (2018).

Qin, B., Zhang, G. & Zhang, W. Shield excavation analysis: Ground settlement & mechanical responses in complex strata. Structural Durability & Health Monitoring (SDHM)18 (2024).

Samadi, H. & Hassanpour, J. Epb-tbm cutterhead torque and thrust modelling in rock tunnels through an analytical method and tsfs model. Heliyon10 (2024).

Cao, S., Cui, J., Fang, Y. & Deng, R. Performance of slurry tbm tunnelling in sandy cobble ground—a case study in lanzhou. KSCE J. Civ. Eng. 23, 3207–3217 (2019).

Peck, B. Deep excavation and tunnelling in soft ground, state of the art volume. In 7th ICSMFE, vol. 4, 225–290 (1969).

O’reilly, M. P. & New, B. Settlements above tunnels in the united kingdom-their magnitude and prediction. In Proc. Tunnelling’82, Institution of Mining and Metallurgy. London, 173–181 (1982).

Ong, D. E. L. et al. Sustainable Pipe Jacking Technology in the Urban Environment (Springer, 2022).

Han, X., Li, N. & Standing, J. R. An adaptability study of Gaussian equation applied to predicting ground settlements induced by tunneling in china. Yantu Lixue (Rock Soil Mech.) 28, 23–28 (2007).

Zhou, P. Y., Song, Z. P., Wang, J. B., Zhang, Y. W. & Tian, X. X. Prediction method for ground surface settlement induced by bias tunnel based on stochastic medium theory. Chin. J. Geotechn. Eng. 47, 589–598 (2025).

Lambrughi, A., Rodríguez, L. M. & Castellanza, R. Development and validation of a 3d numerical model for tbm-epb mechanised excavations. Comput. Geotech. 40, 97–113 (2012).

Wang, X.-T., von Schmettow, T., Chen, X.-S. & Xia, C.-Q. Prediction of ground settlements induced by twin shield tunnelling in rock and soil-a case study. Undergr. Space 7, 623–635 (2022).

Lee, C.-J., Wu, B., Chen, H. & Chiang, K. Tunnel stability and arching effects during tunneling in soft clayey soil. Tunn. Undergr. Space Technol. 21, 119–132 (2006).

Acknowledgements

The authors gratefully acknowledge the financial support received from the National Natural Science Foundation of China (51868017) for the completion of this work.

Author information

Authors and Affiliations

Contributions

L.P.: conceptualization, data collection, numerical modeling, editing, writing. P.L.: conceptualization, data collection, editing, writing. Q.D.: editing, writing. R.H: editing, writing. T.S.: editing, writing. S.Y.: editing, writing D.N.: data collection. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Peng, L., Huang, R., Seiki, T. et al. Study of the influence of deviations in both jacking force and cutterhead torque during shield tunnelling in soft ground. Sci Rep 15, 26947 (2025). https://doi.org/10.1038/s41598-025-12637-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-12637-9