Abstract

Prefabricated construction is a key strategy for achieving a low-carbon transformation in the construction sector. In the context of national policies and standards aimed at promoting an increase in the prefabrication rate, recent investigations have revealed that the environmental benefits of prefabricated construction cannot be consistently realized, and the lack of data on the development of prefabricated construction has resulted in limited related research. To address this issue, this paper tackles the issue of inadequate data on indicators pertaining to the growth of prefabricated construction by utilizing crawler technology. It employs the super-efficiency slack-based measure (SBM) model to assess the comprehensive energy-saving and emission-reduction efficiency of China’s construction industry. Using the Technology-Organization-Environment (TOE) framework and threshold regression models construct an impact mechanism model to study the main driving factors of energy conservation and emission reduction (ECER) in the construction industry, with a particular focus on the development of prefabricated construction and its associated threshold effects. The results indicate that: (1) China’s construction industry’s ECER efficiency shows a fluctuating growth trend, with the national average efficiency ranging between 0.6 and 0.8, and significant regional disparities. (2) At this stage, the prefabrication rate, policy effectiveness, and the number of patent applications are key factors affecting the ECER efficiency of the construction industry, with the prefabrication rate and policy effectiveness exhibiting a double-threshold effect. (3) The optimum ECER outcomes are obtained by keeping the prefabrication rate between 50% and 60%, and the effectiveness of policies in fostering these goals is trending downward. Therefore, controlling the rate at which new buildings are prefabricated, comprehending the efficacy of policy standards, and raising the technological level of prefabricated construction are all practical ways to increase the construction industry’s efficiency in reducing emissions and conserving energy. This study offers a theoretical foundation and decision-making basis for relevant authorities in formulating measures and quantifying indicators, contributing to the development of prefabricated construction and enhancing ECER efficiency in the construction industry.

Similar content being viewed by others

Introduction

Construction has traditionally been a high-carbon-emitting industry in China. To help the country meet its carbon peak target by 2030, China must transform its construction industry’s production processes and reduce carbon emissions in the infrastructure sector1.

In recent years, prefabricated construction, which is characterized by standardization, industrialization, and large-scale production methods, has emerged as a transformative paradigm. It is helping China’s construction industry transition towards green and low-carbon development first2. Numerous academics have noted that the growth of prefabricated construction is a crucial step in advancing the construction industry’s transition to a low-carbon economy and achieving objectives for ECER. The construction methods of prefabricated buildings provide significant advantages in terms of material savings, energy conservation, and water conservation3.

The 14th Five-Year Plan proposes to vigorously develop prefabricated buildings, establish standardized design and production systems, and enhance their comprehensive benefits. Driven by the formulation of relevant national policies and standards, the technical standard system of prefabricated buildings has been continuously improved, with production efficiency and research and development capability being steadily enhanced4. However, the positive environmental benefits of China’s prefabricated buildings do not play out stably5, and the increase in the assembly rate may also lead to negative environmental impacts6. Due to the lack of official statistics on prefabricated construction development data, existing studies mainly focus on exploring the ECER effects of individual prefabricated projects and the impact of micro-level factors on the ECER effects of prefabricated buildings. There is a lack of research explaining how prefabricated buildings affect the overall ECER effect of the construction industry, and the specific influence trends of factors such as assembly rates and policies remains unclear7. Therefore, it is essential to conduct a quantitative analysis of the impact of prefabricated building development on ECER in the construction sector, identify the main influencing factors and study the trend of their threshold effects, and elucidate the prefabricated building’s particular impact pathways.

This paper obtains data on the development of prefabricated construction through crawler technology. It explores the major factors influencing ECER in the construction industry and their mechanisms using cointegration analysis and threshold regression models.

The paper’s structure is set out as follows: A review of related literature makes up the second section. Section 3 describes the data and methodologies used in this paper. Section 4 offers the findings and discussion. Section 5 compiles the findings and provides policy recommendations.

Literature review

Environmental impact benefits of prefabricated buildings

It has been demonstrated that, in comparison to standard cast-in-place buildings, assembled buildings have some environmental advantages that can successfully encourage the growth of ECER techniques in this field. Teng et al.8 empirically analyzed the emission reduction effect of assembled buildings from the variables of building type and prefabrication level, and found that the assembled buildings can achieve an average of 15.6% of the total emission reduction. Sun et al.9 used the Honghui Park project in Shenyang to establish a carbon emission assessment system built with prefabricated assembly construction, and the results confirmed that adopting assembly construction methods can effectively reduce carbon emissions during the building fabrication stage. Most research on the environmental advantages of prefabricated buildings is based on one or more case studies, and complete life cycle environmental assessments are used to examine how assembled buildings provide ecological benefits. Jaillon et al.10 carried out empirical measurements on construction projects in Hong Kong and discovered that the utilization of prefabricated components can lead to a 52% reduction in construction waste compared to traditional construction methods. Aye et al.11 concluded that prefabricated steel structure systems gradually increase the reuse rate of materials, which can significantly reduce energy consumption and the amount of construction materials. Hong et al.12 used an input-output model to show that prefabricated concrete structures will have several times higher material consumption and carbon emissions compared to steel structures. Ji et al.13 demonstrated that prefabricated buildings have relatively low carbon emissions.

However, few studies have looked at the mechanism underlying the assembly building’s environmental benefits in relation to ECER generally. In summary, most research to date has supported the assembly building’s contribution to ECER from a macro viewpoint.

The impact of ECER effects in the construction industry

For the ECER influence mechanism and policy formulation in the construction industry, Li Ruyong14 used system dynamics simulation to examine the overall mechanism of influence of industrial investment structure, science and technology input ratio, energy consumption structure, per capita domestic energy consumption, and other factors under carbon peak conditions in his study. He Jing et al.15 conducted a comparative analysis of the main resource loads in the construction and operation process of the Chinese construction industry. They concluded that businesses should give equal consideration to energy saving and emission reduction during this process. At present, several researchers are conducting theoretical studies on the influencing factors of prefabricated buildings on the construction industry and carbon emissions, and the development of assembly construction16 is similarly affected by organizational, technological, environmental, and other factors. Existing research results show that policy regulations, technology level, and assembly rate have an impact on reducing the energy consumption of prefabricated buildings17. This paper adopts the TOE theoretical framework to put forward the hypothesis of the influence of prefabricated buildings on ECER efficiency from three dimensions: organization, technology, and environment.

The specific determination of the assembly rate in the assembly building project will also have a profound impact on the construction materials and energy resource consumption of the whole project. Li et al.6 calculated the carbon emissions of a prefabricated building case based on the BIM model, and pointed out that the prefabricated construction method could reduce the carbon emissions of the unit building area in this case by 1.87 kg CO2, and changing the prefabrication rate can reduce the physical carbon emissions of the building. Some scholars have pointed out that an increase in the assembly rate can promote the development of assembled buildings18. Although increasing the assembly rate from 0 to about 60% will increase the difficulty of project management and material input to a certain extent, the labor cost in the decorative part can be saved by 83.7%, the mechanical cost can be saved by 22.4%, and the cost of measures can be saved by 42.6%. At the same time, the overall construction period can be reduced by about 2 months, and the comprehensive benefits are remarkable5.

Nonlinear effects of assembly rate and the introduction of the threshold regression model

However, domestic research on the assembly rate is not uniform; some scholars have pointed out that rising assembly rates do not always translate into lower carbon emissions19. The rise in assembly rate in a certain range will significantly drive the incremental cost as well as the growth of resource and material consumption20. The impact of assembled buildings on ECER in the construction industry may cause a sudden structural change when the value of an influencing factor reaches a specific value, generating a threshold effect. In order to deeply analyze what kind of non-linear influence relationship exists between the two, the threshold regression model is regarded as one of the main research methods for this kind of problem by scholars, and related research has been widely distributed in the theoretical analysis of various fields. Wu Zhenhua21 tested that the local innovation level has a significant threshold effect on rural industrial structure optimization through the systematic GMM and panel threshold model, while the expenditure of regional research financial funds promotes the optimization of rural industrial structure under the dual threshold condition.

Therefore, this study introduces the threshold regression model into the research mechanism of the impact of assembly building on ECER in the construction industry, to explore the non-linear impact relationship between the two, and to help policymakers formulate scientific and reasonable development strategies.

Compared to the traditional efficiency evaluation models, the super-efficiency data envelopment analysis (DEA) model can compensate for the shortcomings of the conventional DEA method, which cannot identify the most effective unit or the most efficient decision-making unit. The results calculated by both are between 0 and 1. However, in practical applications, there are even situations where the efficiency values of multiple decision-making units are all 1. This not only makes it impossible to further rank the efficiency evaluation but also reduces the importance of the efficiency evaluation22. Since the SBM model can well solve the problem that multiple efficiency values of 1 cannot be sorted, the SBM model is gradually replacing the DEA model.

By incorporating key factors for the development of prefabricated buildings such as the assembly rate into the threshold regression model, this study, based on the existing literature, delves deeper into the influence of the assembly rate on policy effectiveness, making up for the current deficiency in empirical research in the field of prefabricated buildings and providing a reference for improving the current situation of energy conservation and emission reduction in the construction industry.

Methods and data

Research hypotheses

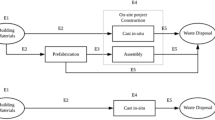

The theoretical framework of T-O-E (Technology-Organization-Environment) was proposed by Tornatzky and Fleischer in 1990. This model is characterized by its high level of generality, flexibility, and practicality, categorizing influencing factors into three groups: organization, technology, and environment. It serves as a comprehensive system analysis framework based on the context of technology application23. Organizational, technological, and environmental issues also have an impact on the development of prefabricated structures in the process of influencing the construction industry’s efficiency in reducing emissions and saving energy. Therefore, this section analyzes the factors influencing ECER from the three major dimensions of organization, technology, and environment, and proposes relevant research hypotheses. The model of the influencing factors and their pathways is shown in Fig. 1.

Environmental dimension

Environmental factors mainly refer to the industry structure in which an organization operates, external pressures and supports, and the institutional environment. At the environmental level, researchers have primarily focused on the extent of government policy support and regional development levels. Studies have shown that standardizing the production of components can effectively improve component utilization, reduce material waste, and lower costs24. Preferential tax policies, financial and loan subsidies from the state and relevant departments25 have also promoted the development of prefabricated buildings. By formulating macro-level promotion policies for prefabricated construction and improving relevant regulations and standards for prefabricated building components, the government can reduce the intensity of energy and material consumption, this is the impact of policy effectiveness. Overall, enhancing the policy effectiveness in the prefabricated construction industry can provide effective guidance and standardization for its development26. Thus, the following hypothesis is put out in this paper:

H1

In the construction sector, there is a positive correlation between ECER efficiency and policy effectiveness.

Technical dimension

Technological factors focus on the inherent characteristics of the technology itself and its relationship with the organization, as well as the basic technological conditions of the organization27. Researchers in the technological dimension often pay attention to the level of innovation, degree of perfection, infrastructure, and technical talent in the field. Gao Ming et al.28 indicated that the direct effect of technological progress on the construction industry is manifested in improving energy efficiency and achieving energy-saving effects. Prefabricated enterprises, by selecting new building materials, enhance the technical level in key areas, and strengthen energy efficiency at the production stage of building materials29. Based on this, we can speculate that prefabricated technology, with its creative and eco-friendly benefits, speeds up the construction industry’s modernization and transformation, boosts output and energy efficiency, and eventually increases the sector’s efficiency in reducing emissions and saving energy. Considering data acquisition and causality, the quantity of patent applications is a reliable indicator of a field’s degree of technological advancement30. Therefore, this paper thinks from the technical dimension and chooses the number of patent applications to make assumptions:

H2

The number of patent applications is positively correlated with ECER efficiency of the construction industry.

Organizational dimensions

Organizational factors mainly include organizational scale, institutional arrangements, and resources owned by the organization31; existing research often starts with “enterprise resources” such as investment in scientific research funding and personnel, organizational size, and organizational management capabilities. The organizational dimension factors affecting the ECER efficiency in prefabricated buildings include the assembly rate, the number of industrial bases, the new construction area, and output value of prefabricated buildings, and the production capacity of production bases.

The assembly rate indicates the percentage of prefabricated components used in construction compared to the total number of similar structural components. It is a key measure for assessing the quality of prefabricated building construction and serves as the primary basis for local government departments to develop financial support policies for prefabricated construction32. When the assembly rate increases from 0 to about 60%, the reduction in the use of cast-in-place components significantly decreases resource consumption and pollutant emissions on construction sites. The prefabrication rate may increase building costs, however, in the decoration part, labor costs can be saved by 83.7%, mechanical costs by 22.4%, and measurement costs by 42.6%, and the overall construction period can be reduced by about 2 months, with considerable comprehensive benefits33. However, carbon emissions do not necessarily decrease with an increase in assembly rates. Due to limited production levels of prefabricated buildings in China, excessively high assembly rates can put too much pressure on component manufacturers, requiring more building materials and thus bringing more negative environmental impacts.

In 2017, the Ministry of Housing and Urban-Rural Development issued the “Management Measures for Prefabricated Building Industrial Bases,” selecting industry enterprises capable of demonstrating leadership and driving effects to serve as prefabricated building industry bases. Several dozen demonstration cases have been established in various provinces and cities. The construction of prefabricated building industrial bases can cultivate a large number of advanced scientific and management talents and lay the foundation for the development of new building systems34. Therefore, treat it as a variable and formulate hypotheses for research.

The newly constructed prefabricated building area in China grew from 114 million square meters to 630 million square meters between 2016 and 2020. Additionally, the prefabricated building industry’s yearly output value went from 384.75 billion yuan in 2016 to 100.5 billion yuan in 201835. The increase in the market share of the prefabricated construction industry in the construction field has stimulated investors’ capital investment in prefabricated construction enterprises, positively impacting the reduction of energy intensity; however, China’s prefabricated construction industry is still in the developing stage, and under the same conditions, prefabricated buildings require more building materials and consume more fossil energy. The construction industry’s ability to save energy and reduce emissions is adversely affected by the growing market share of the prefabricated building sector, which intensifies the need for extra fossil fuel input. Therefore, the specific impact of the newly constructed area and the output of prefabricated buildings on the efficiency of ECER remains unclear.

The production capacity of a prefabricated building manufacturing base refers to the number or scale of prefabricated building components produced within a specific period. With the expansion of production and construction scale, the market demand for prefabricated components has also increased36, requiring greater production capacity from prefabricated production bases. Although prefabricated buildings in China are currently more expensive than traditional cast-in-place structures and have a relatively low supply efficiency, industrial bases’ capacity to produce prefabricated components is steadily increasing. However, due to limited production technology, the production of prefabricated components often leads to more building material consumption and an increase in total fossil energy consumption, negatively affecting energy structure adjustment.

In conclusion, this paper makes the following hypotheses:

H3

There are non-linear variations in how the assembly rate affects the building industry’s ECER efficiency.

H4

The building industry’s effectiveness in reducing emissions and conserving energy is favorably connected with the number of industrial bases.

H5

Prefabricated building output value and new construction area have a nonlinear impact on the construction industry’s ability to reduce emissions and conserve energy.

H6

The building industry’s effectiveness in reducing emissions and conserving energy is inversely connected with the manufacturing capacity of production bases.

Method

Using cointegration analysis and threshold regression models, this study examines the major variables and the mechanisms that influence how prefabricated building development affects ECER in the construction sector. The ECER efficiency is measured using the super-efficient SBM model, and web crawling technology is used to gather information on key development indicators like the floor area and output value of prefabricated structures.

Super-efficient SBM model

The SBM (Slack Based Measure) model was first proposed by Tone (2003). When evaluating a decision-making unit (DMU), this model removes itself from the reference set of the production frontier, allowing the measurement of the DMU efficiency value to be greater than 1. This effectively addresses the issue of multiple efficiency values being equal to 1 and thus unsortable, making it used in energy efficiency assessments to accurately measure the impact on energy efficiency due to poor output. In this model, each different region in China is considered as a DMU37, and the specific model is shown as Eq. (1):

In Eq. (1), n represents the number of DMUs. Each DMU consists of m inputs, s desirable outputs, and r undesirable outputs. λ denotes the weights and proportions of the corresponding input or output elements. The input variable Xij represents the i-th input of the j-th DMU. ydp is the p-th desirable output of the j-th DMU, and ydp is the q-th undesirable output of the j-th DMU. ρ is the ECER efficiency value. When ρ is less than 1, it indicates that the DMU is in an inefficient state. When ρ is greater than 1, it signifies that the DMU is efficient, and the higher the value of ρ, the greater the efficiency.

Threshold regression models

The main purpose of the threshold effect is to show how the parameters of the independent variable suddenly alter their influence on the dependent variable over various ranges38. That is when the dependent variable exceeds a certain critical value; the parameters of the independent variable will change, and the functional relationship will also change. In this study, the dependent variable is the construction industry’s efficiency in reducing emissions and using less energy, whereas the independent variable is a factor in the development of prefabricated buildings.

By separating the influence of threshold variables on explanatory variables, the threshold model separates internal and external factors and characterizes the nonlinear correlation between independent and dependent variables. The mathematical formula of the single threshold regression model is as follows:

where Z is the explanatory variable affected by the threshold variable; q is the threshold variable; I takes 1 if the condition in brackets holds, otherwise 0; η is the threshold for estimating the model; µ is denoted as the random error term, µ~iid(0, σ2)

where η1 and η2 are thresholds for model estimation.

Data sources

Data on energy efficiency and emission reduction indicators

The ECER efficiency of the building industry is a key index that comprehensively considers the output, energy consumption, and pollution emission of the industry, and emphasizes the coordination and unification of economic benefits and ecological environmental benefits39. This study, based on data integrity, utilized input-output panel data from 30 regions across mainland China (excluding Tibet, Hong Kong, Macau, and Taiwan), spanning the years 2005 to 2019. The original data is from the official publication, such as “China Statistical Yearbook,” “China Energy Statistical Yearbook,” “China Environmental Statistical Yearbook,” and “China Construction Industry Statistical Yearbook.” Interpolation methods were used to fill in the gaps in the data. It referenced research methods from other industries on these topics to develop a methodology for measuring ECER efficiency. The metrics used in this method are calculated as follows:

(1) Actual Inputs. The input indicators include three categories of capital, labor, and resource inputs, represented respectively by the total assets of the enterprise (in 10,000 yuan) and the total number of self-owned construction machinery and equipment at the end of the year (in 10,000 units)40, the number of people engaged in the construction industry (in 10,000 people), the total water supply (in 10,000 tons), electricity consumption (in 10,000 kWh), and the consumption of eight major energy sources such as natural gas and coal (in 10,000 tons), as well as the consumption of five major building materials such as steel and wood (in 10,000 tons)41.

(2) Intended output. The total output of the building industry (in 10,000 yuan) and the completed floor area of buildings (in 10,000 square meters) are selected for measurement.

(3) Undesired Outputs. The calculation method for carbon emissions is improved based on existing methods42, with the specific calculation method as shown in Eq. (4). Additionally, inhalable particulate matter is selected as an undesired output.

Where CO2 is Total carbon dioxide emissions from the construction sector (T); Ei is Consumption of different types of energy required to build and manufacture the building; NCVi is Average low calorific value of different energy sources; CEFi is Energy Carbon emission factors (kg/TJ); Oi is Oxidation rate of energy; Ee is Electricity used in the manufacture of building products; a is Carbon emission factors for electricity energy (kg/kWh); Cj is Consumption Steel Wood Cement Glass Aluminum; αj is Carbon dioxide emission factors for building materials; βj is Recovery factors for building materials.

Using Max DEA 8.0 software as a benchmark, we calculated the ECER efficiency of the construction industry in 30 regions across China through the super-efficiency SBM model. The empirical measurement results are shown in Fig. 2. China’s construction industry’s ECER efficiency shows a fluctuating growth trend, with a significant decline in 2010 and a notable recovery after the implementation of energy-saving and emission-reduction efforts in 2017. The national average efficiency fluctuates between 0.6 and 0.8. Spatially, there are significant differences in efficiency changes across regions. Developed areas, including cities like Beijing, generally have much better static efficiency in ECER efforts compared to other regions.

Multi-source data processing

Prefabricated construction is an important method for the transformation and upgrading of the construction industry. However, no scholars or institutions have yet organized and publicly released data on this topic, resulting in scattered and complex information, with news reports being the primary source. Web scraping technology is an effective means to obtain rich foundational data under these circumstances. This study selects information websites related to prefabricated construction that have good timeliness and comprehensiveness, such as “Prefabricated Building Network” and “Prefabricated Construction Website”. Using keywords like “prefabricated”, “precast”, and “industrialized”, relevant data is scraped. After location analysis, screening, and extraction, an Excel web scraping database is exported. To enhance data reliability, keyword filtering was also performed. The data was then categorized by province, city, and year, and processed according to the following indicators and methods43.

-

(1)

Technical dimension.

The number of patent applications: Based on the Soopat patent database, searches were conducted using the keywords “prefabricated,” “precast,” and “industrialized.” The filtered patent data was then categorized and organized by year and region.

-

(2)

Organizational dimension.

on demonstration projects from local government websites. It is calculated as a weighted average of the ratio of prefabricated component usage to the above-ground building area in typical regional demonstration projects. For regions lacking assembly rate data, the regional assembly rate development target for that year is used as a supplement.

Number of industries (JDSL): The relevant data is derived from the crawler data, which is synthesized by the number of national industrial bases and the number of provincial industrial bases. The calculation formula is as follows:

Where \(\:{n}_{1}\) is the Number of national industrial bases, \(\:{n}_{2}\) is the Number of provincial industrial bases.

Assembly building area and output value: Derived from news reports or official statistical data, calculated on an annual basis.

Production base capacity: The relevant data is obtained through web scraping, and the comprehensive capacity is derived from the combined precast concrete capacity and steel component capacity. The specific calculation formula is as follows:

Where Jdcn is Production base capacity; Hntcn is Precast concrete capacity (Wm³); \(\:\rho\:\) is Concrete density (2.5 kg/m³); Gjgcn is Steel component capacity (Kt).

-

(2)

Environmental dimension.

Policy effectiveness: The corresponding data is based on the annual release of relevant standards, regulations, policies, and laws by various provinces and cities. Drawing on the calculation method43, the effectiveness is calculated based on the textual content and the number of enactments. The specific calculation formula is as follows:

Where Zcxl is Policy effectiveness; \(\:{m}_{1}\) is Application phases; a is the overall number of issued scores; \(\:{m}_{2}\) is the number of policies issued.

To further enhance the authenticity and rigor of the empirical research findings, we have implemented the following data analysis procedures: (1) Because various variables about the construction of prefabricated structures have missing values, this study uses the moving average approach to interpolate and supplement the missing data in order to maintain the rigor of the data and models; (2) Logarithmic transformation is used to the explanatory variables, which include the number of patent applications, production base capacity, and the newly created area of prefabricated buildings. This approach serves two purposes: it reduces heteroscedasticity caused by variations in time series, and it clarifies the economic implications of the subsequent model results36; (3) The explanatory variables, including the prefabrication rate, the number of industrial bases, and policy effectiveness, are not logarithmically transformed and are used in their original scale values.

Results and discussion

Smoothness check

In order to avoid the problem of ‘pseudo-regression’, all-time series data were tested for smoothness, and the results are shown in Table 1. The findings demonstrate that every variable is stable since every ADF value is higher than the critical value at the specified 5% significance level. Consequently, there can be a long-term balance between ECER efficiency and development indicators for prefabricated buildings.

Cointegration test

The Engle-Granger two-step verification approach is used in this study to ascertain if the development aspects of prefabricated structures and the ECER performance of the construction sector are cointegrated.

The results of the model regression analysis are shown in Table 2 below. Among them, The adjusted R2 is 0.779060, close to 1, which is a good fit for the equation as a whole. The F-test is also passed at the 1% significance level with a value of 88.56502, which indicates the relevance of the model’s linear relationship. However, only assembly rate (Zpl), policy effectiveness (Zcxl), and the number of patent applications (Zlsl) passed the t-test at a 1% significance level, indicating that the regression coefficients are significant and that the linear equation. In particular, ECER efficiency will increase by 0.579% for every 1% rise in assembly rate, by 0.202% for every 1% increase in policy effectiveness, and by 0.001% for every 1% rise in the number of patent applications.

The unit root test results of the residual term µ of the regression equation are given in Table 3, and the residual term µ is stable. At the 1% significance level, the ADF value of the t-test is greater than the critical value, rejecting the null hypothesis. The stability of the residual µ allows us to conclude that there exists a long-term cointegration relationship. As a result, there is a long-term, consistent cointegration relationship between the quantity of patent applications, assembly rate, policy effectiveness, and the construction sector’s energy and emission reduction efficiency. Therefore, they will be analyzed further as key factors affecting the efficiency of ECER in prefabricated construction.

Threshold test and regression

In order to explore the specific effects of the above variables, a threshold regression model was developed to investigate whether the variables are non-linearly related.

Existence test for threshold effect

The test results are shown in Table 4. When the F value is greater than the boundary value of the confidence interval and the P value is less than the significance level, the null hypothesis can be rejected, indicating that the test result is significant. With ZPL as a threshold variable and explanatory variable, The F(ZPL) is greater than the critical values of the confidence interval.it is significant at the 1% level under the single and double threshold test; it is not substantial under the triple threshold test. The influence of assembly rate on the effectiveness of ECER can be divided into three discussion intervals, according to the aforementioned judgment criteria, which also indicate a double threshold for the threshold effect. For the ZCXL, the F-value under single threshold testing is 97.83, which is significant at the 1% level; under triple threshold testing, the F-value is 24.11, with a p-value of 0.5267, which is insignificant. Based on the evaluation criteria, it is believed that there is a double threshold effect. The impact of ZCXL on ECER efficiency in the construction industry should subsequently be divided into three intervals for discussion.

Under the single threshold test, the number of ZLSL as a threshold and explanatory variable is not significant. The threshold effect is deemed to be nonexistent based on the evaluation criteria mentioned above. The number of patents and the building industry’s effectiveness in reducing emissions and saving energy do not have a non-linear relationship, and hence cannot be included in the threshold regression model that follows. Therefore, the statistical inference results of the relationship between assembly rate, policy effectiveness, and the building sector’s efficiency in reducing emissions and conserving energy all support the existence of threshold effect.

Threshold estimates

If the existence of a threshold effect is determined, a precise threshold value is estimated. Hansen4 determined the existence of the threshold effect and then tested the threshold using the likelihood ratio estimator. Hansen’s Bootstrap optimization search method computes the corresponding 95% confidence interval and estimates the threshold value on the threshold variable’s distribution interval. The results are shown in Figs. 3 and 4.

The ordinates in the figure represent the relevant LR values, while the horizontal coordinates represent the threshold parameter values. The LR value at the 95% significance level is displayed by the dotted line; the smaller the LR value, the more likely it is that the data will be near the true threshold. The dual-threshold approach necessitates two search rounds to identify the two thresholds independently, with each search round choosing only the lowest point of the LR value as the threshold estimate for that round. Assembly rate (Zpl), the threshold variable in the single threshold regression model, has an estimated threshold value of 0.62. The search for the LR value minimum point threshold of the double-threshold regression model is estimated at 0.62. This means that when the target of regional prefabricated buildings is 51% and 62%, the impact of prefabricated buildings on ECER efficiency changes. Policy effectiveness (Zcxl), as a threshold variable, has an estimated value of 3.5 under the single-threshold regression model and 2.8 under the double-threshold regression model. This indicates that when the regional government promulgates policy standards, the policy effectiveness for construction enterprises reaches quantitative values of 2.8 and 3.5, respectively, and the impact of policy effectiveness on ECER efficiency will change.

Threshold effect regression results

Based on the results of threshold effect testing and threshold solving, Table 5 presents the threshold effect regression results of prefabricated buildings on ECER efficiency in the construction industry, with Zpl as the threshold variable and Zcxl as the explanatory variable.

The regression coefficient in the double threshold regression model is 0.6593695, and it is significant at the 1% level when the assembly rate is less than 51% of the initial threshold value. The regression coefficient, which is important at the 1% level, is 1.094661 when the assembly rate falls between 51% and 62%. When the assembly rate is higher than the second threshold value of 62%, the regression coefficient is 0.4848524 and is significant at 1% level. The economic implication is that when the assembly rate of locally assembled buildings is generally low, the improvement of the assembly rate can pull the ECER efficiency of the local construction industry; when the assembly rate of locally assembled buildings reaches between 51% and 62%, it will have a positive effect on the ECER efficiency, i.e. in line with the current technological level of prefabricated building development, while it will minimize the use of cast-in-place parts in new buildings44. When the assembly rate of local prefabricated buildings is too high, that is, more than 62%, the positive effect on ECER efficiency of the local construction industry is significantly weakened, even lower than the positive pulling effect of 51% assembly rate, that is, more prefabricated components are invested in new buildings, and too high technical requirements cannot match the current technical level, which will achieve half the result with twice the effort. The environmental benefits obtained are lower than those obtained by investing in fewer prefabricated components.

When the policy effect is less than the first threshold of 2.8, the regression coefficient is 0.2667179, which is significant at 1% level; 0.2042897 and significant at the 1% level when the policy effect is between 2.8 and 3.5; and 0.0848474 and significant at the 1% level when the policy effect is greater than 3.5. The economic implication is that when the government introduces policy standards and the policy effectiveness on construction enterprises is relatively low, a modest increase in policy effectiveness can lead to significant improvement in ECER efficiency in the regional construction industry. When the policy effectiveness exceeds 2.8, its positive effect on the ECER efficiency diminishes to some extent, though the overall effect remains positive. When the policy effectiveness surpasses 3.5, its positive impact on the ECER efficiency becomes negligible and approaches 0.

In the control variables, the regression coefficients of economic development (proxied by the per capita completed output value of the construction industry, Pgdp) and energy structure (the ratio of energy consumption of the construction industry to total regional energy consumption, Nyjg) are both significantly positive across all four models. Notably, the energy structure variable (Nyjg) exhibits the largest regression coefficient among them. This indicates that economic development and energy structure optimization are the main impetus for the growth of ECER efficiency in the construction industry43. The regression coefficients of industrial structure (Cyjg) and energy intensity (Nyqd) are significantly negative, indicating that the high proportion of regional construction output value and energy intensity may hinder the improvement of ECER efficiency in the regional construction industry. Meanwhile, the impact of regional technological innovation on the reduction of consumption in the construction industry is minimal. This phenomenon may be attributed to insufficient promotion efforts for technological advancements in most regions of China.

In summary, after identifying “patent applications”, “assembly rate”, and “policy effectiveness” as key factors, we verified the relevant hypotheses. The assembly rate has a “weak-strong-weak” promotion effect on the efficiency of the construction industry’s ECER, confirming the H3 hypothesis of a nonlinear relationship. This validates existing research suggesting that prefabricated buildings have environmental benefits, while also highlighting that excessively increasing the input of prefabricated components can lead to significant energy consumption from inefficient production stages, thereby weakening the assembly rate’s ECER effect. The positive but diminishing trend of policy effectiveness contrasts with previous studies recommending improved policies, rejecting the positive correlation proposed in H1. The number of patent applications shows a continuous promoting effect, also rejecting the original hypothesis. Our study quantifies the influence trends between multidimensional key factors and the ECER effects in the construction industry, identifies critical value points for maximum positive impact, and addresses gaps in current empirical research on prefabricated buildings. It provides a basis for measuring policy effectiveness, enhancing technological levels, and improving the current state of energy conservation and emission reduction in the construction industry in reality.

Conclusions and implications

Based on the Super-efficient SBM model, this study first assesses the ECER efficiency of the Chinese construction sector from 2005 to 2019. It then uses crawler data to identify important factors influencing these sectors’ ECER efficiency and employs a threshold regression model to examine the threshold effects of these factors. The research results show:

(1) China’s construction industry’s ECER efficiency shows a fluctuating growth trend, with overall efficiency not high and significant regional differences. The eastern region, which includes developed cities such as Beijing, with its rapid industrial restructuring, accounts for more than 70% of the initial set of national demonstration projects for prefabricated buildings, and its emission reduction efficiency data is significantly better than other regions; while the western region includes cities such as Inner Mongolia, with slow industrial restructuring, generally has lower efficiency levels.

(2) The prefabrication rate, the efficacy of policies, and the quantity of patent applications are all correlated over the long run with the building industry’s efficiency in reducing emissions and saving energy. These three factors are the key organizational, environmental, and technological dimensions influencing the impact of prefabricated building development on the ECER efficiency of the construction industry. Targeted development of prefabricated buildings should concentrate on the prefabrication rate, policy, and technological level, which aligns with China’s policy direction of maintaining a prefabrication rate of no less than 50%, building a standardized design and production system for prefabricated buildings, and promoting intelligent upgrades in prefabricated building production and construction (14th Five-Year Plan).

(3) The prefabrication rate and policy effectiveness have dual threshold effects on the ECER efficiency, while the number of patent applications has no threshold effect. The prefabrication rate promotes efficiency, with the most significant promotion effect observed within the range of 51–62%. Beyond this range, the promotion effect significantly decreases and is lower than the promotion effect in the range of 0 to 51%. Therefore, solely pursuing an increase in the prefabrication rate may have counterproductive effects. Policy effectiveness generally promotes ECER efficiency, but as policy effectiveness continues to improve, the promotion effect weakens and may even turn inhibitory. The promotion effect of the number of patent applications on ECER efficiency is relatively stable38. Therefore, regulating the prefabrication rate of new buildings, controlling policy effectiveness, and improving the technological level of prefabricated buildings are effective ways to enhance ECER efficiency.

In light of the previously mentioned research findings, this article suggests the following actions to optimize the environmental benefits of prefabricated structures and achieve ECER goals in the construction industry:

-

(1)

In the building sector, speed up efforts to reduce emissions and save energy. With a pattern of “high in the east and low in the west,” China’s building industry now has a poor overall ECER level. On the one hand, green construction should be quickly implemented in construction enterprises. By establishing demonstration cases, increasing training on sustainable development concepts, and providing targeted technical support to reduce energy consumption and pollution during the construction process, and promote the low-carbon transformation of the construction industry45. On the other hand, to fully raise the ECER level of China’s construction industry, a mutual assistance model between eastern and western regions can be adopted to address the issue of uneven national development. Specific cities can be designated for targeted support, and economic project cooperation and resource allocation can be improved.

-

(2)

Regulate the prefabrication rate of new buildings. Prefabrication rate is a key indicator of prefabricated buildings’ environmental advantages and has contributed significantly to the construction industry’s efforts to use less energy46. However, the increase in this indicator should not be the sole target or evaluation criterion. The government should control the prefabrication rate of new prefabricated buildings between 50% and 60% by gathering expertise from industry experts and leading companies, and by formulating guidelines for the development of prefabricated construction to ensure maximum energy-saving and carbon-reduction benefits.

-

(3)

Reasonably formulate policy standards for prefabricated building development. At present, China’s prefabricated building development system is in its initial stages and still needs improvement. The government encourages the growth of prefabricated construction enterprises by combining mandatory and incentive regulations47. For example, projects with higher levels of standardization are required to use prefabricated construction. Incentives such as funding or additional floor area are provided for prefabricated projects. The effectiveness of mandatory policy standards should be adjusted promptly to ensure the healthy development of the industry.

-

(4)

Technological innovation is an important means to reduce consumption and save resources in the construction industry. In recent years, the technological level of prefabricated buildings in China has continuously improved, but there is still a gap compared to developed countries. The impact of technological advances on the construction industry to reduce consumption is still large48. Therefore, research topics and development funds for prefabricated construction should be increased, actively promoting the use of green building materials in actual projects, and quickly achieving breakthroughs in key prefabricated construction technologies.

This paper provides a strong basis for enhancing the environmental benefits of prefabricated buildings as well as the industry’s efficiency in these areas by examining the key factors and procedures influencing how prefabricated building development influences the reduction of waste in the construction sector. This study’s consideration of factors is restricted, and some factors could not be empirically studied due to data unavailability. Additionally, the relevant data obtained for this article comes from China. Due to the lack of official statistics, the collected data is relatively limited, which imposes certain constraints on research accuracy. Future research can fill data gaps, improve the analysis of other influencing factors, and further expand empirical data as prefabricated construction develops. This will assist relevant policy-making bodies in formulating directions and measures for energy conservation and emission reduction in the construction industry.

Data availability

Data is provided within the manuscript files.

References

Delmastro, C., Lavagno, E. & Mutani, G. Chinese residential energy demand: Scenarios to 2030 and policies implication. Energy Build89, 49–60. https://doi.org/10.1016/j.enbuild.2014.12.004 (2015).

Huang, B., Mauerhofer, V. & Geng, Y. Analysis of existing building energy saving policies in Japan and China. J. Clean. Prod.112, 1510–1518. https://doi.org/10.1016/j.jclepro.2015.07.041 (2016).

Cao, X. et al. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 109, 131–143. https://doi.org/10.1016/j.jclepro.2015.04.120 (2015).

Tan, X. et al. Carbon emission and abatement potential outlook in China’s building sector through 2050. Energy Policy118, 429–439. https://doi.org/10.1016/j.enpol.2018.03.072 (2018).

Yanli, S. U. N., Baohui, L. J. X. I. A. & Shanglai, L. I. U. Study on carbon emission evaluation of prefabricated Building at materialization stage. J. Shenyang Jianzhu University(Natural Science). 34 (05), 881–888 (2018).

Shengnan, L. J. L. Research on carbon footprint assessment of prefabricated concrete in Building stage. Constr. Econ. 42 (01), 101–105. https://doi.org/10.14181/j.cnki.1002-851x.202101101 (2021).

Tavares, V., Lacerda, N. & Freire, F. Embodied energy and greenhouse gas emissions analysis of a prefabricated modular house: The Moby case study. J. Clean. Prod.212, 1044–1053. https://doi.org/10.1016/j.jclepro.2018.12.028 (2019).

Teng, Y. et al. Reducing Building life cycle carbon emissions through prefabrication: evidence from and gaps in empirical studies. Build. Environ. 132, 125–136. https://doi.org/10.1016/j.buildenv.2018.01.026 (2018).

Sun, Y., Liu, J. & Xia, B. Study on carbon emission evaluation of prefabricated Building at materialization. Stage Shenyang Jianzhu Daxue Xuebao (Ziran Kexue Ban). Nat. Sci. 34 (5), 881–888 (2018).

Jaillon, L., Poon, C. S. & Chiang, Y. H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag.29(1), 309–320. https://doi.org/10.1016/j.wasman.2008.02.015 (2009).

Aye, L. et al. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 47, 159–168. https://doi.org/10.1016/j.enbuild.2011.11.049 (2012).

Hong, J. et al. Life-cycle energy analysis of prefabricated Building components: an input–output-based hybrid model. J. Clean. Prod. 112, 2198–2207. https://doi.org/10.1016/j.jclepro.2015.10.030 (2016).

Ji, Y. et al. Comparing greenhouse gas emissions of precast in-situ and conventional construction methods. J. Clean. Prod. 173, 124–134. https://doi.org/10.1016/j.jclepro.2016.07.143 (2018).

Ruyong, L. Simulation analysis of energy consumption and carbon emission system of Beijing city based on system dynamics. (2016).

Jing, H. E., Zhonglun, W. M. Z. H. A. N. G., Min, L. I. & Hongxia, S. H. I. Equal attention should be paid to both construction and operation of Buildings for energy efficiency and emission reduction: findings from current data on resource and environment loads in china’s Building industry. Sci. Technol. Rev. 36 (05), 8–13 (2018).

Faludi, J., Lepech, M. & Loisos, G. Using life cycle assessment methods to guide architectural decision-making for sustainable prefabricated modular buildings. J. Green. Building 7, 151–170. https://doi.org/10.3992/jgb.7.3.151 (2012).

Tumminia, G. et al. Life cycle energy performances and environmental impacts of a prefabricated Building module. Renew. Sustain. Energy Rev. 92, 272–283. https://doi.org/10.1016/j.rser.2018.04.059 (2018).

Ji, Y. et al. Comparing greenhouse gas emissions of precast in-situ and conventional construction methods. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2016.07.143 (2016).

Meixia, W. G. L. Empirical analysis and research of comprehensive benefits of prefabricated concrete buildings. Building Struct. 47 (10), 32–38. https://doi.org/10.19701/j.jzjg.2017.10.007 (2017).

Bonamente, E. et al. Environmental impact of industrial prefabricated buildings: Carbon and energy footprint analysis based on an LCA approach. Energy Procedia61, 2841–2844. https://doi.org/10.1016/j.egypro.2014.12.319 (2014).

Zhenhua, W. Research on threshold effect of technological innovation on industrial structure optimization. Forum Sci. Technol. China (04), 1–11. https://doi.org/10.13580/j.cnki.fstc.2021.04.002 (2021).

Choi, Y., Yu, Y. & Lee, H. A study on the sustainable performance of the steel industry in Korea based on SBM-DEA. Sustainability 10, 173. https://doi.org/10.3390/su10010173 (2018).

Tornatzky, L. G. & Fleischer, M. And A.K. Chakrabarti, Processes of Technological Innovation (The Processes of Technological Innovation, 1990).

Jinxiu, Z. X. X. & Research on Carbon Emissions of Assembly Building Life Cycle based on LCA. Take a light steel assembly integrated Villa in Chongqing as an example. Constr. Econ. 40 (01), 107–111. https://doi.org/10.14181/j.cnki.1002-851x.201901107 (2019).

Zhao-hui, Z. L. Development Level Evaluation of Regional Prefabricated Building Industry in China. J. Civil Eng. Manage. 36 (01), 55–61. https://doi.org/10.13579/j.cnki.2095-0985.2019.01.009 (2019).

Guo, F. et al. Analysis of achievable residential energy-saving potential and its implications for effective policy interventions: A study of Xiamen City in Southern China. Renew. Sustain. Energy Rev. 62, 507–520. https://doi.org/10.1016/j.rser.2016.04.070 (2016).

Zhang, Y. & He, Z. Brief analysis of the development and application of green building design and green energy-saving buildings. Iran. J. Sci. Technol. Trans. Civ. Eng.48(2), 1131–1141. https://doi.org/10.1007/s40996-023-01198-4 (2024).

Xueping, G. M. Y. L. W. Analysis of the forming path of technology progress rebound effect: an example of construction industry. Sci. Technol. Manage. Res.. 38 (22), 118–127 (2018).

Lu, W. & Yuan, H. Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renew. Sustain. Energy Rev. 28, 804–811. https://doi.org/10.1016/j.rser.2013.08.048 (2013).

Ma, M. et al. A methodology to assess china’s Building energy savings at the National level: an IPAT–LMDI model approach. J. Clean. Prod. 143, 784–793. https://doi.org/10.1016/j.jclepro.2016.12.046 (2017).

Walker, R. Internal and External Antecedents of Process Innovation: A review and extension. Public. Manage. Rev. https://doi.org/10.1080/14719037.2013.771698 (2014).

Chen, S. Practice of carbon trading at home and abroad and its enlightenment to China’s construction industry carbon market construction. Constr. Econ.42(09), 5–9. https://doi.org/10.14181/j.cnki.1002-851x.202109005 (2021).

Yan, Z. & Wang, X. Research on energy conservation and emission reduction evaluation system and methods for construction projects. Ind. Saf. Environ. Prot. 39(01), 83–86 (2013).

Oladokun, M., Motawa, P. & Banfill, P. Understanding and Improving Household Energy Consumption and Carbon Emissions Policies: A System Dynamics Approach. (2012).

Yang, Y. et al. Energy conservation and emissions reduction policy simulation about energy-consuming enterprises. J Syst Simul 28(04), 972–978 (2016).

Kim, M. J., Oh, M. W. & Kim, J. T. A method for evaluating the performance of green buildings with a focus on user experience. Energy Build66, 203–210. https://doi.org/10.1016/j.enbuild.2013.07.049 (2013).

Xue, M. & Harker, P. T. Note: Ranking DMUs with infeasible super-efficiency DEA models. Manage. Sci.48(5), 705–710. https://doi.org/10.1287/mnsc.48.5.705.7805 (2002).

Miao, K., Li, K. & Su, L. Panel threshold models with interactive fixed effects. J. Econ. 219 (1), 137–170. https://doi.org/10.1016/j.jeconom.2020.05.018 (2020).

Onat, N. C., Kucukvar, M. & Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input-output hybrid life cycle assessment approach. Build. Environ.72, 53–62. https://doi.org/10.1016/j.buildenv.2013.10.009 (2014).

Apergis, N. et al. Energy efficiency of selected OECD countries: A slacks-based model with undesirable outputs. Energy Econ.51, 45–53. https://doi.org/10.1016/j.eneco.2015.05.022 (2015).

McWhinney, M. et al. Energy star product specification development framework: Using data and analysis to make program decisions. Energy Policy33(12), 1613–1625. https://doi.org/10.1016/j.enpol.2004.02.001 (2005).

Liu, L. Research on the evolution of energy consumption intensity in China’s construction industry. (2019).

ingyun, Z. e.C.i.H., study on the relationship between the factors affecting the quality of prefabricated Building. Constr. Econ. 42 (10), 95–98. https://doi.org/10.14181/j.cnki.1002-851x.202110095 (2021).

Lubo, K. F. L. Analysis on Spatial distribution and driving factors of carbon emissions in provincial construction industry. Constr. Econ. 40 (08), 102–106. https://doi.org/10.14181/j.cnki.1002-851x.201908102 (2019).

Lai, K. E. et al. Quantification process of carbon emissions in the construction industry. Energy Build. 289, 113025. https://doi.org/10.1016/j.enbuild.2023.113025 (2023).

Zhou, T. et al. The green and low-carbon development pathways in the urban and rural Building sector in Shaanxi Province. China Energy Build. 306, 113952. https://doi.org/10.1016/j.enbuild.2024.113952 (2024).

Zhang, C. & Luo, H. Research on carbon emission peak prediction and path of china’s public buildings: scenario analysis based on LEAP model. Energy Build. 289, 113053. https://doi.org/10.1016/j.enbuild.2023.113053 (2023).

Zhu, C. et al. Factors influencing embodied carbon emissions of china’s Building sector: an analysis based on extended STIRPAT modeling. Energy Build. 255, 111607. https://doi.org/10.1016/j.enbuild.2021.111607 (2022).

Acknowledgements

This work was supported by the Beijing Social Science Foundation Project(22JJB017).

Author information

Authors and Affiliations

Contributions

Y.Q. and X.H. contributed to the conceptualization, design, data analysis, and manuscript drafting. Y.L. prepared the original draft. Y.J. contributed to the study’s design and critically reviewed the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qi, Y., He, X., Li, Y. et al. Threshold effect study on the development of prefabricated buildings for energy conservation and emission reduction in the construction industry. Sci Rep 15, 27269 (2025). https://doi.org/10.1038/s41598-025-12811-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-12811-z