Abstract

Geopolymer concrete (GPC) is an eco-friendly alternative for conventional concrete. It exploits industrial by-products in production to reduce the environmental impact and improve sustainability. This study focuses on envisaging the 28-day compressive strength of cenosphere-based geopolymer concrete incorporating copper slag using Artificial Neural Networks (ANN). The assimilation of ANN models in predicting the compressive strength of cenosphere-based geopolymer concrete with copper slag offers a promising approach to sustainable construction. By precisely forecasting the compressive strength of concrete based on the ingredient proportions, these models can rationalise the design process. The test results signposted that the developed model gives higher accuracy (> 98.6%), capability and flexibility in predicting the compressive strength of geo-polymer concrete incorporated with cenosphere and copper slag.

Similar content being viewed by others

Introduction

Concrete has been used as a fundamental material in the construction industry for millennia. It is important to note that ordinary Portland cement (OPC) is the most often utilized cement type in the production of concrete1. Its remarkable mechanical strength and heat conductivity when utilized in concrete are probably the reasons for this. But it’s important to recognize that OPC manufacturing has a major impact on environmental issues, mostly due to its high carbon dioxide (CO2) emissions2. In the process of making cement, limestone is calcined at temperatures higher than 1350oC, producing CO2 and calcium oxide3. According to the research currently in publication, the calcination process accounts for 40% of the CO2 emissions related to the manufacturing of cement4. The indirect emissions produced when fuel is burned for kiln heating are the second-largest source of pollution. Consequently, OPC manufacturing makes a substantial contribution to greenhouse gas emissions worldwide53,54. According to research, the building industry is presently responsible for around 8% of the total CO2 emissions that are present in the atmosphere. Global awareness of the need to provide a variety of sustainable cementitious alternatives to lessen the significant environmental effects caused by the building industry has increased due to the fast-rising CO2 emissions5. Researchers have created a unique kind of cementitious material called geopolymer to lessen its negative effects on the environment. Because geopolymer has a lower water reactivity than OPC, it is usually created from industrial waste that must be activated by an alkali solution6.

Davidovits used the word geopolymer in the 1970s to describe a type of mineral binders produced by a process called geopolymerization7. This procedure involves a synthesis reaction between alkali polysilicates acting as activators and aluminosilicate minerals acting as precursors. An Al–O–Si link is formed as a result of this reaction8. Utilizing alkaline activation to create silicon and aluminum-rich precursors is the most effective and well-known technique for starting geopolymerization9. In geopolymer cementitious composites, cement was either entirely or partially replaced with materials enriched with SiO2 and Al2O3 components, also known as pozzolanic materials68,69. After that, they interact with an alkaline solution to be stimulated into reactivity6.

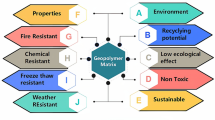

Geopolymer concrete consists of Si-Al minerals. By and large, geopolymer concrete has higher mechanical and durability properties than conventional concrete with superior fire and heat resistance. Several pozzolanic materials, viz., fly ash67cenosphere, silica fume, bottom ash, ground granulated blast slag, were used to enrich binding properties in geo polymer concrete1,2,3,4,5,6,7,8. These days, a lot of scholars are learning more about the use of ash/slag microspheres in the creation of different kinds of concrete3,4,5. The inclusion of ash and slag microspheres has been demonstrated to dramatically enhance packing density, which in turn increases the product’s strength and fluidity. Cement paste samples were mixed with varying quantities of water and ash/slag microspheres ranging from 0 to 60%. According to the findings, adding up to 40% ash microspheres to cement materials considerably raises their packing density4,6. The inclusion of microspheres enables the cement paste’s water film to thicken, with the gaps partially filled with microspheres and the corresponding amount of water in the voids evacuated. It is well known that the thickness of the water film is a crucial factor that is taken into account when constructing mortars and concrete mixes, and that it affects the rheology, adhesiveness, and strength of the mortar5. Cenosphere is considered a vital source for alumino-silicate in the production of GPC. Copper slag was used in a polymeric matrix as a fine aggregate. Higher strength gain has been observed for cenosphere and copper slag-based geopolymer composites than the conventional concrete9,10,11,12.

The strength development of polymeric matrix is complex in nature; ANN is the optimal tool for assessing the compressive strength of geo-polymer. An Artificial Neural Network is a functional component of deep learning, a subset of machine learning which requires training large neural networks on vast datasets13,14,15,16. ANN is a computational model stimulated by the structure and function of the human brain, using interconnected nodes (neurons) to process and transfer information. ANN is an influential and reliable tool for learning patterns from data and making predictions, especially in complex and non-linear scenarios17,18,19.

Artificial intelligence system has the competency of learning from the past examples and relevant data. This feature makes ANN a promising tool to solve complex engineering problems. The systems are generally capable of assessing information and could make predictions to adapt to new information based on the input20,21,22,23,24. It is very difficult to predict the compressive strength of a polymeric matrix, which has a complex nature, especially with non-linear relationships. For such cases, ANN could approximate the results obtained from the experiments and find solutions for the intricate engineering problems25,26,27,28.

Several studies have been carried out to predict the compressive strength of concrete using ANN. In this study, owing to higher exactitude, ANN models were trained with data obtained from the experiments. The trained ANN model has been validated and considered to predict the influence of various materials on the 28-day compressive strength of polymeric composite29,30,31. By and large, the 28-day compressive strength is considered a reliable indicator to assess its long-term performance. Hence, the model has been developed to predict the 28-day strength. The novelty of this study lies in its specific focus on a unique combination of cenosphere and copper slag as partial replacements in geopolymer concrete. These materials, though studied individually to some extent, have not been comprehensively modelled together using ANN for strength prediction. The objective of this study is to develop and apply ANN models to accurately predict the 28-day compressive strength of GPC incorporating cenosphere and copper slag. By leveraging industrial by-products and advanced computational techniques, the study aims to enhance the sustainability of construction practices while optimizing the mix design process through high-accuracy strength prediction.

Data collection

Various mix proportions comprising cenosphere, sand, copper slag, sodium hydroxide, sodium silicate and water were considered as input to train the network33,34. From experimentation, a 69-set of data associated with compressive strength of geopolymer was collected to train the network, and from the literature, a 291-set of data was considered; a total of 360 distinct mix designs were considered for modelling. Different mix proportions of geopolymer mixes considered as control parameters have been furnished in Table 1.

This complete dataset endorsed the ANN to learn the non-linear relationships among the different mix proportions and the resulting compressive strength. The architecture of ANN has been designed to consider the variability in input parameters, with hidden layers and neurons optimized through iterative training processes. The model’s performance was evaluated using metrics such as Mean Squared Error (MSE) and the coefficient of determination (R²), ensuring its predictive accuracy and reliability. By systematically varying the parameters, the model gives insights into the compressive strength assessment of polymeric composites.

Creation of neural network model

The Levenberg-Marquardt algorithm was adopted to train the neural network. A single-layer feed-forward neural network system was developed. Based on the values of the correlation coefficient and Mean Absolute Percentage Error (MAPE), the performance of the network was analysed35,36,37,38. Neural networks comprise 3 layers, viz. input, hidden and output layers. The hidden layer is connected by weights, bias, and activation functions. Each layer is connected to the others through several synthetic neurons. Output has been produced by an activation function using weighted inputs39,40,41,42. The following principles have been considered while selecting a neural network.

Input node selection based on independent variables

Each input node in the neural network corresponds to an independent variable influencing the concrete’s compressive strength. By aligning the number of input nodes with the number of these variables, the model ensures comprehensive data representation. This approach allows the network to capture the intricate relationships between mix components and their impact on strength development43,44,45.

Minimization of hidden layers to reduce training time

To enhance computational efficiency and reduce the risk of overfitting, the network architecture was streamlined by limiting the number of hidden layers. A simpler architecture accelerates the training process and improves generalization to unseen data. This strategy aligns with best practices in neural network design, where the complexity of the model is balanced against the size and diversity of the dataset46,47,48.

Optimal neuron allocation to prevent overfitting

Determining the appropriate number of neurons in the hidden layers is crucial for model performance. An excessive number of neurons can lead to overfitting, where the model captures noise instead of underlying patterns. Conversely, too few neurons may result in underfitting, failing to capture the complexity of the data. The model employed a balanced approach, selecting enough neurons to learn the data’s intricacies without compromising its ability to generalize49,50. The architecture of the neural network model used in this study is illustrated in Fig. 1.

Training and testing of a neural network

Generally, a single hidden layer is preferred in most of the high-performance neural networks for supreme applications. In this study, a neural network comprising an input layer with 6 nodes, a hidden layer with 12 nodes and an output layer with a single node has been developed to analyse the non-linear behaviour of the polymeric composite. In order to optimize the performance of the network, numerous trials have been conducted with different numbers of hidden nodes52,55.

As a result of experimentation, a neural network consisting of 12 hidden nodes exhibited the best predictive accuracy for the compressive strength prediction. The neural network stopped training once generalisation was obtained and the increased mean squared error (MSE) value was ensured on the validation set. Mean squared error (MSE) is the average squared difference between the input and the targeted output. Based on the MSE value, the correlation between the output and targets has been assessed.

The mean squared error is calculated from the following Eq. (1)65.

Where N is the number of data used, ti and a.i. are the output and target values, respectively. The regression plot of the network is shown in Fig. 2. R value represents the percentage of error. If the R value is 1, then the correlation acquired by the neural fitting tool is very close. R value of 0.989 and 0.946 was obtained for training and testing, respectively56,57,58. The overall status of the network is shown in Fig. 3.

Validation of the ANN model

The experimental results were correlated with the different mix proportions of cenosphere and copper slag incorporated concrete matrix to validate the efficiency of the developed neural network model. The compressive strength of the polymeric composite at a standard curing period of 28 days has been tested. Figure 4 shows the percentage of error with experimental values.

The obtained results were compared with the results of the ANN model. The percentage error was calculated between the test values and the predicted values through the ANN model63,64,65,66. The graphical comparison of actual and predicted results is illustrated in Fig. 4. The close alignment between both predicted and actual values indicates the reliability and predictive strength of the model.

Results and discussions

Figure 5 illustrates the comparison of experimental results and the predicted results from the developed model. The compressive strength data of cenosphere and copper slag added geopolymer composite obtained from the experimental investigation have been considered as the output data set for training the ANN model66. The target output has been assigned as the actual compressive strength value of the polymeric composite, which is obtained from experimental verification. The prediction has been made for each individual compressive strength test result using an ANN model. The best curve fit of the form y = 1.043 × 0.992 has been derived with an R2 value of 0.98 between the predicted strength and the actual compressive strength to represent the relationship59. The high coefficient of determination, with a value of 0.98, indicates that the predicted compressive strength is in proximity to the actual values obtained from the test results with minimal deviations. It was observed that there were a few fluctuations in the MSE due to the iterative nature and convergence behaviour of the back propagation algorithm, but it was observed that there was no major impact found due to these variations on the overall prediction accuracy. The predicted results through the ANN model were very close to the real-world test data. This clearly evidenced the robustness and reliability of the developed ANN model in the strength prediction of complex polymeric matrices63. The accuracy of the developed model shows that ANN is an effective tool to predict the 28-day compressive strength based on the mix proportions of the constituents and processing parameters of the geo-polymer concrete incorporated with cenosphere and copper slag. The statistical evaluation of the predicted and experimental compressive strength values reveals a MSE of 0.840 MPa and a Mean Absolute Error (MAE) of 0.668 MPa. These low error values indicate that the ANN model demonstrates excellent predictive performance and closely approximates the actual experimental outcomes.

The MSE, which penalizes larger errors more significantly due to its squared nature, reflects the standard deviation of prediction errors. A value below 1 MPa implies that the model’s predictions are highly reliable and consistent across varying sample indices. Similarly, the MAE, which represents the average magnitude of absolute differences between predicted and observed values60being less than 0.7 MPa, further confirms the accuracy of the model with minimal deviation on average. The Mean Absolute Percentage Error (MAPE) is 2.19%, indicating that, on average, the predicted compressive strength values deviate from the experimental values by only about 2.19%. This very low percentage reflects the high accuracy and reliability of the ANN model in predicting compressive strength across different samples. A MAPE value below 5% is generally considered excellent in engineering applications, further validating the model’s effectiveness64. It demonstrates that the model can be confidently used for practical purposes, such as optimizing geopolymer concrete mix designs incorporating cenosphere and copper slag, with minimal prediction error relative to actual performance. These results suggest that the ANN model effectively captures the complex nonlinear relationships among the input variables in cenosphere and copper slag-based geopolymer concrete62. The close agreement between predicted and experimental strengths highlights the model’s robustness and practical applicability for mix design optimization in sustainable construction. Such predictive capability can significantly reduce the need for trial-and-error experimental procedures, saving both time and resources in material development and quality control.

The residual vs. predicted plot shown in Fig. 6. The residuals are evenly scattered around the zero line (red dashed line), indicating that the ANN model does not show clear bias or systematic error in its predictions61,63. Most residuals fall within a narrow band (± 2 MPa), suggesting good model accuracy. The absence of a discernible pattern confirms that the residuals are randomly distributed, which supports the model’s assumption of homoscedasticity. Overall, the plot confirms that the model performs consistently across the predicted values and reliably estimates compressive strength.

The “Error vs. Predicted Values” Fig. 7 illustrates the absolute difference between experimental and predicted compressive strength values across the range of predictions made by the model. Each point represents the magnitude of prediction error for a specific predicted strength value. Most errors are below 1.0 MPa, indicating that the model provides highly accurate predictions across most data points. However, a few outliers with errors exceeding 1.5 MPa suggest that the model underperforms slightly at certain predicted values, possibly due to variability in the experimental data or underrepresented input conditions. Importantly, the absence of a clear trend or systematic pattern in the distribution of errors supports the assumption that the model does not suffer from heteroscedasticity or structural bias. This randomness in error spread confirms that the ANN model maintains consistent prediction accuracy throughout the compressive strength range, making it reliable for practical use in geopolymer concrete strength prediction with minimal deviation.

Conclusion

The results attained from the neural network model clearly indicated that the 28-day compressive strength of the cenosphere-based geo-polymer concrete comprising copper slag can be effectively modelled using ANN with higher accuracy. The reliability of the model is mainly governed by the comprehensiveness of the experimental data utilised in the learning pattern of the network, and the high level of exactness obtained by the model confirms its efficiency.

-

The ANN model demonstrated excellent performance in predicting the compressive strength of geopolymer concrete incorporating cenosphere and copper slag, with a strong correlation (R² = 0.98) and low error values (MSE = 0.840 MPa, MAE = 0.668 MPa, MAPE = 2.19%).

-

The minimal deviation in the percentage of error highlights the robustness of the model, which is mainly influenced by the competence of the learning algorithm adopted during the training phase of the network.

-

The higher level of accuracy ascertains the robustness of the model and ensures that the developed ANN model can simulate the compressive strength of the geo-polymer concrete incorporated with cenosphere and copper slag.

-

The residual and error plots showed a random and unbiased distribution, indicating that the model’s predictions are consistent across different strength values without significant systematic errors.

Limitations

The model is trained exclusively on compressive strength data from specific mix proportions of cenosphere and copper slag-based geopolymer composites, limiting its applicability to other material systems or mix designs outside this dataset. Its predictive ability may decline when extrapolated beyond the trained data range, and its black-box nature restricts the interpretability of how input variables influence outcomes. Although fluctuations in MSE were observed due to the backpropagation algorithm’s convergence behaviour, they had minimal impact in this study; however, such sensitivity could affect model stability in other scenarios. Additionally, the exceptionally high R² raises concerns about possible overfitting in the absence of rigorous cross-validation. The model also lacks uncertainty quantification, which is critical for real-world decision-making, and does not address the potential influence of data quality or experimental noise.

Data availability

Data used in the study is present in the manuscript.

References

Jiang, Y., Li, H. & Zhou, Y. Compressive strength prediction of fly Ash concrete using machine learning techniques. Buildings 12, 690 (2022).

Peng, Y. & Unluer, C. Analyzing the mechanical performance of fly ash-based geopolymer concrete with different machine learning techniques. Constr. Build. Mater. 316, 125785 (2022).

Kuang, F., Long, Z., Kuang, D., Liu, X. & Guo, R. Application of back propagation neural network to the modeling of slump and compressive strength of composite geopolymers. Comput. Mater. Sci. 206, 111241 (2022).

Li, Y., Shen, J., Lin, H. & Li, Y. Optimization design for alkali-activated slag-fly Ash geopolymer concrete based on artificial intelligence considering compressive strength, cost, and carbon emission. J. Build. Eng. 75, 106929 (2023).

Kumar, P., Pratap, B., Sharma, S. & Kumar, I. Compressive strength prediction of fly Ash and blast furnace slag-based geopolymer concrete using convolutional neural network. Asian J. Civ. Eng. 25, 1561–1569 (2024).

Amran, M., Huang, S. S., Debbarma, S. & Rashid, R. S. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 324, 126722 (2022).

Biswas, R. et al. Efficient soft computing techniques for the prediction of compressive strength of geopolymer concrete. Comput. Concr. 28, 221–232 (2021).

Khan, M. A. et al. Geopolymer concrete compressive strength via artificial neural network, adaptive neuro fuzzy interface system, and gene expression programming with K-fold cross validation. Front. Mater. 8, 621163 (2021).

Ahmed, H. U., Mohammed, A. S., Mohammed, A. A. & Faraj, R. H. Systematic multiscale models to predict the compressive strength of fly ash-based geopolymer concrete at various mixture proportions and curing regimes. PLoS ONE 16, e0253006. (2021).

Nguyen, K. T., Nguyen, Q. D., Le, T. A., Shin, J. & Lee, K. Analyzing the compressive strength of green fly Ash based geopolymer concrete using experiment and machine learning approaches. Constr. Build. Mater. 247, 118581 (2020).

Su, Y. et al. Mechanical characteristics and solidification mechanism of slag/fly ash-based geopolymer and cement solidified organic clay: A comparative study. J. Build. Eng. 71, 106459 (2023).

Dehghani, A., Aslani, F. & Panah, N. G. Effects of initial SiO2/Al2O3 molar ratio and slag on fly ash-based ambient cured geopolymer properties. Constr. Build. Mater. 293, 123527 (2021).

Karolina, R., Tarigan, J., Hardjasaputra, H. & Silalahi, R. A. Analysis of Geopolymer Mortar Compressive Strength Based on Fly Ash and GGBFS as Patch Repair Material. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, ; 1195, p. 012032. (2023).

Nagajothi, S. & Elavenil, S. Effect of GGBS addition on reactivity and microstructure properties of ambient cured fly Ash based geopolymer concrete. Silicon 13, 507–516 (2021).

Zhang, H. et al. Deterioration of ambient-cured and heat-cured fly Ash geopolymer concrete by high temperature exposure and prediction of its residual compressive strength. Constr. Build. Mater. 262, 120924 (2020).

Tayeh, B. A., Zeyad, A. M., Agwa, I. S. & Amin, M. Effect of elevated temperatures on mechanical properties of lightweight geopolymer concrete. Case Stud. Constr. Mater. 15, e00673 (2021).

Kotop, M. A., El-Feky, M. S., Alharbi, Y. R., Abadel, A. A. & Binyahya, A. S. Engineering properties of geopolymer concrete incorporating hybrid nano-materials. Ain Shams Eng. J. 12, 3641–3647 (2021).

Kashem, A. et al. Hybrid data-driven approaches to predicting the compressive strength of ultra-high-performance concrete using SHAP and PDP analyses. Case Stud. Constr. Mater., 20, e02991., (2024).

Alyami, M. et al. Estimating compressive strength of concrete containing rice husk Ash using interpretable machine learning-based models. Case Stud. Constr. Mater. 20, e02901 (2024).

Karim, R., Islam, M. H., Datta, S. D. & Kashem, A. Synergistic effects of supplementary cementitious materials and compressive strength prediction of concrete using machine learning algorithms with SHAP and PDP analyses. Case Stud. Constr. Mater., 20, e02828. (2024).

Mei, X. et al. Development of a hybrid artificial intelligence model to predict the uniaxial compressive strength of a new aseismic layer made of rubber-sand concrete. Mech. Adv. Mater. Struct. 30 (11), 2185–2202 (2023).

Li, C., Mei, X., Dias, D., Cui, Z. & Zhou, J. Compressive strength prediction of rice husk Ash concrete using a hybrid artificial neural network model. Materials 16 (8), 3135 (2023).

Elemam, W. E., Abdelraheem, A. H., Mahdy, M. G. & Tahwia, A. M. Prediction and optimization of self-consolidating concrete properties. ACI Mater. J. 119 (1), 91–104 (2022).

Barkhordari, M. S., Armaghani, D. J., Mohammed, A. S. & Ulrikh, D. V. Data-driven compressive strength prediction of fly Ash concrete using ensemble learner algorithms. Buildings 12 (2), 132 (2022).

Emad, W. et al. Prediction of concrete materials compressive strength using surrogate models In Structures 46, pp. 1243–1267. (2022).

Han, Q., Gui, C., Xu, J. & Lacidogna, G. A generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Constr. Build. Mater. 226, 734–742 (2019).

Nisar, N. & Bhat, J. A. Experimental investigation of rice husk Ash on compressive strength, carbonation and corrosion resistance of reinforced concrete. Australian J. Civil Eng. 19 (2), 155–163 (2021).

Amin, M. N. et al. Promoting the suitability of rice husk Ash concrete in the Building sector via contemporary machine intelligence techniques. Case Stud. Constr. Mater. 19, e02357 (2023).

Iftikhar, B. et al. Predictive modeling of compressive strength of sustainable rice husk Ash concrete: ensemble learner optimization and comparison. J. Clean. Prod. 348, 131285 (2022).

Khursheed, S., Jagan, J., Samui, P. & Kumar, S. Compressive strength prediction of fly Ash concrete by using machine learning techniques. Innov. Infrastruct. Solut. 6, 149 (2021).

Onyelowe, K. C. et al. AI mix design of fly Ash admixed concrete based on mechanical and environmental impact considerations. Civ. Eng. J. 9, 27–45 (2023).

Wadhawan, S., Bassi, A., Singh, R. & Patel, M. Prediction of compressive strength for fly ash-based concrete: critical comparison of machine learning algorithms. J. Soft Comput. Civ. Eng. 7, 68–110 (2023).

Song, H. et al. Predicting the compressive strength of concrete with fly Ash admixture using machine learning algorithms. Constr. Build. Mater. 308, 125021 (2021).

Liang, W. et al. Mixed artificial intelligence models for compressive strength prediction and analysis of fly Ash concrete. Adv. Eng. Softw. 185, 103532 (2023).

Ahmad, A. et al. Prediction of compressive strength of fly Ash based concrete using individual and ensemble algorithm. Materials 14, 794 (2021).

Mohammed, A. et al. M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly Ash. J. Mater. Res. Technol. 9, 12416–12427 (2020).

Khalaf, A. A., Kopecskó, K. & Merta, I. Prediction of the compressive strength of fly Ash geopolymer concrete by an optimised neural network model. Polymers 14, 1423 (2022).

Demir Sahin, D., Isik, E., Isik, I. & Cullu, M. Artificial neural network modeling for the effect of fly Ash fineness on compressive strength. Arab. J. Geosci. 14, 1–4 (2021).

Barkhordari, M. S., Armaghani, D. J., Mohammed, A. S. & Ulrikh, D. V. Data-driven compressive strength prediction of fly Ash concrete using ensemble learner algorithms. Buildings 12, 132 (2022).

Khan, K. et al. Compressive strength Estimation of fly ash/slag based green concrete by deploying artificial intelligence models. Materials 15, 3722 (2022).

Qi, S. et al. Dynamically relative position encoding-based transformer for automatic code edit. IEEE Trans. Reliab. 72, 1147–1160 (2022).

Li, Y., Shan, Y., Liu, Z., Che, C. & Zhong, Z. Transformer fast gradient method with relative positional embedding: A mutual translation model between english and Chinese. Soft Comput. 27, 13435–13443 (2023).

Charoenkwan, P., Nantasenamat, C., Hasan, M. M., Manavalan, B. & Shoombuatong, W. BERT4Bitter: A bidirectional encoder representations from Transformers (BERT)-based model for improving the prediction of bitter peptides. Bioinformatics 37, 2556–2562 (2021).

Zhu, H., Lee, K. A. & Li, H. Discriminative speaker embedding with serialized multi-layer multi-head attention. Speech Commun. 144, 89–100 (2022).

Sah, A. K. & Abulaish, M. D. C. K. I. D. A Multi-Head Attention-based deep neural network model leveraging Classwise knowledge to handle imbalanced textual data. Mach. Learn. Appl. 17, 100575 (2024).

Ding, Y., Jia, M., Miao, Q. & Cao, Y. A novel time–frequency transformer based on self–attention mechanism and its application in fault diagnosis of rolling bearings. Mech. Syst. Signal. Process. 168, 108616 (2022).

Kumar, S. & Solanki, A. An abstractive text summarization technique using transformer model with self-attention mechanism. Neural Comput. Appl. 35, 18603–18622 (2023).

Hrycej, T., Bermeitinger, B. & Handschuh, S. Number of attention heads vs. Number of Transformer-Encoders in computer vision. ArXiv ArXiv:2209.07221 (2022).

Liu, H. I. & Chen, W. L. X-transformer: A machine translation model enhanced by the self-attention mechanism. Appl. Sci. 12, 4502 (2022).

He, X., Li, C., Zhang, P., Yang, J. & Wang, X. E. Parameter-efficient model adaptation for vision transformers. In Proceedings of the AAAI Conference on Artificial Intelligence, Washington, DC, USA, 7–14 February, 37, 817–825. (2023).

Elshaarawy, M. K., Alsaadawi, M. M. & Hamed, A. K. Machine learning and interactive GUI for concrete compressive strength prediction. Sci. Rep. 14, 16694 (2024).

Kumar, P., Gogineni, A., Kumar, A. & Modi, P. A comparative analysis of machine learning algorithms for predicting fundamental periods in reinforced concrete frame buildings. Iran. J. Sci. Technol. Trans. Civil Eng. 49, 2257–2276. https://doi.org/10.1007/s40996-024-01560-0 (2024).

Kumar, P. S. et al. A sustainable bioengineering approach for enhancing black cotton soil stability using waste foundry sand. Int. J. Low-Carbon Technol. 20, 1112–1120. https://doi.org/10.1093/ijlct/ctaf054 (2025).

Kumar, P., Gogineni, A. & Ammarullah, M. I. Sustainable bioengineering approach to industrial waste management: LD slag as a cementitious material. Discover Sustain. 6 (1), 1–9. https://doi.org/10.1007/s43621-025-00981-9 (2025).

Sharma, S., Kumari, S. & Gogineni, A. Predicting Monthly River Discharge Using Bayesian Optimisation-Based SVR. Soft Computing and Geospatial Techniques in Water Resources Engineering: Select Proceedings of HYDRO 2023, 397, 113. (2025).

Paswan, R. K., Gogineni, A., Sharma, S. & Kumar, P. Predicting split tensile strength in Portland and geopolymer concretes using machine learning algorithms: a comparative study. J. Building Pathol. Rehabilitation. 9 (2), 129. https://doi.org/10.1007/s41024-024-00485-5 (2024).

Kumar, P. et al. Thermal Performance Prediction for Alkali-Activated Concrete Using GGBFS, NaOH, and Sodium Silicate. Civil Engineering Infrastructures Journal https://doi.org/10.22059/ceij.2024.369661.1996 (2024).

Gogineni, A., Chintalacheruvu, M. R. & Kale, R. V. Modelling of snow and glacier melt dynamics in a mountainous river basin using integrated SWAT and machine learning approaches. Earth Sci. Inf. 17 (5), 4315–4337. https://doi.org/10.1007/s12145-024-01397-1 (2024).

Sharma, S., Kumar, A., Bano, S. & Kumar, P. Soft computing techniques for analysing the mechanical properties of egg shell powder-based concrete: DOI registering. Adv. Civil Architectural Eng. 15 (28), 119–132. https://doi.org/10.13167/2024.28.9 (2024).

Kumar, P., Sharma, S. & Pratap, B. Prediction of compressive strength of geopolymer fiber reinforced concrete using machine learning. Civil Eng. Infrastruct. J. https://doi.org/10.22059/ceij.2024.364871.1956 (2024).

Pratap, B., Kumar, P., Shubham, K. & Chaudhary, N. Soft computing-based investigation of mechanical properties of concrete using ready-mix concrete waste water as partial replacement of mixing portable water. Asian J. Civil Eng. 25 (2), 1255–1266. https://doi.org/10.1007/s42107-023-00841-9 (2024).

Gogineni, A., Panday, I. K., Kumar, P. & Paswan, R. K. Predictive modelling of concrete compressive strength incorporating GGBS and alkali using a machine-learning approach. Asian J. Civil Eng. 25 (1), 699–709. https://doi.org/10.1007/s42107-023-00805-z (2024).

Kumar, P., Pratap, B., Sharma, S. & Kumar, I. Compressive strength prediction of fly Ash and blast furnace slag-based geopolymer concrete using convolutional neural network. Asian J. Civil Eng. 25 (2), 1561–1569. https://doi.org/10.1007/s42107-023-00861-5 (2024).

Gogineni, A., Panday, I. K., Kumar, P. & Paswan, R. K. Predicting compressive strength of concrete with fly Ash and admixture using xgboost: a comparative study of machine learning algorithms. Asian J. Civil Eng. 25 (1), 685–698. https://doi.org/10.1007/s42107-023-00804-0 (2024).

Kumar, P. & Pratap, B. Feature engineering for predicting compressive strength of high-strength concrete with machine learning models. Asian J. Civil Eng. 25 (1), 723–736. https://doi.org/10.1007/s42107-023-00807-x (2024).

Gogineni, A., Kale, R. V., Roy, S., Modi, P. & Kumar, P. Spatial assessment of snow cover patterns in the Sutlej river basin using machine learning approaches and remote sensing data. Phys. Chem. Earth Parts A/B/C. 103996 https://doi.org/10.1016/j.pce.2025.103996 (2025).

Kumar, P., Gogineni, A. & Upadhyay, R. Mechanical performance of fiber-reinforced concrete incorporating rice husk Ash and recycled aggregates. J. Building Pathol. Rehabilitation. 9 (2), 144. https://doi.org/10.1007/s41024-024-00500-9 (2024).

Pratap, B., Paswan, R. K. & Kumar, P. Mechanical and micro-characterization of alkali‐activated concrete under high‐temperature exposure. Struct. Concrete. 26 (2), 1911–1923. https://doi.org/10.1002/suco.202301157 (2025).

Kumar, P., Pratap, B. & Sahu, A. Recycled aggregate with GGBS geopolymer concrete behaviour on elevated temperatures. J. Struct. Fire Eng. 16 (1), 118–137. https://doi.org/10.1108/JSFE-07-2024-0019 (2025).

Acknowledgements

The authors gratefully thank the authors’ respective institutions for their strong support of this study.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

G. K. Arunvivek: Conceptualization, Data curation, Formal analysis, Investigation, Writing - original draft. S. Anandaraj: Supervision, Validation, Visualization, Investigation, Review, and editing. Pramod Kumar: Project administration, Data curation, Formal analysis, Investigation, Writing – original draft, Writing – review and editing. Bheem Pratap: Writing – original draft, Writing – review & editing. Regasa Yadeta Sembeta: Writing – original draft, Writing – review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical statement

This study did not involve human participants or animals; no ethical approval was required. All research procedures adhered to relevant ethical guidelines and best practices for non-human and non-animal research.

Consent to publish

Not applicable.

Informed consent to participate

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Arunvivek, G.K., Anandaraj, S., Kumar, P. et al. Compressive strength modelling of cenosphere and copper slag-based geopolymer concrete using deep learning model. Sci Rep 15, 27849 (2025). https://doi.org/10.1038/s41598-025-13176-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-13176-z