Abstract

Nickel hydroxide (Ni(OH)₂) is a promising electrode material for supercapacitors due to its high theoretical capacitance. However, its practical performance is hindered by limited cycle stability, poor electrical conductivity, and sluggish ion transport. To overcome these limitations, this study introduces a novel strategy involving high-energy X-ray irradiation-induced functionalization to enhance the electrochemical properties of Ni(OH)₂ electrodes. Pristine Ni(OH)₂ was subjected to 15 MV X-ray irradiation at a dose of 10–20 Gy, utilizing Compton scattering to induce controlled surface-level modifications while preserving the bulk crystal structure. Physicochemical characterizations including XRD, Raman spectroscopy, FTIR, and ICP-MS revealed the introduction of new surface functionalities and optimized ion diffusion pathways, without compromising isotopic or crystallographic integrity. Electrochemical performance was evaluated in 1.0 M Na₂SO₄ electrolyte. The irradiated electrode (f-Ni(OH)₂) demonstrated a specific areal capacitance of 671.2 mF·cm⁻² at a scan rate of 1 mV·s⁻¹, marking a 41% improvement over its non-irradiated counterpart (474.7 mF·cm⁻²). Galvanostatic charge-discharge measurements yielded a high capacitance of 1253.5 mF·cm⁻² at 1.0 mA·cm⁻². Electrochemical impedance spectroscopy further confirmed enhanced ion and electron kinetics, with a decrease in solution resistance from 18.4 Ω to 13.0 Ω. Critically, the f-Ni(OH)₂ electrodes retained 99.2% of their initial capacitance after 5,000 continuous cycles, demonstrating exceptional long-term stability. The observed improvements place f-Ni(OH)₂ within the performance range of microsupercapacitor technologies, highlighting their strong potential for future integration into miniaturized energy storage platforms. This work represents the first demonstration of using high-energy X-ray irradiation to functionalize metal hydroxides for energy storage applications, offering a scalable, chemical-free, and cost-effective approach to engineer next-generation supercapacitor electrodes. The findings provide new insights into radiation-matter interactions for material engineering, offering a promising route toward high-performance, long-lifespan energy storage systems.

Similar content being viewed by others

Introduction

The ever-increasing global demand for energy, driven by the proliferation of portable electronics, electric vehicles, and renewable energy systems, has intensified the need for efficient, durable, and sustainable energy storage technologies1,2. Traditional energy storage solutions, such as batteries, offer high energy densities but often suffer from limited power densities and cycle lives3,4. In contrast, electrochemical capacitors, or supercapacitors, have emerged as promising alternatives due to their ability to deliver high power densities, rapid charge-discharge capabilities, and excellent cycle stability5,6. These attributes make supercapacitors highly attractive for a range of applications, including microelectronics, grid energy management, and hybrid energy systems where quick energy delivery and long operational lifetimes are essential7,8,9.

At the heart of supercapacitor performance lies the choice of electrode materials, which critically determine energy storage capacity, charge-discharge kinetics, and device longevity10,11. A wide variety of electrode materials has been explored to optimize supercapacitor efficiency, including carbon-based materials12,13,14,15conductive polymers16,17,18metal chalcogenides and transition metal oxides19,20. Among these, metal hydroxides have attracted significant interest due to their high theoretical specific capacitance, rich redox chemistry, and relatively low cost21,22,23. Nickel hydroxide (Ni(OH)₂), in particular, stands out as a highly promising electrode material owing to its high theoretical capacitance (~ 2082 F·g⁻¹), environmental benignity, and facile synthesis routes24,25,26,27. Despite these advantages, the practical application of Ni(OH)₂ in supercapacitors remains limited by several intrinsic drawbacks. These include relatively poor electrical conductivity, sluggish ion transport kinetics, and structural degradation during prolonged cycling, which collectively hinder its long-term electrochemical stability and rate capability28. Various modification strategies have been proposed to address these challenges, such as composite formation with conductive carbon matrices, doping with foreign elements, and nanostructuring techniques28,29,30,31,32. However, these approaches often involve complex, costly, and time-consuming fabrication processes that are difficult to scale up for industrial applications. Moreover, conventional modification techniques may introduce additional phases or defects that adversely affect material purity and stability.

In recent years, radiation-based material modification methods have gained attention as innovative approaches for surface engineering33. High-energy X-ray irradiation offers unique capabilities for inducing controlled structural and chemical changes in materials without the need for harsh chemical environments or high-temperature treatments. The fundamental mechanisms underlying X-ray–material interactions, such as the photoelectric effect, Compton scattering, and pair production, allow for localized excitation, ionization, and atomic rearrangement, enabling precise tuning of surface properties34,35,36. While X-ray irradiation has been successfully applied to modify polymers37ceramics38and carbonaceous materials39,40its application to transition metal hydroxides, and particularly to Ni(OH)₂, remains largely unexplored.

The current literature reveals a significant gap concerning the use of high-energy X-ray irradiation as a functionalization technique for Ni(OH)₂ to enhance its electrochemical properties for supercapacitor applications. Few studies have investigated the effects of X-ray–induced surface modification on the physicochemical, optical, and electrochemical behavior of different types of materials39,40,41,42,43,44,45,46,47. Even fewer have focused on harnessing Compton scattering and related high-energy interactions to achieve surface functionalization without compromising the bulk crystalline structure, a critical requirement for ensuring material stability during long-term cycling.

Bearing all in mind, the present study pioneers the use of high-energy (15 MV) X-ray irradiation to functionalize Ni(OH)₂ electrodes, aiming to overcome the inherent limitations of pristine Ni(OH)₂. By using the energy transfer processes associated with X-ray irradiation, this work introduces new surface functionalities, enhances ion transport pathways, and stabilizes the electrochemical environment of the electrode material. Detailed structural, chemical, and electrochemical characterizations confirm that the functionalized Ni(OH)₂ (f-Ni(OH)₂) exhibits significantly improved areal capacitance, reduced internal resistance, and superior cycle stability compared to its non-irradiated counterpart. This study also pioneers the use of high-energy X-ray irradiation for the functionalization of transition metal hydroxides, establishing a scalable and chemical-free approach to fabricate electrodes with microsupercapacitor-level performance. This approach offers a transformative pathway for the development of high-performance, long-lifespan energy storage devices, bridging the gap between fundamental radiation-matter interaction research and practical energy applications.

Experimental

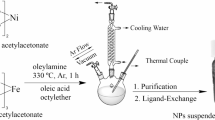

High-energy X-ray irradiation procedure

The functionalization of Ni(OH)₂ was carried out through exposure to high-energy X-ray irradiation. 1.5 g Ni(OH)₂ powder was homogeneously distributed within a petri dish to form a uniform layer, with the thickness strictly controlled to be below 1 mm to ensure consistent irradiation across the sample surface. The sample was irradiated using a 15 MV linear accelerator at a dose rate of 1000 monitor units (MU) per minute. The source-to-sample distance was fixed at 100 cm, and the total absorbed dose ranged between 10 and 20 Gy. The irradiation process was designed to induce surface-level modifications predominantly through Compton scattering and related high-energy photon-matter interaction mechanisms, while maintaining the integrity of the bulk crystal structure. The irradiated product is denoted as functionalized-Ni(OH)₂ (f-Ni(OH)₂) throughout this work.

Electrode fabrication

Electrodes were fabricated by preparing a composite mixture containing Ni(OH)₂ or f-Ni(OH)2 (electrode active materials), carbon black (as conductive additive), and PVDF binder in a mass ratio of 5:3:1. The mass ratio of 5:3:1 was selected based on its proven effectiveness in balancing electrochemical performance and mechanical stability for metal hydroxide-based supercapacitor electrodes. Ni(OH)₂, being inherently non-conductive, requires sufficient conductive additive to establish a robust electron transport network. A 3-part proportion of carbon black ensures improved charge transfer and reduced internal resistance across the electrode. Simultaneously, limiting the PVDF binder to 1 part prevents excessive surface coverage, thus preserving electrolyte accessibility and ion transport. This formulation was optimized through preliminary tests (data not shown), which confirmed that deviations from this ratio either reduced mechanical integrity or led to compromised electrochemical properties. The powders were thoroughly mixed and dispersed in an appropriate amount of N-methyl-2-pyrrolidone to form a homogeneous slurry. After solvent evaporation at 60 ˚C oven, the mixture was pressed under a uniaxial pressure of 15,000 psi to form circular pellets of uniform dimensions. The final electrode mass was adjusted to ca.45 mg to ensure consistent electrochemical measurements across samples. The pelletized electrodes were dried under vacuum at 80 °C for 12 h before use.

Physical and chemical characterizations

Structural and chemical characterizations of Ni(OH)₂ and f-Ni(OH)₂ powders were performed to assess the effects of X-ray irradiation. X-ray diffraction (XRD) patterns were recorded to evaluate the crystallinity and phase integrity. The crystalline structure of the films is confirmed by using X-ray diffractometer (XRD) model Rigaku RadB in the scanning angle (2θ) range of 10–90 degrees with CuKα radiation with a wavelength of λ = 1.54056 Å. Raman spectroscopy (WITec-Alpha M+, 532 nm laser) was conducted to probe surface vibrational modes, while Fourier-transform infrared (FTIR) spectroscopy (A Perkin Elmer Spectrum 400 spectrometer with 4 cm−1 resolution and 10 scans per spectrum) was employed to identify functional groups and detect surface chemical modifications. Inductively coupled plasma mass spectrometry (ICP-MS) (AGILENT-7500 A) analysis was carried out to examine possible changes in isotopic composition following irradiation.

Electrochemical characterization

All electrochemical evaluations were performed in a three-electrode configuration in 1.0 M Na₂SO₄ aqueous electrolyte to isolate and systematically assess the intrinsic properties of the electrode materials without the influence of full-cell asymmetries or electrolyte mass loading effects. A Pt wire served as the counter electrode, and a saturated calomel electrode (SCE) was used as the reference electrode. Cyclic voltammetry (CV) measurements were performed within a potential window of − 1.0 V to + 1.0 V at various scan rates ranging from 1.0 to 100.0 mV·s−1. Galvanostatic charge-discharge (GCD) tests were conducted at current densities between 1.0 and 5.0 mA·cm−2. Electrochemical impedance spectroscopy (EIS) measurements were carried out in the frequency range from 0.01 Hz to 100 kHz with an amplitude of 5 mV. All electrochemical measurements were conducted at room temperature using an IVIUMSTAT A06061 potentiostat/galvanostat system.

Results and discussions

Structural and chemical characterization

The structural integrity and surface modifications induced by high-energy X-ray irradiation were first investigated using X-ray diffraction (XRD) analysis. Figure 1a presents the XRD patterns of the pristine Ni(OH)₂ and the f-Ni(OH)₂ samples. The phase identification of both pristine and f-Ni(OH)₂ samples was conducted by comparing the recorded XRD patterns with the standard reference file from the Joint Committee on Powder Diffraction Standards (JCPDS Card No. 14–0117), corresponding to the β-Ni(OH)₂ phase48,49. The major diffraction peaks observed at 2θ ≈ 18.7°, 33.1°, 38.5°, 52.1°, and 59.3° can be indexed to the (001), (100), (101), (102), and (110) crystallographic planes of hexagonal β-Ni(OH)₂, respectively24,48,50. In addition to the major reflections, weaker high-angle peaks are observed near 2θ ≈ 71.6° and 77.5°, corresponding to the (103) and (201)/(203) planes of β-Ni(OH)₂, respectively, consistent with JCPDS Card No. 14–011751. Although these reflections are of low intensity, their presence further confirms the preservation of the long-range crystalline order after X-ray irradiation. These reflections are in good agreement with the standard β-phase, confirming the retention of the layered hydroxide structure after high-energy X-ray irradiation.

Notably, a broad and low-intensity feature was observed near 2θ ≈ 15° in both pristine and irradiated samples. This peak does not correspond to a standard β-phase reflection but can be attributed to the (003) plane of α-Ni(OH)₂, as indexed in JCPDS Card No. 38–071552,53. In fully hydrated α-Ni(OH)₂, this basal reflection typically appears at lower angles (~ 11.3°–12.2°). However, it has been reported to shift toward higher angles (13°–15°) upon partial dehydration, interlayer collapse, or environmental exposure53,54,55. Given that both samples exhibit this feature regardless of irradiation, it is likely related to structural disorder or minor interstratified α-like domains inherent in the pristine Ni(OH)₂ material, possibly induced during ambient storage. The slightly increased intensity in the irradiated sample may reflect additional surface rearrangement induced by high-energy exposure, although no sharp α-phase peaks are observed. These findings suggest that while the dominant phase remains β-Ni(OH)₂, a small fraction of structurally disordered or dehydrated α-Ni(OH)₂-like regions may coexist, giving rise to the broad feature at ~ 15°. The main β-phase reflections remain sharp and unchanged, confirming that the irradiation primarily induces surface-level modifications without compromising the crystallographic integrity of the bulk structure. The absence of new diffraction peaks further confirms that the functionalization process selectively alters the surface chemistry while maintaining the bulk phase integrity of Ni(OH)₂.

These structural modifications at the surface are further supported by Raman spectroscopy results shown in Fig. 1b. Both pristine and irradiated Ni(OH)₂ samples exhibit a strong Raman band around 2922 cm⁻¹, attributed to the stretching vibration of hydroxyl (OH⁻) groups associated with the Ni(OH)₂ lattice. In addition to the common features, a new peak emerged near 2850 cm⁻¹ in the f-Ni(OH)₂ spectrum, which is absent in the pristine sample24. This new vibrational mode is indicative of local chemical rearrangements, potentially corresponding to newly formed hydroxyl-related configurations or surface defects induced by X-ray interaction. The appearance of this feature suggests that X-ray irradiation successfully introduced additional active sites at the material surface, which can facilitate improved redox reactions during electrochemical cycling.

Further insights into the chemical bonding environment were obtained via FTIR spectroscopy, as shown in Fig. 2. Both Ni(OH)₂ and f-Ni(OH)₂ samples displayed characteristic absorption bands at 635 cm−1, 1360 cm−1, and 1600 cm−1, corresponding to Ni–O stretching vibrations and O–H bending modes. These observations confirm that the primary chemical structure of Ni(OH)₂ was maintained following irradiation56,57. Notably, in the high wavenumber region, a shift in the hydroxyl stretching vibration band from 3283 cm−1 in pristine Ni(OH)₂ to approximately 3307 cm⁻¹ in f-Ni(OH)₂ was recorded. This shift indicates a change in the hydrogen bonding network and suggests modifications in the surface chemical environment, likely arising from the interaction of high-energy X-ray with surface hydroxyl groups56,57. Such modifications are expected to enhance ionic transport and improve pseudocapacitive behavior by creating more favorable redox-active sites.

Ni(OH)₂ is readily converted into NiOOH or its intermediate phase, Ni–O–OH, particularly under electroactive environments or oxidative conditions. This transformation commonly occurs during the β-Ni(OH)₂ → γ-NiOOH phase transition and can be triggered by exposure to high-energy oxidative stimuli such as X-ray irradiation. The formation of Ni–O–OH species is highly probable via mechanisms including Compton scattering and the photoelectric effect initiated by incident X-ray. Such high-energy radiation can induce deprotonation of hydroxide ions, promoting the formation of oxygen-bridged nickel oxyhydroxide species (Ni–O–OH). The spectral differences observed in FTIR and Raman analyses provide evidence supporting this transformation. Accordingly, the following surface reaction may occur post-irradiation:

Ni(OH)2 \(\:\underrightarrow{high\:energy\:X-ray\:}\) Ni-O-OH + H+ + e−

This process results in the formation of an electroactive surface, which can significantly enhance charge storage capability. The generation of Ni–O–OH species introduces additional redox-active sites, thereby facilitating faradaic reactions that contribute to improved pseudocapacitive behavior. As a result, this structural transformation may lead to increased specific capacitance and enhanced overall electrochemical performance of the electrode material, making it particularly attractive for advanced supercapacitor applications.

ICP-MS analysis was conducted to examine potential changes in the isotopic composition after irradiation (Table 1). The major isotopic distribution of nickel (Ni-58, Ni-60, Ni-61, and Ni-62) remained stable, confirming that the irradiation process did not induce significant bulk transmutation or atomic disintegration. However, trace amounts of radioactive isotopes such as Ni-59 and Ni-63 were significantly reduced after irradiation, indicating a purification effect. Although these isotopes are present at extremely low levels and do not directly contribute to electrochemical performance, their depletion enhances the material’s safety and stability profile for potential energy storage applications. After irradiation, a significant reduction in the isotopes Ni-59 and Ni-63 has been observed. This phenomenon is likely not due to isotope decay, but rather attributed to surface ion exchange processes or the desorption of these isotopes from the surface due to their relatively low stability.

Collectively, these structural and chemical characterizations demonstrate that high-energy X-ray irradiation effectively functionalized the surface of Ni(OH)₂ while preserving its bulk crystalline framework. The introduced surface defects, modified hydroxyl groups, and enhanced active sites are anticipated to contribute significantly to the improved electrochemical behavior observed in the subsequent analyses.

Evaluation of electrochemical characterizations

The electrochemical behavior of pristine and X-ray irradiated Ni(OH)₂ electrodes was investigated by CV analysis using a three-electrode system over a potential window from − 1.0 V to + 1.0 V at various scan rates ranging from 1 to 100 mV·s⁻¹. The resulting voltammograms, presented in Fig. 3, reveal profound differences between the pristine and irradiated electrodes, clearly reflecting the beneficial effects of X-ray surface functionalization. The CV curves of the pristine Ni(OH)₂ electrode (Fig. 3a) exhibit relatively narrow profiles with distorted shapes, particularly at lower scan rates. The current response is modest, and the capacitive behavior appears limited, suggesting sluggish electrochemical kinetics and poor ionic accessibility to active sites. As the scan rate increases, the current density declines sharply, and significant distortion of the CV curves is observed, indicative of diffusion-limited charge storage and slow faradaic processes. These results highlight the intrinsic limitations of pristine Ni(OH)₂, including low electrical conductivity and limited redox-active surface areas, which restrict its charge storage performance. In contrast, the f-Ni(OH)₂ electrode (Fig. 3b) demonstrates a substantially enhanced electrochemical response. At all scan rates, the f-Ni(OH)₂ voltammograms show significantly higher current densities compared to the pristine sample, with broader and more symmetric curves. The f-Ni(OH)₂ electrode maintains a well-defined capacitive response even at high scan rates such as 100 mV·s−1, reflecting excellent rate capability and efficient ion diffusion within the electrode structure. The improved current retention with increasing scan rate suggests a lower internal resistance and enhanced charge transfer kinetics, both of which are critical for high-power energy storage applications. The calculated specific capacitance values from CV voltammograms (Cs, CV; mF.cm−2) were tabulated in Table 2. At a scan rate of 1 mV·s−1, the f-Ni(OH)₂ electrode achieves a specific areal capacitance of 671.2 mF·cm−2, representing an approximately 41% enhancement over the pristine Ni(OH)₂ electrode, which exhibits 474.7 mF·cm−2 under identical conditions. This significant improvement is attributed to the structural and chemical modifications induced by high-energy X-ray irradiation. The X-ray treatment is believed to create defect-rich regions, increased surface roughness, and localized chemical disorder, thereby increasing the density of electrochemically active sites. These modifications facilitate improved electrolyte penetration, faster redox reactions, and enhanced ion adsorption-desorption dynamics at the electrode–electrolyte interface.

Mechanistically, the improvement in electrochemical performance can be explained by the interactions induced during X-ray irradiation. High-energy photons primarily interact with the Ni(OH)₂ structure through Compton scattering, leading to localized energy deposition that causes bond reorganization, surface atom displacement, and generation of shallow traps. These newly created surface states act as active centers for faradaic reactions, enhancing pseudocapacitive behavior. The emergence of new vibrational bands around 2850 cm−1 in the Raman spectra of f-Ni(OH)₂ further confirms the formation of chemically modified surface groups that can participate in charge storage processes. Additionally, shifts observed in FTIR spectra indicate changes in hydrogen bonding and hydroxyl environments, which likely improve the proton-coupled electron transfer mechanisms.

The difference between the two electrodes becomes even more pronounced at higher scan rates. While the pristine Ni(OH)₂ electrode exhibits a sharp decrease in current density with increasing scan rate highlighting ion transport limitations, the f-Ni(OH)₂ electrode retains a substantial portion of its current response. This behavior suggests that the irradiated surface supports faster ion diffusion and more efficient electron transport, minimizing resistive losses during rapid cycling. The reduced peak separation and smoother current-voltage profiles of f-Ni(OH)₂ indicate lower polarization and superior electrochemical reversibility, both of which are critical for high-performance supercapacitor applications. All together, the CV analysis demonstrates that high-energy X-ray irradiation transforms the electrochemical behavior of Ni(OH)₂ by creating a surface that combines high pseudocapacitive activity with excellent rate capability. The resulting f-Ni(OH)₂ electrodes achieve enhanced areal capacitance, faster redox kinetics, and improved structural stability, positioning them as strong candidates for integration into advanced microsupercapacitor and high-power energy storage systems.

To further evaluate the charge storage performance and internal resistance characteristics of pristine and high energy X-ray irradiated Ni(OH)₂ electrodes, GCD and EIS analysis were conducted. GCD curves were recorded over a potential window of − 1.0 V to + 1.0 V at current densities ranging from 1.0 to 5.0 mA·cm−2, and the resulting voltage–time profiles are shown in Fig. 4a and b for pristine Ni(OH)₂ and f-Ni(OH)₂ electrodes, respectively. The GCD curves of the pristine Ni(OH)₂ electrode (Fig. 4a) exhibit non-linear voltage profiles, with significant IR drops and shorter discharge times across all current densities. These characteristics are indicative of high internal resistance, sluggish charge propagation, and limited capacitive behavior, particularly under elevated current loads. As the current density increases, the discharge time decreases rapidly, confirming that the electrode cannot maintain stable redox reactions under fast cycling conditions. The poor rate performance and cycle stability can be attributed to low ionic diffusivity, limited redox-active surface area, and inefficient electron transport pathways inherent to the bulk Ni(OH)₂ structure. On the other hand, the GCD curves of the f-Ni(OH)₂ electrode (Fig. 4b) show significantly extended discharge durations and more symmetric charge–discharge profiles, especially at lower current densities. At 1 mA·cm−2, the f-Ni(OH)₂ electrode delivers a discharge time of approximately 7000 s, compared to ~ 4500 s for the pristine counterpart, reflecting a substantially higher areal capacitance. Even at high current densities of 5 mA·cm−2, the irradiated electrode maintains a relatively flat voltage plateau and reduced IR drop, suggesting improved electrochemical reversibility and lower resistance. The specific capacitance values calculated from the GCD curves (Cs, GCD; mF.cm−2) (Table 2) reveal that the f-Ni(OH)₂ electrode consistently outperforms the pristine Ni(OH)₂ at all current densities. At 1.0 mA·cm−2, the f-Ni(OH)₂ electrode achieves a specific capacitance of 1253.5 mF·cm−2, representing a ~ 25% improvement over the pristine sample (1002.5 mF·cm−2), and retains higher capacitance even at 5.0 mA·cm−2 (89.0 vs. 57.4 mF·cm−2), indicating superior rate capability and efficient charge storage under high current conditions. This enhancement is attributed to the increased surface reactivity, reduced resistance, and improved ion-accessibility imparted by high-energy X-ray irradiation. The enhanced GCD behavior of the irradiated electrode is strongly correlated with the surface-level modifications induced by X-ray exposure. At an energy level of 15 MV, the dominant radiation–matter interaction mechanism is Compton scattering, which disrupts surface bonds, generates structural defects, and partially amorphizes the electrode surface without compromising bulk crystallinity. These physical modifications result in a more disordered, defect-rich interface with improved electrolyte wettability and a higher density of electrochemically active sites. Additionally, the appearance of new hydroxyl-related vibrational bands, as confirmed by Raman and FTIR spectroscopy, supports the formation of favorable redox environments that contribute to the observed pseudocapacitive behavior.

Electrochemical impedance spectroscopy further elucidates the impact of irradiation on charge transfer and internal resistance. The Nyquist plots shown in Figs. 4c compare the impedance response of the pristine Ni(OH)₂ and f-Ni(OH)₂ electrodes, respectively. In the high-frequency region, the intercept of the real axis represents the solution resistance (Rs), while the semicircle diameter reflects the charge transfer resistance (Rct). As a result of fitting the EIS spectra using the Randles equivalent circuit mode, the Rs value of the Ni(OH)₂ electrode was observed to be 18.4 Ω, whereas this value decreased to 13.0 Ω for the f-Ni(OH)₂ electrode. Furthermore, while the Rct value for the Ni(OH)₂ electrode increased for the f-Ni(OH)₂ electrode. This increase can be attributed to the presence of high-energy surface defects, amorphous domains, or oxidized passive regions formed during the irradiation process, which may introduce additional resistance to electron transfer. Indeed, the functionalization process enhanced the interaction between electrolyte ions and the electrode surface, thereby increasing the pseudocapacitance. However, the structural distortions or atomic-level changes that occurred during this process likely imposed limitations on the electron transport pathways, ultimately slowing down the charge transfer kinetics. In other words, while the functionalization improved the capacitive performance, it also introduced complexity to the system’s electrochemical kinetics, thereby explaining the apparent inconsistency between the EIS and CV/GCD results. This discrepancy highlights that charge transfer and ion diffusion can be affected independently, and that each electrochemical characterization technique reflects a different aspect of the overall energy storage process.

ICP-MS data indicate a marked reduction in trace radioactive isotopes such as Ni-59 and Ni-63 following X-ray irradiation. Although present in extremely low concentrations, these isotopes may contribute to lattice strain or electronic inhomogeneity under operating conditions. Their depletion suggests that X-ray treatment leads to a purification of the electrochemically active surface, which may reduce defect-related recombination or non-productive redox sites, thereby improving overall electrode stability and response. Moreover, while the concentration of Ni isotopes such as Ni-58, Ni-60, Ni-61, and Ni-62 remains stable, the radiation-induced excitation of surface-bound ions could alter local electron density, coordination environments, or valence states, all of which play a role in modulating electrochemical behavior. These modifications, although not directly reliant on isotopic transmutation, reflect the fine balance between atomic structure and charge storage efficiency a relationship that X-ray irradiation uniquely enables by driving targeted surface functionalization without the introduction of foreign elements. The GCD and EIS analyses confirm that high-energy X-ray irradiation is an effective and scalable tool for enhancing the electrochemical performance of Ni(OH)₂ electrodes. By simultaneously reducing internal resistance, increasing active site density, and stabilizing redox behavior, the irradiated electrodes demonstrate the characteristics necessary for application in long-cycle, high-rate, and microscale supercapacitor devices.

One of the most significant challenges facing Ni(OH)₂-based electrode materials is their inherently poor long-term cyclic stability, primarily caused by irreversible structural degradation, volumetric changes, and loss of electroactive sites during repeated redox cycling. In previously reported studies, pristine Ni(OH)₂ electrodes typically exhibit capacity retention values in the range of 60–85% after 3000–5000 cycles, especially under high current densities or potential scan rates (Asaithambi et al. 2023). These limitations have significantly hindered their commercial viability in durable supercapacitor applications. As a result of 5000 CV cycles conducted at a scan rate of 500 mV·s−1, the pristine Ni(OH)₂ electrode exhibited a capacitive retention of 96.3%. In contrast, the X-ray irradiated f-Ni(OH)₂ electrode in this study exhibits outstanding electrochemical stability, retaining 99.2% of its initial capacitance after 5,000 consecutive CV cycles at a potential scan rate of 500 mV·s−1 (Fig. 5). The near-overlapping CV curves of the 1 st and 5000th cycles indicate negligible structural degradation, high coulombic efficiency, and remarkable redox reversibility. This superior performance can be attributed to the X-ray-induced formation of a defect-rich yet structurally robust surface that accommodates repeated ion insertion/extraction with minimal phase disruption. Moreover, the increased chemical homogeneity and the possible purification of surface-active sites evidenced by isotope depletion (e.g., Ni-59, Ni-63) may contribute to the enhanced durability and suppression of side reactions. In all measurements, the initial and final CV curves of both electrodes nearly overlap, indicating excellent structural integrity. However, the differences observed between the Ni(OH)₂ and f-Ni(OH)₂ electrodes at low scan rates largely disappeared at this high scan rate. This can be explained by the insufficient time available for redox reactions to fully occur at such a rapid scan rate of 500 mV·s−1. These findings place f-Ni(OH)₂ among the most stable Ni-based hydroxide electrodes reported to date, and position high-energy X-ray irradiation as a transformative strategy for engineering ultra-stable pseudocapacitive materials.

Table 3 presents a comparative summary of various nickel hydroxide-based electrode systems with different modifications and electrolytes, highlighting their specific capacitance, cycle stability, and performance metrics. Among the entries, f-Ni(OH)₂ demonstrates a remarkable enhancement in electrochemical performance, especially when compared to pristine Ni(OH)₂ and several reported advanced composites. Specifically, the f-Ni(OH)₂ electrode exhibits a high areal capacitance of 1253.5 mF·cm−2 (GCD) in 1.0 M Na₂SO₄, representing a ~ 25% improvement over the unmodified Ni(OH)₂ (1002.5 mF·cm−2). This enhancement can be directly attributed to the formation of electroactive Ni–O–OH species induced by X-ray irradiation, which introduces additional redox-active sites and promotes improved ion diffusion and charge storage behavior. Notably, this was achieved without any compositional additives or hybridization strategies, setting it apart from most other systems in the literature that rely on carbon-based composites or MOF-derived architectures. While other reported systems, such as Ni(OH)₂@ZIF-67 and Ni(OH)₂/Ni foam structures, demonstrate higher gravimetric capacitance values (up to 1950 F·g−1), these results are typically obtained in alkaline media (KOH) and involve complex fabrication processes and hybrid structures. In contrast, this study use a neutral electrolyte (Na₂SO₄) ensuring better biocompatibility and stability, which is advantageous for real-world, environmentally friendly applications. In terms of cycling performance, the f-Ni(OH)₂ electrode also exhibits excellent stability with 99.2% capacitance retention over 5000 cycles, outperforming or matching other entries such as the Ni(OH)₂/Carbon Nanotube composite (92%) and the Ni(OH)₂@ZIF-67 hybrid (94.8%).

Conclusions and future directions

This study presents a novel and effective strategy for enhancing the electrochemical performance of Ni(OH)₂ electrodes through high-energy X-ray irradiation-induced surface functionalization. By utilizing 15 MV X-ray exposure, structural disorder and redox-active surface defects were selectively introduced without compromising the bulk crystallinity of the material. Physicochemical analyses confirmed that the irradiation process preserved the Ni(OH)₂ phase while modifying surface bonding environments, as evidenced by Raman and FTIR spectroscopic shifts and the emergence of new vibrational features. These changes contributed to the formation of more accessible, ion-conductive, and electrochemically favorable surface states. More importantly, the FTIR and Raman spectra provide compelling evidence that Ni(OH)₂ is transformed into a Ni–O–OH structure upon irradiation. The removal of protons from the structure, along with an increased presence of electronegative atoms such as oxygen, may have facilitated enhanced charge storage on the surface. Electrochemical characterizations revealed that the irradiated f-Ni(OH)₂ electrode exhibited superior performance in all key metrics compared to its pristine counterpart. The specific areal capacitance reached 1253.5 mF·cm−2 at 1.0 mA·cm−2, and the electrode maintained a robust capacitive response even at high scan and current rates. EIS further confirmed reduced solution and charge transfer resistance, consistent with improved ion/electron kinetics. Most notably, the f-Ni(OH)₂ electrode demonstrated exceptional cycling stability, retaining 99.2% of its initial capacitance after 5000 cycles at 10 mA·cm−2 outperforming most previously reported Ni(OH)₂-based systems. This outstanding durability is attributed to the stabilized redox interface, reduced defect recombination, and possible isotopic purification observed post-irradiation.

The approach described herein represents a scalable, chemical-free route for tuning the surface properties of transition metal hydroxides, thereby unlocking their full potential for advanced energy storage applications. The results mark a substantial advancement in the development of stable and high-performance supercapacitor electrodes, particularly for microscale energy systems. Future studies should focus on integrating f-Ni(OH)₂ into full two-electrode symmetric or asymmetric device architectures to evaluate practical energy and power densities. Additionally, thin-film deposition of irradiated materials on flexible or micro-patterned substrates could enable the fabrication of miniaturized or wearable microsupercapacitors. Combining this radiation-assisted surface engineering method with other strategies such as heteroatom doping, hybrid composite formation, or 3D structuring may further boost device performance. Finally, a deeper exploration of irradiation parameters such as dose, energy, and exposure time could help fine-tune defect chemistry and electrochemical response, broadening the applicability of this method to other classes of electroactive materials.

Data availability

Data can be made available upon reasonable request.

References

Dubal, D. P., Ayyad, O., Ruiz, V. & Gómez-Romero, P. Hybrid energy storage: The merging of battery and supercapacitor chemistries. Chem. Soc. Rev. https://doi.org/10.1039/c4cs00266k (2015).

Dzikunu, P. et al. Waste-to-carbon-based supercapacitors for renewable energy storage: progress and future perspectives. Mater. Renew. Sustain. Energy. 14, 8 (2025).

Gupta, D., Liu, S., Zhang, R. & Guo, Z. Future long cycling life cathodes for aqueous Zinc-Ion batteries in Grid‐Scale energy storage. Adv. Energy Mater. https://doi.org/10.1002/aenm.202500171 (2025).

Vanaraj, R., Arumugam, B., Mayakrishnan, G. & Kim, S. C. Advancements in Metal-Ion capacitors: bridging energy and power density for Next-Generation energy storage. Energies (Basel). 18, 1253 (2025).

Khan, K. et al. Going green with batteries and supercapacitor: Two dimensional materials and their nanocomposites based energy storage applications. Prog. Solid State Chem. https://doi.org/10.1016/j.progsolidstchem.2019.100254 (2020).

Muzaffar, A., Ahamed, M. B. & Hussain, C. M. Green supercapacitors: Latest developments and perspectives in the pursuit of sustainability. Renew. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2024.114324 (2024).

Pantrangi, M. et al. Flexible micro-supercapacitors: materials and architectures for smart integrated wearable and implantable devices. Energy Storage Mater. 73, 103791 (2024).

Rashid Khan, H. & Latif Ahmad, A. Supercapacitors: Overcoming current limitations and charting the course for next-generation energy storage. J. Ind. Eng. Chem. 141, 46–66 (2025).

Oyedotun, K. O. et al. Advances in Supercapacitor Development: Materials, Processes, and Applications. J. Electronic Mater. https://doi.org/10.1007/s11664-022-09987-9 (2023).

Reenu, S., Phor, L., Kumar, A. & Chahal, S. Electrode materials for supercapacitors: A comprehensive review of advancements and performance. J. Energy Storage. https://doi.org/10.1016/j.est.2024.110698 (2024).

Lakshmi, K. C. S. & Vedhanarayanan, B. High-Performance Supercapacitors: A Comprehensive Review on Paradigm Shift of Conventional Energy Storage Devices. Batteries https://doi.org/10.3390/batteries9040202 (2023).

Sahoo, P. K. et al. Recent progress in graphene and its derived hybrid materials for high-performance supercapacitor electrode applications. RSC Advances https://doi.org/10.1039/d3ra06904d (2024).

Wang, Y. et al. Recent progress in carbon-based materials for supercapacitor electrodes: A review.. J. Mater. Sci. https://doi.org/10.1007/s10853-020-05157-6 (2021).

Jin, Y. et al. Recent advances of carbon dots based emerging materials for supercapacitors applications. J. Energy Storage https://doi.org/10.1016/j.est.2024.111118 (2024).

Zhang, M. & Peng, L. Research progress of biomass-derived carbon for the supercapacitors. Mater. Res. Expr. https://doi.org/10.1088/2053-1591/ad1013 (2024).

Shaheen Shah, S. et al. Recent Progress in Polyaniline and its Composites for Supercapacitors. Chem. Rec. https://doi.org/10.1002/tcr.202300105 (2024).

Tadesse, M. G., Ahmmed, A. S. & Lübben, J. F. Review on conductive polymer composites for supercapacitor applications. J. Composites Sci. https://doi.org/10.3390/jcs8020053 (2024).

Wang, Y., Ding, Y., Guo, X. & Yu, G. Conductive polymers for stretchable supercapacitors. Nano Res. https://doi.org/10.1007/s12274-019-2296-9 (2019).

Mustaqeem, M. et al. Rational design of metal oxide based electrode materials for high performance supercapacitors – A review. J. Energy Storage. 55, 105419. https://doi.org/10.1016/j.est.2022.105419 (2022).

Theerthagiri, J. et al. Recent advances in metal chalcogenides (MX; X = S, Se) nanostructures for electrochemical supercapacitor applications: A brief review. Nanomaterials https://doi.org/10.3390/nano8040256 (2018).

Shi, F., Li, L., Wang, X. L., Gu, C. D. & Tu, J. P. Metal oxide/hydroxide-based materials for supercapacitors. RSC Advances. https://doi.org/10.1039/c4ra06136e (2014).

Nguyen, T. & de Montemor, M. Metal Oxide and Hydroxide–Based Aqueous Supercapacitors: From Charge Storage Mechanisms and Functional Electrode Engineering to Need-Tailored Devices. Advanced Sci. https://doi.org/10.1002/advs.201801797 (2019).

Yang, Q. et al. Metal oxide and hydroxide nanoarrays: Hydrothermal synthesis and applications as supercapacitors and nanocatalysts. Prog. Nat. Sci.: Materials International. https://doi.org/10.1016/j.pnsc.2013.06.015 (2013).

Hall, D. S., Lockwood, D. J., Bock, C. & MacDougall, B. R. Nickel hydroxides and related materials: A review of their structures, synthesis and properties. Proc. Royal Soc. Mathematical, Phys. Eng. https://doi.org/10.1098/rspa.2014.0792 (2015).

Yuksel, R., Coskun, S., Kalay, Y. E. & Unalan, H. E. Flexible, silver nanowire network nickel hydroxide core-shell electrodes for supercapacitors. J . Power Sources. 328, 167–173. https://doi.org/10.1016/j.jpowsour.2016.08.008 (2016).

Li, H. B. et al. Amorphous nickel hydroxide nanospheres with ultrahigh capacitance and energy density as electrochemical pseudocapacitor materials. Nat Commun. 4, 1894. https://doi.org/10.1038/ncomms2932 (2013).

Dai, X. et al. Ni(OH)2/NiO/Ni composite nanotube arrays for high-performance supercapacitors. Electrochim Acta. 154, 128–135. https://doi.org/10.1016/j.electacta.2014.12.066 (2015).

Brisse, A. L., Stevens, P., Toussaint, G., Crosnier, O. & Brousse, T. Ni(OH)2 and NiO based composites: Battery type electrode materials for hybrid supercapacitor devices. Materials https://doi.org/10.3390/ma11071178 (2018).

Senthil, R. A. et al. Insights on Ni-based layered double hydroxides for electrochemical supercapacitors: Underlying aspects in rational design and structural evolution. J. Energy. Storage. https://doi.org/10.1016/j.est.2023.108305 (2023).

Gao, X. et al. Self-Grown 1D/2D Ni(OH)2 nanofiber/nanosheet on corn stigma-derived carbon for high-performance hybrid supercapacitors. Appl. Surf. Sci. 609, 155448. https://doi.org/10.1016/j.apsusc.2022.155448 (2023).

Wu, W. et al. Rational design of hierarchical Ni(OH)2–MnO2 nanoflowers @Ti3C2Tx nanosheets heterostructure as advanced symmetric supercapacitors. J. Mater. Sci. Mater. Electronics. 34, 855. https://doi.org/10.1007/s10854-023-10202-6 (2023).

Li, D. et al. Excellent performance supercapacitors with the compounding of Ni(OH)2 and ZIF-67 derived Co-C-N nanosheets as flexible electrode materials. Nanoscale Adv. 4, 4381–4390 (2022).

Kumari, R., Prajapati, M. & Kant, C. R. X-Ray Irradiation-Induced enhancement of supercapacitive properties of Bio-derived activated carbon. J. Electron. Mater. 53, 4985–4996 (2024).

Als-Nielsen, J. X-rays and matter - the basic interactions. Comptes Rendus Physique https://doi.org/10.1016/j.crhy.2008.01.002 (2008).

Chantler, C. T. & Creagh, D. C. X-ray interactions with matter. https://doi.org/10.1107/s1574870722001549(2022).

Serman, N., Goaz, P. & Pharoah, M. Production of X-rays and interactions of X-rays with Matter. Columbia University (2000).

Clough, R. L. High-energy radiation and polymers: A review of commercial processes and emerging applications. Nucl. Instrum. Methods Phys. Res. B . 185, 8–33. https://doi.org/10.1016/S0168-583X(01)00966-1 (2001).

Koroni, C., Olsen, T., Wharry, J. P. & Xiong, H. Irradiation-Induced Amorphous-to-Crystalline Phase Transformations in Ceramic Materials. Materials. https://doi.org/10.3390/ma15175924 (2022).

Bardi, N. et al. X-ray irradiation-induced structural changes on single wall carbon nanotubes. Radiation Phys. Chemistry. 140, 34–37. https://doi.org/10.1016/j.radphyschem.2017.03.008 (2017).

Itoh, C., Uotome, K., Kisoda, K., Murakami, T. & Harima, H. Structural change of single-walled carbon nanotube induced by soft X-ray irradiation. Nucl. Instrum. Methods Phys. Res. B. 266 , 2772–2775. https://doi.org/10.1016/j.nimb.2008.03.114 (2008).

Chenakin, S. P., Silvy, R. P. & Kruse N. X-ray induced surface modification of aluminovanadate oxide. Catal Letters. 102, 39–43 (2005).

Adriaens, A., Quinn, P., Nikitenko, S. & Dowsett, M. G. Real time observation of X-ray-induced surface modification using simultaneous XANES and XEOL-XANES. Anal Chem. 85 , 9556–9563. https://doi.org/10.1021/ac401646q (2013).

Ebert, T. et al. Enhanced brightness of a laser-driven X-ray and particle source by microstructured surfaces of silicon targets. Phys. Plasmas. 27, 043106. https://doi.org/10.1063/1.5125775 (2020).

Wagner, A. J., Han, K., Vaught, A. L. & Howard fairbrother, D. X-ray induced modification of semifluorinated organic thin films. J. Phys. Chem. B . 104, 3291–3297. https://doi.org/10.1021/jp9933368 (2000).

Kwon, Y. B. et al. X-ray-induced changes in wettability. Langmuir. 25, 1927–1929. https://doi.org/10.1021/la804081k (2009).

Kim, T. K., Yang, X. M., Peters, R. D., Sohn, B. H. & Nealey, P. F. Chemical modification of self-assembled monolayers by exposure to soft x-rays in air. J. Phys. Chem. B. 104, 7403–7410. https://doi.org/10.1021/jp000145s (2000).

Ishino, M. et al. Nanoscale surface modifications and formation of conical structures at aluminum surface induced by single shot exposure of soft x-ray laser pulse. J Appl. Phys. 109, 013504. https://doi.org/10.1063/1.3525980 (2011).

Li, J., Zhao, W., Huang, F., Manivannan, A. & Wu, N. Single-crystalline Ni(OH)2 and NiO nanoplatelet arrays as supercapacitor electrodes. Nanoscale. 3 , 5103–5109. https://doi.org/10.1039/C1NR10802F (2011).

Witt, J. A., Mumm, D. R. & Mohraz, A. Microstructural tunability of co-continuous bijel-derived electrodes to provide high energy and power densities. J. Mater. Chem. Mater. 4 , 1000–1007. https://doi.org/10.1039/C5TA06260H (2016).

Sun, S. et al. Nickel-foam-supported β-Ni(OH)2 as a green anodic catalyst for energy efficient electrooxidative degradation of azo-dye wastewater. RSC. Adv. 8, 19776–19785. https://doi.org/10.1039/C8RA03039A (2018).

Qin, Z. et al. A Facile synthesis of three dimensional β-Ni(OH)2 composed of ultrathin nanosheets for high performance pseudocapacitor. J. Inorg. Organomet. Polym. Mater. 30 , 2089–2097. https://doi.org/10.1007/s10904-019-01360-4 (2020).

Wu, M. S., Zheng, Y. R. & Lina, G. W. Three-dimensional carbon nanotube networks with a supported nickel oxide nanonet for high-performance supercapacitors. Chemical Commun. 50, 8246–8248. https://doi.org/10.1039/C4CC02725F (2014).

Akhtar, M. S., Wejrzanowski, T., Komorowska, G., Adamczyk-Cieślak, B. & Choinska, E. Microwave-assisted hydrothermal synthesis of αβ-Ni(OH)2 nanoflowers on nickel foam for ultra-stable electrodes of supercapacitors. Electrochim. Acta. 508, 145284 (2024).

Li, Y. et al. Synthesis of α-Ni(OH)2 with hydrotalcite-like structure: precursor for the formation of NiO and Ni nanomaterials with fibrous shapes. Chemical Eng. J. 136 , 398–408. https://doi.org/10.1016/j.cej.2007.06.001 (2008).

Ramesh, T. N. & Kamath, P. V. The effect of stacking faults on the electrochemical performance of nickel hydroxide electrodes. Mater. Res. Bull. 43 , 2827–2832. https://doi.org/10.1016/j.materresbull.2008.06.010 (2008).

Provis-Evans, C. B., Farrar, E. H. E., Grayson, M. N., Webster, R. L. & Hill, A. K. Highly sensitive real-time isotopic quantification of water by ATR-FTIR. Anal. Chem. 92, 7500–7507. https://doi.org/10.1021/acs.analchem.9b05635 (2020).

Litvak, I., Anker, Y. & Cohen, H. On-line in situ determination of deuterium content in water via FTIR spectroscopy. RSC Adv. 8, 28472–28479 (2018).

Funding

This research was supported by Erciyes University Scientific Research Projects Coordination Unit under the project code FAPD-2024-13943.

Author information

Authors and Affiliations

Contributions

İ.A.K., O.K., and C.K. were responsible for the conceptualization of the study and wrote the main manuscript text. E.C., S.E.B.K., and İ.A.K. conducted the investigation. E.C., O.K., and C.K. contributed to data curation, formal analysis, and the visualization of the results, including the preparation of figures and tables. İ.A.K. coordinated project administration. All authors contributed to the review and editing of the manuscript during the revision stage and approved the final version of the manuscript prior to submission.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Karaman, O., Ceyran, E., Bolsu Kariper, S.E. et al. High-energy X-ray irradiation-induced functionalization of Ni(OH)₂ for enhanced supercapacitor electrodes. Sci Rep 15, 29194 (2025). https://doi.org/10.1038/s41598-025-13250-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-13250-6