Abstract

The primary objectives of this study were to evaluate the kinetics of Acori tatarinowii rhizoma (ATR) and to investigate how hot air drying at different temperatures affected the surface texture and sensory quality of the ATR. The drying kinetics of ATR were evaluated at five temperature levels (35, 45, 55, 65, and 75 ℃). Among the tested models, the Cubic model showed the best performance. It exhibited higher fitting accuracy with (\({R}^{2}=0.978-0.999\)) across all temperature conditions. Moreover, this model demonstrated lower error metrics (\({\chi }^{2}\), SSE, and RMSE) with minimal variations between temperatures. These results indicate that the Cubic model is the most suitable for characterizing the drying behavior of ATR under the studied conditions. The activation energy (\({E}_{a}\)) value of ATR dried by hot air drying was calculated as \(33.145\text{kJ}\cdot {mol}^{-1}\). Complementary analyses using scanning electron microscopy(SEM) and Heracles NEO ultra-fast gas chromatography analysis revealed temperature-dependent microstructural changes and volatile profile variations in ATR. 11 odor components were identified, with key thermal-modulated volatility patterns observed. Notably, methyl dodecanoate showed significantly higher concentrations at 65 °C than at 75 °C (P < 0.05). Overall, combined with the apparent properties of scanning electron microscopy and the color results of the colorimeter, thin-layer hot air drying at 65 ℃ can significantly enhance the final quality of ATR while preserving the odor profile and color properties and providing optimum medicinal characteristics. This study provides the first comprehensive analysis of drying temperature effects on ATR, uniquely correlating thermal parameters with surface morphology, microstructural evolution, and volatile compound preservation. By resolving the longstanding knowledge gap in ATR post-harvest processing, the work establishes quantitative criteria for industrial drying optimization, offering a science-based framework to balance efficiency and phytochemical quality.

Similar content being viewed by others

Introduction

Acori tatarinowii rhizoma (ATR) is the dried rhizome of Acorus Tatarinowii Schott1. It has invigorating and phlegm-eliminating, spirit-awakening and intelligence-enhancing, diaphoretic and appetizing effects. ATR contains volatile components, which are the main material basis for its efficacy. It has the characteristic of being highly heat-sensitive and is prone to drug loss2. The Chinese Pharmacopoeia (2020 edition) stipulates that the processing and drying of ATR in the production area is done in the sun, which is affected by climatic conditions and prone to mold and deterioration.

Microwave drying enhances dehydration efficiency but may cause over-drying due to inadequate heat and mass transfer regulation. Spray drying similarly accelerates the process but risks degrading thermolabile compounds3. Freeze-drying, involving water sublimation under controlled pressure/temperature, minimizes thermal damage but remains commercially limited by high costs and low throughput. Vacuum drying omits the freezing step yet may compromise structural integrity4. Supercritical drying, while preserving food microstructure above solvent critical points, shares similar economic constraints3.

Artificial drying methods, such as hot air drying5, are widely used in food and pharmaceutical processing to remove moisture, improve preservation by minimizing natural drying time, and prevent spoilage or degradation. Due to its practicality, low cost, and proven effectiveness, hot air drying6 is typically regarded as the ideal technique for drying plant-derived food components7. Compared with drying in the sun or in the shade, it offers the advantages of controlled temperature and weather resilience. The plant material is spread out in suitable equipment in thin layers, with a rapid flow of heated air traveling through each layer, resulting in significantly increased drying efficiency. For therapeutic herbs, this can ensure better medicinal quality8. However, the drying mechanism is unknown, the quality degradation mechanism in the drying process is unknown, and the drying end point is difficult to judge9; the problem of 'over-drying’ or 'under-drying’ often occurs. Excessive drying temperature can easily lead to the deterioration of the color of medicinal materials, the loss of volatile oil, and the degradation of active ingredients10,11. Inadequate drying temperature or too long, inefficient drying may result in the moisture content of medicinal materials not meeting the standards set by the Chinese Pharmacopoeia (2020 edition)12, making them susceptible to mold and biodegradation. It even causes the change of taste and loss of efficacy, resulting in the deterioration of the quality of aromatic Chinese herbal slices13.

At present, the existing research used different drying models to simulate the changes in the water ratio of American ginseng14, Fructus aurantii15, and purple cabbage powder6 during hot air drying at different temperatures and accurately predicted the water change rule, which provided new ideas for studying the drying characteristics and quality of ATR. In this study, five empirical models, including the cubic, logarithmic, binomial, two-term exponential, and Newton, were used to fit and verify the relationship between water ratio and time in the drying process. Zhang et al. investigated five drying methods for square bamboo shoots, analyzing the browning degree, color, rehydration capacity, and appearance of dried products. The study demonstrated that a precise cubic model effectively describes moisture variation over time across different drying methods, offering a reliable tool for analyzing and predicting moisture loss during the drying process16.

Electronic sensory evaluation systems primarily consist of E-nose, E-eye, and E-tongue, which are capable of assessing the odor, color, and taste of samples. Intelligent sensory analysis technology, based on human sensory bionics, integrates sensor arrays with data processing units and pattern recognition systems to detect samples17,18. This technology offers advantages such as high precision and excellent reproducibility, providing a scientific and data-driven complement to traditional sensory evaluation methods19,20,21. It is increasingly being applied in the production and development of food and pharmaceutical products22,23,24,25. The Heracles NEO ultra-fast gas phase electronic nose8,26,27,28 was used to determine the changes of odor components of ATR samples dried by hot air at different temperatures. Combined with the apparent properties and color of the scanning electron microscope and colorimeter, this study provided theoretical support and an experimental basis for improving the quality control of ATR processing and the optimization of the drying process.

The purpose of this research was to evaluate the effect of different temperatures on the drying kinetics and quality characteristics of ATR, including color difference, microstructure, and odor compositions, using intelligent sensory evaluation.

Materials and methods

Sample preparation

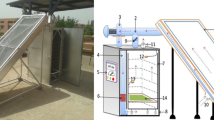

The ATR used in the experiment was produced in Fuzhou City, Jiangxi Province, China. The fresh, undamaged, and grey-brown ATR was selected as the test material. It was stored at 4 °C for a maximum of 2 weeks after purchase. The purified ATR samples were cut into 2 mm-thin slices. 100 g of processed ATR samples were dried at 35, 45, 55, 65, and 75 °C in a forced-air oven (BPG-9070A, 1500 W, Shanghai Yiheng Instrument Co., Ltd., Shanghai, China). The temperature range of 35 °C to 75 °C was selected based on a comprehensive consideration of protecting heat-sensitive components, balancing drying efficiency and energy consumption, ensuring experimental feasibility, referencing literature, and avoiding the effects of extreme temperatures. This range allows for a systematic study of the impact of temperature on the drying kinetics and product quality of Acori Tatarinowii Rhizoma (ATR), providing a scientific basis for industrial production. The samples were evenly spread in a single layer on a 15 cm diameter tray. Heat was generated by built-in heaters in the oven walls, with a natural convection air velocity of 2.0 m/s and a relative humidity of 6.00 ± 0.50%. A ventilation outlet (5 cm diameter) at the rear of the oven allowed exhaust gas to escape. During the 0 to 60 min drying period, the tray was removed and weighed every 5 min using an electronic balance (FA2004A, Shanghai Precision Scientific Instrument Co., Ltd., China). From 60 to 180 min, weighing was conducted every 10 min, and from 180 to 300 min, every 20 min. Drying continued until the constant weight was attained. The procedure involved in this research is shown as Fig. 1. The various components of the hot air-drying system are the air inlet, handle, blower motor, air outlet, display, switch, wind speed adjustment button, insulation layer, heater, and trays, as demonstrated through a schematic diagram in Fig. 2.

Calculation of drying characteristic parameters

The data measured each time were used to draw the drying curve, including the dry basis moisture content, the drying rate, and the moisture ratio that changed with time29,30.

Calculation of dry basis moisture content

The ATR was placed in a rapid moisture analyzer and dried at 105 °C until the quality did not change. The wet and dry weights of the fresh ATR were recorded; the equation to determine the water content can be expressed as31:

where M is the moisture content of ATR, \({\text{W}}_{w}\) is the wet weight of ATR, \({\text{W}}_{d}\) is the dry weight of ATR.

Calculation of the moisture ratio

Moisture ratio (MR) at different times could be expressed as32:

where \({M}_{0}\) is the initial dry basis moisture content of ATR.

Calculation of drying rate

The drying rate (DR) of ATR in the drying process is described as24:

Mathematical model of ATR drying kinetics

In order to study the drying characteristics of ATR, it is of great significance to describe the drying process of ATR as accurately as possible. In the drying process of ATR, five empirical models are used, as shown in Table 1, to fit the experimental drying data at different temperatures.

To assess the goodness of fit, the statistical correlation coefficient R2, chi-squared value χ2, and root mean square error (RMSE) were utilized. In general, higher R2, along with lower χ2 and RMSE, indicates better outcomes for model fitting36.

Effective diffusion coefficient(\({\mathbf{D}}_{\mathbf{e}\mathbf{f}\mathbf{f}}\)) and activation energy(\({\mathbf{E}}_{\mathbf{a}}\))

Effective diffusion coefficient(\({\mathbf{D}}_{\mathbf{e}\mathbf{f}\mathbf{f}}\))

In the hot-air drying process of ATR, it is generally believed that the internal water flow of ATR is diffusion (liquid or steam). Because the drying process of ATR is under unsteady conditions, in the whole analysis process, combined with the experimental data, the moisture (\({{\varvec{D}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\)) of the drying process of ATR can be calculated according to the formula (4).37

Where L is the thickness (m) of the thin-layer ATR experimental sample, n is the number of experimental samples, and t is the duration of the experiment. This equation may be used to assess whether a linear relationship exists between \(\text{ln}MR\) and time by taking the natural logarithm of each side (giving Eq. (5), as shown below). Plotting the experimental drying data according to Eq. (5) usually yields the answer, and if the expected linear relationship between \(\text{ln}MR\) and drying time (t) is observed, the \({D}_{eff}\) may be derived from the slope of the line38.

Activation energy(\({\mathbf{E}}_{\mathbf{a}}\))

The diffusion of water inside the material is related to the temperature of the material, and the relationship conforms to the Arrhenius equation. The activation energy (\({E}_{a}\)) represents the starting energy required for the unit molar moisture of the steaming method during the drying process. The larger the (\({E}_{a}\)) of the material indicates that it is more difficult to dry. The relationship between (\({D}_{eff}\)) and (\({E}_{a}\)) can be expressed using the Arrhenius Eq. (6).36

Where \({D}_{eff}\) is the effective water diffusivity\(\left( {m^{2} \cdot s^{ - 1} } \right)\), \({D}_{eff}\) is the constant of the diffusivity at infinite high temperature \(\left( {m^{2} \cdot s^{ - 1} } \right)\), \({E}_{a}\) denotes the activation energy(\(\text{kJ}\bullet {\text{mol}}^{-1}\)) , \(R\) is the general gas constant(\(8.314\text{J}\bullet {\text{mol}}^{-1}\bullet {\text{K}}^{-1}\)) , \(T\) is the absolute temperature ( \(K\)). The activation energy may therefore be calculated by plotting \(\text{ln}{D}_{eff}\) against 1/T.

Microstructural analysis

Scanning electron microscopy (SEM) is an instrument that utilizes the interaction between an electron beam and a sample surface to generate signals for observing surface morphology and microstructure. The effects of different drying temperatures on the microstructure of ATR samples were investigated by scanning electron microscopy (SEM). Adjustments were made with reference to relevant research methods39,40. The sample mounted on the double-sided tape was sprayed with a thin layer of gold film and then imaged using the FEI-Quanta250 instrument (Waltham, Massachusetts, USA) at an accelerated voltage of 15 kV.

Determination of color

Electronic Eye Technology, an optical imaging analysis system simulating human visual perception, enables quantitative detection of sample morphological features, including chromatic parameters, geometric features, and surface texture. Following system stabilization, instrument calibration was performed using a 24-color reference plate (5 nm aperture, D65 illuminant) with optimized lens exposure (top–bottom illumination, single snapshot mode) and focal length adjustment. Powdered ATR samples (passed through a No. 5 sieve) from different drying temperatures were uniformly distributed in Petri dishes for image acquisition41. Triplicate measurements were conducted with recorded color indices and proportional distributions, expressed as mean ± standard deviation.

Analysis of Heracles Neo ultra-fast gas phase electronic nose

The Heracles NEO ultra-fast e-nose system is a gas chromatography-based technology primarily used for volatile organic compound (VOC) analysis and odor profiling. The samples with different drying temperatures were crushed and passed through a No. 5 sieve. The detection conditions of Heracles NEO were as follows: The sample weight was 0.25 g, the incubation temperature was 45 °C, the incubation time was 5 min, the rotation speed of the incubation furnace was 250 r⋅min-1, the initial temperature of the trap was 40 °C, the final temperature of the trap was 250 °C, the shunt rate of the trap was 10 mL⋅min-1, the capture duration was 14 s, the inlet temperature was 200 °C, and the inlet pressure was 10 kPa. The injection volume was 500 μL, the injection rate was 125 μL⋅s-1, the injection time was 9 s, the valve temperature was 250 °C, the initial temperature of the column temperature was 50 °C, and the column temperature was programmed from 1.0 °C⋅s-1 to 80 °C, 3.0 °C⋅s-1 to 250 °C, and maintained for 21 s. The collection time was 110 s, and the FID gain was 12. The N-alkanes C6 to C16 (Restek France, Lisses, France) were detected using the same method as sample testing, and then the RI values of each unknown component were calculated based on MXT-5 and MXT-1701 chromatographic columns.

HS-GC–MS and HPLC analysis

HS-GC–MS analysis

Headspace sampling conditions

Precisely weigh 2.0 g of ATR powder (passed through a No. 5 sieve) dried at different temperatures and place each sample into a 20 mL headspace vial. After sealing, position the vials in the sample tray. The headspace conditions were set as follows: vial heating temperature at 110 °C, loop temperature at 120 °C, transfer line temperature at 130 °C, and vial equilibration time of 16 min before analysis42.

HS-GC–MS detection conditions

Chromatographic separation was performed using an Agilent HP-5 quartz capillary column (0.25 mm × 30 m, 0.25 μm). The inlet temperature was maintained at 250 °C. The temperature program was as follows: initial temperature at 50 °C (held for 3 min), ramped at 3 °C·min⁻1 to 70 °C (held for 1 min), then increased at 7 °C·min⁻1 to 110 °C, followed by a 20 °C·min⁻1 ramp to 160 °C, then a 2 °C·min⁻1 rise to 185 °C (held for 5 min), and finally a 10 °C·min⁻1 ramp to 240 °C. The carrier gas flow rate was 0.8 mL·min⁻1 with a split ratio of 20:1, and the injection volume was 1.0 μL.

The mass spectrometric conditions included an electron ionization (EI) source operated at 70 eV, with the ion source temperature set at 230 °C and the quadrupole temperature at 150 °C. The transfer line temperature was maintained at 280 °C. Data acquisition was performed in full-scan mode, covering a mass range of m/z 35–55043.

Volatile component analysis

Following the methods described in Sections "Headspace Sampling Conditions" and "HS-GC–MS Detection Conditions", the total ion chromatograms (TICs) of ATR samples dried at different temperatures were obtained. The acquired chromatograms were processed using Data Analysis 2013 for peak integration. The resulting spectra were compared against the NIST 17.L mass spectral library for compound identification. Peaks in the TICs were subjected to mass spectral scanning, and the generated spectra were matched against the NIST database. Only compounds with a match factor ≥ 90% were retained, and final identification was confirmed via CAS registry numbers.

HPLC analysis

Chromatographic conditions

The chromatographic separation was carried out on a Waters TC-C18 column (250 mm × 4.6 mm, 5 µm) using a mobile phase composed of methanol (A) and 0.1% formic acid aqueous solution (B) with the following gradient elution program: 0–10 min at 38% A, 10–21 min from 38 to 43% A, 21–25 min from 43 to 74% A, and 25–38 min maintained at 74% A, with a constant flow rate of 0.8 mL·min⁻1. The detection wavelength was set at 257 nm for quantifying β-asarone, the column temperature was maintained at 30 °C, and the injection volume was 10 µL44.

Preparation of mixed reference standard solution

Accurately weighed amounts of β-asarone reference standard were dissolved in pure methanol to prepare a standard solution containing 66 µg·mL⁻1 β-asarone, which was stored for further use.

Preparation of test sample solutions

Accurately weighed 0.2000 g of ATR powder (dried at different temperatures) was placed in a 50 mL conical flask, and 20.0 mL of 80% methanol was precisely added. The flask was weighed, subjected to ultrasonic extraction for 30 min, allowed to cool to room temperature, and reweighed. The lost solvent was replenished with methanol to the original weight. The mixture was shaken and filtered, and the successive filtrate was passed through a 0.45 µm organic membrane filter before analysis.

Satistical analysis

The experimental data were analyzed using Excel 2020, and the experimental data were linearly fitted and plotted with Origin 2021 software. Quantitative analysis was performed using an external standard curve. The NIST 2014 mass spectrometry library was searched to identify different volatile components. Alpha Soft 17.0 (Toulouse, France) was used to perform multivariate statistical analysis on the olfactory fingerprints of each sample. Analysis of variance (ANOVA) was applied to the data, and multiple comparisons were performed using Duncan’s multiple range test with the SPSS software (SPSS 26.0, IBM). All measurements were carried out in triplicate; values were presented as mean values with standard deviations.

Results and discussion

Analysis of drying characteristics

Dry basis moisture content curve of ATR

The drying curves of dry basis moisture content are shown in Fig. 1. According to the mass of ATR at different times and the corresponding calculation formula, the data were processed and analyzed by Origin 2020b (64-bit) software, revealing a faster drying rate in early and middle stages, slowing in the later stage. The moisture content continued to decrease with time. The increase of temperature leads to the shortening of total drying time. Moisture content decreased over time, and higher temperatures significantly reduced drying time: 5 h at 35 °C, 3.67 h at 45 °C, 2.50 h at 55 °C, 2 h at 65 °C, and 1.83 h at 75 °C. It can be seen that the drying temperature has a significant effect on the drying time of ATR.

Drying rate curve of ATR

The drying rate (DR) versus time curve is shown in Fig. 3. The drying rate at 35 °C exhibited a more gradual decrease in comparison to that observed at higher temperatures (i.e., 45 °C, 55 °C, 65 °C, 75 °C). A significant decrease was recorded at 75 °C. Higher temperatures resulted in faster drying rates and shorter drying times, indicating that the drying temperature had a significant effect on the drying rate of ATR.

Drying mathematical model fitting

According to the data given in advance, the drying kinetics of ATR were studied by using the selected typical model. The drying process is a complex yet systematic mass and heat transfer process that was directly related to the characteristics of the material and the external environment 45. The statistical results are shown in Table 2. According to the mean statistical parameter (MSP) of these five models at different temperatures, the Cubic model is identified as the optimal choice, demonstrating excellent performance across all temperatures and proving suitable for fitting and predicting the drying process of ATR, which has the highest MSP of \({R}^{2}\) and the lowest MSP of \({\chi }^{2}\) and SSE, The Logaritmic and Binomil models are considered suboptimal, performing well at low temperatures but requiring caution at high temperatures. The Newton model demonstrated relatively poor fitting performance among all models46.

Drying model fitting verification

In order to verify the validity of the Cubic model, the actual MR and predicted MR of the moisture ratio at different drying temperatures were compared. The results show that these experimental values are located near the straight line, as shown in Fig. 4. which indicates that the Cubic model is effective in predicting the change of moisture ratio during the drying process of ATR from 35 °C to 75 °C.

The predicted MR by the Cubic model vs. the actual MR at five temperatures (A); the relationship between effective ln \({{\varvec{D}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\) and temperature (B). The predicted MR by the Cubic model vs. the actual MR at different temperatures (C1:35 ℃; C2:45 ℃; C3:55 ℃; C4:65 ℃; C5:75 ℃).

Effect on effective moisture diffusivity(\({\mathbf{D}}_{\mathbf{e}\mathbf{f}\mathbf{f}}\)) and activation energy(\({\mathbf{E}}_{\mathbf{a}}\))

According to the regression of the experimental ln \(MR\) in the cooling period and the corresponding time, the effective diffusion coefficients were 4.50246 \(\times\) 10–9, 6.98052 \(\times\) 10–9, 1.00399 \(\times\) 10–8, 1.53243 \(\times\) 10–8, 1.93458 \(\times\) 10–8, respectively. ANOVA revealed significant differences in \({{\varvec{D}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\) values among different temperatures. the \({{\varvec{D}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\) increases with the increase of temperature. The natural logarithm of \({{\varvec{D}}}_{{\varvec{e}}{\varvec{f}}{\varvec{f}}}\) is a function of the reciprocal of absolute temperature. The effective energy (\({E}_{a}\)) can be estimated to be \(33.145\text{kJ}\cdot {mol}^{-1}\). While the activation energy for the drying process of Moslae herba was determined as \(37.29\text{kJ}\cdot {mol}^{-1}\). confirming the reliability of the research findings47.

Microstructural analysis

For each temperature (35, 45, 55, 65, 75 °C), three samples were selected. Images were captured at four magnifications (50 × , 400 × , 1000 × , and 2000 ×), with three replicates per magnification, resulting in 12 images per sample. All images were taken at the central region of each sample. The surface texture of medicinal materials is a key quality assessment parameter. In this study, scanning electron microscopy (SEM)48,49 was used to analyze the surface microstructure of ATR at different drying temperatures (Fig. 5). The circular vascular bundle structure remained intact, with dense starch granules evenly distributed on the inner and outer surfaces of the vascular tissue at different drying temperatures. As drying temperature increased, ATR exhibited more pronounced surface shrinkage, likely due to rapid moisture loss. The results showed that the morphology of epidermal cells of ATR showed obvious shrinkage after drying45. In general, ATR under different drying temperature conditions had good morphostructural characteristics and uniform texture. The functional relevance of the observed microstructural alterations to drying characteristics, pharmaceutical efficacy, and comprehensive performance metrics constitutes a determinant factor. As shown in Fig. 5, the surface texture of the thin-layer dried samples at 35 °C shrinks, and the pores are dispersed, while the samples dried at 45 °C and 55 °C have larger skin shrinkage, but the pores are more evenly distributed on the surface. Enhanced pore uniformity under moderate thermal conditions promotes synchronous dehydration kinetics (critical quality attribute) and regulates post-processing moisture migration, consequently governing storage stability performance. The ATR samples dried at 75 °C showed significant epidermal folds, and the outer wall also produced arched longitudinal warts. Severe thermal-induced surface deformation compromises epidermal barrier function, risking active compound degradation, rehydration capacity, and storage stability. At the same temperature, the keratin cords of ATR were radially arranged into many bundles; each bundle had 3 to 5 short keratin cord-like structures representing the organization of vascular bundles, key structures for the transport of water, nutrients, and potentially bioactive compounds within the fresh material50. Following drying at 45 °C and 55 °C, the keratin layer of ATR developed characteristic hemispherical bulges, forming a critical protective barrier. Post-drying integrity of this layer directly influences functional performance: preservation enhances mechanical resistance, reduces microbial susceptibility, and moderates moisture permeability—collectively safeguarding bioactive compounds and extending storage stability. Conversely, excessive structural damage (e.g., at 75 °C) compromises this barrier function. The texture of the keratin layer was a round bulge, uniform in size and unclear in boundary. The loss of water during the drying process explains the reason for the change of surface structure51. The image shows significant shrinkage on the ATR surface at 75 °C, whereas no apparent morphological changes occur at 65 °C. This indicates that 65 °C drying optimally preserves the structural integrity of the ATR’s morphological properties, vascular bundles, and protective keratin layer. This preservation is essential for maintaining high drying quality (minimizing damage), ensuring the potential efficacy by protecting active compounds and transport structures, and supporting long-term storage stability through an intact protective barrier, thus maximizing overall product performance.

Morphological characteristics (SEM) of ATR using hot air drying at different temperatures. Note: The microstructure of fresh ATR using hot air drying at 35 °C (A, magnified at 50 × , 400 × , 1000 × and 2000 ×), The microstructure of fresh ATR using hot air drying at 45 °C (B, magnified at 50 × , 400 × , 1000 × and 2000 ×), The microstructure of fresh ATR using hot air drying at 55 °C (C, magnified at 50 × , 400 × , 1000 × and 2000 ×), The microstructure of fresh ATR using hot air drying at 65 °C (D, magnified at 50 × , 400 × , 1000 × and 2000 ×), The microstructure of fresh ATR using hot air drying at 75 °C (E, magnified at 50 × , 400 × , 1000 × and 2000 ×).

Color evaluation

The lightness value (L*), red-green value (a*) and yellow-blue value (b*) were used to represent each color number, and the total color value (E*ab) was calculated10. The range of L* from 0 to 100 corresponds to the color from black to white; a* from positive to negative corresponds to the color from red to green; the b* from positive to negative corresponds to the color from yellow to blue; and the calculation formula is E*ab = [ (L*) 2 + (a*) 2 + (b*) 2] 1/2. The larger the E*ab, the brighter the color. In addition, the total color difference (ΔE*ab) represents the color difference between the two color numbers, but it cannot represent the color distortion52,53,54,55,56. The calculation formula is ΔE*ab = [ (ΔL*) 2 + (Δa*) 2 + (Δb*) 2] 1/2. The chromaticity value of the sample at 35 °C ~ 75 °C is shown in Table 3.

The experimental results showed that L* showed an overall upward trend after ATR drying, and 0 indicated that the color became darker after drying. a* showed an overall upward trend and was positive, indicating that the color became more red after the drying temperature was increased; the b* showed an overall upward trend but was still positive, indicating that the color changed from blue to yellow but was still biased towards blue after the temperature was increased. The overall E*ab showed a downward trend after the increase of drying temperature, indicating that the color became darker after the increase of drying temperature. That is, after the drying temperature increases, the overall brightness becomes darker, the redness value increases, and the blueness value decreases. Therefore, the color of ATR slices at 65 °C is redder and lighter, which is consistent with the description of ATR decoction pieces in the 2020 edition of the Chinese Pharmacopoeia as 'white or slightly red’1.

Effects of different drying temperatures on the odor characteristics of ATR

Principal component analysis (PCA)

PCA is an unsupervised pattern recognition method. It extracts several factors with large eigenvalues and can reflect the sample information variables for linear classification. It can visually display the differences between samples in multidimensional space and can also display the distribution between variables. The chromatographic peaks separated by the ultra-fast gas phase electronic nose were used as the influencing factors for PCA, and the results are shown in Fig. 5. In the PCA model, the contribution rate of the first principal component (PC1) was 94.38%, the contribution rate of the second principal component (PC2) was 5.203%, and the contribution rate of the third principal component (PC3) was 0.3532%. In this study, Heracles Neo ultra-fast gas phase electronic nose software Alphasoft 11.0 was used for chemometric analysis. These findings clearly suggested that the PCA of the E-nose data could be used to distinguish the odor characteristics and morphological features of ATR under different drying conditions.

Discriminant factor analysis (DFA)

The DFA method is a statistical method for determining the category of individuals. Based on PCA, it widens the difference between different groups of data as much as possible and narrows the difference between similar groups of data as much as possible so as to establish a better identification data model and better reflect the difference of samples32. These constant differences between groups are used to identify unknown samples for classification. Commonly used applications include traceability of origin, identification of raw materials, etc.54 As shown in Fig. 6, this DFA analysis showed that the characteristics of hot-air drying ATR at different temperatures were very different. The distribution areas of the five temperatures are concentrated, which can be clearly distinguished and grouped into five categories.

The results of PCA and DFA usually match the results of fingerprint identification. Odor fingerprints can successfully distinguish and identify ATR dried at different temperatures, and the enrichment and dispersion of some odor molecules identified by electronic nose analysis (Table 4 and Fig. 7) showed that 11 components were related to odor.

The volatile profile of hot air-dried ATR reveals critical temperature-dependent relationships between compound stability, therapeutic function, and sensory attributes. Key bioactive terpenes—linalool (anti-inflammatory, antimicrobial)57 and limonene (analgesic)58—persist optimally at 65 °C, while myrcene degrades at 75 °C, indicating thermal vulnerability of synergistic effects. Sensory-defining compounds include methyl nonanoate (coconut/fruity; lost at 55 °C but recovered at 65 °C) and thermally stable p-methylacetophenone (bitter almond), collectively shaping decoction palatability. Geosmin (earthy odor) emerges ≥ 45 °C as a potential authenticity marker. Ethanol evaporation above 35 °C eliminates solvent-like off-notes. Crucially, 65 °C drying maximizes therapeutic integrity (preserving linalool/limonene synergy), sensory balance (methyl ester retention), and botanical authentication (geosmin), while minimizing degradation of thermally labile alkanes (e.g., 5-ethyl nonane). These findings directly link volatile chemistry to ATR’s pharmaceutical efficacy and organoleptic quality, resolving the functional ambiguity noted in Table 4.

Statistical analysis using PERMANOVA demonstrated significant thermal modulation of volatile organic compound (VOC) profiles (global P = 0.001), revealing three distinct thermal response patterns. The thermal behavior of volatile compounds exhibited distinct temperature-dependent patterns, with thermolabile components such as 5-ethyl nonane (C11H24) and 2-nonanol (C9H10O) reaching maximum concentrations at 45 °C (P < 0.001), indicative of optimal volatilization at intermediate temperatures. Concurrent thermal degradation was observed for methyl nonanoate (C10H20O2), showing significant reduction at 45 °C (P < 0.05). While most analytes demonstrated remarkable compositional stability in the high-temperature range (55–75 °C, P > 0.05), methyl dodecanoate (C13H26O2) constituted a notable exception with significant variation (P < 0.05). Multivariate analysis established 65 °C as the critical thermal threshold, effectively preserving both pharmacologically active terpenoids (e.g., linalool, C10H18O) and organoleptically significant markers (e.g., geosmin, C12H22O), with detailed compositional profiles presented in Table 5.

The Heracles NEO ultra-fast gas-phase electronic nose, a novel rapid odor analyzer, mimics the human olfactory system and offers sensory insights into volatile components27,28,32. A comparative analysis of the MXT-5 chromatograms for ATR samples subjected to varying drying temperatures was conducted, yielding qualitative analysis results and variations in peak areas, which were further corroborated with information from the Arochembase database (Table 3). The chromatographic peaks of ATR dried at various temperatures were compared to analyze the number of peaks and the corresponding changes in peak area, revealing differences in specificity. The relationship between odor ratios at different drying temperatures can be observed intuitively, as illustrated in Fig. 8. The spectrum indicates that the number and peak area of chromatographic peaks at 65 °C and 75 °C increased during the first 10–20 s. This observation suggests that higher temperatures initially enhance the release or formation of volatile compounds, likely due to increased thermal energy facilitating the volatilization of odor components. However, within 60 to 80 s, the number of chromatographic peaks at various drying temperatures remained relatively constant, while the height of these peaks exhibited significant changes with increasing temperature. This suggests that although the types of volatile compounds present were similar, their concentrations were affected by temperature. Elevated temperatures likely facilitated the evaporation of specific compounds, resulting in variations in peak intensity. Within 80 to 110 s, the peak height of the chromatographic peak decreased with the increase of temperature. It shows that the odor components of ATR increased, and some decreased, with the increase of drying temperature. The odor concentration of methyl dodecanoate at 65 °C was increased and was significantly higher than that at 75 °C, demonstrating that moderate temperatures preserve key odorants, whereas elevated temperatures may induce thermal degradation or excessive volatilization.

HS-GC–MS and HPLC analysis

HS-GC–MS analysis

Analysis of HS-GC–MS results from ATR dried at different temperatures (35 °C, 45 °C, 55 °C, 65 °C, and 75 °C) revealed that the major chromatographic peaks in the 64–68 s retention time range corresponded to asarone compounds, including α-asarone and β-asarone. The experimental data demonstrated a bell-shaped response curve for peak areas of asarone components with increasing drying temperature. The maximum response values for these characteristic peaks were observed at 65 °C, indicating optimal retention of asarone compounds at this temperature. When the temperature was elevated to 75 °C, a significant reduction in peak area was noted, likely attributable to volatilization or thermal degradation of these components. Comparative analysis across temperature conditions demonstrated that 65 °C effectively promotes the release of asarone compounds while preventing thermal-induced losses. These findings establish 65 °C as the optimal drying temperature for ATR, providing critical evidence for standardizing its processing protocol. The results offer valuable insights for quality control in the production of this medicinal herb. As shown in Fig. 9.

HPLC analysis

Experimental results demonstrated that varying drying temperatures (35 °C, 45 °C, 55 °C, 65 °C, and 75 °C) exerted significant effects on the content of β-asarone (peaks at 1800–1900) in ATR. HPLC analysis revealed a distinct unimodal pattern in the peak area of this bioactive compound, with values initially increasing and subsequently decreasing with rising temperature. Within the temperature range of 35–65 °C, the extraction efficiency of β-asarone exhibited a positive correlation with temperature elevation, reaching a maximal peak area at 65 °C. This observation suggests that 65 °C represents an optimal condition for facilitating the dissolution of the target compound while maintaining its thermal stability. However, a marked reduction in peak area was observed at 75 °C, likely attributable to thermal degradation or volatilization of this heat-labile constituent. These findings, which corroborate previous results obtained from electronic nose and GC–MS analyses, collectively establish 65 °C as the optimal drying temperature for ATR. This temperature not only maximizes the preservation of this pharmacologically active component but also demonstrates practical feasibility for industrial-scale applications. Future studies should include replicate experiments to validate the reproducibility of these findings, along with comprehensive analyses of additional bioactive constituents to fully optimize the drying process parameters. As shown in Fig. 10.

A: HPLC chromatograms of ATR dried at different temperatures. Note: Purple means ATR odor fingerprint at 75 °C, green means ATR odor fingerprint at 65 °C, blue means ATR odor fingerprint at 55 °C, red means ATR odor fingerprint at 45 °C, black means ATR odor fingerprint at 35 °C. B: HPLC chromatogram of β-asarone.

Conclusions

By using modern drying methods, a higher quality and more valuable final product in terms of health is obtained compared to traditional methods59. In hot air (HA) drying, there is a gradual transfer of heat from the material surface to the interior due to the temperature difference between the hot surface and the colder interior of the material60. The drying process involves circulating air in a closed environment over the material to be dried, which is then heated to provide more controlled drying conditions compared to open sun drying59. The heating of the drying air is accomplished by passing it over a suitable collector and then transmitting it to the food and pharmaceutical products through natural or forced convection61,62,– 63. This process continues until the food and pharmaceutical products reach the desired level of moisture. Compared to sun drying, food and pharmaceutical products dried in a controlled environment are cleaner and experience less change in natural color, taste, odor, and volatile components. Controlled drying protects the food and pharmaceutical products from adverse environmental conditions59. However, hot air drying has a significant drawback in that it can be slow and inefficient, particularly during the falling rate period, which can negatively impact the quality of the food and pharmaceutical products in terms of odor profiles, color, texture, and volatile compounds60,64,65,66. When selecting a dryer, other important factors to consider include energy efficiency, ease of operation and maintenance, environmental impact, and cost-effectiveness67. In the microwave (MW) drying method, the electromagnetic field affects the whole material, and the water molecules in the material are directly targeted68, thus a selective heating is performed, resulting in a shorter drying time. As a result of the application of continuous MW energy, some negative quality characteristics, such as burns in the material and hardening on the product surface59, develop as a result of high temperature/power applied to the dried material. Drying processes employing elevated temperatures, pressures, or power inputs may compromise product color, texture, and sensory attributes. The selected drying method influences water phase transitions and mass transfer, potentially generating capillary forces that alter microstructure4,69. Therefore, a comprehensive evaluation of these factors is necessary to select the most suitable drying method for the ATR slices to be dried.

The cubic model-derived parameters demonstrated significantly higher accuracy in characterizing the drying kinetics of ATR compared to other evaluated models. Comprehensive analysis revealed that ATR samples subjected to varying drying temperatures (35–75 °C) exhibited distinct odor profiles when assessed using the Heracles NEO ultra-fast gas chromatography electronic nose system, with eleven characteristic volatile compounds being identified. Integration of morphological characterization through scanning electron microscopy and chromatic evaluation via colorimetric analysis collectively indicated that 65 °C represents the optimal drying temperature for ATR. This conclusion is further supported by intelligent sensory evaluation coupled with drying kinetic analysis, which demonstrates that 65 °C drying not only enhances process efficiency by reducing both drying duration and operational costs but also minimizes detrimental effects on product quality parameters including morphological characteristics, volatile composition, and color stability. The present investigation successfully established an interdisciplinary approach combining mathematical modeling with empirical observations of moisture migration dynamics and quality attribute evolution during ATR processing, thereby providing both theoretical and practical guidance for addressing critical challenges in ATR production.

Notwithstanding this study provides valuable insights into ATR drying optimization, several methodological constraints must be acknowledged to properly contextualize the findings. First and foremost, the experimental design was limited to conventional hot-air thin-layer drying within the 35–75 °C temperature range. This narrow focus prevented evaluation of emerging dehydration technologies that have demonstrated superior quality preservation for thermolabile phytopharmaceuticals, particularly microwave-vacuum drying, lyophilization, and infrared-convective hybrid systems70. These technologies are of particular relevance to the industry of thermolabile phytopharmaceuticals. Equally important is the reliance on instrumental odor analysis without complementary human sensory evaluation. Although the Heracles Neo ultra-fast GC-E-nose provided high-resolution volatile profiling, the absence of standardized sensory validation (following ISO 13,299:2016 protocols with a panel of ≥ 10 trained assessors) represents a significant limitation in translating instrumental data to consumer-relevant quality parameters. Additionally, it is important to note that pharmacological verification was not integrated. This is a crucial aspect, as it is essential to quantify the principal bioactive constituents (for example, β-asarone via UPLC-QTOF-MS) and to perform functional bioassays of therapeutic efficacy (AChE inhibition, IC50 determinations, ORAC antioxidant indices). Despite being essential for correlating process-induced physicochemical alterations with clinical functionality, these aspects remain unaddressed. These defined omissions underscore critical research imperatives for subsequent investigation.

In order to advance the mechanistic understanding and industrial applicability of ATR processing, three prioritised research trajectories emerge from this study’s interdisciplinary framework: Primary emphasis should be placed on comparative evaluation of advanced dehydration technologies. A systematic assessment of microwave-vacuum drying, lyophilization, and pulsed infrared-convection systems would provide essential data on their relative merits for preserving microstructural integrity, volatile compounds, and energy efficiency compared to conventional methods. Concurrently, validation studies must bridge the gap between instrumental analysis and human perception. This requires implementing standardized sensory evaluation protocols with trained panels to establish clinically meaningful thresholds for machine-derived quality metrics, ensuring technological measurements align with consumer acceptance parameters. Another important consideration involves investigating the thermal degradation kinetics of key bioactive compounds. Future work should employ triple-quadrupole LC–MS/MS to monitor β-asarone stability under various processing conditions, correlating residual concentrations with pharmacological activity through established bioassays. Such evidence-based approaches will enable true quality-by-design optimization of ATR production processes. The implementation of evidence-based thresholds has the potential to address the existing gaps between process-induced physicochemical alterations and therapeutic functionality. Ultimately, this will facilitate knowledge-driven optimisation of commercial-scale ATR production through a convergent multidisciplinary strategy. These critical research directions will be pursued through systematic investigation.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

National Pharmacopoeia Committee. Pharmacopoeia of the People’s Republic of China. Part I. Beijing: Chin Med Sci Press; 2020.

Wang, M. et al. Acorus tatarinowii Schott: a review of Its botany, traditional Uses, phytochemistry, and pharmacology. Molecules 28, 4525 (2023).

Pravallika, K., Chakraborty, S. & Singhal, R. S. Supercritical drying of food products: An insightful review. J. Food Eng. 323, 111375. https://doi.org/10.1016/j.jfoodeng.2022.111375 (2022).

Santhalakshmy, S. et al. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 274, 37–43. https://doi.org/10.1016/j.powtec.2015.01.016 (2015).

Ashtiani, S. H. M. et al. Cold plasma pretreatment improves the quality and nutritional value of ultrasound-assisted convective drying: the case of goldenberry. Dry Technol. 40(8), 1639–1657 (2022).

Yue, et al. Physical and chemical properties of purple cabbage as affected by drying conditions. Int. J. Food Prop. https://doi.org/10.1080/10942912.2021.1953070 (2021).

Sufer, O. & Palazoglu, T. K. A study on hot-air drying of pomegranate kinetics of dehydration, rehydration and effects on bioactive compounds. J. Therm. Anal. Calorim. 137(6), 1981–1990 (2019).

Yu, L. et al. Rapid gas-phase electronic nose combined with artificial neural network for rapid identification of three Schisandra decoction pieces and research on odor difference markers. J. Chin. Med. Mater. 53(5), 1303–1312 (2022).

Xiong, Y. et al. GC-MS combined with principal component analysis to compare the differences in chemical composition of volatile oils of Patchouli before and after drying. Guid. J. Tradit. Chin. Med. Pharm. 25(3), 83 (2019).

Li, Y. et al. A study on the quantitative transfer of volatile components in clinical preparations-taking an example of Mentha haplocalyx. Chin. J. Tradit. Chin. Med. Pharm. 46(15), 3780 (2021).

Liu, X. et al. Based on partial least squares method and hydrophilic-lipophilic balance value to explore the material basis of Angelica volatile oil emulsification. Chin. J. Tradit. Chin. Med. Pharm. 46(14), 3583 (2021).

National Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China. Part IV. Beijing: Chin Med Sci Press; 2020. 233

Wang, S., Jin, J. & Suo, R. Evaluation of solar drying on drying behaviour and drying kinetics of penaeus vannamei. J. Aquat. Food Prod. Technol. https://doi.org/10.1080/10498850.2022.2048156 (2022).

Wang, D., Ma, M. & Zhao, Z. American ginseng slice drying and optimization: effect of different drying methods on drying kinetics and physicochemical properties. Processes. https://doi.org/10.3390/pr12061226 (2024).

Effects of hot air drying on drying kinetics. quality and flavor changes of Fructus aurantii. J. Essent. Oil Bear Plants. https://doi.org/10.1080/0972060X.2024.2325098 (2024).

Zhang, J. B. et al. E-eye, flash GC E-nose and HS-GC-MS combined with chemometrics to identify the adulterants and geographical origins of Ziziphi Spinosae Semen. Food Chem. 424, 136270. https://doi.org/10.1016/j.foodchem.2023.136270 (2023).

Ouyang, Q. et al. Instrumental intelligent test of food sensory quality as mimic of human panel test combining multiple cross-perception sensors and data fusion. Anal. Chim. Acta. 841, 68–76 (2014).

Fikri, N. A. et al. Development of human sensory mimicking system. Sens. Lett. 9(1), 423–427 (2011).

Jiang, S. et al. Characterization of stewed beef by sensory evaluation and multiple intelligent sensory technologies combined with chemometrics methods. Food Chem. 408, 135193 (2023).

Rosa, A. R. D. et al. Fusion of electronic nose, electronic tongue and computer vision for animal source food authentication and quality assessment-a review. J. Food Eng. 210, 62–75 (2017).

Wang, T. et al. Research progress of intelligent sensory analysis technology in food flavor. J. Food Saf. Qual. Insp. 14(8), 37–43 (2023).

Ghasemi-Varnamkhasti, M., Mohtasebi, S. S. & Siadat, M. Biomimetic-based odor and taste sensing systems to food quality and safety characterization: an overview on basic principles and recent achievements. J. Food Eng. 100(3), 377–387 (2010).

Cao, X., Chen, J. & Islam, M. N. Effect of Intermittent microwave volumetric heating on dehydration, energy consumption, antioxidant substances, and sensory qualities of Litchi fruit during vacuum drying. Molecules 24, 4291 (2019).

Chuwattanakul, V. & Eiamsa-ard, S. Hydrodynamics investigation of pepper drying in a swirling fluidized bed dryer with multiple-group twisted tape swirl generators. Case Stud. Therm. Eng. 13, 100389 (2019).

Doymaz, I. The kinetics of forced convective air-drying of pumpkin slices. J. Food Eng. 79, 243–248 (2007).

Shen, C. et al. Characterization of selected commercially available grilled lamb shashliks based on flavor profiles Using GC-MS, GC × GC-TOF-MS, GC-IMS, E-nose and E-tongue combined with chemometrics. Food Chem. 423, 136257 (2023).

Wang, Q. et al. Discrimination and characterization of volatile flavor compounds in fresh oriental Melon after Forchlorfenuron application using electronic nose (E-Nose) and headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS). Foods. 12, 1272 (2023).

Wei, G., Dan, M., Zhao, G. & Wang, D. Recent advances in chromatography-mass spectrometry and electronic nose technology in food flavor analysis and detection. Food Chem. 405, 134814 (2023).

Gökçe, K. Ö. The experimental study and modelling the drying kinetics of mussels using ultrasound assisted vacuum drying. J. Indian Chem. Soc. 98, 100148 (2021).

Zhao, Y. T. et al. Mathematical modeling and influence of ultrasonic pretreatment on microwave vacuum drying kinetics of Lotus (Nelumbo nucifera Gaertn.) Seeds. Dry Technol. 35, 553–563 (2016).

Xu, W. et al. Effect of far infrared and far infrared combined with hot air drying on the drying kinetics, bioactives, aromas, physicochemical qualities of Anoectochilus roxburghii (Wall.) Lindl. LWT-Food Sci Technol. 162, 113452 (2022).

Zhu, G. F. et al. Rapid identification of Pogostemonis Herba and its odor fingerprint based on Heracles Neo ultra-fast gas phase electronic nose. Chin. Tradit. Herb Drugs. 53, 1320–1327 (2022).

Royen, M. J., Noori, A. W. & Haydary, J. Experimental study and mathematical modeling of convective thin-layer drying of apple slices. Processes. 8, 1562 (2020).

Bai, S., Liu, L. & Yu, H. Thermal and dielectric properties of Wolfberries as affected by moisture content and temperature associated with radio frequency and microwave dehydrations. Foods. 11, 3796 (2022).

Rani, P. & Tripathy pp.,. Modelling of moisture migration during convective drying of pineapple slice considering non-isotropic shrinkage and variable transport properties. J. Food Sci. Technol. 57(10), 3748–3761 (2020).

Du, Y. J. et al. Drying kinetics of paddy drying with graphene far-infrared drying equipment at different IR temperatures, radiations-distances, grain-flow, and dehumidifying-velocities. Case Stud. Therm. Eng. 43, 102780 (2023).

Ashtiani, S. H. M., Salarikia, A. & Golzarian, M. R. Analyzing drying characteristics and modeling of thin layers of peppermint leaves under hot-air and infrared treatments. Inf. Process Agric. 4, 128–139 (2017).

Li, M. et al. Rapid evaluation of Ziziphi Spinosae Semen and its adulterants based on the combination of FT-NIR and multivariate algorithms. Food Chem. 20, 101022 (2023).

Yue, Y. et al. UPLC-Q-TOF/MS-based serum metabolomics reveals potential anti-tumor mechanism of Banxia Xiexin decoction in colorectal cancer mice. Chin. J. Integr. Med. 30, 623–632 (2023).

Zhang, H. L. et al. Optimal drying models for different drying methods of Chimonobambusa quadrangularis shoots and their effects on the appearance quality of dried bamboo shoots. Guizhou Agric. Sci. 52(2), 124–132 (2024).

Anglart, H., Li, H. & Niewinski, G. Mechanistic modelling of dryout and post dryout heat transfer. Energy 161, 352–360 (2018).

Tang, Y. et al. Profiling complex volatile components by HS-GC-MS and entropy minimization software: An example on Ligusticum chuanxiong Hort. J. Pharm. Biomed. Anal. 218, 114854. https://doi.org/10.1016/j.jpba.2022.114854 (2022).

Li, S. L. et al. Preparation and quality evaluation of volatile oil microemulsion nasal spray from Acorus tatarinowii. Chin. Tradit. Herb. Drugs. 50(8), 1935–1941 (2019).

Tian, M. Y. et al. Anti-inflammatory effects and related mechanisms in vitro and in vivo of Hedychium coccineum rhizome essential oil. J. Ethnopharmacol. 328, 118103. https://doi.org/10.1016/j.jep.2024.118103 (2024).

Wang, T. et al. Evaluation of the effect of ultrasonic pretreatment on the drying kinetics and quality characteristics of cCodonopsis pilosula slices based on the grey correlation method. Molecules 28, 5596 (2023).

Xie, M. et al. Effect of drying kinetics, volatile components, flavor changes and final quality attributes of Moslae herba during the hot air thin-layer drying process. Molecules 28, 3898 (2023).

Bai, J. W. et al. Three-dimensional appearance and physicochemical properties of pleurotus eryngii under different drying methods. Foods. 12, 1999 (2023).

Deng, L. et al. High humidity hot air impingement blanching (HHAIB) enhances drying rate and softens texture of apricot via cell wall pectin polysaccharides degradation and ultrastructure modification. Food Chem. 261, 292–300 (2018).

Guan, J. et al. Evaluate how steaming and sulfur fumigation change the microstructure, physicochemical properties and in vitro digestibility of Gastrodia elata Bl. starch. Front. Nutr. 9, 1087453 (2022).

Zhang, J. et al. Effect of combined infrared hot air drying on yam slices: Drying kinetics, energy consumption, microstructure, and nutrient composition. Foods. 12, 3048 (2023).

Subramaniam, S., Wen, X. & Jing, P. One-step microwave curing-dehydration of Gastrodia elata Blume: relationship between phytochemicals, water states and morphometric characteristics. Ind. Crops Prod. 153, 112579 (2020).

Munekata, P. E. S., Finardi, S. & de Souza, C. K. Applications of electronic nose, electronic eye and electronic tongue in quality, safety and shelf life of meat and meat products: a review. Sensors. 23, 672 (2023).

McCaig, T. N. Extending the use of visible/near-infrared reflectance spectrophotometers to measure colour of food and agricultural products. Food Res. Int. 35, 731–736 (2002).

Wu, D. & Sun, D. W. Colour measurements by computer vision for food quality control-A review. Trends Food. Sci. Technol. 29, 5–20 (2013).

Cui, Y. X. et al. Quality evaluation based on color grading: Quality discrimination of the Chinese medicine Corni Fructus by an E-eye. Sci. Rep. 9, 17006 (2019).

Wang, Y. et al. Monitoring the withering condition of leaves during black tea processing via the fusion of electronic eye (E-eye), colorimetric sensing array (CSA), and micro-near-infrared spectroscopy (NIRS). J. Food Eng. 300, 110534 (2021).

Kaimoto, T. et al. Involvement of transient receptor potential A1 channel in algesic and analgesic actions of the organic compound limonene. Eur. J. Pain. 20(7), 1155–1165. https://doi.org/10.1002/ejp.840 (2016).

Soysal, Y. Microwave drying characteristics of parsley. Biosyst. Eng. 89(2), 167–173. https://doi.org/10.1016/j.biosystemseng.2004.07.008 (2004).

Arslan, A., Soysal, Y. & Keskin, M. Comparing hot air drying kinetics and color quality of organic and conventional sweet red peppers. J. Agric. Sci. 25(2), 271–283. https://doi.org/10.37908/mkutbd.747675 (2020).

Mumba, J. Design and development of a solar grain dryer incorporating photovoltaic powered air circulation. Energy Convers. Manag. 37(5), 615–621. https://doi.org/10.1016/0196-8904(95)00205-7 (1996).

Tiris, C., Tiris, M. & Dincer, I. Experiments on a new small-scale solar dryer. Appl. Therm. Eng. 16(2), 183–187. https://doi.org/10.1016/1359-4311(95)00048-8 (1996).

Soysal, Y. et al. Intermittent microwave convective drying of red pepper: Drying kinetics, physical (colour and texture) and sensory quality. Biosyst. Eng. 103(4), 455–463. https://doi.org/10.1016/j.biosystemseng.2009.05.010 (2009).

Talens, C. et al. Effect of microwave power coupled with hot air drying on process efficiency and physico-chemical properties of a new dietary fibre ingredient obtained from orange peel. LWT-Food Sci. Technol. 77, 110–118. https://doi.org/10.1016/j.lwt.2016.11.036 (2017).

Arslan, A. & Alibaş, İ. Assessing the effects of different drying methods and minimal processing on the sustainability of the organic food quality. Innov. Food Sci. Emerg. Technol. https://doi.org/10.1016/j.ifset.2024.103681 (2024).

Arslan, A., Soysal, Y. & Keskin, M. Comparative investigation of drying and quality characteristics of organic and conventional black carrots dried by intermittent microwave and hot air. J. Tekirdag Agri. Faculty. 20(3), 591–604. https://doi.org/10.33462/jotaf.1169657 (2023).

Sabarez, H. Drying of food materials. In Reference Module in Food Sciences (ed. Sabarez, H.) (Elsevier, 2016).

Vega-Mercado, H., Góngora-Nieto, M. M. & Barbosa-Cánovas, G. V. Advances in dehydration of foods. J. Food Eng. 49(4), 271–289 (2001).

Lee, B. S., Choi, Y. H. & Lee, W. Y. Drying characteristics of apple slabs after pretreatment with supercritical CO₂. J. Food Sci. Nutr. 16(3), 261–266 (2011).

Vetralla, M. et al. A study about the effects of supercritical carbon dioxide drying on apple pieces. Int. J. Food Eng. 14(2), 186–190 (2018).

Ashtiani, S. H. M. et al. Impact of gliding arc plasma pretreatment on drying efficiency and physicochemical properties of grape. Innov. Food Sci. Emerg. Technol. 63, 102381 (2020).

Acknowledgements

Thanks go to the Research and Development Center of Jiangzhong Pharmaceutical company for help and encouragement.

Funding

This research was funded by the Chinese Medicine Concoction Technology Inheritance and Innovation Project of the State Administration of Traditional Chinese Medicine (NO.GZY-KJS-2022–051), Standardization project of Jiangxi Provincial Standard Committee of Traditional Chinese Medicine (NO.2025A15), Jiangxi Province High-level Undergraduate Teaching Team of ‘Undergraduate Teaching Team of Proprietary Chinese Medicines’ (NO.2252201013), Jiangxi University of Chinese Medicine Virtual Teaching and Research Office (NO.2252300109), The first scientific and technological innovation team (NO.CXTD22003), Scientific and technological research project of Jiangxi Provincial Department of Education (NO.GJJ218920), University-level scientific research project of Nanchang Medical College (NO.NYXJ-2024–061), and the APC was funded by Lingyun Zhong.

Author information

Authors and Affiliations

Contributions

Conceptualization, Y.-N.L. and J.-L.Z.; methodology, Y.-N.L., J.-L.Z. and S.-L.M.; software, Y.-N.L.; validation, Y.-N.L., J.-L.Z., L.-Y.Z. and S.-L.M.; formal analysis, K.S.; investigation, K.S., J.-Y.G. and Y.-X.M.; resources, J.-Y.G.; data curation, R.-P.W.; writing—original draft preparation, Y.-N.L.; writing—review and editing, Y.-N.L., R.-P.W. and Y.-X.M.; visualization, R.-P.W. and F.-Y.C.; supervision, L.-Y.Z.; project administration, L.-Y.Z. and Y.-H.Y.; funding ac-quisition, J.-L.Z. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Le, Y., Shi, K., Wang, C. et al. Drying kinetics and characteristics of Acori tatarinowii rhizoma under hot air thin-layer drying at different temperatures. Sci Rep 15, 30447 (2025). https://doi.org/10.1038/s41598-025-13497-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-13497-z