Abstract

Rock mechanical properties undergo significant deterioration in high-temperature environments, resulting in reduced rock mass strength and stability. To reveal the strength degradation patterns and deformation characteristics of fractured surrounding rock in deep high-temperature tunnels, this study conducted stress path loading and unloading tests on rock specimens subjected to various high temperatures. These tests were based on the stress evolution characteristics of the fractured zone in high-temperature tunnels, using an MTS815 rock mechanics servo testing machine. Results show that high temperatures induce varying degrees of damage to rock specimens, with damage severity increasing as temperature rises. A temperature of 300 °C is identified as the critical damage-sensitive zone for high-temperature rock specimens. As temperature increases, the strength, cohesion, and internal friction angle of initially damaged high-temperature rock specimens all exhibit decreasing trends of varying magnitudes. Peak strength degradation is most significant, with a maximum reduction of 67.38% and a minimum of 18.49%. Additionally, cohesion undergoes a sudden change at 300 °C, decreasing by 44.31%, while the internal friction angle shows a less substantial reduction. Throughout the experiment, both circumferential strain and volumetric strain increase noticeably. Volumetric strain changes from negative to positive values, which signifies substantial dilation. Rock specimens that have undergone high-temperature damage exhibit clear characteristics of strain softening and residual strength following the attainment of peak strength. The ultimate macroscopic failure is primarily characterized by mechanisms associated with combined shear failure.

Similar content being viewed by others

Introduction

Extensive research and engineering experience have shown that the instability and failure of surrounding rock in deep underground projects, particularly in deeply buried tunnels, are primarily caused by stress changes after excavation and the degradation of rock strength. In the case of deeply buried tunnels subjected to high ground temperatures, the combined effect of high temperature and high ground stress results in the formation of fracture zones in the surrounding rock1,2,3,4. Within these zones, the rock’s strength progressively diminishes as fracture damage develops5. The strength characteristics of the deep surrounding rock, serving as primary load-bearing component of the tunnel support system, are crucial factors in the design of tunnel support structures and the determination of optimal support timing. Therefore, studying the strength degradation patterns of fractured surrounding rock in deep, high-temperature environments is of great significance for ensuring the long-term safety and stability of tunnel operations.

A substantial amount of macro and meso-experimental studies have been conducted by researchers worldwide. These studies focus on the physical and mechanical properties, microstructure characteristics, and strength attributes of rocks subjected to high temperatures6. The findings indicate that under high-temperature conditions, rock density and wave velocity exhibit an inverse relationship with temperature increase, while elastic modulus and compressive strength show a progressive deterioration trend with rising temperatures7,8,9,10,11,12,13. After exposure to high temperatures, the internal microcracks in rocks expand and proliferate with increasing thermal load10. At temperatures exceeding 573 °C, a transition in microcrack typology is observed, shifting from predominantly intergranular to transgranular formations. This transition is identified as the primary mechanism underlying fracture and failure in rocks exposed to high temperatures. The synergistic effect of high ground temperature and high ground stress may induce localized distortion of the plastic zone in surrounding rock. This can further promote the expansion of the plastic region, thereby causing different levels of thermal damage and fracturing in the rock mass14]– [15. These experimental studies collectively elucidate the thermal damage effect of high temperatures on rocks, and highlight the significant alterations in their physical, mechanical, and strength properties.

The high-temperature experiments conducted on intact rock specimens have revealed, from multiple perspectives, the detrimental and deteriorating impacts of high temperatures on the physical and mechanical properties of rocks16. Tunnel excavation processes induce disturbances that exert a destructive influence on the surrounding rock, leading to the formation of a fractured zone of variable extent proximal to the exposed surface. This phenomenon significantly diminishes the strength of the surrounding rock17 and can lead to instability and failure. During the excavation of deep tunnels subjected to high temperatures, the high thermal conditions exacerbate the brittle failure propensity of the rock mass18. This heightened susceptibility to failure leads to damage and fracturing when influenced by both high temperature and high ground stress19. The strength variations in the surrounding rock before and after failure under the stress path of deep, high-temperature tunnel excavation are highly complex. Currently, there is a scarcity of research on the strength degradation patterns of surrounding rock during the excavation of deep, high-temperature tunnels. In actual engineering applications, the high ground temperatures have already induced a degree of damage to the surrounding rock. This pre-existing damage, coupled with the complex stress disturbances during excavation, leads to strength reduction and deterioration of strength parameters in the surrounding rock, directly affecting the safe and stable operation of the tunnel. Moreover, the quantitative identification of such failure mechanisms is crucial for successful deep excavation projects. However, this issue has received limited attention in existing research, indicating a need for further study to address this knowledge gap.

The strength, deformation, and failure behavior of anisotropic rocks under high temperatures is a key concern in deep underground engineering. However, to the best of our knowledge based on available literature, the mechanical behavior of anisotropic rocks under true triaxial compression coupled with high temperatures has not yet been investigated. Additionally, the relationship between temperature and stress-induced anisotropy remains largely unexplored. To clarify the strength degradation patterns of surrounding rock in deep, high-temperature tunnels after fracturing under the combined effects of high temperature and excavation stress paths, a laboratory experiment was designed. Based on the characteristic stress change patterns of surrounding rock in deep, high-temperature tunnels, a specialized stress loading and unloading path was developed for high-temperature damaged rock specimens. By adhering to this stress path and controlling various post-peak unloading points, rock specimens with varying degrees of high-temperature damage were obtained. A multi-level confining pressure and multiple peak yield test method was employed to measure the strength parameters of these damaged specimens under different confining pressures. The evolution of strength and deformation characteristics was analyzed, and the degree of damage in high-temperature rocks was quantitatively assessed using the stress reduction ratio at the unloading point. This approach allowed for the analysis of strength degradation patterns in fractured surrounding rock within deep, high-temperature tunnels and expounded the evolution of shear strength parameters in rock specimens damaged by heat.

Experimental materials and methods

Preparation of heat-damaged rock samples

The rock specimens used in the experiment were obtained from the high-temperature section of the Bulunkou Tunnel project in Xinjiang, China. According to chemical analysis, these rocks are classified as belonging to the sub-alkaline series in terms of rock chemistry. They represent active continental margin granite, characterized by a well-consolidated rock mass with few joints and high strength. It is generally accepted that this rock mass formed in a plate subduction environment and exhibits typical features associated with granite. In accordance with ISRM recommended standards, the rocks were precisely machined into cylindrical specimens with dimensions of 50 mm in diameter and 100 mm in height. Prior to testing, all specimens were subjected to a two-week air-drying period in a well-ventilated laboratory environment to minimize the influence of natural moisture content on test results. To ensure result reliability and comparability, density and wave velocity of each specimen were measured before heat treatment, and specimens exhibiting anomalous density or wave velocity values were excluded. The selected samples exhibited an average density of 2.58 g/cm3, with mean P-wave and S-wave velocities of 4315 m/s and 2975 m/s, respectively. X-ray diffraction (XRD) analysis determined the primary mineral compositions of the rock consist of 57.68% albite, 35.58% quartz schist, and 6.74% biotite.

The rock specimens were categorized and subjected to heat treatment in a high-temperature furnace (SG-XL1200). The heating rate was set at 2 °C/min, and specimens were maintained at the target temperature for a duration of 2 h upon reaching the desired thermal level. The target temperatures were established at 20, 150, 300, 400, and 500 °C. For each temperature level, five samples were assigned, as shown in Fig. 1. Notable surface color changes in the specimens became apparent at temperatures exceeding 300 °C.

Upon completion of the heat treatment, the specimens were quickly removed from the furnace, and 1 cm cubic samples were prepared from rocks treated at various temperatures for carbon coating. These specimens were then analyzed using a Quanta250 Scanning Electron Microscope (SEM) system to evaluate the microstructure damage caused by heat exposure. This process yielded heat-damaged rock specimens, which were subsequently used for triaxial compression tests and multi-stage loading triaxial tests involving multiple yield points.

Experimental boundary conditions and stress path design for high-temperature rock specimens

Utilizing the MTS815 electro-hydraulic servo rock mechanics testing system, as shown in Fig. 2, uniaxial compression tests and triaxial tests were conducted on rock specimens subjected to various high-temperature levels. The rock samples for uniaxial compression tests were labeled A1-A5, and those for triaxial tests were labeled B1-B5. The experimental boundary conditions and characteristic confining pressure values are listed in Table 1. Through the execution of uniaxial and triaxial tests on high-temperature rock specimens, corresponding stress-strain curves were obtained, which facilitate the analysis of strength degradation characteristics under diverse stress paths and boundary conditions.

To identify the strength parameters of each high-temperature damaged rock specimen and mitigate the impact of dispersion on indoor test results, a single-sample multi-level confining pressure and multiple yield point test method was implemented20. The stress path for the multi-level confining pressure and multiple yield point test is displayed in Table 1; Fig. 3. This new stress path can accurately simulate the complex stress changes and adjustment processes experienced by the surrounding rock of deep tunnels during and after excavation. Furthermore, it enables an effective analysis of the varying degrees of damage and rupture in high-temperature surrounding rock.

High-temperature treatment induced the development of micro-fracture surfaces within the rock samples, which introduced in a degree of damage and fracturing, as shown in Fig. 4. These micro-fracture surfaces altered the internal structure of the intact rock specimen, changing its load-bearing structure. Consequently, this change inevitably resulted in a decrease in the rock’s load-bearing capacity and strength parameters.

The initially heat-damaged rock specimens, designated C1 to C5, were subjected to multi-stage loading triaxial tests with multiple yield points. The test boundary conditions and stress loading paths are shown in Table 1; Fig. 3. The specific loading protocol was implemented as follows: similar to conventional triaxial tests, the confining pressure was gradually increased to a predetermined value (σ1 = σ3= 5 MPa) and then maintained while axial loading proceeded until the yield point was reached under the corresponding confining pressure. At this point, the loading mode was immediately altered, keeping the axial pressure constant while increasing the confining pressure to the next level (σ3 = 10 MPa). The confining pressure was then held constant, and axial loading resumed until the yield point (i.e., the peak inflection point) was reached under the corresponding confining pressure. This loading sequence was repeated to complete the yield test at a confining pressure of 15 MPa. Finally, the confining pressure was raised to 25 MPa until the rock specimen exhibited post-peak failure, thereby obtaining the post-peak stress variation law and failure characteristics of the rock. The designed stress loading and unloading path effectively simulates the strength degradation patterns and deformation failure characteristics of the surrounding rock induced by stress state changes after the excavation of high-temperature deep tunnels.

Experimental results and analysis

Microscopic damage characteristics of high-temperature rock specimens

Extant studies have demonstrated that the microstructure of rock specimens undergoes significant changes when subjected to high temperatures21. Under ambient temperature conditions, rocks typically exhibit a limited number of internal micropores and fissures. The mineral particles within the rock are tightly bonded, resulting in high degree of overall structural integrity, as shown in Fig. 4a. At 150 °C, localized microcracks begin to appear, with maximum crack widths of approximately 20 μm, as observed in Fig. 4b. As temperatures rise, these microcracks propagate and progressively develop into continuous fissures, while additional fine microcracks form in proximity, with maximum microcrack widths reaching about 30–40 μm. At 300 °C, a preliminary network of microfissures forms within the rock matrix. When temperatures reach 500 °C, the maximum microcrack width increases further, and these microfissures expand, widen, and interconnect to form an extensive microcrack network, as shown in Fig. 4e. Under high-temperature conditions, the expansion of microcracks in the rock leads to significant structural damage in the specimen22.

Evolution of uniaxial compressive strength in high-temperature damaged rock specimens

As the temperature increases, the slope of the linear elastic stage exhibits a decreasing tend. A significant reduction is observed at 300 °C, accompanied by a distinct yield stage and plateau, as shown in Fig. 5. Beyond 300 °C, the rock specimens exhibit increased plasticity and a notable decrease in peak strength. At 20 °C, the peak strength is recorded at 147.08 MPa; at 300 °C, it drops to 101.23 MPa; and upon reaching 500 °C, the peak strength further declines to 81.21 MPa. By analyzing the characteristics of uniaxial peak strength, we observe an inverse relationship between peak stress and temperature, with a maximum strength degradation of 44.78%. This indicates that exposure to high temperatures induces significant structural damage in the rock mass.

Strength and deformation characteristics of high-temperature damaged rock specimens

From the triaxial test results of rock specimens B1 to B5, the peak strengths under 25 MPa confining pressure are 114.28 MPa, 104.27 MPa, 96.73 MPa, 91.65 MPa, and 84.53 MPa, respectively. As temperature increases, the peak strength of the rock specimens shows a gradual decreasing trend, but the reduction is relatively modest. High temperatures lead to the development of thermal cracking, as shown in Fig. 4. Meanwhile, confining pressure inhibits crack propagation during compression, either preventing or delaying the formation of new fracture surfaces, thus altering the load-bearing structure of the rock. This phenomenon explains the relatively modest decrease in peak strength. When loading the high-temperature damaged rock specimens to 80% of their peak strength under the corresponding confining pressures, and the confining pressure is subsequently reduced gradually, a slow increase in axial stress σ1 is observed. This is accompanied by a continuous rise in axial strain ε1. Such behavior indicates that these high-temperature damaged specimens possess significant axial plastic flow characteristics. Furthermore, near the point of confining pressure unloading, as shown in Fig. 6, these specimens exhibit notable residual strength properties.

From the complete stress-strain curves of high-temperature damaged rock specimens subjected to pre-peak confining pressure unloading, it can be inferred that as temperature of the specimen gradually increases, the peak strength decreases correspondingly. Additionally, the slope of the elastic stage in the stress-strain curve diminishes significantly. Circumferential strain gradually increases and becomes more pronounced, while volumetric strain changes from negative to positive, indicating significant expansion during the test. Peak strength decreases noticeably, and post-peak behavior exhibits distinct plastic characteristics. After unloading, both circumferential and volumetric strains gradually increase. This suggests that rock specimens subjected to high-temperature conditions exhibit certain softening characteristics, which become more pronounced at higher temperatures. These findings align with the results reported in literature21. When T ≥ 400 °C, the slope of the elastic stage in the stress-strain curve shows a significant decrease. Additionally, the circumferential strain increases substantially, the peak strength decreases markedly, and the post-peak behavior exhibits pronounced plastic characteristics.

Evolution of strength degradation in high-temperature damaged rock specimens

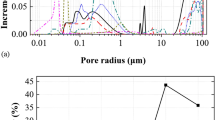

Multi-stage confining pressure and multiple peak yield tests were conducted on rock specimens damaged by high temperatures. These tests yielded complete stress-strain curves for various high-temperature damaged specimens under different confining pressures, as shown in Fig. 7. These stress-strain curves exhibit four distinct peak values, each followed by a transient decrease in axial stress. Under each confining pressure level, the stress-strain curves show a distinct strain hardening stage prior to peak strength, accompanied by modest increases in volumetric and circumferential strains. The rapid application of confining pressure at this point constrains further deformation, indicating that while the rock specimen has reached peak yield under that specific confining pressure level, it has not experienced complete failure. After the application of the final confining pressure level, the rock specimen displays a marked strain softening stage and a residual strength stage post-peak. At this point, both circumferential and volumetric strains increase significantly, with volumetric strain changing from negative to positive, demonstrating significant volumetric expansion. This behavior indicates that the rock specimen has only then experienced overall failure.

The peak strength values corresponding to the multi-stage confining pressure and multiple peak yield tests for high-temperature damaged rock samples are presented in Fig. 7; Table 2. Under the same confining pressures, rock specimens subjected to higher temperatures exhibit reduced peak strength values, indicating that high temperatures induce strength degradation in the rock under identical confining pressure levels. The higher the temperature, the greater the magnitude of strength degradation23. In high-temperature geothermal environments, temperature significantly affects the strength degradation of surrounding rock, especially at higher temperatures where it can cause substantial damage to rock mass strength24. The thermal stress generated by high temperatures initiates damage within the rock mass. When this damage reaches a critical threshold, it interacts synergistically with the stress state induced by excavation disturbances, leading to fracturing of the surrounding rock and ultimately resulting in structural instability.

In multi-stage confining pressure and multiple peak yield tests conducted on high-temperature initially damaged rock specimens, the primary failure mode is combined shear failure. However, the specific failure patterns vary depending on the degree of initial damage. Macroscopic cracks primarily manifest as combined shear-splitting cracks oriented along the loading direction. In specimens with low initial high-temperature damage, the macroscopic fracture surface generally consists of one diagonal main shear fracture surface and a secondary shear fracture surface that is oblique to the specimen axis. Conversely, for specimens with high initial high-temperature damage, the macroscopic fracture surface usually comprises 1–2 diagonal combined shear fracture surfaces and multiple secondary shear fracture surfaces that are oblique to the specimen axis. Due to the influence of high-temperature thermal cracks, the specimens tend to fail into loose blocks, as shown in Fig. 8.

The single-block method is used to determine the strength parameters of damaged rock specimens20. For quantitative analysis of strength degradation in damaged specimens, the stress reduction ratio is utilized25. This approach involves using the ratio of stress at the post-peak unloading point to the stress at the peak point to characterize the damage variable of high-temperature rock specimens, allowing for a quantitative evaluation of the degree of strength degradation. The stress reduction ratio for intact rock specimens is defined as 0, suggesting no initial damage. A larger stress reduction ratio Dσ for high-temperature damaged rock specimens indicates more severe damage. Based on the definition of stress reduction ratio and the complete stress-strain curves from multi-stage confining pressure and multiple peak yield tests of high-temperature damaged rock specimens in Fig. 7, the post-peak stress reduction ratios for damaged specimens at various temperature levels are calculated. These results are presented in Table 3. As temperature gradually increases, the stress reduction ratios for different specimens also increase, indicating that high temperatures exacerbate the initial damage to the specimens. This observation corroborates the microscopic structural damage of the specimens under high-temperature conditions, as illustrated in Fig. 4, and aligns with the findings in literature 21.

Compared to intact rock specimens, high-temperature initially damaged rock samples exhibit a notable degree of peak strength degradation regardless of their damage level. The degradation ranges from 18.49 to 67.38%, as shown in Fig. 9. The extent of peak strength degradation and stress reduction ratios increase with higher temperatures. In comparison to intact rock samples at T = 20 °C, specimens exposed to 150 °C display peak strength reductions of 24.85%, 23.98%, 15.90%, and 16.14% under various confining pressures. At 500 °C, these reductions increase to 60.37%, 59.71%, 54.68%, and 40.85%, respectively. This substantial reduction in strength can be attributed to the damage induced by thermal stress. Such thermal stress promotes the expansion of pre-existing cracks and the formation of new cracks within the rock. This process ultimately leads to rock fracturing26 and a marked decrease in the strength of the surrounding rock mass.

A critical zone for strength degradation in high-temperature damaged rock specimens is observed in relation to the stress reduction ratio. When this ratio exceeds 0.27 (T = 300 °C), strength degradation becomes increasingly sensitive to stress reduction, with minor increases in the ratio resulting in substantial strength degradation. The temperature of 300 °C represents a critical threshold for rock specimens27. Beyond this temperature, microscopic damage intensifies significantly, as shown in Fig. 4(c), leading to the formation of a continuous network of fissures within the rock mass. Under the prescribed stress loading and unloading conditions, rock specimens exposed to high temperatures experience a significant reduction in peak strength. This finding highlights the substantial strength-damaging effect of high temperatures on the strength of rock specimens and their increased propensity for fracture and failure.

Degradation patterns of shear strength parameters in high-temperature damaged rock samples

Exposure to high temperatures results in varying degrees of damage in rock specimens. To analyze the degradation patterns of strength parameters in these thermally altered samples, we propose treating the initially damaged samples as new load-bearing structures. These structures can be characterized by two primary strength properties, namely cohesion c and internal friction angle ϕ. By utilizing the complete stress-strain curves obtained from multi-stage confining pressure and multiple peak yield tests, the relationship between peak strength and various confining pressure levels for high-temperature damaged rock specimens can be established, as illustrated in Fig. 10. Through regression analysis of these curves, mathematical expressions that relate peak strength to confining pressure can be derived. Comparing these expressions with the strength parameters of intact rock specimens, a quantitative assessment of the degradation patterns in the strength parameters of high-temperature damaged rock specimens can be conducted.

From Fig. 9, the peak strength of high-temperature damaged rock specimens exhibits a positive relationship with increasing confining pressure, which follows a clear linear pattern. By employing the Mohr-Coulomb criterion, linear regression analysis can be conducted on the relationship between peak strength and confining pressure to expound the variations in the internal friction angle and cohesion as functions of confining pressure. Utilizing the linear Mohr-Coulomb strength criterion, regression analysis is performed on the peak strengths under four distinct levels of confining pressure, i.e., 5, 10, 15, and 25 MPa. This analysis is performed using the following equation:

where A and B are both strength criterion parameters, which can be expressed as:

where c and φ are the cohesion and internal friction angle of the high-temperature damaged rock mass, respectively. Using Eqs. (2) and (3), we can derive the cohesion and internal friction angle (equivalent parameters) for rock specimens with different degrees of damage. The calculation results are listed in Table 4.

The cohesion c and internal friction angle ϕ of high-temperature damaged rock specimens generally exhibit a decreasing trend as the stress reduction ratio at the post-peak unloading point increases, as demonstrated in Fig. 11. The reduction in cohesion c is more significant, with a maximum degradation of 70.88%. At 300 °C, the cohesion of the high-temperature rock specimens undergoes a significant change, showing the most substantial degradation, a 44.31% reduction compared to that of intact rock specimens. In contrast, the degradation of the internal friction angle is less severe, with a maximum reduction of 28.84%.

The synergistic influence of high temperatures and stress loading paths serves as the primary mechanism underlying strength degradation in the surrounding rocks of deep tunnels within high-geothermal environments. This degradation is governed by intrinsic thermodynamic mechanisms and structural responses. As temperature increases, thermal stress induces structural loosening within the rock matrix, weakening interparticle bonding and thus reducing cohesive resistance. Higher temperatures further promote the expansion of pre-existing microcracks, which collectively diminish the rock’s mechanical integrity. Additionally, thermal expansion occurs under high temperatures, and subsequent cooling induces residual stresses within the rock matrix. These stresses elevate the likelihood of fracture development. The cumulative impact of these phenomena manifests in a reduction of the rock’s internal friction angle.

At 25 °C and 100 °C, the majority of grains remain intact, with clear grain boundaries and visible transgranular and intergranular cracks. Notably, the degree of damage to the grains is slightly more pronounced at 100 °C compared to 25 °C, as evidenced by the crushing of edges in a small number of grains. At 300 °C, the majority of grain edges, as well as some entire grains, are crushed, and the boundaries of most grains become indistinct. These findings indicate that the rock powder on the failure surface is primarily composed of crushed rock grains. Consequently, the high temperature of 300 °C appears to alter the strength of individual rock grains and the bonding strength between them, thereby impacting the microscopic failure mechanisms of the rock.

Conclusions

(1) High temperatures induce significant initial damage to rock structures. The temperature of 300 °C represents a critical damage-sensitive zone for high-temperature rock specimens. Upon reaching this threshold, microscopic damage in the samples progressively intensifies, forming a continuous network of fissures. This phenomenon indicates that thermal stress resulting from high temperatures causes substantial damage to rock structures. When the damage accumulates to a certain threshold, it facilitates crack propagation and initiates new fractures, ultimately leading to rock failure.

(2) Throughout the experiment, circumferential strain exhibits a gradual increase, while volumetric strain changes from negative to positive values, indicating significant expansion. After the unloading phase, both circumferential and volumetric strains continue to increase gradually. At temperatures of T ≥ 400 °C, the slope of the stress-strain curve’s elastic stage decreases significantly, accompanied by a notable reduction in peak strength. Circumferential strain increases markedly, while post-peak behavior demonstrates clear plastic characteristics and exhibits pronounced residual strength properties at the confining pressure unloading point.

(3) High-temperature initially damaged rock specimens exhibit significant strength degradation compared to intact rock samples, with the peak point serving as the critical point for peak strength degradation. Utilizing the stress reduction ratio to quantify the degree of strength damage, the maximum degradation reaches 67.38%, with a minimum of 18.49%. Higher environmental temperatures lead to greater damage and more significant strength degradation.

(4) Under varying confining pressures, the Mohr-Coulomb strength parameters (cohesion c and internal friction angle ϕ) of high-temperature damaged rock specimens decrease with increasing damage. The degradation of cohesion c is more significant, reaching 70.88%. The temperature of 300 °C represents a threshold at which cohesion undergoes a sudden change, showing the maximum degradation of 44.31% compared to intact samples. This research reveals the strength degradation patterns of fractured surrounding rocks in deep high-geothermal tunnels. The cohesion and internal friction angle of high-temperature damaged rocks demonstrate a strong correlation with temperature, and changes in these parameters reflect the degree of rock damage in high-temperature environments. Understanding these parameter changes is crucial for ensuring the safe and stable operation of practical engineering projects.

The intact nature of the rock mass at the sampling site, characterized by minimal jointing and high strength, indicates that the test results hold significant reference value for the stability analysis of surrounding rock in underground engineering. The limited number of rock samples necessitates further investigation into the loading and unloading behavior of rock samples with pre-existing damage and fractures under high-temperature conditions, as well as triaxial compression tests conducted under various confining pressures. Plastic parameter values at unloading points of rock samples exhibiting different degrees of damage and fracture must be determined individually, and a strength attenuation model for surrounding rock in deep tunnel fractures should be established.

Data availability

The datasets generated or analyzed during the current study are not publicly available due to confidentiality agreements, but are available from the corresponding author on reasonable request.

References

Qian, Q. The characteristic scientific phenomena of engineering response to deep rock mass and the implication of deepness[J]. J. East. China Inst. Technology: Nat. Sci. 27 (1), 1–5 (2004).

Goldin, B. A. et al. High-temperature carbidization of carboniferous rocks. Dokl. Earth Sc. 427, 968–970 (2009).

Yang, S. Q. et al. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments [J]. Geothermics 65, 180–197 (2017).

Lakirouhani, A. et al. Physical and mechanical properties of sandstones from Southern zanjan, north-western Iran[J]. Baltica 35 (1), 23–36 (2022).

Jia, P. & Zhu, W. C. Mechanism of zonal disintegration around deep underground excavations under triaxial stress. Insight Numer. test[J] Tunn. Undergr. Space Technol. 48, 1–10 (2015).

Ásmundsson, R. et al. High temperature instruments and methods developed for supercritical geothermal reservoir characterisation and exploitation-The HiTI project. Geothermics 49, 90–98 (2014).

Peng, J. et al. Physical and mechanical behaviors of a thermal-damaged coarse marble under uniaxial compression[J]. Eng. Geol. 200 (12), 88–93 (2016).

Wei, G. et al. Full-scale loading test for shield tunnel segments: Load-bearing performance and failure patterns of lining structures[J]. Undergr. Space. 20, 197–217 (2025).

Feng, X. T. et al. Evolution of the Mechanical and Strength Parameters of Hard Rocks in the True Triaxial Cyclic Loading and Unloading Tests [J]. Int. J. Rock Mech. Min. Sci. 131104349 (2020).

Zhang, W. et al. Experimental study of the effect of high temperature on primary wave velocity and microstructure of limestone[J]. Environ. Earth Sci. 74 (7), 1–10 (2015).

Tian, H., Ziegler, M. & Kempka, T. Physical and mechanical behavior of claystone exposed to temperatures up to 1000°C [J]. Int. J. Rock Mech. Min. Sci. 70, 144–153 (2014).

Yin, T. B., Li, X. B. & Yin, Z. Q. Study and comparison of mechanical properties of sandstone under static and dynamic loadings after high temperature [J]. Chin. J. Rock Mechan. Eng. 31 (2), 273–279 (2012).

Chen, S., Yang, C. & Wang, G. Evolution of thermal damage and permeability of Beishan granite[J]. Appl. Therm. Eng. 110, 1533–1542 (2017).

Jolfaei, S. & Lakirouhani, A. Sensitivity analysis of effective parameters in borehole failure, using neural Network[J]. Adv. Civil Eng., 2022(1): 1–16 .

Wang, W. et al. Malignant development process of plastic zone and control technology of high stress and soft rock roadway [J]. J. China Coal Soc. 40 (12), 2747–2754 (2015).

Akdag, S. et al. Effects of Thermal Damage on Strain Burst Mechanism for Brittle Rocks Under true-triaxial Loading Conditions [J]511657–1682 (Rock Mechanics and Rock Engineering, 2018). 6.

Mcclurem, W. & Home, R. N. Correlations between formation properties and induced seismicity during high pressure injection into granitic rock[J]. Eng. Geol. 175, 74–80 (2014).

Hui, Q., Zhang, J. & Jiang, H. Study on the characteristics and distribution laws of plastic zone induced by Deep-buried High-geostress hydraulic tunnelling in jointed rock Mass[J]. Mod. Tunn. Technol. 58 (4), 86–94 (2021).

Jiang, H., Li, H. & Hou, X. Statistical damage model of rocks reflecting strain softening considering the influences of both damage threshold and residual strength[J]. Arab. J. Geosci. 286 (13), 1–8 (2020).

Kovari, K. et al. Suggested methods for determining the strength of rock materials in triaxial compression: revised version [J]. Int. J. Rock. Mech. Min. Sci. Geomech. Abstracts. 20 (6), 285–290 (1983).

Tian, W. et al. Meso-fracture mechanism of granite specimens under high temperature and confining pressure by numerical simulation [J]. Chin. J. Rock Mechan. Eng. 41 (9), 1810–1819 (2022).

Kumari, W. G. P. et al. Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: an application to geothermal energy extraction[J]. Geothermics 64, 44–59 (2017).

Jia, P. et al. Physical and mechanical properties and related microscopic characteristics of high-temperature granite after water-cooling [J]. Rock. Soil. Mech. 42 (6), 1568–1578 (2021).

Wang, Z. et al. Influence of high temperature on surrounding rock damage of underground coal gasification [J]. J. China Coal Soc. 47 (6), 2270–2278 (2022).

Niu, S. et al. Experimental study of strength degradation law of surrounding rock in fractured zone of deep roadway [J]. Chin. J. Rock Mechan. Eng. 31 (8), 1587–1596 (2012).

Laouafa, F. et al. Overview and Modeling of Mechanical an Thermomechanical Impact of Underground Coal Gasification exploitation[J]21547–576 (Mitigation & Adaptation Strategies for Global Change, 2014). 4.

Feng, Z. et al. Critical temperature of permeability change in thermally cracked granite[J]. J. China Coal Soc. 39 (10), 1987–1992 (2014).

Acknowledgements

This research was funded by the National Natural Science Foundation of China, grant number 52369021; and “Tianshan Talent” Cultivation Program, grant number 2024TSYCCX0037; and “Tianshan Talents” Excellent Engineer plan project, grant number 2024-2026.

Author information

Authors and Affiliations

Contributions

Data curation, editing, software, and analysis, H.J.; supervision and validation, Z.J.; methodology, project administration, and guidance, G.W.; writing—review and editing, T.Y. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jiang, H., Zhang, J., Wei, G. et al. Experimental study of strength degradation in fractured surrounding rock of deep high-temperature tunnels. Sci Rep 15, 28704 (2025). https://doi.org/10.1038/s41598-025-13595-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-13595-y