Abstract

The accidents of coal and gas outburst happening from 2013 to 2024 in Guizhou Province have been counted in accordance with the occurrence year, accident grade, accident location and occurrence month in this paper. The average number of the accidents and the dead persons are 1.75 and 14.92 respectively in each year, which can be understand from the statistics. The accidents are only distributed in the relatively major accident and the major accident and happen in Bijie district and the deaths distribute in LiuPanshui district mostly; the least number of the accidents and deaths arise in Guiyang district; the accidents and deaths separate in March mostly and there are no accidents in February and September. In addition, the risk factors of coal and gas outburst are divided into 4 first-level risk factors including personnel, equipment, environment and management and 18 secondary risk factors such as physical and mental quality of workers and so on. It can be concluded by risk assessment flowchart model that the equipment risk factor influences the coal and gas outburst risk system furthest and the personnel risk factor influences secondly and the environment risk factor influences thirdly and the management risk factor influences least. Finally, the associated countermeasures have been proposed in this paper. The above researches can provide the prevention of coal and gas outburst with the reliable and scientific foundation.

Similar content being viewed by others

Introduction

The accident of coal and gas outburst has been the first killer for the safety production of coal mines, which is reasoned that the lighter consequence is the asphyxia leading to injury and death of several persons and the heavier is the explosion leading to the death of numerous persons and the destruction of the coal mine. The coal resource is abundant in Guizhou Province that the coal resource occupies more than 40% in the area of Guizhou Province, which makes Guizhou Province called ‘the major coal producing province’1,2. The number of the coal and gas outburst accidents and the deaths have downgraded via the reinforced prevention and control of the coal and gas outburst in recent years, but the accident still occurs and the hidden trouble will be upgraded along with the increase of deep mining. Therefore, the problem associated with improving the situation of the high frequency of the coal and gas outburst is worthy of being considered.

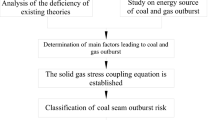

Being aimed at the prevention and control of the coal and gas outburst, the domestic and foreign scholars have researched and explored deeply and founded new prevention solutions and techniques continuously3. Japan, Poland, France, Russia, Germany and so on have increased the awareness of preventing the coal and gas outburst since the first coal and gas outburst arising in France in 1834 and have developed some solutions such as immediate response, hierarchical management, expert system, microseismic technology and so on, which is in the front ranking4,5,6. Mou J, Cheng L, Teng T, Cao, Z. Z et al. proposed some methods of preventing the coal and gas outburst including determining the sensitivity of the prediction index in a new manner, hydraulic fracturing and incorporating NMR measurement and triaxial loading chamber and using a folding catastrophe model and so on7,8,9,10; Wang F, Tian W, et al. measured the parameters of coal samples such as the adsorption constant, the initial velocity of gas diffusion (ΔP) and so on on the basis of langmuir adsorption model11,12; Qiao Z et al. proposed some control principles on the basis of deep mining mechanics theory and the evolution of the damage in the coal containing methane in the influence of shock loads13; Gray I, Shepherd J, Creedy D P, Hargraves A J, Wilson P, et al. considered that the geological structure and the magma’s invasion of the coal seam are the key factors of triggering coal and gas outburst based on the mathematical statistics, experimental analysis and so on14,15,16,17,18; Halbaum H W found that the outburst happens more easily the gas pressure curve of the front end of working face is increasingly steep19; Rowan H, Telfer W H, et al. concluded that the pulverized coal bag plays a key role in initiating the coal and gas outburst20,21; Li, D. G et al. addressed hydraulic support resistance determination in deep coal pillar caving faces at Zhaogu No. 2 Mine22.

As for the domestic researches on the prevention of coal and gas outburst, Jianyu Liu, Enyuan Wang, Xuecai Xie, et al. analyzed the occurrence mechanism of coal and gas outburst and proposed some precaution methods, including the prevention technology of the disaster combining outburst and shock, the essential technology of the prediction, detection and early warning and the sensibility analysis and probability inference and so on23,24,25; Li Chenwu et al. presented a solution of estimating the reliability of the measures of preventing coal and gas outburst being suitable for excavation face and judged the application effect26; Chaojun Fan, Cheng Zhai, Que Kong, Shuai Ma et al. counted and analyzed coal and gas accidents in Guizhou Province and our country and proposed some preventing suggestions or key importance, such as the main control factor of the accident, the distribution features of coal and gas outburst index and the characteristics of outburst and so on27,28,29,30.

The above scholars all don’t research the coal and gas outburst accidents in Guizhou Province from the perspective of system theory and never count the accidents happening in the latest years. Coal and gas outburst accidents in Guizhou Province were calculated and analyzed and system dynamics theory was made use of to research quantitatively the coal and gas outburst accidents on the basis of risk assessment flow graph model in this paper in order to expose the critical risk factors of the coal and outburst accident. Meanwhile, the countermeasures were presented. The above researches provide the prevention of coal and gas outburst with the reliable and scientific foundation.

The statistic and analysis of coal and gas outburst accidents in Guizhou Province

By year of occurrence

The number of accidents and deaths of coal and gas outburst in Guizhou Province from 2013 to 2024 has been showed in Fig. 1. From the picture, the annual averages of accident and death are 1.75 and 14.92 respectively from 2013 to 2024. The highest numbers of accident and death exist in 2014 and 2013 separately, which are totally 5 and 45. The least numbers of accident and death exist in 2016, 2020 and 2024, which are all totally 0.

From 2013 to 2016, the number of accidents and deaths integrally present a declining trend. The decrease amplitude of the number of accidents and deaths from 2015 to 2016 are both larger than that from 2014 to 2015. From 2016 to 2019, the number of accidents and deaths globally present a growth trend; the number of accidents and deaths from 2017 to 2019 respectively presents the situation of the same amplitude of growth and descent and upgrades gradually. The absolute amount of decline of accidents and deaths from 2019 to 2020 are both higher than that from 2015 to 2016 and the absolute amount of growth of accidents and deaths from 2020 to 2021 are both lower than that from 2016 to 2017. The number of accidents and deaths from 2021 to 2024 both present a declining trend and the decrease amplitude of the number of accidents and deaths from 2023 to 2024 are both larger than that from 2021 to 2022.

From the above statistic, it can be showed that the change of the amount of coal and gas outburst accident presents a four-rise and four-fall trend whose cycle is 3 ~ 4 years and that the change of death presents a two-rise and three-fall trend whose cycle is 2 ~ 4 years. Based on an overview of 2013 ~ 2014, the figures of the accidents and fatalities of coal and gas outburst in Guizhou Province arise the rise trend twice in 2016 ~ 2017 and 2020 ~ 2021 and the increase amplitude of the fatality’s amount is far larger than that of the accident’s amount; the above phenomenon makes us consider that the coal and gas outburst accident can’t still be controlled fundamentally and the situation of the prevention of coal methane and safety management are still severe.

By grade of accidents

The amounts of accidents and fatalities of coal and gas outburst from 2013 to 2024 are calculated by grade of accidents, which is showed in Table 1. From Table 1, the number of accidents separates mostly in the moderate accident in 2013 ~ 2024 and the amount is totally 14 and occupies 66.67%; the number separates secondly in the major accident in 2013 ~ 2024 and the amount is totally 7 and occupies 33.33%; there are no general accidents and extra-major accidents in this period. The numbers of fatality made by moderate accidents and major accidents are 79 and 100 and occupies 44.13% and 55.87% respectively.

The amount of years existing the moderate accident occupies 66.67% in the 12 years from 2013 to 2024 in Guizhou Province, which explains that the moderate accident has a high frequency and its prevention must be attached importance to. Although the amount of major accidents is 0.5 times as many as that of moderate accidents from 2013 to 2024, the amount of major accidents’ fatality is 1.27 times as many as that of moderate accidents and the average fatality of major accidents is 2.53 times as many as that of moderate accidents. In the meanwhile, the amount of years existing major accidents has occupied over 40% in the 12 years, which means that the major accidents still have the symptom of existence and the prevention still can’t be ignored. Furthermore, the number of accidents and fatalities of moderate coal and gas outburst all present a four-rise and four-fall trend and those of major coal and gas outburst all present a one-rise and two-fall trend, which shows that the fluctuation of moderate accidents is far stronger than that of major accidents.

By accident locations

The amounts of accidents and fatalities of coal and gas outburst from 2013 to 2024 are calculated by accident locations, which is showed in Fig. 2. The accidents and fatalities of coal and gas outburst mostly distribute in Bijie district and LiuPanshui district respectively whose amounts are 9 and 76 respectively and whose proportions are 42.86% and 42.46% respectively; the accidents and fatalities all least distribute in Guiyang district whose amounts are 2 and 12 respectively and whose percentages are 9.52% and 6.70%. The above situations can be known from Fig. 2.

LiuPanshui district and Bijie district are both areas possessing abundant coal resource and coal and gas outburst mines distribute mostly in the 2 districts. Coal and gas outburst accident easily leads the major injury and death and property damage, which makes Bijie and LiuPanshui get the highest amount in accidents and fatalities. In spite that the number of accidents in LiuPanshui is less than that in Bijie and the number of fatalities in Bijie is less than LiuPanshui, the fatal persons led by an accident averagely in LiuPanshui(12.67 persons per accident) are more than that in Bijie(5.89 persons per accident).

To sum up, the situation of safety production in coal mines of Bijie and LiuPanshui are both pessimistic. In spite that the accidents and fatalities distribute least in Guiyang district, an accident can make 6 people dead averagely. As a provincial capital and a battle position of coal resource in Guizhou, the safety production management in Guiyang need to be enhanced emphatically for the purpose of guaranteeing the safe supply of coal resource.

By month of occurrence

The amounts of accidents and fatalities of coal and gas outburst from 2013 to 2024 are calculated by month of occurrence, which is showed in Fig. 3. From the Fig. 3, it can be seen that the amount of accidents and fatalities mostly separate in March, which are totally 4 and 43 and occupy 19.05% and 24.02% respectively. There are no accidents in February and September.

On the basis of the analysis of the occurrence of accidents in all quarters, the amount of accidents and deaths in the 4th quarter is equivalent to that in the 1st quarter. Spring Festival is between January and February in many times and most employees in coal mines would like to return their own hometowns to celebrate Spring Festival, so the demand for producing coal.

resource is relatively small and the numbers of accidents and fatalities from January to February declines largely. The period from February to March is the return-to-work time in coal mine enterprises and enterprises enhance the production in a large manner so as to ensure the production index, which makes the risk of coal and gas outburst accident accumulated and the amounts of accidents and fatalities from February to March increase exquisitely. The weather is becoming warm from March to June and the demand for electricity and coal resource is small relatively and the time from May to June is our country’s safety production activity month, so the amounts of accidents and fatalities degrade integrally and there are minimums in May and June. Summer is from June to August and the demand for electricity is relatively high, which makes a higher demand for coal production and the numbers of accidents and fatalities entirely and elastically raise once again. Autumn is from August to September and the weather is cool and the demand for electricity in this period is small, which makes a lower demand for coal production and the numbers of accidents and fatalities decrease again. The fourth quarter is from September to December and a number of enterprises accelerate the production working for the purpose of the production target and the annual maximum profit; in the meanwhile, the demand for coal resource from November to December(or winter)is exceedingly high; the above reasons lead the amounts of accidents and fatalities rise elastically and integrally in the 4th quarter.

Study on flow chart model of risk assessment of coal and gas outburst accident in Guizhou Province

Coal and gas outburst accident is influenced synthetically by various factors and its security risk system is a sophisticated and dynamic system. The flow chart model of risk assessment is a method being used of researching the mechanism of feedback control and the mode of dynamic behavior which exist in the complicated system on the basis of system dynamics theory. The system’s dynamic behaviors is simulated by constructing the causal loop diagram and flow chart, which makes the internal law associated with the behavior change of the system analyzed accurately.

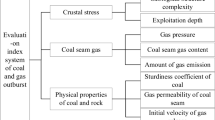

Coal and gas outburst risk factors system analysis and weight determination

The risk factor system of coal and gas outburst accident can be divided into four risk factors of first-level indicators including personnel, equipment, environment and management. The sub-system of personnel risk factor can consist of the physical and mental quality of the workers, the safety awareness of the workers, the working hours of the workers and the ability of the safety management personnel and so on. The sub-system of equipment risk factor can include the degree of intelligent monitoring system, the load degree of intelligent equipment, the safety of intelligent equipment components and the aging degree of intelligent equipment and so on. The sub-system of environment risk factor can involve coal mining underground wind speed, coal mining underground space suitability, coal mining underground visibility, coal mining underground engineering layout, coal mining underground temperature and coal mining depth and so on. The sub-system of management risk factor can contain safety training and education, safety supervision level, effectiveness of safety measures and soundness of safety rules and regulations and so on.

The weight is determined by entropy weight method and G1 method in this paper, which is as follows:

-

1.

The steps of determining the weight based on entropy weight method

-

(1)

Standardization of original data. Supposed that there are n evaluation indicators and s evaluation objects, the original data matrix can be seen in the first formula:

$$R = \left[ {\begin{array}{*{20}c} {r_{11} } & \cdots & {r_{1s} } \\ \vdots & \ddots & \vdots \\ {r_{n1} } & \cdots & {r_{ns} } \\ \end{array} } \right]$$(1)In this formula: \(r_{ns}\)—the degree of membership of the s-th evaluation object associated with the n-th evaluation indicator.

The standardized matrix can be showed in the second formula:

$$R = \left( {r_{ij} } \right)_{n \times s}$$(2)In this formula: \(r_{ij}\)—the evaluation indicator’s standardized membership degree. Its calculation is as follows:

-

①

The higher the data is, the better the indicator is:

$$r_{ij} = \frac{{x_{ij} - \min x_{ij} }}{{\max x_{ij} - \min x_{ij} }}$$(3) -

②

The lower the data is, the better the indicator is:

$$r_{ij} = \frac{{\max x_{ij} - x_{ij} }}{{\max x_{ij} - \min x_{ij} }}$$(4) -

(2)

The entropy of the i-th indicator(ei)can be defined in the follow formula

$${e_i} = - K\sum\limits_{j = 1}^n {{f_{ij}}} \ln {f_{ij}}$$(5)In this formula: \(K = \frac{1}{\ln n}\), \(f_{ij} = \frac{{r_{ij} }}{{\sum\limits_{i = 1}^{n} {r_{ij} } }}\), and defined fij is equal to 0, fijlnfij is 0.

-

(3)

Define the difference coefficient of the i-th indicator(αi), which is from the 6th formula

$$\alpha_{i} = \frac{{1 - e_{i} }}{{\sum\nolimits_{i = 1}^{n} {\left( {1 - e_{i} } \right)} }}$$(6) -

(4)

Calculate the weight of the i-th indicator, which is following in the 7th formula

$$w_{i} = \frac{{\alpha_{i} }}{{\sum\nolimits_{i = 1}^{n} {\alpha_{i} } }}$$(7)

-

①

-

2.

The steps of determining the weight based on G1 method.

-

(1)

Compare the importance. The importance degree between xn-1 and xn determined by experts is defined as rk and the values of rk can be seen in Table 2.

Table 2 Assignment table. -

(2)

Calculate the weight coefficient(wk), which is showed in the 8th and 9th formula

$$w_{n} = \left( {1 + \sum\limits_{k = 2}^{n} {\prod\limits_{i = k}^{n} {r_{i} } } } \right)^{ - 1}$$(8)$$w_{k - 1} = r_{k} w_{k}$$(9) -

(3)

Amend the weight determined by G1 method. The weight is modified by entropy weight method after determining the subjective weight and objective weight, the modification can be seen in the 10th formula:

$$\varphi = e_{j} \eta_{i} + \left( {1 - e_{i} } \right)w_{j}$$(10)In this formula: \(\varphi\) is the modified weight value; \(\eta_{i}\) is the subjective weight; \(w_{j}\) is the objective weight.

The entropy and weight of all risk factor indicators based on entropy weight method are following in Table 3, which are calculated according to the above steps and expert scoring.

Table 3 The weight calculation results of each factor ( entropy weight method ). All risk factors can be arranged and compared according to G1 method. The sub-systems of personnel risk factor, equipment risk factor, environment risk factor and management risk factor are defined as a1, a2, a3 and a4 respectively and yi is defined as the arranged factor’s weight. In descending order, the 4 risk factors can be arranged as‘a1, a4, a2 and a3’. The comparison of importance among 4 risk factors are defined as r2, r3 and r4 which are equal to 1.2, 1.3 and 1.1 respectively. To sum up, the result is as follows:

$$\sum\limits_{k = 2}^{4} {\prod\limits_{j = k}^{4} {r_{j} } = } 4.246$$From the 8th formula, it can be got as follows:

$$y_{4} = \frac{1}{1 + 4.246} = 0.189$$From the 9th formula, it can be got as follows:

\(w_{3} = w_{4} *r_{4} = 0.207\), \(w_{2} = w_{3} *r_{3} = 0.269\), \(w_{1} = w_{2} *r_{2} = 0.322\).

In accordance with the above process, all risk factor indicators’ weight can be calculated by G1 method and the result is showed in Table 4.

According to the above method, the entropy is used for amending all secondary index risk factors and the result is showed in Table 5.

Table 4 The weight of each risk factor index of coal and gas(Calculated by G1 method). Based on Tables 3 and 4, the entropy is used for amending all risk factors of first-level indicators and the result is as follows:

-

Personnel risk factor’s weight: y1 = 0.161*0.322+(1-0.161)*0.206 = 0.220.

-

Equipment risk factor’s weight: y2 = 0.723*0.207+(1-0.723)*0.421 = 0.265.

-

Environment risk factor’s weight: y3 = 0.125*0.189+(1-0.125)*0.194 = 0.192.

-

Management risk factor’s weight: y4 = 0.181*0.269+(1-0.181)*0.179 = 0.194.

Table 5 The weight correction value of each risk index factor of coal and gas outburst. -

(1)

-

(1)

Coal and gas outburst safety risk system dynamics model establishment and simulation

The establishment of model

In accordance with the analysis of the risk system of coal and gas outburst, it can be ensured that coal and gas outburst security risk system consists of 4 sub-systems namely personnel, equipment, environment and management. The software Vensim-PLE is applied to the design of the causality diagrams of all above sub-systems and the integral coal and gas outburst security risk system, which is reflected in Fig. 4. In the meanwhile, the Loops of Vensim-PLE can be used for presenting the feedback loops of all risk sub-systems, which is presented in Table 6.

The above causality diagrams are transferred into the stock flow diagrams, which is showed in Fig. 5.

The simulation research

For the reason that the reliability of expert scoring data should be ensured, the variable initial value is set in the range of 0 to 1. 0 means that the probability of the accident’s appearance led by a factor is 0 and 1 means that the probability of the accident’s appearance led by a factor is exceedingly high. According to the data of expert scoring, all risk factors’ initial values are exhibited in Table 7.

In accordance with all risk factors’ initial values and weight values, the flow graph model equations which are reflected in Table 8 can be established.

On the basis of the constructed flow graph model equations, the equations are added into the flow graph model by using the software Vensim-PLE. The time of this simulation is set as 5 months and the level of coal and gas outburst safety risk system starts from 0. The safety level trend chart of coal and gas outburst risk system is showed in Fig. 6(a). Next, the initial values of all risk factor sub-systems are reduced by 0.05 and the safety level trend chart of coal and gas outburst risk system is showed in Fig. 6(b). The variation of safety level of coal and gas outburst which is resulted by changing the initial values is following in Fig. 7.

Guizhou coal and gas outburst risk system safety level trend chart. Current represents that the initial value is not changed; current 1 represents the coal and gas outburst risk system safety level trend resulting from a 0.05 reduction in the initial values of personnel risk’s all factors while keeping other factors unchanged; current 2 represents the coal and gas outburst risk system safety level trend resulting from a 0.05 reduction in the initial values of equipment risk’s all factors while keeping other factors unchanged; current 3 represents the coal and gas outburst risk system safety level trend resulting from a 0.05 reduction in the initial values of environment risk’s all factors while keeping other factors unchanged; current 4 represents the coal and gas outburst risk system safety level trend resulting from a 0.05 reduction in the initial values of management risk’s all factors while keeping other factors unchanged)

The means of all simulation data of ‘current’ existing all columns are calculated. Then, the mean of ‘current’ is subtracted by the average of ‘current1’ and the result is used to divide the mean of ‘current’, which produces the rate of change belonging to ‘current1’. Based on the above solution, the simulations of ‘current2’, ‘current3’ and ‘current4’ can be dealt and the dealt result can be seen in Table 9. From Table 9, it can be understood that the rates of change of personnel risk system, equipment risk system, environment risk system and management risk system are 5.30%, 5.70%, 4.47% and 4.10% respectively. Finally, the degree of influence on coal and gas outburst risk system is that: the equipment risk factor influences the coal and gas outburst risk system furthest and the personnel risk factor influences secondly and the environment risk factor influences thirdly and the management risk factor influences least.

Countermeasure research

In recent years, the efficiency of governing coal and gas outburst accidents is exceedingly wonderful, but the prevention and control is still complex and strict. Not only is safety awareness strengthened, the bottom line of security stuck and the security line built, but the prevention of accidents should be used for improving the level of coal mine safety production in the aspects of personnel, equipment, environment and management and so on. Like this, coal and gas outburst accident can be prevented and controlled effectively and the safe and efficient supply of coal resource is able to be guaranteed completely.

Strengthen safety training education and professional talent team construction

According to the statistic of coal and gas outburst accidents, it can be found that numerous accidents are led by the reason that the individual can’t take measures or eliminate the outburst hazard of coal seam. For instance, on January 18th of 2013, a major coal and gas outburst accident appeared in JinJia coal mine which belongs to Guizhou Panjiang refined coal incorporated company located in LiuPanshui. One of the reasons for this major accident is that coal seam 18 − 1 in the area has a stronger outburst hazard and the regional outburst prevention measure called rock cross-cut coal can’t be executed completely and the data of regional measures effect test can’t be measured reasonably.

Aiming at the prevention of coal and gas outburst accident, the safety training education for employees should be enhanced such as transmitting the instruction and the spirit of the meeting related to safety production carefully and richly in pre-class meeting and so on and accomplishing safety reminders and notifications. Leaderships of coal mine enterprise should play a demonstrative and leading role and lead by example and promise to comply with safe production regulations openly, which makes a top-down safety culture establish. The coal mine enterprise not only should enhance the inner employees’ training and education, but also introduce the relative talents with a high quality and a high technical ability and equip the supervisory engineering staffs which are enough for the demand of production. In the meanwhile, young production individuals are supposed to be accelerated to become production backbones with an excellent quality, a prominent ability and full experiences through the mechanism of ‘the old teach the new and the excellent teach the poor’ and establish the professional talent team being aimed at preventing the methane disasters such as coal and gas outburst.

Press ahead with the mechanization and automation transformation of coal mines and strengthen scientific and technological breakthroughs

From the above analysis based on system dynamics, it can be understood that the influence of equipment on the accident risk system is higher than that of personnel. Equipment plays a key role in preventing the accident in many time. For instance, on November 2nd of 2013, there was a moderate coal and gas outburst accident in HuangShuiba coal mine which is located in Jinsha county of Bijie city. One of the reasons for this accident is that the methane monitor can’t detect the concentration of methane after blasting due to human causes, which makes the monitor not detect the change of methane concentration immediately at the time of triggering the accident.

Coal mine enterprises are obliged to upgrade the level of equipment. Besides the routine care and maintenance and the standardized management must be accomplished, it is more important to press ahead with the mechanization and automation transformation of coal mines. In the meanwhile, coal mine enterprises are responsible for learning and practicing new equipment and new technologies and contributing to scientific researches and strengthening scientific and technological breakthroughs in the precaution of coal and gas outburst. For example, the technology of artificial intelligence such as Deepseek can try being added into the prevention of coal and gas outburst, which can make the prevention artificial and intelligent and so on.

With outburst prevention measures as the core focus, while advancing probing and enhanced drainage alongside other measures

In terms of the appearance of coal and gas outburst accident, the outburst hazard of coal seam is an objective and essential factor. At the same time, the complicated geological structure and the characteristics of soft and low permeability existing in coal seam often become one of the important causes of leading accident. For instance, on June 11th of 2014, there was a major coal and gas outburst in Xinhua coal mine which belongs to Liuzhi Industrial and Mining Group located in LiuPanshui. One of the reasons for this accident is that the soft of coal seam M6 lead the constructed boreholes collapsing, which affects the efficiency of drainage seriously. On March 12th of 2013, there was a major coal and gas outburst in Machang coal mine which belongs to Guizhou Gemudi Mining incorporated company located in LiuPanshui. One of the reasons for this accident is that the excavated roadway in 13,302 floor gas drainage roadway exists the complicated geological structure, which makes the coal seam exposed repeatedly in the process of excavating.

First of all, the working of identifying the outburst hazard of coal seam should be implemented in a good and careful manner based on ‘detailed rules for prevention and control of coal and gas outburst’ and the mining operation only can be started after taking regional comprehensive outburst prevention measures and determining to be safety in accordance with effect of regional measures, especially the outburst coal seam in the outburst mine; the effect of regional measures should be taken to identify the outburst hazard of coal seam in the period of mining and the mining operation can be only begun after determining to safety and carrying out security safeguards; it should be noticed that the local prevention outburst measure must be supplemented when there is the outburst coal seam in local areas31. In addition, coal mine enterprises are responsible for enhancing the advanced detection to the geological structure and analyzing the geological structure scientifically so that the coal seam position, stratum occurrence and structural form can be understood immediately and accurately, which makes the countermeasures executed targeted in different geological structures. Moreover, coal mine enterprises are obliged to positively popularize, experiment and apply all various of technical equipment, construction technologies and management measures and so on which can improve drilling efficiency, hole completion rate and degrade the nozzle of the soft coal seam and so forth so that the drainage efficiency of soft coal seam can be guaranteed, especially the soft coal seam possessing the characteristics of low permeability and high gas pressure and so on.

Implement primary responsibility for work safety and strengthen regulatory oversight and monitoring and enhance cooperation among industry, academia and research institutes

From the statistics of coal and gas outburst accidents, nearly all accidents result from the poor management which mainly includes ‘not implementing primary responsibility for work safety’, ‘poor safety management’, ‘organizing the production with violating regulations’, ‘unfulfillment of monitoring data’ and ‘premeditating to conceal accidents’ and so on. For example, on March 2nd of 2022, there was a moderate coal and gas outburst accident in Limin coal mine belonging to Guizhou Strong Prosperity Group Investment incorporated company located in Guiyang. One of the reasons for this accident is that the primary responsibility for work safety isn’t implemented and the accident is concealed. On August 6th of 2018, there was a major coal and gas outburst accident in ZiMuga coal mine located in Panzhou city of LiuPanshui. One of the reasons for this accident is that Chuangcheng (Guizhou) Branch doesn’t measure the basic parameter of methane according to the relative procedures and regulations and submits the fake report of the basic parameter of methane.

Accomplishing the safety management is the basic guarantee of implementing the policy of safety first, prevention first and comprehensive treatment, which provides safeguarding support for the enterprise’s development32. To begin with, all enterprises and departments have to implement primary responsibility for work safety by themselves, enhance the awareness of responsibility and law governing associated with safety, consummate the effective safety production responsibility system and ensure effective enforcement of work safety protocols. In addition, coal mine enterprises must strengthen the safety management and guarantee the technologies and measures to be implemented and organize the production based on laws and regulations. The methane management is in the main position, but the others such as roof and blasting can’t also be ignored. Serious violations such as reckless adventurism and concealing the accident should be prohibited and the requirement of ‘Detailed rules for prevention and control of coal and gas outburst’ should be implemented strictly. Thirdly, the institute and department being responsible for measuring the data are supposed to work in accordance with ‘Comprehensive management measures for coal mine gas prevention and control in Guizhou province’ so that the basic parameter of safety production in coal mines can be measured and monitored accurately. The rough measuring and monitoring led by time saving is strictly prohibited and the institute and department should be responsible for the determined results. Last but not least, the supervision departments have to increase the force of inspecting the hidden trouble, which means that coal mine enterprised are forced to observe the rules and understand the bottom line by the strict law enforcement so that the methane drainage and prevention of outburst can be accomplished properly and effectively. Meanwhile, the cooperation among industry, academia and research institutes should be reinforced in order to stimulate the technology innovation and level improvement in coal mine enterprises, which makes the coal industry’s ballast function applied.

Conclusions

-

1.

The statistic of coal and gas outburst accidents in Guizhou Province from 2013 to 2024 has been made in this paper based on the occurrence year, accident grade, accident location and the occurrence month. The change of the amount of coal and gas outburst accident presents a four-rise and four-fall trend whose cycle is 3 ~ 4 years and that the change of death presents a two-rise and three-fall trend whose cycle is 2 ~ 4 years. The moderate accident has a high frequency and the major accidents still have the symptom of existence in future. Bijie district and Liupanshui district are the regions with the highest number of coal and gas outburst incidents and the highest death toll, respectively. The amount of accidents and fatalities mostly separate in March.

-

2.

The risk factor system of coal and gas outburst accident can be divided into 4 risk factor subsystems according to 4 risk factors of first-level indicators called personnel, equipment, environment and management and 4 risk factor subsystems can be totally divided into 18 secondary index risk factors which conclude physical and mental quality of the workers and so on. The equipment risk factor influences the coal and gas outburst risk system furthest and the management risk factor influences least.

-

3.

Not only is safety awareness strengthened, the bottom line of security stuck and the security line built, the prevention of coal and gas outburst accident should be used for improving the level of coal mine safety production in 4 aspects including‘strengthen safety training education and professional talent team construction’, ‘press ahead with the mechanization and automation transformation of coal mines and strengthen scientific and technological breakthroughs’, ‘with outburst prevention measures as the core focus, while advancing probing and enhanced drainage alongside other measures’ and‘implement primary responsibility for work safety and strengthen regulatory oversight and monitoring and enhance cooperation among industry, academia and research institutes’.

-

4.

The risk assessment flow graph model is only the foundation of the theory, which means that the combination of theory and practice can only guarantee the reliability of the model. Meanwhile, all risk factors can influence each other, which should be considered in ascertaining the degree of all risk factor subsystems.

Data availability

All formulas, data and diagrams generated or used during the study have been appeared in this paper.

References

Long, Z. B. The Development and Use as Well as the Problems and Suggested Solutions of Coal Resource in Guizhou Province (Guizhou University, 2007).

Li, C. Risk Assessment of One-Ventilation and Three-Prevention System of a Mine in Guizhou Based on HSE (Guizhou University, 2018).

Dennis, J. B. Review of coal and gas outburst in Australian underground coal mines. Int. J. Min. Sci. Technol. 29 (6), 815–824 (2019).

Gao, M. M. Warning of Coal and Gas Outburst Accident (Liaoning Technical University, 2015).

Kursunoglu, N. & Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 88, 63–72 (2019).

Zhu, N. N., Zhang, L., Fan, X. S. & Shu, L. Y. Early warning model of outburst danger based on micro-seismic monitoring technique. Coal Mine Saf. 49 (02), 155–158 (2018).

Mou, J., Liu, H., Zou, Y. & Li, Q. A new method to determine the sensitivity of coal and gas outburst prediction index. Arab. J. Geosci. 13 (12), 465 (2020).

Cheng, L. et al. Hydraulic fracturing and its effect on gas extraction and coal and gas outburst prevention in a protective layer: a case study in China. Int. J. Oil Gas Coal Technol. 23 (4), 427–449 (2020).

Teng, T., Chen, Y. L., Wang, Y. M. & Qiao, X. R. In situ nuclear magnetic resonance observation of pore fractures and permeability evolution in rock and coal under triaxial compression. J. Energy Eng. 151 (4), 04025036 (2025).

Cao, Z. Z. et al. Disaster-causing mechanism of spalling rock burst based on folding catastrophe model in coal mine. Rock Mech. Rock Eng. 58 (7), 1–14 (2025).

Wang, F., Liang, Y. & Zou, Q. Correlation between coal and gas outburst risk and adsorption properties of coal seams. Energy Sci. Eng. 7 (3), 974–985 (2019).

Tian, W. et al. Water injection into coal seams for outburst prevention: the coupling effect of gas displacement and desorption Inhibition. ACS Omega. 9 (26), 28754–28763 (2024).

Qiao, Z., Li, C., Wang, Q. & Xu, X. Principles of formulating measures regarding preventing coal and gas outbursts in deep mining: based on stress distribution and failure characteristics. Fuel 356, 129578 (2024).

Gray, I. Outburst Risk Determination and Associated Factors (Australian Coal Research Ltd., 2015).

Shepherd, J., Rixon, L. K. & Griffiths, L. Outbursts and geological structures in coal mines: a review. Int. J. Rock. Mech. Min. Sci. Geomech. Abstracts. 18 (4), 267–283 (1981).

Creedy, D. P. Geological controls on the formation and distribution of gas in British coal measure strata. Int. J. Coal Geol. 10 (1), 1–31 (1988).

Hargraves, A. J. Instantaneous outbursts of coal and gas-a review. Australas Inst. Min. Metall. Proc (Australia), 285. (1983).

Wilson, P. Instantaneous outbursts of carbon dioxide in coal mines in Lower Silesia, Germany. Trans. Am. Inst. Min. Metall. Eng. 94, 88–136 (1931).

Halbaum, H. W. Discussion of J. Gerrard’s paper ‘instantaneous outburst of Fire-damp and coal,broad oak colliery’. Inst. Min. Eng. 10552, 258–265 (1899).

Rowan, H. An outburst of coal and firedamp at Valley Field Colliery, Newmills, Fife. Trans. Inst. Min. Engrs. 42, 127–128 (1911).

Telfer, W. H. Discussions of rowan’s paper on ‘an outburst of coal and firedamp at Valley Field Colliery, Newmills, Fife’. Trans. Inst. Min. Engrs. 42, 274–287 (1911).

Li, D. G. et al. A new determination method of hydraulic support resistance in deep coal pillar working face. Sci. Rep. 15 (1), 19158 (2025).

Liu, J. Y., Gao, W. C., Li, P., Meng, R. & Hu, Y. G. Prevention and control technology of coupling disasters induced by outburst shock based on gas extraction. J. Heilongjiang Univ. Sci. Technol. 35 (01), 32–42 (2025).

Wang, E. Y., Zhang, G. R., Zhang, C. L. & Li, Z. H. Research progress and prospect on theory and technology for coal and gas outburst control and protection in China. J. Coal. 47 (01), 297–322 (2022).

Xie, X. C. Organization-Oriented Studies on the Causes of Coal and Gas Outburst Accidents and its Preventive Applications (China University of Mining & Technology, 2021).

Li, C. W. & Qiao, L. Failure determination method regarding local outburst prevention measures for coal and gas outburst. J. China Coal Soc. 49 (S2), 924–933 (2024).

Fan, C. J. et al. Spatial and Temporal distribution of coal and gas outburst accidents in China from 1950 to 2022. J. Liaoning Tech. University(Natural Sci. Edition). 43 (03), 279–287 (2024).

Zhai, C. et al. Reflection and prospect on the prevention of gas outburst disasters in China’s coal mines. J. China Univ. Min. Technol. 52 (06), 1146–1161 (2023).

Kong, Q., Wu, G. Y., Zhong, F. & Chen, J. M. Coal and gas outburst features in Guizhou mining areas and its prevention countermeasures. Min. Autom. 42 (02), 22–26 (2016).

Ma, S., Li, S. Q., Qin, Z. D., Fang, X. T. & Du, Y. Q. Study on regularity of coal and gas outburst accidents in Guizhou Province. Clean. Coal Technol. 17 (06), 89–91 (2011).

Cheng, Y. P. Mine Gas Prevention. (China University of Mining and Technology Press, 2023).

Tian, S. C. & Jing, G. X. Safety Management, 2nd ed (Mechanical Industry Press, 2016).

Acknowledgements

Yongzhi LIU discloses support for the research of this work from the central government guided the local science and technology development fund project in 2024(Qian ke he zhong yin di[2024]039). Guangyu SUN discloses support for the research of this work from Liupanshui Teachers ' College Fund Project(LPSSYQNPY202101). Shiwei WANG discloses support for the research of this work from Liupanshui Normal University Discipline Direction Team Funding Project(LPSSY2023XKTD02).

Funding

Yongzhi LIU discloses support for the research of this work from the central government guided the local science and technology development fund project in 2024(Qian ke he zhong yin di[2024]039). Guangyu SUN discloses support for the research of this work from Liupanshui Teachers ' College Fund Project(LPSSYQNPY202101). Shiwei WANG discloses support for the research of this work from Liupanshui Normal University Discipline Direction Team Funding Project(LPSSY2023XKTD02).

Author information

Authors and Affiliations

Contributions

Guangyu SUN wrote the main manuscript.Niaz Muhammad Shahani and Xiangtao KANG checked and modified the manuscript.Chaoxin QI provided the related statistics of coal and gas outburst in Guizhou Province from 2013 to 2024.Yongzhi LIU and Shiwei WANG accomplished the study on flow chart model of risk assessment of coal and gas outburst accident in Guizhou Province.Hu YUE made the countermeasure research.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, G., Shahani, N.M., Kang, X. et al. Study on statistical analysis and prevention of coal and gas outburst accidents in Guizhou Province. Sci Rep 15, 28611 (2025). https://doi.org/10.1038/s41598-025-14025-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-14025-9