Abstract

This paper proposes an improved speed control method for a dual-induction motor drive powered by a single five-leg voltage source inverter. Generally, dual- and multi-motor drive systems are widely used in electric vehicles, traction systems and in several industrial applications. The proposed solution utilizes field-oriented control scheme as basis. The space vector pulse-width modulation technique was used to generate the output voltages. The main purpose of the proposed solution is to utilize the additional degree of freedom provided by a dual-motor drive system. The improved speed control system consists of two blocks: an additional computation block and a rotor flux position control block. The proposed control technique allows for effective control of the rotor speed of two independent three-phase IMs, regardless of load conditions. Under limited conditions, when the rotor speeds of both motors are the same, the proposed rotor flux position control allows to achieve higher modulation indexes and decrease energy losses as well. Simulation studies were carried out in PLECS software, the obtained results proved the effectiveness of the proposed control scheme. To identify the feasibility and effectiveness of the proposed control system, an experimental validation was conducted. Simulation and experimental results are shown and discussed in this paper.

Similar content being viewed by others

Introduction

The multi-motor drive systems (MMDS) have been frequently investigated during the last decades. Such solutions are attractive thanks to several benefits, such as low cost, high efficiency and performance. MMDS can be found in textile and steel manufacturing processes, electric vehicles (EVs) and traction systems1,2,3. In industrial applications, the permanent magnet synchronous motors (PMSMs) are utilized4,5. Due to the lower cost and robustness, the induction motors (IMs) are also used in these applications6,7. The publications covering MMDS concern the topologies of the voltage source inverters8,9,10,11,12, pulse-width modulation (PWM) techniques1,5,6,13,14,15, and control for PMSMs and IMs16,17 working in such application. The solutions proposed there utilize three groups of inverters: five-leg inverters1,2, four-leg inverters7,17, mono-inverter dual-parallel system4, and the nine-switch inverters18. The research is concentrated on reduction of MMDS costs by minimizing the number of switching devices and/or minimizing the switching losses.

The five-leg inverter is one of the most popular solutions used in MMDS. Two three-phase inverters are replaced by a single five-phase inverter, where one phase of each motor is connected to the same inverter leg19,20,21. For those drive systems, several modulation methods have been proposed: sinusoidal double-zero sequence (DZS)22, space-vector pulse-width modulation (SVPWM)1,5, or the two-arm modulation techniques13,14. Moreover, various control approaches have been proposed as well, including: direct torque control (DTC)23,24, field-oriented control (FOC), hysteresis control25, and model predictive control (MPC)26,27,28.

Some publications propose utilizing an additional degree of freedom of the DMDS to increase the dc-link usage or reduce the current component in the common phase. Such solutions have been presented for both four-leg29 or for five-leg30 inverters. The operational conditions for these control methods are the same—two IMs should operate at the same speed regardless of the load condition. These conditions provide the possibility to control the mutual position of the machines’ rotor fluxes to decrease the losses in the common inverter leg.

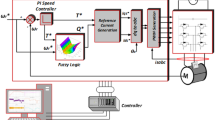

This paper presents an improved speed control method for a five-leg voltage source inverter (VSI) powering a dual-induction motor drive system, Fig. 1. The DMDS drive consists of two IMs and is controlled using FOC method and SVPWM technique. The improved speed control method is proposed herein to control the mechanical speed of two three-phase IMs, regardless of the load condition. Moreover, the proposed control scheme minimizes the common phase losses by reducing the inverter common-leg current, and can also be used to increase the modulation index, depending on the mutual rotor fluxes’ position. Figure 2 presents the impact of the mutual fluxes’ position on: the common-leg current (Fig. 2b) and the modulation index (Fig. 2a). The reference value for the mutual position of fluxes may be chosen using the characteristic presented in Fig. 2, depending on the desired results. Conventional control schemes have not offered an increase in the VSI modulation index. A higher modulation index results in a greater effective value of the output voltage, improving the control system efficiency (higher voltage can be generated while the DC-link voltage remains the same).

The main contribution of this paper is to present the idea of mutual rotor fluxes’ position control in terms of the minimization of the common leg current and the maximization of the modulation index for a five-leg VSI powering two IMs. The common-leg current minimization has been proposed in some publications29,30,31. This minimization results in total energy loss reduction. The reduction in energy losses might reach up to 32.5% for certain operational conditions, i.e. when both motors have the same frequency and operate at the same speed31. The implementation of rotor flux position control is a one of the approaches aimed to decrease the current amplitude in the common leg. Compared to the solutions presented in29,30, the control scheme proposed here allows to obtain a similar performance in motor control without the usage of complicated predictive control. A well-known and widely used FOC scheme is utilized, previously investigated in31. The proposed solution expands the possibility of controlling the mutual fluxes’ position into uneven load operation and decreases the impact of the change in mutual fluxes’ position on the angular speed, compared to the work31.

Proposed control scheme

The power circuit of a two level five-leg inverter supplied dual IMs is shown in Fig. 1. The semiconductors in the common leg should be selected for the current load two times higher than in the rest of inverter legs. Conventional control schemes for a five-leg VSI will not provide the control of current amplitude in the common leg at various operational conditions.

The proposed control scheme is shown in Fig. 3, where two FOC subsystems, the mutual flux position controller and the flux correction unit have been presented. The principal idea of the proposed control system is to shift the induction motors’ operational points to under-excitation or close to the over-excitation areas while working with different loads. The rotor flux position can be calculated from the estimated flux components for each motor. The position controller operates in d–q coordinates, directly affecting the q-axis current, while the d-axis current is adjusted by a correction of the reference flux value. This approach allows to minimize the speed difference of rotors during the flux position control activation by the excitation control. The excitation control is obtained by the correction in reference flux values calculated from the d-axis current. For dynamic-state operations, i.e. during a step change in the rotor speed, the excitation control is switched off, to maintain the same dynamics for both motors.

The flux correction unit is based on the induction machine mathematical model in d–q coordinates:

Applying d–q coordinates for flux components for field-oriented control (FOC):

After the (5) implementation, the (1)–(4) in steady-state mode are equal to:

The rotor flux component could be calculated from (8):

where:

Figure 4 shows the flux correction unit and provides a step by step description of how the flux correction and position control are realized. The initial step of the proposed algorithm is to choose the IM (indexed as I and II) that should be considered as the main motor during the control algorithm’s execution. This decision is taken based on the torque values of each motor—the motor with lower electromagnetic torque will be considered as the main motor, as shown in the flowchart, Fig. 4. The second step is to verify the operating conditions (steady- or dynamic-state). Following the difference in rotor speeds of IMs, the uniform speeds can be maintained. To achieve this, during the dynamic-state operation, no correction to the reference flux is introduced. In the steady-state operation, when the rotor speeds are similar, the algorithm provides the correction to the reference flux. This correction allows to maintain uniform speeds and follow the position of reference fluxes even for unequal loads. At this stage, the algorithm determines the flux correction using the following relation:

where \(Te^{II}\) and \(Te^{I}\) are the second and first motor torques, respectively.

Next, the correction algorithm verifies, whether a signal from the mutual flux position controller should be injected or not. If the calculated value is not equal to zero, the reference flux should be changed once again. The second correction is based on the output value of the mutual position controller, which is the last step of the correction algorithm. The value of the corrected reference flux should be obtained by (10) as follows:

where N is the motor number, and \(i_{inj}^*\) is a mutual flux position controller output signal.

As mentioned previously, in terms of the same dynamic characteristics of IMs during the working cycle, the proposed algorithm traces the difference in the IMs rotor speeds. If this difference exceeds the allowed area, the flux correction block is deactivated and the system uses the original flux reference values for both motors. At that case, the injected current components from the position controller \(i_{inj}^*\) and \(i_{inj}^{**}\) are calculated as:

Following the proposed control scheme and the flowchart shown in Fig. 4, the improved speed control of dual IMs powered by a single five-leg VSI can be obtained. The rotor flux position controller regulates the mutual position of IM fluxes and thanks to this the maximum modulation index can be improved or the common-leg current can be decreased.

Simulation and experimental results

Simulation studies

The simulation studies were conducted using the PLECS software package (version 4.7.6, https://www.plexim.com). During the studies, the control scheme’s effectiveness and machines’ performance under different load conditions were investigated and are shown further. The presented figures show: the mutual position of fluxes, inverter output currents, rotor angular speed, and the error of the rotor angular speed. Simulation results were obtained with step changes in: the angular speed, the load conditions, and the mutual flux position in order to analyze the control system’s behavior in steady- and dynamic-states.

Figure 5a shows the initial stage, when both motors have the same load and reference rotor speeds. At the time of 0.7 s, when the IMs operate in the steady-state, the position control system starts the regulation process and the mutual flux position value achieves the setpoint at the time of 0.95 s. Moreover, the current amplitude in the common phase decreases almost to zero, simultaneously with the change in the mutual flux position. During the mutual flux position regulation process, the speed difference of rotors does not exceed 0.4%. The load step change has been applied at the time of 1.8 s, when the loads for both machines were defined with the ratio of 4:3. The reference rotor speeds are changed at the moment of 2.8 s. Identifying the dynamic-state and the different load conditions, the control system turns-off the reference flux correction, keeping the same dynamics for both machines. Simultaneously, it tries to control the mutual flux position and decrease the speed difference of rotors. The rotor speed difference does not exceed 3.6%, and error in the mutual flux positions does not exceed 5°.

Rotor speed, common- and another-leg currents, mutual flux position and speed difference of rotors: (a) common-leg current minimization after mutual flux position controller introduction (cursor I), load change (cursor II) and the zero-speed crossing under different loads; (b) load equalization (cursor I) and the speed-change (cursor II) when both motors have the same loads.

Figure 5b shows step changes in the load and rotor speed values. At the time of 4.0 s, a step change in the load has been applied, with the same value for both machines. A step change in the speed has been applied at the moment of 5.0 s, when the reference rotor speed was changed from \(-\,0.3\) to 0.75. During the load change the speed difference of rotors does not exceed 0.4%, and the mutual flux position error is not exceed 2°. For the speed step change these value are: 1.3% and 3° respectively.

The common phase current amplitude depends not only on the mutual flux position, but on the load conditions as well. Figure 6a shows the dual drive system’s response when the load conditions for the machines were set with a ratio of 1:2. The reference mutual flux position is set to 177°. The common phase current amplitude increased due to the change in load conditions at the time of 6.5 s. The speed difference of rotors does not exceed 0.6%.

Figure 6b shows a change in the mutual flux position under the different load conditions, with the load ratio of 1:2. At the time of 7.4 s, the mutual flux position change from 177° to 150° has been applied. The rotor speed difference does not exceed 0.25%, while the amplitude of the common phase current increases, as expected from the relation shown in Fig. 2b.

Experimental studies

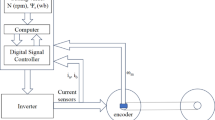

The experimental studies were carried out at the test setup consisting of two dual-IM drives and a five-phase, two-level VSI. One of the DMDS is the investigated system, while the other is used to generate the load torque. Both drive systems use identical three-phase motors and inverters. Table 1 shows the parameters of the experimental setup. The experimental setup is shown in Fig. 7. The VSI utilizes a digital signal processor (ADSP-21263) and an FPGA board (Altera Cyclone II EP2C8F256I8), programmed using the software development environments VisualDSP++ 5.0 (https://www.analog.com) and Quartus II 9.0 (https://www.intel.com), respectively.

The parameters for the FOC controllers used for both Machine I and Machine II are the same and are as follows (where kp is the proportional gain and ki is the integral gain): rotor speed controller: \(kp = 10\), \(ki = 0.003\), flux controller: \(kp = 1\), \(ki = 0.001\), \(i_{sd}\) and \(i_{sq}\) controllers: \(kp = 0.5\), \(ki = 0.001\). The mutual flux position controller was implemented with the following parameters: \(kp = 3.5\), \(ki = 0.0001\). The execution times on the ADSP-21263 processor were measured to be 23 µs for the traditional FOC with SVPWM, 26 µs for the proposed control scheme with SVPWM, and 95 µs for the MPC method proposed in30.

During the experimental investigation, the estimated rotor speeds \(\omega _r^{I},\omega _r^{II}\), torques \(Te^I,Te^{II}\), mutual flux position and common-phase current was registered and presented in Figs. 8, 9 and 10, each dedicated to a specific test. Figure 8a shows the response to a step change in the mutual flux position from 0° to 120°, and to 177°. The common-phase current amplitude has decreased as expected, so the proposed approach might be used to reduce the energy losses. To verify the system’s performance at various loads, the step change in the motor load was applied and the system’s response is shown in Fig. 8b.

The proposed control scheme keeps a desired mutual flux position and minimizes the common phase current regardless of the applied load. The results presented in Fig. 8 were obtained in a steady-state operation. The system’s dynamic response to a step change in the rotor speeds is shown in Fig. 9, where the proposed control system’s effectiveness in dynamic-mode was investigated. Figure 9a shows the response to a speed change from 0.3 to 0.4 and back to 0.3, for similar load torques applied to each motor. Figure 9b shows the same speed change, but for different loads, i.e. when the torques are not equal.

Additionally, the mutual flux position variations were investigated. The Fig. 10a and b show the system’s dynamic response to a step change in the mutual flux position from 177° to 120°, and back to 177°, for equal and different load torques, respectively.

Experimental tests for the rated motor parameters are shown in Figs. 11, 12 and 13, for step changes in: the mutual flux position, speed and load. The step change in the mutual flux position was carried out for the reference speed of 0.95 p.u. The speed change was performed for a mutual flux position of 0°. The results of experimental research presented in Fig. 11 were obtained for the operational point, when the torque generated by one of the motors was two times higher than in the other, i.e. \(Te^I=0.15\) and \(Te^{II}=0.3\). In Fig. 12, the response of the system to a step change in the load torque is shown. The proposed control system keeps the mutual flux position constant, however, this results in different speed values of both motors. Even in the extreme case, i.e for an 8 times higher load of one of motors Fig. 12b, the required mutual angle position (e.g. 100°) can still be obtained, while the speed difference is about 0.06 p.u. (for the reference speed values 0.9 p.u. for both motors). The impact of different load values was shown in Fig. 13a and b, where the torque of the first motor was estimated as \(Te^I=0.51\) and \(Te^{I}=0.67\), respectively. The estimated torque of the second motor was \(Te^{II}=0.11\) for both registrations. At 5 times the load difference, the speed difference was 0.03 p.u., while a seven times higher load results in 0.05 p.u. of speed difference. The mutual flux position remains fully controlled.

The influence of the mutual flux position on the modulation index during experimental tests was shown in Fig. 14. In Fig. 14 the reference modulation indexes’ (\(m_{ref}^I\), \(m_{ref}^{II}\)) waveforms are presented. These modulation indexes were determined using the standard equation for the modulation index: \(m=\frac{V_{generated}}{2V_{DC}}\). To calculate the reference modulation indexes the reference voltages (to be generated), determined by the two FOC control algorithms (one for each of the motors), were used. In Fig. 14 the obtained modulation indexes are shown (\(m_{out}^I\), \(m_{out}^{II}\)), depending on the mutual flux position. As shown in (Fig. 14a), the maximum available modulation index decreases with with an increase in the mutual flux position. Transition to the overmodulation region occurred for a mutual flux position close to 60° (Fig. 14a)—the obtainable modulation indexes differ from the reference ones. High frequency harmonics appear for the values of the mutual flux position greater than 60°, as a result of overmodulation. The mutual flux position of 150° allows both to increase the obtainable modulation indexes (Fig. 14c) and to reduce the current in the common-leg. In Fig. 14b and c slight differences in the maximum modulation index for 120° and 150° are visible. For 150° the minimal value of \(m_{out}\) is higher than for 120°, i.e. 0.6 for 150 (Fig. 14c) compared to 0.57 for 120° (Fig. 14b).

Reference (\(m_{ref}\)) and obtained (\(m_{out}\)) modulation indexes for both motors, mutual flux position (\(\Theta ^{dif}_{\psi }\)), and drive 1 angular speed (\(\omega _r\)). (a) the step change in mutual flux position from 0° to 120°; (b) the same variables shown for the mutual flux position 120°, (c) and 150°.

Obtained experimental results prove the effectiveness of the proposed control strategy. The systems performance at the working points featured in Table 2 is characterized by reduced energy losses (180°/− 180°), a higher modulation index (0°), or improvements over the conventional schemes in both aspects (150°/− 150°). The energy losses are sum of both—the conduction and switching losses in all inverter transistors. With a mutual flux position of 150°, the total energy losses are 22.5% lower than for conventional control schemes, thanks to a reduction of the current amplitude in the common phase. At this working point the common-phase current ratio is equal to 0.55 of the other phase current. A slight improvement in the modulation index is also available here, with the maximum modulation index being 3.5% higher than in conventional solutions.

Conclusion

The proposed control scheme offers an improvement in the total energy losses and available modulation index. The control scenario can be chosen according to the application requirements: the rotor flux position control might be used to achieve a better utilization of DC-link voltage, to get a lower values of common phase current, or a “trade-off” between both. The main purpose of this control scheme is to inject the output signal of the mutual flux position controller to the q-axis current control loop, when the dual-IMs work with same or nearly equal angular rotor speed. The proposed flux correction unit provides additional abilities in operating with same or different loads. The effectiveness of the proposed control method was proven using both simulation results and experimental studies. However, it can be noted that unequal load conditions introduce additional disturbances to the system; despite the proposed control scheme effectiveness, the proposed approach should be further investigated to improve the system’s performance under different load conditions.

Data availability

All data generated and analyzed during this study are available upon request. Researchers interested in accessing the data should contact the corresponding author.

References

Jones, M., Vukosavic, S., Dujic, D., Levi, E. & Wright, P. Five-leg inverter PWM technique for reduced switch count two-motor constant power applications. IET Electr. Power Appl. 2, 275–287. https://doi.org/10.1049/iet-epa:20070497 (2008).

Su, G.-J. & Hsu, J. A five-leg inverter for driving a traction motor and a compressor motor. IEEE Trans. Power Electron. 21, 687–692. https://doi.org/10.1109/TPEL.2006.872366 (2006).

Tang, L. & Su, G.-J. High-performance control of two three-phase permanent-magnet synchronous machines in an integrated drive for automotive applications. IEEE Trans. Power Electron. 23, 3047–3055. https://doi.org/10.1109/TPEL.2008.2005374 (2008).

Brando, G., Piegari, L. & Spina, I. Simplified optimum control method for monoinverter dual parallel PMSM drive. IEEE Trans. Ind. Electron. 65, 3763–3771. https://doi.org/10.1109/TIE.2017.2758751 (2018).

Geng, Q. et al. An improved PWM method of five-leg VSI fed dual-PMSM system with duty cycles regulation. IEEE/ASME Trans. Mechatron. 27, 5771–5779. https://doi.org/10.1109/TMECH.2022.3190690 (2022).

Lee, J.-H., Lee, J.-S. & Ryu, J.-H. Carrier-based discontinuous PWM method for five-leg inverter. IEEE Access 8, 100323–100336. https://doi.org/10.1109/ACCESS.2020.2998177 (2020).

Kezuka, N., Oka, K. & Matsuse, K. Characteristics of independent two induction motor drives fed by a four-leg inverter. In 2010 IEEE Energy Conversion Congress and Exposition, 2114–2120 (IEEE, 2010). https://doi.org/10.1109/ECCE.2010.5618259.

Odeh, I. C., Lewicki, A., Morawiec, M. & Ojo, J. O. A five-leg three-level dual-output inverter. IEEE Trans. Circuits Syst. II Express Briefs 70, 690–694. https://doi.org/10.1109/TCSII.2022.3211273 (2023).

Hamouda, M., Blanchette, H. F. & Al-Haddad, K. A hybrid modulation scheme for dual-output five-leg indirect matrix converter. IEEE Trans. Ind. Electron. 63, 7299–7309. https://doi.org/10.1109/TIE.2016.2594038 (2016).

Wang, R., Ai, L. & Liu, C. A novel three-phase dual-output neutral-point-clamped three-level inverter. IEEE Trans. Power Electron. 36, 7576–7586. https://doi.org/10.1109/TPEL.2020.3032124 (2021).

Haruna, J. & Hoshi, N. A novel three-level inverter which can drive two PMSMs. In IET Conference Publications, vol. 2014 (2014). https://doi.org/10.1049/cp.2014.0376.

Wang, R., Yuan, S., Liu, C., Guo, D. & Shao, X. A three-phase dual-output t-type three-level converter. IEEE Trans. Power Electron. 38, 1844–1859. https://doi.org/10.1109/TPEL.2022.3153073 (2023).

Dujic, D., Jones, M., Vukosavic, S. & Levi, E. A general PWM method for a (2n + 1)-leg inverter supplying n three-phase machines. IEEE Trans. Ind. Electron. 56, 4107–4118. https://doi.org/10.1109/TIE.2009.2014909 (2009).

Talib, M. H. N., Ibrahim, Z., Rahim, N. A. & Hasim, A. S. A. Implementation of space vector two-arm modulation for independent motor control drive fed by a five-leg inverter. J. Power Electron. 14, 115–124. https://doi.org/10.6113/JPE.2014.14.1.115 (2014).

Talib, M., Ibrahim, Z., Rahim, N. A. & Hasim, A. A. Analysis on speed characteristics of five leg inverter for different carrier based PWM scheme. In 2012 IEEE International Power Engineering and Optimization Conference, 96–101 (IEEE, 2012). https://doi.org/10.1109/PEOCO.2012.6230842.

Yeam, T.-I. & Lee, D.-C. Design of sliding-mode speed controller with active damping control for single-inverter dual-PMSM drive systems. IEEE Trans. Power Electron. 36, 5794–5801. https://doi.org/10.1109/TPEL.2020.3028601 (2021).

Ito, S., Moroi, T., Kubo, Y., Matsuse, K. & Rajashekara, K. Independent control of two permanent-magnet synchronous motors fed by a four-leg inverter. IEEE Trans. Ind. Appl. 51, 753–760. https://doi.org/10.1109/TIA.2014.2332637 (2015).

Oka, K. et al. Characteristic comparison between five-leg inverter and nine-switch inverter. In 2007 Power Conversion Conference—Nagoya, 279–283 (IEEE, 2007). https://doi.org/10.1109/PCCON.2007.372981.

Jones, M., Dujic, D., Levi, E., Bebic, M. & Jeftenic, B. A two-motor centre-driven winder drive fed by a five-leg voltage source inverter. In 2007 European Conference on Power Electronics and Applications, 1–10 (IEEE, 2007). https://doi.org/10.1109/EPE.2007.4417243.

Oka, K., Ohama, Y., Kubota, H., Miki, I. & Matsuse, K. Characteristic of independent two AC motor drives fed by a five-leg inverter. In 2009 IEEE Industry Applications Society Annual Meeting, 1–8 (IEEE, 2009). https://doi.org/10.1109/IAS.2009.5324838.

Oka, K., Nozawa, Y. & Matsuse, K. Improved method of voltage utility factor for PWM control method of five-leg inverter. In 2006 37th IEEE Power Electronics Specialists Conference, 1–5 (IEEE, 2006). https://doi.org/10.1109/pesc.2006.1711820.

Jing, G. & Zhou, C. Control strategy for a five-leg inverter supplying dual three-phase PMSM. IEEE Access 8, 174480–174488. https://doi.org/10.1109/ACCESS.2020.3025392 (2020).

Wang, W., Zhang, J., Cheng, M. & Cao, R. Direct torque control of five-leg dual-PMSM drive systems for fault-tolerant purposes. J. Power Electron. 17, 161–171. https://doi.org/10.6113/JPE.2017.17.1.161 (2017).

Yaakop, N. M., Ibrahim, Z., Sulaiman, M. & Talib, M. Speed performance of SVPWM direct torque control for five leg inverter served dual three-phase induction motor. In 2012 IEEE International Power Engineering and Optimization Conference, 323–328 (IEEE, 2012). https://doi.org/10.1109/PEOCO.2012.6230883.

Wang, W., Zhang, J. & Cheng, M. A dual-level hysteresis current control for one five-leg VSI to control two PMSMs. IEEE Trans. Power Electron. 32, 804–814. https://doi.org/10.1109/TPEL.2016.2535294 (2017).

Lim, C. S., Rahim, N. A., Hew, W. P. & Levi, E. Model predictive control of a two-motor drive with five-leg-inverter supply. IEEE Trans. Ind. Electron. 60, 54–65. https://doi.org/10.1109/TIE.2012.2186770 (2013).

Lim, C. S., Levi, E., Jones, M., Rahim, N. A. & Hew, W. P. FCS-MPC-based current control of a five-phase induction motor and its comparison with PI-PWM control. IEEE Trans. Ind. Electron. 61, 149–163. https://doi.org/10.1109/TIE.2013.2248334 (2014).

Choi, D., Lee, J.-S., Lim, Y.-S. & Lee, K.-B. Priority-based model predictive control method for driving dual induction motors fed by five-leg inverter. IEEE Trans. Power Electron. 38, 887–900. https://doi.org/10.1109/TPEL.2022.3203961 (2023).

Song, Y. et al. Minimization of capacitor voltage difference for four-leg inverter dual-parallel IM system. IEEE Trans. Power Electron. 37, 3969–3979. https://doi.org/10.1109/TPEL.2021.3121699 (2022).

Lim, Y.-S., Lee, J.-S. & Lee, K.-B. Advanced speed control for a five-leg inverter driving a dual-induction motor system. IEEE Trans. Ind. Electron. 66, 707–716. https://doi.org/10.1109/TIE.2018.2831172 (2019).

Kondratenko, D., Lewicki, A. & Łuksza, K. Augmented speed control scheme of dual induction motors with mutual flux angle control loop. Arch. Electr. Eng. 72, 915–930. https://doi.org/10.24425/aee.2023.147418 (2024).

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

D.K.: conceptualization, methodology, software, investigation, validation, writing–original draft preparation, funding acquisition; D.K., A.L. and K.Ł.: visualization, writing–review and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kondratenko, D., Lewicki, A. & Łuksza, K. Improved speed control of dual induction motor drive powered by a single five-leg VSI. Sci Rep 15, 31637 (2025). https://doi.org/10.1038/s41598-025-14132-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14132-7