Abstract

This study investigates the significant factors on weld quality in the resistance spot welding of quench and partitioning advanced high-strength steel. Attention is laid emphasis on nugget formation and growth, weldability range (lobe curve), nugget size and shape (macrostructural features), coating effects, mechanical properties, and fracture behavior of resistance spot welds. As zinc-coated steel sheets are widely applied in body-in-white in automotive industry, coating’s effect on weld quality is particularly significant. The research establishes correlations of nugget macrostructure, coating effects, and the following mechanical properties and fracture characteristics of the welds. Key conclusions recognize that Zn coating significantly alters the nugget formation mechanism by reducing the electrical contact resistance. Compared with uncoated samples, Zn-coated steels require a larger welding current for nugget formation because the major heat generation transforms from contact resistance to bulk resistance within the steel sheet. This reduction in contact resistance heating leads to larger nuggets for the same weld conditions. The uncoated samples show greater hardness of fusion zone and tensile-shear strength than coated samples, recording peak load-bearing capacities of 28 kN and 24 kN for medium heat input conditions, respectively. The critical welding current to transition into pullout failure mode was 9.5 kA for uncoated samples and 9.0 kA for coated samples. These findings highlight the complex interplay among coating presence, process conditions, and nugget shape attributes, all of which are crucial for predicting the mechanical performance and failure mode of resistance spot welds in Zn-coated QP980 steel.

Similar content being viewed by others

Introduction

The automotive industry faces challenges of fuel efficiency improvement and CO2 emission reduction while maintaining exceptional passenger safety. To address these demands and thus to make lightweight body-in-white (BIW), advanced high strength steels (AHSS) have been developed as a critical solution. Speer et al.1 pioneered a novel heat treatment process known as “Quenching and Partitioning (Q&P or QP)” leading to the development of QP steel as a third-generation AHSS. This innovative steel offers a remarkable combination of high strength and high ductility making it exceptionally well-suited for automotive BIW applications due to its superior energy absorption capacity during real crash events. Furthermore, QP steel boasts a significant cost-effectiveness compared to its competing second-generation AHSSs2.

Resistance spot welding (RSW) is the primary joining process for body-in-white (BIW) assemblies in the automotive industry. Its popularity is due to advantages such as high automation levels and rapid production rates. Despite the development of advanced welding methods such as friction stir welding, laser welding and electron beam welding, which enable the joining of both similar and dissimilar materials3,4, RSW continues to be the preferred choice for automakers. This preference is attributed to its aforementioned abilities to facilitate the cost-effective mass production of durable BIW structures while maintaining process efficiency and reliability. Building on the development of QP980 steel by Speer et al.1, subsequent research has focused on optimizing its resistance spot welding conditions to explore suitable resistance spot welding approaches and conditions for this newly developed steel. Researchers, including Fan et al.5,6,7 and Nadimi et al.8 have focused on the relationship between the microstructure and mechanical properties of QP980 RSW joints. Additionally, Ding et al.9 and Wang et al.10 have investigated the fatigue behavior of QP980 resistance spot welds, analyzing their relationship with weld microstructure. Furthermore, Liu et al. 11 have delved into the mechanical properties of welds joined using a double-pulse RSW technique. This research revealed that the second pulse (heat) does not significantly affect the fusion zone microstructure while its main influence was on the weld nugget size.

While investigating the relationship between microstructure evolution and the mechanical properties of resistance spot welds is crucial, it is equally important to study nugget formation and growth, as well as the factors influencing nugget size. Nugget size is the primary parameter controlling the mechanical performance of the weld and significantly influences RSW failure mode12. Additionally, it helps determine the weldable current range of the steel (welding lobe). Theoretical and experimental models13,14 confirm a direct correlation between heat input and nugget size. Joule’s Law dictates that heat input increases with both current and welding time15,16. Both bulk and contact resistances play key roles in heat generation. Kim et al.17 investigated the nugget growth in multi-pulse welding of CP1180 steel, revealing the effect of each pulse. They reported that the first pulse improves sheet contact area, the second creates a wide and strong corona bond, and the third one forms a sufficiently large nugget. This multi-pulse technique is claimed to improve nugget size and mechanical performance; it also delays the expulsion to occur at higher welding currents due to the corona bond enlargement during the second pulse17. The use of a pre/post-heating step is also common in other welding techniques as it can modify the final microstructure of the weld and can directly affect the mechanical properties4. Pouranvari et al.18 highlighted that welding current and duration influence nugget size, but this effect reaches a saturation limit. They further explored the relationship between the critical nugget size needed for failure mode transition in terms of the sheet thickness and the hardness ratio of failure location to the weld nugget. Additionally, they claimed that excessive electrode pressure could reduce the nugget size. Resistance spot welding of coated sheets (Zn or Al–Si coating) for BIW applications presents challenges due to the coating’s impact on contact resistance at both the sheet-to-sheet and sheet-to-electrode interfaces. This variation in electrical contact resistance (ECR) affects the weld nugget formation and growth because ECR governs heat generation in RSW. Geslain et al.19 compared the effects of Al–Si and Zn coatings on nugget growth in three sheets resistance spot welding process. They found that Al–Si coating promotes non-uniform heat distribution due to its higher ECR while Zn coating with lower ECR facilitates initial heating and nugget formation at sheet-to-sheet interface. Similar observations were reported by Ji et al.20 for hot-stamped boron steel. Zn vaporization between the Zn-coated sheets increases the vapor pressure of zinc at the faying surface, potentially leading to expulsion. Additionally, thicker Zn coatings elevate ECR resulting in rapid nugget formation making the control of the nugget size challenging. Ighodaro et al.21 confirmed the higher ECR of Al–Si coating compared to Zn coating in hot-stamped steels. Consequently, Zn-coated sheets require lower welding currents to achieve a suitable nugget size. However, Zn-coated sheets are more prone to interfacial failure at low currents, while Al–Si-coated welds tend to fail in pullout failure mode. Notably, no significant difference was observed in the energy absorption to failure between the joints with different coating types. Harlin et al.22 investigated the effect of Zn coating on a triple low-carbon steel sheet assembly. They attributed the extended initial heating observed in Zn-coated sheets to the lower electrical resistivity of Zn. A higher welding current for Zn-coated sheets is essential compared to uncoated sheets to achieve similar nugget sizes at low welding current conditions. Sevim et al.23 compared the microstructure and mechanical properties of RSW joints in both galvanized and uncoated DP450 and DP600 steels. They reported no significant influence of the coating on microstructure but observed lower hardness in galvanized steel joints. Additionally, the coating did not significantly affect the tensile-shear strength (TSS) of the welds. Similarly, Emre and Kaçar24 found that Zn coating in galvanized TRIP800 steel reduced the nugget size compared to uncoated TRIP800 without affecting the weld microstructure. Weber and Goklu25 observed that increasing the welding time extends the weldable current range (WCR) for both coated and uncoated AHSSs. However, for coated sheets, optimizing the welding time and electrode force is crucial to achieve a wider WCR.

Although numerous studies have examined the resistance spot welding (RSW) behavior of QP980 steel, the specific influence of zinc coatings on weld nugget growth mechanisms remains unexplored. A comprehensive understanding of zinc’s role in nugget initiation and development is critical for optimizing weld performance in body-in-white (BIW) automotive applications. This study addresses this gap by providing a detailed mechanistic analysis of nugget formation during RSW of zinc-coated QP980 steel. Unlike prior research, which primarily focused on macroscopic mechanical properties or microstructure-property relationships, our work investigates the underlying thermal and metallurgical processes driving nugget growth. By correlating coating characteristics, process parameters, and geometric evolution of the nugget, we offer new insights into heat generation dynamics and failure mode control—advancing the fundamental understanding of third-generation advanced high-strength steel (AHSS) weld behavior.

Experimental procedure

Material

In this research, bare and Zn-coated (hot dip galvanized; GI) QP980 steel sheets of 2 mm thickness were supplied by Saipa automotive company as the experimental materials. The chemical composition and mechanical properties of the alloy are reported in Table 1. The chemistry of the steels was characterized by spark emission spectroscopy (SES) method following ASTM E415-17 standard. The coated QP980 steel had a coating thickness of 5.94 µm as shown in Fig. 1a. The energy dispersive spectroscopy (EDS) results of the coating layer are represented in Fig. 1b, meanwhile, scanning electron microscopy (SEM) micrograph from the faying surface of the uncoated QP980 steel (Fig. 1c) confirms the absence of the Zn coating. The microstructure of the as-received steel sheets is characterized using optical microscopy (OM) and SEM.

Welding procedure

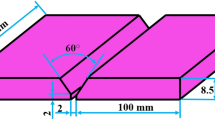

Resistance spot welding of the alloy was performed using an AC pedestal RSW machine. Class 2 RWMA truncated cone electrodes with a face diameter of 8 mm were utilized for the welding process. Welding parameters were established according to the ISO 18,278–2 standard26 implementing a four-pulse welding schedule on the alloys. The specific welding parameters are presented in Table 2, while the schematic of the welding schedule is depicted in Fig. 2. Squared coupons of 25 mm × 25 mm dimensions were provided from steel sheets for metallography and microhardness evaluation. Rectangular coupons of 25 mm × 100 mm dimensions were provided for tensile-shear test.

Microstructural and macrostructural observations

Cross-sections of the welded samples were prepared following conventional metallographic techniques for subsequent observations. LePera’s color etching27 was employed to help phase identification in the as-received alloy microstructure, which was then examined using Zeiss Axio Imager. Z2m optical microscopy (OM) and Philips XL30 scanning electron microscopy (SEM). Nital etchant was used to prepare the welded samples for macrostructural and weld geometric analyses.

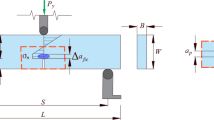

Mechanical tests and failure mode analysis

Vickers microhardness test was performed using a load of 200 g and a dwell time of 15 s. The distance between two consecutive indentations was 200 µm. The path of the hardness indents is schematically illustrated in Fig. 3a. To investigate the strength of RSW joints, the tensile-shear test (TST) was employed. The maximum load and displacement for each sample were derived from the corresponding load–displacement curves. Additionally, the failure modes of the joints were observed and recorded after TST. A schematic of TST sample is shown in Fig. 3b.

Results and discussion

Base metal microstructure

Figure 4 presents OM micrographs of color-etched as-received alloys. Figure 4a, b corresponds to the uncoated QP980 steel sheet, while Fig. 4c, d depicts the coated QP980 steel. The microstructure of both steel sheets consists of a ferritic matrix, martensite, and blocks of retained austenite. Figure 5 shows SEM images of the same materials: (a–b) the uncoated sample and (c–d) the coated sample. During the quench and partitioning (Q&P) process, two types of martensite are produced: tempered martensite (TM), which forms after the first quench and partitioning steps, and fresh martensite, which forms after the final quench step. Both martensite types are visible in the SEM micrographs of Fig. 58.

Weld nugget microstructure

A general view of weld-zones for coated and uncoated QP980 RSWs is shown in Fig. 6a, b receptively, which provide a wide field view of weld-zones and their microstructure. As observed, there is no significant difference in the microstructure of the fusion zones and both samples present a cast structure of mainly columnar martensite. A similar observation can be made regarding the heat-affected zones of both coated and uncoated samples, where martensite is the predominant microstructure and phase. This indicates that the coating does not significantly influence the microstructure of the weld zone.

Macrostructure and nugget formation

Figure 7 presents cross-sectional micrographs of the nugget for corresponding welding currents in both coated and uncoated QP980 steel sheets. At 5.5 kA, no bonding occurred in the coated sample, and in the uncoated sample, the generated heat only resulted in the formation of a heat-affected zone (HAZ) with evidence of solid-state transformations as no molten material was observed. At 6.0 kA, the coated sample again fails to form a nugget, whereas the uncoated sample forms a small nugget at the faying surface. This delay in nugget formation for coated samples is attributed to their lower electrical resistivity and higher thermal conductivity at the faying surfaces due to zinc presence.

For welding currents of 6.5 kA and above, the coated samples exhibit a rapid increase in nugget size and width, indicating a change in the formation mechanism. Beyond this threshold, the coated samples consistently produce larger nuggets than the uncoated samples. This can be explained by the combined effect of lower electrical contact resistance (ECR) in coated samples and the inherent increase in electrical resistance of QP980 steel with temperature rising. The lower ECR allows higher bulk resistance within the sheets to contribute to heat generation and the temperature-dependent resistance of the steel promotes nugget growth in the bulk. This shift in heat generation leads to the formation of larger nuggets in coated samples at higher welding currents. In other words, during heat generation in the coated steel sheets, nugget formation initiates at the steel bulk while in uncoated steels, nugget first forms at the faying surfaces of the sheets. This difference in the nugget formation mechanisms is schematically shown in Fig. 8. Additionally, Fig. 9 presents high-speed camera cinematography captured during RSW of a coated AHSS steel sheet10,15,18,26,27. The observations in Fig. 9 support the schematic representation of the nugget formation mechanism depicted in Fig. 8. It is evident that nugget formation initiates at the bulk of the steel sheets, with the bulk resistance of coated AHSS steel serving as the primary source of heat generation, in contrast to the low resistivity of the Zn-coating on the faying surface. However, in some coatings such as Al–Si coatings high electrical resistance of coating leads to the initiation of nugget growth from the faying surface of sheets28.

Figure 10 presents graphs illustrating the variations of the key geometrical attributes of the welds with changes in welding current indicating the effects of heat generation and the coating presence. The discussion on nugget size variation (Fig. 10a) has been mentioned previously. However, it is noteworthy to mention that both coated and uncoated samples exhibit an “r-curved” behavior in this graph (nugget growth behavior) indicating a saturation limit. This saturation indicates a balance between heat generation (from contact and bulk resistance) and cooling (via the material and water-cooled electrodes). Figure 10b shows nugget width versus welding current. For coated samples, nugget appears at low current (due to the zinc-induced heating delay). However, once formed, the nugget width in coated samples remains relatively constant with increasing the welding current. Conversely, the uncoated samples display a significantly different pattern. In contrast to the rapid increase seen in coated samples, the nugget width in uncoated samples demonstrates a slower and more linear relationship with welding current. This difference can be attributed to the varying mechanisms of nugget growth. In coated samples, the bulk resistance of the sheets plays a crucial role in heat generation. Consequently, a sharp increase in nugget width (rapid growth of the nugget toward the thickness of sheets) is observed due to this efficient heat source. The main heat source for the uncoated samples is the contact resistance at the faying surface, followed by the temperature-dependent resistivity. This means that heat must propagate from a single source to both sheets, necessitating more time and heat input compared to the coated samples, where nugget formation begins from both bulk and the faying surface due to a dual-source mechanism (see Fig. 8).

(a) weld nugget variation with welding current, (b) weld nugget width variation with welding current, (c) corona bond width variation with welding current, and (d) electrode indentation depth variation with welding current for coated and uncoated QP980 steel sheets and (e) a schematic of geometrical attributes of the weld nugget.

The presence of a zinc coating on steel narrows the weld lobe compared to resistance spot welding of uncoated steel. This is attributed to the shift in the heat source from contact resistance to bulk resistance, significantly influencing the minimum welding current required for nugget formation. It can be said that the lower strength of zinc compared to AHSS makes it flow more easily under electrode force, reducing the gaps between faying surfaces caused by surface roughness. These gaps significantly increase contact resistance. Additionally, zinc’s lower resistivity (compared to AHSS) further affects the efficiency of this heat source, in contrast to the bulk resistivity. The eventual constant state reached by both coated and uncoated sample types reflects the balance achieved between heat generation and cooling and the mentioned saturation limit. Significantly, both coated and uncoated samples exhibit a slight decrease in nugget width at higher currents. This can be attributed to expulsion phenomenon and increased electrode indentation at higher welding current values.

Figure 10c depicts the variation of corona bond width with changing the welding current. The coated samples demonstrate a consistent trend in corona bond width, while the uncoated samples do not exhibit a clear pattern. This unstable trend of variation in the corona bond size for the uncoated sample in comparison to the coated sample may refer to the difference in nugget formation and growth mechanisms. The heat generation source for the uncoated sample is the contact resistance of the faying surface, which is highly sensitive and depends on numerous factors. In contrast, the heat generation source for the coated sample is the bulk resistance of the steel sheet which exhibits a predictable and consistent increase with temperature. The presence of a corona bond acts as a barrier against molten metal expulsion, potentially expanding the weldable current range (WCR) for the alloy due to the delayed occurrence of expulsion.

Figure 10d illustrates the relationship between electrode indentation depth and welding current. A clear direct correlation is evident, with higher currents and increased heat inputs resulting in a greater volume of molten metal and an expanded heat-affected zone (HAZ). However, increased electrode indentation can negatively impact weld quality in terms of load bearing capacity and energy absorption capability. Notably, coated samples demonstrate greater indentation depths at higher welding currents compared to uncoated samples. This phenomenon can be attributed to the enhanced thermal conductivity of the coated samples, which facilitates a larger HAZ and softens the material. Additionally, the slightly larger nugget size in coated samples makes them more susceptible to indentation. Figure 10e provides a schematic representation of how each geometrical attribute is measured.

Vickers microhardness

Figure 11 shows the microhardness profiles from the base metal to the weld center for the 8 kA welds. Hardness rises from the base metal into the heat-affected zone (HAZ) due to martensite formation during the rapid RSW thermal cycle. In the fusion zone (FZ), the hardness reaches a high, nearly constant value as the microstructure becomes fully lath martensite upon rapid cooling8,11. The coated sample’s FZ hardness is lower than that of the uncoated sample. A similar trend has been reported for coated TRIP800 steel welds24. This hardness difference may arise partly from the coating’s high thermal conductivity, which spreads the heat and refines the microstructure. Another factor is that the uncoated steel has a higher carbon content (0.216% vs. 0.183%), and carbon is a key element controlling steel hardness and hardenability. Together, these effects explain why the uncoated weld has a harder FZ.

Tensile-shear test and failure mode analysis

Tensile-shear loading represents a practical testing method that simulates the second mode of crack propagation which is a common failure mechanism in resistance spot welds.

A standardized sample geometry, as previously shown in Fig. 3b is employed for tensile-shear tests (TST). Following the TST procedure, the resulting load-displacement curve of the RSW joint presents valuable information about its behavior under real crash stress. Key parameters like peak load (Pmax), maximum displacement (Lmax), and absorbed energy can then be extracted from this curve and used to assess the joint’s strength and ductility. These parameters are schematically shown in Fig. 12a on a typical load-displacement curve. Figure 12b presents the load-displacement curves for coated and uncoated samples welded at a welding current of 8 kA.

The curve for the uncoated sample exhibits superior performance compared to the coated sample, as evidenced by a higher peak load (Pmax) as reported in Table 3. A higher Pmax directly translates to greater tensile-shear strength (TSS) indicating the uncoated sample’s ability to withstand a larger shear force before failure. The coated sample exhibits a slightly higher Lmax value in Table 3. Lmax represents the maximum displacement that the joint experiences before failure. While a higher Lmax might suggest a degree of improved ductility in the coated sample; it is crucial to consider this in conjunction with the lower Pmax. The larger area under the curve for the uncoated sample in Fig. 12 signifies it can absorb more energy before failure. This superior energy absorption capability is a crucial factor for RSW joints, as it reflects their capacity to withstand impact and dynamic loading conditions. The observed differences in mechanical performance between the coated and uncoated samples can be attributed to the variations in microhardness profiles as shown in Fig. 11. The harder fusion zone (FZ) of the uncoated sample likely contributes to its higher TSS, while the higher heat conductivity of the coated steel, as discussed previously, may influence the formation of a finer microstructure in its FZ, potentially leading to a slight increase in ductility.

Typically, the coating on steel does not significantly influence the microstructural evolution during welding, and both specimens exhibit a martensitic phase in the fusion zone (FZ). However, the change in the heat source in presence of a zinc coating may impact the grain structure in the FZ, warranting further experiments and observations, particularly through Electron Backscatter Diffraction (EBSD) analysis. The superior tensile-shear properties of the uncoated steel can be attributed to its higher FZ hardness. Previous studies8,29,30,31 have demonstrated that the interfacial failure load in AHSS steel is primarily governed by FZ hardness rather than FZ fracture toughness; therefore, higher hardness in the FZ is advantageous for tensile shear properties. The increased FZ hardness in the uncoated steel is linked to its higher carbon content in the base material.

Post-fracture analysis of resistance spot welds after TST reveals two primary failure modes: pullout failure (PF) and interfacial failure (IF) modes (see Table 4). The factors governing weld failure mode and post-test behavior can be categorized into four main attributes12,15,29,30,31,32: geometric factors (fusion zone size, sheet thickness, electrode indentation depth), loading conditions, material properties (chemical composition, microstructure, mechanical properties), and the presence of defects, discontinuities, heterogeneities, and stress concentrations. Figure 13 visually depicts the two dominant failure modes observed in RSW joints after tensile-shear testing as follows:

-

Pullout failure (PF) Figure 13a this failure mode is characterized by fracture occurring outside the weld nugget. Crack initiation can potentially occur in the base metal BM, FZ, HAZ, or FZ/HAZ boundary. Base metal properties, the presence of discontinuities, and the specific loading conditions applied during testing significantly influence the crack initiation location.

-

Interfacial failure (IF) Figure 13b in this mode, the crack propagates through the nugget material. Resistance spot welds exhibiting IF mode are considered undesirable due to their lower energy absorption capacity compared to PF mode welds in a real crash event. The superior energy absorption observed in PF welds is attributed to the longer crack propagation path and area through the material surrounding the nugget33,34.

Nugget diameter is established as the most critical geometric factor influencing RSW joint mechanical performance. It is primarily controlled by heat input parameters such as welding current and welding time16. A well-defined direct relationship exists between nugget diameter and welding current. Increasing the welding current leads to the formation of a larger nugget due to more heat generation. However, at high enough heat inputs (high enough welding currents), this dependence weakens as heat balance is achieved. There is a critical nugget diameter for transition in failure mode from IF to PF. Observations from Fig. 10a suggest that the critical nugget size for this transition was achieved at a welding current of 9.5 kA for the uncoated sample and 9 kA for the coated sample. This difference is likely due to a shift in the growth mechanism—from contact resistance to bulk resistance—as the primary heat source. Consequently, uncoated samples reach the critical size for failure mode transition at lower welding currents. This factor should be carefully considered when determining appropriate welding currents for steel based on coating conditions, ensuring optimal settings to prevent excessively high welding currents and expulsion. Also, electrode indentation depth can increase the chance of poll-out failure mode based on the literature31; the electrode indentation depth of the coated samples welded above welding current of 9 kA was higher than that of uncoated samples, hence based on that they tend to fail in PF mode.

The higher welding current requirement for the uncoated sample can be attributed to the fact that the coated samples exhibit larger nuggets at the same welding currents, reaching the critical diameter for failure transition at lower currents. It can also be attributed to higher ductility and Lmax in in the coated samples. Utilizing higher welding currents can also guarantee PF mode, although expulsion phenomena might occur during welding. The conventional criterion for failure mode transition (Dc = 4 √to5, where Dc is the critical nugget diameter and t is sheet thickness) proposed by ANSI/AWS/SAE35 has been demonstrated to be inaccurate in predicting the actual Dc value for several materials8,15,34,36. Similarly, the Dc formula proposed by JIS37 predicts a critical nugget size within the PF range, but it is significantly higher than the actual value and is accompanied by expulsion. The lack of validity in these criteria highlights shortcomings in current failure mode analysis approaches. These formulas solely consider geometric factors, neglecting the crucial role of material properties. In essence, the failure mode results from a competition between the shear plastic strain in the FZ, leading to IF, and stress localization outside the FZ, leading to PF. This stress localization can manifest as necking due to increased strain concentration in lower-strength areas, crack initiation from discontinuities like notches, or a combination of both8,36. Ultimately, failure occurs in the path of the least resistance against deformation which needs less energy for crack propagation. Technically, “resistance” refers to the material’s hardness, defined as its resistance to deformation, and specifically for metals, it is the resistance to plastic deformation38. Therefore, the hardness ratio between the FZ and the location with the lowest hardness where PF would occur (pullout failure location (PFL)) is important for the failure behavior. A higher ratio promotes failure outside the FZ (PF). Pouranvari and Marashi investigated this effect and proposed a more comprehensive criterion incorporating both geometric and material factors33.

Building upon the discussion presented, gaining a mossre comprehensive understanding of nugget formation and growth mechanisms39 is crucial for optimizing the selection of process parameters and enhancing overall process design. Such insights enable the development of more robust and efficient welding strategies tailored to specific material properties and application requirements. For further analysis, it is imperative to conduct detailed investigations into the fracture mechanisms and fractography of the welds. This includes characterizing the fracture surface morphology, identifying dominant failure modes, and understanding the influence of microstructural features and welding parameters on fracture behavior. Such studies would provide valuable information on the mechanical performance and reliability of welds, ultimately contributing to the advancement of resistance spot welding practices in demanding engineering applications.

Conclusions

The following conclusions can be derived from the current research after studying the factors affecting the weld quality in resistance spot welding of advanced high strength steels:

-

1.

The presence of Zn-coating postponed nugget formation in coated steel caused a transition in the nugget formation mechanism and made the bulk resistance of the steel sheet as the primary heat-generating source.

-

2.

The main heat generation source in zinc coated steel is bulk resistance while in uncoated steel is the contact resistance of faying surfaces. This change in the nugget formation and growth mechanism leads to smaller nuggets for coated steel at lower welding currents and larger ones for uncoated at higher welding currents.

-

3.

Due to the fact that the bulk resistance is the governing mechanism in coated steel, the coated sample had a normal corona bond trend while the uncoated sample showed an unstable trend.

-

4.

The welds of uncoated steel sheets exhibited higher fusion zone hardness than the coated ones. The uncoated sample had higher tensile-shear strength and energy absorption capacity than the coated sample.

-

5.

The coated samples had a lower critical welding current for failure mode transition from IF to PF than the coated sample.

-

6.

The factors governing the weld mechanical behavior and failure mode can be categorized into four main attributes: geometric factors (fusion zone size, sheet thickness, electrode indentation depth), loading conditions, material properties (chemical composition, microstructure, mechanical properties), and the presence of defects, discontinuities, heterogeneities, and stress concentrations.

Data availability

All data generated or analysed during this study are included in this published article.

References

Speer, J., Matlock, D. K., De Cooman, B. C. & Schroth, J. G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 51, 2611–2622. https://doi.org/10.1016/S1359-6454(03)00059-4 (2003).

Wang, L. & Speer, J. G. Quenching and partitioning steel heat treatment. Metallogr. Microstruct. Anal. 2, 268–281. https://doi.org/10.1007/s13632-013-0082-8 (2013).

Raj, S. & Biswas, P. Experimental investigation of the effect of induction preheating on the microstructure evolution and corrosion behavior of dissimilar FSW (IN718 and SS316L) joints. J. Manuf. Process 95, 143–159. https://doi.org/10.1016/j.jmapro.2023.04.021 (2023).

Raj, S. & Biswas, P. Mechanical and microstructural characterizations of friction stir welded dissimilar butt joints of Inconel 718 and AISI 204Cu austenitic stainless steel. Mater. Charact. 185, 111763. https://doi.org/10.1016/j.matchar.2022.111763 (2022).

Fan, C.-L., Ma, B.-H., Chen, D.-N., Wang, H.-R. & Ma, D.-F. Spall strength of resistance spot weld for QP steel. Chin. Phys. Lett. 33, 036201. https://doi.org/10.1088/0256-307X/33/3/036201 (2016).

Fan, C. et al. Uniaxial compression properties of fusion zone martensite in resistance spot-weld for QP980 steel. Weld. World 63, 161–166. https://doi.org/10.1007/s40194-018-0646-y (2019).

Fan, C., Wang, H. & Ma, D. Dynamic compression properties of the resistance spot welding of high strength steels under varying temperature conditions. Adv. Mater. Sci. Eng. 2021, 1–9. https://doi.org/10.1155/2021/9953319 (2021).

Nadimi, N., Yadegari, R. & Pouranvari, M. Resistance spot welding of quenching and partitioning (Q&P) third-generation advanced high-strength steel: Process microstructure performance. Metall. Mater. Trans. A. 54, 577–589. https://doi.org/10.1007/s11661-022-06903-y (2023).

Ding, Z., Bing, Y., Qin, X. G., Duan, J. C., Huang, W. C., Mao, Z. & Liang, Q. Study on high-cycle shear fatigue behavior of two kinds of spot-welded 980 Mpa ultra-high-strength steels. In S. of A. Engineers (Ed.), Proceedings of the 19th Asia Pacific Automotive Engineering Conference & SAE-China Congress 2017: Selected Papers 1035–1044 (Springer Singapore, 2019). https://doi.org/10.1007/978-981-10-8506-2_69.

Wang, B. et al. Investigation on fatigue fracture behaviors of spot welded Q&P 980 steel. Int. J. Fatigue 66, 20–28. https://doi.org/10.1016/j.ijfatigue.2014.03.004 (2014).

Liu, X. D. et al. Mechanical properties in double pulse resistance spot welding of Q&P 980 steel. J. Mater. Process Technol. 263, 186–197. https://doi.org/10.1016/j.jmatprotec.2018.08.018 (2019).

Ashiri, R., Marashi, S. P. H. & Park, Y. D. Weld processing and mechanical responses of 1-GPa TRIP steel resistance spot welds. Weld. J. 97, 157–169. https://doi.org/10.29391/2018.97.014 (2018).

Zhou, K. & Cai, L. Online nugget diameter control system for resistance spot welding. Int. J. Adv. Manuf. Technol. 68, 2571–2588. https://doi.org/10.1007/s00170-013-4886-0 (2013).

Williams, N. T. & Parker, J. D. Review of resistance spot welding of steel sheets part 1 modelling and control of weld nugget formation. Int. Mater. Rev. 49, 45–75. https://doi.org/10.1179/095066004225010523 (2004).

Salimi Beni, S., Atapour, M., Salmani, M. R. & Ashiri, R. Resistance spot welding metallurgy of thin sheets of zinc-coated interstitial-free steel. Metall. Mater. Trans. A 50, 2218–2234. https://doi.org/10.1007/s11661-019-05146-8 (2019).

Pouranvari, M. & Marashi, S. P. H. Critical review of automotive steels spot welding: process, structure and properties. Sci. Technol. Weld. Join. 18, 361–403. https://doi.org/10.1179/1362171813Y.0000000120 (2013).

Kim, J. W., Murugan, S. P., Yoo, J.-H., Ashiri, R. & Park, Y.-D. Enhancing nugget size and weldable current range of ultra-high-strength steel using multi-pulse resistance spot welding. Sci. Technol. Weld. Join. 25, 235–242. https://doi.org/10.1080/13621718.2019.1680483 (2020).

Pouranvari, M., Asgari, H. R., Mosavizadch, S. M., Marashi, P. H. & Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 12, 217–225. https://doi.org/10.1179/174329307X164409 (2007).

Geslain, E., Rogeon, P., Pierre, T., Pouvreau, C. & Cretteur, L. Coating effects on contact conditions in resistance spot weldability. J. Mater. Process Technol. 253, 160–167. https://doi.org/10.1016/j.jmatprotec.2017.11.009 (2018).

Ji, C.-W. et al. Effects of surface coating on weld growth of resistance spot-welded hot-stamped boron steels. J. Mech. Sci. Technol. 28, 4761–4769. https://doi.org/10.1007/s12206-014-1043-0 (2014).

Ighodaro, O. L., Biro, E. & Zhou, Y. N. Comparative effects of Al–Si and galvannealed coatings on the properties of resistance spot welded hot stamping steel joints. J. Mater. Process Technol. 236, 64–72. https://doi.org/10.1016/j.jmatprotec.2016.03.021 (2016).

Harlin, N., Jones, T. B. & Parker, J. D. Weld growth mechanism of resistance spot welds in zinc coated steel. J. Mater. Process Technol. 143–144, 448–453. https://doi.org/10.1016/S0924-0136(03)00447-3 (2003).

Sevim, I., Hayat, F. & Kulekci, M. K. Nucleus geometry and mechanical properties of resistance spot welded coated–uncoated DP automotive steels. Bull. Mater. Sci. 36, 1049–1055. https://doi.org/10.1007/s12034-013-0559-8 (2013).

Ertek Emre, H. & Kaçar, R. Resistance spot weldability of galvanize coated and uncoated TRIP steels. Metals 6, 299. https://doi.org/10.3390/met6120299 (2016).

Weber, G. & Göklü, S. resistance spot welding of uncoated and zinc coated advanced high-strength steels (AHSS)—Weldability and process reliability-influence of welding parameters. Weld. World 50, 3–12. https://doi.org/10.1007/BF03263428 (2006).

ISO standard. ISO 18278-2:2016; Resistance welding Weldability Part 2: Evaluation procedures for weldability in spot welding (2016).

LePera, F. S. Improved etching technique to emphasize martensite and bainite in high-strength dual-phase steel. JOM J. Miner. Met. Mater. Soc. 32, 38–39 (1980).

Saha, D. C., Ji, C. W. & Park, Y. D. Coating behavior and nugget formation during resistance welding of hot forming steels. Sci. Technol. Weld. Join. 20, 708–720. https://doi.org/10.1179/1362171815Y.0000000054 (2015).

Ashiri, R., Mostaan, H. & Park, Y.-D. A phenomenological study of weld discontinuities and defects in resistance spot welding of advanced high strength TRIP steel. Metall. Mater. Trans. A. 49, 6161–6172. https://doi.org/10.1007/s11661-018-4900-0 (2018).

Adkine, A. S. & Biradar, S. K. A review of the effects of resistance spot welding on metallurgical and mechanical characteristics. Weld. Int. 39, 52–65. https://doi.org/10.1080/09507116.2024.2419551 (2024).

Nadimi, N. & Pouranvari, M. Understanding interfacial failure mechanisms of advanced high strength automotive steels resistance spot welds under opening-mode loading. Eng. Fract. Mech. 313, 110627. https://doi.org/10.1016/j.engfracmech.2024.110627 (2025).

Vijayan, V., Ji, Ch. & Park, Y.-D. An investigation into the measurement and evaluation of volumetric voids in advanced high strength steel resistance spot welds. J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-024-10241-y (2024).

Pouranvari, M. & Marashi, S. P. H. Failure mode transition in AHSS resistance spot welds. Part I. Controlling factors. Mater. Sci. Eng. A 528, 8337–8343. https://doi.org/10.1016/j.msea.2011.08.017 (2011).

Sun, X., Stephens, E. V. & Khaleel, M. A. Effects of fusion zone size and failure mode on peak load and energy absorption of advanced high strength steel spot welds under lap shear loading conditions. Eng. Fail Anal. 15, 356–367. https://doi.org/10.1016/j.engfailanal.2007.01.018 (2008).

American welding society. ANSI/AWS/SAE D8.9M:2002 standard (2002).

Tamizi, M., Pouranvari, M. & Movahedi, M. Welding metallurgy of martensitic advanced high strength steels during resistance spot welding. Sci. Technol. Weld. Join. 22, 327–335. https://doi.org/10.1080/13621718.2016.1240979 (2017).

JWES, JIS Z 3140: Method of inspection and acceptance levels for resistance spot welds, (2017).

Dieter, G. E., Bacon, D. & Bacon, D. J. Mechanical Metallurgy (McGraw-Hill, 1988).

Ebrahimpour, A., Mostafapour, A. & Haghi, N. 3D coupled thermal-electrical-structural finite element investigation on the effect of welding parameters on the geometry of nugget zone and HAZ in RSWed TRIP steel joints. Iran. J. Mater. Sci. Eng. 20, 1–18. https://doi.org/10.22068/ijmse.2916 (2023).

Author information

Authors and Affiliations

Contributions

V.F., A.B. and N.N. did the investigation,A. B. write the first draft, M.R.S. provide the alloy Y.-D. P. and M. P. help in revision process of the draft and R.A. designed the work, managed and supervised it and upgraded the draft and revisions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Feizollahi, V., Bahmani, A., Nadimi, N. et al. Factors affecting weld quality in resistance spot welding of advanced high strength steels. Sci Rep 15, 30012 (2025). https://doi.org/10.1038/s41598-025-14174-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14174-x