Abstract

The muzzle brake with compensator is a device mounted on the barrel muzzle to reduce recoil force during gun barrel discharge, experiencing a complex thermo-mechanical condition during its working cycle. Numerical simulation of the brake’s working environment was conducted in a 3D numerical domain using ANSYS Fluent. Temperature and stress fields were obtained through fluid-structure interaction using ANSYS Fluent, Transient Thermal, and Transient Structural. An experiment was carried out to determine the temperature and stress dependency of the brake over time, utilizing thermocouples and strain gauges on the outer surfaces, as well as a thermal camera to monitor temperature changes on the inner surfaces. Comprehensive comparisons between numerical and experimental results were made, showing good agreement. A comparative analysis of the brake’s working cycle, with and without projectile movement, revealed that the presence of a projectile significantly affects the temperature distribution and the maximum brake and compensator forces during the movement period, while its influence on forces impulses and brake efficiency is much smaller. This type of numerical analysis enables better optimization of brake design parameters and material selection for improved resistance and erosion prevention.

Similar content being viewed by others

Introduction

During the firing process, the gases produced by the combustion of the powder charge give momentum to both the projectile and the recoil mass. As the projectile exits the barrel, the gases flowing out also increase the velocity of the recoil mass. This additional momentum during the barrel discharge process puts extra load on the recoil mechanism, or weapon carriage. The products of gunpowder combustion leave the barrel at high pressure and velocity, containing a significant amount of energy. A muzzle brake is a device mounted on the barrel muzzle that uses the momentum of the powder gases to generate a force that counteracts the recoil force. In artillery weapons, the muzzle brake exerts force on the recoiling mass throughout the barrel emptying process, as the breech remains closed. In automatic weapons, the bolt starts disengaging from the barrel while the powder gases are still under pressure, utilizing their energy to increase the bolt’s velocity after unlocking. Afterward, there is a change in the flow field inside the barrel as gases escape through the gap between the powder chamber wall and the cartridge case. Despite this, the muzzle brake continues to decelerate the recoiling parts for a period of time, as the gases near the barrel muzzle cannot quickly change direction due to inertia. This leads to an increase in the relative velocity of the bolt compared to the barrel, positively impacting the firing rate. Muzzle brakes may vary in design, but similar thermodynamic processes occur in most types of brakes.

Authors of the paper1 analyzed various design parameters of muzzle brakes for sniper rifles and conducted optimization. The efficiency of a muzzle brake can be numerically determined in 2D domain if the brake has multiple symmetry planes. In such cases, converting the 3D flow space into 2D is necessary to maintain consistent mass flow. While this approach reduces calculation time, it does not provide precise information about the temperature and stress fields inside the brake. This approach was applied by Jevtić2. Jiang and Wang3 applied numerical method to obtained howitzer muzzle brake efficiency. An experiment was carried out in which the pressures inside the brake were measured, as well as the recoil displacement during time. Good correlation between numerical and experimental results was achieved. Cooke4 analyzed the pressure field on the muzzle baffle of a 105 mm howitzer axisymmetric muzzle brake. Savick5 compared the efficiency of muzzle brakes for a 20 mm gun with different design parameters. Ahmed et al.6 analyzed muzzle brake efficiency using an analytical method and compared it with experimental results. The experiment was based on measuring the recoil force with and without the muzzle brake and later recalculating its efficiency. Two types of muzzle brake were analyzed and for both analytical and experimental results were in good correlation. Lei et al.7 used a fluid-solid coupled method to analyze stress fields during howitzer barrel emptying and investigated the forces generated in each row of the muzzle brake for optimization. The presence of the projectile inside the brake was taken into account and the dynamic mesh in the 3D numerical domain was employed. Yuhao and associates8 performed optimization of two chamber muzzle brake using computational fluid dynamics. Obtained pressure field around the brake was verified by experimental results. Analysis of the gun barrel thermo-mechanical load was performed in9. Authors presented numerical method for heat transfer and stress analysis of the barrel, which was validated by experimental results. Sentürk with associates10 analyzed thermo-mechanical stress condition of the gun barrel during interior ballistic cycle. Temperature distribution in radial and axial directions of the barrel was determined using ANSYS software, while experimental results was obtained from FLIR thermal imager. Analytically and numerically obtained stress distribution results were in good correlation.

In this paper, the muzzle brake that can be mounted on a 12.7 mm machine gun or sniper rifle was numerically analyzed. The analysis assumed the bolt was closed for the entire barrel emptying period to minimize flow field disturbances. Since the considered brake has the compensator, simulation was performed in the 3D numerical domain. The deformations of the brake walls are small compared to the dimensions of the flow space and their influence on the flow field parameters can be neglected. Based on that, one-way fluid-structure interaction (FSI) was employed to analyze the brake stress field. The experiment was carried out by firing from a machine gun on the stand, measuring temperature and stress on the brake outer wall with thermocouples and strain gauges. Since positioning of the thermocouples and strain gauges on the inner surfaces of the brake will cause their damage during the machine gun barrel emptying period, a thermal camera recorded temperature changes on the brake baffles. The muzzle brake analyzed in this study is made of 25CrMo4 steel. Alternatively, 42CrMo4 is also a suitable material for this type of component. Both steels exhibit similar thermal properties, such as specific heat capacity and thermal conductivity, resulting in approximately the same temperature distribution within the brake during its operating cycle. However, 42CrMo4 has a higher yield strength at both room and elevated temperatures, as well as greater hardness due to its higher carbon content. As a result, 42CrMo4 offers improved resistance to erosion compared to 25CrMo4. Internal ballistic calculation was verified by the pressure measuring results provided from the test barrel firing on the stand, and with muzzle velocities measured by the ballistic chronograph. Numerical and experimental results were in good agreement, so it can be concluded that simulated change of the combustion products thermodynamic characteristics corresponds to the realistic one. The numerical model was set for two cases: with and without the projectile motion through the muzzle brake to analyze its impact on pressure and temperature fields. The projectile motion was simulated by using the dynamic mesh. The parameters of the dynamic mesh, which allow for remeshing to decrease calculation time without compromising result accuracy, are described in detail. Although the burst fire is much more critical for thermo-mechanical load, as well as material erosion of the muzzle brake, in this paper the analysis was performed for single firing, in order to verify the numerical model (along with the introduced assumptions) that describes certain thermodynamic phenomena and processes that are difficult to capture experimentally. Established numerical model can be extended to describe processes occurring during burst fire, but it is necessary to take into account the dynamics of the machine gun itself, as well as the cooling of the brake between two shots.

Numerical simulation

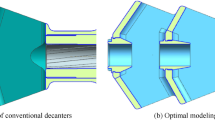

A two chamber muzzle brake with a compensator was analyzed by numerical simulation in a 3D numerical domain. The 3D model of the brake is shown in Fig. 1a. The inclination angle of the side port axis in each row of the muzzle brake is \(20^\circ\). In Fig. 1b, cross-section of the brake can be seen. Considering that the lower surface of the brake forms an angle of \(10^\circ\) with respect to the horizontal plane, the gases that hit the brake baffles will exit through the side ports at an angle in the vertical plane with respect to the horizontal axis, generating the compensator force.

A more precise analysis of thermodynamic processes, requires dividing the brake walls into appropriate segments, as shown in Fig. 1a. On the opposite side of wall 4 is wall 2, contrary to wall 5 is wall 3, to wall 9 is wall 7, to wall 10 is wall 8, to radius 1 is radius 4, to radius 2 is radius 3, to radius 5 is radius 8 and to radius 6 is radius 7.

Model assumptions Numerical simulation was performed using next assumptions:

-

Considering that the projectile surface has a high temperature, when it reaches barrel muzzle, due to the effect of hot propellant gases during its movement through the barrel, and that the gas temperature decreases due to expansion in the muzzle brake, the difference between these temperatures decreases over time. Since the total time of the projectile’s movement through the brake is approximately 0.11 ms, changes in the propellant gases’ thermodynamic characteristics can be neglected due to the heat transfer to the projectile during its movement through the brake. Therefore, only the projectile wall was considered during the simulation.

-

Gas leakage through the gap caused by wear of the projectile jacket during the projectile movement through the barrel can be neglected from the standpoint of their effect on the brake before the projectile reaches the muzzle. Their leakage through the mentioned gap has been taken into account, to a certain extent, in the internal ballistic calculation.

-

The air movement inside the muzzle brake caused by the projectile’s motion in the barrel can be neglected.

-

The influence of the projectile’s rotation on the pressure and velocity field of the gases inside the brake is not taken into consideration

-

The velocity of the machine gun during the recoil and counter recoil process is small compared to the gas velocity and therefore can be neglected.

-

The compensator creates an asymmetric pressure field inside the brake, causing the projectile to move in a direction normal to the brake’s central opening axis. However, the projectile’s displacement in that direction is small relative to the dimensions of the brake’s flow field and was not taken into account.

Governing equations

The continuity equation for species have the next form11:

where \(Y_i\) denotes mass fraction of the i-th species:

The continuity equation for the mixture is:

In Eqs. 1–3, \(\rho _i\) denotes density of species i, \(\rho\) is mean density of the mixture, V is mean velocity, \({\vec {J}}_{i}\) is the diffusion flux of species i

The momentum conservation equation

The energy conservation equation in the gas region

where the deviatoric stress tensor \(({\bar{\bar{\tau }}}_{eff})\) is defined as:

In Eq. 5, the term \(\nabla ({{\bar{\bar{\tau }}}_{eff}}\vec {V})\) represents the viscous heating, h is enthalpy, p is pressure, k is thermal conductivity, \(c_p\) is specific heat capacity, \({{\mu }_{t}}\) is turbulent dynamic viscosity, \(Pr_t\) is turbulent Prandtl number, T is the temperature.

Eqs. 1-5 can be applied to the entire numerical domain filled with gas when the projectile movement is not taken into account. In the opposite case, the aforementioned equations are applied on the subdomains without the dynamic mesh. In the subdomain with dynamic mesh numerical cells moving and deforming. In that case, general Reynolds transport theorem can be written in the following form:

where f represents general scalar or vector, \(V_c\) denotes cell volume, \(A_{cs}\) is the cell surface, \(\vec {V}\) is the velocity vector of the fluid on the cell surface, \(\vec {V}_{cs}\) is the vector velocity of the cell surface, D is the diffusion coefficient

Turbulent flow in the numerical domain was described by the realizable \(\kappa -\epsilon\) model with scalable wall functions. The equations for turbulent kinetic energy (k) and energy dissipation rate \((\varepsilon )\) are:

where

Turbulent viscosity \((\mu _t)\) can be calculated using next equation:

where coefficient \(C_\mu\) is:

where

In Eqs. 8 to 14, \(G_k\) represents the generation of turbulence kinetic energy due to the mean velocity gradients, \(G_b\) is the generation of turbulence kinetic energy due to buoyancy, \(Y_M\) is the contribution of the fluctuating dilatation in compressible turbulence to the overall dissipation rate, \(\Omega _{ij}\) is the mean rate-of-rotation tensor, and \(S_{ij}\) is the mean strain rate.

Turbulent model constants are:

-

turbulent Prandtl number for kinetic energy \(\sigma _k=1\)

-

turbulent Prandtl number for dissipation rate \(\sigma _{\epsilon }=1.2\)

-

turbulent Prandtl number \(Pr_t=0.85\)

-

turbulent Schmidt number \(Sc=0.7\)

The energy conservation equation in the muzzle brake is:

where \(c_{mb}\) denotes specific heat capacity of the muzzle brake material, and \(k_{mb}\) is thermal conductivity of the muzzle brake material.

The boundary condition on the muzzle brake surface for the energy conservation equation is:

where \(h_g\) denotes heat transfer coefficient, \(T_g\) is the gas temperature and \(T_{mbs}\) is the muzzle brake surface temperature, \(q_{rad}\) is radiation heat flux, which is calculated using discrete ordinates radiation model.

Equation of projectile movement is:

where \(V_p\) denotes projectile velocity at arbitrary moment, \(V_{p0}\)-projectile muzzle velocity, \(p_p\)-gas pressure on the projectile, \(A_p\)-projectile surface, \(\vec {n}\)-unity vector of the projectile surface normal, \(\vec {m}\)-unity vector wich is collinear with the muzzle brake central opening axis.

Initial and boundary conditions

In Fig. 2, the numerical domain with the projectile in the brake is shown. The cylinder has a radius of 700 mm, and the domain length is 1400 mm. The muzzle brake was placed in the center of the domain. The outlet boundary surface (position 1) is defined as pressure outlet. The gas parameters at the outlet boundary at the initial moment are: pressure, velocity and temperature. The inlet boundary surface (position 3) is defined as a pressure inlet, requiring the provision of static and total pressure of the gasses as well as total temperature.

To better simulate the gas flow conditions at the boundary during the corresponding expansion of the flow space (barrel muzzle), the inlet boundary is positioned at a certain distance in front of the barrel muzzle. Gas parameters on the inlet boundary as well as in the entire subdomain with propellant gases in the initial position were provided by the interior ballistic calculation. To minimize the number of mesh elements that need to be remeshed during the projectile movement, a subdomain was created along the projectile axis, slightly larger in diameter than the caliber. In order to enable the creation of new mesh elements during the projectile movement, it is necessary to position the bottom of the projectile at a certain distance from the barrel muzzle.

Based on the interior ballistic calculation12, time dependency of the static pressure, velocity and the temperature of the propellant gases at the inlet surface of the numerical domain are shown in Fig. 3a, b and c, respectively.

Since the static pressure at that position in the barrel has almost same values for all three analyzed initial temperatures of the system (T=243K, T=288K and T=323K), the pressure change is presented with one curve on the diagram. At the moment when the projectile leaves the barrel, the gas pressures corresponding to the ambient temperatures 243K, 288K and 323K are 761 bar, 755 bar and 739 bar, respectively. Approximately 0.02 ms later, the flow conditions at the barrel muzzle reach critical values (Mach number M=1), causing the gas pressure to drop to 499 bar, 496 bar and 489 bar for corresponding temperatures. At the beginning of the gas flow through the brake, the gas velocities are 757 m/s (T=243K), 796 m/s (T=288K) and 830 m/s (T=323K). The gas temperatures for the considered ambient temperatures are 2042K, 1980 K and 1908K, respectively.

At the initial position for the numerical simulation, pressure distribution of the gases in the barrel (Fig. 2, position 4) is13:

where \(p_x\) denotes pressure at distance x from the breech, \(p_{pb}\)-pressure at the projectile base, \(\omega\)-propellant charge mass, \({\varphi }_{1}\) coefficient of resistance to the projectile movement, \({m}_{pr}\)-projectile mass, d-caliber, \(d_c\)-propellant chamber diameter, x-distance from the breech, \(x_0\)-chamber length, l-projectile travel, \(W_0\)-chamber volume

Based on the assumption that the gas density behind the projectile is uniform, a linear change of the combustion products velocity along the barrel axis is obtained. Temperature field of the gases in the barrel is determined based on the equation of state for the real gases where the covolume of the gases is taken into account:

where W denotes gas volume, \(\alpha\) is gas covolume, \(m_{gas}\)-mass of the gas and \(R_{gas}\)-gas constant.

In the numerical domain which is filled with air at the initial position, the gas parameters are: pressure \(p=1 bar\), velocity \(V=0 m/s\) and temperature \(T=286.5 K\). The initial temperature of the muzzle brake is \(T=286.5 K\).

The dynamic viscosity of propellant gases as a function of temperature can be written using Sutherland’s equation14:

where

where \({{\mu} _{i}} \) denotes dynamic viscosity, M is molar mass and X is mole fraction.

Specific heat at constant pressure of the combustion products mixture, which is temperature dependence, can be expressed by next equation15:

Thermal conductivity of the combustion gases mixture is also dependent on temperature and can be calculated using Eqs. 20 and 21, but instead of dynamic viscosity of each combustion product (\({{\!\!\mu \!\!}_{i}}\)) in Eq. 21 should be used thermal conductivity. Mol fraction of each combustion product was calculated using thermochemical calculation16 and is presented in Table 1.

Temperature dependencies of the thermal conductivity, heat capacity and dynamic viscosity of each gas can be determined using kinetic theory and is presented in17. The temperature dependence of the specific heat capacity and thermal conductivity of the muzzle brake material can be represented by the following equations, respectively18:

At the initial phase of the gas flow through the muzzle brake, at some parts of the fluid domain the mixture of the propellant gases and the air will appear, and it was modeled using species transport.

During the projectile movement from the muzzle to the first row of openings, gases flow through the gap between the projectile and the brake at velocities that, in certain cross-sections, reach Mach number higher than 3. After the base of the projectile passes through the central opening of each brake chamber, the gases rapidly expand within the chamber, where high velocities are also reached near the brake walls, particularly in the zone close to the outlet cross-section of the side openings. In these mentioned zones, a significant velocity gradient occurs near the brake wall. Considering that viscous heating is proportional to the square of the velocity gradient, it has been taken into account.

The equations that describe flow field were solved by a coupled numerical scheme. The flow space is strongly curved, and in these conditions, a spatial discretization scheme for the pressure field should be PRESTO!11. This scheme uses the pressure on the cell face to calculate the velocity field, making it very useful for mass flow calculations in conditions where gas needs to turn into side ports positioned at a certain angle relative to the flow direction. However, in this analysis second order discretization scheme is used. This scheme uses Taylor series expansion to evaluate the pressure at the cell face based on the pressure at the cell center. To minimize the error of the pressure value at the cell face as well as the velocity and the mass flow through the side ports, mesh cells are made very thin at the muzzle brake chamber entrance. This was achieved by using the inflation layers, which can be seen in Fig. 4. Also, these layers were used at every contact surface between the brake and the gas in order to adequately describe the boundary layer and the heat convection and conduction that occur. The projectile movement was modeled using dynamic mesh. The inflation layers on the projectile surface move along with the projectile without deformation of the cells. In the dynamic mesh zone, only tetrahedral cells was chosen for remeshing, where spring constant factor was set to 1. Maximum cell skewness has the value 0.9, while maximum face skewness was set to 0.7.

Leech19 dealt with the problem of thermal radiation from the hot combustion products of gun powder as the projectile moves through the barrel. The analytical model established that thermal radiation significantly impacts the breech zone, while forced convection is the primary heat transfer mechanism in most of the gun barrel. Similar conditions to those near the bolt can be found in certain parts of the brake where flow velocity is low and gas temperature is high, especially near the symmetry plane of the brake. Therefore, thermal radiation was included in the heat transfer analysis, modeled using the discrete ordinates model. The main combustion products of gunpowder are CO, \(CO_2\), \(N_2\), \(H_2\), and \(H_2O\), with their share in the mixture is shown in Table 1. ANSYS Fluent software was utilized for this analysis, incorporating absorption coefficients and temperature dependencies of the combustion products. The emissivity of the muzzle brake material is 0.7. A stress analysis of the muzzle brake was conducted using fluid-structure interaction. Temperatures of the walls and the pressures acting on them were determined through ANSYS Fluent simulation. As the mechanical properties of the brake material (25CrMo4) are temperature-dependent20, a simulation was run in ANSYS Transient Thermal to obtain the temperature field. The Transient Structural module was then used to analyze the stress field, accounting for thermal strains and stresses due to high temperature gradients on the wall surfaces. Coefficient of thermal expansion, as well as the modulus of elasticity of the brake material change with temperature, and this can be seen in Table 2.

Experimental research

Verification of the mathematical model that describes the internal ballistic cycle and thus the gas parameters at the barrel muzzle during the discharge period, was carried out using the results obtained from the experiment. Experimental results were obtained by firing from a test barrel mounted on a stand, as shown in Fig. 5a. Muzzle velocity of the projectile was measured by a ballistic chronograph positioned 2.5 meters from the muzzle.

Pressure change in time was measured using the piezoelectric sensor KISTLER 6215, which was mounted 25 mm in front of the bolt. The pressure change of the gunpowder gases was obtained experimentally, and through a mathematical model, as shown in Fig. 5b. In both cases, the observation of pressure change began at the start of the projectile movement. The maximum pressure obtained by calculation is reached 0.12 ms before the experimentally measured, and the difference between them is 3.5%.

The difference in projectile movement time through the barrel is approximately 0.2 ms, and the pressure difference when the projectile is at the barrel muzzle is 10.7%. This difference is maintained throughout the barrel emptying period. The mean value of the muzzle velocity obtained experimentally was 822 m/s, while the mathematical model predicts 820 m/s. Based on this, and the good agreement between the experimental and modeled pressure changes, it can be concluded that all gas parameters obtained by the mathematical model can be used in numerical simulations. To verify the numerical model describing the change in gas parameters inside the muzzle brake, experimental tests were performed. The stress field of the brake was measured using two strain gauges placed on the upper side of the brake. These gauges were positioned in a vertical symmetry plane on the upper wall of each brake chamber, as shown in Fig. 6a. Additionally, the temperature change of the brake was measured by thermocouples (type K NiCr-Ni, 0.2 mm) placed on the outer wall of the brake (Fig. 6a). Thermocouples were not placed on the internal surfaces of the brake to avoid damage during gas impact. Due to the short duration of the gases’ flow through the muzzle brake (around 9 ms), as well as the thermal properties of the brake material itself, a relatively small layer of the brake wall heats up to a high temperature within that time, and later, through conduction, the entire muzzle brake heats up. As a result, the thermocouples will detect the temperature rise with a slight delay after the barrel is emptied (the barrel is considered as empty when the pressure of gunpowder gases within is lower than 2 bar). The machine gun was connected to the stand by a spring. The temperature of the muzzle brake during and after the barrel discharge period was determined using a thermal camera FLIR SC620, the characteristics of which are presented in Table 3. Machine gun on the stand, along with thermal and high speed camera, can be seen in Fig. 6b. The position of the thermal camera relative to the muzzle brake is shown in Fig. 6c.

After the barrel is emptied, the inner walls of the brake are at a high temperature. Due to thermal conduction, there will be a change in the temperature field of the brake. The temperature change of the outer surface is shown in Fig. 7a (\(T_{1e}\) and \(T_{2e}\) denote thermocouples 1 and 2, respectively, after filtering results). The same figure also shows the temperature change obtained by the numerical simulation at the positions of the thermocouples (\(T_{1n}\) and \(T_{2n}\) denote numerically obtained temperature changes at the positions of thermocouples 1 and 2, respectively). The diagram does not indicate the time it takes for the temperature of the brake’s outer surface to start to rise. Strain gauges recorded the change in the brake stress conditions during the period of gas movement through it, as well as afterward. This is shown on the diagram in Fig. 7b (\(\sigma _{1e}\) and \(\sigma _{2e}\) denote strain gauges 1 and 2, respectively, after filtering results). Since there are large temperature gradient values in the brake that affect the stress field, temperature compensation of the strain gauges was not included. The same diagram shows the numerical results at the same position of the strain gauges (\(\sigma _{1n}\) and \(\sigma _{2n}\) denote numerically obtained stress changes at the positions of strain gauges 1 and 2, respectively). Considering that the machine gun was allowed to recoil on the stand during firing, it also registers the stresses caused by inertial forces. Since this research does not cover the dynamics of the machine gun, only the results of the strain gauges placed normal to the barrel axis are presented.

Although the gases move through the brake for about 9 ms, it can be observed that even after that period, there is still stress inside the brake. This stress is caused by the temperature gradient in the brake walls. Based on the good agreement between experimental and numerical results, it can be concluded that the numerical model of the gas flow through the muzzle brake can be used to describe the changes in all thermodynamic characteristics of the gas. Additionally, the numerical model accurately describes the behavior of the brake material under complex thermomechanical conditions.

Calibration of the thermal camera was performed using the reference source Black Body TCB-4D, within a temperature range of 273 K to 323 K. At the proving ground, the temperature of the brake prior to firing was measured using thermocouples and compared with the temperature readings obtained from the thermal camera. Based on this comparison, the surface emissivity was set to 0.7, with reflected and atmospheric temperatures at 286.5 K, and a relative humidity of 70%. In Fig. 8a, the temperature distribution in the machine gun barrel and the muzzle brake 2 seconds after the projectile leaves the barrel is shown. The diagram in Fig. 8b illustrates the temperature changes of two points obtained through thermal camera and numerical analysis. The first considered point was approximately 5 mm from the edge of the second baffle orifice, while the second point was on the middle of the first baffle’s outer surface. To avoid the influence of gunpowder gases around the brake on the thermal camera measurements, as well as barrel oscillations after recoil and counter-recoil periods, the first second after the projectile leaves the brake was not taken into consideration. At that moment, the difference between numerical and experimental results is about 4% for both points. Based on the diagram in Fig. 5b, it can be seen that the calculated gas pressure, and consequently the temperature, are higher than the real values during the barrel emptying. This will affect the changes in the brake temperature field over time during the gas flow through the brake, as well as later, during the cooling period. By 5.2 seconds, the difference for point 1 is 10.5%, but this difference decreases thereafter. For the second point, the largest difference between numerical and experimental results is 11%, occurring after 2.4 seconds. For both analyzed points, it can be noticed that temperature drop obtained by numerical simulation is faster than in real conditions. In reality, there is a possibility of the presence of a certain small amount of gunpowder gases around the machine gun and the muzzle brake, which reached these areas by flow from the rear of the barrel after the bolt is opened, as well as through gap between the gas piston and the cylinder, which are not included in the numerical simulation. Although gunpowder gases have a higher thermal conductivity coefficient and specific heat capacity than air, meaning they would cause faster cooling of the brake, they also cause the temperature increase of the surrounding environment of the brake. That will decrease the temperature difference between the brake and gas around it and thereby reducing the heat transfer. For both points of interest, the difference in observed temperature between the measured data and the numerical simulation does not exceed 0.6 K, and the stated deviation can be considered acceptable within the camera’s accuracy margin.

Temperature measuring with thermal camera: (a) machine gun barrel and muzzle brake 2 s after the projectile leave the barrel, (b) temperature change of the two measuring points (\(T_{1n}\), \(T_{2n}\)-numerical results for points 1 and 2; \(T_{1t}\), \(T_{2t}\)- thermal camera results for points 1 and 2).

Projectile influence

In Fig. 9, the maximum temperature change of wall 1 is shown, obtained by numerical simulation with and without the projectile.

After 0.02 ms, a temperature rise occurs in both analyzed cases. When considering the projectile movement, the maximum temperature reaches 562 K, while in the opposite case, the temperature rises to 476 K. In both cases, the maximum temperature occurs very close to the barrel muzzle. Near the wall in that zone, without the projectile, the gas velocity is 250 m/s, while the angle between the velocity vector and the surface is \(42^o\). The gas temperature is 1590 K. When the projectile is taken into account, the velocity is 325 m/s and the angle that the vector makes with the surface is \(23^o\). The gas temperature is 1880 K. At that moment, the bottom of the projectile leaves wall 1 and enters the first cavity of the brake. This results in a sudden expansion of the gas in the cylindrical section of the brake, leading to a temperature drop of approximately 150 K near the wall. Consequently, the amount of heat transferred from the gas to the wall decreases. Due to the high temperature gradient at the wall surface, and the fact that the thermal conductivity of steel increases at lower temperatures, this leads to a efficient heat conduction through the brake material, contributing to a drop in the surface temperature of wall 1 by about 70 K. As the temperature gradient near the wall decreases, the rate of heat conduction through the steel is reduced. Additionally, since the specific heat capacity of steel decreases with temperature, less energy is required to raise the wall’s surface temperature. As a result, the maximum temperature of wall 1 begins to rise again after approximately 0.05 ms.

When the projectile leaves the muzzle brake, a flow with approximately the same field characteristics as in the case without the projectile will be established inside. This will result in a similar change in the maximum temperature over time.

In Fig. 10, the maximum temperature change of wall 3 is shown for the two aforementioned cases. When the projectile is taken into account, the maximum temperature will occur after 0.07 ms (460 K) near radius 2 (Fig. 1). In that zone, a dominant vortex flow with a gas temperature of about 1070 K is present. The high value of pressure (140 bar) will cause a decrease in velocity in the vortex from 105 m/s to 20 m/s, leading to a 50\(\%\) drop in the heat transfer coefficient. The specific heat capacity of the brake material rises with temperature increase, and the high temperature gradient in that zone will cause intense heat conduction, resulting in a decrease in the temperature of wall 3. The maximum temperature, in both analyzed cases, is reached at approximately 2.2 ms, but the presence of the projectile will result in a 70-degree smaller value. As mentioned earlier, establishing approximately the same flow field when the projectile leaves the brake will result in similar temperature changes in both analyzed cases.

The diagram showing the maximum temperature change of wall 4 is depicted in Fig. 11. The numerical simulation taking the projectile into account indicates that gases impact wall 4 after 0.04 ms with a velocity of 1900 m/s. The gas temperature near the wall at that moment is 670 K. In the absence of the projectile, the impact velocity is 1550 m/s, but the gas temperature is 960 K. The heat transfer coefficient is approximately 25% higher when considering the projectile, resulting in a 50 K increase in the first peak of wall 4 temperature. In both analyzed cases, the maximum temperature is reached at roughly the same time, but without the projectile, it is 160 degrees higher. The presence of the projectile leads to a higher pressure at the side port entrance, causing faster expansion of gases in the chamber. As a result, gases hit the baffles at a greater distance from the central opening edge of the first baffle compared to the case without the projectile. This positioning of the maximum temperature point results in heat conduction occurring in more directions when the projectile is considered, leading to a quicker decrease in maximum temperature.

In Fig. 12a, the temperature distribution of the brake walls at t=0.05 ms is presented, while Fig. 12b shows the temperature distribution when the maximum temperature is reached.

Figure 13a illustrates the change in muzzle brake force over time when the projectile moves through the brake, compared to when its movement is not considered. The forces shown were calculated based on the pressure distribution along the muzzle brake walls. As observed, the brake begins generating force in the direction opposite to the recoil force at 0.04 ms, when the projectile is inside the brake. The maximum force of 17.3 kN is reached at 0.055 ms, at which point the projectile is nearly exiting the first chamber of the brake. Approximately 0.06 ms after the projectile exits the brake, flow field parameters became approximately equivalent as in the case without the projectile. Consequently, the force generated by the brake changes similarly in both cases until the barrel is fully emptied. Figure 13b shows the compensator force over time, both with and without the projectile. The compensator begins generating force at the same moment regardless of the presence of the projectile. The maximum compensator force of 1.25 kN is reached at 0.05 ms. This force increase is primarily due to a pressure spike in the radius 3 zone, with a peak of 150 bar near the symmetry plane and an average pressure of 110 bar. At this point, the projectile is about 30 mm away from exiting the first chamber. After 0.15 ms, when the projectile is about 50 mm in front of the muzzle brake exit, the gas flow parameters inside the brake become identical to those in the case without the projectile. Therefore, the projectile’s influence on the compensator’s operation can be considered negligible.

Figure 14a and b show the time-dependent mean pressure on walls 4 and 9, respectively, for both analyzed cases. The diagrams illustrate pressure changes up to 1 ms, during which the projectile’s influence is noticeable. Beyond this point, the flow field behaves similarly in both cases. Although a gap exists between the projectile and the inner surface of the brake, allowing some gas to flow around the projectile through this gap, it is insufficient to cause a significant pressure rise at the first muzzle baffle. When the bottom of the projectile passes wall 2, the flow area for gases behind the projectile increases. Consequently, a larger amount of gas impacts wall 4, causing the pressure to rise to 78 bar just as the projectile exits the first brake chamber (t = 0.05 ms). This high pressure around the stagnation point at the baffle leads to an earlier deflection of gas from the barrel into the side port, along with the acceleration of gas near the baffle wall. As a result, the pressure at the baffle begins to decrease. Until the end of the brake’s working cycle, the flow field in the case with the projectile results in a lower mean pressure on wall 4 compared to the case without the projectile. A similar process occurs in the second chamber, though with lower pressure values.

Muzzle brake and compensator forces

The forces generated by the muzzle brake and compensator can be determined in two ways. First, they can be calculated by summing all the pressure forces exerted by the powder gases on the walls of the muzzle brake and then projecting the resultant force in the desired direction:

where \(\overrightarrow{F}\) represents the muzzle brake force, p is the pressure that act on the observed muzzle brake surface, A is the surface area, \({{\overrightarrow{n}}_{i}}\) unit area vector and k is the number of parts into which the surface of the gas brake is divided (in Fig. 1 - wall 1, wall 2, ...).

Viscous forces of the gases that act on the muzzle brake surfaces can be neglected.

Another way to determine the force generated by the muzzle brake is to apply the balance equation for momentum of the propellant gases:

where \(W_{mb}\) denote the control volume of the muzzle brake, p, \(\rho\) and V represent the pressure, density and velocity, respectively, \(\beta _c\) is Boussinesq correction coefficient, n is the number of inlet surfaces, m is the number of outlet surfaces \({{{\vec {F}}}_{m}}\) is the body force.

Boussinesq correction coefficient was introduced to avoid the error that arises from averaging the velocity field, and is determined using the following equation:

where \(\rho _{avg}\) denote average density over the control surface and \(V_{avg}\) is average velocity normal to the control surface and A is the area of the control surface.

This coefficient can be determined numerically, which requires fine mesh at the control surface and very small time step, if the flow is transient. For fully developed turbulent flow \(\beta _c\approx 1.02\), but it can be lower, which depends on Reynolds number. At the muzzle brake entrance this coefficient is around 1.005. Because of the high velocity values, the velocity profile at that surface is close to uniform. At the first central opening, during the gas flow, a small recirculation zone will form, which will affect the velocity profile and due to that, correction coefficient will vary form 1.05 to 1.07. At the first row of side openings of the brake, a recirculation zone will appear, which at the beginning of the gas flow will be only in the inlet zone of the opening but will affect the position of the velocity vectors at the outlet cross-section of the opening. Therefore, by 0.5 ms, the correction coefficient will reach a value of 1.75. As the flow continues, the angle between the outlet velocity vector and the axis of the side opening decreases, causing the coefficient value to drop to 1.07 (t = 3 ms). After that, the recirculation zone increases, and at a certain point, the outlet surface of the opening will be within the vortex itself. This will cause the correction coefficient to rise above 5 in the final phase of the muzzle brake working cycle. In the second row of openings, a recirculation zone also appears at the inlet, but the vortex is smaller, and the opening itself is longer compared to the first row. For this reason, the vortex has less influence on the position of the velocity vectors at the opening outlet surface, so the correction coefficient is around 1.07 at t = 3 ms, after which it increases to 2.5 at t = 5 ms. It will maintain approximately that value until the end of the gas flow through the brake.

The first term on the right-hand side of Eq. 26 represents the force generated by the change in gas momentum within the control volume. The second and third terms correspond to the gas momentum fluxes through the inlet and outlet boundary surfaces of the control volume, respectively. In this study, the acceleration of the muzzle brake during the weapon’s recoil cycle was not considered. Consequently, the final term was omitted, as the weight of the propellant gases is negligible compared to the other forces. By applying Eq. 26, it is possible to determine the force exerted by each row of muzzle brake ports, as the numerical domain is divided into a specific number of subdomains. Figure 15a shows the forces generated due to local changes in the momentum of the propellant gas within the muzzle brake along the brake axis \((F_{mb,loc})\) and perpendicular to the axis \((F_{comp,loc})\). Although both forces have relatively large magnitudes compared to the total forces generated in their respective directions, their short duration means their overall influence on the total force can be disregarded. Figure 15b illustrates the forces acting on the recoil mass during the barrel emptying phase: the force exerted by the muzzle brake, calculated using Eq. 25, and the pressure force of the propellant gases acting on the bolt. As can be observed, the muzzle brake force exceeds the force acting on the bolt throughout the entire barrel emptying phase, indicating that the maximum velocity, and therefore momentum of the recoil mass is achieved when the projectile reaches the barrel’s muzzle.

After-effect coefficient when the muzzle brake is not mounted on the weapon can be calculated using next equation6:

where \(\kappa\) is specific heat ratio, \(p_{mu}\)-pressure at the barrel muzzle when the projectile leaving the barrel, \(W_0\)-volume of the powder chamber, s-cross sectional area of the rifled part of the barrel, \(l_{pr}\)-projectile travel length, \(\omega\)-gun powder mass, \(V_0\)-initial velocity of the projectile.

Impulse characteristics of the muzzle brake can be expressed in the next form:

where \(M_0\) denotes recoil mass of the weapon, \(W_{\tau ,mb}\) is velocity of the recoil mass at the end of the barrel emptying when the muzzle brake is mounted, \(W_{mu}\) is velocity of the recoil mass when the projectile is at the barrel muzzle, \(W_{\tau }\) is velocity of the recoil mass at the end of the barrel emptying without the muzzle brake, \(I_{mb}\) is the impulse of the muzzle brake force, \(I_{bb}\) is the impulse of the pressure force that acts on the bolt during gun barrel emptying.

After-effect coefficient when the weapon firing with the muzzle brake on, is:

The efficiency of the muzzle brake can be determined using next equation:

where \(m_{pr}\) is the projectile mass.

Gun and ammunition parameters which influence on the muzzle brake efficiency are shown in Table 4.

In Table 5 are shown impulses of each row of the muzzle brake and compensator, as well as the total impulse of the brake (\(I_{mb}\)) and compensator (\(I_{comp}\)). \(I_{bb}\) denotes impulse of the gases that act on the bolt and \(\xi\) is the muzzle brake efficiency. As can be seen, when the projectile is not taken into account, the impulse of the brake force is 0.4% higher compared to the case with the projectile. In contrast, the presence of the projectile increases the compensator force impulse by 3.7%. Additionally, the projectile slightly affects the muzzle brake efficiency, reducing it by 0.2%.

Conclusion

In this study, the flow field in a muzzle brake with a compensator was analyzed using numerical simulations, and next conclusions can be obtained:

-

A fluid-structure interaction (FSI) model was used to determine the temperature and pressure fields within the brake. Given that the deformations of the brake walls were minimal and negligible compared to the dimensions of the brake’s flow space, their influence on the pressure field inside the brake was also considered negligible. Therefore, a one-way FSI was performed to assess how the gas flow impacted the solid structure. Due to the high-temperature gradients within the brake walls, significant thermal deformations and stresses were observed. A dynamic mesh was employed to analyze the impact of the projectile’s movement through the brake.

-

Internal ballistics calculations were verified by test-firing from a barrel, where pressure and projectile muzzle velocity were measured. The maximum pressure obtained from the mathematical model was 3.5% higher than the experimental results, while the difference during the barrel emptying phase was 10.7%. The discrepancy between the numerically calculated and experimentally measured projectile muzzle velocities was 2 m/s.

-

Temperatures and stresses in the brake were measured using thermocouples and strain gauges placed on the outer surface, and a thermal camera was used to monitor temperature changes over time on the inner surfaces of the muzzle brake baffles. The temperature change at two points on the brake was analyzed, and the results showed a deviation between the numerical and experimental values of 4% to 11%.

-

The maximum temperature of Wall 1, in the presence of the projectile, was 45K higher than when the projectile was absent. The analysis revealed that the projectile’s movement affected the temperatures on Walls 3 and 5, which exhibited nearly identical distributions. In both cases, the maximum temperature was reached after 2.2 ms and was 70K lower when the projectile was present. The largest temperature difference was observed on Wall 4, amounting to 160K. Furthermore, when accounting for the projectile’s movement, the temperature distribution on the inner surface of the brake became more uniform.

-

The numerical analysis also indicated that while the projectile’s movement affected the maximum force exerted on the brake, it did not impact the total impulse on the brake.

-

The proposed numerical model provides deeper insight into the thermodynamic processes and phenomena occurring within the muzzle brake compared to existing analytical models. This enables better optimization of brake design parameters and material selection, particularly in terms of resistance and erosion prevention. Such optimization is especially crucial when applying new manufacturing technologies, like 3D printing, which allows for the creation of complex geometries.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request

References

Sherif, M. S., Abdelsalam, O. R. & Aboul, M. H. Design optimisation of muzzle brake for sniper rifle. Defence Sci. J. 68, 438–444. https://doi.org/10.14429/dsj.68.12754 (2018).

Jevtić, D. Analysis of Influenting Parameters on the Dynamics of the Automatic Gun During Firing [in serbian]. Ph.D. thesis, Faculty of Mechanical Engineering, University of Belgrade, Belgrade (2020).

Jiang, K. & Wang, H. Numerical simulation and experimental test on muzzle brake efficiency. In International Conference of Information Technology, Computer Engineering and Management Sciences (Nanjing, Jiangsu, China, 24-25 September 2011).

Cooke, C. H. Application of an explicit tvd scheme for unsteady, axisymmetric, muzzle brake. Int. J. Numer. Methods Fluids 7, 621–633 (1987).

Savick, D. S. Test comparison for 20mm perforated muzzle brakes. Tech. Rep. ARL-MR-31, Aberdeen Proving Ground, MD, USA (1993).

Ahmed, N. Z., Jerković, D. D., Hristov, N. P. & Abaci, W. B. Analytical and experimental investigation of the muzzle brake efficiency. FACTA UNIVERSITATIS Series: Mechanical Engineering https://doi.org/10.22190/FUME220418028A (2022).

Lei, H. X., Wang, Z. J. & Zhao, J. L. Stress analysis of muzzle brake by using fluid-solid coupled method. J. Eng. Sci. Technol. Rev. 9, 48–55. https://doi.org/10.25103/jestr.094.07 (2016).

Yuhao, L., Pu, Q. & Qiang, L. Numerical simulation and experiment of double chamber brake based on cfd. Sci. Rep. 13, 17785. https://doi.org/10.1038/s41598-023-45010-9 (2023).

Degirmenci, E. et al. Thermo-mechanical analysis of double base propellant combustion in a barrel. Appl. Thermal Eng. 102, 1287–1299. https://doi.org/10.1016/j.applthermaleng.2016.04.062 (2016).

Sentürk, A., Isık, H. & Evci, C. Thermo-mechanically coupled thermal and stress analysis of interior ballistics problem. Int. J. Thermal Sci. 104, 39–53. https://doi.org/10.1016/j.ijthermalsci.2015.12.019 (2016).

ANSYS Inc, 275 Technology Drive Canonsburg, PA 15317. ANSYS Fluent User’s Guide (January 2022).

Micković, D. Gun Interior Ballistic Cycle Modelling Based on the Two-Phase Flow [in serbian]. Ph.D. thesis, Faculty of Mechanical Engineering, University of Belgrade, Belgrade (1999).

Micković, D., Jaramaz, S., Elek, P., Jaramaz, D. & Micković, D. Determination of pressure profiles behind projectiles during interior ballistic cycle. J. Appl. Mech. 80(3), 031402 (2013).

Broomley, L. A. & Wilke, C. R. Viscosity behavior of gases. Ind. Eng. Chem. 43, 1641–1648 (1951).

Abu-Nada, E., Al-Hinti, I., Akash, B. & Al-Sarkhi, A. Thermodynamic analysis of spark-ignition engine using a gas mixture model for the working fluid. Int. J. Energy Res. 31, 1031–1046. https://doi.org/10.1002/er.1296 (2007).

Micković, D. & Jaramaz, S. The tcc-computer code for thermo-chemical calculations [in serbian] (Weapon Systems Department, Faculty of Mechanical Engineering, Belgrade, Serbia, 1996).

Abaci, W. B., Hristov, N., Ahmed, N. Z., Jerković, D. & Drakulić, M. Determination of the gun barrel walls temperature distribution and its experimental validation during multiple-shots firing process. Int. J. Thermal Sci. 179, 107667. https://doi.org/10.1016/j.ijthermalsci.2022.107667 (2022).

Akçay, M. & Yükselen, M. A. Unsteady thermal studies of gun barrels during the interior ballistic cycle with non-homogenous gun barrel material thermal characteristics. J. Therrmal Sci. Technol. 4, 75–81 (2014).

Leech, W. J. An analytical study of thermal radiation in gun tubes. Research Directorate, Weapons Laboratory at Rock Island, Research, Development and Engineering Directorate, U.S. Army Weapons Command (1972).

Atlas of Stress-Strain Curves, Materials Park, OH 44073-0002: ASM International (2002).

Acknowledgements

This research has been supported by the Ministry of Science, Technological Development and Innovations of the Republic of Serbia, through the Grant No. 451-03-65/2024-03/200105 from 05.02.2024. which is gratefully acknowledged.

The authors would like to thank to the Military Technical Institute from Belgrade, Agency for Testing, Stamping and Marking of Weapons, Devices and Ammunition from Kragujevac, as well as Zastava Arms from Kragujevac for providing experimental research.

Author information

Authors and Affiliations

Contributions

N.M. was responsible for conceptualization, resources, writing—review and editing, project administration, supervision and D.J. was responsible for methodology, investigation, formal analysis, visualization, writing—original draft. Both authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Miloradović, N., Jevtić, D. Numerical and experimental analysis of muzzle brake thermo-mechanical load. Sci Rep 15, 30199 (2025). https://doi.org/10.1038/s41598-025-14632-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-14632-6