Abstract

Cemented Coal Gangue Backfill (CCGB) plays a pivotal role in sustainable mining practices, as its uniaxial compressive strength (UCS) directly dictates backfill stability, mining safety, and operational efficiency. However, existing research has yet to fully elucidate how key mix proportion parameters synergistically influence UCS across different curing stages, leaving a critical gap in optimizing CCGB performance. This study addresses this limitation by systematically investigating the factors governing CCGB’s UCS under varied mix designs. First, single-factor tests identified optimal ranges for critical variables: mass concentration (80%–81%), fly ash content (3–4 kg), and fine gangue ratio (35%–45%). Using the response surface method (RSM), we then developed quadratic polynomial regression models for 1-day and 28-day UCS, which demonstrated excellent fit with R² values of 0.9672 and 0.9575, respectively. Our results reveal that the interaction between mass concentration and fly ash content exerts a more significant impact on UCS than the fine gangue ratio alone. Additionally, microscopic analysis indicates that during hydration, pozzolanic reactions and cement hydration reactions proceed in alternation rather than isolation—a mechanism previously underexplored in literature.

Similar content being viewed by others

Introduction

As a green mining technology, backfill mining has attracted extensive attention in recent years. This technology is conducive to excavating the coal under buildings, water bodies, railways, and above confined water. With the gradual depletion of coal resources in Eastern China, some coal mine enterprises had made great progress in implementing cemented backfill mining technology1,2. The cemented backfill mining had a significant effect on improving the efficiency of mining, preventing surface subsidence in the mining area, extending the service life of mine, and recycling the solid wastes in mining3,4.

The support of the roof and surrounding rock is the key of the cemented backfill mining technology. It is necessary to form a resilient support overburden control system dominated by backfill material. As shown in Fig. 1, the backfill material is pumped to the backfill areas first and then it should be protected by the backfill hydraulic support until the self-supporting strength develops5,6,7. At this time, the backfill material only provides appropriate support to the roof. When the fully mechanized mining face was advanced, the backfill material should be designed to bear the weight of the roof. Therefore, the mechanical properties of backfill materials, especially the uniaxial compressive strength is particularly important.

To investigate the uniaxial compressive strength (UCS) of cemented coal gangue backfill (CCGB), prior studies have established scenario-dependent strength requirements. Lupin-modified models are widely employed for early-age UCS prediction of backfill materials8,9. Field engineering data indicate that under hydraulic support, CCGB requires a minimum early strength of 0.17 MPa, while post-isolation support removal necessitates 28-day UCS ≥ 4 MPa10. For mere mined-out area filling, a UCS of 1 MPa suffices11. Shi et al. reported on-site 28-day CCGB with a minimum UCS of 2.3 MPa and elastic modulus of 53.66 MPa12. Zhang et al. explored the influence of coarse aggregate gradation, demonstrating that CCGB’s UCS and elastic modulus exhibit a non-monotonic relationship with the fractal dimension of coarse aggregate particle distribution13. In practical mining, as working faces advance, backfill materials must transition from temporary support-dependent stability to independent roof-bearing capacity14, necessitating tailored mechanical properties. Additionally, material components (e.g., binders, chemical admixtures) have been identified as key UCS-influencing factors15,16. Pre-engineering validation via mix proportion optimization remains critical to ensure compliance with scenario-specific requirements17,18,19. These divergent UCS benchmarks underscore the need for targeted optimization, motivating this study to quantify how mix proportions regulate CCGB’s UCS to align with varied engineering demands.

Compared with orthogonal experiment, RSM fully considers the random error of experiment. It has the advantages of continuous prediction model, high accuracy and simultaneous study of multi-factor interaction20. RSM can be used to analyze the interaction of multiple factors, and the corresponding regression equation can be constructed. It has been used to explore the development law of uniaxial compressive strength of CCGB under the action of different factors21. RSM was used as it quantifies synergistic interactions between mix parameters, which single-factor tests cannot. It enabled robust UCS regression models with fewer trials, critical for optimizing CCGB mix proportions efficiently.

To investigate the multi-factor effects on CCGB mix proportions, the response surface method (RSM) was employed for experimental design. Compared with orthogonal experimental designs, RSM provides a more rigorous accounting of random experimental errors, characterized by continuous predictive modeling capabilities, high precision, and the ability to simultaneously assess multi-factor interactions22. Distinct from single-factor analyses, RSM quantifies synergistic effects between variables and facilitates the construction of regression equations, which has been validated in studies exploring the UCS development patterns of CCGB under diverse influential factors23,24. In this research, RSM enabled the establishment of robust UCS regression models with a reduced number of trials, thereby supporting the efficient optimization of CCGB mix proportions.

Therefore, the mass concentration, fly ash content and fine gangue ratio influencing factors were selected as influencing factors to explore the influence of mix proportion on the uniaxial compressive strength of CCGB. SEM and XRD were used to analyze the effect of mix proportion on the uniaxial compressive strength of CCGB from hydration mechanism. This provides an effective analytical method for studying the uniaxial compressive strength of CCGB.

Materials and methods

Raw materials

The economics of CCGB hinges on cost control and value creation. Repurposing gangue reduces waste disposal and virgin aggregate costs, while partial replacement of cement with low-cost additives like fly ash cuts binder expenses by 15–30%. On-site production and optimized logistics (pipelines for short distances, trucks for longer hauls) balance upfront and operational costs. Long-term benefits include lower subsidence remediation, 10–25% higher ore recovery, and eligibility for green incentives. Tuning mix proportions enhances cost-effectiveness, making CCGB economically viable.

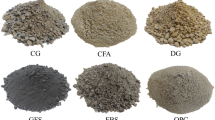

Accordingly, cement, fly ash, and coal gangue were selected as raw materials for CCGB. The P·O 42.5 cement was from Jiaozuo, Henan Province. Its specific surface area was 342 m2/kg. The Class II fly ash was selected from Jiaozuo, Henan Province. Its specific surface area was 637 m2/kg. The coal gangue was selected from Datong, Shanxi Province. Table 1 shows the continuous grading of coal gangue, according to the Chinese standard “Technical specification for construction of concrete pumping”25. Figure 2 shows the particle size distribution of coal gangue, fly ash and cement.

Specimen preparation

The benchmark group was mass concentration of 80%, fly ash content of 3 kg, and fine gangue ratio of 40%. The specimen preparation process is illustrated in Fig. 3. In accordance with the Chinese standard NB/T 51070-201726, the raw materials were mixed in an SDD-30 concrete mixer for 5 minutes. Subsequently, the mixture was poured into 100 mm×100 mm×100 mm concrete test molds. After 24 hours of curing, the specimens were demolded and transferred to a standard concrete curing room maintained at 20 °C with a relative humidity of 98% for further curing.

Test process

In compliance with Chinese standard NB/T 51070-201714, uniaxial compressive strength measurements were performed on 1-day and 28-day cured specimens, respectively. Figure 4 depicts the testing procedure. For each group, three test blocks were tested, and the results were averaged to a precision of 0.01 MPa. The hydration products of specimens in each group were analyzed via a Smart-Lab X-ray diffractometer (XRD) with a diffraction angle range of 5–75° and a scanning rate of 10°/min. Furthermore, the microtopography of specimens in each group was observed using a scanning electron microscope (SEM).

Uniaxial compressive strength test

This test used the Box–Behnken Design (RSM-BBD) in the Design Expert 8.0.6 software27,28,29. On the basis of the benchmark group, single-factor test was needed to determine the value range of each influencing factor. Respectively, the mass concentration, fly ash content and fine gangue ratio were recorded as X1, X2 and X3. And the response values were the 1-day-old and 28-day-old uniaxial compressive strength of CCGB, as Y1 and Y2.

Single-factor test

The mixing proportions of single-factor test specimens were shown in Table 2. The single-factor test results were shown in Table 3. As the appropriate value range of RSM-BBD test were mass concentration ranging from 80% to 81%, fly ash content ranging from 3kg to 4 kg and fine gangue ratio ranging from 35% to 45%. In this range, the uniaxial compressive strength of CCGB was relatively stable to meet the requirements of early strength and late strength, which was helpful to keep the filling area relatively stable.

RSM-BBD test

Based on single-factor test results, the RSM-BBD test of three-factor-three-level were designed. Table 4 was the levels of factors. Table 5 was the RSM-BBD test results. The regression models of Y1 and Y2 were obtained by the quadratic polynomial nonlinear fitting, as shown in Eqs. (1) and Eqs. (2).

.

Table 6 showed the results of variance analysis for the regression models. A larger F-value and smaller P-value indicate a more significant influence of the factor. Factors with a P-value less than 0.05 are considered significant and could be used for subsequent optimization design. When the P-value for “Lack of Fit” exceeds 0.05, the “Lack of Fit” is deemed non-significant22. The results reveal that the P-value of the regression models was less than 0.01, demonstrating that the regression models exhibit high precision across the entire fitting range.

Results analysis

Effect of single-factor

In Table 6, both Y1 and Y2, the F-values of X1 were the largest. It showed that the mass concentration had a significant effect on uniaxial compressive strength. The larger mass concentration was helped to shorten the particle spacing, then improved the cohesion of CCGB. Therefore, high mass concentration can increase uniaxial compressive strength of CCGB.

For the F-values of X2, increasing the fly ash content can greatly increase uniaxial compressive strength of CCGB. Increasing the fly ash content would improve the particle gradation and the homogeneity of CCGB due to the morphologic effect and the filling effect of fly ash. Due to the large specific surface area of fly ash, more free-water will be absorbed. The micro-aggregate effect of fly ash can improve the cohesion and water-retaining property of the system, and reduce the void fraction, which was conducive to the formation of three-dimensional flocculation structures, so as to improve the uniaxial compressive strength of CCGB.

For the F-values of X3, changing the effect of fine gangue ratio on uniaxial compressive strength was non-significant. Under the same conditions, the content of fine particles in the system was increased with the fine gangue ratio increasing. However, the filling effect was not obvious due to the larger particle size of fine gangue. When the amount of little fine gangue content was small, the cement paste coating cannot be formed in the system and the three-dimensional flocculation structure was unstable. And during the test process, the segregation phenomenon was found to be more obvious. With the increase of the fine gangue ratio, optimizing the aggregate gradation, reducing the particle gap, and building more three-dimensional flocculation structures, then the mechanical properties of CCGB were improved. However, with the further increase of fine gangue ratio, the free-water content of the system reduced and the chemical condensation effect of the hydration reaction of cementing materials weakened. The physical and mechanical properties of CCGB weakened finally.

Interactions of effect factors

In Table 6, the F-values of X1 X2 were the largest which indicated that the significant interaction between mass concentration and fly ash content for uniaxial compressive strength of CGB. Fig. 5 showed that the interaction between mass concentration and fly ash content on the 1-day-old and 28-day-old uniaxial compressive strength of CGB with 40% fine gangue ratio. Keeping the constant fine gangue rate, increasing the mass concentration and fly ash content could reduce the water-binder ratio and introduce a large number of fine particles. It could make the internal particle distribution more uniform, increase the paste saturation rate, keep the three-dimensional flocculation structure tending, and increase the uniaxial compressive strength of CGB. In Fig. 5, the contour was closer to an ellipse. This indicates a more significant interaction between the two factors30,31. Compare with 28-day-old uniaxial compressive strength of CGB, the interaction effect of mass concentration and fly ash content had a greater influence on 1-day-old uniaxial compressive strength. Moreover, the 3D surface of 1-day-old uniaxial compressive strength had a more obvious concave-convex, indicating a more significant interaction with mass concentration and fly ash content22.

Analysis of hydration products

Fig. 6 presents the XRD analysis patterns of CCGB with optimal mix proportions at different curing ages. As illustrated in the figure, the specimens typically contain such cement hydration products as quartz (SiO2), calcium hydroxide (Ca(OH)2), ettringite (AFt), and mullite. In the filling material, Ca(OH)2 originates primarily from two sources: the majority is generated through cement hydration, while a minor portion results from the reaction between free calcium oxide (f-CaO) and water. Consequently, the progression of cement hydration and pozzolanic reactions can be characterized by comparing the Ca(OH)2 crystal content in specimens with optimal mix proportions across different ages.

As observed from Fig. 6, the diffraction peaks of Ca(OH)₂ within the 10°–20° range exhibit relatively high intensity in specimens at early curing stages (1d, 3d), indicating a higher Ca(OH)2 content in specimens at these ages. However, with the elapse of hydration time, the intensity of Ca(OH)2 diffraction peaks (10°–20°) decreases in specimens at the later stage (28d), signifying a gradual reduction in Ca(OH)2 content within the specimens. Given that Ca(OH)2 serves as an essential reactant in the secondary reactions of pozzolanic materials including fly ash and gangue, this phenomenon suggests that the pozzolanic active substances in PASTE mine paste filling materials undergo secondary hydration reactions as hydration proceed.

Fig. 7 showed the microscopic morphology of CCGB at different ages. The fine-needle Aft and hexagonal plate Ca(OH)2 can be obviously found in CCGB at the early hydration time (1-day-old), a large number of needle-bar-granular AFt crystals were formed inside the specimen at the hydration age of 3-day-old to 7-day-old. At the late hydration stage (28-day-old), the content of fine-needle AFt decreased while the content of needle-bar-granular AFt increased and the calcium silicate hydrate (C–S–H) was connected into flocculent reticulate structure. In other words, with the continuous hydration and pozzolanic reaction, the hydration products formed a cohesive structure, blocking pores and enhancing compactness. The uniaxial compressive strength of CCGB improved finally.

Thus, based on the microscopic analysis results, the main hydration process of CCGB can be inferred as follows: On one hand, the hydration reaction of Portland cement generates a large quantity of hydration products. Among them, Ca(OH)2 can act as an activator for the pozzolanic reaction, facilitating its progression. On the other hand, the highly dispersed pozzolanic active substances (such as reactive SiO2) in fly ash and gangue combine with Ca(OH)2 to undergo pozzolanic reaction, producing calcium silicate hydrate gels and calcium aluminate hydrate gels with calcium silicate hydrate as the main component, while promoting the forward progress of cement hydration reaction. In fact, the pozzolanic reaction and cement hydration reaction proceed alternately; they are mutually conditional and restrictive, rather than simply isolated. To a certain extent, the pozzolanic reaction consumes the hydration products of cement and reduces the alkalinity of the filling material, thereby accelerating the cement hydration reaction process. This cycle repeats until the reactants are completely consumed. Based on the above mechanism, the main chemical reaction equations of CCGB can be summarized as shown in Eqs. (3) to (5):

where: x denotes the molar ratio of CaO to SiO2, commonly referred to as the calcium-silicon ratio and abbreviated as C/S.

Conclusions

The main conclusions of this study are summarized as follows:

-

(1)

Through single-factor test, this study determined the appropriate value range of influencing factors: 80%–81% mass concentration, 3kg–4 kg fly ash content, and 35%–45% fine gangue ratio.

-

(2)

Based on the results of 15 groups of tests designed by RSM, the quadratic polynomial regression models between the 1-day-old and 28-day-old uniaxial compressive strength of CCGB were established. The regression coefficients R2 of the regression equation were 0.9672 and 0.9575. Compared to fine gangue ratio, the interaction between mass concentration and fly ash content had a more significant impact on uniaxial compressive strength of CCGB.

-

(3)

At the early stages of hydration, the hydration rate of cement clinker was higher than that of pozzolans reaction. The main hydration products were C–S–H, Ca(OH)2, and fine-needle AFt. With the hydration stages continue, the pozzolanic reaction and cement hydration reaction were alternate rather than simply isolated.

This study investigates 1-day and 28-day UCS of CCGB via RSM. Research efforts could be extended to investigate the UCS of CCGB by incorporating other types of solid wastes, including steel slag, furnace slag, tailings, and construction debris. Activating the potential cementitious properties of industrial solid wastes such as gangue and fly ash would significantly advance the resource-oriented reuse of solid wastes. The regression models constructed via RSM-BBD and the optimized mix proportions of CCGB are only applicable to the value ranges of each factor specified in this study. For specimens with alternative mix proportions, the appropriate range of factor levels needs to be redefined.

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request. All data, models, and code generated or used during the study appear in the submitted article.

References

Yin, S. et al. A systematic review of paste technology in metal mines for cleaner production in China. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2019.11959 (2020).

Tan, Y. et al. Study of the spatial strength distribution patterns and microstructure characteristics of ultra-fine tailings cemented paste backfill. Sci. Rep. https://doi.org/10.1038/s41598-024-83816-3 (2025).

Du, X. et al. Failure characteristics of large unconfined cemented gangue backfill structure in partial backfill mining. Constr. Build. Mater. 194, 257–265. https://doi.org/10.1016/j.conbuildmat.2018.11.038 (2019).

Ai, C. et al. Analysis of physical characteristics and mechanism of retarder to stratified cemented backfill. Sci. Rep. https://doi.org/10.1038/s41598-024-64507-5 (2024).

Liao, X. et al. New development and prospect of backfill mining theory and technology. J. China Univ. Min. Technol. 44 (03), 391–399. https://doi.org/10.13247/j.cnki.jcumt.000330 (2015).

Hu, B. et al. Review and development status of backfill coal mining technology in China. Coal Sci. Technol. 48 (09), 39–47. https://doi.org/10.13199/j.cnki.cst.2020.09.004 (2020).

Liu, J., Li, X. & He, T. Application status and the prospect of backfill mining in Chinese coal mines. J. China Coal Soc. 45 (01), 141–150. https://doi.org/10.13225/j.cnki.js.YG19.1063 (2020).

Zhang, X. et al. Experimental research for influencing factors on properties of paste fillings materials. J. Shandong Univ. Sci. Technol. 31 (03), 53–58. https://doi.org/10.16452/j.cnki.sdkjzk.2012.03.007 (2012).

Lu, P. Design of strength of cemented backfill pillar. Jiangxi Nonferrous Met. 2 (13), 48–53. https://doi.org/10.13264/j.cnki.ysjskx.1990.02.013 (1990).

Dong, W. Study on cement mortar fluidity and compressive strength by different aeolian sand dosage. Bull. Chin. Ceram. Soc. 32 (09), 1900–1904. https://doi.org/10.16552/j.cnki.issn1001-1625.2013.09.010 (2013).

Mamadou, F. & Mukesh, P. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 32 (10), 819–828. https://doi.org/10.1016/j.cemconcomp.2010.08.002 (2010).

Shi, J. et al. Experimental research on mechanical properties of Gangue-Paste backfill material in mine. Min. Metall. Eng. 34 (05), 10–13. https://doi.org/10.3969/j.issn.0253-6099.2014.05.003 (2014).

Zhang, T. et al. Experimental investigation on Coaras materal gradation optimization of gangue paste. J. Xi’an Univ. Sci. Technol. 37 (04), 492–499. https://doi.org/10.13800/j.cnki.xakjdxxb.2017.0407 (2017).

Sandeep, P., Debasis, D. & Sreenivas, T. Variability in the rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 29 (9), 2211–2220. https://doi.org/10.1016/j.apt.2018.06.005 (2018).

Wang, H. et al. Using coupled Rheometer-FBRM to study rheological properties and microstructure of cemented paste backfill. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2019/6813929 (2019).

Kou, Y. et al. Rheological properties of cemented paste backfill with Alkali-Activated slag. Minerals. 10 (3). https://doi.org/10.3390/min10030288 (2020).

Zhao, Y. et al. Characterization of coarse aggregate morphology and its effect on rheological and mechanical properties of fresh concrete. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2021.122940 (2021).

Cavusoglu, I., Yilmaz, E. & Yilmaz, A. O. Additivity effect on properties of cemented coal fly Ash backfill containing water-reducing admixtures. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2020.121021 (2020).

Feng, G. et al. Mix ratio optimization of cemented coal gangue backfill (CGB) based on response surface method. J. Residuals Sci. Technol. 13(03),175–184. https://doi.org/10.12783/issn.1544-8053/13/3/1.

Zhao, X. et al. Mix proportion and microscopic characterization of coal-based solid waste backfill material based on response surface methodology and multi-objective decision-making. Sci. Rep. https://doi.org/10.1038/s41598-024-56028-y (2024).

Khan, M. I. et al. Design optimization and statistical modeling of cementitious Grout containing irradiated plastic waste and silica fume using response surface methodology. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2020.121504 (2021).

Zhu, L. et al. Rheological properties of cemented coal gangue backfill based on response surface methodology. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2021.124836 (2021).

Yin, S. et al. Study on strength regression and slurry optimization of cemented backfill based on response surface method. J. Cent. South. Univ. (Sci. Technol.). 51 (06), 1595–1605. https://doi.org/10.11817/j.issn.1672-7207.2020.06.014 (2020).

Hou, Y. et al. Analysis of strength growth law of mixed aggregate cemented backfill based on BBD response surface method. Mater. Rep. 34 (07), 14063–14069 (2020). https://doi.org/10.11896/cldb.19070227.

Chinese Building Industry Standard. Technical Specification for Construction of Concrete Pumping, JGJ/T 10-2011 (Beijing, 2011).

Chinese Energy Industry Standard, Method of material testing of paste filling in mines, NB/T 51070-017, Beijing, China (2017).

Wu, A. et al. Optimization of flocculation and settling parameters of tailings slurry by response surface methodology. Miner. Eng. https://doi.org/10.1016/j.mineng.2020.106488 (2020).

del Barco Carrion, A. J. et al. Optimisation of liquid rubber modified bitumen for road pavements and roofing applications. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2020.118630 (2020).

Niroshan, N., Sivakugan, N. & Veenstra, R. L. Laboratory study on strength developmentin cemented paste backfills. J. Mater. Civ. Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001848 (2017).

Sun, Q. et al. Study of localized deformation in geopolymer cemented coal gangue-fly Ash backfill based on the digital speckle correlation method. Constr. Build. Mater. 215, 321–331. https://doi.org/10.1016/j.conbuildmat.2019.04.208 (2019).

Li, Q. et al. The dosage of superplasticizer in cemented coal waste backfill material based on response surface methodology. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2019/5328523 (2019).

Acknowledgements

This work was supported by the Natural Science Foundation of Henan Province of China (222300420123).

Author information

Authors and Affiliations

Contributions

Z.Z.: Writing-original draft, experiments-designing and performing, data analysis, verification results. K.D.: Writing-reviewing, methodology, conceptualization, data curation. Z.J.: Writing-review and editing, supervision, project administration, investigation. T.S.: Data curation, funding acquisition. Y.H.: Formatted the manuscript, organized references, prepared submission files.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, Z., Deng, K., Jin, Z. et al. Uniaxial compressive strength of cemented coal gangue backfill based on response surface methodology. Sci Rep 15, 29837 (2025). https://doi.org/10.1038/s41598-025-14635-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-14635-3