Abstract

Poly(ether-ether-ketone) (PEEK) is a high-performance thermoplastic with excellent mechanical strength, thermal stability, and chemical resistance, making it attractive for applications like biomedical implants and prostheses. However, neat PEEK suffers from a high friction coefficient and pronounced wear in sliding contacts. In this work, composites of PEEK with Cobalt-Chromium (CoCr) alloy powder were fabricated by centrifugal powder compaction and vacuum sintering. Four composite compositions, with weight percentages of 10%, 20%, 30%, and 40% of CoCr, were produced. Scanning electron microscopy analysis confirmed uniform dispersion of CoCr particles within the PEEK matrix. Differential scanning calorimetry and thermogravimetric analysis showed that CoCr addition did not significantly alter PEEK’s melting temperature or thermal stability. Microhardness increased with filler loading, with the 40% CoCr composite achieving a 40% hardness improvement over neat PEEK. Ball-on-disk tests against steel revealed that all composites exhibited significantly reduced wear loss by 84% compared to neat PEEK, while maintaining a friction coefficient typical for PEEK-steel contacts. Overall, the PEEK/CoCr composites demonstrate enhanced hardness and wear resistance while retaining PEEK’s favorable thermal properties, suggesting their potential for applications requiring better tribological performance than unfilled PEEK.

Similar content being viewed by others

Introduction

Polymer-metal composites represent a significant advancement in materials science, offering unique combinations of properties that cannot be achieved by either constituent alone. Among high-performance thermoplastics, PEEK has garnered substantial attention due to its exceptional thermal stability, mechanical strength, and chemical resistance, which make it suitable for high-demand applications such as aerospace, automotive, and biomedical devices1,2,3. Particularly in orthopedics and dentistry, PEEK has gained popularity due to its favorable biocompatibility, radiolucency, and sterilization resistance2,4,5,6. Despite these advantages, neat PEEK demonstrates poor tribological behavior under dry sliding conditions, including a high coefficient of friction (COF) and substantial wear, limiting its service life in load-bearing or articulating components7,8,9,10.

To overcome these limitations, researchers have developed various PEEK-based composites by incorporating functional fillers aimed at improving frictional and wear behavior. These can be broadly categorized into solid lubricants, ceramic reinforcements, fiber reinforcements, and metallic fillers11,12,13,14,15,16,17. Among solid lubricants, polytetrafluoroethylene (PTFE), graphite, and molybdenum disulfide (MoS₂) have been widely used to reduce COF by forming transfer films during sliding9,15,18. For example, Burris et al.19 showed that PEEK/PTFE composites achieved ultralow wear rates (2 × 10⁻⁹ mm³/N·m) and a low COF (0.12). Similarly, carbon fiber/PTFE/graphite hybrid composites have achieved COF values below 0.2 against Co-Cr alloy surfaces20.

Ceramic fillers such as titanium dioxide (TiO₂), alumina (Al₂O₃), and silica (SiO₂) significantly improve hardness and wear resistance due to their intrinsic rigidity and load-bearing capabilities21,22. Titanium-based ceramic composites have been effectively used in biomedical crowns and load-bearing implants23. Fiber reinforcements, especially carbon and glass fibers, provide substantial improvements in strength and stiffness, although often at the cost of increased brittleness and anisotropy24,25,26.

Metallic fillers present a relatively underexplored but promising route to enhance both the mechanical and thermal properties of PEEK. Metals such as silicon, titanium, and aluminum offer improved dimensional stability, thermal conductivity, and surface hardness21,27. Oladele et al.28 provided a comprehensive review of polymer composites, emphasizing the potential of metallic fillers to improve mechanical strength and durability for structural applications. Goyal et al.29 demonstrated that the incorporation of aluminum nitride particles into PEEK significantly enhanced its thermomechanical properties, including glass transition temperature and modulus. Ochoa-Putman et al.30 emphasized the critical role of interfacial adhesion in determining the mechanical performance of polymer-metal composites, highlighting how chemical treatment of metal surfaces improves compatibility with polymer matrices. Furthermore, Dobrzańska-Danikiewicz et al.31 explored processing techniques for polymer-metal composites and noted that conventional methods often result in non-uniform dispersion of metal fillers, adversely affecting structural integrity. More specifically, Thiruchitrambalam et al.32reviewed the current state and future prospects of metal-reinforced PEEK composites, identifying processing challenges and potential applications. However, as observed by Siraj et al.7systematic investigations into the tribological properties of metal-reinforced PEEK composites remain limited. Notably, CoCr alloys are established biomaterials due to their wear resistance, corrosion resistance, and proven biocompatibility, making them ideal candidates for reinforcing polymers intended for medical applications33,34,35. Li et al.36 characterized the microstructure of biocompatible CoCr alloys, highlighting their potential for medical implants. Wu et al.37 investigated the properties of CoCr dental alloys fabricated via selective laser melting, demonstrating superior mechanical performance compared to conventional casting methods. In the context of composite materials, Senra et al.38 explored the potential of CoCr-reinforced polymers for biomedical applications, reporting enhanced bioactivity and mechanical properties. The superior wear resistance of CoCr alloys, as documented by Yan et al.39 suggests their potential as reinforcement materials for improving the tribological performance of polymers.

Previous work on PEEK composites has primarily focused on improvements achieved through carbon fibers, ceramic reinforcements, and hybrid lubricating fillers, but these approaches have notable limitations. Short carbon fibers (10–30%) can reduce wear rates by up to an order of magnitude compared to neat PEEK by carrying contact loads and suppressing plastic deformation, though excessive fiber contents (> 30%) can lead to embrittlement and abrasive damage to counterfaces40. Nano-silica fillers have been shown to lower friction by acting as rolling elements and by smoothing the polymer transfer film, but agglomeration above 10 vol% often causes crack initiation and elevated wear41.

Although a few hybrid composite studies have combined CoCr with solid lubricants like hexagonal boron nitride to balance hardness and lubricity, the independent contribution of CoCr to PEEK’s tribological and thermal behavior remains largely unexplored42,43,44. Ma et al.45 demonstrated the potential of hard fillers to improve microhardness by 19% using calcium silicate, but there are no studies that have systematically examined PEEK/CoCr binary systems. Moreover, understanding the role of metal content in influencing thermal stability and crystallinity is critical for expanding the applicability of these composites to more demanding environments.

In terms of characterization, Doumneg et al.8,46 employed thermal analysis techniques to study the crystallization behavior of PEEK composites, while Puhan et al.8,46 conducted comprehensive tribological assessments of PEEK-based materials under various wear modes. Beckford et al.15 investigated the effect of ceramic particles on the tribological characteristics of PEEK, providing valuable insights into wear mechanisms. Rui et al.47 demonstrated that powder metallurgy techniques, including compaction and sintering, enable the incorporation of high-volume hydroxyapatite fillers into polymer without degrading the polymer matrix, achieving uniform dispersion and enhanced bioactivity.

Traditional processing methods like melt compounding, compression, and injection molding often lead to issues such as particle agglomeration and weak interfacial bonding32. Advanced processing techniques have been developed to address the challenges associated with polymer-metal composites. Tsukamoto demonstrated that centrifugal casting could effectively distribute carbon nanotubes in metallic matrices, suggesting its potential for polymer-metal systems48. Similarly, Lu et al.49 optimized processing parameters for CF/PEEK composites, highlighting the importance of controlling the thermal history to achieve the desired properties. Although centrifugal powder compaction is known to improve filler dispersion, its use with PEEK/CoCr composites has not been well studied. This work applies the method to evaluate its effectiveness in enhancing structure and properties for these systems50.

This study aims to investigate the microstructural, thermal, mechanical, and tribological characteristics of PEEK/CoCr composites fabricated by powder centrifugal compaction and vacuum sintering. Four compositions, PC(10), PC(20), PC(30), and PC(40), containing 10%, 20%, 30%, and 40% of CoCr by weight, respectively, were synthesized and characterized using scanning electron microscopy with energy-dispersive spectroscopy, differential scanning calorimetry, thermogravimetric analysis, microhardness testing, and ball-on-disk tribometry. By focusing on a binary PEEK/CoCr system, this research fills a critical gap in the literature and evaluates the potential of metal-filled PEEK composites for advanced engineering and biomedical applications where enhanced wear resistance and hardness are required without compromising thermal stability.

Experimental

Materials

Polyetheretherketone (PEEK) powder (Victrex 450PF, UK) and cobalt-chromium (CoCr) alloy powder (MSE Supplies, USA) were employed as the base materials in this study. The particle size distribution (PSD) of both powders was measured by laser diffraction using a Mastersizer 3000 with an Aero S dry powder disperser operating at 1 bar (Malvern Panalytical, UK). The median particle diameter of the PEEK powder was determined to be approximately 38 μm. For the CoCr powder, the PSD analysis yielded D10 = 40.5 μm, D50 = 62.4 μm, and D90 = 86.1 μm, indicating a relatively broad particle size distribution. These percentile values correspond to the particle diameters below which 10%, 50%, and 90% of the total volume of particles are found, respectively. The span S, a parameter commonly used to characterize distribution width, was calculated using the formula:

The morphology of the CoCr powder, observed using a scanning electron microscope (SEM), is shown in Fig. 1.

Composite Preparation

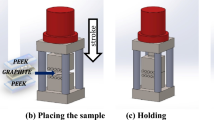

PEEK and CoCr powders were measured and premixed in proportions to yield 10%, 20%, 30%, and 40% by weight of CoCr. The weight and corresponding volume fractions of PEEK and CoCr are presented in Table 1. The prepared powder mixtures were inserted into the aluminum dies and loaded into the centrifugal machine [Allegra X-14 Beckman Coulter Inc. Brea, USA]. The powder mixture in the die, tilted along the horizontal axis, was subjected to a centrifugal force of 3000 G for 180 min. This method promotes uniform blending of the dense metal particles with the lighter polymer powder while simultaneously compacting the mixture. After mixing, the compacted powder blends were molded and sintered. Sintering was carried out in a vacuum furnace to avoid oxidation of the metal. The specimens were slowly heated to 360 °C, slightly above the melting temperature of PEEK 343 °C, and held for a duration for 30 min, to ensure complete melting of PEEK matrix and encapsulation the metal particles. Then the specimens cooled down slowly to minimize residual stresses. The sintered composites were removed and cut into test samples for further characterization.

Characterization methods

The fabricated PEEK/CoCr composites were sectioned for microstructural analysis using a wet abrasive cut-off machine (Brillant 220, QATM, Mammelzen, Germany). The cross-sectional surfaces were subsequently polished using a series of silicon carbide abrasive papers with grit sizes of 800, 1200, and 2500, followed by fine polishing with alumina suspensions of 1 μm, 0.3 μm, and 0.05 μm particle sizes. Microstructural characterization was performed using a scanning electron microscope (JSM-IT200, JEOL, Japan) operated at an accelerating voltage of 15 kV in secondary electron mode. Prior to imaging, a thin conductive gold layer (~ 5 nm) was sputter-coated onto the samples to facilitate high-resolution SEM and Energy Dispersive X-ray Spectroscopy (EDS) analysis.

Thermogravimetric analysis (TGA) was conducted using STA 449 thermal analyzer (Netzsch, Germany) to determine the thermal decomposition behavior of both neat PEEK and its CoCr-filled composites. The measurements were carried out under a nitrogen atmosphere with a constant heating rate of 10 °C/min, ranging from 30 °C to 1000 °C, followed by a 90-minute isothermal hold at the maximum temperature.

Differential scanning calorimetry (DSC) was performed using a 300 Caliris Supreme analyzer (Netzsch, Germany) to evaluate the melting behavior and degree of crystallinity of the materials. Approximately 10 mg of each sample was heated from 30 °C to 500 °C at a constant rate of 10 °C/min under a nitrogen atmosphere.

Based on the difference in melting enthalpy of the crystalline region and amorphous region, the crystallinity Xc can be calculated according to the following equation51:

where ΔHm is the melting enthalpy of PEEK or PEEK/CoCr composites, and ΔH⁰ is the enthalpy of 100% crystalline PEEK (ΔH⁰=130 J/g).

Vickers microhardness (Shimadzu HMV-G31) testing was conducted on the polished cross-sections using a standard microhardness tester. A load of 10 N was applied with a dwell time of 10 s for each indentation. Ten measurements were taken for each sample at randomly selected regions, carefully avoiding direct indentation on large metal particles. The Vickers hardness (HV) was calculated based on the diagonal lengths of the indentations, and average values with standard deviations were reported.

All tribological tests were conducted in a laboratory environment under dry sliding conditions. The ambient temperature and relative humidity were maintained at approximately 26 °C and 12%, respectively. A ball-on-disk tribometer (Anton Paar, Austria) was used to evaluate the friction and wear behaviour in a reciprocating sliding configuration in accordance with ASTM G99. The counterface was a steel ball (AISI 52100) with a diameter of 6 mm, sliding against a flat sample surface. The test setup had a radius of 10 mm and a reciprocating angle of 10°, generating linear back-and-forth motion. The sliding frequency was set at 2.00 Hz, corresponding to a maximum linear speed of 0.99 cm/s. A constant normal load of 10 N was applied during testing, and the sliding motion was carried out for 5000 cycles. The apparent coefficient of friction was calculated as the ratio of the measured frictional force to the applied normal load, allowing for the evaluation of frictional behavior under controlled and repeatable conditions.

Results and discussion

Composite morphology and interfacial characteristics

The microstructural evolution of PEEK/CoCr composites with varying metallic content was systematically examined using SEM. Figure 2 displays representative SEM images of PC(10), PC(20), PC(30) and PC(40) composites. It is noteworthy that during sectioning and polishing, partial detachment of CoCr particles occurred, leading to the formation of hollows on the polished surfaces.

The incorporation of CoCr particles leads to substantial changes in microstructural features across the composition range. In PC(20) (Fig. 2b), spherical metallic particles ranging from approximately 5 to 50 μm are uniformly embedded in the PEEK matrix, with minimal signs of agglomeration. The particle-matrix interfaces appear clearly defined, suggesting interfacial diffusion or bonding during the sintering process.

With increasing CoCr content in PC(30) (Fig. 2c), a notable increase in particle number density is observed, accompanied by a reduction in interparticle spacing. Nevertheless, the distribution remains relatively uniform, indicating that centrifugal compaction effectively mitigates particle clustering even at elevated filler contents. In PC(40) (Fig. 2d), the highest particle concentration is achieved, and instances of particle-particle contact become more frequent. This may indicate the onset of a percolation threshold, wherein the metallic phase begins to form quasi-continuous networks within the polymer matrix.

Higher magnification SEM analysis (Fig. 1) reveals significant morphological details of the CoCr particles. Many particles exhibit internal porosity and complex surface textures, likely originating from the powder metallurgy process used for their fabrication. Some particles display crater-like surface indentations and protuberances, which could contribute to mechanical interlocking with the surrounding PEEK matrix, thereby enhancing interfacial bonding and mechanical performance. The preservation of particle sphericity throughout all composite formulations implies that the processing conditions of powder compaction were sufficiently controlled to prevent deformation or fragmentation of the metallic phase. Such morphological uniformity is essential for ensuring consistent mechanical and thermal behavior of the composite system. Furthermore, the lack of visible interfacial gaps suggests good wetting and adhesion between the polymer matrix and the CoCr reinforcement, which is critical for efficient stress transfer in load-bearing applications.

Further high-resolution SEM observations (Fig. 3) provide insight into the interface between CoCr particles and the PEEK matrix. CoCr particle surfaces exhibit varied microscale roughness, which may facilitate mechanical interlocking with the thermoplastic matrix.

Detailed inspection reveals localized zones of intimate contact between the matrix and CoCr particles. These regions represent potential sites of enhanced interfacial bonding. Notably, the CoCr particles exhibit excellent shape transcription within the PEEK matrix, indicating no deformation or smearing during processing and suggesting strong micromechanical interlocking at the interface, as indicated by arrows. Interfacial adhesion, internal porosity, and particle morphology are key microstructural features expected to strongly influence the mechanical response of the composites.

DSC analysis

The curves and results of DSC analysis for PEEK and PEEK/CoCr composites are presented in Fig. 4; Table 2. These results indicate that both PEEK and its composites exhibit a melting range rather than a sharp melting point, which is typical of semi-crystalline polymers. The variation in crystal size and perfection leads to melting over a range of temperatures, with PEEK typically exhibiting melting between 290 and 360 °C. The melting point of neat PEEK was determined to be approximately 343 °C, a value that remains unchanged with the incorporation of CoCr.

The melting behavior of PEEK/CoCr composites shows that the inclusion of metallic reinforcement does not significantly shift the melting point but does impact the enthalpy of fusion and, thus, the degree of crystallinity. For instance, the melting enthalpy (ΔHₘ) for neat PEEK was measured at 53 J/g, which corresponds to a crystallinity of 41%. In contrast, PEEK composites with 10%, 20%, 30%, and 40% CoCr exhibited ΔHₘ values of 48.3 J/g, 48.5 J/g, 49.2 J/g, and 49.3 J/g, resulting in crystallinity levels of 37%, 37%, 38%, and 38%, respectively.

It is important to note that the CoCr alloy particles do not contribute directly to the endothermic melting peak in the DSC scans. CoCr is thermally inert in the measurement range, as its melting point (1380–1420 °C) lies well beyond both the melting temperature of PEEK (343 °C) and PEEK’s decomposition onset (520 °C). The filler’s effect on crystallinity is therefore indirect, arising from the reduced PEEK fraction and restricted chain mobility, which slightly lower the enthalpy of fusion and degree of crystallinity, as reflected in Table 2.

While DSC provides a reliable bulk measure of crystallinity, complementary techniques such as X-ray Diffraction (XRD) or Raman spectroscopy can yield additional insights into surface crystalline lattice structure. Recent studies have demonstrated that DSC may slightly overestimate PEEK’s absolute crystallinity due to overlapping thermal transitions, whereas XRD can underestimate crystallinity because of amorphous halo overlap, Raman offers localized structural information and often correlates well with bulk techniques52,53,54. Future studies incorporating XRD or Raman spectroscopy alongside DSC would provide a more complete picture of crystallinity in PEEK/CoCr composites.

TGA analysis

TGA was performed under a nitrogen atmosphere to investigate the thermal stability and resin content of PEEK and PEEK/CoCr composites. The TGA curves are presented in Fig. 5, and the corresponding residual mass data are summarized in Table 3.

All samples of PEEK and PEEK/CoCr composites exhibited a characteristic weight loss starting at approximately 520 °C, in agreement with typical decomposition behavior of PEEK-based materials55. A rapid mass loss was observed in the range of 550–620 °C, indicating the primary decomposition phase, which is attributed to the cleavage of aromatic ether and ketone bonds in the PEEK backbone. As the temperature increased, this bond dissociation was accelerated by radical-induced chain scission, leading to the evolution of volatile decomposition products such as CO, CO₂, and low molecular weight phenolics51.

Beyond 620 °C, the decomposition rate gradually decreased and stabilized after approximately 750 °C, marking the transition to a residual carbonaceous phase and thermally stable inorganic components.

Notably, PEEK exhibited the highest total weight loss, retaining approximately 54% of its original mass at 800 °C. In contrast, the PEEK/CoCr composites exhibited a progressive increase in residual mass with higher CoCr content. At 800 °C, the PC(10), PC(20), PC(30), and PC(40) samples retained 63%, 67%, 73%, and 76% of their original mass, respectively. This trend confirms the presence and high thermal stability of the CoCr filler, which remains undegraded within the evaluated temperature range.

The thermal degradation process can be divided into four stages. From 25 to 520 °C, the material remains stable with minimal mass loss. Between 520 and 620 °C, rapid decomposition occurs due to volatile product release. From 620 to 750 °C, the degradation rate slows as stable residues form. Above 750 °C, the process stabilizes, with no further significant mass change due to the presence of thermally inert residues like carbonized matrix and CoCr.

Microhardness investigation

Figure 6 presents the microhardness values of neat PEEK and PEEK/CoCr composites as a function of cobalt-chromium filler content. The hardness increases from 26.5 HV for unfilled PEEK to 28.3 HV, 31.5 HV, 32.0 HV, and 37 HV for PC(10), PC(20), PC(30), and PC(40), respectively. This represents a maximum hardness enhancement of approximately 40% in PC(40) compared to the pristine matrix.

The incorporation of 10% filler in PC(10) resulted in an initial 6.8% improvement, followed by a more pronounced increase of 19% and 21% for PC(20) and PC(30) respectively. Further increasing the CoCr content in PC(40) led to a significant 40% improvement over neat PEEK, highlighting the continued reinforcement effect at higher loadings.

The overall increase of 40% in PC(40) aligns well with previously reported results for PEEK composites filled with 40wt% ceramic reinforcements (Al₂O₃), which demonstrate comparable improvements in microhardness56.

The observed increase in microhardness of the PEEK/CoCr composites may be primarily attributed to the higher intrinsic hardness of the CoCr alloy (approximately 450 HV) compared to that of the PEEK matrix (26.5 HV). The incorporation of hard metallic particles within the softer thermoplastic matrix effectively constrains local plastic deformation under indentation. In addition, the relatively uniform dispersion of CoCr particles and the decrease in interparticle distance with increasing filler loading contribute to enhanced indentation resistance. As the metallic content rises, the spatial proximity of CoCr particles within the matrix increases, forming a more interconnected reinforcing network that impedes localized deformation.

To support the experimental findings, the microhardness of the composites was also predicted using a modified Halpin-Tsai model, which is commonly used in micromechanics to estimate the effective mechanical properties of composite materials57. In this adaptation, the modulus terms are substituted with hardness values, as follows56:

where Hc is the predicted composite hardness, Hm and Hf are the matrix and filler hardnesses, respectively, Vf is the filler volume fraction, η = [(Hf/Hm − 1)/(Hf/Hm + \(\:\xi\:\))] and \(\:\xi\:\) = 1 (spherical particles).

Experimental and predicted (from Eq. 3) microhardness values of neat PEEK, PC(10), PC(20), PC(30) and PC(40) composites.

A comparison between the experimentally measured and Halpin-Tsai-predicted hardness values is presented in Fig. 6. While the model accurately reflects the increasing trend in hardness with filler loading, it underestimates the absolute values by a margin that grows with increasing CoCr content. The differences between experimental and predicted values ranged from 3.6 HV for PC(10) to 8.5 HV for PC(40), suggesting that the Halpin-Tsai model, although useful as a first approximation, does not fully capture the complexity of the reinforcement mechanisms involved. These deviations can be attributed to factors not accounted for in the analytical model, such as enhanced interfacial adhesion, localized micromechanical interlocking, crystallinity changes in the PEEK matrix, and possible particle-particle interaction. Moreover, as the filler content approaches the percolation threshold, the formation of quasi-continuous metallic reinforcement networks may further amplify the resistance to deformation.

Tribological assessment

Friction

Figure 7 presents the evolution of friction coefficients for PEEK composites with varying filler contents over 5000 sliding cycles. All materials exhibited characteristic tribological behavior with an initial running-in period followed by steady-state friction regimes.

Neat PEEK demonstrated a relatively stable friction coefficient starting at approximately 0.177 and gradually decreasing to 0.17 by test completion. This behavior aligns with previous studies on PEEK materials, which typically exhibit friction coefficients of 0.18–0.2 against steel counterfaces13,18. The observed reduction in friction coefficient during extended cycling suggests the development of plastic deformation, a phenomenon well-described for PEEK-based materials8. A key factor in PEEK’s tribological performance is the formation of a stable transfer film on the counterface. PEEK is a semi-crystalline polymer that can transfer a thin layer to the mating surface during sliding, which in turn helps reduce friction and wear. Studies have shown that maintaining a robust transfer layer is critical for minimizing wear, especially in high-pressure or long-life applications, as the absence or thinning of the film under severe conditions can lead to metal-on-polymer contact and higher wear58.

The PEEK/CoCr composites demonstrated distinct frictional responses depending on filler concentration. PC(10) exhibited the highest steady-state coefficient of friction (µ ≈ 0.183) along with a gradually increasing trend over time. This behavior suggests that the filler content is insufficient to provide effective load-bearing support, resulting in limited improvement in tribological performance. This observation is consistent with literature findings that reinforcing fillers, particularly at low concentrations, may not provide adequate load distribution to significantly alter wear mechanisms from the adhesive and abrasive modes typically observed in neat PEEK41. In contrast, PC(20) achieved a lower and more stable COF (µ ≈ 0.182), indicating a more favorable filler-to-matrix ratio that enhances frictional stability under dry sliding conditions. This improvement can be attributed to better load distribution through the composite structure, as the CoCr particles begin to carry a portion of the contact load and help prevent large-scale plastic deformation of the PEEK matrix.

Higher filler concentrations in PC(30) and PC(40) yielded progressively lower friction coefficients µ ≈ 0.18 and µ ≈ 0.175, respectively. This mild decrease can be attributed to the increased surface hardness reducing the real contact area and adhesive junctions at the interface, because the CoCr particles themselves do not provide any solid lubrication, the overall friction levels remain moderate. Notably, the PC(40) sample showed more frequent friction fluctuations during sliding, indicating slight instabilities in the tribolayer at the highest filler loading. This is due to the micro-scale inhomogeneities and occasional protruding metal particles causing intermittent metal-metal contacts, a phenomenon also reported in other highly filled PEEK composites where excessive filler leads to uneven contact conditions and can weaken the composite structure13.

Unlike composites with solid lubricant fillers or carbon fibers that show dramatic friction reductions, the CoCr-filled PEEK composites maintained friction coefficients within the typical PEEK-steel range (0.17–0.183). This indicates that CoCr particles provide mechanical reinforcement through increased hardness but do not fundamentally alter the sliding mechanism or provide lubricious properties like graphite, PTFE, or carbon fibers58,59,60. The hard CoCr particles likely create a more heterogeneous contact interface with localized metal-metal contact points compared to the continuous polymer transfer films formed by neat PEEK. This explains the moderate friction levels across all compositions and the increased fluctuations in PC(40), where protruding particles cause intermittent direct metal contact.

In summary, adding CoCr up to 40% produces no drastic change in COF, with all samples maintaining friction in the expected PEEK-steel range. The gradual reduction with increasing filler content reflects improved load distribution and surface hardness rather than fundamental lubrication changes, highlighting that filler selection should match the intended tribological function.

Wear performance analysis

Figure 8 presents SEM micrographs of the worn surfaces of neat PEEK and its composites after dry sliding against stainless steel. The worn surface of neat PEEK, shown in Fig. 8(a, b), displays a characteristic combination of abrasive and adhesive wear mechanisms. Pronounced ploughing grooves and wedge-like formations indicate the prevalence of adhesive interactions, where localized material transfer and plastic deformation dominate. The central region of the wear track exhibits distinct wedge-shaped features, resulting from the reattachment of loosened wear debris back onto the polymer surface. This re-deposition is attributed to the cyclic loading and unloading during reciprocating motion at low sliding speeds, which promotes the entrapment and compaction of flaky debris within the tribological contact. Additionally, interaction with the hard asperities of the stainless steel counterface induces micro-cutting, leading to the removal of material in the form of fine flakes or wear particles. Such combined wear behavior is typical for unfilled PEEK in dry sliding conditions, where severe plastic deformation and adhesive interaction can also induce microstructural changes in the polymer due to frictional heating and shear.

In contrast, the PEEK/CoCr composite samples display markedly improved wear surfaces with a significant reduction in adhesive wear features. PC(10) exhibited severely damaged surface regions and relatively larger metallic wear debris compared to PC(20) after the sliding test. Unlike neat PEEK, the composite surfaces showed no evident signs of adhesive wear under dry sliding conditions. This improvement is attributed to the presence of CoCr filler particles, which act as protective reinforcements, shielding the polymer matrix from direct interaction with the hard asperities of the stainless steel counterface and thereby reducing the wear loss. This shifts the dominant wear mechanism from adhesive-abrasive in neat PEEK to abrasive wear with filler interactions in composites.

As the filler content increases, the worn surfaces become progressively smoother and show fewer signs of gross damage. The PC(20) composite shows a more uniform wear track with shallower grooves compared to PC(10), and importantly, no obvious adhesive patches or chunks are observed, indicating that the addition of 20% CoCr has largely suppressed the adhesive wear mechanism. Minimal material removal was observed on the wear tracks of PC(30) and PC(40), characterized by relatively smooth and intact surfaces with only shallow grooves and slight localized deposits of wear debris near the trailing edges.

Figure 9 further supports these findings by presenting the mass loss data for all tested compositions. Neat PEEK exhibited a wear mass loss of 19.7 µg/N·m, significantly higher than its reinforced counterparts. The addition of CoCr particles led to a progressive decrease in both wear depth and mass loss, with mass loss values for PC(10), PC(20), PC(30), and PC(40) measured at approximately 11.0, 7.0, 3.3, and 3.1 µg/N·m, respectively. This represents an overall reduction in wear mass of 84% for PC(40) compared to unfilled PEEK, with PC(10) showing nearly a 45% reduction compared to neat PEEK.

However, a diminishing effect was observed at the highest filler concentration: the wear reduction from PC(30) to PC(40) was minimal. This plateau suggests the existence of threshold filler content beyond which additional reinforcement offers a limited tribological advantage. Similar behavior has been reported in other PEEK composite systems. For instance, Yan et al.18 showed that beyond 0.7 wt% GO or 20 wt% MoS₂, additional filler did not significantly reduce wear rates and, in some cases, introduced instability due to poor dispersion or matrix weakening. Once a critical volume fraction of hard particles is reached, the polymer matrix is sufficiently protected such that wear is already minimized, and extra filler has a smaller incremental effect. Extremely high filler fractions may even risk slight wear increases or friction fluctuations due to issues like filler agglomeration or matrix embrittlement.

The trend of decreasing wear with increasing filler content follows the predictions of Archard’s wear law, which correlates wear volume inversely with material hardness under constant load and sliding conditions61. This relationship is corroborated by the progressive increase in microhardness observed with higher CoCr content further confirming the dominance of mechanical reinforcement in governing wear performance. This load-bearing effect is analogous to the role of ceramic or fiber fillers used in other studies to enhance wear resistance of polymers. Lin et al.41 demonstrated that in a PEEK composite coating reinforced with oriented carbon fibers, sliding perpendicular to the fiber direction led to significantly lower friction and wear, because the fibers carried the load and distributed shear stresses more effectively. In a PEEK/CoCr composites, the spherical CoCr particles act in a similar capacity as micro-scale bearings or barriers, reducing the effective contact area of the polymer. In fact, Lin et al.41 found that introducing nanoscale silica particles at a sliding interface helped to reduce adhesion and friction by a “rolling” action of the particles and by preventing direct polymer-steel contact.

The tribological enhancements observed in PEEK/CoCr composites significantly lower wear loss while maintaining a moderate friction coefficient are in good agreement with recent studies on reinforced PEEK systems. As reported by Dhakal et al.40 that adding 10% carbon fiber to PEEK reduced wear and eliminated adhesive failure without substantially altering the friction coefficient. Overall, the materials developed in this study, specifically PC(30) and PC(40), offer valuable combinations of moderate friction (µ ≈ 0.18 − 0.175) and excellent wear resistance. These characteristics make them suitable candidates for numerous tribological applications where extended component lifetime under moderate load conditions is prioritized over extremely low friction.

Conclusions

In this study, PEEK/CoCr composites were successfully fabricated using centrifugal powder compaction and vacuum sintering, and their microstructure, thermal properties, microhardness, and tribological behavior were systematically investigated. The key conclusions are as follows:

-

1.

The centrifugal powder compaction technique effectively dispersed CoCr particles (5–50 μm) within the PEEK matrix, enabling uniform distribution without significant agglomeration or void formation.

-

2.

The addition of CoCr filler up to 40 wt% increased the microhardness of PEEK by approximately 40%, with PC(40) reaching 37 HV compared to 26.5 HV for neat PEEK. This enhancement is primarily attributed to the intrinsic hardness of CoCr and improved interfacial matrix-particle micromechanical interlocking.

-

3.

Thermal analysis confirmed that the inclusion of CoCr particles did not significantly alter the melting temperature of PEEK (343 °C) but resulted in a slight reduction in crystallinity by 3–4%, indicating minimal interference with the polymer’s thermal stability.

-

4.

Tribological testing under dry sliding conditions demonstrated a substantial reduction in wear loss for PEEK/CoCr composites, with up to 84% wear loss reduction in PC(40) compared to neat PEEK. The coefficient of friction remained stable across all compositions (0.17–0.18), showing no lubricating effect from the metallic filler.

-

5.

SEM analysis of worn surfaces revealed a transition from adhesive and abrasive wear mechanisms in neat PEEK to predominantly abrasive wear with reduced plastic deformation in CoCr-filled composites, confirming the reinforcing effect of CoCr particles in wear resistance.

These findings demonstrate that CoCr-filled PEEK can deliver markedly improved hardness and wear resistance while retaining thermal properties and frictional behavior comparable to neat PEEK, making these composites strong candidates for high-load, wear-critical applications. Future studies could investigate the fatigue behavior and long-term stability of these composites and explore hybrid filler systems to simultaneously optimize wear resistance and friction behavior. Additionally, validation in application relevant environments would further support the use of PEEK/CoCr composites in high-performance engineering and biomedical applications.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Kurtz, S. M. PEEK Biomaterials Handbook (William Andrew, 2019).

Kurtz, S. M. & Devine, J. N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 28, 4845–4869 (2007).

Sariyev, B. et al. Thermal properties and mechanical behavior of hot pressed peek/graphite thin film laminate composites. Sci. Rep. 13, 1–12 (2023).

Panayotov, I. V., Orti, V., Cuisinier, F. & Yachouh, J. Polyetheretherketone (PEEK) for medical applications. J. Mater. Sci. Mater. Med. 27, 1–11 (2016).

Naghavi, S. A. et al. Stress shielding and bone resorption of press-fit polyether–ether–ketone (PEEK) hip prosthesis: a sawbone model study. Polym. (Basel). 14, 4600 (2022).

Moharil, S., Reche, A. & Durge, K. Polyetheretherketone (PEEK) as a Biomaterial: An Overview. Cureus 15, (2023).

Siraj, N., Hashmi, S. A. R. & Verma, S. State-of‐the‐art review on the high‐performance Poly (ether ether ketone) composites for mechanical, tribological and bioactive characteristics. Polym. Adv. Technol. 33, 3049–3077 (2022).

Puhan, D. & Wong, J. S. S. Properties of polyetheretherketone (PEEK) transferred materials in a PEEK-steel contact. Tribol Int. 135, 189–199 (2019).

Pedroso, J. M., Enger, M., Bandeira, P. & Magalhães, F. D. Comparative study of friction and wear performance of PEK, PEEK and PEKK binders in tribological coatings. Polymers (Basel) 14(19), 4008 (2022).

González-Castillo, E. I. et al. Thermal and tribo-mechanical properties of high-performance poly(etheretherketone)/reduced graphene oxide nanocomposite coatings prepared by electrophoretic deposition. J. Mater. Sci. 58, 10370–10388 (2023).

Senthil, M. et al. Influence of fillers on the thermal and mechanical properties of biocomposites: an overview. Biofibers and Biopolymers for Biocomposites: Synthesis, Characterization and Properties 111–133 (2020).

Fu, S. Y., Feng, X. Q., Lauke, B. & Mai, Y. W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. B Eng. 39, 933–961 (2008).

Perumal, A., Kaliyamoorthy, R. & Kumar, V. Impact of recovered silicon particles incorporation on tribo-characteristics of a Poly ether ether ketone Polymer composite. High. Perform. Polym. 35, 863–879 (2023).

Nikzad, M., Masood, S. H. & Sbarski, I. Thermo-mechanical properties of a highly filled polymeric composites for fused deposition modeling. Mater. Des. 32, 3448–3456 (2011).

Beckford, S., Wang, Y. A. & Zou, M. Wear-resistant PTFE/SiO2 nanoparticle composite films. Tribol. Trans. 54, 849–858 (2011).

Tanahashi, M. Development of fabrication methods of filler/polymer nanocomposites: with focus on simple melt-compounding-based approach without surface modification of nanofillers. Materials 3, 1593–1619 (2010).

Zaaba, N. F., Ismail, H. & Saeed, A. M. A review: metal filled thermoplastic composites. Polymer-Plastics Technol. Mater. 60, 1033–1050 (2021).

Yan, Y., Jiang, C., Huo, Y. & Li, C. Preparation and tribological behaviors of lubrication-enhanced peek composites. Appl. Sci. (Switzerland). 10, 1–15 (2020).

Burris, D. L. & Sawyer, W. G. A low friction and ultra low wear rate PEEK/PTFE composite. Wear 261, 410–418 (2006).

Zhang, X. et al. Wettability and frictional studies of PEEK composites against Co-Cr alloys with surface textures. Polym. (Basel). 15, 4006 (2023).

Kuo, M. C., Tsai, C. M., Huang, J. C. & Chen, M. PEEK composites reinforced by nano-sized SiO2 and Al2O3 particulates. Mater. Chem. Phys. 90, 185–195 (2005).

Díez-Pascual, A. M. & Díez-Vicente, A. L. Nano-TiO2 reinforced PEEK/PEI blends as biomaterials for load-bearing implant applications. ACS Appl. Mater. Interfaces. 7, 5561–5573 (2015).

Roberts, E. E., Bailey, C. W., Ashcraft-Olmscheid, D. L. & Vandewalle, K. S. Fracture resistance of titanium‐based lithium disilicate and zirconia implant restorations. J. Prosthodont. 27, 644–650 (2018).

Callister, W. D. Jr & Rethwisch, D. G. Materials Science and Engineering: an Introduction (Wiley, 2020).

Zheng, H. et al. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. B Eng. 233, 109639 (2022).

Chawla, K. K. Composite Materials: Science and Engineering (Springer Science & Business Media, 2012).

Zaaba, N. F., Ismail, H. & Saeed, A. M. A review: metal filled thermoset composites. Polymer-Plastics Technol. Mater. 61, 13–26 (2022).

Oladele, I. O., Onuh, L. N., Siengchin, S., Sanjay, M. R. & Adelani, S. O. Modern applications of polymer composites in structural industries: A review of philosophies, product development, and graphical applications. Appl. Sci. Eng. Progress. 17, 6884 (2024).

Goyal, R. K., Tiwari, A. N., Mulik, U. P. & Negi, Y. S. Effect of aluminum nitride on thermomechanical properties of high performance PEEK. Compos. Part. Appl. Sci. Manuf. 38, 516–524 (2007).

Ochoa-Putman, C. & Vaidya, U. K. Mechanisms of interfacial adhesion in metal–polymer composites–Effect of chemical treatment. Compos. Part. Appl. Sci. Manuf. 42, 906–915 (2011).

Dobrzańska-Danikiewicz, A. D., Gaweł, T. G. & Karska, M. Manufacturing of metal-polymer composites for medical applications. Archives Mater. Sci. Eng. 89, 9–19 (2018).

Thiruchitrambalam, M., Kumar, D. B., Shanmugam, D. & Jawaid, M. A review on PEEK composites–Manufacturing methods, properties and applications. Mater. Today Proc. 33, 1085–1092 (2020).

Garcia-Mendez, M. C. et al. In vitro biocompatibility evaluation of a new Co-Cr-B alloy with potential biomedical application. Met. (Basel). 11, 1267 (2021).

Ramirez-Ledesma, A. L., Lopez, H. F. & Juarez-Islas, J. A. Evaluation of chill cast Co-Cr alloys for biomedical applications. Met. (Basel). 6, 188 (2016).

Al Deen, H. H. J. J. Using of CoCr alloys in biomedical applications. Iraqi J. Mech. Mater. Eng. 21, 320–328 (2021).

Li, H., Wang, M., Lou, D., Xia, W. & Fang, X. Microstructural features of biomedical cobalt–chromium–molybdenum (CoCrMo) alloy from powder bed fusion to aging heat treatment. J. Mater. Sci. Technol. 45, 146–156 (2020).

Wu, L., Zhu, H., Gai, X. & Wang, Y. Evaluation of the mechanical properties and porcelain bond strength of cobalt-chromium dental alloy fabricated by selective laser melting. J. Prosthet. Dent. 111, 51–55 (2014).

Senra, M. R., de Marques, M., Monteiro, S. N. & F. V. & Poly (ether-ether-ketone) for biomedical applications: from enhancing bioactivity to reinforced-bioactive composites—an overview. Polym. (Basel). 15, 373 (2023).

Yan, Y., Neville, A. & Dowson, D. Tribo-corrosion properties of cobalt-based medical implant alloys in simulated biological environments. Wear 263, 1105–1111 (2007).

Dhakal, N., Espejo, C., Morina, A. & Emami, N. Tribological performance of 3D printed neat and carbon fiber reinforced PEEK composites. Tribol Int. 193, 109356 (2024).

Lin, L., Ecke, N., Huang, M., Pei, X. Q. & Schlarb, A. K. Impact of Nanosilica on the friction and wear of a PEEK/CF composite coating manufactured by fused deposition modeling (FDM). Compos. B Eng. 177, 107428 (2019).

Zalaznik, M., Kalin, M., Novak, S. & Jakša, G. Effect of the type, size and concentration of solid lubricants on the tribological properties of the polymer PEEK. Wear 364, 31–39 (2016).

Bahadur, S. & Gong, D. The action of fillers in the modification of the tribological behavior of polymers. Wear 158, 41–59 (1992).

Deshwal, D., Belgamwar, S. U., Bekinal, S. I. & Doddamani, M. Critical review of reinforcement effect in PEEK tribology and its usage in biomedical, coating and bearing applications. Polym. Plast. Technol. Mater. 64(8), 1–30 (2025).

Ma, R. & Tang, T. Current strategies to improve the bioactivity of PEEK. Int. J. Mol. Sci. 15, 5426–5445 (2014).

Doumeng, M. et al. Effect of size, concentration, and nature of fillers on crystallinity, thermal, and mechanical properties of polyetheretherketone composites. J Appl. Polym. Sci 139(5), 51574(2022).

Ma, R. & Guo, D. Evaluating the bioactivity of a hydroxyapatite-incorporated polyetheretherketone biocomposite. J. Orthop. Surg. Res. 14, 1–13 (2019).

Tsukamoto, H. Tribological characterization of carbon nanotube/aluminum functionally graded materials fabricated by centrifugal slurry methods. J. Compos. Sci. 5, 254 (2021).

Lu, C. et al. The optimization of process parameters and characterization of high-performance CF/PEEK composites prepared by flexible CF/PEEK plain weave fabrics. Polym. (Basel). 11, 53 (2018).

Sariyev, B., Aldabergen, A., Akzhigitov, D., Golman, B. & Spitas, C. Fabrication of highly compacted green body using Multi-Sized al powder under a centrifugal force. J. Manuf. Mater. Process. 6(4), 79 (2022).

Lu, C. et al. Comparison and analysis of measurements for crystallinity of PEEK and CF/PEEK composites. Polym. Compos. 1–12 https://doi.org/10.1002/pc.29418 (2024).

Prajapati, S. K. & Gnanamoorthy, R. Dry sliding wear behaviour of 3D printed polyetheretherketone with varying layer thickness. J. Manuf. Process. 148, 1–10 (2025).

Doumeng, M. et al. A comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym. Test. 93, 106878 (2021).

Prajapati, S. K. & Gnanamoorthy, R. Effect of the infill percentage of 3D printed polyetheretherketone under the dry sliding condition. J. Manuf. Process. 131, 2073–2081 (2024).

Patel, P. et al. Mechanism of thermal decomposition of poly(ether ether ketone) (PEEK) from a review of decomposition studies. Polym. Degrad. Stab. 95, 709–718 (2010).

Goyal, R. K., Tiwari, A. N. & Negi, Y. S. Microhardness of peek/ceramic micro- and nanocomposites: correlation with Halpin-Tsai model. Mater. Sci. Engineering: A. 491, 230–236 (2008).

Zhu, S., Wu, S., Fu, Y. & Guo, S. Prediction of particle-reinforced composite material properties based on an improved Halpin–Tsai model. AIP Adv. 14(4), 045339(2024).

Rodiouchkina, M. et al. Tribological behaviour and transfer layer development of self-lubricating polymer composite bearing materials under long duration dry sliding against stainless steel. Wear 484, 204027 (2021).

Hou, X., Hu, Y., Hu, X. & Jiang, D. Poly (ether ether ketone) composites reinforced by graphene oxide and silicon dioxide nanoparticles: mechanical properties and sliding wear behavior. High. Perform. Polym. 30, 406–417 (2018).

Burris, D. L. & Sawyer, W. G. Tribological behavior of PEEK components with compositionally graded PEEK / PTFE surfaces. Wear 262(1–2), 220–224 (2007).

Holmberg, K. & Matthews, A. Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineeringvol. 56 (Elsevier, 2009).

Acknowledgements

This research work was funded by the Committee of Science of the Ministry of Education and Science of the Republic of Kazakhstan via grant №AP23488642 “Compact Compliant Resilient Wind turbine architecture (COREWind)” project and grant №AP22686136.

Author information

Authors and Affiliations

Contributions

Conceptualization, B.S.; methodology, B.S.; synthetic materials and performance characterization, B.S., A.M., A.A. and A.K.; investigation, B.S. and A.A.; resources, A.M. and A.A.; data curation, B.S. and A.A.; writing of the original draft preparation, B.S., A.K. and A.M.; writing of review and editing, B.S., B.G. and H.J.R.; visualization, B.S., H.J.R.; supervision, B.G. and C.S.; project administration, B.G. and C.S.; funding acquisition, A.A. and C.S.; All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sariyev, B., Amrin, A., Mergenbay, A. et al. Thermal, hardness, and tribological assessment of PEEK/CoCr composites. Sci Rep 15, 28724 (2025). https://doi.org/10.1038/s41598-025-14776-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-14776-5