Abstract

This study investigates the thermal and mechanical performance of geopolymer concrete incorporating recycled coarse aggregate (RCA) and copper slag (CS) as sustainable alternatives to natural aggregates. The geopolymer binder comprises fly ash (FA) and ground granulated blast furnace slag (GGBS), activated by a 12 M NaOH solution. RCA replaced 30% of natural coarse aggregate to form recycled aggregate concrete (RAC), while CS replaced natural fine aggregate in 20% increments up to 100% in RCA based geopolymer concrete to study its effect on compressive, split-tensile, and flexural strengths at ambient (27 °C) and elevated temperatures (100 °C, 300 °C, 500 °C, 700 °C). The experimental findings revealed that integrating CS improved both mechanical and residual thermal properties of RCA-based geopolymer concrete up to 45% and 41%, respectively, over the control mix. The optimal mix exhibited maximum mechanical performance with 30% RCA and 40% CS. This contributes to enhanced fire resistance, sustainability, and reduced dependency on natural resources.

Similar content being viewed by others

Introduction

The construction industry heavily relies on natural resources, leading to significant environmental depletion. Utilizing industrial by-products as construction materials offers a sustainable alternative, reducing waste and conserving resources. This approach aligns with the sustainable development principle of reuse1. Materials such as fly ash (FA), Ground Granulated Blast Slag (GGBS), recycled coarse aggregate (RCA), and CS can effectively replace traditional concrete components without compromising structural integrity2,3. By integrating these alternative materials, the industry can lower carbon emissions, minimize landfill waste, and decrease the extraction of raw materials4,5. Additionally, sustainable construction practices enhance durability, cost efficiency, and environmental resilience.

Portland Cement (PC) is the primary binder in concrete production, but its manufacturing process significantly contributes to global greenhouse gas emissions6,7. PC production accounts for approximately 7% of human-made CO₂ emissions8 mainly due to the calcination reaction, which releases CO₂ when limestone (CaCO₃) is converted to lime (CaO), and the high energy demand of cement manufacturing. Each contributes roughly 50% of the emissions9,10. Around 4 billion tons of PC are produced annually, making it a crucial material in construction. However, this demand is expected to rise sharply, with projections estimating global PC consumption will reach 6 billion tons annually by 206011. Given its environmental impact, researchers are exploring alternative materials and energy-efficient processes to reduce cement-related emissions while meeting the growing construction needs of an expanding global population.

The FA and GGBS-based geopolymers have recently gained more popularity as traditional binders. Geopolymer concrete, an environmentally friendly alternative to traditional PC concrete, utilizes industrial by-products such as FA and GGBS as primary binders. Several studies have explored the influence of different proportions of FA and GGBS on the strength characteristics of geopolymer concrete12,13. Parashar et al. (2022)61 found that incorporating GGBS alongside FA significantly enhanced compressive strength due to the higher calcium content in GGBS, which improves early-age strength development. Similarly, Vignesh and Vivek (2015)14 demonstrated that geopolymer concrete containing 60% FA and 40% GGBS exhibited superior mechanical properties to mixtures with lower GGBS content. These findings align with Jawahar and Mounika (2016)15 who reported that increasing the GGBS proportion up to 50% resulted in higher strength values due to enhanced geo-polymerization reactions.

Further studies have validated the impact of FA and GGBS ratios on the long-term performance of geopolymer concrete16,17. Nagajothi and Elavenil (2021)18 highlighted that adding GGBS to fly ash-based geopolymer concrete improved its microstructural properties, improving its durability and strength retention. Prusty and Pradhan (2023)19 examined the durability aspects and found that a balanced combination of FA and GGBS enhanced strength and improved resistance to chloride penetration. Additionally, Ali et al. (2022)20 and Xie et al. (2019)21 emphasized that optimal blending of FA and GGBS contributed to better workability, early strength gain, and long-term stability. The mix design approach proposed by Mallikarjuna Rao and Gunneswara Rao (2018)22 further reinforced that an increased GGBS percentage accelerates strength development, making geopolymer concrete a viable alternative for structural applications. These collective findings underscore the crucial role of fly ash-GGBS proportions in optimizing the performance of geopolymer concrete.

Recycled coarse aggregate (RCA) has been widely studied as a sustainable alternative to natural coarse aggregate in concrete12,17. Research has shown that the percentage replacement of RCA significantly influences concrete’s mechanical and durability properties. Kwan et al. (2012)23 and Rahal (2007)24 observed that increasing RCA content reduces compressive strength, primarily due to the adhered mortar on RCA, which weakens the interfacial transition zone. However, Martínez-Lage et al. (2012)25 reported that replacing up to 50% of natural coarse aggregate with RCA can maintain acceptable strength and workability. Additionally, treatment techniques such as pre-soaking and surface coatings have been suggested by Raman and Ramasamy (2021)26 to enhance the performance of RCA in concrete. Chakradhar et al. (2011)27 further emphasized the importance of proper mix design and treatment methods to improve the durability properties of recycled aggregate concrete (RAC), ensuring its feasibility for structural applications.

The CS has emerged as a viable alternative to natural sand in concrete, with various studies evaluating its effect on strength and durability. Dos et al. (2017)28 demonstrated that incorporating CS as fine aggregate enhances the density and compressive strength of concrete due to its angular shape and improved particle packing. Sahu et al. (2024)29 found that replacing up to 40% of natural sand with CS results in optimum strength performance, beyond which excessive slag content can lead to increased water demand and potential durability concerns. Similarly, Sharma and Khan (2017)30 observed improved self-compacting concrete properties with CS, particularly in workability and resistance to chloride penetration. Maharishi et al. (2021)31 reported that up to 40–50% replacement results in optimal strength enhancement, while excessive replacement may lead to increased density and reduced durability. However, excessive replacement beyond 50% may lead to strength reductions and increased permeability, as Lori et al. (2019)32 observed. Similarly, the incorporation of CS as fine aggregate in geopolymer concrete gained attention to the researchers in the recent decade due to its glassy, angular nature along with low water absorption property. According to the researchers65,66,67 the geopolymer concrete made with copper slag showed higher mechanical and microstructural performance than those made with NFA. Overall, incorporating CS in concrete mitigates the environmental impact of industrial waste and improves key performance attributes when used within optimal replacement limits.

Geopolymer concrete (GPC) based on FA and GGBS has gained attention for its enhanced performance under elevated temperatures. Research by Pratap and Kumar (2024)12 indicates that FA-GGBS-based GPC exhibits a notable decline in compressive strength beyond 300 °C, with microstructural degradation leading to increased porosity and crack formation. Similarly, Yu et al. (2024)33 investigated the residual mechanical properties of FA-GGBS geopolymer mortar and concrete under high temperatures. Their study revealed that strength degradation begins beyond 150 °C due to phase transitions and microstructural changes. Similarly, Qu et al. (2020)34 explored the thermal resistance of FA/GGBS-based geopolymer mortar under sustained loads. Their findings indicated that, up to 300 °C, geopolymer mortar outperformed Portland cement mortar. However, at 500 °C and 700 °C, its performance deteriorated due to severe damage from the combined effects of high load levels and heat exposure. The best part of the study is that while FA-GGBS geopolymer materials exhibit promising thermal resistance at moderate temperatures, their stability diminishes significantly at extreme heat levels.

Comparatively, studies focusing on FA-based geopolymer concrete without GGBS reveal a more pronounced loss of mechanical integrity at elevated temperatures. Rao and Kumar (2020)35 demonstrated that FA-based GPC exhibits higher susceptibility to thermal cracking due to its lower calcium content, which influences geopolymer gel stability. Turkey et al. (2022)36 investigated the impact of glass powder in fly ash-based geopolymer concrete (GPC) under high temperatures. They found that at 550 °C and above, GPC experienced dehydration and structural damage, compromising its integrity. This highlights the thermal limitations of GPC with glass powder as a supplementary material. Manzoor et al. (2024)37 critically reviewed geopolymer concrete behaviour under high temperatures, reaffirming that FA-based mixtures suffer significant strength reductions due to excessive microcracking and matrix disintegration. This aligns with Yasaswini and Rao (2020)38 observations that FA-based GPC undergoes considerable shrinkage and loss of bond integrity when exposed to temperatures exceeding 500 °C. These studies collectively highlight the superior thermal resistance of GGBS-incorporated geopolymer concrete over FA-based counterparts, making it a more viable option for high-temperature applications.

Research on the behaviour of RAC at elevated temperatures has demonstrated that thermal exposure significantly influences its mechanical and durability properties. Salahuddin et al. (2019)39 and Shaikh (2018)40 reported that RAC experiences a reduction in compressive strength and modulus of elasticity with increasing temperature due to the higher porosity and weaker interfacial transition zones (ITZs) compared to natural aggregate concrete. Laneyrie et al. (2016)41 further noted that high-performance RAC exhibits better residual strength retention than normal-strength RAC, suggesting that the mix design plays a crucial role in thermal stability. Additionally, Chen et al. (2021)42 highlighted that fracture behaviour is more pronounced in RAC after thermal exposure, as microcracks and interfacial debonding between the aggregate and cement matrix intensify beyond 300 °C. Salau et al. (2015)43 reinforced these findings, indicating that RAC suffers a considerable loss of strength due to thermal degradation of the recycled aggregate and the residual mortar attached to it. These studies collectively suggest that while RAC can sustain moderate temperatures, its performance deteriorates significantly at high temperatures due to increased thermal-induced cracking and microstructural instability.

Similarly, incorporating CS as fine aggregate in concrete exposed to elevated temperatures has been investigated for its thermal resistance and microstructural changes. Ameri et al. (2021)44 and Chaitanya et al. (2024)45 found that concrete containing CS exhibits enhanced thermal resistance due to its dense microstructure and lower porosity than conventional sand-based concrete. However, Sahu et al. (2024)46 observed that at temperatures exceeding 600 °C, CS-based concrete experiences a decline in mechanical strength, attributed to the expansion and oxidation of metallic compounds within the slag, leading to internal cracking. Nabahati et al. (2023)47 further examined the bond properties of steel reinforcement embedded in CS concrete, revealing that elevated temperatures reduce the bond strength due to microstructural degradation. Al Jabri (2006)48 emphasized the high thermal conductivity of CS, which can lead to increased heat transfer and potential differential thermal stresses within the concrete matrix. These studies indicate that while CS improves thermal stability at moderate temperatures, its long-term behaviour at extreme heat requires further optimization to mitigate strength losses and microstructural degradation.

The literature study revealed that the addition of CS as fine aggregate showed a positive impact on different types of concrete at elevated temperature. However, limited study has been done to analyse the effect of CS on geopolymer concrete at high temperature exposures. In the earlier research work by Pratap and Kumar (2024)12 and Kumar et al. (2025)49 fly ash (FA) and ground granulated blast furnace slag (GGBS) were optimized in geopolymer concrete under high temperatures and subsequently optimized RCA in this composition. The novelty of the present research work to analyse the effect of CS on the residual behaviour of RCA-based geopolymer concrete. CS is incorporated up to 100% with the increments of 20% as natural fine aggregate (NFA) and assess the mechanical properties such as compressive, flexural, and split tensile strength with mass loss of RCA based geopolymer concrete at room temperature (27 °C) and high temperatures (100 °C, 200 °C, 500 °C, and 700 °C).

Materials and methodology

Materials in the experimental programme

The researchers utilized natural fine and coarse aggregate, recycled coarse aggregate (RCA), CS, GGBS, alkali solution, and fly ash (Fig. 1). The present study employed locally available river sand as a natural fine aggregate (NFA) from the Kharki River in Jamshedpur. The crushed granite of 20 mm down is used as a natural coarse aggregate (NCA) obtained from the local supplier to ensure it meets the standard quality requirements for concrete production.

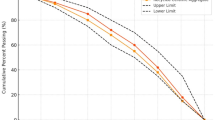

The FA and GGBS are obtained from Tata Steel, Jamshedpur, India. The chemical composition of binding materials (GGBS and fly ash) is determined by performing X-ray fluorescence (XRF) analysis to verify suitability. The fly ash used in this study is Class F, which is characterized by a low calcium oxide (CaO) content. The details are presented in Table 1. CS (Fig. 1), a waste by-product collected from the copper industry, replaces the fine aggregate due to its low water absorption characteristics and glassy texture. The recycled coarse aggregate (RA) obtained from the demolished concrete partially replaces coarse aggregate after being properly crushed and sieved. All aggregates have undergone grading analysis in accordance with IS: 2386 (1963) Part-I50. Table 2 lists the laboratory test results on the physical characteristics of aggregates, whereas Table 1 provides the chemical analysis of NFA and CS. As shown in Fig. 2, the grading curve for aggregates indicated that the nominal sizes of all the aggregates are satisfied as per IS: 383 (2016)51. A poly-carboxylic ether-based superplasticizer is incorporated to enhance the workability and mechanical properties of the concrete. An alkali solution with a concentration of 12 M NaOH is prepared and used to produce a geopolymer concrete mix.

Mix design, casting, and testing of specimens

The present study builds upon earlier research that established the foundational mix design parameters. Initially, Pratap and Kumar (2024)12 optimized a geopolymer mix comprising ground granulated blast furnace slag (GGBS), fly ash, and an alkali activator solution with 12 M sodium hydroxide (NaOH). Subsequently, Kumar et al. (2025)49 refined this mix by incorporating recycled coarse aggregates (RCA) as a partial replacement for conventional aggregates, ranging from 0 to 50%. Their findings identified 30% RCA replacement as optimal, delivering superior compressive strength under ambient and elevated temperatures. Building on these findings, the current investigation prepared a total of seven trial mixes, presented in Table 4. The first trial mix is the geopolymer control mix that was prepared with GGBFS, FA and an alkali activator solution with 12 M sodium hydroxide (NaOH). The second trial mix is the RAC mix, which was prepared by incorporating 30% RCA as natural coarse aggregate. Another five trial mixes were prepared by incorporating CS up to 100% at 20% increments as natural fine aggregates to RCA-based geopolymer concrete. The mix designations are systematically labelled as R0C0, R30C0, R30C20, R30C40, R30C60, R30C80, and R30C100, where “R” denotes recycled coarse aggregate and “C” signifies copper slag content. This approach allows for detailed performance evaluation based on varying CS replacement in a geopolymer matrix with 30% RCA. The alkaline-to-binder ratio adopted for this study is 0.43. Table 3 in the present study outlines the specific mix designs, detailing the proportions of GGBS, FA, NFA, CS, NCA, RCA, and alkali solutions. All constituent materials were mixed to ensure a homogeneous blend, critical for achieving the concrete’s targeted mechanical and durability properties. For each concrete mix, materials were thoroughly mixed (Fig. 2a), cast into moulds (Fig. 2b), and subjected to thermal curing in an oven at 65 °C for 24 h. This initial thermal curing phase accelerates the polymerisation or hydration reactions, particularly in geopolymer or thermally activated cementitious systems. Following this phase, the specimens were demoulded and stored under ambient conditions at approximately 27 °C for further curing.

The mechanical performance of the mixes was evaluated through a series of standardized tests conducted at ambient and elevated temperatures, confirming with IS 516: 202170. For compressive strength testing, cube specimens with dimensions of 150 mm were utilized (Fig. 3a). Split tensile strength was determined using cylindrical specimens with 150 mm diameter and 300 mm height (Fig. 3b). In comparison, prism specimens of size 100 × 100 × 300 mm were used for flexural strength tests (Fig. 3c). Table 3 represents the details of specimen casted under ambient and elevated temperature conditions for performing different test and determining mechanical performance of various geopolymer mixes.

Heating procedure

To assess the effect of CS on recycled aggregate GGBS-based geopolymer concrete at elevated temperature, the specimens after 28 days curing were exposed to different temperature exposures of 100 °C, 300 °C, 500 °C and 700 °C. The specimens were subjected to elevated temperature exposure using an electrically operated muffle furnace, as illustrated in Fig. 4.

A consistent heating rate of 10 °C/min was maintained, following the methodologies reported by Tung et al. (2022)52 and Sahu et al. (2025)53 to achieve the target temperatures while minimising thermal gradients. This controlled heating protocol ensured uniform heat distribution across the specimen mass, reducing the risk of thermal shock or uneven internal stresses. Upon reaching the designated temperature, the specimens were held isothermally for two hours to allow complete thermal penetration and stabilization within the core of the material. This step is crucial for replicating sustained high-temperature exposure conditions. After the heating phase, the furnace was switched off, and the specimens were allowed to cool gradually within the closed furnace for 24 h. This slow cooling approach prevents microcracking and preserves the integrity of the thermally exposed specimens.

Various mechanical tests were performed to assess the residual properties of geopolymer specimens, including compressive strength, split-tensile strength, and flexural strength, as per IS 516: 202170. The complete experimental setup for these evaluations is illustrated in Fig. 5. In addition to mechanical performance, mass loss measurements were conducted on specimens subjected to elevated temperatures to investigate thermal stability. These assessments aimed to quantify water loss and evaluate the extent of pore structure degradation, providing insight into the thermal resistance and durability of the geopolymer matrix under high-temperature conditions.

Discussion of the results

Workability of fresh geopolymer mixes

The workability of different Geopolymer mixes obtained from slump cone test are presented in Fig. 6. indicating decreased nature of workability after substitution of CS in the RCA based geopolymer mix. The Geopolymer mixes exhibited about 9%, 20%, 29%, 38% and 47% lower workability compared to control mix (R0C0) after introduction of 20%, 40%, 60%, 80% and 100% CS respectively. The irregular with angular form of CS grain s, as well as their higher specific gravity than that of NFA retards the flowability of Geopolymer mixes, leading to decreased workability. These observations are aligned with aligns with previous studies Sarkar et al. 202471 and Arunachelam et al. 202272. However, the workability of Geopolymer mixes can further be improved by adjusting the super plasticizer dosages, thereby, obtaining a greater slump value. This can widen its application scope, including complicated structural parts or greater flowability.

Mechanical properties at room temperature

Compressive strength

The compressive strength behaviour of RCA-based geopolymer mixes incorporating varying percentages of CS as a partial replacement for fine aggregate is presented in Fig. 7, after oven curing durations of 3, 7, and 28 days. The experimental data reveal a significant enhancement in compressive strength across all curing periods when CS is integrated with 30% RCA. Specifically, compared to the control mix (R0C0), the incorporation of 40% CS resulted in strength gains of approximately 19% at 3 days, 15.2% at 7 days, and 15.8% at 28 days. Furthermore, when benchmarked against the 30% RAC mix without CS (R30C0), the strength improvements were even more pronounced, reaching 28%, 19.87%, and 20.23% at 3, 7, and 28 days, respectively.

The optimal compressive strength was observed in the R30C40 mix, which combined 30% RCA with 40% CS. This enhancement is attributed to several interrelated factors. Firstly, the glassy and angular nature of CS improves particle interlocking and bond strength, leading to better microstructural integrity44. Secondly, the lower water absorption capacity of CS enhances workability and minimizes excess porosity, thereby producing a denser matrix29. Thirdly, CS’s higher specific gravity and bulk density than natural sand contributes to a more compact and load-bearing structure. Additionally, the amorphous phase of CS actively participates in the alkali-activation process, promoting geo-polymerization and increasing early and long-term strength54. These observations align with Sreenivasulu et al. (2020)55 which have consistently demonstrated the beneficial role of CS in enhancing the mechanical properties of geopolymer concrete.

The compressive strength of RCA-based geopolymer mixes shows a positive trend with an increase in CS content by up to 40%. However, beyond this threshold, strength gains diminish. Compressive strength decreases at 100% CS replacement by approximately 14% at 3 days, 12.5% at 7 days, and 12% at 28 days compared to the 40% CS mix (R30C40). This reduction is attributed to the excessive CS content, which tends to settle during the fresh.

state, leading to segregation. The displaced free water creates voids and microfractures within the matrix, adversely affecting the densification and continuity of the geo-polymeric network. Additionally, the mix becomes thicker and less workable, hindering proper compaction and homogeneity46.

Split-tensile strength

Figure 8 presents the split tensile strength results of RCA-based geopolymer mixes incorporating varying proportions of CS as a partial replacement for fine aggregate, measured after 3, 7, and 28 days of oven curing. The results demonstrate a consistent enhancement in tensile strength, including CS, across all curing ages. Specifically, when up to 40% of fine aggregate was replaced with CS, the tensile strength increased by approximately 29%, 41%, and 49% at 3, 7, and 28 days, respectively, compared to the reference mix (R0C0). Compared to the RAC mix without CS (R30C0), tensile strength improvements of up to 58%, 85%, and 88% were observed at the same respective curing periods upon complete CS replacement (100%).

Among the tested mixes, the blend with 30% RCA and 40% CS (R30C40) exhibited the highest split tensile strength. This enhancement is attributed to CS particles’ angular morphology and surface texture, which improve the mechanical interlock and bonding between the recycled aggregates and the geopolymer matrix. The sharp-edged nature of CS contributes to better cohesion between old adhered mortar and the fresh binder, thereby enhancing the overall tensile performance of the mix29. As illustrated in Fig. 8, the split-tensile strength of geopolymer mixes incorporating CS increases beyond 40% replacement compared to reference concrete and RAC mixes. However, the rate of strength gain diminishes with higher CS content. Strength improvements are marginal at 100% CS substitution, approximately 3% at 3 days, 2.45% at 7 days, and 6.5% at 28 days, relative to the reference mix (R0C0). This attenuation in strength gain is likely attributed to CS particles’ smoother and glassier texture, adversely affecting the geopolymer matrix’s interfacial bond. Such surfaces can trap excess free water, particularly at higher substitution levels, leading to a weaker matrix and reduced tensile strength development30.

Flexural strength

Figure 9 presents the flexural strength development of RCA-based geopolymer mixes incorporating varying proportions of CS after 3, 7, and 28 days of oven curing. The observed trend in flexural strength aligns with compressive and split tensile strength behaviours. Including CS enhances flexural strength, with peak performance at 40% CS replacement. Beyond this threshold, strength slightly declines, likely due to excess fines or reduced matrix cohesion. Nevertheless, mixes with higher CS content still outperform the reference and RAC-only mixes, demonstrating the beneficial role of CS in improving mechanical properties up to an optimal limit. The geopolymer mix incorporating 40% CS and 30% RCA (R30C40) exhibited the highest split-tensile strength among all tested mixes. Compared to the reference mix (R0C0), the R30C40 mix demonstrated strength improvements of 26%, 35%, and 45% at 3, 7, and 28 days, respectively. Relative to the recycled aggregate concrete mix (R30C0), enhancements of 79%, 65%, and 78% were observed. These strength gains are attributed to the physical characteristics of CS, particularly its higher compressibility, which enhances the deformability and crack-bridging capacity of the geopolymer matrix44.

Residual properties at elevated temperature

Compressive strength

Figure 10 illustrates the compressive strength behaviour of RCA-based geopolymer mixes under varying thermal exposures. Specifically, Fig. 10(a) presents the compressive strength trends across different temperature levels, while Fig. 10(b) depicts the relative compressive strength at various CS replacement levels after thermal exposure. At a moderate exposure of 100 °C, a slight increase in compressive strength is observed in all mixes compared to ambient conditions. This strength gain is attributed to the internal moisture in the mix, which facilitates continued hydration of GGBFS particles, enhancing the matrix densification12,56,60.

Including CS significantly improves the residual compressive strength of RAC-based geopolymer composites across all temperature levels (23 °C to 700 °C). The maximum strength gains relative to reference concrete without CS were recorded as 15%, 18%, 25%, 26%, and 41% at 23 °C, 100 °C, 300 °C, 500 °C, and 700 °C, respectively, with 100% CS and 30% RCA. R30C40 exhibited the highest residual compressive strength enhancement of all tested mixes compared to R30C0, with strength increases of 20%, 21%, 33%, 35%, and 69% across the same temperature range. The enhanced thermal resistance of R30C40 mix is primarily due to the lower thermal expansion coefficient and reduced water absorption of CS particles compared to NFA. These properties reduce thermal-induced voids and microcracks, improving structural integrity at elevated temperatures53. This highlights the synergistic effect of CS and RCA at optimal replacement ratios. In contrast, the Geopolymer mixes beyond 40% CS, displayed the least improvement, indicating potential drawbacks at higher CS contents. The increased amount of CS in the mix increased the free water level and at higher temperature the degree of voids are more due to the evaporation of free water which increased the porosity of the mix and degrades the residual strength of the mix44.

Figure 10(a) illustrates that as the exposed temperature increases; all mixes reduce compressive strength relative to their room temperature strength. This strength loss is attributed to hydrated products’ dehydration and chemical breakdown at elevated temperatures57. Notably, the strength reduction is more significant when the mixes are heated to 700 °C, where the complete decomposition of calcium hydroxide leads to the formation of voids and cracks, resulting in substantial structural degradation. However, the inclusion of CS in the mix mitigates the rate of strength reduction in RCA-geopolymer mixes compared to those without CS.

Figure 10(b) presents the effect of CS incorporation at various replacement levels on the relative compressive strength of RCA-geopolymer mixes exposed to temperatures ranging from 100 to 700 °C. The relative compressive strength of each CS mix was calculated relative to its room temperature strength. The data shows a consistent increase in relative compressive strength as the CS content increases up to 40%. Beyond this point, the strength decreases marginally with a further increase in CS content to 100%. The enhanced performance of CS-blended RAC-geopolymer concrete can be attributed to the formation of an amorphous Fe (OH)3 or Fe (OH)2 gel, which fills the matrix’s pores and gaps after decomposition at higher temperatures, effectively improving the material’s thermal stability and structural integrity58. At higher temperature, the hydrated products formed in the CS based geopolymer mixes began to decompose alongside Ca (OH)2 and CSH phases and filled the matrix’s gaps and pores to maintain strength58. The use of CS as fine aggregate may enhanced the basic strength of Geopolymer concrete under alkali conditions.

Split-Tensile strength

The split-tensile strength of RCA-based geopolymer mixes after exposure to different thermal exposures is graphically represented in Fig. 11. The changes in compressive strength with the variation of temperature exposures are depicted in Fig. 11 (a), and the relative compressive strength at various replacement levels of CS after various thermal exposures is shown in Fig. 11(b). The split-tensile strength of all geopolymer mixes follow the same trend as observed in compressive strength.

Figure 11 (a) depicts a marginal increase in split-tensile strength at 100 °C temperature for all geopolymer mixes; the strength decreases with the increased temperature. However, the addition of CS enhanced the residual tensile strength of RAC-geopolymer mix about 49%, 52%, 53%, 44% and 28% at 23, 100, 300, 500 and 700 °C temperature exposures, respectively, with respect to reference concrete. The improved tensile strength of CS blended RAC-geopolymer mix is due to the reduced thermal expansion characteristics of CS compared to NFA, which prevents microcracks from forming in the interfacial transition zone53. The influence of elevated temperatures (300 to 700 °C) on the split tensile strength of RCA-geopolymer mixes was evaluated. All mixes reduced split tensile strength relative to their room temperature strength due to significant water loss at higher temperatures. This moisture loss weakens the internal structure, contributing to the decline in strength. However, the incorporation of CS exhibited a notable retardation of strength reduction. Specifically, CS addition mitigated the rate of tensile strength loss in RCA-geopolymer mixes when exposed to elevated temperatures. Figure 11(b) illustrates the effect of CS replacement levels on the relative split tensile strength after exposure to temperatures ranging from 100 to 700 °C. As depicted, adding CS improved the relative tensile strength at all temperatures tested, with the enhancement being most pronounced at CS contents up to 40%. Beyond this threshold, further increases in CS content led to a marginal decrease in the relative tensile strength. This behaviour suggests an optimal CS content of around 40% for maximising the thermal performance of RCA-geopolymer mixes in terms of split tensile strength under high-temperature exposure.

Flexural strength

The flexural strength of RCA-based geopolymer mixes subjected to various thermal exposures is presented in Fig. 12. Figure 12(a) illustrates the change in flexural strength as the temperature increases from 300 °C to 700 °C. As temperature exposure increases, the flexural strength of geopolymer mixes decreases. However, at 100 °C, all mixes demonstrated improved flexural strength, likely due to additional hydration of cement pastes or rehydration of the mortar present in the RCA. Adding CS enhanced the flexural strength of RAC-geopolymer mixes across all temperature exposures. In particular, the R30C40 mix, which included 30% recycled aggregates and 40% CS, exhibited the highest strength gains compared to RAC without CS. This mix demonstrated strength increases of 77%, 84%, 83%, 89%, and 97% after exposure to 23 °C, 100 °C, 300 °C, 500 °C, and 700 °C, respectively. With its lower thermal expansion compared to NFA, the incorporation of CS mitigates the formation of weak planes from microcracks and voids that occur under high-temperature conditions, thus enhancing the material’s strength at elevated temperatures44.

All mixes demonstrated reduced flexural strength compared to their room temperature values when exposed to temperatures between 300 and 700 °C, primarily due to the dehydration and decomposition of hydrated phases at elevated temperatures. However, including CS in RCA-geopolymer mixes slowed the rate of strength loss relative to the room temperature strength.

Figure 12 (b) illustrates the impact of CS at various replacement levels on the relative flexural strength of RAC-geopolymer mixes after exposure to temperatures ranging from 100 to 700 °C. As shown, adding CS improved the relative flexural strength across all tested temperatures, with the enhancement being more significant as the CS content increased up to 40%. Beyond this threshold, further increases in CS resulted in a slight decrease in relative flexural strength, indicating a diminishing return at higher CS replacement levels.

Mass loss

The mass loss of various geopolymer concrete specimens with differing shapes and compositions was evaluated by measuring their weight before and after exposure to elevated temperatures. This analysis aimed to investigate the thermal behaviour of geopolymer concrete under varying conditions. Figures 13, 14 and 15 illustrate the mass loss trends for cube, cylinder, and prism specimens subjected to temperatures ranging from 100 to 700 °C. All specimens exhibited an apparent increase in mass loss with rising temperature. In the initial range of 25 to 100 °C, the mass loss was primarily attributed to the evaporation of free water occupying voids and micro-cracks within the matrix, as reported by Sedaghatdoost et al. (2019)59. Between 100 and 300 °C, an estimated mass loss of 8% occurred due to the decomposition of hydration products and the release of chemically bound water, consistent with findings by Gong and Ueda (2018)60. At higher temperatures, specifically 500 °C and 700 °C, the mass loss reached approximately 8.45% and 11%, respectively. This elevated loss is attributed to the breakdown of key binding gels such as calcium silicate hydrate (CSH) and calcium alumino silicate hydrate (CASH), leading to significant microstructural degradation44,63,64. These findings highlight the temperature-dependent deterioration mechanisms in geopolymer concrete.

As illustrated in Figs. 13, 14 and 15, the RAC mix labelled R30C0 exhibited a greater mass loss with increasing temperature across all specimen geometries (cube, cylinder, and prism). This behaviour is primarily attributed to highly porous adhered mortar on the surface of RCA, which facilitates significant moisture evaporation at elevated temperatures29,62. Specifically, at 700 °C, R30C0 specimens experienced mass losses of approximately 7.68%, 8.76%, and 11% for cube, cylinder, and prism forms, respectively. Incorporating CS into the RAC-geopolymer system mitigated this mass loss, with the reduction becoming more pronounced as CS content increased. For instance, the R30C20 mix (30% RCA and 20% CS) showed reduced mass losses of 6%, 7%, and 9% under the same thermal exposure for the respective specimen shapes. Moreover, the R30C100 mix demonstrated even lower mass losses of 4.34%, 5%, and 7% for cube, cylinder, and prism specimens, respectively, at 700 °C. The improved thermal stability in CS-blended RAC-geopolymer composites is primarily due to the low water absorption and smooth surface texture of CS particles. These characteristics enhance the interfacial transition zone by minimizing moisture retention and reducing internal stresses, thereby decreasing the formation of microcracks and voids around aggregates44,46. This highlights the beneficial role of CS in enhancing the high-temperature performance of RAC-geopolymer composites.

Scanning electron microscope (SEM)

Figure 16 shows SEM pictures of concretes at various temperatures of specimens R30C40 at 23 °C, 100 °C, and 700 °C. It can be observed that as the temperature increased from 23 °C to 100 °C, the strength of the specimens increased (Fig. 16 b). It may be due to the increase in hydration and formation of the C-S-H gel. Figures 16(a) and 16(b) show the thick gel structure. At 700 °C, the geopolymer gel structure began to deteriorate Fig. 16 (c). The geopolymer gel structure suffered significant degradation, with faults including disintegration, rupture, and gaps appearing, particularly at 700°C68.

. Examining the samples’ microstructures and compressive strength values at high temperatures revealed a correlation between the samples’ deteriorating microstructures and their decline in compressive strengths69. The microstructures of slag-based concretes develop fractures that widen as the temperature rises, reducing the concrete’s fire resistance and residual compressive strength. For specimens R30C40 on GGBS, at 23 °C, might be regarded as the optimum specimen. RCA has a lower thermal expansion coefficient. Under high temperatures, this widening gap led to internal pressures and fractures in the concrete66. This was one of the causes of the significant strength loss that occurred as the ratio of RCA in concrete subjected to high temperatures rose. The dehydration of calcium silicate hydrate to calcium silicates, which results in the formation of white-needle-shaped bundles69 is evident in samples subjected to 700 °C (Fig. 16c).

Conclusions

This study investigates the thermal performance of RCA-based geopolymer composites incorporating copper slag (CS) as fine aggregate. The specimens were exposed to elevated temperatures, and their mechanical and physical responses were evaluated through compressive strength, split tensile strength, flexural strength, and mass loss tests. The main findings of this study are as follows:

-

The mechanical properties of RCA-based geopolymer concrete are improved significantly at ambient temperature after the addition of CS up to 40% as fine aggregate. The increased strength is attributed to the low water absorption property and glassy texture of CS particles.

-

Incorporating CS boosted the compressive strength of RAC-geopolymer mixes to 15%, split-tensile strength to 49% and flexural strength to 45%, respectively, over the reference mix (R0C0).

-

Incorporation of CS also enhanced the fire resistance behaviour of RCA-based geopolymer concrete, which is attributed to the lower thermal properties of CS than NFA, causing fewer voids and cracks at higher temperatures.

-

The addition of CS increased the residual compressive strength of RAC-geopolymer concrete up to 41% over the reference mix (R0C0) and 69% over RAC without CS (R30C0) after exposure to a temperature of up to 700 °C. The mix R30C40 attained maximum residual compressive, split tensile, and flexural strength compared to the other geopolymer mixes.

-

At higher temperatures, the mass loss rate of RCA-based geopolymer mixes is reduced to 46% over the reference mix by adding CS up to 100% as fine aggregate. The lower thermal expansion property and smooth texture of CS particles reduced the stress in the aggregate-binder interface, causing fewer pores and voids and making the geopolymer concrete highly temperature resistant.

The findings of the above experimental study show that incorporating CS as fine aggregate proved to be more beneficial in terms of strength, which improved the residual performance of geopolymer concrete, establishing the concrete’s higher fire resistance. Furthermore, utilisation of the waste materials: RCA, CS, FA and GGBS in place of virgin materials encourages sustainable development in the building sector, preserving natural resources and reducing waste disposal and environmental issues.

Data availability

Data used in the study is present in the manuscript.

References

Krannich, A. L. & Reiser, D. United nations sustainable development goals 2030, the. In Idowu, S.O., Schmidpeter, R.,Capaldi, N., Zu, L., Del Baldo, M., Abreu, R. (eds) Encyclopedia of Sustainable Management 3862–3867 (Springer International Publishing, 2023). https://doi.org/10.1007/978-3-031-25984-5_178

Liang, G., Liu, T., Li, H. & Wu, K. Shrinkage mitigation, strength enhancement and microstructure improvement of alkali-activated slag/fly Ash binders by ultrafine waste concrete powder. Compos. Part. B: Eng. 231, 109570 (2022).

Akturk, B. et al. Hydration kinetics and performance of sodium carbonate-activated slag-based systems containing reactive MgO and Metakaolin under carbonation. Cem. Concr. Compos. 132, 104617 (2022).

Shukla, B. K. et al. Sustainable construction practices with recycled and waste materials for a circular economy. Asian J. Civil Eng. 25 (7), 5255–5276 (2024).

Rivera-Lutap, J. A., Cruz, D., Jacinto, O. G., Vael, J. M. & Muhi, M. M. L. M. D., Alternative Building Materials for a Sustainable Built Environment: A Literature Review. In International Conference on Energy Engineering and Environmental Engineering (pp. 235–246). Cham: Springer Nature Switzerland. (2023), August.

Kocak, Y., Tascı, E. & Kaya, U. The effect of using natural zeolite on the properties and hydration characteristics of blended cements. Constr. Build. Mater. 47, 720–727 (2013).

Bengar, H. A. & Shahmansouri, A. A. A new anchorage system for CFRP strips in externally strengthened RC continuous beams. J. Building Eng. 30, 101230 (2020).

Taylor, M., Tam, C. & Gielen, D. Energy efficiency and CO2 emissions from the global cement industry. Korea 50 (2.2), 61–67 (2006).

Yang, K. H., Song, J. K. & Song, K. I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 39, 265–272 (2013).

Ávalos-Rendón, T. L. et al. Synthesis of Belite cements at low temperature from silica fume and natural commercial zeolite. Mater. Sci. Engineering: B. 229, 79–85 (2018).

Samimi, K., Kamali-Bernard, S., Maghsoudi, A. A., Maghsoudi, M. & Siad, H. Influence of pumice and zeolite on compressive strength, transport properties and resistance to chloride penetration of high strength self-compacting concretes. Constr. Build. Mater. 151, 292–311 (2017).

Pratap, B. & Kumar, P. Effect of the elevated temperature on the mechanical properties of geopolymer concrete using fly Ash and ground granulated blast slag. J. Struct. Fire Eng. 15 (3), 409–425 (2024).

Kumar, P., Gogineni, A. & Ammarullah, M. I. Sustainable bioengineering approach to industrial waste management: LD slag as a cementitious material. Discover Sustain. 6 (1), 1–9 (2025a).

Vignesh, P. & Vivek, K. An experimental investigation on strength parameters of flyash-based geopolymer concrete with GGBS. Int. Res. J. Eng. Technol. 2 (2), 135–142 (2015).

Jawahar, J. G. & Mounika, G. Strength properties of fly Ash and GGBS based geopolymer concrete. Asian J. Civ. Eng. 17 (1), 127–135 (2016).

Pratap, B., Paswan, R. K. & Kumar, P. Mechanical and micro-characterization of alkali‐activated concrete under high‐temperature exposure. Struct. Concrete. 26 (2), 1911–1923. https://doi.org/10.1002/suco.202301157 (2025).

Kumar, P., Gogineni, A. & Upadhyay, R. Mechanical performance of fiber-reinforced concrete incorporating rice husk Ash and recycled aggregates. J. Building Pathol. Rehabilitation. 9 (2), 144 (2024).

Nagajothi, S. & Elavenil, S. Effect of GGBS addition on reactivity and microstructure properties of ambient cured fly Ash based geopolymer concrete. Silicon 13 (2), 507–516 (2021).

Prusty, J. K. & Pradhan, B. Evaluation of durability and microstructure evolution of chloride added fly Ash and fly Ash-GGBS based geopolymer concrete. Constr. Build. Mater. 401, 132925 (2023).

Ali, A. A., Al-Attar, T. S. & Abbas, W. A. Mechanical performance of blended fly ash-based geopolymer concrete with GGBS and Metakaolin. Eng. Technol. J. 40 (5), 819–831 (2022).

Xie, J., Wang, J., Rao, R., Wang, C. & Fang, C. Effects of combined usage of GGBS and fly Ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part. B: Eng. 164, 179–190 (2019).

Mallikarjuna Rao, G. & Gunneswara Rao, T. D. A quantitative method of approach in designing the mix proportions of fly Ash and GGBS-based geopolymer concrete. Australian J. Civil Eng. 16 (1), 53–63 (2018).

Kwan, W. H., Ramli, M., Kam, K. J. & Sulieman, M. Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 26 (1), 565–573 (2012).

Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 42 (1), 407–415 (2007).

Martínez-Lage, I., Martínez-Abella, F., Vázquez-Herrero, C. & Pérez-Ordóñez, J. L. Properties of plain concrete made with mixed recycled coarse aggregate. Constr. Build. Mater. 37, 171–176 (2012).

Raman, J. V. M. & Ramasamy, V. Various treatment techniques involved to enhance the recycled coarse aggregate in concrete: A review. Mater. Today: Proc. 45, 6356–6363 (2021).

Chakradhara Rao, M., Bhattacharyya, S. K. & Barai, S. V. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 44, 205–220 (2011).

Dos Anjos, M. A. G., Sales, A. T. C. & Andrade, N. Blasted copper slag as fine aggregate in Portland cement concrete. J. Environ. Manage. 196, 607–613 (2017).

Sahu, A., Kumar, S., Srivastava, A. K. L. & Chidambaram, S. J. Performance of recycled aggregate concrete incorporating copper slag at elevated temperature. Iran. J. Sci. Technol. Trans. Civil Eng. 42, 4023–4042 (2024).

Sharma, R. & Khan, R. A. Durability assessment of self-compacting concrete incorporating copper slag as fine aggregates. Constr. Build. Mater. 155, 617–629 (2017).

Maharishi, A., Singh, S. P. & Gupta, L. K. Strength and durability studies on slag cement concrete made with copper slag as fine aggregates. Materials Today: Proceedings, 38, 2639–2648. (2021).

Lori, A. R., Hassani, A. & Sedghi, R. Investigating the mechanical and hydraulic characteristics of pervious concrete containing copper slag as coarse aggregate. Constr. Build. Mater. 197, 130–142 (2019).

Yu, M. et al. Residual mechanical properties of GGBS-FA-SF blended geopolymer concrete after exposed to elevated temperatures. Constr. Build. Mater. 411, 134378 (2024).

Qu, F., Li, W., Tao, Z., Castel, A. & Wang, K. High temperature resistance of fly ash/GGBFS-based geopolymer mortar with load-induced damage. Mater. Struct. 53, 1–21 (2020).

Rao, A. K. & Kumar, D. R. Comparative study on the behaviour of GPC using silica fume and fly ash with GGBS exposed to elevated temperature and ambient curing conditions. Materials Today: Proceedings, 27, 1833–1837. (2020).

Turkey, F. A., Beddu, S. B., Ahmed, A. N. & Al-Hubboubi, S. K. Effect of high temperatures on the properties of lightweight geopolymer concrete based fly Ash and glass powder mixtures. Case Stud. Constr. Mater., 17, e01489. (2022).

Manzoor, T., Bhat, J. A. & Shah, A. H. Performance of geopolymer concrete at elevated temperature – A critical review. Constr. Build. Mater. 420, 135578 (2024).

Yasaswini, K. & Rao, A. V. Behaviour of geopolymer concrete at elevated temperature. Mater. Today: Proc. 33, 239–244 (2020).

Salahuddin, H., Nawaz, A., Maqsoom, A. & Mehmood, T. Effects of elevated temperature on performance of recycled coarse aggregate concrete. Constr. Build. Mater. 202, 415–425 (2019).

Shaikh, F. U. A. Mechanical properties of concrete containing recycled coarse aggregate at and after exposure to elevated temperatures. Struct. Concrete. 19 (2), 400–410 (2018).

Laneyrie, C. et al. Influence of recycled coarse aggregates on normal and high performance concrete subjected to elevated temperatures. Constr. Build. Mater. 111, 368–378 (2016).

Chen, W., Peng, L. & Yang, H. Fracture behaviors of concrete incorporating different levels of recycled coarse aggregate after exposure to elevated temperatures. J. Building Eng. 35, 102040 (2021).

Salau, M. A., Oseafiana, O. J. & Oyegoke, T. O. Effects of elevated temperature on concrete with Recycled Coarse Aggregates. In IOP Conference Series: Materials Science and Engineering (Vol. 96, No. 1, p. 012078). IOP Publishing. (2015), October.

Ameri, F. et al. Physico-mechanical properties and micromorphology of AAS mortars containing copper slag as fine aggregate at elevated temperature. J. Building Eng. 39, 102289 (2021).

Chaitanya, B. K. et al. Microstructural and residual properties of self-compacting concrete containing waste copper slag as fine aggregate exposed to ambient and elevated temperatures. Infrastructures 9 (5), 85 (2024).

Sahu, A., Kumar, S., Srivastava, A. K. L. & Pratap, B. Performance of recycled aggregate concrete using copper slag as fine aggregate. J. Building Eng. 82, 108364 (2024).

Nabahati, F., Mousavi, S. S. & Dehestani, M. Effect of high temperature exposure on bond properties of steel deformed rebar embedded in self-consolidating concrete containing copper slag as fine aggregate. J. Mater. Civ. Eng. 35 (12), 04023439 (2023).

Al Jabri, K. S. Copper Slag as Fine Aggregate for High Performance Concrete85 (WIT Transactions on the Built Environment, 2006).

Kumar, P., Pratap, B. & Sahu, A. Recycled aggregate with GGBS geopolymer concrete behaviour on elevated temperatures. J. Struct. Fire Eng. 16 (1), 118–137 (2025).

IS 2386. (part-I), Methods of Test for concrete-Particle Size and Shape (Bureau of Indian Standard, 1963).

IS 383. Coarse and Fine Aggregate for concrete-specification (Bureau of Indian Standard, 2016).

Tung, T. M., Babalola, O. E. & Le, D. Experimental investigation of the performance of ground granulated blast furnace slag blended recycled aggregate concrete exposed to elevated temperatures. Clean. Waste Syst. 4, 100069 (2023).

Sahu, A., Kumar, S., Srivastava, A. & Anurag, H. Experimental investigation on the performance of ground granulated blast furnace slag and copper slag blended recycled aggregate concrete exposed to elevated temperatures. J. Building Eng. 105, 112531 (2025).

Singh, J. & Singh, S. P. Development of alkali-activated cementitious material using copper slag. Constr. Build. Mater. 211 (Jun), 73–79 (2019).

Sreenivasulu, C., Guru Jawahar, J. & Sashidhar, C. Effect of Copper Slag on Micro, Macro, and Flexural Characteristics of Geopolymer Concrete. Journal of Materials in Civil Engineering, © ASCE, ISSN 0899–1561.

Albidah, A., Alqarni, A. S., Abbas, H., Almusallam, T. & Al-Salloum, Y. Behaviour of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures. Constr. Build. Mater. 317, 125910. https://doi.org/10.1016/j.conbuildmat.2021.125910 (2022).

Ozbayrak, A., Kucukgoncu, H., Aslanbay, H. H., Aslanbay, Y. G. & Atas, O. Comprehensive experimental analysis of the effects of elevated temperatures in geopolymer concretes with variable alkali activator ratios. J. Building Eng. 68, 106108. https://doi.org/10.1016/j.jobe.2023.106108 (2023).

Sivasakthi, M., Jeyalakshmi, R. & Rajamane, N. P. Fly Ash geopolymer mortar: impact of the substitution of river sand by copper slag as a fine aggregate on its thermal resistance properties. J. Clean. Prod., 279,123766 .

Sedaghatdoost, A., Behfarnia, K., Bayati, M., Vaezi, M. & Sadegh Influence of recycled concrete aggregates on alkali-activated slag mortar exposed to elevated temperatures. J. Build. Eng. 26, 100871 (2019).

Gong, W. & Ueda, T. Properties of self-compacting concrete containing copper slag aggregate after heating up to 400◦C. Struct. Concrete. 19, 1873–1880 (2018).

Parashar, A. K., Sharma, P. & Sharma, N. Effect on the strength of GGBS and fly Ash based geopolymer concrete. Mater. Today: Proc. 62, 4130–4133 (2022).

Nuaklong, P., Jongvivatsakul, P., Pothisiri, T., Sata, V. & Chindaprasirt, P. Influence of rice husk Ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly Ash geopolymer concrete. J. Clean. Prod. 252, 119797 (2020).

Nuaklong, P. et al. pre-and post-fire mechanical performances of high calcium fly Ash geopolymer concrete containing granite waste. J. Buil Eng. 44, 103265 (2023).

Nuaklong, P. et al. Strength and post-fire performance of fiber-reinforced alkali-activated fly Ash concrete containing granite industry waste. Const. Build. Mater. 392, 131984 (2021).

Deep, A. & Sarkar, P. Enhancing sustainability in concrete construction: utilizing copper slag for improved properties of geopolymer concrete. Const. Build. Mater. 453, 139044 (2024).

Haque, M., Ankur, N., Meena, A. & Singh, N. Carbonation and permeation behaviour of geopolymer concrete containing copper slag and coal ashes. Developments Built Environ. 16, 100276 (2023).

Lu, X. et al. Mechanical properties and hydration of fly ash-based geopolymers modified by copper slag. Mater. Today Comm. 39, 108914 (2024).

Yaswanth, K. K., Revathy, J. & Gajalakshmi, P. Influence of copper slag on mechanical, durability and microstructural properties of GGBS and RHA blended strain hardening geopolymer composites. Constr. Build. Mater. 342, 128042 (2022).

Topal, Ö., Karakoç, M. B. & Özcan, A. Effects of elevated temperatures on the properties of ground granulated blast furnace slag (GGBFS) based geopolymer concretes containing recycled concrete aggregate. Eur. J. Environ. Civil Eng. 26 (10), 4847–4862 (2022).

IS 516. (part-I), Hardened Concrete — Methods of Test Part 1 Testing of Strength of Hardened Concrete Sect. 1 Compressive, Flexural and Split Tensile Strength (Bureau of Indian Standards, 2021).

Deep, A. & Sarkar, P. Enhancing sustainability in concrete construction: utilizing copper slag for improved properties of geopolymer concrete. Constr. Build. Mater. 453, 139044 (2024).

Arunachelam, N., Maheswaran, J., Chellapandian, M. & Ozbakkaloglu, T. Effective utilization of copper slag for the production of geopolymer concrete with different NaOH molarity under ambient curing conditions. Sustainability 14 (23), 16300 (2022).

Acknowledgements

The authors gratefully thank the authors’ respective institutions for their strong support of this study.

Author information

Authors and Affiliations

Contributions

Anasuya Sahu: Conceptualization, Data curation, Formal analysis, Investigation, Writing - original draft. Pramod Kumar: Project administration, Data curation, Formal analysis, Investigation, Writing – original draft, Writing – review and editing. Bheem Pratap: Writing – original draft, Writing – review & editing. Abhilash Gogineni: Supervision, Validation, Visualization, Investigation, Review, and editing. Regasa Yadeta Sembeta: Writing – original draft, Writing – review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical Statement

This study did not involve human participants or animals; no ethical approval was required. All research procedures adhered to relevant ethical guidelines and best practices for non-human and non-animal research.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sahu, A., Kumar, P., Pratap, B. et al. Thermal and mechanical performance of geopolymer concrete with recycled aggregate and copper slag as fine aggregate. Sci Rep 15, 28968 (2025). https://doi.org/10.1038/s41598-025-15153-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-15153-y

Keywords

This article is cited by

-

Enhancing sustainability in RC beams with magnetically treated mixing water for improved flexural performance

Scientific Reports (2025)

-

Performance of geopolymer concrete with over-burnt brick aggregates influence of binder composition and sustainability

Innovative Infrastructure Solutions (2025)