Abstract

To improve the effect of bio-cemented loess, taking into account the characteristics of phosphogypsum and the biochemical principle of enzyme-induced calcium precipitation (EICP), a series of mechanical and microscopic tests are designed and carried out to systematically analyze the enhancement effect of phosphogypsum enhanced EICP solidified loess and the enhancement mechanism. Concentrations of urea and calcium chloride as variables, and unconfined compressive strength (UCS) as an indicator to determine the optimal solution ratio of EICP. Subsequently, different phosphogypsum incorporation ratios were considered to determine the optimal mix proportion for EICP-phosphogypsum co-stabilized loess.The results showed that the addition of phosphogypsum can effectively improve the UCS, water stability, shear strength, and compression characteristics of EICP solidified loess. The phosphogypsum-EICP method has a better effect on improving the strength and water stability of loess with the content of phosphogypsum at 1.0%, compared with the loess treated by EICP, the strength of the specimen with 1.0% phosphogypsum content increased by 19.7%. The microstructure of the solidified loess specimens indicates that the calcium carbonate crystals generated by EICP fill the pores in the loess, thereby reducing its porosity. In addition, phosphogypsum reacts with water to produce hydration, resulting in stronger cementation between calcium carbonate and soil particles.

Similar content being viewed by others

Introduction

Loess is distributed in the arid region of Northwest China, comprising 6.6% of the total land area1,2. The composition of loess minerals is special with 70% clastic minerals and 30% clay minerals.There are many undesirable engineering properties of the loess soil, such as loose structure3,4,5large porosity6,7,8high compressibility9,10,11and strong collapsibility12,13,14,15. Untreated loess is highly susceptible to geological disasters, for example subsidence16,17,18 landslides19,20,21,22, and collapses23,24,25which is not directly used in subgrade engineering. Therefore, it is necessary to improve the stability and strength of loess soil to meet the construction requirements26.

At present, the common methods used to solidify loess soil include physical reinforcement27,28,29,30,31chemical reinforcement32,33,34,35,36, and biological reinforcement37,38,39,40. Among these, the construction process of the physical reinforcement method is more complex and costly. Although the chemical reinforcement method is relatively simple to construct, the chemical reagents used are more expensive, and some of the reagents are toxic, which have certain adverse effects on soil and vegetation. With the rise of environmental protection concepts such as “lucid waters and lush mountains” and “carbon neutrality”, enzyme induced carbonate precipitation (EICP), as a new soil reinforcement method, has received extensive attention from scholars both domestically and internationally in recent years41,42,43.

The application potential of EICP technology in soil treatment has been widely studied. Zhang et al. studied the stability of EICP technology in soil remediation under complex conditions and confirmed that EICP can significantly improve the erosion resistance of loess and provide new insights into the remediation of heavy metal-polluted loess sites. However, they did not study the ability of EICP technology to improve the strength of loess44. Martin et al. found that EICP can create bio-cemented soil columns, which is a feasible method for foundation improvement, It has been confirmed that EICP can effectively treat soil45. Almajed compared soil treated with EICP with soil treated using traditional methods and demonstrated that EICP technology has a higher soil solidification capacity than cement, but the reinforcement capacity of EICP technology alone is very limited46. In recent years, research on EICP technology for soil treatment has gradually shifted its focus to studying the combined effects of EICP and other materials on soil. Tong et al. conducted disintegration experiments and found that combining EICP with fibre technology can improve the disintegration resistance of loess, but the fibres are brittle, their strength does not increase significantly, and they are costly and harmful to the environment47. Chen et al. used recycled tyre rubber particles combined with EICP technology to reinforce loess, demonstrating that the combination of rubber particles and EICP technology can increase the strength of modified loess by nearly 50%. However, the study focused on lower confining pressures, resulting in limited applicability48. Arab adopted the DOE method in his design and found that sodium alginate (SA)-modified EICP samples had better water retention properties than conventional EICP-treated soils, providing an efficient and environmentally friendly alternative for soil stabilisation and improvement49.

In summary, the existing EICP technology for solidifying loess has disadvantages such as poor effectiveness, limited applicability, and high costy. In order to improve its strength and stability, it is necessary to find a new material combining with EICP technology to treat loess. Phosphogypsum, as a solid waste product and a by-product of industrial production, has been used in recent years for soil improvement. The addition of phosphogypsum in the loess can reduce the plastic limit and improve its engineering properties. Phosphogypsum has a positive impact on loess improvement, and EICP technology can also enhance soil strength. However, the synergistic effects of combining phosphogypsum with EICP technology during the loess consolidation process require further investigation.

This study designed and conducted a series of mechanical and microscopic tests to investigate the synergistic effect of phosphogypsum and EICP technology in the consolidation of loess for the first time. Uniaxial compression tests (UCS) were used to explore the optimal ratio of EICP solution. then, considering different phosphogypsum content levels, a series of tests were conducted to discuss the uniaxial compressive strength (UCS), water stability, shear strength, and compressive characteristics of phosphogypsum-EICP consolidated loess, determining the optimal mixture ratio for EICP-phosphogypsum joint consolidation of loess. Additionally, the microscopic mechanism of phosphogypsum-EICP consolidated loess was studied. This study provides reliable scientific basis for soil reinforcement in loess regions and offers a feasible solution for the pollution-free treatment of industrial by-product phosphogypsum, demonstrating good economic benefits.

Materials and methods

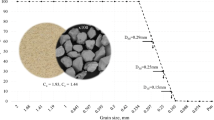

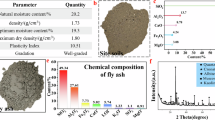

Loess soil and phosphogypsum

The loess used in the test was collected from a building foundation pit in Shaanxi Province, China, at a depth of 2~3 m, as shown in Figure 1(a). The soil texture is uniform and yellow-brown. The clay content of the loess used in the experiment was 25.83%, the silt content was 66.63%, and the sand content was 7.54%. The internal friction angle of the loess used in this study was 7.2°, and the cohesion was 20.7 kPa. The natural air-dried loess soil sample was passed through a 2 mm sieve, and the basic physical indicators are shown in Table 150. Figure 1( b ) shows the X-ray diffraction (XRD) analysis results of loess47. From the figure, it can be seen that its main components are quartz, albite, and calcite.

The selected industrial solid waste material, phosphogypsum, is a gray-white powder. When exposed to water, it solidifies into a hard solid and exhibits a certain degree of water absorption. The main components and parameters are also presented in Table 2.

During sample preparation, the prepared EICP solution is poured into the loess and thoroughly mixed. The mixture is then formed into samples and placed in a curing chamber for seven days.

(a) Photos of sampling points at the site, and (b) XRD images47.

EICP solution

The EICP solution is prepared by mixing urease solution with cementing solution. Two main sources of urease in EICP solution: one is extracted urease from plants such as soybeans and concanavalin; and the other is produced urease from bacteria51,52,53. In this experiment, plant-derived urease was used, sourced from soybean. The preparation process of the urease solution is shown in Figure 2, soybean flour and deionized water were mixed at a mass ratio of 1:10 in a beaker. The mixture was stirred for 30 min using a magnetic stirrer, then uniformly transferred into centrifuge tubes. The solution was centrifuged at 3000 rpm for 30 min. After centrifugation, the supernatant in the tubes was collected as the urease solution.

The cementing solution is a mixture of urea and calcium source solution, which can be selected as calcium chloride and urea content ratios of 1.0:0.5, 1.0:1.0, 1.0:1.554, and 1.0:2.0 mol/L to explore the optimal ratio of calcium chloride solution to urea. Additionally, the prepared cementing solution and the bean enzyme solution were used to prepare the EICP solution concentrations of 0.5, 1.0, 1.5, and 2.0 mol/L respectively. The prepared EICP solution is shown in Table 3.

Methods

Unconfined compressive strength (UCS) test

The apparatus is a strain unconfined pressure equipment, which includes a load cell, a pressurized frame, and lifting spirals, etc. The UCS test can be divided into two parts to explore the strength and mechanism of the solidified loess soil: the first part is to determine the optimal ratio of EICP in the solidified loess, mainly considering the factors as the ratio of different calcium chloride solution concentrations to urea and different EICP solution concentrations; Based on the optimal EICP solution ratio in the first part, the second part is to add the phosphogypsum into the mixed samples. Samples with phosphogypsum contents (PC) of 0%, 0.4%, 0.8%, 1.0%, and 1.2% were prepared for the UCS test. In the experiment, the dimensions of the test samples was 50 mm diameter and 100 mm height50.

Soaking test

EICP solidified loess soil samples with the five PCs mentioned in the UCS test are placed in soaking boxes to observe changes in the surface and internal structure of the samples during the same time, the specimens were photographed at 10 s, 10 min, 30 min, 1 h, 2 h, and 24 h respectively for documentation. This test aims to analyze the water stability properties. The evaluation indicators mainly included the time required for disintegration, the surface smoothness of the sample after soaking, and the number of scattered soil particles in the soaking box55.

Compressive test

The consolidation test is conducted by WG-2B single lever consolidation apparatus, which consists of consolidation container, pressurization equipment, and deformation measurement equipment. The experiment adopted the standard consolidation method with a total of six sets of tests with PC of 0%, 0.4%, 0.8%, 1.0%, 1.2%, and pure loess with EICP solution. The test employed a staged loading sequence of 12.5 kPa, 25 kPa, 50 kPa, 100 kPa, 200 kPa, 400 kPa, 800 kPa, and 1600 kPa. Each pressure level was maintained for 24 h or until the specimen deformation rate decreased below 0.01 mm per hour. After recording stabilized readings, the next pressure increment was applied sequentially until test completion50.

Direct shear test

The apparatus used in the experiment is the ZJ-2 strain controlled direct shear equipment. The test method is the fast shear test. There are four vertical stress are applied to the samples, i.e., 100 kPa, 200 kPa, 300 kPa and 400 kPa. The shear rate is set to 0.8 mm/min.

Results

Optimal solution ratio of EICP

Figure 3 shows the stress-strain curve of the UCS test with different calcium chloride to urea ratios for the same EICP concentration. It can be seen that the UCS of the EICP solidified loess soil is more than double that of the pure loess soil. The compressive capacity of the solidified loess soil sample has been significantly improved, which preliminarily demonstrates the solidified effect of EICP on loess soil. Figure 3 (a) shows the peak strength of the EICP solidified loess soil falls into a narrow band, but that a sightly improvement at a certain extent compared to the strength of pure loess soil when C (cc): C (ur) is 1:0.5. However, it can be found from Figure 3 (b) that there is a clear distinction among the UCS values of each EICP solidified loess soil sample, with the order being 1.5 mol·L-1>2.0 mol·L-1>1.0 mol·L-1>0.5 mol·L-1, when C (cc): C (ur) is 1:1. The same trends can also be observed in Figure 3 (c) and (d). This can be explained by the fact that a higher of the concentration of calcium chloride results in lower mobility of calcium ions, which slightly inhibits the ionic strength of the solution Almajed et al.56. Therefore, the optimal concentration of EICP solution can be taken as 1.5 mol in the current study.

Figure 4 displays the variation of the UCS with the cementation solution concentration (CSC) under different C (cc): C (ur). It can be observed that the UCS increases with an increase in cementation solution concentration firstly, and then decreases when the cementation solution concentration exceeds 1.5 mol·L-1. Interesting, the UCS increases with an increase in cementation solution concentration when C (cc): C (ur) is 1:0.5. This trend differs from the other three concentration ratios, indicating that the cementation solution concentration used in this type did not reach the optimal concentration for solidifying loess. Additionally, the UCS of the EICP solidified loess soil when C (cc): C (ur) is 1:1.5 is the highest among the other C (cc): C (ur). At this point, compared to the UCS of 143 kPa for native soil, the UCS of solidified soil with a binder concentration of 1.5 mol/L was 515 kPa, an increase of nearly five times. Figure 5 shows the failure morphology of EICP solidified loess soil with different CSC when C (cc): C (ur) is 1:1.5. The sample has cracked from the middle along an oblique line and is completely separated into upper and lower parts with most of the surrounding soil scattered under the condition of CSC being 0.5 mol·L-1. When the CSC are 1.0 mol·L-1 and 2.0 mol·L-1, the samples are not completely fractured. However, they have no bearing capacity at all, and the surrounding soil of them are scattered severely. When the CSC is 1.5 mol·L-1, cracks can be observed; however, the soil blocks did not appear depressions along the cracks. The transverse deformation was smaller than that of the other three conditions, and the scattering of the surrounding soil is also better. It is verified that the strength of EICP solidified loess soil with C (cc): C (ur) of 1:1.5 was the highest when the CSC is 1.5 mol·L-1.

Water stability

Figure 6 shows the comparison of soaking test results between unsolidified loess soil and EICP solidified loess soil. As can be seen from Figure 6 that the unsolidified loess soil has been disintegrated after being soaking in water for about 10 min. While, the EICP solidified loess soil disintegrates completely for about 24 h. It can indicate that the water stability of unsolidified loess soil is worse than that of EICP solidified loess soil. This can be explained by the fact that the unsolidified loess soil has a looser structure and larger porosity, which weakens the cohesive among the soil particles, resulting in rapid disintegration during soaking57. For EICP solidified loess soil, the calcium carbonate generated by the EICP solution can effectively fill the porosity within the samples, making the loess structure more compact, reducing porosity, and greatly enhancing water stability compared to unsolidified loess soil. But the EICP solidified loess exhibits obvious disintegration characteristics at 1 h, indicating that the water stability of the samples need to be strengthened.

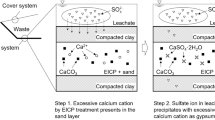

In general, phosphogypsum can agglomerate soil particles, reduce porosity, and increase the interlocking force among soil particles. It also can be served as a fine solid to fill the voids. Phosphogypsum can react with water to form hydrates, generating hydrated gypsum cementitious substances. These cementitious substances can fill the micro-pores within the soil, forming a relatively solid cementitious system to enhance the water stability of solidified loess.

Figure 7 shows the soaking test results of the phosphogypsum addition on the basis of EICP solidified loess with PC = 0.4%, 0.8%, 1.0% and 1.2%58, respectively. It can be found that the water stability increases first, and then decreases with an increase in PC. In Figure 7(a), the solidify effect of phosphogypsum is not obvious compared to the EICP solidified loess soil. It can explain that the added PC is insufficient, resulting in inadequate pore filling. Figure 7 (d) shows the solidify effect of phosphogypsum is not obvious when PC = 1.2%. The main reason is that phosphogypsum has the ability to absorb water. When the PC is too much, it can affect the reaction of EICP solution, reduce the generation of calcium carbonate, and subsequently impact the solidify effect. When PC = 1% (Figure 7(d)), small pores appear on the surface of the sample at t = 10 min. At t = 1 h and t = 2 h, the pores become larger and more numerous. At t = 24 h, the sample completely disintegrates, with smaller gaps on the outer surface and smaller scattered soil particles. When PC = 1% (Figure 7(c)), the sample surface remained intact at t = 10 min. At t = 1 h, fragmentation occurred in the lower left corner, but the sample surface remained smooth. At t = 2 h, no significant expansion of the cracks was observed. At t = 24 h, the sample was completely destroyed, with a smooth outer surface, no cracks, and no scattered soil particles. Therefore, EICP can enhance the water stability, and its combination with phosphogypsum can further improve the water stability of loess soil. The appropriate PC is 0.8%~1.0% for the EICP solidified loess soil in the current study.

Compression characteristics

Figure 8 shows the compression curves of the EICP solidified loess soil with different PC obtained from the compression test. Figure 8(a) is the e-p curve of the specimen, which can visualise the trend of the change of the pore ratio of the specimen with the pressure; Figure 8(b) is the e-lgp curve, according to the shape of the compression curve, it can make a judgement on the compressibility of the soil in a qualitative way; the steeper the curve is, the more the soil is compressed, and vice versa, the less compressed it is. It can be seen that the void ratio of the sample exhibits a non-linear decreasing trend with the increase in consolidation pressure. It can be observed from Figure 8 (a) that the compression coefficient decreases with the increasing of consolidation pressure. The test data from Figure 8 (a) can be rewritten in the single logarithmic coordinate, as shown in Figure 8 (b). The finding is that the tangent slope of the curves gradually increases with increasing the consolidation pressure. The unsolidified loess soil has a larger tangent slope at all levels of pressure. All the analyses mentioned above indicated that the compressibility of unsolidified loess soil is greater than that of EICP- phosphogypsum solidified loess soil. The PC effect on the void ration with the order being 1%>0.8%>1.2%>0.4%>0%.

Figure 9 shows the relationship between the compression indexes and consolidation pressure of the EICP solidified loess soil with different PCs. It can be found from Figure 9(a) that the compression modulus increases first, and then decreases with the increasing of consolidation pressure for the unsolidified loess soil. While, the compressive modulus shows an increasing trend with the increasing of consolidation pressure for the EICP solidified loess soil with different PCs. The compression modulus of the EICP solidified loess soil with PC = 1.0% is the largest among the other samples. When the PC = 1%, the compression modulus is 195% higher than that of unsolidified loess soil. While the EICP solidified loess soil increased by 111% compared to unsolidified loess soil. The reason may be explained that the content of calcium carbonate is the main factor affecting the consolidation effect. Additionally, the cohesive generated by the addition of phosphogypsum acts as an auxiliary material, jointly enhancing the consolidation compression characteristics of the loess. The compression coefficient of unsolidified loess soil is much higher than that of solidified loess soil, and the difference in compression coefficient among the EICP solidified loess soil with different PCs is relatively small, as shown in Figure 9(b). This indicates that the compressibility of the EICP solidified loess soil with different PCs is significantly reduced compared to unsolidified loess soil.

Strength characteristics

-

(1)

UCS: Figure 10 shows the stress-strain relation of the EICP solidified soil with different PCs. It can be found that the UCS has increased to a certain extent compared to the EICP solidified soil without phosphogypsum and is significantly higher than that of unsolidified loess soil. The UCS of the EICP solidified soil with PC =0.4% is not greatly improved. The reason can be explained by the fact that the soil particles cannot cohesively bond into a whole when the PC is too small, which prevents the solidifying effect from being fully realized. The UCS increases sequentially when the PC ranges from 0.8% to 1.0%, indicating that the cohesion of soil particles becomes stronger, and the bonding between soil particles becomes tighter when the PC is higher. However, the strength of solidified soil decreases when the PC = 1.2%. It can be explained that an excessive amount of phosphogypsum will affect the reaction process of calcium carbonate generated by the EICP solution, reducing the generation of calcium carbonate and subsequently impacting the strength of the solidified loess.

-

(2)

Shear strength by direct shear test: Figure 11 shows the stress-displacement of the EICP solidified loess soil with different PCs under different vertical pressures, i.e., 100 kPa, 200 kPa, 300 kPa, and 400 kPa. It can be seen that the curves of unsolidified loess soil exhibit strain hardening regardless of the vertical pressure. However, the curves of the EICP solidified loess soil with different PCs exhibit strain softening when the vertical pressure is 100 kPa and 200 kPa. As the increases vertical pressure, the strain softening is weakened. Parts curves of samples exhibit strain hardening. The shear strength of the solidified loess soil was significantly improved compared to the unsolidified loess soil under the same vertical pressure. And the EICP- phosphogypsum solidified loess soil exhibited slightly higher strength than the EICP solidified loess soil. In addition, the shear strength increases as the PC range from 0.1% to 1.0%. When the PC = 1.2%, the shear strength decrease. The conclusion is consistent with the UCS analysis mentioned above.

Figure 12 shows the changes in shear strength with different vertical pressure of unsolidified and solidified loess soil according to the test data from Figure 11. The fitting lines is the relationship between the cohesion and internal friction angle of the unsolidified and solidified loess soil. The equations are also shown in Figure 12 (R2≥0.98). Figure 13 shows the changes in the internal friction angle and cohesion of the samples with the various PCs. It can be found that the PC can improve both the internal friction angle and cohesion of the solidified soil. Figure 13(a) presents that the internal friction angle increases first, and then decreases with an increase in PC of the EICP solidified loess soil. And the peak value occurs when the PC = 1.0%. Figure 13(b) shows that the cohesion increase with an increase in PC. It can be explained by the fact that the cementation effect and filling effect are not pronounced when the PC is small. On the contrary, the cementation ability of soil particles increases and the soil particles become larger when the PC is larger.

Microstructure

Figure 14 shows the mic-structure of the unsolidified and solidified loess soil using scanning electron microscope (SEM) test to explore the microscopic mechanism. Figure 14(a) shows the unsolidified loess soil at the magnification of 110×. It can observe that the pores among the soil particles are larger, and the connections are not tight enough. Figure 14(b) shows the EICP solidified loess soil at the magnification of 100×. It can be observed that after the loess sample is cured, the generated calcium carbonate fills the pores, making the soil layer more compact and significantly reducing the porosity. While Fig. 14(c) shows the EICP solidified loess soil in Figure 14(b) at the magnification of 1010×. It can be clearly observed that the calcium carbonate crystals cement the soil particles together, connecting multiple particles into a cohesive whole. Figure 14(d) shows EICP-phosphogypsum solidified loess soil with PC = 1% at the magnification of 100×. It can be seen that compared the sample with phosphogypsum becomes more compact compared to the EICP solidified loess soil. In addition to filling the pores with calcium carbonate, phosphogypsum reacts with water to produce hydrocephalus gel, which further fills the pores59,60. Figure 14 (e) shows EICP-phosphogypsum solidified loess soil in Figure 14(d) at the magnification of 200×. It can be observed further that the cross-section of the solidified loess soil is relatively flat. There is hardly any porosity in the surface of the sample. This is the reason why the water stability characteristics and direct shear strength are significantly improved after the addition of phosphogypsum. The flow of water within the soil is hindered when the soil porosity is reduced, thereby slowing down the penetration rate of water. At the same time, the reduction in porosity increases the contact area and interaction force between soil particles, making the internal structure of the soil more stable, which enhances the cohesion and shear strength of the soil.

Conclusion

In general, phosphogypsum can agglomerate soil particles, reduce porosity, and increase the interlocking force among soil particles. It also can be served as a fine solid to fill the voids. Phosphogypsum can react with water to form hydrates, generating hydrated gypsum cementitious substances. These cementitious substances can fill the micro-pores within the soil, forming a relatively solid cementitious system to enhance the water stability of solidified loess. The mechanism by which EICP solidifies loess involves extracting urease from plants to catalyse the decomposition of urea, utilising a calcium ion source to induce the precipitation of large amounts of calcium carbonate during the enzymatic reaction. As seen in the SEM electron microscope images, the hydrated gypsum cementitious substances formed by phosphogypsum and water fill the microporous spaces within the calcium carbonate deposits in loess, thereby enhancing the solidification effect of EICP technology on loess.

In this paper, the feasibility of phosphogypsum enhanced EICP method for loess solidification is studied. Through immersion test, UCS test, direct shear test, compression test, and microscopic test, the mechanical properties and microstructure of loess solidified with phosphogypsum and EICP are discussed, and the following conclusions are drawn:

-

(1)

With the increase of urea concentration, the generation of calcium carbonate first increases and then decreases. Too high urea concentration would inhibit the activity of urease and affect the generation of calcium carbonate, and the optimal ratio is C(cc): C(ur) = 1:1.5. The concentration of cementation solution also affects the generation of calcium carbonate, and the optimal concentration of cement is 1.5 mol·L-1.

-

(2)

The combination of EICP and phosphogypsum can effectively improve the unconfined compressive strength and water stability of loess. Compared with the loess treated by EICP, the strength of the specimen with 1.0% phosphogypsum content increased by 19.7%. It is found that the stabilization time of EICP-phosphogypsum treated loess after water immersion is significantly increased and the disintegration rate is reduced by the water immersion test.

-

(3)

The shear strength of EICP-phosphogypsum solidified loess is slightly higher than that of the specimens treated with EICP solution. With increasing phosphogypsum content, the cohesion gradually increases, but the internal friction angle exhibits a tendency to increase first and then decrease. The compressibility characteristics of loess specimens treated by EICP and phosphogypsum have been significantly improved.

-

(4)

The SEM images can further verify the mechanical test results and reveal the mechanism of EICP-phosphogypsum solidified loess. It is observed that the calcium carbonate crystals generated by EICP will fill the pores in the loess and reduce the porosity. In addition, phosphogypsum reacts with water to produce hydration, resulting in stronger cementation between calcium carbonate and soil particles.

-

(5)

This study provides reliable scientific basis for soil reinforcement in loess regions. In practical engineering applications, the experimental results can be referenced to use a binder solution with a ratio of C(cc): C(ur) = 1:1.5 and 1.5 mol·L-1, combined with 1% phosphogypsum, for loess solidification. This provides a feasible solution for the pollution-free treatment of phosphogypsum, an industrial by-product, and offers good economic benefits.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Li, X., Zan, J., Yang, R., Fang, X. & Yang, S. Grain-size-dependent geochemical characteristics of middle and upper pleistocene loess sequences from the Junggar basin: implications for the provenance of Chinese Eolian deposits. Palaeogeography Palaeoclimatology Palaeoecology. 538. https://doi.org/10.1016/j.palaeo.2019.109458 (2020).

Zhan, L. et al. Performance of a compacted loess/gravel cover as a capillary barrier and landfill gas emissions controller in Northwest China. Sci. Total Environ. 718. https://doi.org/10.1016/j.scitotenv.2020.137195 (2020).

Song, J. et al. Study on fractal characteristics of mineral particles in undisturbed loess and Lime-Treated loess. Materials 14. https://doi.org/10.3390/ma14216549 (2021).

Wei, T. T., Fan, W., Yu, N. Y. & Wei, Y. N. Three-dimensional microstructure characterization of loess based on a serial sectioning technique. Eng. Geol. 261. https://doi.org/10.1016/j.enggeo.2019.105265 (2019).

Zheng, H., Li, X. A., Deng, Y. H., Hao, Z. T. & Wen, F. Study on the influence of initial state on loess erosion characteristics and microscopic mechanism. Sustainability 15 https://doi.org/10.3390/su15054676 (2023).

Li, X. et al. Quantification of macropores of Malan loess and the hydraulic significance on slope stability by X-ray computed tomography. Environ. Earth Sci. 78. https://doi.org/10.1007/s12665-019-8527-2 (2019).

Sun, H., Xie, M. X., Cui, W. W., Xie, X. W. & Zong, S. T. Research progress of loess reinforcement technology: A bibliometric network analysis. Constr. Build. Mater. 436. https://doi.org/10.1016/j.conbuildmat.2024.136942 (2024).

Wang, L., Cheng, W. C. & Xue, Z. F. The Use of Agricultural Waste Straw to Enhance Loess Shearing Behaviour: An Experimental Investigation. Advances in Materials Science and Engineering 2020. (2020). https://doi.org/10.1155/2020/2978128

Li, G. K. et al. Stability evaluation model for loess deposits based on PCA-PNN. Geomech. Eng. 27, 551–560. https://doi.org/10.12989/gae.2021.27.6.551 (2021).

Li, Z., Lv, S. X., Liu, L. L., Guo, J. & Liu, T. Compressive deformation characteristics of sintered loess after being saturated with water. Int. J. Geomech. 24. https://doi.org/10.1061/ijgnai.Gmeng-9828 (2024).

Wang, X. Y., Song, Q. Y. & Gong, H. Research on deformation law of deep foundation pit of station in core region of saturated soft loess based on monitoring. Adv. Civil Eng. 2022 https://doi.org/10.1155/2022/7848152 (2022).

Chen, L. F., Chen, K., He, G. Y. & Liu, Z. Q. Research on the prediction model of loess collapsibility in Xinyuan county, Ili river Valley area. Water 15 https://doi.org/10.3390/w15213786 (2023).

Hou, Y. F., Li, P. & Wang, J. D. Review of chemical stabilizing agents for improving the physical and mechanical properties of loess. Bull. Eng. Geol. Environ. 80, 9201–9215. https://doi.org/10.1007/s10064-021-02486-x (2021).

Nan, Y. L., Wei, Y. N., Liu, K. & Cao, Y. B. Quantitative 3D Characterization of Pore Structure in Malan Loess from Different Regions of the Loess Plateau. Water 15. (2023). https://doi.org/10.3390/w15173151

Yang, J.L.; Li, S.Y.; Di, H.G.; Liu, D.R.; Wang, X.; Zhao, J.Y. Experimental investigations on the physico-mechanical and microstructural properties of loess reinforced with anionic polyacrylamide. Construction and Building Materials. (2023). https://doi.org/10.1016/j.conbuildmat.2023.134124

Liao, M.J.; Zhang, R.; Lv, J.C.; Yu, B.; Pang, J.T.; Li, R.; Xiang, W.; Tao, W. Subsidence Monitoring of Fill Area inYan’an New District Based on Sentinel-1A Time Series Imagery. Remote Sensing. (2021). https://doi.org/10.3390/rs13153044

Tang, F. Q., Lu, J. X. & Li, P. F. A prediction model for mining subsidence in loess-covered mountainous areas of Western China. Curr. Sci. 116, 2036–2043. https://doi.org/10.18520/cs/v116/i12/2036-2043 (2019).

Zhao, B. C. et al. Prediction method for surface subsidence of coal seam mining in loess Donga based on the probability integration model. Energies 15 https://doi.org/10.3390/en15062282 (2022).

Cheng, W. C., Duan, Z., Xue, Z. F. & Wang, L. Sandbox modelling of interactions of landslide deposits with terrace sediments aided by field observation. Bull. Eng. Geol. Environ. 80, 3711–3731. https://doi.org/10.1007/s10064-021-02144-2 (2021).

Lian, B. Q. et al. Formation mechanism analysis of irrigation-induced retrogressive loess landslides. Catena 195. https://doi.org/10.1016/j.catena.2019.104441 (2020).

Meng, Z. J., Ma, P. H. & Peng, J. B. Characteristics of loess landslides triggered by different factors in the Chinese loess plateau. J. Mt. Sci. 18, 3218–3229. https://doi.org/10.1007/s11629-021-6880-6 (2021).

Yu, Z. B., Chang, R. C. & Chen, Z. Automatic detection method for loess landslides based on GEE and an improved YOLOX algorithm. Remote Sens. 14. https://doi.org/10.3390/rs14184599 (2022).

Hong, Q. Y., Lai, H. P. & Liu, Y. Y. Failure analysis and treatments of collapse accidents in loess tunnels. Eng. Fail. Anal. 145. https://doi.org/10.1016/j.engfailanal.2022.107037 (2023).

Xu, Z. G., Cai, N. G., Li, X. F., Xian, M. T. & Dong, T. W. Risk assessment of loess tunnel collapse during construction based on an attribute recognition model. Bull. Eng. Geol. Environ. 80, 6205–6220. https://doi.org/10.1007/s10064-021-02300-8 (2021).

Zhang, Y., Hu, Z. Q. & Xue, Z. J. A new method of assessing the collapse sensitivity of loess. Bull. Eng. Geol. Environ. 77, 1287–1298. https://doi.org/10.1007/s10064-018-1372-9 (2018).

Zhang, Y. C., Yao, Y. G., Ma, A. G. & Liu, C. L. In situ tests on improvement of collapsible loess with large thickness by down-hole dynamic compaction pile. Eur. J. Environ. Civil Eng. 24, 156–170. https://doi.org/10.1080/19648189.2017.1370393 (2020).

Gao, C. H., Du, G. Y., Liu, S. Y., He, H. & Zhang, D. W. The microscopic mechanisms of treating collapsible loess with vibratory probe compaction method. Transp. Geotechnics. 27. https://doi.org/10.1016/j.trgeo.2020.100492 (2021).

Jiang, X. M., Hou, L. L., Shang, S. P., Xu, L. F. & Yu, H. F. Physical Modeling of a Shallow-Buried Metro Tunnel in the Soft Loess Layer Using Similarity Theory. Advances in Civil Engineering 2022. (2022). https://doi.org/10.1155/2022/5587116

Liu, Y., Han, D. D., Liu, N. A. & Wang, W. T. Reinforcement mechanism analysis of lattice beam and prestressed anchor rod system for loess slope. Front. Earth Sci. 11. https://doi.org/10.3389/feart.2023.1121172 (2023).

Xu, T. Y. et al. Real-Time monitoring method for layered compaction quality of loess subgrade based on hydraulic compactor reinforcement. Sensors 20. https://doi.org/10.3390/s20154288 (2020).

Yan, Q., Li, S. C., Xie, C. & Li, Y. Analytical solution for bolted tunnels in expansive loess using the Convergence-Confinement method. Int. J. Geomech. 18. https://doi.org/10.1061/(asce)gm.1943-5622.0000989 (2018).

Lian, B. Q., Peng, J. B., Zhan, H. B. & Cui, X. S. Effect of randomly distributed fibre on triaxial shear behavior of loess. Bull. Eng. Geol. Environ. 79, 1555–1563. https://doi.org/10.1007/s10064-019-01666-0 (2020).

Wang, X. G., Liu, K. & Lian, B. Q. Experimental study on ring shear properties of fiber-reinforced loess. Bull. Eng. Geol. Environ. 80, 5021–5029. https://doi.org/10.1007/s10064-021-02243-0 (2021).

Wu, Z. P. et al. Shear strength and mesoscopic characteristics of basalt Fiber-Reinforced loess after Dry-Wet cycles. J. Mater. Civ. Eng. 34. https://doi.org/10.1061/(asce)mt.1943-5533.0004225 (2022).

Yang, B. H. et al. Strength characteristics of modified polypropylene fiber and cement-reinforced loess. J. Cent. South. Univ. 24, 560–568. https://doi.org/10.1007/s11771-017-3458-0 (2017).

Yuan, K. Z., Ni, W. K., Lu, X. F. & Zhu, M. Experimental study on the performance of the modified loess by polypropylene fiber mixed with bentonite and cement. Bull. Eng. Geol. Environ. 81. https://doi.org/10.1007/s10064-022-02800-1 (2022).

Li, Q. et al. Relative contribution of root physical enlacing and biochemistrical exudates to soil erosion resistance in the loess soil. Catena 153, 61–65. https://doi.org/10.1016/j.catena.2017.01.037 (2017).

Vergani, C., Chiaradia, E. A., Bassanelli, C. & Bischetti, G. B. Root strength and density decay after felling in a silver Fir-Norway Spruce stand in the Italian alps. Plant. Soil. 377, 63–81. https://doi.org/10.1007/s11104-013-1860-4 (2014).

Yang, Y. et al. Review of Managing Soil Organic C Sequestration from Vegetation Restoration on the Loess Plateau. Forests 14. (2023). https://doi.org/10.3390/f14101964

Yang, Y. D. et al. Evaluation of the Reinforcement Performance of Loess Slopes Affected by Rainfall Infiltration. Geofluids 2022. (2022). https://doi.org/10.1155/2022/5359809

Wang, H. X. et al. Induced CaCO3 mineral formation based on enzymatical calcification for bioremediation under different pressure conditions. J. Petrol. Sci. Eng. 216. https://doi.org/10.1016/j.petrol.2022.110787 (2022).

Wu, L., Miao, L., Sun, X. & Wang, H. Enzyme-Induced carbonate precipitation combined with Polyvinyl alcohol to solidify aeolian sand. J. Mater. Civ. Eng. 33. https://doi.org/10.1061/(asce)mt.1943-5533.0004009 (2021).

Yuan, H., Liu, K., Zhang, C. & Zhao, Z. Mechanical properties of Na-montmorillonite-modified EICP-treated silty sand. Environ. Sci. Pollut. Res. 29, 10332–10344. https://doi.org/10.1007/s11356-021-16442-5 (2022).

Zhang, K. & Zhang, S. Feasibility study of applying Enzyme-Induced carbonate precipitation (EICP) without calcium source for remediation of Lead-Contaminated loess. Buildings 14 (6). http://dx.doi.org/10.3390/ buildings14061810 (2024).

Martin, K. K., Tirkolaei, H. K. & Kavazanjian, E. Jr. Mid-scale biocemented soil columns via enzyme-induced carbonate precipitation (EICP). Soils Found. 61, 1529–1542. https://doi.org/10.1016/j.sandf.2021.09.001 (2021).

Almajed, A. et al. Enzyme-Induced carbonate precipitation (EICP)-Based methods for ecofriendly stabilization of different types of natural sands. J. Clean. Prod. 274 https://doi.org/10.1016/j.jclepro.2020.122627 (2020).

Tong, Z. et al. Experimental study on solidified loess by Enzyme-Induced carbonate precipitation combined with polypropylene fiber. J. Test. Eval. https://doi.org/10.1520/jte20240353 (2025).

Chen, Y. et al. Experimental study on shear mechanical properties of improved loess based on rubber particle incorporation and EICP technology. Front. Earth Sci. 11. https://doi.org/10.3389/feart.2023.1270102 (2023).

Arab, M. G. et al. Optimizing the compressive strength of sodium Alginate-Modified EICP-Treated sand using design of experiments. J. Mater. Civ. Eng. 36 (4). https://doi.org/10.1061/jmcee7.Mteng-16400 (2024).

GB/T 50123 -. Standard for geotechnical testing method. [S]. Beijing: Standards Press of China, 2019. (2019).

Anbu, P., Kang, C. H., Shin, Y. J. & So, J. S. Formations of calcium carbonate minerals by bacteria and its multiple applications. Springerplus 5 https://doi.org/10.1186/s40064-016-1869-2 (2016).

Cui, M. J., Lai, H. J., Wu, S. F. & Chu, J. Comparison of soil improvement methods using crude soybean enzyme, bacterial enzyme or bacteria-induced carbonate precipitation. Geotechnique 74, 18–26. https://doi.org/10.1680/jgeot.21.00131 (2022).

Zhao, Q. et al. Factors affecting improvement of engineering properties of MICP-Treated soil catalyzed by bacteria and urease. J. Mater. Civ. Eng. 26. https://doi.org/10.1061/(asce)mt.1943-5533.0001013 (2014).

Cui Meng, F. et al. Multi-experiment study on calcium carbonate precipitation induced by soybean urease [J]. Rock. Soil. Mech., (11): 1–9. (2022).

HJ/T 166-2004. Technical Specification for Soil Environmental Monitoring. [S] (Standards Press of China, 2004).

Almajed, A., Tirkolaei, H. K. & Kavazanjian, E. Jr. Baseline investigation on Enzyme-Induced calcium carbonate precipitation. J. Geotech. GeoEnviron. Eng. 144. https://doi.org/10.1061/(asce)gt.1943-5606.0001973 (2018).

Huo, B. et al. Experimental study on the disintegration characteristics of undisturbed loess under rainfall-induced leaching. Catena 233. https://doi.org/10.1016/j.catena.2023.107482 (2023).

Zhang, Y. Study on the Strength Characteristics and Microstructure of Phosphogypsum Stabilised Soil [D]DOI: 1027047 (Guizhou University, 2022).

Chen, Y., Gao, Y., Ng, C. W. W. & Guo, H. Bio-improved hydraulic properties of sand treated by soybean urease induced carbonate precipitation and its application part 1: water retention ability. Transp. Geotechnics. 27. https://doi.org/10.1016/j.trgeo.2020.100489 (2021).

Zhuang, C. et al. Microbially-Induced calcium carbonate precipitation test on yellow sandstone based on LF-NMR monitoring. Int. J. Environ. Res. Public Health. 19 (24). https://doi.org/10.3390/ijerph192416860 (2022).

Acknowledgements

The authors would like to acknowledge the financial funded by Key Laboratory of Degraded and Unused Land Consolidation Engineering, the Ministry of Natural Resources (Grant No. SXDJ2024-05).

Author information

Authors and Affiliations

Contributions

Data curation, Yuanquan Guo; Formal analysis, Zhiyi Zhang; Funding acquisition, Xuewen Rong; Investigation, Tao Dang; Resources, Baozhen Liang; Software, Fangchen Ma; Writing – original draft, Yuanzhu Ji; Writing – review & editing, Yuanzhu Ji and Yuanquan Guo.All authors will be updated at each stage of manuscript processing, including submission, revision, and revision reminder, via emails from our system or the assigned Assistant Editor.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dang, T., Ji, Y., Guo, Y. et al. Experimental research on the feasibility of phosphogypsum-enzyme induced carbonate precipitation (EICP) solidified loess. Sci Rep 15, 29683 (2025). https://doi.org/10.1038/s41598-025-15229-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-15229-9