Abstract

Cardboard is among the most widely used material to make packaging for goods and products, often used with a short life cycle. Study of literature shows how fiber obtained from pulp in the recycling process can be used in different fields, and numerous experiments are underway. One of the fields of interest is the construction industry, but there has been a strong lack of structured studies about the performance of new products from the recycling process and about impacts during life. For this reason, two corrugated cardboard panels for architectural and insulation use, obtained from recycled material, were designed and tested. Insulating properties have been the subject of previous studies while Life Cycle Assessment, acoustic and mechanical tests were carried out, which provided promising results. In particular, from an acoustic point of view, the panels have proven to be effective mainly at low frequencies. From a mechanical point of view, the stress–strain curves are comparable to those of other studies, although the numerical results are strongly influenced by environmental conditions as well as the manufacturing process. Finally, the LCA analysis highlighted very low impact values, also thanks to the recycling of the product at the end of its life.

Similar content being viewed by others

Introduction

Corrugated cardboard is one of the main materials used for packaging products of all kinds, both for the transport of loose products in stock and for the retail sale of individual goods. In the past, it was used using a typical approach of the so-called linear economy, “take, make, dispose”, but currently in the European context very high annual recycling rates have been achieved, starting with a careful selection of suppliers1 to researching techniques for improving the properties of recycled cardboard1. In fact, according to Bruna Alves2, from 2008 to 2022, the recycling rate of paper and cardboard packaging waste in the European Union has never been lower than 80%. By searching the web of science database with the keywords “recycling” and “cardboard” and “packaging” without placing time constraints, 262 research products are present, with an increase in production from 2000 to today and distributed in the different areas of engineering, environment, energy, chemistry, … Given the recyclability characteristic of paper materials, it is analyzed if the cardboard used to make packaging, once recycled, could contribute to the creation of products intended for other purposes, perhaps even with a longer useful life than that which characterizes packaging, and to be intended for construction. Refining the search by adding the keyword “building*” only 12 products are obtained, four of which are prior to 1995. Among the remaining eight, Smith et al.3 propose the creation of innovative panels made of cardboard packaging, egg boxes, loose polyester and felt. These panels were then tested experimentally to use them in indoor environments to improve thermal and acoustic comfort. Viczek et al.4 use the ashes of different materials deriving from packaging, in particular cardboard, as an additive in the cement production process. In addition to the topic of the creation of new materials, Gonzàlez et al.5 explore into the field of research concerning the management of packaging waste in the construction sector, demonstrating through case studies in the Mediterranean area how the policies implemented to encourage separate waste collection on construction sites have been unsuccessful. Finally, the last topic of interest is the one related to the performance analysis, in fact Asdrubali et al.6,7 analyze two typologies of multilayer corrugated cardboard panels, usually applied in the packaging industry. In particular, the main results of the study show that cardboard panels derived from packaging present promising acoustic and thermal performances as well as in terms of environmental impact analysis. Some of the same authors, Secchi et al.8 have then developed a Life Cycle Assessment analysis to evaluate any environmental advantages compared to conventional acoustic materials, demonstrating a potential reduction of energy and greenhouse gases during the production process. Also Jasiołek et al.9 focused their studies on LCA analysis. Specifically, they designed six paper-based building envelope panel solutions for use in permanent buildings in temperate climates. After analyzing their thermal characteristics, they conducted LCA analysis employing the ecoinvent database and showed that most of the solutions have environmental advantages over traditional solutions.

Some studies concern, even if indirectly, aspects related to construction. For example, Liuzzi et al.10 develop a new material using waste paper derived from non-hazardous urban waste. In particular, it is an insulating panel for internal use, made according to different compositions with different percentages of recycled material. While Mahdi et al.11 incorporate finely worked municipal waste cardboard into an innovative concrete mix whose performance characteristics were then studied through a program of experimental tests. A similar approach is also employed by Lamounier Faria et al.12 employing cardboard tube scraps used as formwork to produce building insulation material. They demonstrate, using thermographic data, a significant increase in the thermal insulation of the building to which they applied the new product. Benallel et al.13 study materials composed of cardboard reinforced with fibers sourced from date palm trees glued with water and studied their thermal, acoustic and hygroscopic properties. Also related to the analysis of the properties of innovative materials, Mathewes et al.14 are interested in this topic, studying panels made of recycled cardboard aggregates in different weight compositions and biodegradable binders. Corn starch, lime, clay were used and physical, thermal and mechanical properties were studied.

Cripps11 create a small cardboard building to address the related challenges in terms of design, manufacturing, construction, and cost definition. Similarly, also for Distefano et al.15, who present a temporary emergency house based on a prefabricated cardboard system called Archicart, which is suitable for making parts of buildings or complete housing modules. They then carried out the thermal analysis of the performance measured on site. Instead, Betts et al.16 create twelve sandwich beams with a recycled corrugated cardboard core and analyze their mechanical performances, demonstrating that these beams behave similarly to those with a foam core. Rotilio17,18 creates a sensorized panel, produced with waste from the industrial production process of paper and cardboard intended for construction and analyzes its thermal performances. Finally, Diarte and Vazquez19 also focus on the theme of the modular house, developing the design and generating the manufacturing instructions for some parts of the building. The research on the state of the art has highlighted how the interest in the use of cardboard derived from packaging is a hot topic in the international panorama but future use will be possible only thanks to the knowledge of the actual performance of the material.

Structural use is perhaps the most complex to manage and the furthest to achieve in a generalized form. This is because the concept of material is very broad and complex, with numerous compositions obtainable from a chemical and physical point of view. Therefore, the typologies should be standardized in order to be able to provide reliable and comparable results. In fact, the mechanical properties vary greatly depending on the type of starting mixture and depend on a variety of factors: the type of fibers chosen, the additives and the glue substances added, the production process, the final density20. They are also strongly influenced by some external factors such as humidity, the increase of which determines the opening of the bonds between the fibres, a condition which is associated with a significant decrease in the elastic modulus of the material and of all those quantities which depend on it, such as the tensile strength21. Some authors22 estimated that a 1% increase in the moisture content of the material results in a loss of about 10% of its mechanical strength, while others20 highlighted how temperature variations are not associated with evident modifications of the material properties. Another important aspect to consider in terms of mechanical properties is related the methods of application of the loads. In fact, many authors23 noted how the creep phenomenon (the visco-elastic deformation resulting from the long-term application of a constant load) in the case of cardboard has a significant impact.

For the above, given the evident variability of the results, it is very important to provide detailed information on the sample investigated, the environmental conditions and the methods of applying the load. Furthermore, given the anisotropy of the material, three fundamental directions are conventionally identified to define the mechanical properties of paper and elementary paper products, machine direction (MD), cross-machine direction (CD)24 and direction of thickness (ZD). They depend on the paper manufacturing process, during which the fibers are aligned mainly in the longitudinal development direction of the bobbin (MD) rather than in the transversal direction (CD). For this reason, at least in their elementary configuration, they present different resistance values in the directions mentioned. In literature it is also possible to find some analytical formulas that correlate the mechanical properties associated with MD with those of CD, however the existing studies are rather limited. As argued, it is evident that the research field concerning the use of cardboard in construction is still in a preliminary study phase, especially in terms of performance and impact analysis. Therefore, starting from a previous study17, two cardboard panels of equal dimensions but made up of two corrugated cardboard layers, both 100% recycled fibers, were studied and were tested from a mechanical and acoustic point of view to evaluate their usability as component elements of architectural panels. Furthermore, to evaluate the convenience of using cardboard also from an environmental point of view, the Life Cycle Assessment was developed.

Materials

In this research, two types of samples consisting of several layers of corrugated cardboard made from 100% recycled fiber were tested. The cardboard used comes from single-layer paper bobbins that are assembled in a corrugator using cornstarch, which, at high temperatures, results in the reinforcement of the substrate. No other thickening materials are used in order to have low or no ecotoxicological impact. In turn, the paper used comes from the Comieco recycling chain, selected to eliminate impurities, and has FSC certification.

The layers forming the samples are glued together with water-based vinyl glue for a total thickness of about 10 cm, following a pattern characterized by the rotation of the fluting direction by 90 degrees every two layers. The layers forming X-type samples are made of a B-flute combined with a C-flute board, while the once forming Y-type samples are made of two E-flute boards overlapped (Fig. 1). The different composition results in a significant variation in the amount of material per square meter and, consequently, in all properties depending on it. The technical specifications of the tested samples are reported in Tables 1 and 2. Since cardboard is a hygroscopic material, some of its properties can vary depending on environmental moisture, so it is always essential to specify the hygrothermal conditions of the environment when conducting tests on cardboard elements.

Methods

The section illustrates the methodology used to analyze the performance of the two panels described in chapter 2, from an acoustic and mechanical point of view, and the one used to measure the environmental impacts through the Life Cycle Assessment (LCA) approach. The paragraph is therefore divided into three main sections.

Methods for assessing acoustic properties

The acoustic characterization was carried out with the samples intended to be positioned vertically to separate two contiguous environments.

Standards

The acoustic tests were based on the standards ISO 16283-1:201425, ISO 717-1:202026, ISO 3382-2:200827, IEC 61672-1:201328, IEC 61260-1:201429.

Equipment

Two different measurement procedures were employed using a non-standardized test machine. The apparatus consists of two wooden boxes of equal size, each measuring 80x70x50 cm, giving an interior volume of about 0.30 m3. Each box has one open vertical face so that, when placed facing each other, the two boxes form a single unit. The perimeter contact surface between the boxes is lined with rubber to minimize sound losses. One of the boxes contains a loudspeaker that can be connected to a device for emitting sounds; in this case, a PC was used as the sound source. The other box has a hole sized for the insertion of a standardized sound level meter, which allows the measurement of the incoming sound wave’s power. Two different sound level meters were used:

-

a CESVA SC-20c, capable of measuring the overall sound power of the received sound without distinguishing frequencies.

-

a Brüel & Kjær 2250, capable of receiving an entire acoustic spectrum, which can subsequently be decomposed into frequencies.

Method 1

The sound is emitted by the loudspeaker in octave bands and the intensity of the sound pressure level is measured by means of a sound level meter in the receiving box. First of all, the test is performed with the empty system, i.e., the sound is emitted by the loudspeaker and its intensity is measured by the sound level meter without any sample being placed between the two boxes. Then, the measurements are repeated with the samples placed alternately between the sending and the receiving box. The difference between the average value of the sound pressure level value detected with the empty system (L1) and the one measured after the introduction of each sample (L2) represents the amount of acoustic energy retained by the cardboard element, according to the following formula:

D is the Sound Level Difference index, which assumes a different value for each octave band. This is the most basic index about sound insulation properties related to a partition element dividing two adjacent spaces.

Method 2

A sound whose acoustic spectrum simultaneously contains multiple frequencies is emitted. A sound level meter capable of receiving and processing a complete sound spectrum is employed. This type of equipment can also measure the sound reverberation time in the receiving box. The sound level difference D is standardized to a reference reverberation time of 0.5 s, according to the formula:

where DnT = Standardized Sound Level Difference. D = Sound Level Difference. T = Reverberation Time in the receiving room.

As in the previous case, the procedure is first performed without placing any sample between the boxes, and then repeated including the carboard elements. For each configuration, the measurement is repeated several times with the sound emitted for approximately 15 s. By splitting the spectrum into frequencies, the Standardized Sound Level Difference index can be calculated for each 1/3 octave band. To convert these frequency-dependent values into a single unique value, which is the Weighted Standardized Level Difference infdex DnTw, the reference curve shifting method is then used, according to the standard ISO 717-1. The index is expressed in the form:

where DnTw = value of the shifted A-weighting reference curve corresponding to the frequency of 500 Hz; C = adaptive term used when the source sound is characterized by a pink noise. Ctr = adaptive term applied to DnTw measurement when the acoustic field is characterized by a low frequency noise.

Methods for assessing mechanical properties

Equipment and main standards

To perform the tests, an Ibertest Tensile and Compression Testing Machine and a computer with the WinTest32 management software installed are used, according to the procedures described below. While possible standards for similar intended uses are UNI EN 408:201230, ISO 1924-2:200931.

Compression test

Corrugated cardboard is an orthotropic material, meaning it exhibits different mechanical behaviour in its three principal directions. In this case, the anisotropy between x and y directions was mitigated by alternating the fluting direction in layering, so mechanical tests were conducted following only two different setups. In both these load cases, the cubic specimens were placed between two stiff loading plates, with the compressive load applied to the top of each sample at a constant speed. For each stratigraphic type, in the first scenario the load was applied perpendicular to the layers orientation, while in the second scenario the load was applied parallel to the direction of the corrugated cardboard boards. During each test, the failure mechanisms were observed and the peak values in terms of maximum applied load were reported.

Bending test

For the three-point bending tests, beam elements were positioned in the machine, supported by two parallel rollers at their ends. The load was applied at the beams’ midspan at a constant speed. Also in this case, for each type of samples the test was carried out according to two different load configurations. In the first configuration, the load was applied orthogonally with respect to the orientation of the cardboard boards, while in the second setup, the load was applied parallel to them. Different failure mechanisms were observed, and the load value at which the fracture begin, if reached, was recorded.

Life cycle analysis

The life cycle analysis allows to know the environmental impacts and pollutants associated with the product intended for construction. This analysis was carried out in compliance with ISO standards, 14040:200632 and 14044:202133. According to these international standards, the study must consist of four phases34, namely: (1) the goal and scope definition, (2) the life cycle inventory analysis, (3) the life cycle impact assessment, (4) the life cycle interpretation. With regard to phase 3), the CML-IA baseline method was used, one of the LCIA methodologies most widely used in the scientific literature for LCA analyses35, which elaborates the problem-oriented approach (midpoint), allowing a more transparent evaluation and limiting uncertainties as much as possible.

Results and discussion

Acoustic analysis

Environmental condition

The environment in which the tests were conducted was characterized by an internal temperature of 23 °C and a Relative Humidity value of 45%. Before the test, the cardboard samples had been stored in a room with a RH value of approximately 52% for 30 days. Therefore, this is the value taken into account to describe the state of the material, as the duration of the tests was not sufficient for its significant variations.

Method 1 tests

The sound was emitted in octave bands with the representative frequencies of 250 Hz, 500 Hz, 1k Hz, 2k Hz,

4k Hz, 8k Hz and 16k Hz via PC. The intensity of the sound pressure level in the receiving box was measured by means of a CESVA SC-20c sound level meter. First, the test was carried out with the empty system, in order to have the comparison term for the subsequent tests. For each octave band, the procedure was repeated five times in the same way. The result of each measurement was directly read on the sound level meter and manually reported on a sheet. The mean value was then calculated. The so obtained values constitute the “L1” terms in the formula for calculating D. The same procedure was then carried out by placing X-type (Fig. 2) and Y-type samples between the sending and the receiving box. The so obtained values constitute the “L2” terms. The Sound Level Difference Index was then calculated for each frequency, for both the samples. No value was discarded in any of the. Table 3 shows the test results.

Tests Execution. Execution of the acoustic tests according to the first methodology on the X-type sample (top left) and according to the second methodology on the Y-type sample (bottom left); the execution of the compression tests according to the first load case on a Y-type sample (top centre) and according to the second load case on a X-type sample (bottom centre); the execution of the bending tests according to the first load case on the X-type sample (top right) and according to the second load case on a Y-type sample (bottom right).

The D index is mainly useful for comparing different types of samples, rather than providing the actual sound insulation value for a specific material, as it does not take into account the internal conditions of the receiving space. Aware of the limitations of the testing method, it resulted that both stratigraphic typologies show quite good values for low frequencies (< 500 Hz), lower values in frequencies between 500 and 2k Hz (with the absolute minimum around 1k Hz) and again quite good values towards high frequencies. The samples behave almost in the same way, only differing in high frequencies with the type X sample providing better values.

Method 2 tests

A sound whose acoustic spectrum simultaneously contains all the frequencies from 125 to 3150 Hz was emitted via a PC. The intensity of the sound pressure level in the receiving box was measured using a Brüel & Kjær 2250 sound level meter. First, the test was carried out with the empty system to provide a comparison term. Then, the same process was carried out for the X-type and Y-type B samples (Fig. 2). In all three cases, the measurement procedure was repeated five times. The sound level meter recorded the received sound pressure level data while also evaluating the reverberation time within the box. The data were then processed so that the Standardized Sound Level Difference Index (DnT) could be obtained for each third of an octave. The results are shown in Fig. 3.

Being able to consider the system’s internal reverberation time, this testing method provides more reliable results. The Standardized Level Difference Index (DnT) can be used to quantify, assess and compare the airborne sound insulation provided by different partition components, assuming that they are homogeneous and follow the mass law. The qualitative behaviour observed in the previous test is confirmed, even though this method considers a smaller frequency range. For the Standardized Level Difference Index (DnT), the type X sample shows good values at low frequencies, peaking at 53 dB around 160 Hz and 20 dB at 500 Hz. A minimum of about 15 dB is detected at 1250 Hz, with the index rising again towards high frequencies. The type Y sample does not peak as high at high frequencies, but performs quite well over a wider range, from 100 to 400 Hz. The absolute minimum, very punctual, is reached around 1000 Hz, consisting in a value of 13 dB. The differences between the two graphs are minimal, indicating similar behaviour for both samples. Considering the Weighted Standardized Level Difference Index (DnTw), they both provide a nominal value of 20 dB, with the only difference lying in the adaptive term Ctr, which is − 1 for the type A and − 2 for the type B.

Mechanical analysis

Environmental condition

The laboratory had an internal temperature of approximately 20° and a relative humidity value of 44%. Before the tests, cardboard samples had been stored in the same room for a week.

Compression tests

In both setups, the compressive load was applied on the top of each cubic specimen with a constant speed of 0.0504 kN/s. Load application was extended beyond the first plasticisation to observe material’s behaviour. For each stratigraphy and load case, the test was repeated for a variable number of attempts (“observations” values in Table 4). The equipment provided data about force and displacement measured during the tests, along with their graphical representation. The behaviour of the samples reflected the internal structure of the material. When the load is applied perpendicular to the orientation of the layering plane, in the first scenario, the samples stand up with several identical horizontal layers. In this case, the deformation occurs due to the progressive compression of the corrugated sheets, until the complete flattening of all of them. In the force–displacement graphs (Fig. 4), it can be observed an initial linear segment. When one of the boards reaches plasticization, the sample’s resistance decreases and then rises again, until another layer is compressed. The peak resistance reached at each failure progressively increases, as the load-bearing section changes with the reduction of internal voids and the consequent increase in the sample’s density. The undulating pattern characterizing the force–deformation graphs reveals the layered composition of the material. In the X-type graphs, the presence of two different flutings (B + C) can be identified by observing the jump around the midpoint of the path, while, for the Y-type, the uniformity of the layering is evident. For each sample, the force and deformation values associated with the failure of the first layer was identified. The average values for each stratigraphy were then calculated, resulting in an average applied force of 1.484 kN with a corresponding deformation of 8.67 mm for type X samples, and a force of 2.040 kN with a deformation of 5.29 mm for type Y samples. After complete compression, the samples reached their minimum height, approximately 4 cm for type X and 5 cm for type Y. At the end of the tests, the samples deformation is partially recovered, but they never returned to their original dimensions. In the second scenario, when the load is applied parallel to layers orientation (Fig. 2), the samples are characterized by a constant cross-sectional section, made up with several vertical arranger boards. Once plasticization begins, deformation progresses steadily and continuously for the entire thickness of the sample. In this case, the force–deformation graphs exhibit an initial linear segment, corresponding to the force required to initiate the plasticization, followed by a nearly horizontal path, corresponding to a constant and continuous deformation. Additional failure mechanisms can emerge, connected to the delamination of adjacent layers caused by the failure of the glue under shear stress. This phenomenon results in a sudden drop in the specimen’s resistance, corresponding to discontinuities in the more common force–deformation graph or in completely different paths. The physical deformation in this load case is always permanent and irreversible. For each specimen, the force and deformation values associated with the initiation of plasticization were identified. For each type, the average values were then calculated, excluding the data related to breakage due to glue failure. The type X stratigraphy resulted in an applied force of 12.509 kN associated with a deformation of 3.91 mm, while the type Y provided a force of 15.48 kN associated with a deformation of 3.79 mm.

All the measurements related to compression tests are collected in Table 4. The table also shows the variance and to compare the means of two groups a t-test has been performed. As indicated, with the exception of a single case, it can be concluded that the results are statistically significant. This means there’s enough evidence to reject the null hypothesis and conclude that the difference between the means of the two groups is unlikely to have occurred by chance.

In the first load case, samples reach plasticization under relatively low forces (1.5–2 kN), with the overall resistance depending on that of the corrugated sheets. Although Y-type stratigraphy shows slightly better resistance, both types exhibit low compression resistance values, making the material poorly suited for supporting this kind of compression loads. The two stratigraphic types show a qualitatively similar behaviour also in the second load case, but samples plasticization is caused by loads that are significantly higher (12–15 kN), with Y-type samples showing higher resistance due to the greater number of layers.

Bending tests

The three-point bending tests were carried out with the samples positioned on parallel rollers placed at a distance of 900 mm between them. The load was applied at the beam midspan with a constant speed of 0.08 kN/s. The test was carried out three times for each stratigraphy, in both load cases. Due to limitations of the equipment, it was not always possible to bring cardboard beams to breaking point, but plasticization phenomena were always observed (Fig. 5).

In the first scenario, the load was applied perpendicular to the orientation of the cardboard layers. During the tests, the applied force and the corresponding mid-span displacement of the beam were measured. For X-type samples, the tensile failure of the lower fibers subjected to tensile stress was never reached, even with a mid-span deflection of almost 100 mm. In this case, the load was primarily absorbed by the plasticization of the upper and central layers at the mid-span, and to a minor extent, by local plasticization phenomena at the lateral support points. Y-type samples, which have proven to be more rigid and resistant to compression, showed a slightly different behaviour. The local deformation at mid-span was less pronounced and the breakage of the lower sheets always occurred. Additionally, one of the Y-type samples experienced delamination between layers. Because of the different deformation conditions reached by the two types of samples, it is not meaningful to compare the values obtained. Table 5 reports the maximum force values reached during the test, which, as mentioned, do not always coincide with the breaking load, along with the corresponding mid-span deflection of the beam. For X-type samples, the measured values resulted in an average maximum applied force of 1.288 kN, associated with a displacement of 33.09 mm. On the other hand, Y-type samples reached the breakage of the lower fibers with an average maximum applied force of 1.407 kN, corresponding to a displacement of 60.84 mm.

In the second load case, when the load was applied parallel to the direction of the layers (Fig. 2), the samples always experienced breakage, with a failure mechanism characterized by the tearing of the sheets composing the stratigraphy. For X-type samples, the layers broke in groups until the breakage of the entire section, producing a step-like graph. In the case of Y-type samples, the process was more uniform, leading to a brittle failure that occurred all at once after a brief phase of local plasticization at the load application point. The breaking load values measured with the corresponding mid-span deflection of the beam can be read in Table 5. For the X-type stratigraphy, the failure occurred with an average force of 2.218 kN, corresponding to a deflection of 22.76 mm, while for the Y-type stratigraphy, the average force was 2.433 kN associated to a deflection of 13.43 mm. The difference in the failure load magnitude for the two stratigraphic types is minimal. All the measurements related to compression tests are collected in Table 5. The table also shows the variance and to compare the means of two groups a t-test has been performed. As indicated, it can be concluded that the results are statistically significant. This means there’s enough evidence to reject the null hypothesis and conclude that the difference between the means of the two groups is unlikely to have occurred by chance.

Comparisons with literature

As already highlighted, the existing literature concerning products made of cardboard for construction is very limited, but it is possible to make comparisons with previous studies.

From an acoustic point of view, even if the numerical results provided by the test are not comparable with available data concerning other materials, as they strictly depend on the specific execution conditions, it can be highlighted that according to Klimek et al.36 paper-based products are an excellent alternative due to their absorption and insulation properties. In their study the maximum acquired sound reduction index, for a paper double-wall, reached 26 dB. They also highlight that, similarly to the authors’ research, higher density and multi-layer configurations generally improve acoustic properties. Manuela Neri3 analyses the acoustic performance of 7 cm thick panels made of end-of-life materials, namely cardboard packaging, egg boxes, bulk polyester, and felt, revealing a weighted sound reduction index of 19 dB, a weighted sound absorption coefficient of 0.30, and a noise reduction coefficient of 0.64. Although these values are lower than those of common commercial insulating products, they are promising and worthy of being taken into consideration for future developments. Finally, Mazaherifar et al.37 analyses different properties of two different panels derived from defibrated fibers from both unprinted and printed cardboard as the primary materials. From an acoustic point of view, even though the types of panels are different from those of the authors, they also find good acoustic behaviour at medium frequencies, between 670 and 750 Hz, as Walter et al.38 confirm the best behaviour overall at low frequencies, in particular in the range 125–300 Hz.

Regarding the mechanical properties, similarly to the research, Zulaikah et al.38 perform monoaxial compression tests along the three main directions, but using specimens with dimensions equal to about half of the X-type and Y-type samples. Comparing the stress–strain curves it is possible to notice the same trend more curl or wave lines deriving from the corrugated medium or flute effect. In particular, the behavior of the stress–strain curve obtained from the compression test generated results similar to the cited study but also to others39,40. The main differences exist in the generation of the curve and in the progressive crushing methods40 which, according to Zulaikah et al.38, could derive from the flute manufacturing process41 or even from environmental conditions, in particular relative humidity. In fact, as the humidity content in corrugated cardboard increases, the compression load decreases exponentially42. With regard to the characteristics of the specimens, Fortin et al.40 analyze samples with corrugated cardboard layers with the same orientation or, similarly to the research, with alternating 90° orientation. The results of the compression tests reveal how the first typology provides better values and this is particularly important to guide the authors’ future research. Finally, Zulaikah et al.38 highlight how it is still difficult to predict and conclude when and how the fracture under load will occur in the presence of a material such as corrugated cardboard, precisely because of its anisotropy and great possibility of variability in the composition of the layer.

Life cycle analysis

The main objective of the study is to evaluate the environmental impact of the panels described in chapter 2. The functional unit to which the results of the study were referred was defined as the mass in kg of panel that involves a thermal resistance R equal to 1 mq K/W6,43. This functional unit, which is the most widespread in literature35, provides information on the amount of insulation material needed to achieve a specific thermal resistance during the insulation life of the panel and is a value known from previous studies17 (Table 6). The system boundaries chosen are "from cradle to cradle", that is: extraction and processing of raw materials and production; transport, distribution, assembly, use and maintenance, finally reuse, recovery and recycling. In the second phase of the study, the inventory analysis (LCI) was performed, quantifying all materials and related processes using the Ecoinvent v.3.7.1 database.

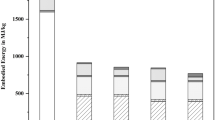

Following the inventory analysis, the life cycle impact assessment (LCIA) was performed for the two types of panels, the results of which are reported in Table 7 and Fig. 6. In particular, the results of the impact assessment section relating to the characterization phase, mandatory pursuant to the aforementioned ISO 14040 and ISO 14044 standards, are reported. In this phase, the environmental impacts were quantified in the relevant units of measurement.

From the table and especially the graph, it is clear that the Y-type sample has significantly higher impacts in percentage terms than the X-type one. The Global Warming at 100 years (GWP100a) of the Y-type panel is equal to 8.003 kg CO2 eq while that of the X-type one is equal to 3.435, or much less than half. From the point of view of pollutants, the greatest difference is in the Abiotic depletion category while the smallest is in the Terrestrial ecotoxicity.

Normalizing the flows of all unit processes towards the functional unit, the impacts shown in Fig. 7 were obtained. From the data, it is clear that the category with the greatest impact is that of marine aquatic ecotoxicity, impacting both panels but especially panel Y. Abiotic depletion follows, while the other pollutants appear to have decidedly lower values. From the GWP point of view, the X-type panel has a value equal to 6.48E-13 kg CO2 eq while Y-type one equals 1.59E-12 kg CO2 eq. These low values are due to the system boundary that considers the end-of-life phase as a recycling or reuse process, ensuring that the materials are not wasted but continue to be used in a closed cycle. By comparing the results obtained with those defined in other studies collected and analyzed by Stefan Füchsl et al.35, for the same functional unit, the GWP value obtained is better than those of the market leading materials stone wool, glass wool, EPS, XPS, PUR, cork.

Conclusions and future developments

The article presents a study aimed at investigating the performance characteristics of two samples of panels intended for construction, made with corrugated cardboard deriving from the recycling of packaging processes and their environmental impact. To this end, tests were conducted to examine the acoustic insulation capacity and mechanical resistance provided by these corrugated cardboard panels and also Life Cycle Assessment. From an acoustic point of view, the results show that the two cardboard stratigraphies under examination can provide good levels of insulation and that, therefore, if they were used to create architectural panels, they could successfully contribute to the creation of high-performance elements in the context of environmental acoustic control. In relation to the mechanical tests, it can be stated that it was possible to acquire important qualitative and quantitative information about the behavior that the two examined stratigraphies assume when subjected to compression and bending stresses, also allowing the differences that exist between them to be identified. The two stratigraphic typologies have shown to differ from each other to a minimal extent and, in any case, in no case have the results obtained appeared to suggest the possibility of autonomous structural use of the same. Therefore, to create a functional and safe system, the resistance that corrugated cardboard elements can provide should be associated with components made of other materials. Finally, from an environmental perspective, panels reveal low GWP values, thanks to the fact that they are recycled, therefore with materials managed according to circular principles.

Although the preliminary results are encouraging, even compared to the state of the art, it is useful to remember that the literature regarding the use of recycled cardboard in construction is still very limited and therefore it is necessary to conduct further investigations.

In this contest the study carried out can represent the starting point for a more complex research path, to be expanded and deepened through analyses and experiments that are increasingly specific, complete and detailed. In fact authors already have a new campaign of experimental tests underway with further tests including other types of panels, again consisting of layers assembled according to different geometries. In any case, the actual possibilities of using cardboard in construction have already emerged clearly and are part of an emerging research trend that sees recycled cardboard as the object of deep interest by the contemporary scientific community.

Data availability

Data are available upon request to the corresponding author.

References

Najibzadeh, Z., Maleki, H. R. & Niroomand, S. An extended goal programming approach with piecewise penalty functions for uncertain supplier-material selection problem in cardboard box manufacturing systems. Sci. Rep. 14, 20714 (2024).

Bruna Alves. Recycling rate of paper and cardboard packaging waste in the European Union (EU-27) from 2005 to 2022. Statista 2025 https://www.statista.com/statistics/974705/recycling-rate-of-paper-and-cardboard-packaging-waste-in-the-eu/ (2024).

Neri, M. Thermal and acoustic characterization of innovative and unconventional panels made of reused materials. Atmosphere (Basel) 13, 1825 (2022).

Viczek, S. A., Aldrian, A., Pomberger, R. & Sarc, R. Origins of major and minor ash constituents of solid recovered fuel for co-processing in the cement industry. Waste Manag. 126, 423–432 (2021).

González Pericot, N., Villoria Sáez, P., Del Río Merino, M. & Liébana Carrasco, O. Production patterns of packaging waste categories generated at typical Mediterranean residential building worksites. Waste Manag. 34, 1932–1938 (2014).

Asdrubali, F. et al. Experimental and numerical characterization of innovative cardboard based panels: Thermal and acoustic performance analysis and life cycle assessment. Build Environ. 95, 145–159 (2016).

Asdrubali, F. et al. Innovative cardboard based panels with recycled materials from the packaging industry: Thermal and acoustic performance analysis. Energy Procedia 78, 321–326 (2015).

Secchi, S. et al. Experimental and environmental analysis of new sound-absorbing and insulating elements in recycled cardboard. J. Build. Eng. 5, 1–12 (2016).

Jasiołek, A., Noszczyk, P. & Łątka, J. F. Paper-based building envelopes—Thermal and environmental properties of original envelope designs. Energy Build 289, 113062 (2023).

Stefania, L., Chiara, R. & Francesco, M. Experimental analysis of building components with paper and textile waste. Energy Effic. 17, 42 (2024).

Cripps, A. Cardboard as a construction material: a case study. Build. Res. Inf. 32, 207–219 (2004).

Faria, D. L. et al. Valorization of cardboard waste in the production of polyurethane biocomposites: A new and environmentally friendly material for civil construction. Constr. Build Mater. 462, 139902 (2025).

Benallel, A., Tilioua, A. & Garoum, M. Development of thermal insulation panels bio-composite containing cardboard and date palm fibers. J. Clean Prod. 434, 139995 (2024).

Mathews, J. M., Vivek, B. & Charde, M. Thermal insulation panels for buildings using recycled cardboard: Experimental characterization and optimum selection. Energy Build 281, 112747 (2023).

Distefano, D., Gagliano, A., Naboni, E., Sapienza, V. & Timpanaro, N. Thermophysical characterization of a cardboard emergency kit-house. Math. Model. Eng. Probl. 5, 168–174 (2018).

Betts, D., Sadeghian, P. & Fam, A. Structural behavior of sandwich beams with flax fiber–reinforced polymer faces and cardboard cores under monotonic and impact loads. J. Architect. Eng. 26, 12 (2020).

Rotilio, M. Product innovation between circular economy and Industry 40. TECHNE J. Technol. Archit. Environ. 22, 192–200. https://doi.org/10.36253/techne-10598 (2021).

Rotilio, M. Technology and resilience in the reconstruction process. A case study. In International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences - ISPRS Archives vol. 54 (2020).

Diarte, J. & Vazquez, E. Building from Waste Cardboard—A Grammar for the Design and Fabrication of a Customized Modular House with Waste Cardboard and Wood-framed Panels 465–474 (2020). https://doi.org/10.52842/conf.caadria.2020.1.465.

Östlund, S. & Niskanen, K. Mechanics of Paper Products (De Gruyter, 2021). https://doi.org/10.1515/9783110619386.

Tanaka, A. et al. Wet creping of paperboard. Nord Pulp. Pap. Res. J. 38, 47–57 (2023).

Diarte, J. & Shaffer, M. Cardboard architecture. Enquiry ARCC J. Archit. Res. 18, 17–40 (2021).

Łątka, J. F. et al. Properties of paper-based products as a building material in architecture—An interdisciplinary review. J. Build. Eng. 50, 104135 (2022).

Fallah, M., Zarei, H. & Paggi, M. A novel in-situ micro-mechanical testing of paper fracture and its stochastic network model. Int. J. Solids Struct. 300, 112930 (2024).

ISO 16283-1:2014. Acoustics — Field Measurement of Sound Insulation in Buildings and of Building Elements, Part 1: Airborne Sound Insulation (2014).

ISO 717-1:2020. Acoustics — Rating of Sound Insulation in Buildings and of Building Elements, Part 1: Airborne Sound Insulation (2020).

ISO 3382-2:2008. Acoustics—Measurement of Room Acoustic Parameters, Part 2: Reverberation Time in Ordinary Rooms (2008).

International electrotechnical committee. IEC 61672-1:2013 Electroacoustics—Sound level meters—Part 1: Specifications. In International Standard vol. ISBN 9782832210871 1–103 (2013).

International electrotechnical committee. EC 61260-1:2014 Electroacoustics—Octave-band and fractional-octave-band filters, Part 1: Specifications. vol. ISBN 9782832214176 1–88 (2014).

UNI EN 408:2012. Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties (2012).

UNI EN ISO 1924-2:2009. Paper and Board—Determination of Tensile Properties—Part 2: Constant Rate of Elongation Method (20 Mm/Min).

UNI EN ISO 14040:2021. Environmental management—Life cycle assessment—Principles and framework.

UNI EN ISO 14044:2021. Environmental management—Life cycle assessment—Requirements and guidelines.

Cucchiella, F. et al. Renovation wave: A bioeconomy panel produced with waste. J. Clean Prod. 467, 142868 (2024).

Füchsl, S., Rheude, F. & Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 5, 100119 (2022).

Klimek, A., Łatka, J. F., Nieradka, P. & Dobrucki, A. Application of cellulose and paper-based products in building acoustics. Arch. Acoust. https://doi.org/10.24425/aoa.2024.148791 (2024).

Mazaherifar, M. H., Timar, M. C., Georgescu, S. V. & Cosereanu, C. Sustainable thermal and acoustic insulating panels from recycled cardboard. BioResources 20, 4115–4135 (2025).

Zulaikah, S., Triawan, F., Budiman, B. A., Romadhon, Y. & Kamaludin, D. Study on the mechanical properties and behavior of corrugated cardboard under tensile and compression loads. Mater. Sci. Forum 1092, 45–54 (2023).

Chaudhary, A. K., Gope, P. C. & Singh, V. K. Studies on Fracture Performance of Bio-fiber-Silica-glass Fiber Reinforced Epoxy Hybrid Composites 363–368 (2011). https://doi.org/10.1007/978-1-4614-0222-0_44.

Fortin, G. Y., Elbadry, E. A. & Hamada, H. Crashworthiness of cardboard panels reinforced with braided glass fiber rods for vehicle side impact protection. J. Reinf. Plast. Compos. 37, 1387–1401 (2018).

Gallo, J., Cortés, F., Alberdi, E. & Goti, A. Mechanical behavior modeling of containers and octabins made of corrugated cardboard subjected to vertical stacking loads. Materials 14, 2392 (2021).

Hung, D. V., Nakano, Y., Tanaka, F., Hamanaka, D. & Uchino, T. Preserving the strength of corrugated cardboard under high humidity condition using nano-sized mists. Compos. Sci. Technol. 70, 2123–2127 (2010).

Ardente, F., Beccali, M., Cellura, M. & Mistretta, M. Building energy performance: A LCA case study of kenaf-fibres insulation board. Energy Build 40, 1–10 (2008).

Acknowledgements

Authors thank Pack System S.r.l. of Albano Laziale (Rome), Italy, a corporate partner in the research, for assembling the panels under research and providing all necessary information on the origin of the materials. They also thank the laboratories of the Escuela Técnica Superior de Arquitectura and the laboratories of the Escuela Técnica Superior de Ingeniería de Edificación at the Polytechnic University of Valencia, Spain, for their support in conducting the acoustic and mechanical tests.

Funding

The research presented in the article was partially funded by “MULTIFId”, Multifunctional panels for new smart factories project, financed by the Fund for Sustainable Growth, Smart Factory Desk, Ministe rial Decree 05.03.2018 Chapter III.

Author information

Authors and Affiliations

Contributions

M.R conceived the experiments and the research; C.A. conducted the acoustic and mechanical experiments and collected the data; M.R. and F.C. developed LCA; M.R, C.A. and F.C. analyzed and validate the results; M.R. and C.A. writing—original draft preparation; M.R. writing, revising—final preparation; M.R. and F.C. supervised the article; M.R. funding acquisition; M.R. is the corresponding author. All authors edited, reviewed and improved the manuscript. All authors have read and agreed to the version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Additional Information

The acoustic tests were conducted in March 2023 at the laboratories of the Escuela Técnica Superior de Arquitectura at thePolytechnic University of Valencia, Spain. The mechanical tests were conducted in March 2023 at the laboratories of the Escuela Técnica Superior de Ingeniería de Edificaciónat the Polytechnic University of Valencia.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rotilio, M., Cucchiella, F. & Antonetti, C. Preliminary studies on recycling cardboard packaging into building products. Sci Rep 15, 34180 (2025). https://doi.org/10.1038/s41598-025-15372-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-15372-3