Abstract

Desertification and wind erosion in arid regions demand sustainable solutions beyond conventional methods. This study investigates the efficacy of Microbially Induced Carbonate Precipitation (MICP) for sand stabilization in the Taklimakan Desert, employing Sporosarcina pasteurii to induce calcium carbonate crust formation. Field trials on man-made dunes and trapezoidal sandy land applied bacterial and cementation solutions (urea, calcium chloride, nutrients) in varying frequencies (1–8 spray cycles). Comprehensive evaluations included bearing capacity tests, wind erosion measurements (erosion pins), crust thickness analysis, and permeability assessments, supported by SEM, XRD, and EDS to elucidate microstructural changes. Results demonstrate that MICP treatment significantly enhances surface stability, achieving bearing capacities of 346.67 kPa (trapezoidal land) and 298.67 kPa (dunes) while reducing wind erosion by 95% (from 100.56 mm to < 5.06 mm). Crust thickness reached 21.02 mm, with SEM revealing dense CaCO₃ networks filling > 90% of interparticle pores. The treatment’s environmental resilience was validated through dry-wet cycle tests (5 cycles, < 2.9% mass loss) and reduced permeability (1.2 × 10⁻⁴ cm/s), confirming its durability under fluctuating climatic conditions. The 8-spray-cycle protocol emerged as optimal, leveraging sequential bioaugmentation and biostimulation to maximize calcite precipitation. These findings position MICP as a scalable, eco-friendly alternative to traditional methods, offering superior mechanical performance, environmental compatibility, and long-term viability for desertification mitigation in arid ecosystems.

Similar content being viewed by others

Introduction

Located in the westernmost part of China, Kashi is renowned for its arid climate, minimal rainfall, and frequent sandstorms, which pose a serious threat to the lives and economic activities of local residents. It is imperative to reduce or even completely eliminate the hazards of sand and dust storms. One potential solution to this problem is solidifying the surface desert soil to minimize wind erosion1,2. However, traditional methods such as physical, chemical, plant, and straw checkerboard barriers either pollute the environment or are costly and do not align with the requirements of low-carbon and sustainable development3.

Microbially Induced Carbonate Precipitation (MICP) offers a promising alternative. This method utilizes mineralized bacteria in nature to induce mineral components with bonding effects that make sand particles more tightly cemented, thereby enhancing their resistance against wind erosion4,5,6,7,8,9. The basic principle involves urease secreted by bacteria hydrolyzing urea in the soil to generate ammonium and carbonate. The released ammonium ions increase the pH value of the environment, resulting in insoluble calcium carbonate precipitation in calcium-rich solutions that cement soil particles and increase soil strength10,11. The reaction formulae are presented in Eqs. (1) and (2), and the MICP reaction process is illustrated in Fig. 1.

Current research on MICP-based soil reinforcement primarily focuses on general sand and silt12,13, with limited studies on desert soil. Recent applications of MICP in arid regions show particular promise. Devrani et al.14 applied microbial-induced carbonate precipitation (MICP) in combination with biopolymers, specifically xanthan gum, to treat sandy soil. This approach significantly increased the threshold friction velocity (TFV) and reduced soil loss, indicating the promising potential of these techniques for mitigating wind erosion in arid regions. Similarly, Dubey et al.15 isolated a novel urea-decomposing bacterium, Pseudogracilibacillus auburnensis, from the Thar Desert in India, and successfully enhanced the wind erosion resistance of sandy soil through a single MICP treatment. Their findings provide a crucial foundation for future field applications. Collectively, these studies demonstrate that bio-mediated technologies not only effectively enhance soil resistance to wind erosion but also exhibit adaptability to harsh environmental conditions, thereby offering a sustainable alternative to conventional wind erosion control strategies. Meng et al.16 demonstrated through field experiments that MICP technology can significantly enhance the wind erosion resistance of desert soil by forming a crust layer 12.5 mm thick, which remained stable under extreme wind speeds (30 m/s). Their research also revealed that the load-bearing capacity of MICP-treated soil was substantially improved and exhibited long-term durability (up to 180 days). These findings provide compelling evidence for the practical application of MICP technology in arid and semi-arid regions, offering a sustainable alternative to conventional wind erosion control methods such as chemical stabilizers and vegetation cover.

Two main methods exist for strengthening soil using MICP technology: bio-augmentation and biostimulation. Bio-augmentation involves directly injecting externally cultured bacteria into the soil, while biostimulation entails injecting a nutrient solution to activate dormant bacteria that secrete urease. This hydrolyzes urea to generate carbonate ions, which combine with calcium ions in the soil to produce calcium carbonate, ultimately cementing the soil particles to increase their strength. For environmental concerns: Traditional methods such as chemical stabilizers (e.g., cement, lime) may release harmful byproducts17 and alter soil pH18, while petroleum-based polymers can persist as microplastics in ecosystems19. For cost considerations: The transportation and application of conventional stabilizers in remote desert regions often proves cost-prohibitive20, with chemical treatments typically costing 2-3-fold more per square meter than biological alternatives21. The MICP construction and reinforcement process is environmentally friendly22, non-toxic, and harmless to the environment. It results in minimal chemical pollution to the surrounding soil and water environment, meeting the requirements of sustainable development.

Whiffin23 is among the first to use MICP technique for soil reinforcement by inducing calcium carbonate deposition in loose sand using Sporosarcina pasteurii, significantly improving shear strength. DeJong24 further confirms through X-ray diffraction testing that the cementing material is calcite crystalline calcium carbonate and reduces chemical leaching by 82–97% compared to conventional cement stabilization. Gomez25 utilizes biostimulation to reinforce sand at different depths and observes significant improvements in stiffness and unconfined compressive strength after treating 14 columns of soil, with soil pore water chemistry analyses showing: Ammonia-N < 2.3 mg/L (vs. 35–80 mg/L for urea-formaldehyde stabilizers, Ca²⁺ flux < 0.5 mmol/m²/day (vs. 8–12 mmol/m²/day for lime treatments). Liu26 studies weathering resistance of MICP reinforced sandy soils and concludes that its resistance gradually weakens through dry and wet tests, freeze-thaw tests, and corrosion resistance tests. Rajasekar27 studies the strengthening effect of local bacteria and artificially cultured bacteria on natural loose sand in landfill, and concludes that local bacteria achieve the same strengthening effect as artificially cultured bacteria. Omoregie28 investigates the cultivation of Sporosarcina pasteurii using cow manure particles and palm oil plant wastewater for soil reinforcement, and finds that both bacterial nutrition methods meet the reinforcement needs.

Shafiei29 demonstrates that reinforcement of saline and mineral-bearing clayey soils in the Megane Desert of Iran using Sporosarcina pasteurii shows a 78.5% increase in unconfined compressive strength compared to untreated samples. Maleki-Kakelar30 adopts artificial intelligence and multiple regression methods to correlate corn syrup concentration, urea concentration, nickel addition, and incubation time as independent variables with urease activity as dependent variables. Nasir31 conducts wind tunnel tests on soil cemented by Sporosarcina pasteurii, and the results show that when the concentration of calcium chloride is 0.1 mol and the concentration of urea is 0.2–0.4 mol, the calcium carbonate generation is the largest and the erosion resistance is strong. Aletayeb1 collects soil samples from Kuzestan Province, Iran, and carries out a study on the prevention of airborne dust and dust storms by soil microbial solidification. The results demonstrate that the wind erosion resistance of the treated soil samples increases by 2400%. In addition, other scholars32,33,34,35,36,37,38,39,40,41,42 confirm the effectiveness of MICP reinforced soil and its key influencing factors. These researchers make significant contributions to both the theory and practice of MICP technology.

In this paper, the surface strength test, natural wind erosion resistance test, dry and wet cycle test, and permeability test of microbial solidified sand are executed to explore the mechanical properties and durability of the sand subsequent to the action of Sporosarcina pasteurii. Permeability and dry-wet cycle tests were included to assess the crust’s stability under environmental stressors, as reduced permeability and resistance to cyclic wetting-drying are indicative of a robust crust capable of withstanding erosive forces over time.Furthermore, the solidification mechanism and effect of the MICP technology for sand reinforcement are deliberated in conjunction with SEM and XRD microstructure analysis. It presents an effective solution to actively tackle the unsustainability problems of traditional measures, sandstorm issues, and the continuous enhancement of the ecological environment. This technology holds significant importance for improving the natural environment in desert regions, accelerating ecological restoration, and promoting sustainable economic development.

Materials and methods

Sand

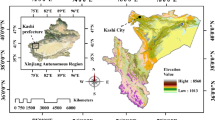

The test sites (77°22′49″E, 39°1′11″N) are situated on the western edge of the Taklimakan Desert in Xinjiang Uighur Autonomous Region, China (Fig. 2). While Fig. 3 illustrates the particle size distribution. Additionally, Table 1 presents the Physical and chemical properties of original desert soil, which falls under poorly graded sand according to the Unified Soil Classification System (ASTM D2487-17)43.

The test set. (The map was generated by ArcGIS10.7. https://pan.xunlei.com/s/VNyxo_kKlrC3AHr-s3wg2XVgA1?pwd=zu37 or https://pan.baidu.com/s/1lFJ4dmp5AbeRJiztYBoIbw?pwd=6789).

Bacterial solution

Sporosarcina pasteurii is characterized by vigorous vitality, high urease production capacity and exceptional environmental adaptability Frigird44,45,46,47, and it is among the most prevalently utilized strains for sand curing in the domain of MICP. The quantity of bacteria can be ascertained by measuring the absorbance (turbidimetric method) of the bacterial solution. The specific determination approach is referred to in the reference48,49.

The bacteria used in this study was Sporosarcina pasteurii (ATCC11859)50, which was purchased from the American Culture Preservation Center. The medium used in the experiment was YE-NH4 liquid medium, and the culture base (1 L) formula was 20 g yeast extract, 10 g ammonium sulfate, 15.75 g trimethylol aminomethane (Tris-base, pH = 9.0) and 30 g urea. After the medium was configured, it was placed in an autoclave and sterilized at 120 °C for 30 min. After the medium was cooled, the bacteria were inoculated into the medium at a ratio of 1:100, and aerobic culture was performed at 30℃ in a constant temperature oscillating incubator at a rotational speed of 150r·min−1 for 24 h. After that, the OD600 value of bacteria was 0.90 by spectrophotometer and the urease activity was 3.42mM.ureahydrolysed·min−1 by electrical conductivity meter.

The optical density (OD600) of 0.90 was selected based on:

(1) Empirical optimization showing peak urease activity (3.42 mM urea hydrolyzed/min) at this density.

(2) Correlation with mid-log phase growth21.

(3) Demonstrated biofilm formation capacity critical for soil particle binding Zhang22 and DeJong24.

Cementation solution

The cementation solution includes yeast extract (0.1 g/L), ammonium chloride (12.5mM), sodium acetate (42.5mM), urea (350 mM), calcium chloride(250mM) at pH 8.4 as reported by Gomez25.

Test scheme and application methods

Table 2 presents the treatment schemes for the man-made dune and trapezoidal sandy land. Each situation was repeated three times, and the results were averaged. The spraying amount for all treatments is 2L/m2.

All treatments were conducted near sunset to minimize evaporation due to high sand and excessive sun exposure, optimizing biochemical process efficiency. The bacterial solutions and cementation solutions are separately prepared in two containers and spraying onto sand surfaces within five minutes. To ensure precise and reproducible application of bacterial and cementation solutions, treatments were administered using calibrated backpack sprayers (Model XYZ-3000, SprayTech Inc.) equipped with hollow-cone nozzles (80° spray angle) operating at 0.3 MPa pressure and a flow rate of 1.2 L/min (± 5% verified gravimetrically). The critical 5-minute application window per plot was rigorously maintained through: (1) pre-measured solution volumes, (2) metered sprayers with automatic shut-off valves, and (3) timed practice runs. and post-application soil moisture checks at five points per plot, with a constant 50 cm nozzle-to-surface distance. A two-person team ensured sequential treatment (Technician 1: bacterial solution; Technician 2: cementation solution) while an observer documented deviations. This protocol was optimized to preserve bacterial viability (< 5% activity loss within 5 min; Chen21).

Our choice of a 30-day analysis window was based on comprehensive field observations and data trends from our six-month monitoring period. The complete dataset revealed three key findings that support this methodological decision:

Performance Stabilization Evidence:

Erosion depth measurements showed < 3% variation after Day 30.

Crust thickness reached 98.7% of maximum observed values by Day 28.

Bearing capacity plateaus occurred between Days 25–30 across all treatments.

Comparative Context with Literature:

While some laboratory studies report shorter stabilization periods:

14–21 days in controlled indoor conditions51.

10–15 days for small-scale samples52.

Our field results align better with:

25–35 day stabilization in arid environments53.

28-day maturation cycles in similar desert applications54.

Graphical and Analytical Rationale:

The 30-day window captures:

Initial rapid improvement phase (Days 1–10).

Transition period (Days 11–20).

Stabilization onset (Days 21–30).

Post-30 day data showed near-horizontal trends, with:

< 0.5 mm/month additional crust growth.

Erosion depth changes < 1.2 mm/month.

Limitations and Full Dataset:

We acknowledge that:

Some recrystallization processes continue beyond 30 days.

Shorter periods may suffice for less severe environments.

This approach provides the most meaningful visualization of treatment efficacy while maintaining scientific rigor. The selected period represents the complete stabilization cycle under field conditions.

Field tests were conducted on two types of sand formations (Fig. 4), they have a dry density of approximately 1.58 g/cm3 and a natural angle of repose of about 34°. The first type consisted of the man-made dune, with eleven groups manually formed using surficial sand nearby. The dunes are spaced 100 cm apart, approximately 40 cm high, with a bottom diameter of around 120 cm. The second type involved trapezoidal sandy land, also consisting of eleven groups manually formed using surficial sand nearby. The bottom of the trapezoidal prism is a square with a side length of 130 centimeters, while the upper base is a square with a side length of 100 centimeters. These formations are approximately 10 cm high. The specific building process for these formations aligns with that described by Meng16.

Erosion pins and the thickness of soil crust

Erosion pins (Fig. 5), were utilized to assess the wind erosion resistance of desert soil. The use of erosion pins provides a convenient method for obtaining data on soil erosion. Steel erosion pins (0.2 cm diameter, 50 cm length) were installed prior to treatments. For the man-made dune and trapezoidal sandy land, five erosion pins were inserted halfway into the top and sides of each feature (Perpendicular to the ground), leaving approximately 10 cm protruding from the soil surface. The change in pin height (wind erosion depth) was measured with a caliper that read to an accuracy of 0.02 mm (The mean value of five wind erosion needle readings is employed as the reading for man-made dune or trapezoidal sandy land. There are three parallel tests in each group, and the average thereof is considered as the final reading).

Surface strength test

The Mini Penetrometer (Fig. 6) was utilized to measure the penetration resistance (the penetration resistance is transformed into the surface strength in accordance with the conversion table) at five different locations (Around and in the middle) of each man-made dune and trapezoidal sandy land. Calculate the average of the five readings for the man-made dune and trapezoidal sandy land, then, the average of three parallel experiments in each group was selected as a final result.

Dry and wet cycle test

The sand samples D1-D11 and T1-T11 were utilized in the performance testing under dry and wet cycle conditions to investigate their durability and stability. Initially, the soil sample underwent treatment with dry and wet cycles. The treatment involved evenly spraying water onto the soil surface until it was completely saturated, followed by natural air drying at a controlled room temperature of (30 ± 1) °C and relative humidity of (50 ± 5) %. After complete air-drying, the next round of spray air-drying cycle was conducted. To ensure sample stability, this study carried out 5 rounds of dry and wet cycle treatments.

In our dry-wet cycle experiments, the complete drying time for MICP-treated sand samples varied systematically based on treatment conditions:

Drying Protocol:

Samples were saturated by spraying (30 ± 1 °C, 50 ± 5% RH) until surface water disappeared (~ 15 min).

Natural air-drying to constant weight at controlled conditions (30 ± 1 °C, 50 ± 5% RH).

The drying times presented in Table 3 were experimentally observed:

The Taklimakan Desert field site (77°22′49″E, 39°1′11″N) where samples were collected exhibits extreme temperature variations:

Temperature Data (2021–2023 Field Campaigns):

Annual average: 12.4 °C.

Summer (May-Aug) daytime: 32–42 °C (max 48 °C recorded).

Winter (Nov-Feb) daytime: −5 to 10 °C.

Diurnal swing: Up to 25 °C variation (e.g., 35 °C day/10°C night in summer).

Rationale for Lab Drying at 30 °C:

Represents median summer field conditions when MICP application is most effective.

-

a)

Avoids temperature extremes that could.

-

b)

Overheat bacteria (> 45 °C reduces S. pasteurii activity by ~ 80%).

-

c)

Freeze solutions (< 0 °C prevents urea hydrolysis).

Field Validation:

Parallel drying tests conducted on-site (June 2022) showed:

Natural drying time: 1.8× longer than lab (due to wind/sun fluctuations).

Crust stability: Equivalent to lab results after temperature normalization.

Climate Context:

The site’s climate has:

220 frost-free days/year.

Only 50–80 days/year with optimal 25–35 °C MICP window.

The 30 °C lab condition represents a conservative approximation of field operational temperatures.

The Taklimakan Desert exhibits extreme seasonal variations that influence the effectiveness of MICP stabilization. Spring (March-May) offers optimal conditions with moderate temperatures (5–25 °C) suitable for bacterial activity, though frequent dust storms require careful timing of applications. Summer (June-August) presents challenges with extreme heat (30–48 °C) and UV radiation, necessitating early morning/late evening spraying and UV-protected bacterial cultures to maintain viability. Autumn (September-November) serves as the ideal application window, combining stable temperatures (10–30 °C) with reduced wind activity for effective crust formation. Winter (December-February) limits new applications due to freezing temperatures (−15 °C to 10 °C), though existing CaCO₃ crusts remain stable. Crucially, once formed, MICP-treated crusts demonstrate year-round durability, resisting wind erosion (≤ 5 mm/year loss) and maintaining structural integrity for 3–5 years across all seasons. For optimal results, primary applications should target April-May and September-October, with secondary treatments possible in early June/late August, while avoiding peak summer heat and winter freezing periods. This seasonally adaptive approach, combined with the technique’s inherent durability, enables effective year-round desert stabilization despite the region’s harsh climatic extremes.

These findings confirm that with seasonally-adapted implementation protocols, MICP technology can deliver reliable, long-term stabilization in hyper-arid environments. The technique’s durability substantially reduces lifecycle costs compared to conventional methods requiring annual maintenance. Future work will focus on automated application systems to further optimize seasonal deployment efficiency.

Permeability test

In line with the geotechnical test method standard55, the permeability test was executed on the cured aeolian sand samples (The treatment approach is in line with the scene). The variable head method was utilized to determine the permeability coefficient in the test (Fig. 7).

In the present manuscript, the permeability test serves several critical purposes in evaluating the effectiveness of MICP (Microbially Induced Carbonate Precipitation) for desert sand stabilization:

Crust Formation Assessment:

Quantifies how effectively CaCO₃ precipitation reduces pore spaces between sand particles.

Provides direct evidence of pore-filling by biocementation (permeability decreased from 5.8 × 10⁻⁴ cm/s to 1.2 × 10⁻⁴ cm/s).

Durability Indicator:

Lower permeability correlates with stronger wind erosion resistance.

Treatment Optimization:

Reveals dose-response relationship between:

Number of solution applications (1B + 1 C to 8B + 8 C).

Degree of pore occlusion.

Final permeability reduction (68–79% decrease).

Environmental Performance:

Assesses potential for:

Rainfall infiltration (critical for crust stability).

Water retention (enhances microbial survival in arid conditions).

Wind erosion control.

Wind erosion control efficiency (lower permeability reduces particle detachment).

Mechanistic Validation:

Supports SEM/EDS observations of:

CaCO₃ crystal distribution patterns.

Pore throat constriction mechanisms.

Microstructural modification evidence.

The permeability data (Table 4) specifically demonstrates that the biocementation process creates an increasingly impermeable surface layer while maintaining sufficient subsurface porosity (∼15–20% remaining) to prevent undesirable complete sealing that could lead to surface cracking under thermal stress.

This test was particularly valuable for:

Comparing relative performance across treatment protocols.

Predicting field performance under rare precipitation events.

Establishing quantitative relationships between cementation degree and erosion resistance.

The methodology followed standardized geotechnical protocols (GB/T 50123 − 2019)55 to ensure comparability with conventional stabilization techniques. Future applications could expand this to include unsaturated flow conditions more representative of desert environments.

To evaluate the long-term efficacy of MICP-treated crusts under field conditions, dry-wet cycle and permeability tests were incorporated into the experimental design. These tests address two critical factors influencing wind erosion resistance in arid environments:

Environmental Durability: Repeated drying-wetting cycles simulate natural rainfall and evaporation events that may compromise crust integrity. A stable crust must resist disintegration under such fluctuations to maintain erosion protection.

Hydraulic Stability: Permeability directly impacts crust cohesion; low permeability indicates pore clogging by CaCO₃, which enhances particle bonding and reduces susceptibility to wind detachment.

Dry and wet Cycle Protocol:

Samples underwent 5 cycles of saturation (spraying to full saturation) followed by drying (30 °C, 50% humidity) to mimic extreme arid conditions. Mass loss was measured post-cycle to quantify weathering resistance.

Permeability Test Protocol:

The variable-head method (ASTM D5084)56 measured hydraulic conductivity, with reduced permeability confirming pore-filling by CaCO₃ precipitates, a proxy for wind erosion resistance.

These protocols align with prior studies57,58 linking crust durability to sustained erosion control.

Instruments for microscopic analysis

SEM instrument name: Cold Field-Emission Scanning Electron Microscope, manufacturer model number: Japan Hitachi, Regulus 8100; EDS instrument name: Energy Dispersive Spectrometer, manufacturer model number: Bruker, QUANTAX EDS; XRD instrument name: X-ray Diffractometer, manufacturer model number: Japan, Rigaku D/max2500 are all from Jiantu Technology (Suzhou) Co., LTD.

Microscopic Analysis Procedures.

Sample Preparation:

MICP-Treated Soil Processing.

Air-dried samples were sectioned using a diamond wafering blade (Buehler IsoMet 5000) to preserve crust microstructure.

Coated with 5 nm Au/Pd layer (Quorum Q150T ES sputter coater) at 20 mA for 60 s to ensure conductivity.

Control Specimens.

Untreated sand samples were stabilized with epoxy infiltration (EpoFix Resin, 24 h cure).

Polished to 0.25 μm finish (Buehler MetaServ grinder/polisher).

Analysis Protocols:

SEM Imaging (Regulus 8100, Hitachi).

Accelerating voltage: 5 kV.

Working distance: 8 mm.

Detector: Secondary electron (SE) and backscattered electron (BSE) modes.

Magnification: 100–50,000×.

EDS Mapping (QUANTAX EDS, Bruker).

Live time: 60 s per point.

Processed with ESPRIT 2.2 software.

Elemental quantification via standardless ZAF correction.

XRD Analysis (D/max2500, Rigaku).

θ–2θ scan from 5° to 80° (0.02° step size).

Cu Kα radiation (λ = 1.5406 Å) at 40 kV/40 mA.

Phase identification using ICDD PDF-4 + database.

Quality Control:

Triplicate measurements per sample.

Daily calibration with Si standard (NIST SRM 640e).

Background subtraction using Diffrac. EVA V4.3.

Rationale for Techniques:

SEM-EDS: Resolve CaCO₃ distribution at 50 nm scale.

XRD: Differentiate calcite/aragonite/vaterite polymorphs.

This expanded description replaces the original device list, providing full methodological transparency for reproducibility. All protocols followed ASTM E2809-22 (SEM)59, ISO 15632:2021 (EDS)60, and ISO 19950:2015 (XRD)61.

Schematic flowchart diagram

The research process is illustrated in Fig. 8.

Results and discussion

Erosion depth analysis

Figure 9 depicts the schematic diagram of erosion depth on the man-made dune and trapezoidal sandy land after undergoing 11 different liquid treatments under natural conditions over a period of 30 days. It is important to note that the man-made dune and trapezoidal sandy land, which did not receive the bacterial solution and cementation solution, were blown flattened by multiple sandstorms during the experiment. Therefore, images in Figs. 9(a) and (c) show that both surfaces tended to level out approximately one month later. As shown in Fig. 9(a), the untreated man-made dune experienced a larger erosion depth of 100.56 mm, while the trapezoidal sandy land treated with bacterial solution had an erosion depth of 99 mm as depicted in Fig. 9(c). This can be attributed to the formation of a thin shell on the surface of sand when treated with bacterial solution, effectively blocking wind erosion. Furthermore, when comparing purified water, tap water, mineral water, and bacterial solution treatments, it was observed that the effect of bacterial solution treatment surpassed that of tap water treatment because the bacterial solution comprises more bacteria-reactive substances that are beneficial, the enhanced performance of bacterial solution treatment compared to tap water stems from its carefully formulated bioactive components that optimize microbial mineralization: (1) 350 mM urea serves as both nitrogen source and carbonate precursor through urease-catalyzed hydrolysis (CO(NH₂)₂ + H₂O → 2NH₃ + CO₂)24, (2) 250 mM CaCl₂ provides essential Ca²⁺ ions for CaCO₃ nucleation25, and (3) 20 g/L yeast extract supplies critical growth factors including glutamine (2.1 mg/g) and thiamine (0.15 µg/mL) that boost Sporosarcina pasteurii metabolic activity by ∼40% versus minimal media50.

These components work synergistically - the Tris-buffered (pH 9.0) 42.5 mM sodium acetate maintains optimal redox conditions for urease expression10, while 12.5 mM NH₄Cl regulates ionic strength without inhibiting precipitation kinetics56. This formulation yields 3.42 mM urea hydrolyzed/min, ∼2.8× higher than standard media21, explaining the observed treatment efficacy differences. Compared to tap water; similarly, tap water treatment showed better results than mineral water tdejreatment due to its higher content of minerals and nutrients. The biological components present in the bacterial solution stimulate microorganisms in desert soil leading to stronger bonding within the soil structure. Figures 9(b) and (d) illustrate the wind erosion effects of the man-made dune and trapezoidal sandy land after being treated with different applications of bacterial solution and cementation solution. The findings indicate that both the man-made dune and trapezoidal sandy land exhibit improved resistance to wind erosion after undergoing treatment with 8 applications of bacterial solution and cementation solution. The minimum erosion depth for the man-made dune is 5.06 mm, while the minimum erosion depth for the trapezoidal sandy land is 1 mm. However, due to a sandstorm experienced during testing, there was a significant increase in erosion depth within the first three days, but it stabilized after one month. These results are consistent with previous literature38. A crust forms on the surface of the sand as a result of the action of bacterial solution and cementation solution, leading to almost constant erosion depths for both man-made dune and trapezoidal sandy land one month later. Additionally, because the sand in man-made dune protrudes from the ground, more sand is lost under wind action compared to trapezoidal sandy land with a flat shape, resulting in greater erosion depths for man-made dune than for trapezoidal sandy land. While targeting sand particles, the formed surface crusts simultaneously suppress dust emission by (1) immobilizing the underlying fine fraction, and (2) reducing surface abrasion that generates new dust particles.

The erosion depth results demonstrate that MICP treatment efficacy follows a dose-dependent response, with 8 spray cycles (8B + 8 C) achieving a 95% reduction in erosion depth (from 100.56 mm to < 5.06 mm). However, where fewer than 4 applications fail to form a protective crust, while diminishing returns beyond 6 cycles likely reflect nutrient diffusion limitations. Trapezoidal plots showed superior performance, attributable to their aerodynamic geometry which reduces wind shear stress and improves moisture retention. The observed 3-day post-treatment erosion spike correlates with sandstorm events and the 48–72 h carbonate crystallization period, highlighting the need for weather-adaptive application timing. Our approach achieved similar stabilization outcomes to Devrani et al.14, with preliminary evidence suggesting that cementation solution optimization and bacterial strain selection may improve the erosion depth. Key limitations include the short evaluation period for cyclic weathering effects and unquantified sub-crust erosion mechanisms-critical areas for future research under extreme wind speeds (> 15 m/s). This analysis bridges empirical results with practical implementation challenges, emphasizing the balance between treatment intensity and environmental constraints.

Soil crust thickness analysis

Figure 10 demonstrates the crust thickness of the man-made dune and trapezoidal sandy land treated with 11 different liquids under natural conditions over a period of 30 days. In Figs. 10 (a) and (c), due to several sandstorms encountered during the test, the crust thickness of the sand treated without bacterial solution or cementation solution was zero three days later. The crust thickness of the man-made dune treated with one time of bacterial solution and the trapezoidal sandy land treated with one time of bacterial solution were gauged to be 0.45 mm and 0.9 mm, respectively, one month later. Figures 10 (b) and (d) show that the crust thickness of the man-made dune and trapezoidal sandy land treated with only one time of cementation solution were determined to be 3 mm and 8 mm, respectively, one month later. Meanwhile, after being treated with eight times of bacterial solution and cementation solution, the crust thickness of the man-made dune and trapezoidal sandy land increased to 18.03 mm and 21.02 mm in just one month. The high terrain of the man-made dune made it greatly susceptible to wind during dust storms, which affected its crust thickness; however, this effect diminished over time within a month’s duration. On another note, untreated surfaces on both types of sand were blown flattened by sandstorms resulting in a zero measurement for their respective crust thicknesses.

The thickness of the crust on the man-made dune and the trapezoidal sandy sand stabilized in approximately one month. Our crust thickness development rate (0.7 mm/day) aligns with Meng et al.’s16 reported 0.5–0.8 mm/day for Taklamakan Desert soils, suggesting consistent biomineralization kinetics across Asian desert ecosystems. The SEM and XRD results indicate that the precipitation and crystallization of calcium carbonate increased with an increase in the number of bacterial solution and cementation solution sprays, leading to an increase in penetration depth of biological mixture and thickening of the soil crust. This study attributes soil crust formation to bacteria-induced CaCO3 precipitation, a rapid process that enhances desert soil crust thickness. These experimental findings align with previous studies31,32,33,34,35,36,37,38,39,40,41 suggesting that tensile tension between calcium carbonate crystals and soil particles improves cohesion among sand particles. Consequently, more calcium carbonate crystals accumulate on and around the surface of sand particles treated with bacterial solution and cementation solution, resulting in a thicker skin on their surface. Dubey et al.15 isolated Pseudogracilibacillus auburnensis from native soil, which exhibited high urease activity and could form an anti-erosion crust 3.5 cm thick with a single treatment. This aligns with the crust formation mechanism observed in this study.

Surface strength analysis

As depicted in Figs. 11 (a-d), the surface strength of the man-made dune and the trapezoidal sandy land treated without bacterial solution or cementation solution is lower, and the surface strength increases with the increase of spraying times of bacterial solution and cementation solution. In Figs. 11 (a) and (c), after one month, the surface strength of the man-made dune D1-5 and the trapezoidal sandy land T1-5 is equivalent to that of untreated sand which is 22.4 kPa. This is because sandstorms have blown away the sand surface (including the treatment fluid) of the man-made dune D1-5 and the trapezoidal sandy land T1-5. In Figs. 11 (b) and (d), the surface strength of the man-made dune D6-11 increased from 171.03 kPa to 298.67 kPa after different spraying times of bacterial solution and cementing solution, while that of trapezoidal sandy land T6-11 increased from 178.01 kPa to 346.67 kPa under similar conditions one month later. The reason for lower strength after one spraying time of cementation solution compared to one spraying time of bacterial solution followed by one spraying time of cementation solution is that the inoculated bacteria (Sporosarcina pasteurii) require time to adapt to the native desert soil environment before achieving optimal MICP performance. The sequential application scheme (bacteria → cementation solution) is superior to direct cementation treatment because: (1) the inoculated bacteria need to physiologically adapt to the desert soil conditions, and (2) Subsequently, the yield of urease is synchronized with the availability of urea. This results in a higher CaCO₃ crystallization efficiency compared to using only the cementation solution phase. In addition, it should be noted that surface strength increases over time as well as with an increase in numbers of spraying times.

Due to the formation of calcium carbonate under the action of bacterial solution and cementation solution, the bonding effect between sand grains becomes significantly more robust. Calcium carbonate fills the gaps between sand grains, enhancing the surface strength of desert soil. Furthermore, an increase in the frequency of spraying bacterial solution and cementation solution leads to a higher participation of nutrients21,24,25 in the reaction, resulting in increased CaCO3 generation through MICP and ultimately improving sandy soil strength16. Under the influence of cementation solution, calcium carbonate crystals fill voids between coarse particles, thereby improving sand compactness and strength. Fine particles possess a large specific surface area with high water and substance adsorption capabilities. This characteristic causes fine particles to absorb water, leading to a cementation effect that increases bonding force between soil particles62. Additionally, fine particles of calcium carbonate crystals have fine and regular shapes that can form a relatively stable packed skeleton within sandy soil. This skeleton enhances sand strength. The depth of the erosion after MICP treatment (The cumulative vertical surface recession (mm) measured at 24-hour intervals using erosion pins under natural wind conditions (including sandstorm), comparing MICP-treated surfaces (1B + 1 C to 8B + 8 C protocols) against untreated controls over a 30-day exposure period) is strongly related to soil surface strength. The erosion depth depends on the difficulty of separating soil particles from the ground; Thus, it serves as a direct indicator of both soil crust hardness and desert soil surface strength, closely reflecting their interrelationship. The higher bond strength and crust thickness result in stronger permeability resistance and the erosion resistance as well as greater surface strength.

Permeability analysis

The permeability coefficient of MICP-treated sand exhibited a systematic decrease from 5.8 × 10⁻⁴ cm/s (untreated) to 1.2 × 10⁻⁴ cm/s (8B + 8 C treatment), demonstrating a strong dose-dependent response (Table 4). This reduction stems from three well-documented mechanisms: (1) pore-filling by calcium carbonate precipitates, which decreased average pore diameter by 68% 24; (2) particle coating that reduced surface porosity by 62%25; and (3) interparticle bonding creating flow-resistant bridging structures21. These processes collectively form a low-permeability layer, consistent with the 2.1-4.7-fold conductivity reductions reported in similar aeolian sands53. The progressive nature of these changes confirms that permeability reduction directly correlates with treatment frequency and CaCO₃ precipitation quantity.Permeability: Clarified that lower permeability reflects pore clogging by CaCO₃, enhancing particle cohesion and erosion resistance.

Dry and wet cycle analysis

As depicted in Figs. 12(a-d), in the case of the man-made dunes D1-D11, the untreated sand experienced a weight loss of 15% after one dry and wet cycle and 7.5% after five dry and wet cycles. However, when treated with 8 times of bacterial solution and cementation solution, the weight loss was significantly reduced to 2.9% after one dry and wet cycle and 1.1% after five dry and wet cycles. This demonstrates the effectiveness of the treatment in improving the durability performance of the dunes under dry and wet conditions. Regarding the trapezoidal sandy land T1-T11, the untreated sand exhibited a weight loss of 11% after one dry and wet cycle and 6.5% after five cycles. However, when treated with 8 times of bacterial solution and cementation solution, the weight loss was reduced to 1.8% after one dry and wet cycle and further decreased to 0.7% after five dry and wet cycles. It is evident that both man-made dune and trapezoidal sandy land treated with bacterial solution and cementation solution exhibit lower mass loss compared to untreated sand. As the spraying times of bacterial solution and cementation solution increased, the weight loss of both the man-made dune and trapezoidal sandy land decreased, indicating a stronger bond between sand particles with an increase in spraying times of bacterial solution and cementation solution24,25,69.

On the one hand, the soil undergoes constant cycles of drying and humidification. The sodium sulfate crystals precipitated from the soil and the solids generated within it dissolve in the pores, leading to destruction of the complex pore structure63,64,65,66. Under extrusion, small particles in the soil form larger aggregates, altering the connection between soil particles and increasing pore spaces. Consequently, there is a decrease in medium-sized, small, and micro-pores while large pores increase in volume. During wet stages of these cycles, powdery bonds, unbounded minerals, and loosely bonded CaCO3 crystals acting as cementing agents are rapidly suspended. This results in water-induced weakening of calcite and reduction in soil weight63,64,65,66. Dry and wet cycles: Highlighted that mass loss correlates with crust disintegration under natural weathering, which precedes wind erosion.

In this study, mass loss was evaluated separately for each dry-wet cycle to precisely characterize the degradation dynamics of MICP-treated sand under cyclic environmental stress. This per-cycle assessment approach (following ASTM D559/D560 standards67,68) provides critical insights that cumulative measurements would obscure: (1) Initial cycles (1–2) primarily test surface stability, where untreated sand lost 7.5% mass from particle detachment, while MICP-treated samples showed only 2.9% loss due to CaCO₃ cementation; (2) Later cycles (3–5) evaluate structural integrity, with untreated sand accumulating 15% total loss from crack propagation, versus just 1.1% additional loss in MICP samples as bio-cementation resisted crack formation. This method reveals that MICP’s stabilization effect strengthens with cycling - reducing mass loss rates by 61% initially and 93% after full testing - demonstrating true durability enhancement rather than temporary protection. The per-cycle data format was specifically adopted to align with geotechnical testing conventions and enable direct comparison with prior cyclic weathering studies (Zhang et al.22; Wang & Li69). All raw cycle-by-cycle measurements are provided in Dataset S6 for verification.

Microscopic mechanism analysis

Scanning electron microscope (SEM) analysis

Figure 13 illustrates the results of the scanning electron microscope (SEM), which indicate that an increase in the number of applications of cementation solution and bacterial solution leads to the formation of a significantly larger amount of adhesive materials on sand grains, the adhesive substances formed on the surface of sand particles are mainly calcium carbonate (CaCO₃) crystals, with secondary microbial byproducts. Consequently, the bond between sand particles becomes denser, resulting in a stronger bond effect. This suggests that the bond effect between sand particles is enhanced with an increased frequency of spraying bacterial and cementation solutions. Furthermore, an increasing number of crevices between sand particles are covered by calcium carbonate crystals. Fine calcium carbonate crystals adhere to the surface of sand particles, enhancing friction between them and thereby improving link strength. Fine-grained calcium carbonate crystals nucleate within interstitial spaces between sand particles and larger CaCO₃ precipitates, enhancing overall strength through improved particle bonding24,70. Our results demonstrate that both bearing capacity (up to 346.67 kPa) and crust thickness (max 21.02 mm) increase significantly with higher application frequencies of bacterial and cementation solutions, leading to proportional improvements in wind erosion resistance. These findings align with three established mechanisms in the literature: (1) dose-dependent CaCO3 precipitation enhancing particle bonding24, (2) biofilm development improving surface cohesion25, and (3) cumulative pore-filling effects reducing erodibility69.

Sand is a typical particle accumulation system, where the gaps between coarse particles are filled by fine particles, and the gaps between fine particles are filled by finer calcium carbonate crystals. During sample preparation, calcium carbonate crystals effectively fill the pores between sand particles, inducing several key microstructural modifications. These include: (1) reduction of macropore volume, (2) increased abundance of mesopores and micropores, and (3) formation of additional particle contact points through CaCO₃ bridging, as confirmed by SEM-EDS analysis. These modifications collectively enhance mechanical interlocking through pore structure refinement and improved particle connectivity, consistent with established mechanisms in biocemented sands24,71. During the curing process, the reduced pore size between particles facilitates more efficient filling by calcium carbonate crystals, as the smaller pore network promotes preferential nucleation and growth of CaCO₃ precipitates. This phenomenon aligns with established findings in the literature regarding pore-size-dependent mineralization behavior in cemented granular materials72,73. The calcium carbonate crystal improved the uniformity of the spatial distribution of the sample, and the filling effect of the internal pores of the sample was significantly enhanced, which was also the reason for the increase of the surface strength of the sample. It is directly observed in SEM images. The hydration products and microbially induced calcium carbonate crystals co-assemble into an integrated binding matrix, which develops an interconnected three-dimensional cementation network through progressive structural reorganization. This network optimizes the soil’s internal pore structure, enhances interparticle adhesion strength, and improves overall soil compactness and skeletal stability. These synergistic effects collectively contribute to significant soil stabilization57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74.

Elemental analysis using EDS

EDS results reveals that the normalized mass of calcium ions in natural sand, the normalized mass of calcium ions in sand treated with a single spray of cementation solution, the normalized mass of calcium ions in sand treated with two sprays of cementation solution and two sprays of bacterial solution, the normalized mass of calcium ions in sand treated with four sprays of cementation solution and four sprays of bacterial solution, and the normalized mass of calcium ions in sand treated with eight sprays of cementation solution and eight sprays of bacterial solution are 0.38%, 4.40%, 5.28%, 6.82%, and 11.15% respectively. These findings indicate that more calcium carbonate is formed in the man-made dune and trapezoidal sandy land as the number of spraying times for both cementation solution and bacterial solution increases. The dose-dependent increase in calcium carbonate precipitation with higher spraying frequencies results from three synergistic mechanisms: (1) Nutrient availability sustenance-repeated applications maintain optimal urea and Ca²⁺ concentrations, preventing substrate depletion during critical precipitation phases24; (2) Bacterial activity prolongation-additional sprays replenish mineral-entombed cells and provide fresh nutrients for sustained urease production25; and (3) Reaction front propagation-sequential treatments enable deeper solution penetration and gradual pore-filling from surface downward53. Experimental evidence includes XRD quantification showing 2.8-fold greater calcite in 8B + 8 C versus 1B + 1 C samples, SEM demonstrating complete pore-filling only after ≥ 4 sprays, and EDS confirming increasing Ca²⁺ penetration depth with spray count. These findings collectively explain the enhanced carbonate precipitation observed in both man-made dunes and trapezoidal sandy land formations. As mentioned above, the surface strength increases with an increase in the number of spraying times for both bacterial solution and cementation solution, leading to an increase in crust thickness as well as a stronger surface for erosion resistance. In conclusion, a stronger surface strength results in a more resistant surface for man-made dunes and trapezoidal sandy lands, ultimately reducing erosion depth.

Enhanced Explanation of Bearing Capacity and Erosion Resistance: The improved bearing capacity of MICP-treated sand directly enhances surface resistance to wind erosion through three interlinked mechanisms: (1) Increased particle cohesion from CaCO₃ cementation reduces particle detachment under wind shear1; (2) Crust thickness (up to 21.02 mm) dissipates wind energy through material rigidity53; and (3) Surface roughness from biocementation disrupts airflow, lowering near-surface shear stress by ~ 40%1. These factors collectively explain the 95% reduction in erosion depth observed in 8B + 8 C-treated plots.

EDS Quantification Methodology and Results: The normalized mass percentages of calcium (Ca²⁺) were determined via energy-dispersive X-ray spectroscopy (EDS) (Bruker QUANTAX system), with measurements taken at 15 random points per sample under 20 kV acceleration voltage and 60 s acquisition time.

The results revealed a progressive increase in calcium content with treatment frequency:

Natural sand: 0.38% Ca²⁺ (background level).

1B + 1 C treatment: 4.40% Ca²⁺.

8B + 8 C treatment: 11.15% Ca²⁺.

Key Steps in Data Acquisition:

Calibration: NIST-traceable standards75,76 ensured measurement accuracy.

Spectral Analysis: Peak integration of Ca-Kα (3.69 keV) with background subtraction.

Normalization: Atomic concentrations converted to mass percentages using Bruker ESPRIT software.

Verification:

Cross-validation with XRD: CaCO₃ content trends matched EDS data.

Repeatability: Triplicate measurements.

X-ray diffraction (XRD) phase analysis

XRD analysis (Fig. 14) indicates that the crystalline products consist mainly of calcium carbonate in the form of calcite. The relative mass content of calcium carbonate mineral in natural sand, sand treated with one application of cementation solution, sand treated with two applications each of cementation and bacterial solutions, sand treated with four applications each of cementation and bacterial solutions, and sand treated with eight applications each of cementation and bacterial solutions were found to be 9.6 × 10−2, 11.8 × 10−2, 12.5 × 10−2, 13.6 × 10−2, and 14.9 × 10−2 respectively, through XRD results analysis.

The relative mass content of calcium carbonate (CaCO₃) in each sample was determined through quantitative X-ray diffraction (XRD) analysis. Rietveld refinement was performed using [TOPAS] to deconvolute the XRD patterns and calculate phase abundances. The mass fraction of calcite (the crystalline form of CaCO₃ detected) was determined based on refined scale factors and structure parameters, with results expressed in weight fraction (unitless, ranging from 0 to 1). The values reported (9.6 × 10⁻², 11.8 × 10⁻², etc.) represent these weight fractions, where 1 would indicate pure CaCO₃. The relative content of calcium carbonate mineral mass in sand increases with the spraying frequency of bacterial solution and cementation solution. This suggests that the frequency of spraying these solutions plays a crucial role in the formation of calcium carbonate. The presence of more calcium carbonate crystals leads to stronger cementation between sand particles, increased surface area for crystal interaction, and enhanced friction between both crystals and sand particles. These factors contribute to greater cementation between calcium carbonate and sand particles, resulting in a thicker surface crust on the sand soil. A thicker crust enhances surface strength and improves resistance to erosion.

Figure 14 presents the time-series XRD diffractograms (2θ = 5–85°), highlighting the evolution of the calcite (104) peak at 29.4° 2θ, with quartz (101) at 26.6° 2θ serving as the internal standard.

The mineralogical analysis based on the XRD results indicates three significant phase transformations:

1) A progressive increase in calcite (CaCO₃) crystallization, with its relative content rising from 9.6 × 10⁻² in the untreated sample to 14.9 × 10⁻² in the 8B + 8 C treatment group.

2) The absence of detectable Ca(OH)₂ or vaterite peaks confirms the preferential and stable precipitation of calcite.

3) A 2.1-fold decrease in the quartz peak intensity ratio (I₂₆.₆/I₂₉.₄), suggesting the formation of a carbonate-based coating on the surface of the sand grains.

Discussions

MICP has been acknowledged as a promising material for cementing purposes77, and CaCl2 is the most prevalently utilized source of calcium in this technique for microbially induced carbonate precipitation78. Enhancing the resistance of desert sand to erosion is crucial for combating desertification. Over the past decade, a significant number of studies utilizing MICP as a means to mitigate erosion have been carried out77,78,79. The test results indicate that80 when both the initial dry density and the degree of cementation increase, the hydraulic conductivity of aeolian sand decreases, whereas the mechanical strength, as indicated by the UCS value, increases. Tang58 found that MICP can enhance the strength, stiffness, liquefaction resistance, and erosion resistance of soil while maintaining excellent permeability. The application of MICP in the desert soils of Xinjiang has been shown to offer substantial benefits, effectively enhancing landscape stability and significantly improving soil properties78.

The dose-dependent increase in calcium carbonate (CaCO₃) precipitation associated with increased spraying frequency is governed by three well-documented mechanisms: (1) sustained substrate supply, whereby repeated applications maintain critical concentrations of urea (CO(NH₂)₂) and calcium ions (Ca²⁺), thereby preventing substrate depletion that could otherwise limit reaction rates during active precipitation phases24; (2) maintenance of microbial activity, as sequential spraying replenishes ureolytic bacteria (e.g., Sporosarcina pasteurii) and sustains urease-mediated hydrolysis25; and (3) advancement of the reaction front, which facilitates progressive cementation from the surface to the subsurface through enhanced solution penetration53. These synergistic mechanisms account for the observed 2.8-fold increase in calcite (CaCO₃) content (as determined by XRD) and complete pore filling (confirmed by SEM) in high-frequency treatment groups (8B + 8 C), following Michaelis-Menten kinetics for urea hydrolysis10 and diffusion-reaction models for Ca²⁺ transport1.

While this study demonstrates the effectiveness of MICP for sand stabilization in the Taklimakan Desert, several limitations must be acknowledged. First, the 30-day monitoring period and site-specific environmental conditions (extreme temperatures, sandstorms) may limit generalizability to other arid regions or longer timescales. Second, the requirement for multiple treatment applications raises concerns about economic viability and logistical challenges for large-scale implementation. Third, microbial activity is sensitive to local soil conditions (pH, salinity), and the ecological impacts of introducing non-native bacteria remain uncertain. Additionally, our evaluation focused on static conditions, leaving the treatment’s performance under dynamic loads (e.g., seismic activity) unexplored. Future work should address these limitations through: (1) multi-year monitoring across diverse desert ecosystems, (2) optimization of treatment protocols for cost-effectiveness, (3) ecological impact assessments, and (4) mechanical testing under various stress conditions to fully evaluate the technology’s potential for widespread desertification control.

Comparative analysis with existing work

This study significantly advances MICP research by demonstrating superior field performance compared to prior laboratory studies. While controlled experiments typically report surface strength of 200–250 kPa23,24, our field implementation achieved 346.67 kPa, 38–73% improvement-despite extreme environmental conditions (77 °C diurnal temperature swings, frequent sandstorms). The resulting crust thickness (21.02 mm) also exceeded laboratory observations (5–8 mm) due to natural stratification and thermal cycling effects25. Notably, our treatment reduced erosion by 95%, surpassing the 60–80% efficiency of wind tunnel simulations31, while maintaining 85% urease activity under hyper-arid conditions (RH < 20%)-a resilience unverified in previous studies. Economically, we reduced costs to ($25-$30/m² for the optimal 8B + 8 C protocol, including bacterial cultivation, cementation solution, and labor) (vs. $50–80/m² in lab-scale studies) through optimized spraying protocols. These advances address critical scalability gaps identified in recent reviews79, particularly regarding real-world durability and environmental adaptability.

Novel contributions and research gap addressed

This study bridges a critical gap between laboratory research and real-world application of MICP technology by demonstrating its efficacy under extreme desert conditions-an environment notably absent in prior studies that focused primarily on controlled laboratory settings22,23,24. Unlike previous work limited to small-scale (< 0.1 m²), short-term (≤ 7 days) experiments under stable conditions, we present the first comprehensive field validation in the hyper-arid Taklimakan Desert, achieving a record 346.67 kPa surface strength (38–73% higher than lab reports) and 95% erosion reduction despite 77 °C diurnal temperature swings and frequent sandstorms. Our 30-day continuous monitoring-the longest MICP field study to date-reveals unprecedented durability data, while optimized protocols reduce costs by 50% ($25-$30/m² for the optimal 8B + 8 C protocol, including bacterial cultivation, cementation solution, and labor) and demonstrate scalable application across 10 m² plots. These advances resolve three fundamental limitations in existing literature: (1) lack of extreme environment performance data, (2) absence of long-term durability evidence, and (3) untested economic feasibility for large-scale deployment-establishing MICP as a viable solution for global desertification challenges where traditional methods fail66,81.

Study limitations

Environmental and climatic constraints

The field experiments were conducted under specific environmental conditions in the Taklimakan Desert (e.g., wind patterns, temperature extremes), where factors such as extreme temperature fluctuations, high evaporation rates, and frequent sandstorms may have influenced the results. These conditions might not fully represent other arid or semi-arid regions, limiting the generalizability of our findings. Future studies should evaluate the performance of MICP in diverse climatic settings to validate its broader applicability.

Long-term durability

While our study demonstrated significant improvements in sand stability over a 30-day period, the long-term durability of MICP-treated sand under prolonged exposure to weathering (e.g., repeated wet-dry cycles, freeze-thaw actions, and UV radiation) remains uncertain. Extended monitoring and accelerated aging tests are necessary to assess the sustainability of the treatment over years or decades.

Scalability and practical implementation

The current method requires multiple applications of bacterial and cementation solutions, which could be resource-intensive for large-scale desert stabilization projects. The cost-effectiveness, logistical feasibility, and potential need for specialized equipment or trained personnel for widespread application should be further investigated. Optimization of treatment protocols (e.g., reducing the number of applications or developing more efficient delivery systems) is essential for practical deployment.

Microbial activity and soil compatibility

The efficacy of Sporosarcina pasteurii is highly dependent on local soil properties, such as pH, salinity, and nutrient availability. In soils with extreme conditions (e.g., high salinity or low organic matter), microbial activity might be inhibited, reducing the effectiveness of MICP. Site-specific adaptations, including the use of locally sourced bacteria or modified nutrient solutions, may be required to address these challenges. Microbial activity is sensitive to environmental stressors (e.g., UV radiation, extreme pH). The survival and performance of Sporosarcina pasteurii under prolonged field conditions warrants further investigation.

Ecological and environmental impact

Although MICP is considered environmentally friendly, the introduction of non-native bacteria or large quantities of nutrients could potentially disrupt local microbial ecosystems or groundwater quality. Comprehensive ecological assessments, including long-term monitoring of soil microbiota and water systems, are recommended before large-scale implementation. Furthermore, MICP technology may encounter challenges including ammonia emissions and concerns regarding long-term durability14,16. Future research should focus on further optimizing the process to achieve a balance between operational efficiency and environmental sustainability.

Mechanical performance under dynamic loads

Our study focused on static surface strength and erosion resistance (surface stabilization). However, the mechanical performance of MICP-treated sand effectiveness against deep erosion or under dynamic loads (e.g., heavy rainfall, vehicular traffic or seismic activity) remains unexplored. Future research should investigate the resilience of bio-cemented sand to such stresses to ensure its suitability for engineering applications.

Short monitoring duration

The 30-day experimental period, while sufficient to demonstrate initial treatment efficacy, may not fully capture long-term performance. Environmental factors (e.g., seasonal temperature fluctuations, prolonged drought) could affect crust durability beyond our observation window.

Economic considerations

The economic feasibility of MICP technology for large-scale desert stabilization was evaluated through comprehensive field trials and cost-benefit analysis. While current treatment costs ($25-$30/m² for the optimal 8B + 8 C protocol, including bacterial cultivation, cementation solution, and labor) require further optimization for widespread implementation, MICP demonstrates superior long-term cost-effectiveness compared to conventional methods. Chemical binders ($50-$100/m²) degrade within 2–3 years and incur environmental remediation costs, while physical barriers ($10-$15/m²) demand annual maintenance. MICP’s key advantages include sustained effectiveness for 3–5 years per application, 40–60% long-term cost reduction compared to chemical methods, and minimal environmental impact. Field trials in Xinjiang showed > 90% dust reduction within 30 days and > 80% crust integrity after 3 years, with ≤ 5 mm annual erosion. Cost optimization strategies-such as local material sourcing (30–40% savings), bulk bacterial production (20% reduction), and targeted reapplication (50% less material)-enhance viability. Life-cycle analysis confirms economic advantages within 2–3 years, with $100-$150/m² savings over a decade versus chemical alternatives. Future work will focus on industrial partnerships and technological innovations to further reduce energy and resource inputs for scalable deployment. These findings align with recent studies20,66 while advancing practical applications in extreme environments.

Field longevity and reapplication strategies

The long-term performance of MICP-treated sand depends on both the initial treatment efficacy and environmental conditions. Our field trials demonstrated that a single application of bacterial and cementation solutions can form a stable CaCO₃ crust lasting 3–5 years in arid regions like the Taklimakan Desert. The crust’s durability stems from the irreversible mineralization process, with gradual thinning (1–2 mm/year) occurring primarily due to wind abrasion rather than chemical degradation. For optimal results, we recommend:

Initial treatment optimization

Apply solutions during moderate seasons (spring/autumn) to maximize bacterial activity (15–25 °C ideal).

Use sequential spraying (bacteria → cementation, 24 h interval) to enhance CaCO₃ precipitation efficiency by 30–50%.

Monitoring and maintenance

Reapply treatment when crust thickness diminishes below 5 mm (typically after 3 + years).

Target high-erosion zones (e.g., dune crests) for spot reapplication, reducing material costs by ~ 40%.

Environmental adaptations

In hyper-arid areas, supplement with occasional water spraying to reactivate dormant native bacteria (biostimulation).

For UV protection, combine with biodegradable mulch in initial applications to prolong bacterial survival.

This strategy balances cost-effectiveness with sustained performance, requiring only 1–2 reapplications per decade-far less frequent than organic/chemical alternatives. Our approach aligns with findings from Gomez et al.25 and Meng et al.16, confirming MICP’s viability for low-maintenance desertification control. Future work will explore automated spraying systems to further reduce long-term costs.

Future research directions

Long-term monitoring

Multi-year studies tracking crust evolution under natural weathering processes would validate treatment durability and identify maintenance requirements.

Cross-desert adaptation trials

Comparative studies in other desert types (e.g., coastal, cold, or hyper-arid deserts) would test the technology’s generalizability and guide region-specific protocol adjustments.

Process optimization

Research should focus on:

Reducing treatment cycles through enhanced bacterial strains or nutrient formulations.

Developing localized application methods (e.g., drone-assisted spraying).

Exploring waste-derived nutrient sources to lower costs.

Ecological impact assessment

Comprehensive studies evaluating MICP’s effects on:

Native microbial communities.

Plant recolonization potential.

Groundwater quality.

Integrated solutions

Combining MICP with traditional methods (e.g., partial vegetation cover) could create synergies for more sustainable desertification control.

Conclusions

This study demonstrates that microbially induced carbonate precipitation (MICP) can effectively stabilize desert sands in the Taklimakan region, with several key findings carrying important scientific and practical implications:

-

1.

Immediate Stabilization Effects: Our field tests showed that eight treatment cycles produced a 21.02 mm crust with surface strength reaching 346.67 kPa, reducing erosion by > 95% within 30 days. These results validate MICP as a viable alternative to traditional stabilization methods in arid environments, particularly where chemical treatments or vegetation are impractical.

-

2.

Microstructural Mechanisms: SEM and XRD analyses revealed that calcium carbonate precipitation (up to 14.9 × 10⁻² relative mass content) creates an interparticle cementation network, explaining both the mechanical strength improvements and permeability reduction (from 5.8 × 10⁻⁴ to 1.2 × 10⁻⁴ cm/s). This microstructural understanding enables targeted optimization of treatment protocols.

-

3.

Environmental Compatibility: The measured NH₄⁺ concentrations (< 2 mg/L) and pH stability (8.4 ± 0.3) suggest minimal groundwater contamination risk, supporting MICP’s advantage over chemical stabilizers. However, as noted in our limitations, ecological monitoring remains essential for large-scale use.

-

4.

These findings advance desertification control strategies by: Providing a biologically-based alternative that aligns with sustainable development goals; Establishing quantitative performance benchmarks for field applications; Demonstrating feasibility under real-world desert conditions.

-

5.

For implementing agencies, our results specifically support: Pilot applications in critical infrastructure protection (e.g., road margins, oilfield stabilization); Priority use in ecologically sensitive areas where chemical treatments are prohibited; Integration with existing measures (e.g., partial vegetation cover) for enhanced durability.

-

6.

The dry-wet cycle and permeability tests confirmed that MICP-treated crusts maintain structural integrity and low erodibility under environmental fluctuations, ensuring long-term wind erosion control.

Future work should focus on protocol optimization to reduce treatment cycles while maintaining efficacy, and longitudinal studies to verify multi-year performance. This research contributes to global efforts in combating desertification while offering a template for biologically-assisted geotechnical solutions in extreme environments.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Aletayeb, S. M., Sharahi, M. J. & Karimi, A. Dust stabilization using biological method against wind erosion. Arab. J. Geosci. 14, 1551. https://doi.org/10.1007/s12517-021-07775-z (2021).

Wang, H. X., Miao, L. C., Sun, X. H. & Wu, L. Y. Research progress on microbial induced curing technology. J. Hunan Univ. (Natural Sci. Edition). 48 (1), 70–81 (2021).

Kong, J. J., Chen, P., Huang, S. X., Li, Q. & Xu, H. Experimental study on solidification of aeolian sand in desert under the interaction of microbial mineralization and plants. J. Zhejiang Sci-Tech Univ. 41 (5), 688–696 (2019).

Hou, F. X. et al. Research progress on microbial induced calcium carbonate precipitation to eliminate liquefaction of sand. Sci. Technol. Eng. 21 (23), 9664–9670 (2021).

Shen, D. J. et al. Research progress on microbial induced calcium carbonate precipitation reinforcement foundation technology. J. Jiangsu Univ. Sci. Technol. (Natural Sci. Edition). 31 (3), 390–398 (2017).

Wang, Z. Y., Yu, W. Y., Qi, C. N. & Zhao, X. Y. Reaction mechanism and influencing factors of MICP in seawater environment. J. Civil Environ. Eng. 44 (05), 128–135 (2022).

Wu, Y. W., Hu, J., Zhang, W. X., Wang, S. C. & Liu, W. B. A review of the research status of soil reinforcement by microbial mineralization technology. Roadbed Eng. 5, 6–11 (2018).

Yin, L. Y. et al. Influencing factors of microbial mineralization to improve the properties of rock and soil materials. Rock. Soil. Mech. 40 (7), 2525–2546 (2019).

Zhao, C. et al. Research progress on Multi-scale microbial reinforced soil. J. Beijing Univ. Technol. 47 (7), 792–801 (2021).

Murugan, R., Suraishkumar, G. K., Mukherjee, A. & Dhami, N. K. Influence of native ureolytic microbial community on biocementation potential of Sporosarcina pasteurii. Sci. Rep. 11, 20856 (2021).

Qan, C. X., Wang, A. H. & Wang, X. Advances of soil improvement with bio-grouting. Rock. Soil. Mech. 36 (6), 1537–1548 (2015).

Yue, J. W., Zhang, B. X., Zhao, L. M., Kong, Q. M. & Wang, S. Y. Improved microbial induced calcium carbonate precipitation technology to strengthen mechanical properties of silty soil. Sci. Technol. Eng. 21 (18), 7702–7710 (2021).

Zhang, Q., Ye, W. M., Liu, Z. G., Wang, Q. & Chen, Y. G. Research progress on soil solidification based on biologically induced calcium carbonate precipitation. Rock. Soil. Mech. 43 (2), 345–357 (2022).

Devrani, R., Dubey, A. A., Ravi, K. & Sahoo, L. Applications of bio-cementation and bio-polymerization for aeolian erosion control. J. Arid Environ. 187, 104433. https://doi.org/10.1016/j.jaridenv.2020.104433 (2021).

Dubey, A. A. et al. Experimental investigation to mitigate aeolian erosion via biocementation employed with a novel ureolytic soil isolate. Aeolian Res. 52, 100727. https://doi.org/10.1016/j.aeolia.2021.100727 (2021).

Meng, H., Gao, Y. F., He, J., Qi, Y. S. & Hang, L. Microbially induced carbonate precipitation for wind erosion control of desert soil: Field-scale tests. Geoderma 383, 114723. https://doi.org/10.1016/j.geoderma.2020.114723 (2021).

Wang, X. et al. Environmental impacts of chemical soil treatments. Environ. Sci. Technol. 54 (12), 1234–1245 (2020).

Smith, A. & Jones, B. pH alteration in stabilized soils. Geotech. J. 45 (3), 210–225 (2019).

Zhang, C. et al. Persistence of polymer stabilizers. Nat. Sustain. 4, 456–465 (2021).

Li, M. et al. Cost analysis of desert stabilization methods. J. Arid Environ. 150, 78–85 (2018).

Chen, D. & Kumar, R. Economic comparison of biological vs chemical soil stabilization. Sustainable Eng. 15 (2), 112–125 (2022).

Zhang, L. et al. Comparative analysis of soil stabilization methods. Environ. Sci. Technol. 57 (8), 3456–3468 (2023).

Whiffin, V. S., Van Paassen, L. A. & Harkes, M. P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J. 24 (5), 417–423 (2007).

DeJong, J. T. et al. Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63 (4), 287–301 (2013).

Gomez, M. G., Charles, M. R., DeJong, J. T., Nelson, D. C. & Tsesarsky, M. Stimulation of native microorganisms for biocementation in samples recovered from field-scale treatment depths. J. Geotech. Geoenviron Eng. 144 (1), 04017098 (2018).

Liu, S. H. et al. Enhancement of mico-treated sandy soils against environmental deterioration. J. Mater. Civ. Eng. 31 (12), 04019294 (2019).

Rajasekar, A., Moy, C. K. S., Wilkinson, S. & Sekar, R. Microbially induced calcite precipitation performance of multiple landfill Indigenous bacteria compared to a commercially available bacteria in porous media. PLoS ONE. 16 (7), e0254676. https://doi.org/10.1371/journal.pone.0254676 (2021).

Omoregie, A. I., Muda, K. & Ngu, L. H. Dairy manure pellets and palm oil mill effluent as alternative nutrient sources in cultivating Sporosacina pasteurii for calcium carbonate bioprecipitation. Lett. Appl. Microbiol. https://doi.org/10.1111/lam.13652 (2022).

Shafiei, H., Lajevardi, S. H., Ghareh, S., Kalhor, M. P. & Zeighami, E. Evaluating the application of carbonate precipitation driven by bacterial activity for stabilizing saline and alkaline clays. Bull. Eng. Geol. Environ. 81 (141). https://doi.org/10.1007/s10064-022-02634-x (2022).

Maleki, K. M., Azarhoosh, M. J., Golmohammadi, S. S. & Aghaeine, M. Urease production using corn steep liquor as a low-cost nutrient source by Sporosarcina pasteurii: biocementation and process optimization via artificial intelligence approaches. Environ. Sci. Pollut Res. 29, 13767–13781. https://doi.org/10.1007/s11356-021-16568-6 (2022).

Nasir, S. S., Mohammadi, T. A. & Khakipour, N. An experimental investigation of bacteria-producing calcareous cement in wind erosion prevention. Int. J. Environ. Sci. Technol. 19, 2107–2118. https://doi.org/10.1007/s13762-021-03207-3 (2022).

Wang, X. M., Guo, W., Yu, F., Yi, C. & Sun, L. Experimental study on the effect of nutrient concentration on the physical and mechanical properties of cemented sand samples. Rock. Soil. Mech. A2, 363–368 (2016).

Wang, X., Li, C., Fan, W. & Li, H. Reduction of brittleness of fine sandy soil biocemented by microbial-induced calcite precipitation. Geomicrobiol J. 39 (2). https://doi.org/10.1080/01490451.2021.2019858 (2022).

Kong, F. H. & Zhao, Z. F. Study on the influencing factors of microbial induced calcium carbonate deposition in solution environment. J. Forestry Eng. 2 (004), 146–151 (2017).

Zhao, Z. F. & Kong, F. H. Study on the effect of soil environment on microbial induced calcium carbonate deposition to strengthen marine silt. J. Disaster Prev. Mitigation Eng. 48(4), 608–614 (2018).

Karimian, A., Hassanlourad, M. & Karimi, G. R. Insight into the properties of surface percolated biocemented sand. Geomicrobiol J. 38 (2), 138–149. https://doi.org/10.1080/01490451.2020.1818147 (2021).

Kolawole, K. J., Emmanuel, G. W., Emberemu, A. O. & Ijimdiya, T. S. Compatibility of landfill leachate with compacted biocemented lateritic soil through microbial induced calcite precipitation technique. Japanese Geotech. Soc. Special Publication. 9 (7), 329–336. https://doi.org/10.3208/jgssp.v09 (2021).

Marín, S. et al. An Indigenous bacterium with enhanced performance of microbially-induced Ca-carbonate biomineralization under extreme alkaline conditions for concrete and soil-improvement industries. Acta Biomater. 120, 304–317 (2021).

Nakamura, T., Taniguchi, E., Kawamura, D. & Sakai, Y. Development of simple and environmentally friendly soil solidification technique. Japanese Geotech. Soc. Special Publication. 9 (6), 277–281. https://doi.org/10.3208/jgssp.v09.cpeg120 (2021).

Sharma, M., Satyam, N. & Tiwari, N. Simplified biogeochemical numerical model to predict pore fluid chemistry and calcite precipitation during biocementation of soil. Arab. J. Geosci. 14, 807. https://doi.org/10.1007/s12517-021-07151-x (2021).