Abstract

With the gradual extension of global coal mining to the deep, the problem of surface subsidence caused by repeated mining of multiple coal seams has attracted much attention. In this paper, the methods of theoretical analysis, numerical simulation and field monitoring are used to study the settlement model and settlement law under the condition of repeated mining of multiple coal seams, and the engineering application is carried out. Through theoretical analysis, it is concluded that there is a linear relationship between the amount of broken expansion of overlying rock mass, the buried depth of coal seam, the thickness of coal seam and the maximum subsidence value of surface. The opening size of surface subsidence basin in multi-coal seam mining is still linear with the mining depth of coal seam. Based on the probability integral method, fully considering the factors such as rock mass expansion and separation caused by repeated mining of unequal thickness and multiple coal seams, the prediction model of surface subsidence caused by repeated mining of multiple coal seams is constructed, and the calculation method and calculation formula of surface subsidence coefficient caused by repeated mining of multiple coal seams are given. The law of overlying strata and surface subsidence caused by repeated mining of multiple coal seams is analyzed by numerical simulation. The results show that the trend of surface subsidence is similar to that of repeated mining (second-layer coal) in multi-coal seam mining area. The subsidence curve is symmetrically distributed in the early stage of mining and asymmetrically distributed in the later stage. The maximum value of surface subsidence is located on the side of open-off cut. The numerical simulation results are highly similar to the calculation results of ' prediction model of surface subsidence caused by repeated mining of multi-coal seam '. The surface subsidence prediction model constructed in this paper is used to predict the coal mine site. The prediction results are compared with the field measurement results. The maximum relative error value of the working face tendency is 5.7%, and the average relative error value is 2.9%. Along the strike of the working face, the maximum relative error value is 6.7%, and the average relative error value is 5%. The overall prediction error is small, which verifies the rationality of the prediction model of the surface subsidence law of multi-coal seam repeated mining.

Similar content being viewed by others

Introduction

The western region of China is rich in coal resources, with a large number of minable coal seams and thick coal seam thickness, presenting superior mining conditions1,2. In recent years, coal mining in this region has gradually shifted from shallow coal seams in the early stage to deep coal seam mining, developed from the initial first seam mining to repeated mining of the second coal seam, and further expanded to repeated mining of the third coal seam3,4. Due to the difference in the number of mined coal seams, the surface subsidence prediction methods in the same mining area also vary. After the first-time coal seam mining, the overburden strata will undergo movement, deformation, and failure. When secondary coal seam mining is carried out, new deformation and failure will occur again in the overburden strata and surface that have already undergone movement and deformation. This phenomenon is referred to as repeated mining5,6. At present, scholars at home and abroad have carried out extensive research on the laws of surface subsidence under repeated mining and achieved abundant results.

In the research on the laws of surface subsidence under repeated mining,Enke Hou7 et al. believed that after the mining of double coal seams, the surface subsidence curve presents a broad and gentle "W" shape. The maximum surface subsidence and the maximum horizontal positive displacement are located near the starting position of the working face, and dense fractures near the position will penetrate to the surface. Junpeng Zou8 et al. believed based on field measurements and discrete element simulations that in the scenario of single coal seam mining, the surface subsidence curve often presents a broad and gentle “bowl” shape; while in the case of double coal seam mining, the surface subsidence curve evolves into a “funnel”-shaped structure with only a single inflection point. Weidong Wang 9 et al. considered that both the initial stage and active stage of surface movement are relatively short. Under the condition of multiple coal seam mining, there are obvious regular changes in surface movement parameters, which are mainly affected by the activation of goafs, leading to a significant increase in the subsidence coefficient during the mining of lower coal seams. In the research on the subsidence coefficient of repeated mining, Yuehan Wang10 et al. derived the calculation method for the subsidence coefficient of the surface and rock mass during the initial mining of coal seams. Through the “activation” mechanism of repeated mining strata, they derived the calculation formula for the surface subsidence coefficient during repeated mining. Weimin Ma11 et al. found that repeated mining significantly alters the original pattern of surface movement and deformation, leading to obvious variation. Additionally, the research team innovatively proposed a calculation method for the subsidence aggravation coefficient, providing important theoretical references and technical support for relevant engineering practices. PR Sheorey12 et al. conducted field measurements in local mines in India, proposed new parameter corrections, and presented an influence function method with new parameters, which can be used to simulate and predict asymmetric surface subsidence. In the research on subsidence prediction methods, Tugrul13 et al. classified surface subsidence prediction methods into three categories according to the principles and approaches of the calculation methods: (1) empirical methods based on measured data; (2) theoretical model methods; (3) influence function methods. Among them, the probability integral method, based on the theory of random media, has been continuously extended, simplified, corrected, and optimized in algorithm. In recent years, this method has been widely used at home and abroad. Huayang Dai14 et al. took the coal seam dip angle as a variable to modify the probability integral method, established a generalized mining subsidence prediction method—vector method, and validated the reliability of the prediction method through field measurement results of Lizuizi Coal Mine and Dahuangshan Coal Mine. Jianwei Cheng15 et al. based on the influence function method, combined with the correction formulas of subsidence coefficient, inflection point offset distance and main influence radius parameters, improved the prediction accuracy of the probability integral method model.

The above research results have laid a solid theoretical foundation for subsequent surface subsidence studies. However, among numerous studies, there are relatively more research results on the laws of surface subsidence caused by repeated mining of double coal seams, while there is a lack of research on the laws of surface subsidence caused by repeated mining of multiple coal seams (three or more coal seams). Additionally, reliable prediction models for repeated mining of multiple coal seams are scarce. Based on previous research, this study analyzes the characteristics of surface subsidence under the condition of repeated mining of multiple coal seams. The model parameters are modified by the principle of rock mass expansion, and the surface subsidence prediction model of multi-coal seam repeated mining is constructed based on the probability integral method. The settlement prediction results are compared with the results of numerical simulation, similar simulation and mine measurement to verify the reliability and accuracy of the model. This aims to provide strong theoretical support and basis for the protection of surface structures and the governance of the surface environment during the surface subsidence process caused by repeated mining of multiple coal seams.

Project overview

Introduction to the mining area

Gongwusu Coal Mine is located in the south of Wuhai City, Inner Mongolia Autonomous Region, under the jurisdiction of Hainan District. It is situated in the southeast of Zhuozishan Coalfield, adjacent to Lutian Coal Mine in the west, Qipanjing Coal Mine in the east, and the National Highway 109 in the north. The area of Gongwusu Coal Mine is an irregular polygon. The minefield is 7.6 km long and 2.3 km wide in the dip direction, delimited by 37 inflection points, covering an area of 15.31 km2. The elevation ranges from + 1200 to + 1289 m, with a height difference of 89 m. In the middle of the minefield lies Gongwusu Sand Gully, which runs through the surface of the southern mining area of the minefield, flowing from east to west into Lasengmiao Gully and then into the Yellow River.

Geological conditions of the mining area

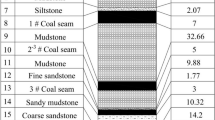

Most coal resources in northwestern China are multi-seam deposits, and many areas have entered or are about to enter the stage of repeated mining of multiple coal seams. Compared with single coal seam mining, repeated mining of multiple coal seams causes a larger range of strata movement. The mining area studied in this paper is currently in the stage of repeated mining of multiple coal seams. The stratum basement of the mining area is Ordovician, and the coal-bearing strata are the Upper Carboniferous Taiyuan Formation and the Lower Permian Shanxi Formation. The overlying strata include the Lower Permian Lower Shihezi Formation (P1x), Upper Permian Upper Shihezi Formation (P2s), Shiqianfeng Formation (P2sh), Triassic, Tertiary, and Quaternary. Among them, the No. 16 coal seam is located in the upper part of the Taiyuan Formation coal measure, with stable thickness and local stratification and gangue interlayers. The immediate roof of the working face is mudstone, the main roof is fine sandstone, the immediate floor is fine sandstone, and the main floor is mudstone, as shown in Fig. 1.

Mining conditions of 021601 working face

The 021601 fully mechanized caving working face is located in the 02 mining area of No.16 coal seam in Gongwusu Coal Mine. The working face has an inclined length of 188 m and a strike length of 1540 m. The mining height of the working face is 3 m, the top-coal caving height is 5.5 m, and the mining-to-caving ratio is 1:1.83. The overlying strata of the working face are the goafs of No.12 and No.9 coal seams. The surface is an irregularly shaped gangue hill, with multiple photovoltaic panels arranged on it. The average height of the surface soil layer within the mining range is 30 m. The schematic diagram of the coal seam mining in the working face is shown in Fig. 2.

Prediction model of initial mining surface subsidence

The coordinate system is established for the initial mining, as shown in Fig. 316. The coordinate system is perpendicular to the mining boundary of the coal seam until the surface is o point. The horizontal axis x points to the direction of coal seam mining along the surface, and the x-axis is the length of the coal seam working face ; the vertical axis z is perpendicular to the ground pointing to the mining boundary, and the z axis is the mining depth of the coal seam.

Based on the theory of random medium, the overlying strata of the coal seam in the mining area are assumed to be homogeneous and equidistant micro-units. When the micro-units of the coal seam are mined, the micro-units of the overlying strata have an equal probability settlement trend to fill the vacancy and approximate the normal distribution. Therefore, the normal distribution probability density function is used as the basic formula of surface subsidence caused by repeated mining. Its basic formula is formula 117,18;

In the formula, r denotes the mining influence radius, m ;

As shown in Fig. 3, based on the superposition principle, when the mining thickness is d units, the strike mining boundary ranges from \(S_{x} = S_{xx}\) to \(S_{x} = S_{xs}\), and the dip mining boundary ranges from \(S_{y} = S_{yx}\) to \(S_{y} = S_{ys}\). For a three-dimensional space, when mining a coal seam with a volume of \(d \times dS_{x} \times dS_{y}\) the theoretical formula for surface subsidence takes the surface subsidence space as the integrand and the working face length as the integration interval. Meanwhile, considering the swelling property of caved rock mass during mining, factors such as the hardness, stability, and fractures of overlying strata directly affect the surface subsidence basin formed after coal seam mining. By comprehensively considering the mining area factors, the calculation formula for the surface subsidence amount at any point in a horizontal coal seam is as follows19,20:

Construction of prediction model of surface subsidence caused by repeated mining of multiple coal seams

Analysis of surface subsidence characteristics of repeated mining in multiple coal seams

The mining of the first coal seam is defined as the initial mining. With the continuous advancement of the mining operation in the mining area and its extension to the deep part, the mining of the third coal seam is defined as the repeated mining of multiple coal seams21,22. After the initial mining of the coal seam, the overburden failure is transmitted from bottom to top, and finally a subsidence basin is formed on the surface. As shown in Fig. 4 (\(\varepsilon_{0}\) is the maximum amount of bulking in the initial mining rock mass, the x axis is the length of the coal seam working face, and the z axis is the mining depth of the coal seam.), when the first layer of coal mining is completed, the surface soil layer will bend and sink, and the overburden will produce separation cracks. The rock strata in the range of abcd will collapse and break to produce bulking, and the amount of bulking is about \(\varepsilon_{0}\), so the coal seam mining space is occupied by three parts : rock bulking, separation cracks and surface subsidence. When repeated mining, that is, the second coal seam mining, within the range of abcd, new rock mass will be broken and expanded on the basis of the initial mining, and the amount of broken expansion will be reduced compared with the amount of broken expansion caused by the initial mining. There is a specific relationship between the two. The coefficient k (the influence coefficient of repeated mining subsidence of multiple coal seams) is used to prove that the rock in the range of a1b1c1d1 breaks and expands, and the overall maximum subsidence value of the surface increases23,24. When the multi-coal seam is repeatedly mined, that is, the third coal seam is mined. At this time, the rock strata within the range of a2b2c2d2 will collapse and break and produce new rock mass expansion. The new rock mass expansion generated by the broken rock strata in abcd and a1b1c1d1 is less than the rock mass expansion generated by the upper coal mining. The rock mass expansion is \(k\varepsilon_{0}\) and \(k\varepsilon_{1}\), respectively. The overburden stress is redistributed during the upper coal mining, and the stress variation range during the multi-coal seam repeated mining is lower than that during the upper coal mining. The fractured and separated rock mass will be further developed and expanded during the repeated mining of multiple coal seams, while ignoring the damage to the floor during the mining of the upper coal seam. That is, when the repeated mining of multiple coal seams is over, after a certain time and space evolution, the maximum surface subsidence expression of repeated mining of multiple coal seams is as follows.

In the formula : d3 is the thickness of coal seam mining when multiple coal seams are repeatedly mined ( such as the thickness of the third coal seam in Fig. 4), m; \(\varepsilon_{0}\) is the initial mining rock mass expansion in the mining area. The three layers of coal in Fig. 4 belong to the same mining area and the strata are similar. It is assumed that \(\varepsilon_{0} = \varepsilon_{1} = \varepsilon_{2}\); among them, \(\varepsilon_{1}\) is the maximum bulking amount of rock mass during repeated mining, and \(\varepsilon_{2}\) is the maximum bulking amount of rock mass during repeated mining of multiple coal seams. H1, H2 and H3 are the mining depth of the first layer of coal, the second layer of coal and the third layer of coal, respectively, m ; k is the influence coefficient of repeated mining subsidence (assuming that the coal seam k of the same mining area is the same and constant), and k can be obtained by the regression of the mining depth, mining thickness and topsoil thickness of the upper coal.

Prediction model construction

As shown in Fig. 4, when the second layer of coal needs to be repeatedly mined after the first layer of coal is first mined, in view of the initial mining-induced surface subsidence and the region has reached a stress equilibrium state, so for the second layer of coal After the end of repeated mining, the subsidence area formed by the initial mining will have residual bulking. Due to the existence of residual bulking, the determination of subsidence parameters during repeated mining operations needs to fully consider the bulking characteristics of the rock layer. At the same time, the field and laboratory observations show that the expansion of the rock mass is linearly distributed with the distance of the coal seam. The formula 425;

In the formula, \(\varepsilon_{z}\) represents the amount of rock mass expansion at the z-axis position in the coordinate system, \(z\): coal seam mining depth, H : represents the mining depth, Hb : represents the height of the topsoil layer ;

When the initial mining of the first coal seam is completed, the weight of some rock mass above the working face is transferred to the coal and rock pillars around the working face in the form of supporting pressure, and the rock mass in the fracture zone is in an unloading state, causing it to expand. The subsidence value of the surface will be less than the mining thickness of the coal seam due to the expansion of the rock mass in the initial mining. According to the formula 4, the maximum subsidence value of the first coal seam in the initial mining is formula 5.

In the formula, \(\varepsilon_{0}\) represents the amount of rock mass expansion in the mining area. Because it is the same mining area, it is assumed that the amount of rock mass expansion caused by mining is \(\varepsilon_{0}\) and \(\varepsilon_{0}\) can be obtained by field observation data.

The maximum subsidence value of the first coal seam after the first mining can also be obtained by the following formula 626,27;

In the formula, the maximum surface subsidence value q of the first mining in w1 represents the subsidence coefficient of the first mining.

The Eq. 7 of the maximum subsidence of the mining area can be obtained by taking the Eq. 6 into the Eq. 5;

The following formula can be obtained by means of integral expansion and term shift;

Formula 8 can be obtained by simple calculation of the maximum amount of rock mass in the mining area 9

In the formula, \(\varepsilon_{0}\) represents the amount of rock mass expansion in the mining area. Because it is the same mining area, it is assumed that the amount of rock mass expansion caused by mining is \(\varepsilon_{0}\), and \(\varepsilon_{0}\) can be obtained by field observation data. Formula 1028,29;

The rock swelling amount of the mining area can be obtained through Eq. 10, and substituting it into Eq. 9 can calculate the surface subsidence coefficient q of the initial mining in the mining area, resulting in Eq. 1130,31;

In view of the fact that the overburden rock has the characteristics of bulking, the bulking area of rock mass formed by the initial mining will produce a new round of bulking of rock mass when multiple coal seams are repeatedly mined. The amount of bulking is reduced compared with the initial mining, and there is a specific correlation between the two, which is characterized by the influence coefficient. The influence coefficient is defined as the influence coefficient k of repeated mining subsidence 10. In the same mining area, based on similar geological and mining conditions and other factors, the default k value remains unchanged. As shown in Fig. 4, when multiple coal seams are repeatedly mined, new rock mass bulking can be calculated by k value in abcd and a1b1c1d1 bulking areas. Therefore, the maximum surface subsidence after repeated full mining of multiple coal seams can be calculated by formula 12.

Formula 13 can be obtained by integral expansion of formula 12, and formula 3 can be obtained by simple operation according to mathematical formula;

In the formula, w3 is the maximum surface subsidence after the end of multi-coal seam mining ; k is the influence coefficient of repeated mining subsidence ; H1 is the mining depth of the first layer of coal, H2 is the mining depth of the second layer of coal, and H3 is the mining depth of multiple coal seams. d3 is the thickness of coal seam during repeated mining of multiple coal seams ;

According to the measured experience, the maximum surface subsidence of repeated mining in multiple coal seams can also be obtained by formula 14.

In the formula, qf is the surface subsidence coefficient of repeated mining in multiple coal seams ;

Substituting Eq. 14 into Eq. 13, the subsidence coefficient of repeated mining of multiple coal seams can be obtained as Eq. 15;

The surface subsidence model of multi-coal seam repeated mining and the surface subsidence model of single coal seam are mainly due to the difference of mining depth, mining thickness and rock mass expansion, and the prediction results will be different. Therefore, the formula 16 of the surface subsidence model of repeated mining in multiple coal seams can be obtained by substituting formula 15 into formula 2.;

In the formula : \(d_{3}\) is the mining thickness of the third coal seam ; \(s_{x}\) is the strike length of the working face ; \(s_{y}\) is the inclined length of the working face ;

Multi-coal seam repeated mining animal similar simulation study

Similar simulation test design

In order to study the surface subsidence and overburden law of multi-coal seam repeated mining in Wuhai mining area, combined with the actual engineering geological conditions of the study area, a physical similarity simulation test was designed. According to the test conditions and similarity criteria, combined with engineering practice, the size of the test bench is determined to be 200 cm × 20 cm × 120 cm (length × width × height), the similarity constant is calculated based on the similarity principle32,33, and the similarity constant is shown in Table 1. The model begins to pave from the fine-grained sandstone of the coal seam floor to the surface in the vertical direction. The relevant materials selected in the paving process need to have a certain strength to simulate the actual rock layer. The aggregate is mainly river sand and fly ash. The cohesive material is gypsum and white powder. The coal seam is prepared with fly ash, and the layered material is 10–20 mesh mica powder.

Model mining scheme : the length of three-layer coal mining is the same. In order to eliminate the influence of boundary, 30 cm coal pillars are set on both sides of the model. The space of 5 cm next to the boundary of the left coal pillar is excavated as the open-off cut of the working face, and then 2 cm is excavated from the open-off cut to the right each time until the boundary of the coal pillar and the end of the three-layer coal mining. The whole process is recorded by high-definition camera. The dial indicator was used to monitor the surface settlement, and the optical photogrammetry system was used to monitor the settlement information of the pre-set landmarks of the model. The similar simulation model diagram is shown in Fig. 5.

Analysis of similar simulation results

Analysis of migration characteristics of overlying strata in multi-coal seam mining

A 5 m excavation is made at 30 m left of the No.9 coal seam as the open-off cut, followed by continuous mining step by step to the right with a step distance of 2 m. When the working face advances to 36 m, initial caving occurs with a caving height of about 9 m. As the face advances to 64 m, beam-structured bed separation forms in the overlying strata. With continuous mining, the roof undergoes periodic breaking, and bed separation fractures continue to develop upward. After the mining of No.9 coal seam is completed, swelling bed separation occurs, with the development height of bed separation fractures reaching about 46 m. At this time, the maximum surface subsidence is approximately 2834 mm, as shown in Fig. 6.

After the No.9 coal seam stabilizes, the same mining method is applied to the No.12 coal seam. When the working face advances to 22 m, the roof of the No.12 coal seam undergoes initial caving. With the advance of the working face, the swelling bed separation continues to develop, expand, and propagate upward. After the mining of the No.12 coal seam is completed, a trapezoidal hinged structure forms in the overburden, causing surface subsidence and forming a subsidence basin. At this time, the overall maximum surface subsidence is approximately 3426 mm, as shown in Fig. 7.

After the No.9 and No.12 coal seams stabilize, the No.16 coal seam is mined, which is defined as repeated mining of multiple coal seams in this paper. When the working face advances to 14 m, the immediate roof of the No.16 coal seam undergoes initial caving with a caving height of about 4 m, and the swelling bed separation develops, expands, and generates new separation zones, as shown in Fig. 8a. When the face advances to 48 m, the main roof of the No.16 coal seam connects with the goaf of the No.12 coal seam, causing overall movement of the overburden and significant swelling bed separation. At this stage, the main roof forms a voussoir beam hinged structure, as shown in Fig. 8b. When the face advances to 58 m, the No.16 coal seam connects with the goafs of both the No.12 and No.9 coal seams, leading to overall downward movement of the overburden. Longitudinal swelling bed separations begin to expand and propagate upward, while transverse separations develop and expand toward the mining direction, with partial closure of some separation zones, as shown in Fig. 8c. When the face advances to 92 m, the longitudinal swelling bed separations reach the surface, generating surface cracks. Transverse separations extend to the surrounding protective coal pillars and reach the surface, increasing the influence radius, expanding the surface subsidence basin, and intensifying the surface subsidence, as shown in Fig. 8d. After the mining of the No.16 coal seam is completed, the overall maximum surface subsidence is 8613 mm.

Analysis of surface subsidence characteristics of multi-coal seam mining

As shown in Fig. 9, the maximum surface subsidence after mining the No.9 coal seam is 2834 mm. The subsidence curve exhibits a symmetric distribution, but the symmetric center is not located at the midline of the mining area; instead, it biases toward the open-off cut side. With the advance of the working face, the position of the maximum surface subsidence moves toward the symmetric center.

As shown in Fig. 10, at the end of 12 # coal seam mining, new surface subsidence occurs, showing stepped subsidence, and the settlement curve is asymmetric. The maximum surface settlement is 592 mm, and the maximum settlement position is biased towards the side of the open-off cut, 20 m away from the middle line of the mining area.

As shown in Fig. 11, when the working face advances to 58 m, the overburden of the No.16 coal seam connects with the goaf of the No.12 coal seam, causing overburden movement, which is manifested as significant surface subsidence. When advancing to 92 m, the longitudinal swelling bed separations develop to the surface, generating surface cracks and remarkable surface subsidence. The area of the subsidence basin is fixed. With the advance of the working face, the boundary of the subsidence basin gradually develops toward the surface cracks, and the subsidence curve shows an asymmetric distribution. After the mining of the No.16 coal seam is completed, new surface subsidence occurs, with the maximum surface subsidence of approximately 5187 mm. The position of the maximum subsidence is located on the open-off cut side, 10 m away from the goaf. The model prediction curve is similar to the surface subsidence curve of repeated mining of multiple coal seams, further verifying the reliability of the model.

Numerical simulation study on repeated mining of multiple coal seams

Establishment of numerical model

To clearly demonstrate surface subsidence and overburden bed separation caused by repeated mining of multiple coal seams, 3DEC numerical simulation software is adopted. Taking Gongwusu Coal Mine as the engineering background, for calculation convenience, thinner strata or strata with similar properties are combined into one layer. The model size is x × y × z = 460 m × 6 m × 194 m. The established numerical calculation model is shown in Fig. 12. When the strike working face is fully mined, overburden failure is the most severe, and the surface subsidence reaches the theoretical maximum value at this time, so the maximum surface subsidence in the dip direction of the working face is not considered. The model is designed for three coal seams mining: the No.9 coal seam has a burial depth of 96.5 m and a mining height of 4.5 m; the No.12 coal seam has a burial depth of 146 m and a mining height of 1 m; the No.16 coal seam in the fully mechanized caving face has a burial depth of 173.5 m, a mining height of 3 m, and a top-coal caving height of 5.5 m. To eliminate boundary effects, 80-m coal pillars are reserved at both ends of the strike working face, and the simulated strike mining length of the working face is 300 m, from 80 to 380 m in the horizontal direction. Each mining step is 10 m, with 3000 calculation steps. The established numerical model is constructed from the floor of the No.16 coal seam to the surface in the vertical direction.

In the numerical model, the constitutive relationship of coal and rock strata adopts Moore–Coulomb criterion, and the constitutive model of joints adopts the Mohr–Coulomb Joint model of surface contact. According to the geological structure conditions, the thickness of each rock layer and different combination modes, the mechanical properties of each rock, the rock mechanics parameters and the measured data of mine exploration, the rock mechanics parameters in the model are determined as shown in Table 234. The boundary conditions of the model are fixed, in which the left and right boundaries of the model are fixed in the x direction, the front and back boundaries of the model are fixed in the y direction, the bottom boundary of the model is fixed in the z direction, and the top boundary of the model is not fixed. A survey line is arranged along the strike of the model surface to record the surface subsidence of each coal seam after excavation.

Analysis of numerical simulation results

The migration characteristics of overlying strata in multi-coal seam mining

After the end of the initial mining, the fracture of the overlying strata, the expansion of the rock and the collapse of the overlying strata show the settlement of the surface. At this time, the maximum settlement value of the surface can reach 3008 mm. During the advancement process, some of the overlying separation layers that have been developed are closed. However, if there is an unclosed broken expansion separation layer, the rock layer at the end of the initial mining gradually tends to be stable after migration. The residual broken expansion of the initial mining is located at the open-off cut and the end of the mining. The distribution of the ' three zones ' of the overlying strata of the coal seam is obvious35,36, as shown in Fig. 13.

When repeated mining occurs, the separation layer produced by the overlying strata is further developed and expanded during the migration process, resulting in a further increase in surface subsidence. The maximum overall surface subsidence value after repeated mining can reach 3713 mm, and the downward mining continues. With the increase of mining depth, the influence radius of strike mining gradually expands, which shows that the surface is the outward expansion of the surface subsidence range, and the overburden separation layer appears37. As shown in Fig. 14.

The continuous downward mining enters the repeated mining stage of multiple coal seams. The development of overburden separation is basically the same as that in the repeated mining stage. The mining thickness and mining depth of 16 # coal seam increase greatly. The development of separation and bulking in the overlying strata are large, and new separation and bulking occur in the overlying strata. At this time, the overall maximum settlement value of the surface can reach 9461 mm, and the external expansion speed of the mining influence radius increases sharply. When the working face of 16 # coal seam advances 60 m, the roof falls for the first time and the separation develops (Fig. 15a) ; when the working face advances to 100 m, the overlying strata collapses in a wide range, and the overlying separation layer in the caving area begins to develop (Fig. 15b). When the working face advances to 200 m, the separation layer develops again, and the separation layer continues to develop upward, the separation layer fracture increases, and the surface will have a large settlement (Fig. 15c). When the working face advances to 300 m, the coal seam strikes and stops, and the cracks at the open-off cut are dense and will lead to the surface, resulting in cracks on the surface, the subsidence basin appears initially, and some separation layers are closed (Fig. 15d). The displacement of overlying strata during the advancing process of multi-seam repeated mining face is shown in Fig. 15.

Characteristics of surface subsidence caused by repeated mining of multiple coal seams

As shown in Fig. 16, when the coal seam is first mined, the surface subsidence curve shows symmetry. During the mining process, the maximum surface subsidence position will change with the continuous advancement of the working face and gradually move towards the middle line of the goaf.

As shown in Fig. 17, when the coal seam is repeatedly mined, the surface subsidence curve in the early stage of mining is symmetrically distributed, and the surface subsidence curve in the later stage is asymmetrically distributed. The maximum surface subsidence position is no longer in the center, but is located on the side of the open-off cut position. At 50 m from the center of the goaf, new subsidence occurs on the surface after repeated mining of the coal seam, and the maximum settlement value is 705 mm.

As shown in Fig. 18, during repeated mining of multiple coal seams, the trend of the surface subsidence curve is similar to that of coal seam repeated mining, with the maximum surface subsidence position also biasing toward the open-off cut side at 70 m from the center line of the goaf. After repeated mining of multiple coal seams, new surface subsidence occurs on the basis of the original subsidence, and the maximum new surface subsidence is 5748 mm. when advancing to 60 m, the roof undergoes initial caving, and due to overburden bed separation and rock swelling, surface subsidence occurs at a slow rate, while when the working face advances to 200 m, the influence of overburden movement from repeated mining of multiple coal seams reaches the surface, causing significant surface subsidence at an accelerated rate, meaning the surface subsidence curve of repeated mining of multiple coal seams can be divided into three parts—slow subsidence rate in the early stage, faster rate in the middle stage, and slow rate in the later stage; by substituting relevant numerical simulation data into Eq. 16, extracting the theoretical predicted subsidence curve along the strike and comparing it with the numerical simulation results, the maximum absolute error of the theoretical prediction is 33 cm, the average absolute error is 7.6 cm, the maximum relative error is 5.4%, and the average relative error is 2.7%, showing small overall errors and high prediction accuracy, which verifies the reliability of the model prediction.

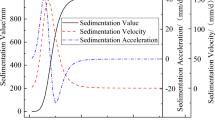

Analysis of the maximum surface subsidence

After the coal seam mining is completed, surface subsidence occurs, and the subsidence process can be divided into three parts: the initial subsidence stage, the active stage, and the decay stage. When the initial mining ends (after the No.9 coal seam mining), the mining advance distance of 0–60 m is defined as the initial subsidence stage of initial mining with a slow subsidence rate, the advance distance of 60–180 m is the active subsidence stage of initial mining with a faster rate, and the advance distance of 180–300 m is the decay subsidence stage of initial mining with a slow rate; after the repeated mining ends (after the No.12 coal seam mining), the advance distance of 0–100 m is defined as the initial subsidence stage of repeated mining with a slow rate, the advance distance of 100–200 m is the active subsidence stage of repeated mining with a faster rate, and the advance distance of 200–300 m is the decay subsidence stage of repeated mining with a slow rate; during the multiple coal seams repeated mining stage (No.16 coal seam mining), the advance distance of 0–100 m is defined as the initial subsidence stage of multiple coal seams repeated mining with a slow rate, which is the same as the early subsidence interval of the repeated mining stage due to the influence of goaf activation, and the No.12 coal seam goaf has little influence on the early stage of No.16 coal seam mining, the advance distance of 100–220 m is defined as the active subsidence stage of multiple coal seams repeated mining with a faster rate, and when advancing to 100 m, the No.12 coal seam goaf starts to activate, increasing the middle subsidence period of multiple coal seams repeated mining, during which large-area subsidence and caving occur in the overlying strata with continuous upward development of bed separation, while the advance distance of 220–300 m is defined as the decay subsidence stage of multiple coal seams repeated mining with a slow rate due to the reduced influence of goaf activation, with bed separation developing to the surface, the boundary of the subsidence basin fixed, and little change in the maximum surface subsidence, as shown in Fig. 19.

Case analysis

This paper selects the No.021601 fully mechanized caving face in Gongwusu Coal Mine, which is located in the No.02 mining area of the 16# coal seam. The working face has a strike length of 544 m, a coal seam thickness of 8.50 m, and an average burial depth of 219 m. The overlying strata of the working face is the No.021201 goaf after repeated mining of the 12# coal seam. To verify the reliability of the surface subsidence model formula for repeated mining of multiple coal seams, 32 measuring points (No.1# to No.32#) and 4 control points (R1 to R4) are arranged along the dip direction of the working face, with the dip survey line 310 m away from the open-off cut of the working face. Along the strike direction of the working face, 23 measuring points (No.33# to No.54#, with the 13# point) and 2 control points (R5, R6) are arranged, with a distance of 20 m between adjacent monitoring points, as shown in Fig. 20.

According to the observation data of the observation station,qf≈ 0.71777,\(\varepsilon_{0}\)≈ 0.03,k≈ 0.45129, r≈188, strike working face range [− sx, sx] = [− 317.8,317.8 ], dip working face range [− sy, sy] = [− 130.8,130.8] are determined. Substituting the data into Formula 16, a three-dimensional map of surface subsidence caused by repeated mining of 16 # multi-coal seams can be obtained. As shown in Fig. 21;

The measured data of trend and tendency are sorted out, and the theoretical prediction results are compared with the measured results according to the location of surface monitoring points, as shown in Fig. 22.

According to the analysis, along the dip direction of the working face, the maximum absolute error of the theoretical prediction is 32 cm, the average absolute error is 9.5 cm, the maximum relative error is 5.7%, and the average relative error is 2.9%. Along the strike direction of the working face, the maximum absolute error of the theoretical prediction is 35 cm, the average absolute error is 6.7 cm, the maximum relative error is 6.7%, and the average relative error is 5%. Compared with the main surface subsidence amount, the overall errors in both dip and strike directions of the working face are small, indicating that the surface subsidence prediction method under repeated mining conditions in multiple coal seam mining areas has similar predicted results to the measured subsidence curves with high prediction accuracy, further verifying the reliability of the prediction model.

Conclusions

-

(1)

Through theoretical analysis, a "prediction model for surface subsidence in repeated mining of multiple coal seams" was established, which improves the conventional prediction method. It was found that under repeated mining of multiple coal seams with different mining thicknesses, there is a linear relationship between the subsidence coefficient and the rock swelling amount in the mining area.

-

(2)

Similar simulation results show that when the working face of the 16# coal seam advances to 92 m, longitudinal swelling bed separations develop to the surface, generating surface cracks. The area of the subsidence basin is fixed, and with the advance of the working face, the boundary of the subsidence basin gradually develops toward the surface cracks, presenting an asymmetric subsidence curve.

-

(3)

Numerical simulation results indicate that the surface subsidence curve of repeated mining of multiple coal seams has asymmetric characteristics. The subsidence process can be divided into three parts: slow subsidence rate in the early stage, faster rate in the middle stage, and slow rate in the later stage. The overall maximum surface subsidence value is 9461 mm, with the maximum subsidence position biasing toward the open-off cut side, 70 m from the center line of the goaf. After repeated mining, new surface subsidence occurs with a maximum value of 5748 mm.

-

(4)

Surface subsidence prediction results show that the prediction method for repeated mining surface subsidence is close to the measured subsidence curve. The maximum relative error along the dip direction of the working face is 5.7%, and the average relative error is 2.9%; along the strike direction, the maximum relative error is 6.7%, and the average relative error is 5%. The overall error is small, and the prediction accuracy is high, verifying the reliability of the subsidence model.

Data availability

The research data in this paper is publicly available in the paper.

References

Shuangming, W., Zhonghui, D., Li, Ma. & Yuping, Z. Research status and future trends of geological assurance technology for coal green development in Western China. Coal Sci. Technol. 47, 1–6 (2019).

Suping, P. & Yinli, Bi. Properties of ecological environment damage and their mechanism of restoration in arid and semi-arid coal mining area of western China. J. China Coal Soc. 49, 57–64 (2024).

Ju, J., Xu, J. & Zhu, W. Influence of overlying key strata structure pre sliding on support failure disaster while mining in thelower coal seam cut across below the upper adjacent coal pillar under shallow cover. J. China Coal Soc. 40, 2033–2039 (2015).

Xiangye, W. U. et al. Scale-span evolution law and mechanical mechanism of surrounding rock cracksin repeateo mining roadway. J. China Coal Soc. S2, 1–14 (2024).

Xiong, Y. et al. Instability control of roadway surrounding rock in close-distance coal seam groups under repeated mining. Energies 14, 5193 (2021).

Ji, J. et al. Research on formation mechanism and evolution pattern of bed separation zone during repeated mining in multiple coal seams. Geofluids 2022, 1–19 (2022).

Hou, E., Cong, T., Xle, X. & Wei, J. Ground surface fracture development characteristics of shallow double coal seam staggered mining based on particle flow. J. Min. Strala Control Eng. 2, 20–28 (2020).

Zou, J., Wang, M., Bai, L. & Yan, C. Numerical study on migration of overlying strata and propogation of cracks during multi-coal seams mining. Front. Earth Sci. 11, 1326597 (2023).

Wang, W., Guo, X., Wang, M., Tian, G. & Li, Y. Surface movement law in shallow multi-seam coal mining. Coal Eng. 55, 136–141 (2023).

Wang, Y., Deng, K., Zhang, D. & Zhou, M. Study on subsidence characteristics of overlying strata under repeated mining conditions. J. China Coal Soc. (1998).

Ma, W. & Zhu, W. Simulation study on repeated mining law of rock strata and surface. J. China Univ. Min. Technol. 8–20 (1984).

Sheorey, P. R., Loui, J. P., Singh, K. B. & Singh, S. K. Ground subsidence observations and a modified influence function method for complete subsidence prediction. Int. J. Rock Mech. Min. Sci. 37, 801–818 (2000).

Unlu, T., Akcin, H. & Yilmaz, O. An integrated approach for the prediction of subsidence for coal mining basins. Eng. Geol. 166, 186–203 (2013).

Dai, H., Zhai, J. & Hu, Y. Testing study on surface displacement of mountainous region with similar material. J. Rock Mech. Eng. 19, 501–504 (2000).

Cheng, J. et al. Overlying strata movement and deformation calculation prediction models for underground coal mines. J. Min. Strata Control Eng. 2, 20–29 (2020).

Wei, T. et al. A novel probability integral method segmental modified model for subsidence prediction applicable to thick loose layer mining areas. Environ. Sci. Pollut. R. 30, 52049–52061 (2023).

Yang, Z. et al. An InSAR-based temporal probability integral method and its application for predicting mining-induced dynamic deformations and assessing progressive damage to surface buildings. IEEE J. Sel. Topics Appl. Earth Observ. Remote Sens. 11, 472–484 (2018).

Yan, W., Guo, J., Yan, S., Yan, Y. & Tang, W. A novel surface subsidence prediction model based on stochastic medium theory for inclined coal seam mining. Adv. Civ. Eng. 2023, 1–11 (2023).

Zhu, X., Guo, G., Liu, H. & Yang, X. Surface subsidence prediction method of backfill-strip mining in coal mining. Bull. Eng. Geol. Environ. 78, 6235–6248 (2019).

Shi, Y., Zhao, M. & Hao, J. Study on numerical models in predicting surface deformation caused by underground coal mining. Geotech. Geol. Eng. 39, 4457–4473 (2021).

Xiong, Y., Kong, D., Wen, Z., Wu, G. & Liu, Q. Analysis of coal face stability of lower coal seam under repeated mining in close coal seams group. Sci. Rep. 12, 509 (2022).

Lv, H., Cheng, Z., Liu, F. & Wei, W. Stress, displacement, and crack evolution of top-coal layers in high-intensity repeated mining with extra-thick coal seam. Comput. Part. Mech. https://doi.org/10.1007/s40571-025-00959-4 (2025).

Deng, K., Zhou, M., Tan, Z. & Xu, N. Experimental study on fracture law of mining rock mass. J. China Univ. Min. Technol. 43–46 (1998).

Guo, W., Han, M., Yang, W. & Ma, Z. Research and application of maximum surface subsidence model under the condition of repeated mining in weakly cemented strata. Coal Sci. Technol. 51, 1–10 (2023).

Deng, K., Zhang, D. & Zhang, Z. Study on prediction and control of surface subsidence in deep mining. J. China Univ. Min. Technol. 29, 52–55 (2000).

Zhou, W. Calculation of the maximum surface subsidence value. Coal Sci. Technol. https://doi.org/10.13199/j.cst.1977.10.37.zhouwq.001 (1977).

Li, J. Study on Surface Subsidence Prediction Method Based on Movement Characteristics of Primary Key Stratum (Liaoning Technical University, 2022).

Kuai, Y. Study on Surface Movement Parmeters of Repeated Mining Under Thick Alluvium-Taking Huainan Coal Mining Area as Example (Anhui University, 2018).

Li, H., Yuan, R., Zai, P., Zhang, Q. & Feng, C. SCA fracturing mechanisms of rock mass and application in overhanging roof structure fragmentation of mine goaf. Processes 13, 1275 (2025).

Cao, J., Huang, Q. & Guo, L. Subsidence prediction of overburden strata and ground surface in shallow coal seam mining. Sci. Rep. 11, 18972 (2021).

Lian, X., Hu, H., Li, T. & Hu, D. Main geological and mining factors affecting ground cracks induced by underground coal mining in Shanxi Province. China. Int. J. Coal Sci. Technol. 7, 362–370 (2020).

Xu, P. et al. Effect of polymeric aluminum chloride waste residue and citric acid on the properties of magnesium oxychloride cement. J. Build. Eng. 101, 111864 (2025).

Xinlei, L., Ziyuan, R., Zhengzheng, C. & Hao, R. Study on coal drawing parameters of deeply buried hard coal seams based on PFC. Sci. Rep. 15, 21934 (2025).

Li, G.-D. et al. A new determination method of hydraulic support resistance in deep coal pillar working face. Sci. Rep. 15, 19158 (2025).

Junzhe, Y., Bowen, H. & Zhenrong, W. Study on distribution characteristics of collapse zone, fissure zone and curved subsidence zone and layered settlement of overburden on 8.8 m super-large mining height coal mining face. Coal Sci. Technol. 48, 42–48 (2020).

Huang, Z. et al. Dividing guideline and emulating determination of “three zones” of the depressing zones overlying a goaf. Chin. J. Eng. https://doi.org/10.13374/j.issn1001-053x.2006.07.001 (2006).

Wu, Q. et al. Physical simulation on spatialdistribution of void fraction in overburden due to repeated mining in North Shaanxi Mining Area. Coal Sci. Technol. 50, 105–111 (2022).

Acknowledgements

I would like to thank the editorial team for their careful reading and the Inner Mongolia University of Science and Technology for their support.

Funding

Basic Research Operating Expenses of Colleges and Universities directly under the Inner Mongolia Autonomous Region, China (2024QNJS102); Natural Science Foundation of Inner Mongolia Autonomous Region, China (2025MS05022).

Author information

Authors and Affiliations

Contributions

The study was initiated and designed with the participation of all authors. G and Q both wrote the first draft of the article, while Dr Z and Prof Z commented on and revised the first draft. The final manuscript was reviewed and approved by all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Yes.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Guo, S., Qiu, S., Zhang, D. et al. Research on surface subsidence laws and prediction models under repeated mining of multiple coal seams. Sci Rep 15, 32103 (2025). https://doi.org/10.1038/s41598-025-15662-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15662-w