Abstract

While existing mathematical formulas have provided empirical references, significant discrepancies were observed in the calculated heat transfer coefficient (HTC) values when these formulations were applied to high-pressure water descaling processes. Consequently, the analysis of the descaling temperature field was rendered inaccurate. This study undertook a systematic investigation of the impacts of various operational variables, including water flow rate, nozzle-to-billet standoff distance, nozzle geometric parameters, and installation configuration, which were subsequently converted into water flux. Following a parametric analysis of the effects of water flux and surface temperature, comprehensive computational fluid dynamics (CFD) simulations were performed to quantitatively assess the HTC in high-pressure water descaling processes. To improve practical applicability, a mathematical model for the HTC in high-pressure water descaling was developed through nonlinear regression analysis, thereby establishing a predictive relationship between process parameters and heat transfer characteristics. The HTC under operational conditions was quantitatively assessed by employing a regression-based mathematical model formulated in this study, which delineated explicit relationships between process variables and thermal transport mechanisms in high-pressure water descaling systems. The HTC values obtained were subsequently utilized in finite element analysis (FEA) to perform numerical simulations of thermal profiles during the descaling process. To validate the thermal behavior predicted by the FEA, real-time infrared thermography measurements of billet surface temperature were conducted during industrial-scale descaling operations, thereby establishing a comparative validation framework between numerical simulations and field-acquired thermal data. The results indicated that the maximum discrepancy between the simulated and measured temperatures was 28 °C, while the minimum discrepancy was recorded at 1 °C. A quantitative correlation was established between the numerical predictions and experimental measurements, thereby affirming the predictive accuracy of the regression-derived HTC model developed in this study.

Similar content being viewed by others

Introduction

In the process of hot rolling, billets are subjected to uniform heating at elevated temperatures prior to the rolling operation. This thermal treatment leads to the formation of thick oxide scales on the surface of the billets due to oxidation reactions, which adhere strongly to the surface. The presence of these oxide layers negatively impacts both the surface integrity and production yield of steel plates, while also contributing to increased wear on the rolling equipment. Therefore, it is imperative to remove the oxide scales from the billet surface before proceeding with subsequent rolling operations. High-pressure water descaling systems have been widely utilized in industrial settings for the effective removal of these scales. This method is particularly favored in hot rolling processes due to its operational flexibility and cost-effectiveness1,2,3,4.

The widespread use of high-pressure water for the removal of iron oxide scale results in unintended cooling effects on the surfaces of steel billets. Notable reductions in temperature are observed when billets are exposed to multiple high-pressure water jets, leading to an undesirable thermal variation. Temperature is a crucial factor in the hot rolling process, as it directly influences the rolling force, while the ultimate microstructure and mechanical properties of steel plates are determined by the final rolling temperature. Therefore, meticulous calculation and regulation of rolling temperature are essential for ensuring quality5,6,7,8.

The HTC at the interface between the billet and water is recognized as a vital factor in the analysis of temperature distribution during the descaling process. Through comprehensive experimental investigations, the Japanese Iron and Steel Association has developed a mathematical model that characterizes the HTC during high-pressure water descaling, with water flow rate and the surface temperature of the billet identified as key variables9. The mathematical relationship has been articulated as presented in Eq. (1):

where h is HTC of high pressure water descaling (W/m2 K). \(T\) is billet temperature (℃). Where ω is the water flux on the surface of billet (L/(min m2)).

Research concerning the regulation of temperature distribution in steel plates has thoroughly examined the relationship between heat transfer coefficients (HTC) and various operational parameters. Kohei et al.10 identified water flux and the pre-descaling surface temperature of rolled materials as dominant factors governing HTC variations. This framework was subsequently extended by Wada et al.,11 who established water pressure as an additional critical parameter influencing HTC characteristics. The relationship is expressed in Eq. (2):

where h is HTC of high pressure water descaling (W/m2 K). \(T\) is billet temperature (℃). Where ω is the water flux on the surface of billet (L/(min m2)).

Sellars12 conducted a comprehensive regression analysis to establish the relationship between the HTC during high-pressure water descaling and various operational parameters, including water pressure, billet surface temperature, and the duration of water cooling. Subsequent studies by Pohanka and Kotrbacek et al.13,14 demonstrated that cooling water temperature significantly influences HTC during high-pressure water treatment, with a comprehensive formulation later derived to describe this relationship. Further, computational simulations by Li et al.15 quantified the dependence of HTC on impact pressure through temperature field analysis of steel plates under varying high-pressure water conditions.

In the context of computational modeling concerning the temperature fields associated with high-pressure water descaling, Madakasira16 established the HTC to be 2000 W/(m2 K) through empirical observations derived from operational experience. The foundational formulation for low-pressure water descaling HTC was first proposed by Sasaki17 and later adapted by Leocadio H.18 for water jet impingement cooling simulations, with simulations producing an HTC of 8000 W/(m2 K). Experiments by multiple research groups19,20 established that the HTC during high-pressure water descaling exhibits significant variability, ranging from 1160 to 25,000 W/(m2 K). Ginzburg21 further linked this parameter to hydrodynamic flow velocity and plate dimensional characteristics through a theoretical framework.

In addition to these theoretical frameworks, laboratory-scale experiments conducted by Choi22 under regulated descaling conditions provided quantitative measurements of the HTC through finite difference analysis, yielding values between 170,000 and 650,000 W/(m2 K). These results led to a pressure-dependent HTC formulation tailored for high-pressure water descaling, expressed as Eq. (3):

where h is HTC of high pressure water descaling (W/m2 K). P is impact pressure of high pressure water (bar).

A thorough examination of the current literature regarding HTC in high-pressure water descaling has systematically delineated essential operational parameters, including water flux, impact pressure, billet surface temperature, hydrodynamic velocity, and volumetric flow rate, that influence this process. Although previous studies have incorporated these variables into multivariate analyses, significant discrepancies—ranging across three orders of magnitude (1160–650,000 W/(m2 K))—remain evident between theoretical predictions and experimental measurements of HTC. This variability, along with non-quantifiable factors present in industrial environments, underscores significant limitations in contemporary modeling approaches. Such deficiencies call for a thorough reassessment of existing models in order to establish comprehensive frameworks that align theoretical predictions with the constraints of practical measurements.

The multifactorial relationships influencing the HTC during high-pressure water descaling can be systematically incorporated through the parameterization of water flux, which includes variables such as hydrodynamic velocity, volumetric flow rate, impact pressure, and the distance between the nozzle and the surface. This research conducted a parametric analysis emphasizing water flux and billet surface temperature as critical factors affecting variations in HTC. Computational fluid dynamics (CFD) simulations were employed to quantify HTC values under various operational conditions, leading to the development of a flux-dependent formulation tailored for high-pressure water descaling applications.

In the context of industrial validation, the formulated model was utilized in finite element analysis (FEA) to forecast temperature distributions based on real production parameters. This research examines the alignment between the simulated temperature distribution and the temperature measurements acquired from the steel billet processing line. The findings demonstrate a strong correlation between the calculated results and the empirical data, as evidenced by a temperature deviation (ΔT) of less than 5% at each measurement point.

In this study, a comprehensive methodological framework consisting of theoretical analysis, computational modeling, and experimental validation was systematically employed. The integrated research structure is visually represented in Fig. 1.

Conversion of process parameters of high pressure water descaling and water flux

The operational equivalence between the parameters of high-pressure water descaling and water flux was determined through a systematic assessment of nozzle flow characteristics, alongside an analysis of the geometry of the nozzle assembly, which encompasses essential dimensions and spatial arrangements. The equation for calculating water flux (Eq. 4) is articulated as follows:

where ω represents the water flux on the surface of the billet (in m3/(min m2)). Q is the flow of water from a single nozzle (m3/min). F is the coverage area of high pressure water sprayed onto billet (m2).

The calculation of water flow can be conducted through two methods: one involves assessing the capacity of the high-pressure water system, while the other entails determining the product of the outlet velocity and the outlet area of the high-pressure water nozzle. The area covered by the high-pressure water applied to the surface of the billet is computed using Eq. (5).

The parameter L corresponds to the longitudinal dimension of the high-pressure water jet impingement zone (m), while B characterizes the transverse jet thickness within the billet processing area (m). The calculation about L, B are shown in Eqs. (6) and (7).

where H represents the target distance of high pressure water jet (m). α is injection angle of high pressure water nozzle (°). β is inclination angle of high pressure water nozzle installation (°). θ is scattering angle of high pressure water nozzle (°).

Increasing the spray angle α enhances the spatial distribution of high-pressure water impingement; however, it concurrently leads to a reduction in mean dynamic pressure, which diminishes descaling efficiency. Conversely, a decrease in α results in heightened localized impact intensity, significantly improving descaling effectiveness within specific impact zones. This geometric trade-off necessitates a proportional arrangement density of nozzles along the header to guarantee comprehensive treatment coverage, which, in turn, escalates operational costs. Consequently, through empirical optimization, the spray angle is limited to a range of 22° to 40° to achieve an optimal balance between descaling performance and economic feasibility.

The tilt angle β requires careful calibration to maintain the integrity of jet momentum. Inadequately small values of β can lead to detrimental fluid interactions between the incoming streams and the reflected flows, resulting in significant reductions in jet pressure. Conversely, excessively large values of β necessitate increased clearance between the nozzle and the surface, which can undermine hydrodynamic performance due to energy losses associated with droplet dispersion. Experimental validation has established that the tilt angle should be constrained within the range of 10° to 35° to achieve optimal efficiency in scale removal while ensuring stable flow dynamics.

The relationship between target distance, injection angle, inclination angle, scattering angle, and nozzle position is shown in Fig. 2. Operational parameters and their variable ranges are summarized in Table 1, serving as a reference for process analysis and model implementation. The values in Table 1 ensure optimal descaling performance, with proven efficacy in industrial applications for scale removal and process efficiency.

The internal structure of the high pressure water descaling nozzle is shown in Fig. 3.

The reduction of the nozzle orifice diameter results in an increase in hydrodynamic impact pressure, which enhances the removal of oxide scale through intensified mechanical impingement. However, excessively narrow diameters can lead to a decrease in volumetric flow, thereby impeding the dissolution of scale due to inadequate delivery of reactants. This presents a trade-off that necessitates a balanced design approach: while restricted orifices can elevate flow velocity to improve HTC, they may also lead to a reduction in surface temperatures as a consequence of Newtonian cooling effects.

A multi-objective optimization framework was subsequently established to simultaneously enhance descaling efficiency and reduce fluctuations in thermal gradients. Empirical data from industrial operations, complemented by theoretical hydrodynamic analyses, identified a 3-mm orifice diameter as the most effective configuration. This setup resulted in scale removal rates surpassing 92%, while ensuring that the billet surface temperature remained within the specified thermal parameters.

Equations (6) and (7) are substituted into Eq. (5). The result of collation is shown in Eq. (8).

Equation (8) is substituted into Eq. (4). The result of collation is shown in Eq. (9).

Equation (9) is the formula for calculating the water flux. The parameters corresponding to different production conditions can be substituted into it to calculate the water flux.

Calculating HTC of high pressure water descaling

Selection of calculating method for HTC

The HTC can be determined through a variety of methodologies, contingent upon the specific working conditions. Sablani et al.23 utilized artificial neural networks to estimate HTC in cubic and semi-infinite geometries. In contrast, Onyango et al.24 addressed one-dimensional transient heat transfer problems employing boundary element methods. Additionally, Manickaraj et al.25 assessed time-dependent HTC through network simulation techniques, while Kim et al.26 characterized the HTC of carbon steel surfaces using two-dimensional finite element analysis.

Sugianto, Malinowski, and Caron27,28,29 employed sophisticated inverse heat transfer techniques to reconstruct HTC, whereas Lim30 utilized CFD to forecast surface HTC distributions in turbulent flow scenarios.

Conventional methods for determining HTC necessitated iterative calculations utilizing inverse heat transfer techniques that were predicated on temperature gradients within the plate. This methodology, however, depended on labor-intensive experimental procedures that involved the installation of numerous thermocouples and extensive data analysis.

In order to address the identified limitations, this research utilizes the CFD methodology to compute the HTC pertinent to high-pressure water descaling processes. Numerical simulations were performed to analyze the multiphase flow dynamics involved in high-pressure water descaling, thereby enabling the assessment of the transient temperature distribution within the steel billet. By incorporating the CFD solution approach, the interfacial HTC at the interface between the water and the steel billet can be directly ascertained through conjugate heat transfer analysis, thereby obviating the necessity for temperature measurements via thermocouples.

Calculation of HTC based on water flux

The HTC for high-pressure water descaling was established through CFD analysis, which took into account the coupled characteristics of flow and thermal fields. The governing equations, which include the conservation of mass, momentum, and energy, were solved using finite volume discretization techniques to simulate conjugate heat transfer mechanisms. This approach facilitated an accurate characterization of the thermohydraulic interactions occurring at the interface between the water and the billet. The foundational equations are presented in Eqs. (10), (11), and (12), respectively.

where u, v represent the component of velocity in the x, y direction (m/s). t is time (s). ρ is fluid density (kg/m3).

where \(\tau_{xx} ,\tau_{yx} ,\tau_{xy} ,\tau_{yy}\) represent the components of internal stress in fluid viscosity (Pa). \(f_{x} ,f_{y}\) represent the mass force components of a unit mass fluid in three directions (Pa). p is the pressure of fluid on microelements (Pa).

where \(c_{p}\) represents specific heat capacity (J/kg K). T is temperature (K). \(S_{T}\) is viscous dissipation term (W/m2).

The models derived from Eqs. (10), (11), and (12) are characterized as transient and are required to accurately depict the dynamic evolution of temperature distributions within the steel billet subjected to high-pressure water impingement. The rapid fluctuations in surface temperature induced by water cooling necessitate the incorporation of time-dependent variables to effectively represent transient thermal conduction. This methodology facilitates the capture of temporal variations in the temperature field, thereby necessitating transient formulations to adequately address the coupled thermomechanical interactions between internal heat conduction and external cooling processes.

At the fluid layer close to the wall, according to Fourier’s law, Eq. (13) can be obtained.

where \(\left. {\frac{\partial t}{{\partial y}}} \right|_{y = 0}\) represents fluid temperature change rate in the normal direction near the wall. \(\lambda\) is thermal conductivity of fluid (W/m K). q is heat flux (W/m2).

The Newton cooling formula is shown in Eq. (14).

where \(\Delta T\) represents temperature difference between object and cooling medium (K).

According to Eqs. (13), (14) and (15) can be derived.

Equation (15) relates the convective heat transfer coefficient to the temperature field of the fluid, making it applicable to both analytical and numerical methods.

The computational approach was based on two primary assumptions. Firstly, it was assumed that there was an exclusive interaction between the high-pressure water stream and the surface of the billet. Secondly, it was posited that forced convective mechanisms were the predominant mode of heat transfer during the cooling process. The convective heat transfer resulting from hydraulic impingement exhibits a thermal efficiency that surpasses 85% when compared to radiative mechanisms. Although radiative transfer begins to occur at billet temperatures exceeding 800 °C, its contribution to the overall heat flux is limited to less than 5% due to cooling durations of less than 15 s. As a result, radiative effects were excluded from the thermal formulation, given their quantified insignificance in relation to convective processes.

The thermal exchange process during high-pressure water descaling is primarily influenced by forced convection, which is initiated by the direct impact of high-velocity water jets on the surface of the billet. This interaction disrupts the thermal boundary layers, facilitating rapid heat removal through advective transport and resulting in heat transfer rates that are 2–3 orders of magnitude greater than those observed during nucleate boiling under similar thermal conditions. In contrast to boiling, which relies on the cycles of vapor bubble nucleation and detachment for energy dissipation, its efficiency is limited by the kinetics of phase change and the Leidenfrost effect at elevated temperatures. The application of high-pressure water jets, characterized by elevated Reynolds and Weber numbers, effectively mitigates the formation of vapor films, thereby circumventing the thermal resistance associated with boiling. Consequently, heat transfer mediated by boiling is excluded from the thermal model, as experimental evidence indicates that its contribution to the total heat flux remains below 3% under industrial conditions.

The high-pressure water jet was characterized as a viscous, incompressible Newtonian fluid exhibiting thermophysical properties that are independent of temperature. To effectively manage the complex dynamics associated with gas–liquid turbulent multiphase flow, a segregated dual-precision solver was utilized to accurately resolve the momentum transport coupled between phases. The Navier–Stokes equations were numerically solved through finite volume discretization, employing second-order upwind spatial differencing alongside implicit temporal schemes.

The impact pressure exerted by high-pressure water on the surfaces of billets exhibits a linear relationship with water flux, which is defined as the volumetric flow rate per nozzle divided by its effective impact area. This hydraulic parameter is thermodynamically linked to heat transfer; an increase in water flux results in a higher surface HTC, thereby enhancing thermal dissipation and promoting surface cooling. The magnitude of water flux is influenced by five operational parameters: the volumetric flow rate of the nozzle, the injection angle, the inclination angle, the scattering angle, and the height of the jet. The latter four geometric parameters determine the effective impact area of the water jet, thereby modulating the intensity of heat transfer through spatial energy distribution. A systematic optimization of these variables allows for precise control over thermal gradients and descaling efficiency. The relationship among these four factors and the configuration of high-pressure water descaling nozzles is depicted in Fig. 2.

The hydrodynamic efficiency of high-pressure water descaling systems is significantly influenced by the geometry of the nozzle, which determines the velocity profiles of the jets and the patterns of the spray. These characteristics have a direct impact on the effectiveness of the descaling process by regulating the distribution of impact pressure and the uniformity of surface coverage. In this investigation, a production-scale descaling nozzle with an outlet diameter of 3 mm, utilized in a plate mill, was examined. The material of the steel billet under consideration was Q235B, and the cooling water was maintained at a temperature of 30 °C.

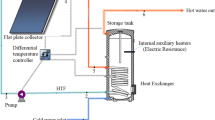

This research examines the characteristics of the external flow field and the velocity distributions that occur downstream of the outlet of a high-pressure descaling nozzle, with the computational domain limited to the free jet region. The high-pressure water supply system, which consists of a centralized pumping station and a manifold distribution piping network, facilitates the delivery of process water to the nozzle assembly. Upon passing through the conical orifice, the water undergoes rapid expansion, resulting in high-velocity impingement on the surface of the steel plate, which is essential for the removal of scale. A simplified two-dimensional model of the flow field is illustrated in Fig. 4.

Due to the limitations of ANSYS Fluent in handling complex geometry meshing, a specialized workflow utilizing Gambit was developed for the purposes of geometry reconstruction and mesh generation. Gambit, recognized as a reliable CFD pre-processor, enables precise discretization of intricate flow domains by employing sophisticated meshing algorithms, which are particularly effective for high-velocity fluid systems characterized by complex boundary geometries.

The meshing strategy utilized for high-pressure water descaling simulations incorporates triangular element discretization in the nozzle exit region to enhance boundary layer resolution, ensuring values are maintained at or below 1.5. Additionally, the strategy optimizes grid orthogonality by rigorously controlling skewness to remain below 0.4. This configuration establishes a dual optimization framework that effectively balances numerical stability, constrained by Courant number limits of 0.25 or lower, with computational efficiency for transient flow analysis. The computational domain, which extends from the nozzle exit to the billet surface, employs a systematically implemented quadrilateral-structured grid topology, characterized by an aspect ratio of approximately 2.3. This design facilitates accurate gradient resolution along the primary flow direction, keeping velocity gradient calculation errors below 3.2%. The segmented grid is illustrated in Fig. 5.

Prior to the computation of the high-pressure water descaling flow field and temperature field using Fluent software, it is essential to import the geometric model created in Gambit into Fluent. Subsequently, the grid must be verified, and the appropriate size units should be established, followed by the selection of the solution method. Given the nature of high-pressure water descaling, which involves two phases—water and air—a multiphase flow model must be employed.

The computational domain utilized for simulations of high-pressure water descaling encompasses both air and water phases. The steel plate is characterized as a wall boundary condition, functioning as a stationary, impermeable barrier that delineates the movements of the liquid and gas phases. This necessitates the implementation of a multiphase flow model to accurately capture the interactions between the phases at the fluid–solid interface. The boundary conditions were established in accordance with operational parameters, with velocity inlet conditions applied at the nozzle entry and pressure outlet conditions enforced at the periphery of the domain.

The water-steel interface was designated with a conjugate heat transfer boundary condition to facilitate a coupled thermal-fluid analysis. Near-wall turbulence was represented using standard wall functions, while other solid boundaries were treated as adiabatic to minimize computational expenses.

The influence of iron oxide scale on HTC was incorporated into the simulation analysis. When steel slabs are subjected to temperatures exceeding 1000 °C, the oxide scale that develops on their surface typically comprises multiple layers. The outermost layer is predominantly composed of Fe2O3, while the intermediate layers are primarily Fe3O4, and the innermost layers consist of FeO31. The volume percentages of these oxides are approximately 95% for Fe2O3, 4% for Fe3O4, and 1% for FeO. At heating temperatures of 1000 °C, 1100 °C, and 1200 °C, the thickness of the oxide scale measures approximately 880 μm, 1090 μm, and 1370 μm, respectively.

The thermal conductivity of the oxide scale present on the surface of steel billets is influenced by its composition and structural characteristics. Specifically, the thermal conductivity values for various iron oxides are as follows: Fe2O3 exhibits a thermal conductivity of approximately 2–3 W/(m K), Fe3O4 ranges from about 5–6 W/(m K), and FeO demonstrates a thermal conductivity of approximately 6–8 W/(m K). Additionally, the density of the iron oxide scale is contingent upon its precise chemical composition, with Fe2O3, Fe3O4, and FeO having densities of approximately 5240 kg/m3, 5180 kg/m3, and 5700 kg/m3, respectively. Furthermore, the specific heat capacity of the oxide scale is reported to fall within the range of 0.5 to 0.8 J/g K.

This article is based on empirical conditions. In the simulation of high-pressure water jetting, the standard k − ε model and wall function methodology were utilized to enhance the accuracy of the simulation. The steel grade employed for this simulation is Q235B, with its physical parameters at 1200 °C integrated into the Fluent custom material library. When addressing unsteady-state problems, it is crucial to establish the initial temperature values for each phase before initiating the simulation. In this investigation, the initial temperature of the steel plate is set at 1200 °C, while the water temperature is established at 30 °C. Following this, the initial volume fractions of the water and gas phases within the computational domain are defined.

The high-velocity dynamics of the water jet during descaling processes required enhanced temporal resolution, with the simulation time step optimized to 1 × 10–5 s to ensure numerical stability and solution precision. Each computational iteration involved 200 convergence cycles, while the total simulation duration was set to 1.6 × 10–2 s to accurately capture transient flow phenomena. Computational efficiency was improved through strategic model simplification, reducing the billet thickness to 10 mm without sacrificing solution validity. This dimensional optimization was validated via comparative analysis of simulation results, confirming the suitability of the selected geometric parameters for thermal-fluid interaction analysis.

A comprehensive parametric analysis was conducted to examine the interdependent effects of water flux and surface temperature on HTC evolution during high-pressure water descaling. Multiphysics simulations were employed to characterize the turbulent flow dynamics, velocity distributions, and thermal boundary layer development across various operational parameters. The study encompassed billet surface temperatures of 1000 °C, 1100 °C, and 1200 °C, with water flux systematically varied from 50 to 300 m3/(min m2) to simulate industrial descaling conditions. The resulting correlations between water flux, surface temperature, and HTC were quantitatively established, as depicted in Fig. 6, offering critical insights into the thermal-fluid interaction mechanisms involved in scale removal processes.

The data illustrated in Fig. 6 demonstrates a positive correlation between volumetric water flux and HTC, with a notable transition point at 120 m3/(min m2). Below this critical flow rate, the shift from laminar to turbulent flow markedly improves convective heat transfer efficiency by promoting enhanced fluid mixing and disrupting the thermal boundary layer, leading to a rapid increase in HTC.

Beyond the critical water flux threshold of 120 m3/(min m2) the HTC enhancement demonstrates asymptotic decline, indicating interfacial thermal saturation. This threshold represents the maximum sustainable thermal transport capacity, where further increases in flux result in diminishing improvements in heat transfer efficiency. Additionally, excessive water flux can lead to the formation of surface films, increasing thermal resistance and hindering convective heat transfer.

Under steady-state water flow conditions, an inverse correlation was identified between billet surface temperature and heat transfer coefficient, indicating the presence of temperature-dependent thermal resistance phenomena at higher temperatures.

Establishment of mathematical model of HTC

Establishment of mathematical model

Considering the correlation between the HTC in high-pressure water descaling and parameters such as water flux and billet surface temperature, a piecewise regression approach was employed to enhance the accuracy of the HTC predictive model. The resulting HTC model is presented in Eq. (16).

where variables a, b, c, d, and m denote the coefficients, and h signifies the HTC (W/m2 K) for high-pressure water descaling, T representing the billet surface temperature (°C).

Regression of Coefficients.

Since Eq. (16) is piecewise function, it is necessary to separately regress and sort out the coefficients for each piecewise function.

When ω is less than or equal to 120 m3/(min m2), h is expressed as Eq. (17).

This is a binary linear equation. Using the stepwise regression analysis method, the regression coefficients are sorted out as follows:

By substituting the coefficients of the above regression into Eq. (17), The result obtained is shown in Eq. (18).

The HTC obtained from Eq. (18) was systematically validated against CFD simulations, as depicted in Fig. 7. The comparative analysis indicated excellent concordance between the experimental data and numerical predictions, with the CFD results closely matching empirical measurements. The maximum deviation in HTC values remained below 4%, and the minimum discrepancies were under 1%, thereby confirming the reliability of the mathematical model parameters and the computational methodology.

When ω > 120 m3/(min m2), h is expressed as Eq. (19).

Equation (19) depicts a bivariate nonlinear regression model, distinguished by three unique parameters that necessitate advanced nonlinear optimization algorithms for accurate estimation32. In this study, a custom MATLAB function was employed to execute the nonlinear regression procedure, resulting in the determination of the coefficients as follows:

The above coefficients were substituted into Eq. (19), and the equation was rearranged as shown in Eq. (20).

The HTC for high-pressure water descaling, determined via Eq. (20), was compared with the HTC obtained through CFD simulations, as illustrated in Fig. 8. The comparison indicates that the results from both methodologies are closely aligned, with a high degree of correlation. The maximum relative deviation between the two datasets was under 2%, demonstrating strong concordance and confirming the precision of the regression model coefficients.

Equations (18) and (20) were summed up, resulting in Eq. (21) as follows:

Equation (21) delineates a mathematical model for high-pressure water descaling HTC, predicated on water flux. When applying Eq. (21) to determine the HTC of high-pressure water, the billet’s surface temperature during the descaling process can be ascertained through empirical measurement or computational analysis. The water flux is derived from the flow rate of the high-pressure water nozzle, considering the nozzle’s structural parameters and installation dimensions.

Discussion and experimental verification

Comparison of calculation results for HTC

Following an extensive review of existing scholarly publications, we identified discrepancies in the thermophysical calculation models for the HTC in high-pressure water jet descaling processes. To facilitate cross-study comparability, we applied dimensional analysis techniques to normalize and recalibrate heterogeneous datasets. By translating water pressure metrics into equivalent volumetric flow rates grounded in fundamental fluid mechanics principles, we unified operational parameters, thereby creating a standardized benchmark for performance assessment.

According to the principles of hydrodynamics, the relationship between outlet flow velocity and water pressure of nozzle is shown in Eq. (22).

where u represents velocity of water flow (m/s). p is the pressure of high pressure water (Pa). \(C_{d}\) is discharge coefficient, the general value is 0.75–0.85. ρ is density of cooling fluids (kg/m3).

According to Eq. (22), the outlet velocity of the nozzle was calculated. By substituting H, Q, α, β, and θ into Eq. (9), the water flux was calculated. The results of Eqs. (1), (2), (3), and (21) are presented in Fig. 9.

Analysis of Fig. 9 demonstrates that Eq. (1) provides the most conservative HTC estimations, with computed values ranging from 16,000 to 68,000 W/(m2 K). This interval signifies the minimum HTC bounds observed among the evaluated methodologies, indicating potential constraints stemming from the foundational assumptions embedded within the mathematical model.

While Eq. (1) delineates a functional correlation among HTC, water flux, and steel plate temperature, its predictive precision is constrained by an inadequately weighted water flux exponent, resulting in consistent underestimation of HTC values. To improve model accuracy, the water flux exponent coefficient necessitates an upward recalibration to more accurately reflect empirical data.

In comparison, Eqs. (2) and (3) yield markedly higher HTC estimations, with Eq. (2) producing values between 120,000 and 360,000 W/(m2 K). However, the excessively large coefficient associated with the water flux term in Eq. 2 introduces substantial predictive bias, requiring a reduction in the coefficient to enhance computational precision and alignment with experimental data.

Equation (3) produces HTC estimations ranging from 170,000 to 650,000 W/(m2 K), indicating a correlation between HTC and impact pressure. However, the excessively high coefficient linked to impact pressure results in systematic overprediction, requiring a downward calibration of the coefficient to improve agreement with empirical data.

The predictive validity of Eqs. (1)–(3) is inherently limited by three fundamental constraints: firstly, the assumption of overly simplified linear correlations between HTC and operational parameters; secondly, the insufficient representation of turbulent flow saturation phenomena within the governing equations; and thirdly, the neglect of asymptotic HTC behavior under high flux-pressure conditions in the mathematical model.

The models fail to accurately capture the transition to turbulent saturation, where HTC augmentation exhibits a progressive decline rather than a linear increase. This deficiency leads to systematic errors in HTC forecasting across various flow regimes, resulting in either overpredictions or underpredictions of the actual convective heat transfer behavior.

Equation (21) yields HTC predictions that lie within the bounds of estimates obtained from alternative formulations, producing numerical values ranging from 20,000 to 100,000 W/(m2 K). However, the predictive validity of these mathematical models cannot be conclusively established solely through computational simulations. Empirical validation via high-precision temperature measurements is essential to verify model accuracy and identify the most representative formulation for practical application in industrial heat transfer processes.

Finite element analysis of temperature field

The calculated HTC values were utilized in thermal field analysis via finite element modeling.33 The numerical study was performed on a production-scale billet sourced from a heavy plate rolling mill. The billet was fabricated from Q235B structural steel, with dimensions of 230 mm in thickness, 1650 mm in width, and 3700 mm in length.

The steel billet was subjected to high-temperature in an industrial furnace. Its thermal profile is assumed to be homogeneous, with an exit temperature of 1160 °C.

Based on on-site measurements, the distance from the heating furnace outlet to the descaling equipment was 5 m, while the distance to the rolling mill was 50 m. The roller conveyance velocity was 1 m per second, resulting in transit times of 5 s to the descaling station and 50 s to the rolling mill.

The spacing between the high-pressure water jet nozzle and the billet surface was 150 mm, with a high-pressure water descaling pressure of 20 MPa. Using Eq. (22), the nozzle’s exit velocity was determined to be 150 m/s at the specified descaling pressure. The nozzle orifice diameter was 3 mm, enabling the calculation of the flow rate per nozzle. Additionally, the spray angle α of the field descaling nozzle was 30 degrees, the inclination angle β was 15 degrees, and the scattering angle θ was 2 degrees. Substituting H, Q, α, β, and θ into Eq. (9) yielded a water flux of 137 m3/(min m2). Subsequently, the billet temperature and the calculated water flux were input into Eq. (21) to determine the HTC, which was calculated to be 48,911 W/(m2 K).

Thermal conduction phenomena across the billet cross-section exhibited bilateral symmetry, facilitating finite element model reduction via quarter-section analysis. The optimized computational domain, measuring 3700 mm in length, 825 mm in width, and 115 mm in height, was strategically chosen to balance simulation efficiency with geometric accuracy. The spatial configuration and boundary conditions of the quarter-model are depicted in Fig. 10, ensuring accurate representation of the full-scale thermal response.

The thermal symmetry of continuous casting billets was utilized to enhance computational efficiency, employing a quarter-section model in finite element analysis. Hexahedral elements, standard in thermal–mechanical simulations, were used for mesh discretization. Element dimensions were kept nominally isotropic during meshing to ensure numerical stability and convergence. A mesh sensitivity analysis indicated that parameter variations remained below 5% across different mesh densities, confirming the adequacy and controlled influence of mesh refinement. The validated mesh configuration is illustrated in Fig. 11.

To enhance the precision of the thermal analysis, both radiative and convective heat transfer mechanisms were incorporated into the temperature field calculation of the billet conveyed via the roller conveyor. The radiative and convective heat transfer coefficients were transformed into their respective equivalent heat transfer coefficients. These formulations are detailed in Eqs. (23), (24), and (25).

where \(h_{r}\) represents radiation heat transfer coefficient (W/m2 K). \(\varepsilon\) is the blackness of billet to the environment. \(T\) is billet temperature (℃). \(\sigma\) is Stephen Boltzmann constant. \(h_{c}\) is natural convection heat transfer coefficient. \(a\) is model coefficients, generally ranging from 1.1 to 2.2. \(h_{rc}\) is comprehensive heat transfer coefficient of radiation and convection.

The high-pressure water descaling process was constrained by phase-specific temporal boundary conditions, as the water impingement only occurs during passage through the descaling chamber. The boundary condition enforcement protocol is organized as follows:

First, air cooling period: from 0 to 5 s (initial thermal equilibration).

Second, descaling period: from 5 to 8.7 s (intensive water quenching).

Third, post-descaling air cooling period: from 8.7 to 53.7 s (secondary thermal recovery).

The continuous casting billet geometry, with a total length of 3700 mm, is segmented into 20 elements (185 mm/element) using a validated industrial discretization method.

To enable a comparative thermal evolution analysis across various billet regions, five nodes were strategically positioned to monitor temperature variations in the core region, surface zone, side area, edge section, and corner location. These nodal positions were selected to capture representative thermal gradients and transient heat transfer characteristics throughout the billet geometry, facilitating a comprehensive evaluation of spatial temperature distribution patterns.

The designated monitoring nodes were strategically deployed to acquire essential thermal signatures: Node 1:Core region temperature, Node 2: Surface zone temperature, Node 3: Side surface temperature, Node 4: Edge section temperature, Node 5: Corner location temperature.

This nodal configuration facilitates the systematic monitoring of spatial temperature gradients across geometrically disparate zones of the billet, yielding comprehensive insights into heat transfer dynamics during the descaling procedure.

Temporal temperature profiles for each monitoring node are illustrated in Fig. 12, demonstrating differential cooling behaviors across billet zones. The core exhibited the slowest temperature decrease, succeeded by the side surface, upper surface, edge, and corner regions. Enhanced cooling was evident in surface-exposed areas (upper surface, edge, corner) due to direct high-pressure water impingement.

Between 5 and 8.7 s, rapid thermal dissipation caused corner temperatures to decrease to 860 °C. After 8.7 s, thermal conduction from the billet interior initiated surface rewarming, with edge and corner temperatures reaching their maxima at approximately 15 s, preceding ambient air cooling.

Comparison of simulated temperature with measured temperature

Field temperature assessments were performed at a heavy plate manufacturing facility utilizing a Raynger 3i handheld infrared thermometer. The instrument specifications included a measurement range of -30 °C to 3000 °C, a targeting system with single/double/cross laser and telescopic sight, and a three-tier automatic accuracy grading based on target conditions.

The instrument was selected for its long-distance measurement capabilities and operational flexibility in industrial settings. Temperature data were acquired from four Q235B-grade billets, with standardized dimensions of 230 mm (thickness) × 1650 mm (width) × 3700 mm (length), to ensure measurement reliability and statistical significance.

Surface emissivity variations, due to differential surface characteristics among isothermal objects, significantly influence infrared radiation emission levels, thereby affecting the measurement accuracy of infrared detection systems. This necessitates precise calibration of emissivity parameters to ensure reliable temperature quantification in infrared thermographic applications.

The emissivity of a steel plate is typically determined empirically. Several factors influence the emissivity of steel plates, including surface temperature, surface morphology, and steel grade. The emissivity value for air-cooled steel plates should be adjusted based on the degree of surface oxidation. Experience suggests that the emissivity of air-cooled steel plates ranges from 0.55 to 0.65 for smooth surfaces and reaches 0.8 when the surface is heavily oxidized. Following high-pressure water descaling, the steel plate’s surface is smooth, and an emissivity of 0.6 is selected for temperature measurement. Before the rolling mill, a small amount of secondary iron oxide scale forms on the continuous casting billet, and an emissivity of 0.7 is used for temperature measurement.

The distance from which measurements are taken significantly impacts the radiant energy detected by infrared thermometers, thus requiring optimal positioning to ensure data accuracy. Although close proximity to the target is ideal, operational safety concerns and the instrument’s long-range measurement capabilities necessitated a standardized measurement distance of 1 m.

To capture spatial temperature variations across continuous casting billets and enhance measurement representativeness, three strategic measurement points were established on each billet: the head section, mid-length position, and tail region. This tri-point sampling strategy allows for a comprehensive characterization of longitudinal temperature gradients while maintaining operational feasibility in industrial settings. Surface temperatures of four billets of identical dimensions were measured.

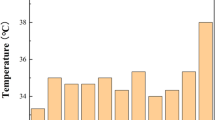

The surface temperatures of the four steel billets were recorded as 1200, 1160, 1100, and 1050 ℃, respectively. The comparison of the measured temperatures with those simulated using the finite element method is presented in Fig. 13.

Comparative analysis of the temperature distribution profiles in Fig. 13 indicates that Eq. (21) exhibits superior predictive accuracy, with simulated results closely correlating with experimental measurements across four distinct heating temperatures. While Eq. (1) produced systematically higher temperature estimates, both Eqs. (2) and (3) yielded values lower than the actual measurements.

The maximum deviation between Eq. (21) simulations and measured data was limited to 28 °C (relative error 2.7%), with minimal discrepancies as low as 1 °C, thus validating the enhanced predictive capability of this formulation for thermal profile estimation.

The peak temperature discrepancy was observed at post-descaling measurement points, potentially attributable to measurement artifacts induced by residual water film formation on the billet surface. This phenomenon underscores the importance of surface condition control during temperature measurement to ensure data reliability in industrial thermal monitoring applications.

The relative error analysis between the simulations derived from Eq. (21) and experimental measurements revealed a maximum deviation of 2.7% and a minimum deviation of 0.1%. This error range, which falls within the 3% threshold established for industrial thermal process applications, indicates adequate accuracy for operational parameter optimization within descaling systems. Therefore, the observed discrepancies are deemed negligible in the context of descaling parameter determination and process control implementation.

Figure 14 presents the comparison of the 95% confidence interval of the finite element method simulation temperature with the actual measured temperature across four distinct temperature points.

Statistical analysis of Fig. 14 indicates that experimental measurements are consistently within the 95% confidence interval of simulation results, thus validating the model’s fidelity and predictive power. This confidence interval, representing the uncertainty range of computational predictions, indicates a 95% probability that true experimental values would fall within the specified bounds in repeated trials, thereby substantiating the formulation’s robustness for industrial thermal process modeling.

Comparative analysis confirmed strong agreement between finite element simulations using Eq. (21) and experimental temperature measurements, with computed temperature fields demonstrating close correspondence with actual thermal distributions. This validation substantiates the accuracy of the HTC model for high-pressure water descaling and confirms the reliability of Eq. (21) for HTC quantification.

The demonstrated predictive capability establishes Eq. (21) as a valid foundation for finite element thermal analysis, providing reliable boundary conditions for temperature field computation in industrial descaling applications.

Discussion and analysis

In summary, Eq. (21) is formulated considering the influence of water flux variations and steel plate surface temperature on the heat transfer coefficient (HTC). While Eqs. (1) and (2) also account for water flux and steel plate surface temperature, they do not incorporate the impact of water flux inflection points on HTC. Equation 3 addresses the effect of high-pressure water impingement pressure on HTC but neglects the influence of steel plate surface temperature. Analysis and comparison in Fig. 9 reveal that Eqs. (1), (2), and (3), which utilize a single functional relationship to describe the correlation between high-pressure water and HTC, yield HTC values that are either underestimated or overestimated.

During high-pressure water descaling, the HTC demonstrates a nonlinear behavior with inflection points, contingent on water flux and steel plate surface temperature. This constitutes the theoretical foundation and primary rationale for employing piecewise functions in its representation.

In regions characterized by low water flux, an increase in water flux leads to enhanced water impingement on the steel plate surface, thereby augmenting the effective heat transfer area. Consequently, heat transfer is predominantly governed by single-phase forced convection and nucleate boiling. The augmentation of water flux significantly promotes these mechanisms, resulting in a rapid increase in HTC with rising water flux. The functional relationship in this phase approximates a power-law relationship.

In high-water-flux regimes, the thermal–hydraulic mechanisms governing high-pressure water heat exchange undergo significant alterations. The heat flux emanating from the steel plate surface is rapidly dissipated by the high-velocity water flow, approaching the physical limit of heat removal per unit area per unit time. Excessive water flux can induce the formation of a thicker water film layer or water accumulation within the impingement zone. Despite the increased water volume, this water film introduces thermal resistance. Heat transfer must then traverse this relatively stagnant or slowly moving water film to be effectively removed by the core water flow. Furthermore, the post-jet impingement flow transitions from a turbulent state to a condition approaching laminar flow, thereby diminishing local heat transfer efficiency. Extremely high water flow velocities and subcooling conditions suppress efficient nucleate boiling, shifting heat transfer dominance towards single-phase convection through the water film layer. Consequently, further increases in water flux exhibit limited efficacy in overcoming the thermal resistance of the water film, resulting in a diminished rate of increase in the HTC.

Piecewise functions offer a more precise representation of this inherent physical boundary. The HTC curve, as a function of water flux, exhibits an inflection point, with distinct slope variations on either side. A single function struggles to accurately capture the significant slope disparities across the two curve segments over the entire water flux range. Piecewise functions facilitate the application of the most appropriate functional form within each segment, thereby enabling accurate characterization.

To bolster the validation of experimental comparisons and simulation calculations, and to enhance the statistical analysis and validation of predictive models, a residual and correlation analysis was performed between the simulation results and experimental data, as presented in Fig. 15 and Table 2.

Referring to Fig. 15, the residual values across the four process conditions exhibit fluctuations within a range of 0.06 to 4.22, all of which are below 4.3. A comparative analysis of these residual values reveals a strong correlation between the values computed using the high-pressure water HTC model developed in this study and the corresponding experimental measurements.

The correlation coefficients between the simulation and experimental data, as presented in Table 2, span from 0.984 to 0.993 across the four process conditions. These coefficients, all exceeding 0.95, underscore the strong agreement between numerical simulations and empirical data, thereby supporting the theoretical foundation for the industrial application of the mathematical model.

Accurate prediction of the HTC is critical in the design of descaling systems and process control, as it directly influences descaling efficiency, steel plate temperature reduction, and final rolling temperature control. Employing a single function, particularly under high water flux conditions, can lead to a significant overestimation of the HTC, as evidenced by the disparities in the results of Eqs. (2) and (3). This can result in an underestimation of the required descaling time or intensity, inaccurate predictions of the steel plate’s temperature drop, which affects rolling process parameters, and inefficient utilization of water resources and pumping energy. Piecewise functions offer a more precise representation of the actual heat transfer behavior near saturation conditions, mitigating these issues and enhancing the predictive accuracy of the model, thus improving the efficacy of process optimization.

Conclusions

A comprehensive investigation was conducted to characterize the HTC during high-pressure water descaling of continuous casting billets. A mathematical model was formulated to correlate HTC with water flux and billet surface temperature, employing systematic parameter analysis followed by validation.

This model was then utilized to compute descaling HTC under operational conditions, with the resulting values integrated into finite element simulations for temperature field prediction. Validation was achieved through a comparative analysis of simulated and experimental temperature profiles, demonstrating a strong correlation that confirms the model’s predictive accuracy and industrial applicability for descaling process optimization. The model’s reliability is substantiated by the congruence between calculated and experimental data, thereby validating the theoretical foundation of the proposed high-pressure water descaling convective HTC model.

Data availability

The datasets generated during the current study are not publicly available due to the deal with manufacture but are available from the corresponding author on reasonable request.

Abbreviations

- HTC:

-

Heat transfer coefficient

- CFD:

-

Computational fluid dynamics

- h :

-

HTC of high-pressure water descaling (W/m2 K)

- T :

-

Billet temperature (℃)

- ω :

-

Water flux on the surface of billet (L/(min m2))

- P :

-

Impact pressure of high pressure water (bar)

- Q :

-

Flow of water from a single nozzle (m3/min)

- F :

-

Coverage area of high pressure water sprayed onto billet (m2)

- L :

-

Length size of the high pressure water injecting into the billet area(m)

- B :

-

Dimension of the width direction of the billet area(m)

- H :

-

Target distance of high pressure water jet (m)

- α :

-

Injection angle of high pressure water nozzle (°)

- β :

-

Inclination angle of high pressure water nozzle installation (°)

- θ :

-

Scattering angle of high pressure water nozzle (°)

- a :

-

b,c,d,m, Coefficient

- u,v :

-

Velocity of water flow in x, y direction (m/s)

- p :

-

Pressure of high pressure water(Pa).

- \(C_{d}\) :

-

Discharge coefficient, the general value is 0.75–0.85

- ρ :

-

Density of cooling fluids (kg/m3)

- \(h_{r}\) :

-

Radiation heat transfer coefficient (W/m2 K)

- \(\varepsilon\) :

-

The blackness of billet to the environment

- \(\sigma\) :

-

Stephen Boltzmann constant

- \(h_{c}\) :

-

Natural convection heat transfer coefficient (W/m2 K)

- a :

-

Model coefficients, generally ranging from 1.1 to 2.2

- \(h_{rc}\) :

-

Comprehensive HTC of radiation and convection (W/m2 K)

- \(\tau_{xx} ,\tau_{yx} ,\tau_{xy} ,\tau_{yy}\) :

-

Components of internal stress in fluid viscosity (Pa)

- \(f_{x} ,f_{y}\) :

-

The mass force components of a unit mass fluid in three directions (Pa)

- \(c_{p}\) :

-

Specific heat capacity (J/kg K)

- \(S_{T}\) :

-

Viscous dissipation term (W/m2)

- \(\lambda\) :

-

Thermal conductivity of fluid (W/m K).

- q :

-

Heat flux (W/m2).

- \(\Delta T\) :

-

Temperature difference between object and cooling medium (K)

References

Kermanpur, A., Ebnonnasir, A., Yeganeh, A. R. K. & Izadi, J. Artificial neural network modeling of high pressure descaling operation in hot strip rolling of steels. ISIJ. Int. 48(7), 963–970. https://doi.org/10.2355/isijinternational.48.963 (2008).

Liu, J. et al. Surface layer characterization of 2205 duplex stainless steel subjected to abrasive water jet descaling. Mater. Today. Commun. 35, 105872. https://doi.org/10.1016/j.mtcomm.2023.105872 (2023).

Chen, Z.-J., Han, H.-Q., Ren, W. & Huang, G.-J. Heat transfer modeling of an annular on-line spray water cooling process for electric-resistance-welded steel pipe. PLoS ONE 10, 7 e0131574. https://doi.org/10.1371/journal.pone.0131574 (2015).

Jing, Y.-A., Yuan, Y.-M., Yan, X.-L., Zhang, L. & Sha, M.-H. Decarburization mechanism during hydrogen reduction descaling of hot-rolled strip steel. Int. J. Hydrogen. Energ. 42(15), 10611–10621. https://doi.org/10.1016/j.ijhydene.2017.01.230 (2017).

Kim, D. W. et al. Effects of finish rolling temperature and yield ratio on variations in yield strength after pipe-forming of API-X65 line-pipe steels. Sci. Rep. 10, 14742. https://doi.org/10.1038/s41598-020-71729-w (2020).

Gao, B. et al. Ultrastrong low-carbon nanosteel produced by heterostructure and interstitial mediated warm rolling. Sci. Adv. 39(6), 1–7. https://doi.org/10.1126/sciadv.aba8169 (2020).

Liu, H.-T. et al. The impact of hot rolling temperature after reheating in the new generation strip casting process on structure-property relationship in extra-low carbon steel. Steel. Res. Int. 87, 501–510. https://doi.org/10.1002/srin.201500128 (2016).

Ahmed, Y. A., Paul, R. & Chen, X.-G. Impact of hot rolling temperature on the mechanical properties and microstructural evolution of hot/cold-rolled AA5083 with Sc and Zr microalloying. Mat. Sci. Eng. A. 896, 146275. https://doi.org/10.1016/j.msea (2024).

Masashi, M. Heat transfer coefficients in the surface temperature range of 400 to 800℃ during water-spray cooling of hot steel product. Tetsu to Hagane 69(2), 268–274. https://doi.org/10.2355/tetsutohagane1955.69.2_268 (1983).

Ohsumi, K., Ohtsuka, T., Hirata, M. & Shioya, M. Dispersion control of steel plate temperature by particle model predictive control. Tetsu to Hagane 99(4), 275–282. https://doi.org/10.2355/tetsutohagane.99.275 (2013).

Wata, T., Oshimi, M. & Ueda, M. Temperature drop of steel by hydraulic descaling for a hot strip rolling mill. Tetsu to Hagane 77, 1458–1464. https://doi.org/10.2355/tetsutohagane1955.77.9_1458 (1991).

Sellars, C. M. Computer modeling of hot working processes. Mater. Sci. Tech-Lond. 1(4), 325–332. https://doi.org/10.1179/mst.1985.1.4.325 (1985).

Michal, P. et al. The effect of water temperature on cooling during high pressure water descaling. Therm. Sci. 22(6), 2965–2971. https://doi.org/10.2298/TSCI160209163P (2018).

Kotrbáček, P., Chabičovský, M., Kominek, J., Resl, O. & Bellerova, H. Influence of water temperature on spray cooling at high surface temperatures. Appl. Therm. Eng. 216, 119074. https://doi.org/10.1016/j.applthermaleng.2022.119074 (2022).

Li, X.-T., Du, F.-S. & Zhang, J.-M. Numerical simulation of temperature field in hot strip rough rolling with descaling by high pressure water. J. Iron. Steel. Res. Int. 17, 39–41. https://doi.org/10.13228/j.boyuan.issn1001-0963.2005.03.010 (2005).

Madakasira, P. P., Binod, B. B. & Ashok, K. L. Thermo-mechanical modeling of two phase rolling and microstructure evolution in the hot strip mill. Part I. Prediction of rolling loads and finish rolling temperature. J. Mater. Process. Tech. 170, 323–335. https://doi.org/10.1016/j.jmatprotec.2005.05.009 (2005).

Sasaki, K., Sugitani, Y. & Kawasaki, M. Heat transfer in spray cooling on hot surface. Tetsu to Hagane 65, 90–96. https://doi.org/10.2355/tetsutohagane1955.65.1_90 (1979).

Leocadio, H. & Passos, J. C. Experimental investigation of heat transfer characteristics during water jet impingement cooling of a high-temperature steel surface. Ironmak. Steelmak. 48(7), 819–832. https://doi.org/10.1080/03019233.2021.1872467 (2021).

Hatta, N., Kokado, J., Nishimura, H. & Nishimura, K. Analysis of slab temperature change and rolling mill line length in quasi continuous hot strip mill equipped with two roughing mills and six finishing mills. Tetsu to Hagane 21(4), 270–277. https://doi.org/10.2355/isijinternational1966.21.270 (1981).

Yanagi, K. Prediction of strip temperature for hot strip mills. Tetsu to Hagane 16(1), 11–19. https://doi.org/10.2355/isijinternational1966.16.11 (1976).

Ginzburg, V. B. High-Quality Steel Rolling: Theory and Practice 1st edn. (CRC Press, New York, 1993). https://doi.org/10.1201/9781466564640.

Choi, J. W. & Choi, J. W. Convective heat transfer coefficient for high pressure water jet. ISIJ Int. 42(3), 283–289. https://doi.org/10.2355/isijinternational.42.283 (2002).

Sablani, S. S., Kacimov, A., Perret, J., Mujumdar, A. S. & Campo, A. Non-iterative estimation of heat transfer coefficients using artificial neural network models. Int J Heat Mass Tran. 48(3–4), 665–679. https://doi.org/10.1016/j.ijheatmasstransfer.2004.09.005 (2005).

Onyango, T. T. M., Ingham, D. B. & Lesnic, D. Inverse reconstruction of boundary coefficients in one-dimensional transient heat conduction. Appl. Math. Comput. 207(2), 569–575. https://doi.org/10.1016/j.amc.2008.11.007 (2009).

Manickaraj, J. & Balasubramanian, N. Estimation of the heat transfer coefficient in a liquid-solid fluidized bed using an artificial neural network. Adv. Powder. Technol. 19(2), 119–130. https://doi.org/10.1163/156855208X293781 (2008).

Kim, H. K. & Oh, S. I. Evaluation of heat transfer coefficient during heat treatment by inverse analysis. J. Mater. Process. Tech. 112(2), 157–165. https://doi.org/10.1016/S0924-0136(00)00877-3 (2001).

Sugianto, A., Narazaki, M., Kogawara, M. & Shirayori, A. A comparative study on determination method of heat transfer coefficient using inverse heat transfer and iterative modification. J. Mater. Process. Tech. 209(10), 4627–4632. https://doi.org/10.1016/j.jmatprotec.2008.10.016 (2009).

Malinowski, Z., Telejko, T., Hadała, B., Cebo-Rudnicka, A. & Szajding, A. Dedicated three dimensional numerical models for the inverse determination of the heat flux and heat transfer coefficient distributions over the metal plate surface cooled by water. Int. J. Heat. Mass. Tran. 75, 347–361. https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.078 (2014).

Caron, E., Daun, K. J. & Wells, M. A. Experimental characterization of heat transfer coefficients during hot forming die quenching of boron steel. Metall. Trans. B 44, 332–343. https://doi.org/10.1007/s11663-012-9772-x (2013).

Lim, C. H., Airoldi, G., Dominy, R. G. & Mahkamov, K. Experimental validation of CFD modelling for heat transfer coefficient predictions in axial flux permanent magnet generators. Int. J. Therm. Sci. 50, 2451–2463. https://doi.org/10.1016/j.ijthermalsci.2011.07.002 (2011).

Osei, R., Lekakh, S. & O’Malley, R. Thermodynamic prediction and experimental verification of multiphase composition of scale formed on reheated alloy steels. Metall. Trans. B 52, 393–404. https://doi.org/10.1007/s11663-020-02023-3 (2021).

Sankar, I. B., Mallikarjuna, R. K. & Gopala, K. A. Prediction of heat transfer coefficient of steel bars subjected to tempcore process using nonlinear modeling. Int. J. Adv. Manuf. Technol. 47, 1159–1166. https://doi.org/10.1007/s00170-009-2240-3 (2010).

Wang, F., Ning, L., Zhu, Q., Lin, J. & Dean, T. A. An investigation of descaling spray on microstructural evolution in hot rolling. Int. J. Adv. Manuf. Technol. 38, 38–47. https://doi.org/10.1007/s00170-007-1085-x (2008).

Acknowledgements

This work was supported by Science and Technology Research Project of Jiangxi Provincial Department of Education (grant number GJJ211821).

Author information

Authors and Affiliations

Contributions

P. Gao wrote the main manuscript text, and Y. Zhuo handled data and regressed formulas. G. D. Sun conducted experiments and organized experimental data. Y. Zhuo and G. D. Sun provided revision suggestions. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Gao, P., Zhuo, Y. & Sun, G. Prediction model of heat transfer coefficient for high pressure water descaling based on water flux. Sci Rep 15, 32081 (2025). https://doi.org/10.1038/s41598-025-15694-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15694-2