Abstract

To simulate the overtemperature service environment of aeroengine turbine stator vanes, thin plate specimens of second-generation single crystal (SX) superalloy DD5 after complete heat treatment were exposed for 1 h, 10 h, 50 h, and 100 h without load at 1100 °C and 1150 °C and then subjected to air cooling treatment. The microstructure (γ′ precipitates, γ matrix, carbides, topological dense phases (TCP)) of the samples under different conditions was analysed by scanning electron microscopy (SEM), and the mechanical properties of the processed samples were studied. The results indicate that the microstructure DD5 alloy was generally stable after thermal exposure at 1100 °C and 1150 °C, and no TCP phase was found after 100 h of exposure. After exposure to 1100 °C, the average size of the γ′ precipitates reached 0.90 µm after 100 h, and some of of the the γ/γ′ interfaces became serrated. At 1150 °C, the average size of the γ′ precipitates reached 1.05 µm after 100 h, and the third γ′ precipitated substantially in the alloy. For both the 1100 °C and 1150 °C exposures, the 870 °C tensile strength increased after 1 h and subsequently decreased and was 0.5% and 5.0% greater after 100 h than that of the standard heat treatment (SHT) samples, respectively. After 100 h of exposure, the rupture life at 980 °C and 250 MPa was 5.9% lower and 1.0% greater than that at 1100 °C and 1150 °C, respectively; the rupture life at 1070 °C and 137 MPa was 1.6% greater and 20.1% less than that at 1100 °C and 1150 °C, respectively; and the rupture life at 1093 °C and 158 MPa was 42.7% and 51.2% less than that at 1100 °C and 1150 °C, respectively.

Similar content being viewed by others

Introduction

Nickel-based single crystal (SX) superalloys play an important role in high-performance aeroengines and gas turbines because they possess favourable high-temperature behavior, e.g., oxidation resistance, thermal corrosion resistance, fatigue strength, fracture toughness and plasticity. SX superalloy vanes have been widely used since they were introduced to industry in the 1980s and have demonstrated excellent performance and durability compared with polycrystalline vanes1,2,3,4,5. In the late 1980s, 2nd generation SX superalloys with 3%wt. of Rhenium (Re), e.g. CMSX-46 and PWA14847, were introduced to the industry, as they exhibited better mechanical properties and 30 °C higher temperature capability.

In recent years, the development of superalloys has focused on the manufacture of SX vanes, and the high manufacturing yield required to meet cost targets is achieved by intentionally adding a small amount of grain boundary (GB) strengthening elements to SX superalloys, which shows that the precise control of these elements can maintain optimal performance and castability of single crystal superalloys8,9,10,11,12,13,14,15.

DD5 is a second-generation nickel-abased SX superalloy that contains GB strengthening elements, i.e., carbon (C), boron (B) and hafnium (Hf). Qin’s research showed that low-angle boundary (LAB) below 14.8° in DD5 superalloy has little impact to 760 °C, 870 °C and 980 °C tensile strength16,17. The introduction of GB strengthening elements enlarges the allowance of LABs, thus promoting casting yields and reducing production costs18,19,20.

Studies showed that topological dense phase (TCP) that rich in Re, Tungsten (W) and molybdenum (Mo) can devastate alloy’s mechanical properties21,22,23,24,25. Although the composition of superalloys is strictly controlled, the intense segregation of Re, W and Mo still makes the precipitation of TCP in dendrite area inevitable during thermal exposure, thus investigating the microstructural and mechanical evolution behavior of SX superalloys is critical to safety concerns.

As a second generation SX superalloy, DD5 is applicable to airfoils with cooling passage for service up to 1100 °C. However the actual service condition of aeroengine is extremely complicated, and the airfoils would experience an overtemperature exposure at certain locations for a short time. For DD5 superalloy, Cui studied the microstructural evolution of SX at 980 °C for up to 5000 h and 870 °C/920 °C for up to 2000 h26,27,28, Gao studied the microstructural evolution at 1000 °C and 1100 °C for 1000 h29, and Lv studied the microstructural evolution under 1038 °C/172 MPa and 871 °C / 552 MPa stress rupture test30. But those studies were carried out with cylindrical bars, whose dimension is significantly different from the airfoil wall thickness of turbine vanes. While studies proved that primary dendrite arm spacing and average size of γ′ precipitates, along with stress rupture life decreases with reduced wall thickness in single crystal superalloys31,32, there is little information about the evolution behavior of DD5 superalloy under aeroengine service conditions. In this work, DD5 superalloy thin plates were thermal exposed at 1100 °C and 1150 °C, and their microstructural and mechanical evolution behaviours were studied.

Experimental

The DD5 master alloy was melted in a single furnace charge and cast into an ingot under vacuum. SX plates with a thickness of 1.5 mm were directionally solidified in an industrial Bridgman furnace along the [001] direction with a constant withdrawal rate of 3.5 mm/min. The primary crystallographic orientation along the axis of the plates in this work was no greater than 10° with respect to the [001] direction using the Laue back-scattered X-ray diffraction technique, and the plates were free of grain defects, e.g., equiaxed grains, freckles, slivers and high-angle boundaries. The chemical compositions of the SX plates are shown in Table 1.

The plates were subjected to standard heat treatment (SHT) in an inert environment as follows: (1300 °C, 2 h, AC)+(1120 °C, 4 h, AC)+(1080 °C, 4 h, AC)+(900 °C, 4 h, AC). Then, the plates were subjected to thermal exposure in a chamber electric furnace with temperatures of 1100 °C and 1150 °C and aging times of 1 h, 10 h, 50 h, and 100 h, respectively. The samples were sectioned from the plates by electrical discharge machining (EDM), and examined by scanning electron microscopy (SEM) after grinding, polishing and etching with an etchant (100 mL HF + 200 mL HNO3 + 100 mL C3H8O3), which dissolves the γ′ precipitates. The mechanical properties of the plates were studied using testing specimens machined from the plates, which had a 10 mm gauge length and a rectangular cross-section with 7 × 1 mm2 area within the gauge length. Tensile testing was conducted at 870 °C, and stress rupture testing was conducted under conditions of 980 °C/250 MPa, 1070 °C/137 MPa and 1093 °C/158 MPa, respectively. The results of each tensile and stress rupture test were the average of three samples.

Results and discussion

Microstructure of standard heat-treated samples

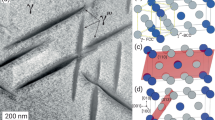

The SHT of the DD5 superalloy consists of a solutioning heat treatment and 3 stages of aging heat treatment. Solutioning heat treatment eliminates the eutectic material and homogenizes the segregated structure in the as-cast microstructure of a single crystal superalloy, and aging heat treatment results in a cubic morphology, an appropriate size and a high-volume fraction of γ′ precipitates, thus optimizing the overall properties of the alloy. Figure 1 shows typical microstructures of SHT DD5 samples. After SHT, the DD5 alloy exhibited a regular cubic γ′ phase with an average size of 0.39 µm, and a volume fraction of 54%. The high saturation in the process of air cooling in primary aging at 1120 °C and secondary aging at 1080 °C promoted the precipitation of the second γ′ phase. For the 870 °C − 4 h third stage aging, the aging time was insufficient to dissolve the second γ′ phase, resulting in massive fine second γ′ precipitates in the matrix channel, which is consistent with Yu’s research33. A small amount of rod-shaped carbides were found in the alloy, and no typical script-rod shaped carbides were found, which is quite different with Cui’s study27.

Microstructure of the thermally exposed samples

Figure 2 shows typical microstructures of thermally exposed samples, and quantitative statistical analysis of the microstructural characteristics was carried out and compared with the SHT samples in Fig. 1, and the results are shown in Fig. 3.

The γ′ precipitates transformed from cubic to sphere after 1100 °C – 50 h exposure and 1150 °C – 10 h exposure, respectively. A significant number of third γ′ precipitates formed in the alloy after 1150 °C – 100 h exposure, while only a small amount was found after 1100 °C – 100 h exposure. The average size of primary γ′ precipitates increased continuously during thermal exposure. The growth rate at 1150 °C was higher than 1100 °C, and the average size reached 0.90 μm and 1.05 μm, respectively.

The exposure temperatures of 1100 °C and 1150 °C in this work are lower than the massive dissolving temperature of the γ′ precipitates of the DD5 alloy. In this process, the evolution of the γ′ precipitates is carried out simultaneously in two processes: the γ′ precipitate growth process and the γ′ precipitate dissolution process. The whole process follows the Ostwald ripening mechanism, i.e., the larger γ′ precipitates grow, and the smaller γ′ precipitates dissolve. The growth of γ′ precipitates is affected by the diffusion of alloying elements, and its laws follow the LSW coarsening theory34:

where rt is the average radius of the precipitated particles after exposure time t; r0 is the average radius of the precipitated particles before exposure; K is the coefficient related to the volume fraction of the precipitated particles; and t is the exposure time. According to the Arrhenius equation35:

where D is the diffusion coefficient, D0 is the diffusion constant which represents the frequency at which atoms and molecules collide in a way that leads to a reaction, R is the ideal gas constant, Q is the activation energy, and T is the absolute temperature.

For a certain alloy, the diffusion constant is determined by its chemical composition, and temperature is an important factor affecting the diffusion of alloying elements; the higher the temperature is, the greater the diffusion coefficient, the faster the diffusion speed of the alloying elements, and the faster the growth rate of the γ′ precipitates. Therefore, under the same exposure time, a higher exposure temperature results in larger primary γ′ precipitates.

With increased exposure temperature and time, more primary γ′ dissolved and precipitated in two patterns during cooling: precipitating adheres the undissolved primary γ′ along (011) plane, resulting in the serrating γ/γ′ interface; and precipitating in the γ matrix forming the third γ′36,37. Some of the γ′ formation element not diffused to the γ′/γ phase interface formed fine second γ′ precipitates in the matrix38.

Figure 4 shows the morphology of the carbides after 100 h of exposure. The rod-shaped carbide was stable during the exposure since no evidence of carbide decomposition was found. The results of energy dispersive spectrometry (EDS) in Fig. 5 showed the carbides in the samples were Ta-rich MC(1).

TCP phases

The matrix electron vacancy number of the DD5 alloy used in this work was calculated according to aerospace standard AS5491 (Eq. (3)). The electron vacancy number of 2.14 was far lower than the σ phase precipitation value of 2.45 ~ 2.52, and the µ and Laves phase precipitation values were 2.3. According to the calculation results, it is predicted that no TCP phases would precipitate during thermal exposure. After the specimen was exposed for 100 h at 1100 °C and 1150 °C respectively, no TCP phase was found in the field of view of any of the metallographic specimens under SEM, and both the calculations and experiments showed that the DD5 alloy exhibited good microstructural stability at temperatures no greater than 1150 °C.

where \(\:{m}_{i}\) is the mass fraction of element i in the alloy and \(\:{\left({\text{N}}_{\text{v}}\right)}_{\text{i}}\) is the number of electron vacancies in element i.

Mechanical properties of the thermally exposed samples

The 870 °C tensile properties of the DD5 alloy after heat treatment at 1100 °C are shown in Fig. 6. The tensile strength increased by 13.1% after 1 h of exposure and then decreased with increasing exposure time and was 0.5% greater than that of SHT after 100 h. The yield strength basically decreased as the exposure time increased, decreasing by 2.4% at 10 h and 11.6% at 100 h. The elongation decreased rapidly after 1 h, decreased by 29%, then increased slightly, and decreased by 21.3% after 100 h.

The 870 °C tensile properties of the DD5 alloy after 1150 °C thermal exposure are shown in Fig. 7. The tensile strength increased by 13.8% after 1 h of exposure and then gradually decreased with increasing exposure time and was 5.0% greater than that of SHT after 100 h. The yield strength basically decreased as the exposure time increased, decreasing by 3.6% at 10 h and 9.5% at 100 h. The elongation decreased with increasing exposure time, decreasing by 15.4% after 50 h and 20.0% after 100 h.

Although the microstructural degradation of the DD5 alloy after exposure at 1150 °C is greater than that after exposure at 1100 °C, the strengthening effect of the γ′ precipitates after 100 h of temperature exposure is not significantly weakened, and the high-temperature tensile properties of the alloys at the two exposure temperatures are basically equivalent and remain at a high level. As the main strengthening phase of superalloys, the morphological changes of the γ′ precipitates will affect the mechanical properties of the alloy. The creep mechanism in the creep steady stage of single crystal alloys at high temperature and low stress is the dislocation climbing mechanism, and the creep mechanism in the acceleration stage is the dislocation cleavage mechanism, in which a large number of dislocations in the γ matrix cut into the γ′ precipitates, resulting in creep fracture39. The fracture mode was a mixture of cleavage and microvoid coalescence mechanisms as shown in Fig. 8. The necking occurred throughout the thickness of the specimens, and all the fracture surface exhibited Lüders band-like phenomenon in {111} fracture facets, which was in line with Ebrahimi’s40 and Li’s41 studies.

The stress rupture properties of the DD5 alloy after heat treatment at 1100 °C are shown in Fig. 9. The stress rupture life of the 980 °C/250 MPa test increased by 18.7% after 1 h, 39.1% after 10 h, and then decreased, which was 26.0% greater than that of the SHT after 50 h, and 5.9% less than that after 100 h. The stress rupture life of the 1070 °C/137 MPa test increased by 63.8% after 1 h, 109.7% after 10 h, and then decreased, which was 20.3% greater than that of the SHT after 50 h and 1.6% greater after 100 h. The stress rupture life of the 1093 °C/158 MPa test increased by 36.0% after 1 h, then stabilized at 50 h, and then decreased significantly, which was 42.7% less than that of the SHT after 100 h.

The stress rupture properties of the DD5 alloy after 1150 °C thermal exposure is shown in Fig. 10. The stress rupture life of the 980 °C/250 MPa test increased by 16.7% after 1 h, which was 8.3% greater than that of the SHT after 50 h and 1.0% greater than that after 100 h. The stress rupture life of the 1070 °C/137 MPa test significantly increased by 71.3% after 1 h and then decreased rapidly, which was 24.3% greater than that of the SHT after 10 h, 16.3% less than that after 50 h, and 20.1% less than that after 100 h. The stress rupture life of the 1093 °C/158 MPa test showed no significant difference after 1 h and then gradually decreased, which was 21.1% less than that of the SHT after 10 h and 51.2% less than that after 100 h.

After 100 h of exposure, the 980 °C/250 MPa and 1070 °C/137 MPa rupture life at 1100 °C and the 980 °C/250 MPa rupture life at 1150 °C are basically equivalent to those of the SHT samples, whereas the rupture life at 1093 °C/158 MPa at both temperatures decreased significantly. During the stress rupture test at high temperature and low stress, the movement of dislocations follows the Orowan dislocation-precipitate bypass mechanism, and a dislocation network is formed at the γ/γ′ interface, which can effectively prevent dislocation movement. As the size of the γ′ precipitates increases, the phase interface decreases, which is detrimental to the strengthening of the alloy. The average size of the γ′ precipitates increases after exposure to 1100 °C and 1150 °C, and the cubization degree decreases significantly; consequently, the obstruction of dislocation movement decreases, resulting in a decrease in the stress rupture life of the alloy.

Conclusions

-

1.

The microstructure of the DD5 alloy was basically stable after 100 h of exposure to temperatures of 1100 °C and 1150 °C, and no TCP phase precipitated.

-

2.

After exposure at 1100 °C, the γ′ precipitates significantly coarsen and grow after 10 h, the average size reaches 0.82 µm after 100 h, and some γ/γ′ phase interfaces serrate. At 1150 °C, the γ′ precipitates coarsen after 1 h, the average size increases to 0.50 µm and reaches 1.05 µm after 100 h, and the 3rd γ′ precipitates substantially precipitate in the alloy.

-

3.

During exposure at 1100 °C and 1150 °C, the tensile strength and stress rupture life increased initially and subsequently decreased. For both the 1100 °C and 1150 °C exposures, the 870 °C tensile strengths after 100 h were 0.5% and 5.0% greater than those of the SHT samples, respectively. After 100 h of exposure, the rupture life at 980 °C and 250 MPa was 5.9% lower and 1.0% greater than that at 1100 °C and 1150 °C, respectively; the rupture life at 1070 °C and 137 MPa was 1.6% greater and 20.1% less than that at 1100 °C and 1150 °C, respectively; and the rupture life at 1093 °C and 158 MPa was 42.7% and 51.2% less than that at 1100 °C and 1150 °C, respectively.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Gell, M., Duhl, D. N. & Giamei, A. F. The Development of Single Crystal Superalloy Turbine Blades [C]//Superalloys 205–214 (1980).

Broomfield, R. W., Ford, D. A. & Bhangu, J. K. Development and turbine engine performance of three advanced rhenium containing superalloys for single crystal and directionally solidified blades and vanes. Trans. ASME 120, 596–608 (1998).

Walston, W. S. et al. Rene’ N6: Third Generation Single Crystal Superalloy [C]. Superalloys 27–34 (1996).

Tin, S., Pollock, T. M. & Murphy, W. Stabilization of thermosolutal convective instabilities in Ni-based single-crystal superalloys: carbon additions and freckle formation. Metall. Mater. Trans. A. 32, 1743–1753 (2001).

Harris, K. & Wahl, J. B. Improved Single Crystal Superalloys, CMSX-4 (SLS)[La + Y] and CMSX-486 [C]//Superalloys 45–52 (2004).

Fullagar, K. P. L. et al. Aero engine test experience with CMSX-4 alloy Single-Crystal turbine blades. Trans. ASME 118, 380–388 (1996).

Cetel, A. D. & Duhl, D. N. Second-Generation Nickel-Base Single Crystal Superalloy [C]//Superalloys 235–244 (1988).

Cutler, E. R., Wasson, A. J. & Fuchs, G. E. Effect of minor alloying additions on the carbide morphology in a single crystal Ni-base superalloy. Scripta Mater. 58, 146–149 (2008).

Zhou, Y. Z. & Volek, A. Effect of carbon additions on hot tearing of a second generation nickel-base superalloy. Mater. Sci. Eng., A 479, 324–332 (2008).

Al-Jarba, K. A. & Fuchs, G. E. Effect of carbon additions on the as-cast microstructure and defect formation of a single crystal Ni-based superalloy. Mater. Sci. Eng., A 373, 255–267 (2004).

Yu, Z. H., Liu, L. & Zhang, J. Effect of carbon addition on carbide morphology of single crystal Ni-based superalloy. Trans. Nonferrous Met. Soc. China 24, 339–345 (2014).

Kong, Y. H. & Chen, Q. Z. Effect of minor additions on the formation of TCP phases in modified RR2086 SX superalloys. Mater. Sci. Eng., A 366, 135–143 (2004).

Hu, Q. et al. Effect of carbon and boron additions on segregation behavior of directionally solidified nickel-base superalloys with rhenium. Trans. Nonferrous Met. Soc. China. 23, 3257–3264 (2013).

Chen, Q. Z. et al. Porosity reduction by minor additions in RR2086 superalloy. Scripta Mater. 51, 155–160 (2004).

Liu, L. R. et al. Effect of carbon additions on the microstructure in a Ni-base single crystal superalloy. Mater. Lett. 58, 2290–2294 (2004).

Qin, J. C. et al. Effect of low angle grain boundaries on mechanical properties of DD5 single crystal Ni-base superalloy. J. Aeronaut. Mater. 37(3), 24–29 (2017). (in Chinese).

Qin, J. C., Cui, R. J. & Huang, Z. H. Effect of low angle grain boundaries on mechanical properties of DD5 single crystal Ni-base superalloy at medium temperature and high temperature. J. Mater. Eng. 48, 114–122 (2020). (in Chinese).

Ross, E. W. & O’hara, K. S. Rene’N4: A First Generation Single Crystal Turbine Airfoil Alloy with Improved Oxidation Resistance Low Angle Boundary Strength [C]//Superalloys 19–25 (1996).

Chen, Q. Z., Jones, C. N. & Knowles, D. M. The grain boundary microstructures of the base and modified RR 2072 bicrystal superalloys and their effects on the creep properties. Mater. Sci. Eng., A 385, 402–418 (2004).

Chen, Q. Z., Jones, C. N. & Knowles, D. M. The microstructures of base/modified RR 2072 SX superalloys and their effects on creep properties at elevated temperatures. Acta Mater. 50, 1095–1112 (2002).

Tian, S. et al. Creep behavior of a 4.5%-Re single crystal nickel-based superalloy at intermediate temperatures. Mater. Sci. Eng., A. 543(5), 104–109 (2012).

Acharya, M. V. & Fuchs, G. E. The effect of Long-Term thermal exposures on the microstructure and properties of CMSX-10 single crystal Ni-base superalloys. Mater. Sci. Eng., A 381, 143–153 (2004).

Neumeier, S., Pyczak, F. & Göken, M. The Influence of Ruthenium and Rhenium on the Local Properties of the γ-and γ′-Phase in Nickel-Base Superalloys and Their Consequences for Alloy Behavior[c]//Superalloys 109–110 (2008).

Rae, C. M., F, Karunaratne, M. S. A. & Small, C. J, et a1. Topologically Close packed phases in an experimental rhenium-containing single crystal superalloy[C]//superalloys 767–777. (2000).

Liu, S. Z. et al. Stress rupture behavior of a single crystal superalloy. Heat Treat. Met. 42(3), 138–142 (2017). (in Chinese).

Cui, R. J. et al. Effect of 980°C Long-term aging on microstructure and properties of DD5 single crystal Ni-base superalloys. Trans. Mater. Heat. Treat. 37(6), 38–42 (2016). (in Chinese).

Cui, R. J. & Huang, Z. H. Microstructural evolution and stability of second generation single crystal nickel-based superalloy DD5. Trans. Nonferrous Metal Soc. China 26, 2079–2085 (2016).

Cui, R. J. et al. Coarsening kinetics of cubic γ′ precipitates of a nickel-based single crystal superalloy after long-term aging. Trans. Mater. Heat. Treat. 41(6), 168–173 (2020). (in Chinese).

Gao, Q. et al. Effect of long-term high temperature aging on microstructure and stress rupture properties of DD5 single crystal superalloy. Foundry 67, 257–260 (2018). (in Chinese).

Lv, P. S. et al. Effect of stress on precipitated phases in DD5 single crystal superalloy during stress rupture tests. Acta Aeronautica Et Astronaut. Sinica. 42(6), 424073 (2021). (in Chinese).

Xu, H. Y. et al. Effect of thickness on microstructure of thin-walled nickel-based single-crystal superalloy castings. J. Mater. Res. Technol. 29, 2912–2917 (2024).

Zhang, L. et al. Stress rupture properties and fracture behavior of thin wall specimens of DD6 single crystal superalloy with [001] direction. J. Aerosp. Power. 34(3), 627–634 (2019). (in Chinese).

Yu, J. et al. Precipitation of secondary γ′ phase of DD6 single crystal superalloy. Rare Metal Mater. Eng. 42(8), 1654–1658 (2013). (in Chinese).

Lifshitz, M. & Slyozov, V. V. The kinetics of precipitation from supersaturated solid solution. J. Phys. Chem. Solids 19, 35–50 (1961).

Feng, D. Metal Physics 492–493 (Science and Technology, 1998). (in Chinese).

Miyazaki, T., Koyama, T. & Doi, M. Effect of coherent strain energy on γ′/γ phase in Ni-Al-Ti alloys. Acta Metall. Mater. 42(10), 3417–3424 (1994).

Shi, Z. X. et al. Microstructure evolution behavior of DD6 single crystal superalloy at different using temperatures. Chin. J. Nonferrous Met. 25(11), 3077–3083 (2015). (in Chinese).

Ren, Y. et al. The effect of long aging time at high temperature on the structure evolution of γ′ phase for a nickel base single crystalline superalloy. Mater. Mech. Eng. 25(4), 7–10 (2001). (in Chinese).

Link, T. et al. <100 > Dislocations in nickel-base superalloys: Formation and role in creep deformation. Mater. Sci. Eng., A. 405(1/2), 254–265 (2005).

Ebrahimi, F., Yanevich, J. & Deluca, D. P. Deformation and fracture of the PWA 1472 superalloy single crystal. Acta Mater. 48, 469–479 (2000).

Li, J. R. et al. Tensile anisotropy of single crystal superalloy DD6. J. Mater. Eng. 12, 6–10 (2008). (in Chinese).

Acknowledgements

The authors thank the National Science and Technology Major Project (J2019-VI-0002-0115) for financial support.

Author information

Authors and Affiliations

Contributions

S.C. wrote the main manuscript text . All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, Sp., Jia, Xy. & Zong, C. Effect of overtemperature exposure on the microstructure and mechanical properties of a DD5 single crystal superalloy. Sci Rep 15, 30664 (2025). https://doi.org/10.1038/s41598-025-15750-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15750-x