Abstract

When roadways in strong mine pressure working faces traverse collapse columns, the complex stress redistribution frequently induces surrounding rock instability and support structure failure. This study investigates the 2702 intake airway crossing the X26 collapse column (75.8 m wide) at Zhangcun Coal Mine through an integrated approach combining theoretical analysis, numerical modeling, and field validation. Using elastoplastic mechanics theory and advanced numerical simulations (Midas GTS NX for 3D modeling and FLAC3D for stress analysis), we characterized the mechanical behavior of the collapse column structure zone, identifying distinct stress regions: a low-stress core zone (< 1 MPa), severe stress reduction zone (5 m radius), stress concentration zone (10 m radius, peak stress 15 MPa), and original rock zone. Theoretical calculations determined a plastic failure range of 50.01 m, informing the design of key engineering parameters: (1) optimized shallow-hole loose blasting with 0.5 m spacing, 1.6 m depth, and 0.6 kg charge per hole, creating effective pressure-relief zones; and (2) a 124.04 m strengthened support range. Numerical simulations demonstrated that the proposed “shallow-hole blasting + bolt-cable-mesh + π-steel shed” composite support system reduces plastic zone extent by 18% (from 195 to 160 mm), decreases roof subsidence by 6.6%, and limits sidewall deformation to < 200 mm. Field monitoring confirmed the system’s effectiveness, maintaining roof displacement within 150 mm and ensuring structural integrity during the 75.8 m crossing. These results provide quantitative guidelines for roadway support design in collapse column areas under high mining-induced stresses.

Similar content being viewed by others

Introduction

As a special geological structure encountered in coal seam mining, the formation and evolution process of collapse columns are complex and changeable1. Their development characteristics and evolutionary laws have always been key challenges affecting the safe and efficient production of coal mines2. During the mining process, collapse columns are prone to causing coal seam damage, roadway deformation, and complex distribution of surrounding rock stress fields, leading to difficulties in supporting the surrounding rock of working face roadways3. At the same time, some collapse columns are water-conductive, which may induce water inrush accidents4, posing a major threat to the safe production of coal mines. To ensure the safe passage of roadway excavation and mining working faces through collapse column areas, highly efficient combined support technologies are urgently needed.

The research on surrounding rock support technology for working face roadways shows a multi-dimensional innovation trend. The traditional engineering analogy method is difficult to meet the surrounding rock control requirements for working faces crossing collapse columns because it does not integrate indicators such as surrounding rock deformation, support cost, and tunneling speed. Scholars have proposed a series of monitoring and prevention schemes through numerical simulation and field tests:

Song et al.5 conducted a mechanical analysis of large-section rectangular roadways crossing collapse column structure zones based on fracture mechanics and the limit equilibrium method, proposing a combined support scheme of “advanced shallow hole grouting + deep flexible pipe grouting + anchor cable mesh”. Jia et al.6 used the Analytic Hierarchy Process (AHP)-entropy weight method for combined weighting, constructed a support effect evaluation system for development roadways crossing collapse columns, and developed an intelligent design system based on Node-Red and FLAC3D. Qian et al.7 carried out a transparent visualization grouting model test for vein-like fissure water-conductive collapse columns, proposed a composite grouting mechanism of pore seepage, splitting grouting, and fissure compaction closure, and conducted field applications. Yao et al.8 adopted a short advance shallow hole weak blasting scheme, combined with TSP advanced geological prediction, advanced support, and grouting water control measures to enhance the self-stability capacity of surrounding rock. Deng et al.9,10 conducted experiments on dry and saturated sandstone, theoretically derived the relationship between fracture toughness and tensile strength, and analyzed the correlation between fracture toughness and strength parameters, providing a theoretical basis for relevant statistical fitting formulas. Li et al.11 used UDEC numerical simulation software to analyze stress distribution and roadway surrounding rock deformation in collapse column structure areas, proposing a collaborative support method of “bolt-mesh-cable + 29U type yieldable support” to effectively control roadway deformation in collapse column areas. Jia et al.12 used discrete fracture network and strain-softening constitutive models to simulate and analyze the surrounding rock failure characteristics when roadways cross collapse columns, and adopted an integrated support of “pre-grouting + bolt-mesh-cable + steel shed” to control surrounding rock deformation. Sun et al.13 used numerical simulation and imaging research technologies to study the wavefield characteristics and imaging of collapse columns in three-dimensional detection of reflected love channel waves outside mining working faces. Mu et al.14 reconstructed the attributes of collapse columns using a bedding branch double-layer grouting method, effectively changing their activity and harmfulness, and established a new exploration technology system for concealed structures centered on 3D seismic, vertical drilling technology, and bedding branch drilling technology. Fei et al.15 aimed at inferred collapse columns in mining working faces, adopting a method combining geophysical exploration and drilling verification to determine a reasonable scheme for detection and mining when collapse columns are encountered again in the future, improving coal recovery rate in working faces. Guan et al.16 identified collapse columns using inversion methods, designed two types of collapse column geological models according to the geological characteristics of coal mine collapse columns, and found that the wave impedance value of overall collapse-type collapse columns was significantly higher than that of coal seams. Zuo et al.17 constructed detailed models of collapse column sliding and bending fracture, used the Discontinuous Deformation Analysis (DDA) method to simulate and analyze the collapse process, and determined that the stability of inverted funnel collapse columns is dominated by bending stress of roof strata, while the movement of columnar collapse columns is mainly caused by sliding instability. Zhang et al.18,19,20,21,22. systematically solved the stability problem of collapse columns under different geological conditions through theoretical modification (criterion optimization), parameter sensitivity analysis, and multi field coupling modeling.

In summary, existing studies have proposed various monitoring and support methods for crossing collapse columns, but there are few reports directly focusing on the surrounding rock control technology of roadways crossing collapse columns. Taking the air inlet roadway of the 2702 working face in Zhangcun Coal Mine crossing the X26 collapse column as the research object, this paper analyzes the mechanical characteristics of the collapse column structure zone in the working face through theoretical analysis and numerical simulation, and proposes a combined roadway support scheme of “shallow hole blasting pressure relief + anchor bolt + anchor cable + steel bar ladder beam + metal mesh + π-shaped steel shed”. Compared to existing research, this paper deeply integrates theoretical analysis, numerical simulation, and field practice, resulting in systematic outcomes with engineering guidance value. The aim is to provide theoretical basis and technical guidance for the surrounding rock control of the roadway crossing the collapse column in the 2702 working face and the safe and efficient mining of the working face, and offer references for working faces under similar conditions.

Engineering overview

Mine geological conditions

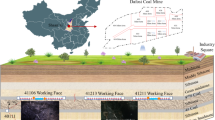

The 27th mining area of Zhangcun Coal Mine is situated in the northwestern part of the mine field. The 2702 working face is centrally located within the 27th mining area. Geographically, it extends westward to the main roadway of the 27th mining area. To the east, it borders the 2609 working face of the 26th mining area; to the north, it adjoins the planned 2701 working face; and to the south, it is adjacent to the village protection coal pillar.

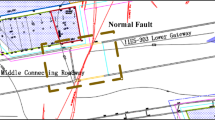

Based on the excavation and detection results of the 2702 working face, the 2702 intake airway has advanced through the X26 collapse column, covering a distance ranging from 87.5 to 163.3 m. The collapse column presents an approximately elliptical planar shape, with a major axis measuring 140.3 m oriented at 357 degrees and a minor axis of 75.1 m. Near the structural zone of the collapse column, cracks are extensively developed in the roof and floor of the coal seam. This phenomenon significantly impairs the integrity of the coal seam, as well as that of the roof and floor, and poses challenges to the support work during the mining process. The plan of the 2702 working face is illustrated in Fig. 1.

The shale properties of the roof and floor of the 3# coal seam in the 2702 working face are depicted in Fig. 2. The coal seam exploited in this working face is part of the No. 3 coal seam located in the lower section of the Shanxi Formation of the Lower Permian. Characterized by minimal thickness variation, the coal seam measures between 5.05 m and 5.55 m in thickness, with an average thickness of 5.30 m. It is buried at a depth of 506.06 m.

Roadway support conditions

The cross-section of the 2702 working face air intake roadway is 5.8 × 3.7 m (width × height), with a rectangular cross-section area of 20.72 m2. The support form is “anchor rod + anchor cable + steel ladder beam + metal mesh”. Anchor rod support parameters: Select metal anchor rods with model MSGLW-500/22 × 2400, the rod body is made of ultra strong heat-treated left-handed ribbed threaded steel bars, the top anchor rod spacing is 0.9 m, the row spacing is 0.9 m, and there are 6 rods in each row; The spacing between anchor rods is 0.75 m, with a row spacing of 0.9 m and 5 rods per row; The anchor cable material is a diameter of Φ 22 mm, 1 × 19 strands of high-strength low relaxation prestressed steel strand, with a length of 6300 mm. The spacing between the top plate anchor cables is 800 mm × 1000 mm, with two anchor cables per row.

Under the existing support conditions, the top plate of the 2702 intake roadway within a range of 180–200 m (10–30 m west of the collapsed column) has experienced anchor rod failure and floor bulging. Therefore, it is necessary to analyze the stress field distribution around the collapsed column and adopt a reasonable surrounding rock control plan to improve the stability of the roadway. The on-site anchor rod failure and floor bulging situation are shown in Fig. 3.

Characteristics of stress field distribution around collapsed columns

In-situ stress test results of X26 collapse column

To understand the distribution of geostress around the X26 collapse column, hydraulic fracturing was employed to measure geostress at the X26 collapse column on the 2702 working face. By observing the roof structure, the hydraulic fracturing stress measurement section can be calibrated. The SYY-56 hydraulic fracturing stress measurement instrument was used to collect real-time pressure and time data during the fracturing process, yielding the hydraulic fracturing curve for each measurement point. The processed data reveals the geostress results at the measurement points, as presented in Table 1.

According to the results of the in-situ stress test in Table 1, the structural stress field of the 2702 working face is dominated by horizontal stress, and the roof and floor of the roadway are prone to tensile failure or bending deformation, which can cause local stress concentration; The direction of the 2702 air intake roadway is north northeast 81°, with an angle of 85.1° with the direction of ground stress, which is nearly perpendicular and belongs to the extremely poor layout direction. It will have a significant impact on the roadway during excavation and requires strengthened support.

Analysis of the mechanical characteristics of collapse column structures

Based on the characteristics of surrounding rock failure within the range of the collapsed column on site, the collapsed column and its boundary are divided into four parts from inside to outside, namely the plastic fracture zone, the plastic stress reduction zone, the elastic stress elevation zone, and the original rock stress zone5. To conduct a mechanical analysis of the X26 collapsed column, the horizontal section of the coal seam surrounding the collapsed column was simplified as a circle. Based on the theories of fracture mechanics and elastic–plastic mechanics23,24,25,26, a mechanical model of stress distribution around the collapsed column was derived, as illustrated in Fig. 4.

As shown in Fig. 4, assuming that the surrounding rock is isotropic within the finite range of the X26 collapse column, the interior of the fracture zone is subjected to uniform shear action, and the maximum principal stress acting on the plane remains unchanged. The equivalent model of a collapsed column has a frustum height of \(h\), an upper surface circumference of \(l_{1}\), an upper surface long axis of \(a_{1}\), a lower surface circumference of \(l_{2}\), a lower surface long axis of \(a_{2}\), and a hypotenuse length of \(l\). The angle between the collapsed column and the lower surface is \(\alpha\).

If the ultimate value of rock shear stress within the circular structural zone of the subsided column is denoted as \(\tau_{0}\), then:

In the formula: \(K_{IC}\)-fracture toughness of rock; \(d\)-crack scale, m.

By integrating Eq. (1), we can obtain the ultimate shear resistance, \(Q{\prime}\), on the interface surrounding the collapsed column.

In the formula: \(a\)-plastic failure plane long axis, m; \(b\)-plastic failure plane short axis, m.

Let \(\tau\) represent the shear stress acting on the plane. Integrating \(\tau = C + \gamma H\tan \varphi\) yields the failure shear force \(Q\) on the entire peripheral interface, where:

When the failure shear force \(Q\) around the collapse column exceeds the ultimate shear resistance \(Q{\prime}\), the surrounding rock in the collapse column structural zone is damaged. According to Eq. (5) and the stress distribution mechanics model surrounding the collapse column, the damage to the surrounding rock is directly proportional to the size of the rock cracks and inversely proportional to its strength. When the roadway passes through the stress-increased area of the collapse column, stress is released into the surrounding rock. The presence of a stress difference in the collapse column structural zone accelerates the creep of the surrounding rock, leading to its plastic failure27. Mining activities on the working face further concentrate stress, expanding the range of rock fragmentation. Based on this, it is imperative to adopt appropriate pressure relief methods, enhance the support strength of the roadway, and bolster the bearing capacity of the surrounding rock to prevent deformation and instability under high stress.

Plastic failure range of X26 collapse column

Building on the previous mechanical analysis of the collapse column structure, it is evident that the mechanical properties and stress state of the surrounding rock within the structure belt are the fundamental determinants of roadway stability in collapse column structure belts. Consequently, enhancing the strength of the surrounding rock and alleviating its stress levels emerge as the pivotal strategies for improving the stability of the roadway surrounding rock. Leveraging the characteristics of the X26 collapse columns and applying the theory of horizontal stress at the plastic zone boundary in elastic–plastic mechanics, the scope of plastic failure in the collapse column can be accurately delineated5.

In the formula: \(R\)-plastic zone boundary radius, m; \(r\)-collapse column radius, take the short axis radius of 38 m; \(\sigma_{s}\)-horizontal stress, taken as 13.17 MPa; \(\sigma_{i}\)-the support force of the collapsed column on the boundary, according to on-site measurements, taken as 5.35 MPa; \(q\)-Strength correction coefficient, \(q = 2C\left( {\frac{1 + \sin \varphi }{{1 - \sin \varphi }}} \right)^{0.5}\).

After calculation, R = 50.01 m can be obtained, and the plastic zone extension range can be further determined to be 12.01 m. Therefore, the key support area for the collapse column in the roadway can be determined to be 124.04 m.

Numerical simulation of stress field in the original rock of X26 collapse column

MIDAS GTS NX can quickly generate initial models, and after importing the models through FLAC3D, high-precision calculations can be achieved.Taking the X26 collapse column passing through the intake roadway of the 2702 working face of Zhangcun Coal Mine as the engineering background, Midas GTS NX was used for 3D modeling, and FLAC3D software was used for numerical calculation of the model. The model size is 200 m (length) × 200 m (width) × 29.89 m (height), with a uniform load of 12.41 MPa applied to the upper part and boundary constraints. The Mohr Coulomb constitutive model is selected for the coal rock mass, and the strain softening model is used for the collapse column. The model consists of 1,497,607 elements and 1,562,764 nodes. The physical and mechanical parameters of the model are shown in Table 2, the support structure parameters are shown in Table 3, and the three-dimensional numerical calculation model is shown in Fig. 5.

The existence of collapse column structural zones can cause stress concentration and release within a certain range, and the vertical stress distribution cloud map can be obtained through numerical simulation calculations. The vertical stress distribution of the collapse column structural zone from inside to outside is “low stress zone severe stress reduction zone stress concentration zone original rock stress zone”; The short axis radius of the stress concentration zone is 10 m, and the short axis radius of the stress reduction zone is 5 m. The maximum vertical stress can reach 15 MPa, and the minimum is less than 1 MPa. High stress difference will accelerate the development of rock fractures, reduce the stability of the rock mass, and sudden release of energy in the stress concentration zone may induce impact ground pressure. Therefore, it is necessary to relieve pressure in the stress concentration zone around the collapse column. The vertical stress distribution and vertical stress curve of the original rock are shown in Figs. 6 and 7, respectively.

Control technology for surrounding rock of roadways in areas affected by collapse columns

Design of shallow-hole loose blasting

Design of loosening blasting parameters

Adopting controlled blasting for stress relief mitigates the impact of blasting on the tunnel, thus enhancing the stability of the surrounding rock mass28. Currently, the diameter of the mining drill bit stands at Φ = 42 mm, with a working face footage of 1.6 m/d. Following the construction principle of ‘mild blasting and short excavation”8, we utilize third-grade emulsion explosives suitable for mining. The spacing between blast holes is determined based on the radius of the fractured zone.

In the formula: \(R_{f}\)-rupture zone radius (m); \(P_{eff}\)-The effective pressure actually sustained by the hole wall (Pa); \(D_{c}\)-The diameter of the medicine roll is taken as 32 mm; \(D_{c}\)-Drill hole diameter, taken as 42 mm;

\(\beta\)- Energy attenuation coefficient, taken as 0.7.

The calculated radius of the crack zone is 0.25 m, which means that cracks or plastic damage will occur within a range of 0.25 m around the blasting. Therefore, the spacing between the boreholes is determined to be 0.5 m. The single hole charge is calculated using the volume formula method:

In the formula: \(q\)-explosive unit consumption, taken as 0.4 kg/m3; \(a\)-The distance between boreholes is taken as 0.5 m; \(b\)-Drill hole spacing, taken as 0.5 m; \(H\)-Rock breaking height, taken as 3.2 m.

The calculated single hole charge amount is 0.32 kg, taking into account energy attenuation and the effects of uncoupled charges. The single hole charge amount is determined to be 0.6 kg in three rolls. The length of the single hole charge section is 0.6 m, and if the length of the blocking section is greater than 20 times the aperture, then the blocking section length of 1 m meets the requirements. The depth of the blast hole is determined to be 1.6 m, the single hole charge amount is 0.6 kg, and the spacing between blast holes is 0.5 m.

Blasting hole arrangement method: The blasting height for rock breaking is the full mining height (3.2 m). The blasting holes are arranged based on the exposed rock conditions, primarily utilizing a six-row configuration. The first row is positioned 0.5 m from the top, with an elevation angle of 17°. The sixth row is situated 0.5 m from the bottom of the rock, with a depression angle of 17°. The spacing between each row of blasting holes is 0.5 m, and all six rows are oriented towards the intake airway side. The blasting plan for the collapse column is illustrated in Fig. 8.

Analysis of the effect of loosening blasting

Blasting simulation was conducted using the internal dynamic load generator of Midas GTS NX numerical simulation software. Since the designed spacing between blast holes was 0.5 m and the length of each hole was 1.6 m, a single row of holes was arranged for numerical simulation to simplify the calculations. The three-dimensional numerical calculation model is illustrated in Fig. 9. When the spacing between blast holes is 0.5 m, the stress distribution between them is uniform, and a significant pressure relief zone is formed in the blasting area, indicating that the existing design scheme achieves good pressure relief effects. The contour map of stress is shown in Fig. 10.

Design of enhanced support for surrounding rock in tunnel

Design of support and reinforcement scheme

The original support scheme for the tunnel is shown in Fig. 11, which consists of “anchor rod + anchor cable + steel ladder beam + metal mesh”. When the working face passes through the collapse column, the stability of the tunnel is poor, and the surrounding rock cannot be effectively controlled. On the basis of the original plan, a strengthened support scheme was designed as shown in Fig. 12: two anchor cables with a spacing of 2700 mm per row on the top plate were changed to three anchor cables with a spacing of 1600 mm per row; The form of anchor rod support for the two sides of the roadway remains unchanged; The new specification is 4600 mm × 3600 mm × 900 mm (beam × leg × shed distance) π-shaped steel shed. The top beam and upright legs of the π-shaped steel shed bear the pressure of the roof and lateral surrounding rock, respectively. The pressure of the collapsed column fracture zone can be evenly transmitted to the bottom plate or deeper stable rock layers through the steel shed29,30, preventing rock collapse or fragmentation.

Analysis of the enhanced support effect on the surrounding rock of the tunnel

Through FLAC3D numerical simulation, the effects of the original support scheme and the strengthened support scheme were compared and analyzed. The stress, displacement cloud map, and plastic zone range of the roadway are shown in Fig. 13. From Figs. 13a and c, it can be seen that when using the original support scheme, the subsidence of the roadway roof can reach 317 mm, and the maximum deformation of the two sides of the roadway can reach 296 mm. From Figs. 13b and d, it can be seen that when using the reinforced support scheme, the subsidence of the roadway roof can reach 297 mm, and the maximum deformation of the two sides of the roadway can reach 278 mm. Adding an anchor cable between the two anchor cables increases the bearing capacity of the roof structure, and the improvement of the stability of the roof structure reduces the stress concentration of the two sides. The decrease in roof subsidence is 6.6%, and the decrease in deformation of the two sides is 6.1%. Compared with the original support scheme (anchor rod + anchor cable + steel ladder beam), the use of strengthened support scheme (adding π—shaped steel shed and blasting pressure relief) reduced the plastic zone range of the surrounding rock of the tunnel from 195 to 160 mm, a decrease of 18%.

On-site engineering application

On-site construction plan

On the basis of determining the blasting parameters, Zhangcun Coal Mine carried out loosening blasting on the collapsed columns from the 75th to 90th day after mining at the 2702 working face, with daily blasting. The loosening blasting area on site is shown in Fig. 15. On site blasting involves blasting 140 holes at a rate of 0.6 kg per hole, for a total of 84 kg. The parameters of the explosives used for loosening blasting are shown in Table 4.

Analysis of the control effectiveness of surrounding rock in roadways

Based on theoretical calculations, the plastic zone of the collapsed column extends over a range of 12.01 m, the enhanced support area for the intake roadway spans 124.04 m, and the X26 collapsed column extends 75.8 m through the 2702 working face roadway. Consequently, the key support area for X26 extends to a distance of 24.12 m before and after the collapsed column. Taking into account the on-site support conditions, it has been comprehensively determined that the area within a 30-m radius before and after the collapsed column requires enhanced support. The specific location of this on-site enhanced support area is depicted in Fig. 14. Stress and displacement monitoring stations have been established at the collapsed column in the intake roadway of the 2702 working face. Stress monitors have been placed on the anchor rods of both sides and the roof to continuously track stress variations on these surfaces. The precise location of the monitoring stations is illustrated in Fig. 14 of Section “On-site construction plan”.

Before the combined support of “shallow hole loosening blasting + strengthened support” for the surrounding rock of the tunnel, the vertical stress around the collapse column was continuously increasing, with an increase rate of 0.17 MPa/d. The displacement of the roof and two sides of the tunnel surrounding rock increased rapidly in the early stage, and then increased at a rate of 0.84 mm/d. After the combined support of the surrounding rock of the tunnel, as the working face was mined, the stress around the collapse column remained stable and did not increase further, indicating the effectiveness of shallow hole pressure relief through blasting in transferring stress within the plastic zone. The displacement of the tunnel’s roof and floor decreased to 0.16 mm/d.

Under the combined support of “shallow hole loosening blasting + strengthened support” for the surrounding rock of the roadway, the stress of the surrounding rock tends to stabilize. The displacement of the roof is controlled within 150 mm, and the displacement of the two sides is less than 200 mm. There is no subsequent failure or damage to the support structure. The stress and displacement monitoring data of the roadway surrounding rock are shown in Figs. 15 and 16, respectively.

Conclusion

-

(1)

The deformation of the surrounding rock in the 2702 working face roadway is primarily influenced by the magnitude and direction of geostress, as well as the X26 collapse column structural zone. The main reason for the instability of the surrounding rock is the increase in shear force resulting from stress concentration.

-

(2)

Based on the theory of elastic–plastic mechanics, the calculated extension range of the plastic zone for the X26 collapse column is 12.01 m, while the reinforced support range for the intake airway is 124.04 m. Numerical simulations reveal a stress distribution pattern around the collapse column, which consists of a low stress zone, a zone with significantly reduced stress, a smaller stress concentration zone, and an original rock stress zone. This clarifies that the stress concentration zone at the contact surface of the collapse column is the key pressure relief area.

-

(3)

The parameters for shallow-hole loosening blasting and the scope of enhanced support have been determined. A joint support scheme consisting of “shallow-hole blasting pressure relief, anchor rod, anchor cable, steel bar ladder beam, metal mesh, and π-shaped steel shed” has been proposed for passing through collapsed columns. The blasting parameters and support effects were simulated using Midas GTS NX and FLAC3D. A loosening blasting scheme with a full mining height, a borehole spacing of 0.5 m, a borehole depth of 1.6 m, and a single-hole charge of 0.6 kg could form a significant pressure relief zone. After strengthening the support, the plastic failure range of the surrounding rock was reduced by 18%, and the subsidence of the roof and the deformation of the two sides were reduced by 6.6% and 6.1% respectively, effectively controlling the deformation of the surrounding rock. Field applications have demonstrated that the combined support scheme ensures the safety of the tunnel as it passes through a 75.8 m wide collapsed column. The stress of the surrounding rock in the tunnel tends to stabilize, with the displacement of the roof controlled within 150 mm. The displacement on both sides is less than 200 mm, and there has been no failure or damage to the supporting structure, ensuring safe and efficient advancement.

Discussion

Limitations

-

(1)

The current study focuses on the geological conditions of the X26 collapse column in Zhangcun Coal Mine, and the universality of the support scheme needs to be verified in other collapse columns with different scales and lithological characteristics.

-

(2)

The numerical simulation assumes isotropy of the surrounding rock, while the actual collapse column area may have complex heterogeneous structures, which could lead to deviations in the predicted results.

-

(3)

The field monitoring period is limited to the working face passing through the collapse column, and the long-term stability of the roadway after mining requires further observation.

Future research directions

-

(1)

Carry out comparative studies on support technologies for collapse columns with different water-conducting properties to establish a targeted control system for water-conductive and non-water-conductive collapse columns.

-

(2)

Introduce advanced monitoring technologies (e.g., micro-seismic monitoring) to dynamically analyze the failure mechanism of surrounding rock in real time, and optimize the support parameters based on big data.

Data availability

All data generated or analysed during this study are included in this published article.

References

Shang, L. Discussion on the support technology and construction process for tunnel excavation through the roof of a collapse column. Contemp. Chem. Res. 3, 118–119 (2020).

Yang, P., Cheng, H. & Shen, B. Exploration and geophysical study on the structural characteristics of X5 collapse column in Shiquan coal mine. Shandong Coal Sci. Technol. 43, 136–143+152 (2025).

Wu, L. Practice of crossing collapse columns in the 61118 fully mechanized caving face at Liuwan coal mine. Jiangxi Coal Sci. Technol. 01, 73–75 (2024).

Ma, J. Analysis of mining methods and safety measures for crossing collapse columns in fully mechanized mining face. Mining Equip. 08, 52–54 (2024).

Song, W. et al. Support technology for large-section rectangular roadways passing through collapse column structural zones. J. Mining Saf. Eng. 36, 1178–1185+1192 (2019).

Jia, C. et al. Optimization of surrounding rock support parameters for development tunnels passing through collapse columns based on AHP entropy weight combination weighting [J/OL]. Coal Sci. Technol. 1–15 [205-06-14].

Qian, Z. et al. High-pressure grouting mechanism and application of vein-like fissure water-conducting karst collapse column [J/OL]. Coal Sci. Technol. 1–12 [2025-06-14].

Yao, H. Smooth blasting in large-section tunnels with weak surrounding rocks. Blasting 37(02), 42–47 (2020).

Deng, H. et al. Development and application of stress and water-rock coupling action test system [J/OL]. Chin. J. Geotech. Eng. 1–8 [2025-06-14].

Deng, H. et al. Study on mechanical properties of pre-peak unloading damaged limestone under reloading. Chin. J. Rock Mech. Eng. 42(06), 1301–1311. https://doi.org/10.13722/j.cnki.jrme.2022.0847 (2023).

Li, X., Hao, C. & Zheng, W. Force analysis and support technology research in collapse column tectonic area. Coal Technol. 39(07), 9–12 (2020).

Jia, C. et al. Failure characteristics and control technology of surrounding rock during roadway passing collapse column. Sci. Rep. 14(1), 28687 (2024).

Sun, H. et al. Study on wave field characteristics and imaging of collapse column in three-dimensional detection with love channel wave reflected outside the working face. Open J. Geol. 10, 1027–1039 (2020).

Mu, J. Study on the reconstruction technology of karst fall column-fault-fracture property in Gubei Coal Mine. China Mining Magaz. 31(8), 151–157 (2022).

Fei, W. Study on underground collapsed column detection technology in mine. CCI 43(10), 52–54 (2020).

Guan, Y., Chen, T., Cui, R., Zhao, L. & Peng, L. Identification of collapse columns using acoustic impedance inversion. Progress Geophys. 31(3), 1320–1326 (2016).

Zuo, J. et al. Investigation on failure behavior of collapse column in China’s coal mine based on discontinuous deformation numerical method. PLoS ONE 14(8), e0219733 (2019).

Zhang, M. M., Liang, L. X. & Liu, X. J. Analysis of the influence of different rock shear failure criteria on wellbore collapse pressure. Chin. J. Rock Mech. Eng. 36(S1), 3485–3491 (2017).

Zhang, M. et al. Influence of multi-planes of weakness on unstable zones near wellbore wall in a fractured formation. J. Nat. Gas Sci. Eng. 93, 104026 (2021).

Zhang, M. et al. Parametric sensitivity study of wellbore stability in transversely isotropic medium based on poly-axial strength criteria. J. Petrol. Sci. Eng. 197, 108078 (2021).

Zhang, M. et al. The modification of Mohr-Coulomb criteria based on shape function and determination method of undetermined parameters. Mech. Mater. 185, 104772 (2023).

Zhang, M. et al. Study of borehole stability of volcanic rock formation with the influence of multiple factors. J. Petrol. Explor. Prod. Technol. 14, 3367–3382 (2024).

Deng, H. et al. Study on mode Ⅰ fracture toughness of sandstone and its correlation with strength parameters. Rock Soil Mech. 33(12), 3585–3591 (2012).

Yang, Q. et al. Rock mass deformation and strengthening theory and non-equilibrium elastoplastic mechanics. Chin. J. Rock Mech. Eng. 20, 106–114 (2005).

Guo, S. Theory of normal space for anisotropic generalized plastic mechanics. Chin. J. Rock Mech. Eng. 13, 2293–2297 (2005).

You, L. I., Si, L. I. & Shiwei, B. A. I. Re-study on elastoplastic stress field of ideal elastoplastic thick-walled cylinder. Chin. J. Rock Mech. Eng. 06, 897–899 (2002).

Zhang, C., Tu, S. H., Bai, Q. S., Zhang, Y. W. & Yang, Q. L. Stress changes around collapse column and the control technology by directly pass in operation in longwall working face. J. China Univ. Min. Technol. 43, 974–980 (2014).

Mu, C. Application of loosening blasting assisted breaking of hard rock strata in coal mining face crossing faults. Energy Energy Conserv. 05, 221–223 (2025).

Wu, Y. et al. Principle and technology of collaborative prevention and control of “pressure relief-support-protection” for deep rockburst roadways. J. Coal Soc. 46(01), 132–144 (2021).

Wang, P. et al. Accumulated damage failure mechanism of anchoring structures under cyclic impact disturbance. Int. J. Min. Sci. Technol. 34(12), 1693–1709 (2024).

Funding

This work was supported by the National Natural Science Foundation of China Project No. 51904145, Basic scientific research project (youth project) of Liaoning Provincial Department of Education in 2022 No. LJKQZ20222322, the Engineering Laboratory of Deep Mine Rockburst Disaster Assessment Open Project No. LMYK2020006, the Liaoning Natural Science Foundation Program Guidance Plan No. 2019-ZD-0045, and the Liaoning Provincial Department of Education Project No. LJ2019JL007.

Author information

Authors and Affiliations

Contributions

H.R. and Longyue He wrote the main manuscript text. Nannan Li and Zhenghao Wang were responsible for figure and table making and data analysis. Songyue Kou collect materials and summarize typesetting. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rong, H., He, L., Li, N. et al. Technical research on surrounding rock control of roadways crossing collapse columns in strong mine pressure working faces. Sci Rep 15, 31905 (2025). https://doi.org/10.1038/s41598-025-15850-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-15850-8