Abstract

This study presents a comprehensive experimental investigation into the impact resistance of stacked composite structures fabricated by hybridizing 3D-printed carbon fiber-reinforced polyether ether ketone (CF-PEEK) with perforated aluminum (Al 3004) foil layers. Both perforated and unperforated Al foil, strategically interleaved within CF-PEEK layers and bonded using epoxy resin. Two critical fabrication parameters fiber orientation (0°, 45°, and 90°) and layer height (0.2 mm, 0.3 mm, and 0.4 mm) were systematically varied using a full factorial design to assess their influence on impact performance. Charpy impact tests were conducted in accordance with ASTM D6110 on both hybrid CF-PEEK/Al foil laminates and CF-PEEK-only specimens. Results indicated a substantial improvement in impact energy absorption and impact strength for the hybrid configurations, with peak values reaching up to 30 J and 402.2 J/m2, respectively at a fiber orientation of 90° and a layer height of 0.2 mm. In contrast, corresponding CF-PEEK-only specimens exhibited significantly lower energy absorption, with maximum values of 17 J and 227.9 J/m2 under the same conditions. Among all parameter combinations, the hybrid specimens with a fiber orientation of 45° and a layer height of 0.3 mm demonstrated the most consistent and enhanced performance. These findings highlight the synergistic effect of metallic reinforcement and optimized printing parameters improves mechanical robustness of additively manufactured composite laminates. This work emphasizes the potential of hybrid additive manufacturing (HAM) approaches in developing lightweight, high-strength materials for aerospace, defense, and impact-critical applications, offering a promising pathway for tailoring structural performance through designable interfacial architectures and controlled fabrication parameters.

Similar content being viewed by others

Introduction

Now days, the demand for multifunctional composite materials with superior mechanical, thermal, and structural characteristics has increased, mostly across sectors such as aerospace, defense, and automotive engineering. These industries seek advanced materials that are not only lightweight and corrosion-resistant, but also capable of withstanding extreme loading conditions. Thermoplastic composites, particularly those reinforced with carbon fibers have gained significant consideration due to their high strength-to-weight ratios, recyclability, and customizable manufacturing potential1. Among high-performance thermoplastics, polyether ether ketone (PEEK) stands out for its exceptional chemical resistance, high thermal stability (melting point ~ 343 °C), and outstanding load-bearing capabilities. When reinforced with carbon fibers (CF), CF-PEEK exhibits superior mechanical performance, making it ideal for advanced structural applications in harsh environments2. The integration of fused filament fabrication (FFF) a form of additive manufacturing (AM) into CF-PEEK processing has unlocked design flexibility and allowed for precise control over part architecture, mostly fiber orientation and deposition parameters3.

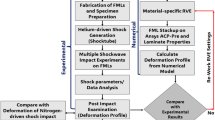

Despite these advantages, CF-PEEK composites often exhibit brittle fracture behavior under high-velocity or impact loading due to limited energy dissipation and inter-laminar bonding deficiencies4. These shortcomings reduce their effectiveness in impact-prone environments, necessitating the exploration of hybrid material strategies. One encouraging solution involves the collaborating of ductile metallic layers, such as aluminum (Al) foils, into the polymer matrix forming a class of materials known as fiber-metal laminates (FMLs). FMLs are renowned for their capability to combine the toughness of metals with the lightweight nature of polymers, leading to enhanced impact resistance and damage tolerance5. Aluminum 3004 alloy foils, in particular, offer attractive properties such as low density, high formability, corrosion resistance, and plastic deformation under impact. When perforated and embedded within fiber-reinforced thermoplastics, these foils promote mechanical interlocking and improve stress transfer, thereby reducing the risk of delamination and improving energy absorption6,7,8. The increased surface area provided by perforations facilitates better bonding when epoxy resins are used as interlayer adhesives. A key challenge in designing this hybrid laminates lies in understanding how additive manufacturing parameters affect mechanical behavior. In FFF, fiber orientation and layer height are particularly influential. Fiber orientation governs the anisotropic nature of strength and stiffness, while layer height impacts interlayer adhesion and void content both of which affect the overall toughness and energy absorption capacity9,10,11. However, the combined influence of these parameters on the impact performance of CF-PEEK and aluminum foil hybrid laminates has not been fully explored, especially within the context of hybrid additive manufacturing (HAM).This study aims to fill that gap by experimentally investigating the impact resistance of stacked hybrid composites fabricated by hybridizing 3D-printed CF-PEEK with perforated Al 3004 foil layers using high-temperature FFF and epoxy-assisted lamination. The experimental design systematically varies two critical process parameters: fiber orientation (0°, 45°, and 90°) and layer height (0.2 mm, 0.3 mm, and 0.4 mm). Charpy impact tests, conducted according to ASTM D6110 standards, are used to evaluate the energy absorption capacity of both CF-PEEK-only and hybrid CF-PEEK/Al specimens. The results provide new insights into how metallic reinforcement and optimized AM parameters can synergistically enhance impact behavior. A detailed analysis reveals that hybrid configurations significantly outperform their monolithic counterparts, particularly at specific orientations and layer heights. This research not only contributes to the fundamental understanding of CF-metal hybrid laminates under impact loading but also establishes a foundation for the development of next-generation structural components optimized through HAM strategies for enhanced safety and durability in critical engineering applications. Figure 1 shows the performed activities schematically.

Materials and methods

Materials

The experimental design, testing techniques, and data procurement were conducted in accordance with relevant ASTM standards to ensure consistency and reproducibility in evaluating the impact resistance of hybrid CF-PEEK/aluminum foil composites. Polyether ether ketone (PEEK) was selected as the primary matrix material due to its high thermal stability, chemical resistance, and mechanical performance. Victrex PEEK 450G (melting point: 343 °C; glass transition temperature: 143 °C; ASTM D6262 compliant) was used, sourced from Victrex plc (United Kingdom). Reinforcement was achieved using chopped carbon fiber (CF) embedded in the PEEK matrix, compatible with fused filament fabrication (FFF). The CF-PEEK filament (1.75 mm diameter; 1.24 g/cm3) was obtained from Toray Industries (Japan) and processed at a nozzle temperature of 200–230 °C and a bed temperature of 0–60 °C, conforming to ASTM D792 and ISO 1133 standards. To enhance impact performance, perforated aluminum foil (3004 alloy) was introduced as a metallic interlayer. Each foil slice was 0.2 mm thick, and four slices were incorporated into the laminate structure. The 3004 alloy was selected for its strength, ductility, corrosion resistance, and established use in fiber-metal laminates8, and was supplied by Hydro Aluminium AS (Norway). The foil conformed to ASTM B209 and DIN 24,041 standards. An epoxy adhesive system comprising Araldite LY 556 resin and HY 951 hardener (2:1 weight ratio) was used to bond the layers. This system, obtained from Huntsman Advanced Materials (Switzerland), followed ASTM D3418 curing conditions and facilitated mechanical interlocking between the aluminum foils and CF-PEEK layers.

Fabrication process and experimental design

All specimens were fabricated using a hybrid additive manufacturing (HAM) approach. CF-PEEK laminates were printed using a high-temperature fused filament fabrication (FFF) 3D printer, equipped with a nozzle capable of reaching 450 °C and a heated bed maintained at 120 °C to ensure dimensional stability and interlayer adhesion. The CF-PEEK filament, containing 30 wt% short carbon fibers (~ 17–20 vol%), was deposited in alternating orientations (0°, 45°, and 90°) at layer heights of 0.2 mm, 0.3 mm, and 0.4 mm. Two categories of specimens were prepared:

(i) CF-PEEK-only laminates, and (ii) Hybrid CF-PEEK + aluminum foil laminates, which incorporated four perforated aluminum 3004 foils (0.2 mm thick) laminated between CF-PEEK layers using Araldite epoxy resin. The hybrid structure consisted of 17 total stacked layers forming a 10 mm-thick Charpy impact test specimen. The aluminum foils were embedded at equal intervals, interleaved with CF-PEEK and epoxy resin layers (0.4 mm), centered around a 5.2 mm-thick printed CF-PEEK core. Each foil contained circular perforations (2 mm diameter, 4 mm pitch), producing an open area of ~ 25% to enable resin infiltration and mechanical interlocking. This configuration enhanced interfacial bonding without compromising foil integrity. Higher perforation density increased resin anchorage but reduced local stiffness, while moderate perforation offered an optimal balance for energy dissipation. After assembly, hybrid laminates underwent compression using a hot press at 120 °C for 10 min to ensure proper epoxy curing and interfacial consolidation. Figures 2 a) and b) provide schematic representations of the hybrid laminate assembly and the FDM process for CF-PEEK-only specimens, respectively, highlighting key process parameters such as layer height, fiber orientation, and resin pathways.

Experimental design

A full factorial design (3 × 3) was employed, considering two parameters (fiber orientation and layer height) at three levels each. Eighteen experimental cases were studied, 9 for each specimen category (CF-PEEK-only and hybrid CF-PEEK/Al).(Table 1).

Specimen fabrication and impact testing procedure

Specimen fabrication

Rectangular specimens measuring 55 mm × 10 mm × 10 mm, each featuring a standard V-notch (2.54 mm deep at a 45° angle with a 0.25 mm radius), were prepared in accordance with the guidelines for evaluating impact strength using the Charpy impact method for notched plastic specimens. These dimensions are commonly employed in experimental or modified testing setups, particularly for composite materials and additively manufactured samples. The composite specimens were fabricated from perforated and unperforated aluminum foil and CF-PEEK and using epoxy resin [Araldite LY 5052 and hardener HY 5052] which was used to bond the aluminum layers to the CF-PEEK substrate. Composite specimens were made from CF-PEEK, a high-strength thermoplastic, reinforced with perforated aluminum foil to improve impact resistance while maintaining lightweight. Araldite LY 5052 epoxy with HY 5052 hardener bonded the layers, chosen for strong adhesion and thermal compatibility. Specimens with fiber orientations of 0°, 45°, and 90° were fabricated by stacking CF-PEEK and aluminum foil layers, and then hot pressed at 280 °C under 1 MPa for 30 min. After slow cooling, specimens were trimmed to 55 × 10 × 10 mm with a standard ASTM D6110 V-notch (2.54 mm deep, 45° angle, 0.25 mm radius).

Consolidation

After printing, specimens were hot-pressed at 280 °C under 1 MPa pressure for 30 min to consolidate layers and cure the resin.

Post-processing

Specimens were cooled slowly inside the press to minimize residual stresses. Edges were trimmed and surfaces polished to ASTM tolerances.

Impact testing procedure

The Charpy impact test was selected due to its suitability for evaluating notch-sensitive, layered composite systems such as CF-PEEK and hybrid CF-PEEK/Al laminates. It offers a standardized and reliable method for assessing energy absorption under high-strain-rate flexural loading, simulating real-world impact conditions. Unlike Izod or drop-weight methods, Charpy testing allows rapid, comparative evaluation of different orientations and layer heights with minimal instrumentation. Prior studies have successfully used this method to detect interfacial failure modes, voids, and fiber pull-out in AM-fabricated composites12,13,14. Impact resistance for both CF-PEEK only and CF-PEEK/Al foil were assessed through Charpy impact tests performed on notched specimens by a pendulum impact tester with an impact energy capacity of 50 J as per ASTM D6110 as illustrated in Fig. 3. Each test were performed at ambient temperature, and the impact strength as the absorbed energy divided by the cross-sectional area at the impact zone. Three replicate specimens were tested for each configuration, and the mean and standard deviation were calculated to assess repeatability. The specimens were positioned horizontally and clamped securely at both ends to replicate boundary conditions consistent with typical impact loading scenarios for structural applications. The test methodology emphasized the assessment of hybridization effectiveness, energy absorption capability, and delamination resistance under transverse impact loading. The influence of fiber orientation and layer height was analyzed using statistical techniques to correlate failure modes with structural architecture. The procedure followed ASTM D6110 standards to ensure consistent and reliable impact energy data for all specimens.

Data recording

The absorbed energy values (in joules) were recorded for each specimen configuration. The mean energy absorption values are recorded and impact strength is computed for both specimens’ categories of CF-PEEK + Hybrid Al Foil.

Data processing and analysis

Experimental data were treated using descriptive statistics and main effect plots to analyze the influence of fiber orientation and layer height. The techniques used were MANOVA, Mean and standard deviation to evaluate repeatability, Main effects plots to visualize the role of each parameter, Interaction plots to identify parameter synergy and Bar charts to compare CF-PEEK-only vs. hybrid cases. All statistical analysis was performed using Minitab 17.

Characterization techniques

Scanning electron microscopy (SEM) was employed to investigate the fracture surfaces of CF-PEEK and hybrid CF-PEEK/perforated aluminum foil composites following Charpy impact testing. The analysis focused on microstructural features and interfacial bonding quality to elucidate the dominant failure mechanisms under high strain-rate loading. Key observations included fiber pull-out, matrix cracking, and signs of interfacial delamination—indicative of stress concentration and poor adhesion at the fiber–matrix and foil–matrix interfaces. All impact tests were conducted under controlled environmental conditions (temperature and humidity), and experimental protocols followed standardized safety and handling procedures. The testing configuration and fracture surface preparation were carefully documented to ensure repeatability and analytical accuracy.

Results and discussion

Impact energy and impact strength comparison of CF-PEEK vs hybrid laminates

The impact energy absorbed by CF-PEEK-only and hybrid CF-PEEK + Perforated Aluminum Foil laminates and their impact strength across various fiber orientations and layer heights is summarized in Tables 2 and 3. The hybrid laminates consistently outperformed CF-PEEK-only specimens in most configurations."The highest recorded absorbed energy for the hybrid system (30.0 J at 0.2 mm and 90° orientation) represents an approximate 215% improvement compared to the corresponding CF-PEEK-only specimen (9.5 J). The results demonstrate a substantial improvement in impact energy absorption, reaching up to 30 J and 402.2 J/m2 under optimal configurations. This enhancement is attributed to the synergistic interaction between the thermoplastic matrix, continuous carbon fiber reinforcement, and the ductile metallic interlayers, which together contribute to improved energy dissipation and crack deflection mechanisms. Statistical analysis confirmed the significance of parameter interaction effects, underscoring the importance of process optimization in tailoring mechanical performance. These findings validate the efficacy of hybridizing CF-PEEK with aluminum foils for applications demanding superior impact resistance, particularly in aerospace, automotive, and defense sectors.

Influence of fiber orientation

Fiber orientation significantly influenced the energy absorption characteristics of both CF-PEEK-only and hybrid laminates. At a 90° fiber orientation, the fibers were line up perpendicular to the direction of impact, resulting in higher deformation energy and better crack arrest, mainly in hybrid specimens. The hybrid structure exhibited synergistic effects, with fiber bridging and metallic plasticity contributing to delayed crack propagation. Conversely, the 0° orientation, where the fibers were parallel to the impact direction, led to reduced energy absorption due to early fiber breakage. This trend was detected across all configurations, with the hybrid specimens showing a notable increase in energy absorption compared to the CF-PEEK-only specimens.

Table 2 presents the impact performance of CF-PEEK and CF-PEEK/Al foil hybrid composites under varying fiber orientations (0°, 45°, 90°) and layer heights (0.2, 0.3, 0.4 mm). Hybrid specimen’s consistently outperformed CF-PEEK-only counterparts, with the highest impact strength (402.14 J/m2) observed at 90° orientation and 0.2 mm layer height. The 0.2 mm height yielded superior interlayer bonding, while performance declined at 0.4 mm due to reduced adhesion. Although 45° orientation enhanced energy absorption at 0.2 mm, it showed instability at 0.3 mm, likely due to fiber misalignment or poor layer integration. Figure 4a shows that a 45° fiber orientation with 0.2 mm layer height achieves the highest impact energy, reflecting optimal load transfer. Figure 4b compares hybrid CF-PEEK/Al foil laminates to CF-PEEK-only specimens, highlighting the hybrids’ superior energy absorption and impact strength due to the metallic interlayers.

Effect of layer height on impact resistance

Layer height played a critical role in the interlayer bonding and overall impact resistance of the composites. Lower layer heights (0.2 mm) facilitated better adhesion between layers, reducing voids during printing and leading to better energy absorption. However, as the layer height increased, especially to 0.4 mm, there was a noticeable decrease in impact energy. This was attributed to poorer interfacial bonding and increased porosity, leading to reduced toughness. Hybrid specimens were less sensitive to layer height, likely due to the mechanical conferring provided by the perforated aluminum foils and epoxy resin. As the layer height increased to 0.4 mm, absorbed energy declined due to reduced interfacial bonding and increased porosity, consistent with prior finding12,13. The hybrid specimen (Fig. 5-a) with 45° fiber orientation at 0.4 mm showed brittle fracture features—fiber pull-out, rupture, and porosity—indicating weak bonding from resin infiltration issues and fiber misalignment. Additive manufacturing of fiber-reinforced thermoplastics offers high strength-to-weight advantages, but process parameters strongly influence impact resistance. Beylergil et al.15 demonstrated via Taguchi and ANOVA methods that infill density and raster angle significantly affect Charpy strength in FDM-fabricated CF/polyamide composites, with SEM revealing voids and delamination. These insights reinforce the importance of controlling void content and interlayer adhesion, central to optimizing CF-PEEK/perforated aluminum foil hybrids for impact performance.

Hybridization effects and failure modes

The inclusion of perforated aluminum 3004 foils in the hybrid laminates enhanced impact resistance by enabling mechanical interlocking between the epoxy, CF-PEEK, and aluminum layers. Arresting crack propagation through energy dissipation at the metal-polymer interface. Redistributing stress, preventing catastrophic failures.

Fracture mechanism analysis

Figure 5-a-b-c, presents SEM images revealing key failure modes in pure and hybrid CF-PEEK composites fabricated via hybrid additive manufacturing and tested under Charpy impact. All images acquired at 15 kV in high-vacuum mode using secondary electron detector.

The hybrid specimen (Fig. 5-a) with 45° fiber orientation and 0.4 mm layer height shows brittle fracture features, including fiber pull-out, ruptured fibers, and porosity indicating poor interfacial bonding, likely due to resin infiltration issues and fiber misalignment. The image clearly shows interlayer voids, fiber pull-out, and poor matrix infiltration, supporting the mechanical results. These features are indicative of weak interfacial bonding and void-induced crack initiation, which significantly reduce impact performance. The prevalence of brittle fracture morphology, coupled with porosity, highlights the critical role of layer height in governing interfacial quality in both single-material and hybrid composite systems. In contrast, the pure CF-PEEK sample (Fig. 5-b) exhibits a smoother, more ductile fracture surface with minimal fiber pull-out and cohesive matrix tearing, suggesting strong fiber–matrix adhesion and efficient energy absorption. The hybrid interface (Fig. 5-c) displays clear delamination, interfacial gaps, and crack propagation confirming weak bonding between CF-PEEK and aluminum as a dominant failure mode. These observations highlight interfacial debonding and delamination in hybrids, while pure CF-PEEK fails primarily through ductile matrix tearing. Improving interface quality through surface treatment or adhesive enhancement is essential for optimizing hybrid composite performance.

Statistical analysis and validation

Multivariate analysis of variance (MANOVA)

To6evaluate the multivariate effects of layer height and fiber orientation on the impact performance of CF-PEEK and CF-PEEK/Al hybrid composites, a comprehensive MANOVA was executed. The analysis considered two dependent variables, impact strength of CF-PEEK/Al hybrid laminates and (ii) impact strength of CF-PEEK-only laminates. The independent variables were layer height (0.2, 0.3, 0.4 mm) and fiber orientation (0°, 45°, 90°).

Effect of layer height

As illustrated in Fig. 6-a, the main effects plot reveals that layer height has a pronounced non-linear influence on the impact energy of CF-PEEK specimens. A peak value is observed at 0.2 mm, suggesting superior interlayer adhesion and minimal void content at this thickness. As the layer height increases to 0.3 mm and 0.4 mm, a noticeable decline in absorbed energy is evident, likely due to increased porosity and diminished bonding between deposited layers. Table 4 shows the results of the multivariate tests for the effect of layer height. All four multivariate criteria Wilks’ Lambda (Λ = 0.274, F (4, 24) = 5.460, p = 0.003), Pillai’s Trace (V = 0.914, F (4, 26) = 5.466, p = 0.002), and Hotelling-Lawley Trace (T = 1.964, F (4, 22) = 5.400, p = 0.003) indicated statistically significant differences. This confirms that layer height has a significant multivariate effect on the composite impact performance.

CF-PEEK only Vs CF-PEEK/Al Foil, MANOVA Results for [a) main and interaction effect of Layer Height Vs Fiber Orientation on impact Strength, b) residual plots, c) main and interaction effects Layer Height Vs Fiber Orientation, d) residual plots] on Impact strength and CF-PEEK only vs CF-PEEK/AL Foil Optimization Plot Graph.

The eigenvalue decomposition revealed two canonical discriminant functions with eigenvalues of 1.5102 and 0.4534, accounting for 76.91% and 23.09% of the explained variance, respectively. The first canonical variate alone explains the majority of the group separation. The corresponding eigenvectors suggest that the CF-PEEK-only impact strength has a stronger loading (0.01084) compared to the CF-PEEK/Al hybrid (0.00259), indicating a greater sensitivity of the monolithic laminate to layer height variations.

Effect of fiber orientation

As Fig. 6-shows, Fiber orientation significantly affects impact resistance. Among the tested orientations, 45° yielded the highest energy absorption, likely due to effective crack deflection and energy dissipation through matrix-fiber interfacial interactions. This observation is aligned with prior research emphasizing the importance of shear-dominated energy transfer in off-axis fiber alignments. The interaction plot further emphasizes the statistical interaction between fiber orientation and layer height. The energy absorption at 45° is strongly influenced by layer height, with 0.2 mm exhibiting a synergistic effect. In contrast, 0° and 90° orientations demonstrate minimal sensitivity to layer height. This confirms that fiber architecture can either mitigate or magnify the influence of manufacturing parameters, necessitating multi-factorial design considerations. Table 5 indicates the results from Wilks’ Lambda (Λ = 0.182, F(4, 24) = 8.073, p < 0.001), Pillai’s Trace (V = 1.098, F(4,26) = 7.909, p < 0.001), and Hotelling-Lawley Trace (T = 2.963, F(4,22) = 8.149, p < 0.001) all established highly significant multivariate differences among groups. Roy’s largest root criterion supported this, with a maximum eigenvalue of 2.2923, further confirming the dominance of fiber orientation in influencing impact strength responses.

Model validation

Residual Analysis for CF-PEEK Residual plots (Fig. 6-B) were used to verify the adequacy of the statistical model. The normal probability plot displays an approximately linear trend, validating the assumption of normality. The versus fits and versus order plots show no visible pattern, indicating randomness and absence of autocorrelation. The histogram presents a roughly symmetrical distribution, confirming the homoscedasticity of residuals. Overall, the model assumptions are met, and the fitted regression can be considered statistically reliable.

Effect of process parameters on hybrid CF-PEEK/Al laminates

Fig. 6-C presents the main effects and interaction plots for hybrid CF-PEEK + aluminum foil laminates. Unlike the CF-PEEK-only results, the highest impact strength was observed at 0° and 90° fiber orientations, with values exceeding 22 J. Interestingly, the 45° orientation showed the lowest energy absorption, in contrast to its performance in the non-hybrid system. This reversal is attributed to misalignment between the CF layers and embedded aluminum foils, which can induce stress concentrations and compromise energy transfer at oblique angles. Layer height remains a critical factor, with 0.2 mm again offering the highest energy absorption, supporting the assertion that stronger interlayer fusion and reduced void content at lower heights benefit the impact performance, even in hybrid systems. The interaction plot substantiates a complex dependency between orientation and layer height. The energy increase at 0.2 mm is most pronounced at 0° and 90°, implying that fiber/metal alignment with the load path maximizes energy dissipation, likely through cooperative crack arrest mechanisms between the polymer matrix and metallic reinforcements.

Residual diagnostics for hybrid laminates

As shown in Fig. 6-D, the residual analysis of hybrid specimens confirms that the fitted model is appropriate. The normal probability plot follows a moderately linear trend. While some deviation is observed, residuals are randomly distributed, and no obvious heteroscedasticity or sequence-based bias is detected. The histogram reflects a generally normal distribution, indicating that no significant violations of regression assumptions occurred.

Multi-objective optimization and desirability

The optimization plot in Fig. 6-E highlights the ideal process parameter combination for hybrid composites. The maximum impact strength is predicted at a layer height of 0.2 mm and fiber orientation of 0°, with a composite desirability of ~ 1.000, confirming the optimality of this setting for maximizing impact resistance. This outcome validates experimental trends and supports the use of desirability-based optimization for additive manufacturing of hybrid composites.

This comprehensive analysis demonstrates that layer height and fiber orientation exhibit statistically significant main and interaction effects on the impact strength of both CF-PEEK only and CF-PEEK/Al laminates. A 0.2 mm layer height consistently maximizes performance due to improved layer fusion. However, the optimal fiber orientation differs by composite type, with 45° best suited for CF-PEEK alone, while 0° benefits hybrid configurations due to better fiber-metal alignment. The statistical models are validated through residual diagnostics, and SEM analysis provides strong physical evidence supporting the mechanical outcomes.

Variance structure and error correlation

The adjusted SSCP matrices showed that the majority of between-group variation attributable to layer height occurred in the CF-PEEK/Al hybrid impact response (SS = 40,071), with a smaller yet remarkable contribution from the CF-PEEK-only laminate (SS = 9723). The error SSCP matrix highlighted significant covariance between the responses, with a partial correlation coefficient of −0.385, this indicates an inverse correlation between the impact strengths of hybrid and non-hybrid laminates when controlling for layer height effects.

Interpretation

Generally, these findings highlight that both layer height and fiber orientation significantly affect the impact behavior of hybrid and monolithic CF-PEEK laminates. Remarkably, fiber orientation exerts a stronger discriminative effect, as evidenced by the higher eigenvalues and F-statistics. These results offer strong statistical validation that optimizing both processing parameters is essential to improving impact resistance in hybrid composite structures.

Validation and literature correlation

The observed improvements in impact resistance align with prior research on metal-polymer hybrid composites. Liu et al.9 reported a 2–3 × improvement in impact resistance using perforated aluminum in fiber-metal laminates. Singh et al.11 emphasized the critical role of layer height optimization in maintaining mechanical integrity of fused filament parts. The energy levels and impact strength observed in this study (up to 30 J and 402.2 J/m2) respectively which significantly exceed typical CF-PEEK performance, validating the synergistic effect of hybrid lamination and additive manufacturing. These findings confirm that hybrid composites, when designed with optimized printing parameters, present a promising solution for impact-resistant applications via additive manufacturing. Table 6 summarizes key findings, showing the highest impact energy (30 J) and strength (402.2 J/m2) for hybrid laminates at 0.2 mm layer height and 90° fiber orientation. The optimal orientation is 90° for both CF-PEEK and hybrid, with hybrids achieving nearly twice the impact performance of non-hybrid laminates.

Discussion highlights

Hybrid CF-PEEK/Al foil laminates expressively outperform CF-PEEK-only specimens across all fiber orientations and layer heights. Lower layer heights improve interlayer bonding, enhancing energy absorption. Perforated aluminum foils contribute to mechanical interlocking, crack arrest, and delamination resistance. The optimal configuration for impact energy absorption was achieved with a hybrid laminate at 0.2 mm layer height and 90° fiber orientation.

Limitations

Despite the promising results demonstrated in this study, several limitations must be acknowledged that open avenues for future research and optimization. This study provides insights into the impact resistance of hybrid composites fabricated via additive manufacturing but has several limitations. It focused on a specific matrix (PEEK), short carbon fibers, and a single aluminum alloy (3004), limiting material variability. Printing speed and temperature were not measured in this study. The numerical model simplified material behavior, potentially overlooking complex failure mechanisms. Environmental factors such as thermal aging, moisture, and UV exposure were not considered.

Conclusion

This study systematically investigated the impact resistance of stacked composite laminates fabricated via hybrid additive manufacturing (HAM), combining 3D-printed carbon fiber-reinforced PEEK (CF-PEEK) with perforated aluminum (Al 3004) foil layers. The effects of fiber orientation (0°, 45°, 90°) and layer height (0.2, 0.3, 0.4 mm) were examined for both CF-PEEK-only and hybrid laminates. Results showed that integrating perforated aluminum foils significantly enhanced impact resistance across all configurations. The best performance 30 J impact energy and 402.2 J/m2 impact strength were achieved with a 0.2 mm layer height and 90° fiber orientation, marking a ~ 310% improvement over the CF-PEEK-only specimen. Fiber orientation and layer height were critical: 90° fibers offered superior crack resistance and energy dissipation, while thinner layers had better interlayer bonding and reduced porosity. The perforated aluminum foils added additional toughness via mechanical interlocking, crack bridging, and plastic deformation, with epoxy bonding improving laminate cohesion. MANOVA confirmed statistically significant effects (p < 0.05) of both process parameters, including their interaction in hybrid specimens. Overall, the CF-PEEK/aluminum hybrid laminates demonstrated excellent lightweight and high-impact performance, offering a promising solution for aerospace, automotive, and ballistic applications requiring tailored damage tolerance and structural resilience.

Future work

Future investigations should explore a broader range of materials, environmental effects, and dynamic testing conditions. Employing continuous carbon fibers and alternative foil types could improve mechanical properties. Expanding testing to include flexural fatigue, fracture toughness, and shear strength would provide a complete performance profile. Dynamic testing and multi-scale characterization using SEM and µCT will enhance understanding of real-world performance and damage mechanisms. Long-term durability should be validated under various environmental conditions, and integrating advanced modeling techniques like FEM and machine learning can optimize design. Additionally, embedding sensors for structural health monitoring would enable real-time performance tracking in high-risk environments.

Data availability

The data will be made available on request from the Corresponding Author.

References

Fidan, I. et al. The trends and challenges of fiber reinforced additive manufacturing. Compos. Struct. 258, 113653. https://doi.org/10.1016/j.compstruct.2020.113653 (2021).

Guraya, T. & Han, S. H. High-performance CF/PEEK composites for aerospace applications: Processing, properties, and challenges. Polymers 14(9), 1862. https://doi.org/10.3390/polym14091862 (2022).

Singh, G., Bedi, P. & Singh, T. Recent developments in CF/PEEK composites processed via FDM: Opportunities and challenges. Polym. Adv. Technol. 34(2), 291–305. https://doi.org/10.1002/pat.5931 (2023).

Zhang, L., Wang, X. & Liu, Y. Impact damage behavior of CF/PEEK composites fabricated via additive manufacturing. Compos. Struct. 290, 115554. https://doi.org/10.1016/j.compstruct.2022.115554 (2022).

Rashid, R., Ali, H. & Sultan, M. Fiber metal laminates: Advances in hybrid composites for lightweight structural applications. Compos. Struct. 317, 117098. https://doi.org/10.1016/j.compstruct.2023.117098 (2023).

Alshahrani, H., Alqahtani, H., Khan, M. & Al-Mansour, F. Enhancement of interfacial bonding in fiber-metal laminates using perforated aluminum foils. Compos. Struct. 292, 115662. https://doi.org/10.1016/j.compstruct.2022.115662 (2022).

Chatterjee, S. & Kakati, B. Mechanical interlocking and bonding improvements in polymer–metal hybrid composites using perforated foils. Polym. Polym. Compos. 31(2), 234–245. https://doi.org/10.1177/09673911231109876 (2023).

Chen, Y., Li, X., Wang, S. & Zhou, Y. Interfacial strengthening of aluminum foil reinforced thermoplastic laminates by perforation-assisted mechanical interlocking. Compos. B Eng. 223, 109132. https://doi.org/10.1016/j.compositesb.2021.109132 (2021).

Liu, X., Zhang, W. & Chen, J. Effect of layer height and raster angle on mechanical properties of FFF-printed thermoplastic composites. Mater. Today Commun. 33, 104727. https://doi.org/10.1016/j.mtcomm.2022.104727 (2022).

Patel, H., Joshi, K. & Shah, D. The role of fiber orientation and printing parameters on mechanical performance of additively manufactured composites. Mater. Res. Express 10(5), 055301. https://doi.org/10.1088/2053-1591/acd0f7 (2023).

Singh, R., Fabbri, P. & Fraternali, F. Additively manufactured fiber-reinforced polymer composites: Process–structure–property relationships. J. Market. Res. 13, 1243–1257. https://doi.org/10.1016/j.jmrt.2021.04.093 (2021).

Fidan, I., Gupta, A. & Hasanov, S. Mechanical characterization of fiber reinforced thermoplastic composites manufactured via FDM. Addit. Manuf. 58, 103017. https://doi.org/10.1016/j.addma.2022.103017 (2022).

Mohan, R., Ramkumar, K. R. & Senthilkumar, V. Influence of process parameters on fracture behavior of 3D-printed fiber-reinforced composites: Charpy impact evaluation. J. Thermoplast. Compos. Mater. 35(12), 1613–1628. https://doi.org/10.1177/08927057221083517 (2022).

Oliveira, M., Costa, M. & Ferreira, F. Charpy impact characterization of fused filament fabricated fiber-reinforced composites: Correlating void content and fracture mechanisms. Polym. Testing 122, 108088. https://doi.org/10.1016/j.polymertesting.2023.108088 (2023).

Beylergil, B., Mutlu, M. & Korkmaz, M. E. Influence of FDM process parameters on Charpy impact strength of CF/polyamide composites: Taguchi–ANOVA and SEM analysis. J. Market. Res. 24, 1930–1944. https://doi.org/10.1016/j.jmrt.2023.05.017 (2023).

Acknowledgements

The authors extend their acknowledgement to the financial support of the European Union under the REFRESH-Research Excellence For REgion Sustainability and High-tech Industries project number CZ.10.03.01/00/22_003/0000048. The authors also extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through Large Research Project under grant number RGP.2/491/46.

Funding

The authors extend their acknowledgement to the financial support of the European Union under the REFRESH-Research Excellence For REgion Sustainability and High-tech Industries project number CZ.10.03.01/00/22_003/0000048. The authors also extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through Large Research Project under grant number RGP.2/491/46.

Author information

Authors and Affiliations

Contributions

Authors Contribution: Every author has significant contribution towards the successful completion of the manuscript. Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Conceptualization: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Data curation: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Formal analysis:, Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Investigation Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Methodology: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Software: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Funding: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Project Administration: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Writing – original draft: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J); Writing – Review & Editing: Mohammed Kaso Sado(M.K.S); Shaik Zainuddin(S.Z); Abdurrahman Aljabri (A.A); Irfan Anjum Badruddin(I.A.B); Jana Petrů(J.P); Muhammad Nasir Bashir(M.N.B); Sarfaraz Kamangar(S.K); Gulam Mohammed Sayeed Ahmed(G.M.S.A); Mukhatar Ahmed Javali(M.A.J);

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sado, M.K., Zainuddin, S., Aljabri, A. et al. Experimental investigation on impact resistance of stacked composite material hybridization by 3D printed CF-PEEK and aluminium foils. Sci Rep 15, 34321 (2025). https://doi.org/10.1038/s41598-025-16608-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16608-y