Abstract

Sapphire (Al2O3) is a commonly used dielectric material with many applications in lasers and optical systems. Owing to its high resistivity to laser induced damage, it is particularly suitable for use in high power laser systems. This work focuses on developing techniques to characterize material modifications in sapphire. These techniques were applied following localized laser induced ablation, commonly referred to as laser-damage, resulting from exposure to single 100-ps and 6-ns pulses. Measurements of fluorescence-based piezospectroscopy and confocal Raman microscopy were performed with spatial resolution on the order of 1 μm. Raman microscopy reveals that the relaxation of material exposed to the rapid laser heating, elastic and viscoplastic deformation, melting, and solidification leads to the formation of a polycrystalline material phase. In addition, narrowband fluorescence lines, referred to as R1 and R2, exhibit pressure-sensitive changes to their spectral profiles, allowing 3D internal stresses to be recorded with spatial resolution of the order of a few micrometers.

Similar content being viewed by others

Introduction

Sapphire is widely utilized in high-performance optical applications due to its exceptional hardness, thermal and chemical stability, high laser-damage resistance, and optical transparency. It can be doped with transition metal ions such as Ti3+ or Cr3+ for use as a laser gain medium or left undoped for applications such as optical windows and lenses1,2.

Sapphire’s inherent high laser-damage resistance stems from its large optical bandgap along with its remarkable mechanical strength, high melting point, and high thermal conductivity. It is noteworthy that previous studies have revealed an array of interesting dependencies of its laser damage performance on various factors. For example, a recent study on the surface-damage threshold of sapphire in the femtosecond regime found a laser-induced–damage threshold (LIDT) between 5.06 and 8.59 J/cm2 depending on the laser polarization relative to crystal orientation3. Specifically, it was found that with the laser directed along the crystalline a axis, the damage threshold has a large dependence on laser polarization. With the laser directed along the c axis, there was no measurable dependence on laser polarization. Similar anisotropic effects have been measured via microindentation4. Earlier studies on femtosecond laser damage in sapphire found that the LIDT changed depending on which crystal face was exposed to the laser5,6. Other studies have examined the effect of the surface finish of sapphire’s optical surfaces on LIDT in the femtosecond, picosecond, and nanosecond regimes7,8,9. These studies revealed that surface finish significantly affects the LIDT for all pulse lengths7,8,9. Another report suggested that doping with Ti3+ can significantly improve sapphire’s damage performance10. While there has been extensive work on the damage threshold of sapphire, little attention has been given to understanding the nature and characteristics of the laser-modified material and surrounding region following its exposure to the extreme conditions (rapid superheating and relaxation) associated with laser induced ablation/damage.

Raman spectroscopy is a powerful tool for analyzing laser-damaged sapphire. Sapphire exhibits multiple Raman-active modes, whose relative intensities depend on the polarization and crystal orientation11. Variations in these intensities are used to infer changes in the material’s microstructure. In addition, trace amounts of Cr3+, typically present even in high purity sapphire, giving rise to two sharp fluorescence peaks known as R₁ and R₂. The positions of these peaks are sensitive to internal stress or pressure, thus enabling piezospectroscopy. A similar method is commonly used to measure pressures up to 150 GPa in diamond anvil cells using ruby (Cr3+-doped sapphire)12,13,14,15. The relation describing the stress-induced shift of these fluorescence peaks under nonisotropic stress states was first introduced by Grabner16. Further work has been done to explain how to apply these correlations to explain peak shifts and broadening under varying stress conditions and material forms, including single-crystal and polycrystalline samples17,18. A recent review of 165 relevant papers has determined accurate values for the piezospectroscopic coefficients used in the framework introduced by Grabner19.

In this paper, Raman microscopy and piezospectroscopy are used to investigate the stresses and microstructural changes induced by laser damage in sapphire from nanosecond and picosecond pulses. Despite the importance of this topic, few studies have measured residual stress in laser-damaged materials. Prior work has primarily been limited to analyzing stress-induced birefringence in laser-damaged silica20,21. Other studies have identified high-pressure phases formed within damage sites22,23, implying extreme conditions during laser interaction. The investigation of residual stress aims to deepen the understanding of laser-damage mechanisms in sapphire and optical materials in general. Laser-damage sites in sapphire are generated using 100-ps and 6-ns pulses. The R-line fluorescence spatial maps and Raman spectra are subsequently recorded. These results are used to extract the triaxiality and levels of residual stresses induced by laser damage and the material structure of the damaged sapphire, both at the surface and below the surface. Several data analysis approaches and interpretations are explored.

Materials and methods

Materials

Optical quality 24.5-mm-diameter, 5-mm-thick sapphire windows were used for laser-damage studies. The windows, obtained from Thorlabs (Part Number: WG31050), were single crystal with the c axis normal to the surface. Sapphire has a hexagonal structure; optical windows are typically cut with the c axis normal to the surface to prevent any birefringence since the basal plane (normal to the c axis) is isotropic.

Methods

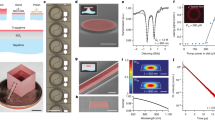

Laser-induced–damage sites on the sapphire samples were generated using two laser systems operating at wavelengths of 355 nm and 1053 nm, with pulse durations of 6 ns and 100 ps, respectively, and a near-normal angle of incidence. The 355-nm laser had a ~ 500-µm-diameter 1/e2 spot size, while the 1053-nm laser had a 320-µm-diameter 1/e2 spot size. Numerous sites on the sapphire windows were exposed to a single pulse at varying fluences (up to 53 J/cm2), giving rise to damage sites with a range of sizes starting with a diameter of the order of 1 µm at damage-initiation fluences. For both laser systems, the generated damage sites had a similar underlying morphology, but for this study, larger sites were selected that provide more-complex structures to help implement the optical spectroscopy techniques presented. This manuscript uses for demonstration one damage site generated by each laser system as a representative example. The first was generated using the 355-nm, 6-ns laser at a peak fluence of 35.38 J/cm2, where the exposed surface was mostly undamaged, containing only a small pit accompanied by a subsurface filament. The second was generated using the 1053-nm, 100-ps laser at a peak fluence of 52.67 J/cm2 and consisted of a larger crater on the input surface as well as a subsurface filament. Optical microscope images of these two damage sites are shown in Fig. 1.

(a) Side view of damage site 1 showing the filament going through the sapphire window. (b) Image of the input surface for damage site (1) The black dashed line shows where R-line fluorescence measurements were taken. (c) Image of the input surface for damage site (2) The numbered spots show locations where fluorescence and Raman spectra were analyzed.

R-line fluorescence and micro-Raman spectra were collected from the damage sites using a confocal Raman microscope (Renishaw Invia) equipped with a 532-nm excitation source, used to probe the damaged material. Based on extensive experimentation, the Raman measurements were performed with the analyzer polarization oriented orthogonal to that of the excitation beam, enabling better selectivity regarding the structure of the modified crystalline material. Light of all polarizations were collected for R-line fluorescence measurements. Fluorescence measurements, collected within the subsurface filament, were recorded using a 20× objective (NA = 0.4). Raman and fluorescence measurements on surface damage were performed using a 100× objective (NA = 0.85).

Fluorescence-based piezospectroscopy was employed to assess residual stress in the damaged regions. Piezospectroscopy is a technique used to determine stress/pressure in a sample based on shifts in spectral features. In sapphire this can be done with the R1 and R2 fluorescence peaks located at 14,404 cm–1 and 14,433 cm–1, respectively16,17,18,19,24. These spectral features are sharp and the shift of peak position under stress/pressure has been well characterized. These fluorescence peaks are emitted due to Cr3+ impurities in sapphire, however, even in high-purity samples, the R-line fluorescence spectrum is typically detectable16,17,18,19,24,25.

Raman spectroscopy was performed to characterize the crystal structure of the modified regions. The Raman spectrum consists of peaks that correspond with the vibrational modes of the crystal, and the relative intensities of the peaks are dependent on crystal orientation as well as the polarization of the excitation source and the polarization of the collected light. By comparing the spectrum collected from the damage sites with that of undamaged sapphire in various orientations, it can be infered how the crystal microstructure has changed in the damaged areas.

Results

The R-line fluorescence spectrum measurements were collected along a cross section of the damage site generated with the 355-nm, 6-ns laser pulse. Each of the two peaks was fitted with a Lorentzian distribution and the central position was recorded. The shift in the location of these peaks compared to the undamaged sample is shown for the case of damage site 1 (see Fig. 1) in Fig. 2.

When focusing the microscope below the surface of the sapphire, the value for the depth of the focal point below the surface is given by

where D is depth, n is the index of refraction (n = 1.77 for sapphire), and z is the vertical position of the microscope stage. The stage was zeroed while focused on the sample’s surface so a value of zero represents a measurement collected on the surface. The depth shown in Fig. 2 were calculated with Eq. (1).

Maps of the shift of the peak position of the R lines collected from damage site 1. Measurements were taken on and below the line shown in Fig. 1b at depths of 0 to 125 μm. (a) Map showing the shift in the R1 peak for different locations in the filament. (b) Map showing the shift in the R2 peak.

It is not possible to focus the microscope below the surface in damage sites with large amounts of surface damage, such as the one shown in Fig. 1c. Instead, measurements of the fluorescence spectra were collected in a grid along the surface. Lorentzian distributions were fitted to the R1 and R2 peaks, and maps of the location and width of the stronger R1 peak, for the damage site shown in Fig. 1c, are shown in Fig. 3. These measurements showed small shifts in the peak positions; however, there was significant broadening of the peaks. Previous studies on uniaxial or isotropic stress in single-crystal samples have seen little to no broadening of the peaks17,18,25.

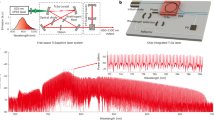

To investigate the underlying mechanism for broadening of the peaks, both Raman and fluorescence spectra were collected from different locations within this damage site. Figure 4 shows the Raman and fluorescence spectra collected from five specific locations (shown in Fig. 1c). For comparison, polarized Raman spectra from a single crystal block of sapphire (in various orientations) and from sapphire powder (grain size ~ 300 nm) were measured. Since the grain size of the powder is small compared to the spot size of the excitation source, the sapphire powder represents an average over all crystal orientations. These spectra are shown in Fig. 5.

(a) Raman spectra collected from each of the five locations shown in Fig. 1c and from the undamaged sapphire. (b) Fluorescence spectra collected from the same locations.

Discussion

In this section, analysis and interpretation of the R-line fluorescence measured in a subsurface filament type damage site (see Fig. 1a and b) will be presented. Subsequently, analysis of Raman and fluorescence spectra collected in a surface damage crater site (see Fig. 1c) will be presented.

Stress distribution in subsurface filaments

The simplest approach to correlate how the R1 and R2 peaks shift with pressure is given by the Eq.

where Δν is the shift in peak position, P is pressure \(\left[ { - {{\left( {{\sigma _{11}}+{\sigma _{22}}+{\sigma _{33}}} \right)} \mathord{\left/ {\vphantom {{\left( {{\sigma _{11}}+{\sigma _{22}}+{\sigma _{33}}} \right)} 3}} \right. \kern-0pt} 3}} \right],\) and Πp is the pressure coefficient. This equation gives a good estimate in most cases, but does not consider the effects of multiaxial stress states. A more-accurate estimate is given by16,17,18,19,24

where \(\sigma _{{ij}}^{ * }\) is the stress tensor, the superscript * indicates that the stress tensor is defined relative to the crystal coordinate system, and Πij is the crystal piezospectroscopic tensor. Values of i, j = 1, 2, and 3 for the indices correspond to the orthogonal a, m, and c crystal axes, respectively. The Einstein summation convention is implied in Eq. (3). For sapphire, the piezospectroscopic tensor is given by16,17,18,19,24

Using these values in Eq. (3) yields

Notice that when the stress is defined in the crystal coordinate system, the shift in peak position has no dependence on shear stress. Values for Πp, Πa, and Πc are given in Table 1.

Using Eq. (2) and the data presented in Fig. 2, a map of the pressure at different locations within the subsurface filament was created. The pressure map is shown in Fig. 6.

Map of pressure below the surface in damage site 1 (see Fig. 1). The map was created based on the location of the R2 peak because it is less affected by triaxial stress than the R1 peak.

On the other hand, to assess the effects of triaxial stress states, Eq. (4) can be rearranged to consider shifts in both peaks (R1 and R2). Thus, the stresses along different crystal directions is determined, leading to the Eq.

The superscripts (1) and (2) identify the values associated with the R1 and R2 peaks, respectively. These results allow us to determine the stress along the c axis and the average stress in the basal plane, as shown in Fig. 7.

(a) Map showing the average stress in the crystal basal plane for damage site 1 (see Fig. 1). (b) Stress in the direction of the crystalline c axis (oriented vertically here).

The results in Fig. 7 clearly show the stress distribution within and near the laser-damage filament. The residual stress along the c axis has 100 to 150 MPa of compressive stress in the center of the filament and does not vary much with depth. On the outer edge of the filament, there is less compressive stress with some areas of tension. The stress in the basal plane is compressive, with a magnitude of up to 200 MPa, and is localized to a few areas. Interestingly, the location with the highest stress in the basal plane has very little stress along the c axis. This is clearly a manifestation of the multiaxial stress state.

Raman spectra analysis

The characterization of surface damage craters, such as damage site 2 in Fig. 1, was performed by combining the information provided by the Raman spectra (see Fig. 4a) and the corresponding fluorescence spectra collected from this site (see Fig. 4b). Raman spectra were used to determine the crystalline microstructure which was subsequently used to guide interpretation of the fluorescence spectra.

The Raman spectra collected from the surface of this damage site can be recreated by superposing spectra collected from the undamaged sapphire window and the polycrystalline powder. This superposition closely matched the Raman spectrum of the damaged sapphire, thus suggesting that the damaged material consists in part of sapphire in the original crystal orientation and in part of a polycrystalline phase with a small grain size of random crystal orientations. The relative weight of each spectrum used to recreate the spectrum of the damaged sapphire was interpreted as the percent of the sampled volume still in the original form and in the polycrystalline form. An example of how this fitting was done for one location is shown in Fig. 8. The results from fitting the five locations measured are shown in Table 2.

It is reasonable to assume that the percentage of the material in polycrystalline form indicates damage severity (material modification) within the site, ranging from 21 to 71%.

Fluorescence peak broadening in surface craters

The R-line fluorescence spectra measured from damage sites with large damage craters exhibited very little shift of the fluorescence peaks; however, there was significant broadening of the peaks. Other studies have shown that under uniaxial or isotropic loading, there is a shift but no broadening of these peaks17,18,25.

Two possible mechanisms for the observed broadening were explored. The first hypothesis is that there is uniform stress across the sampled volume with various crystal orientations leading to a different amount of shift for each crystallite. The second hypothesis is simply that a large stress/pressure gradient/variability across the sampled volume causes the broadening. The results will be interpreted through each hypothesis separately, then the two explanations will be compared.

The first hypothesis is motivated by analysis in Ref.17 showing that under a uniform but anisotropic stress, a polycrystalline sample will exhibit peak broadening arising from a slightly different peak location for each of the crystallites. Figure 9 depicts this scenario. This hypothesis is supported by our analysis of the Raman spectra in Sect. 4.2, showing that the damaged material is polycrystalline with a grain size smaller than the spot size of the excitation source (used for the Raman and piezospectroscopy measurements).

This hypothesis relies on the fact that the sample does not show an equal shift with stress in all crystal directions. For the analysis, it is assumed that the stress in the lab coordinate system is in two dimensions since the measurements are taken on the surface and there is no stress applied normal to the surface. Under these conditions, the principal stress tensor will only have two components:

Converting the lab frame stress to the crystallographic coordinates stress state \(\sigma _{{ij}}^{ * },\) we get

where \(\:\theta\:\) and \(\:\phi\:\) represent the polar and azimuthal angles a crystallites c axis. The amount of shift for any crystal orientation is given by

The R-line fluorescence profile from any individual crystallite can be expressed as

Values for \(I_{0}^{{\left( 1 \right)}},\) \({\gamma ^{\left( 1 \right)}},\) \(\nu _{0}^{{\left( 1 \right)}},\) \(I_{0}^{{\left( 2 \right)}},\) \({\gamma ^{\left( 2 \right)}},\) and \(\nu _{0}^{{\left( 2 \right)}}\) were found by fitting two Lorentzian peaks to the undamaged spectrum. Integration of Eq. (11) through all possible crystal orientations yields the R-line spectral profile of the broadened peaks,

For simplicity, it is assumed that there are equal contributions from all crystal orientations. The best fit of Eq. (12) to our measured data allows estimates of the stresses σ11 and σ22. An example of the best fit found for one of the collected spectra is shown in Fig. 10a.

Table 3 shows the stress results for the five locations shown in Fig. 4. The stresses are tensile and compressive, and of order 5 to 10 GPa. It is clear that the equal and opposite orthogonal normal stresses are equivalent to shear stresses of the same magnitude, i.e., in the range 5 to 10 GPa. Such a shear stress is comparable to the yield shear stress of sapphire, estimated in the range of 3.1 to 8.2 GPa, as found from the correlation of Vickers hardness with yield stress in sapphire4. This view suggests that, following laser-damage, the sapphire surface has undergone extensive plastic (permanent) deformation.

The second hypothesis for peak broadening is that there is a stress/pressure gradient across the sampled volume. To estimate the pressure under this hypothesis, the data was fit with four peaks, where two peaks have the same position, width, and relative intensity as the undamaged sample spectrum (i.e., these two peaks correspond to no pressure). The other two have the same width and relative intensity as the undamaged peaks, but the positions were allowed to shift according to Eq. (2), thus accounting for the presence of pressure. Of course, the damaged area would consist of material under a range of different pressures rather than only two discrete values. However, this approach should give a good estimate by capturing the variation from zero to some pressure. Values of the pressure for the shifted peaks are shown in Table 3, and an example of the best fit found for one of the spectra is shown in Fig. 10b.

The first hypothesis to interpret the broadening of the fluorescence peaks is that the broadening occurs due to different crystal orientations existing within the sampled volume (~ 2 µm in diameter), with each orientation having a different shift. The second hypothesis is that there is a pressure gradient across the sampled volume, causing the shift. The broadening can be explained through hypothesis 1 with orthogonal normal stresses of equal magnitude and opposite sign of the order of 5 to 10 GPa. Alternatively, the broadening could be explained through hypothesis 2 by large pressure gradients in the sampled volume with pressures between 0 and 1.5 GPa in the sampled locations. Each explanation is plausible, and the true nature of the broadening is likely a combination of both reasons.

Conclusions

This work demonstrates that Raman spectroscopy and piezospectroscopy are valuable tools for studying modifications in sapphire arising from its exposure to extreme conditions, namely to laser induced damage for this specific study. Piezospectroscopy effectively measures residual stress, while Raman spectroscopy determines the crystalline nature of the damaged material. It is shown how these techniques can be applied to two example damage sites with distinct damage morphologies.

The first class of damage sites consisted of a subsurface filament and very little damage on the surface. For these damage sites, piezospectroscopy was used to measure residual stress within the subsurface filament. Through consideration of the R1 and R2 sapphire fluorescence peaks, the stress along the c axis and the average stress in the basal plane were resolved. Stresses were observed in the range of − 220 to 93 MPa.

The second class of damage sites consisted of a large crater and a subsurface filament. The large amount of surface damage (surface scattering) precluded measurement of subsurface properties. Surface measurements from the crater revealed broadening of the fluorescence peaks. These peaks can be broadened by two mechanisms: from polycrystalline material under anisotropic stress or by large pressure gradients within the damage site. It was determined that the broadening of peaks was likely a combination of these two effects and that the residual stresses in the crater are on the scale of GPa and comparable to the yield stress in shear for sapphire.

Measurements of Raman spectroscopy were also collected from the second class of damage sites where the relative intensities of Raman peaks were used to determine the polycrystalline modification of the affected material; the material in the crater was between 21% and 71% polycrystalline. The transition from single crystal prior to laser pulse exposure to polycrystalline post-exposure indicates that the material underwent significant plastic deformation.

These findings highlight the effectiveness of piezospectroscopy and Raman spectroscopy in characterizing laser-damage in sapphire. Future work could use these techniques to explore how different laser parameters influence the material transformation.

Data availability

The data in support of the findings of this study will be made available upon reasonable request from the corresponding author.

References

Harris, D. C. Materials for Infrared Windows and Domes: Properties and Performance Vol. 158 (SPIE Optical Engineering, 1999).

Dobrovinskaya, E. R., Lytvynov, L. A. & Pishchik, V. Sapphire: Material, Manufacturing, Applications (Springer Science & Business Media, 2009).

Niu, X. et al. Polarization influence on femtosecond laser-induced surface damage and electron plasma ultrafast dynamics in Sapphire. J. Appl. Phys. 137, 183102 (2025).

Fang, T. Near-surface mechanical properties of optical materials in deterministic microgrinding. PhD thesis, (University of Rochester, 1997).

Qi, L., Nishii, K., Yasui, M., Aoki, H. & Namba, Y. Femtosecond laser ablation of sapphire on different crystallographic facet planes by single and multiple laser pulses irradiation. Opt. Lasers Eng. 48, 1000–1007 (2010).

Wen, Q., Zhang, P., Cheng, G., Jiang, F. & Lu, X. Crystalline orientation effects on material removal of sapphire by femtosecond laser irradiation. Ceram. Int. 45, 23501–23508 (2019).

Uteza, O. et al. Laser-induced damage threshold of sapphire in nanosecond, picosecond and femtosecond regimes. Appl. Surf. Sci. 254, 799–803 (2007).

Bussière, B., Sanner, N., Sentis, M. & Utéza, O. Importance of surface topography on pulsed laser-induced damage threshold of sapphire crystals. Sci. Rep. 7, 1249 (2017).

Gerhard, C., Tasche, D., Munser, N. & Dyck, H. Increase in nanosecond laser-induced damage threshold of sapphire windows by means of direct dielectric barrier discharge plasma treatment. Opt. Lett. 42, 49–52 (2017).

Bussière, B. et al. Bulk laser-induced damage threshold of titanium-doped sapphire crystals. Appl. Opt. 51, 7826–7833 (2012).

Munisso, M. C., Zhu, W. & Pezzotti, G. Raman tensor analysis of sapphire single crystal and its application to define crystallographic orientation in polycrystalline alumina. Phys. Status Solidi B. 246, 1893–1900 (2009).

Mao, H. K., Xu, J. & Bell, P. M. Calibration of the ruby pressure gauge to 800 Kbar under quasi-hydrostatic conditions. J. Geophys. Res. Solid Earth. 91, 4673–4676 (1986).

Silvera, I. F., Chijioke, A. D., Nellis, W. J., Soldatov, A. & Tempere, J. Calibration of the ruby pressure scale to 150 GPa. Phys. Status Solidi (B). 244, 460–467 (2007).

Goncharov, A. F., Zaug, J. M., Crowhurst, J. C. & Gregoryanz, E. Optical calibration of pressure sensors for high pressures and temperatures. J. Appl. Phys. 97, 094917 (2005).

Dewaele, A., Torrent, M., Loubeyre, P. & Mezouar, M. Compression curves of transition metals in the Mbar range: experiments and projector augmented-wave calculations. Phys. Rev. B. 78, 104102 (2008).

Grabner, L. Spectroscopic technique for the measurement of residual stress in sintered Al2O3. J. Appl. Phys. 49, 580–583 (1978).

Ma, Q. & Clarke, D. R. Stress measurement in single-crystal and polycrystalline ceramics using their optical fluorescence. J. Am. Ceram. Soc. 76, 1433–1440 (1993).

He, J. & Clarke, D. R. Determination of the piezospectroscopic coefficients for chromium-doped Sapphire. J. Am. Ceram. Soc. 78, 1347–1353 (1995).

Cook, R. & Michaels, C. Review: Coefficients for stress, temperature, and composition effects in fluorescence measurements of alumina. J. Res. Natl. Inst. Stand. Technol. 122 (2017).

Qi, N. et al. Microscopic three-dimensional inner stress measurement on laser induced damage. Opt. Express. 28, 24253–24261 (2020).

Dahmani, F., Schmid, A. W., Lambropoulos, J. C. & Burns, S. Dependence of birefringence and residual stress near laser-induced cracks in fused silica on laser fluence and on laser-pulse number. Appl. Opt. 37, 7772–7784 (1998).

Salleo, A. et al. Laser-driven formation of a high-pressure phase in amorphous silica. Nat. Mater. 2, 796–800 (2003).

Li, C. H. et al. Structural modification in amorphous silica after exposure to low fluence 355 Nm laser irradiation. Nucl. Instrum. Methods Phys. Res. B. 269, 544–549 (2011).

Cook, R. F. & Michaels, C. A. Stress measurements in alumina by optical fluorescence: revisited. J. Res. Natl. Inst. Stand. Technol. 124, 124020 (2019).

Chai, M. & Brown, J. M. Effects of static non-hydrostatic stress on the R lines of ruby single crystals. Geophys. Res. Lett. 23, 3539–3542 (1996).

Acknowledgements

This material is based upon work supported by the Department of Energy [National Nuclear Security Administration] University of Rochester “National Inertial Confinement Fusion Program” under Award Number DE-NA0004144.

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Contributions

R.M. collected and analyzed fluorescence and Raman measurements and drafted the manuscript. B.H. performed the laser damaging of material and provided support with various material characterization tools. S.D. contributed to the design of the experimental study, the analysis of Raman and fluorescence measurements and provided significant contributions to editing of the manuscript. J.L. contributed to the analysis of fluorescence measurements and to the writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

McBride, R.P., Hoffman, B.N., Demos, S.G. et al. Three-dimensional characterization of modifications in sapphire exposed to laser-induced damage using multimodal spectral microimaging. Sci Rep 15, 31015 (2025). https://doi.org/10.1038/s41598-025-16629-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-16629-7