Abstract

In order to further study the dynamic response of granular systems under impact loading, this paper establishes an SHPB test model of metal powder based on the discrete element method (DEM) of particles using PFC3D software. The High Velocity Compaction (HVC) process is simulated by numerical simulation. The distribution and change rules of particle movement are observed from different angles; the change rules of particle normal velocities at different positions in the particle sample are analyzed; the formation process of force chains under impact is observed; and the change rules of contact forces between particles at different positions are analyzed. From the motion law of the particles, the loading end of the specimen (right side) first obtains a larger initial velocity in the initial stage of loading. From the stress wave propagation analysis, there is a significant stress shear band in the compaction process. From the normal velocity analysis of particles at different locations, the disturbance along the loading direction decays layer by layer, and the decay speed in the outer region near the mold wall is higher than that in the center region. From the formation of inter-particle force chains, the incident wave can form a precursor wave, as the particles are under the action of impact load. Through the change process of the contact force of the particles, the particles will have many impacts during impact loading, and the vibration amplitude will decrease with time. This study highlights the novelty of employing a fully coupled three-dimensional DEM–SHPB modeling framework, which provides a more detailed meso-scale understanding of particle dynamics and improves upon previous approaches to high-velocity powder compaction.

Similar content being viewed by others

Introduction

The High Velocity Compaction (HVC) process has high production efficiency and low preparation cost. The obtained green compacts have high and uniform density, and they can be combined with other processes to produce various parts. It is currently widely used in the preparation of parts in various fields such as the automobile, aerospace and medical equipment. With the continuous development of various industries, higher and more precise requirements are being placed on the properties of powder metallurgy products. However, pore defects, metallographic defects, and cracks all affect the performance of powder metallurgy products, and make their applications somewhat limited. In order to further broaden the application range of powder metallurgy products, it is particularly important to conduct an in-depth study on the mechanism of the HVC process.

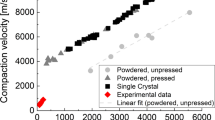

The current research on HCV of metal powders mainly focuses on two scales: macro and meso. The macro-scale is based on the theory, simulation, and experimental analysis of continuum mechanics of elastic-plastic materials, while the particles of the powder are in a discrete state, so the continuum mechanics at the macro-scale cannot fully reveal the dynamic response process of powder forming. Traditional experimental research is difficult to intuitively demonstrate the density distribution of green compacts and their uniformity. Meanwhile, due to the instantaneous characteristics of the HVC process, traditional experimental research cannot dynamically study the densification process of powders in real time, especially at the mesoscale. Therefore, numerical simulation technology based on discontinuous mechanical behavior is a more suitable research method at the mesoscale. Yang1 et al. established a two-dimensional discrete element model of the uniaxial compaction process of metal powders, and analyzed the flow state of particles, the distribution of force chains, and the effects of model parameters such as friction coefficient particle size on the distribution of force chains. Xia2 established a two-dimensional discrete element model for the HVC process of iron-based powders and the results showed that the DEM could accurately simulate the powder flow process, while friction was an important factor affecting the HVC process. Wei et al.3 established a two-dimensional discrete element model of metal powders, and studied the effects of impact velocity, initial porosity, and friction coefficient on the stress wave propagation velocity. Yong et al.4 established a three-dimensional discrete element model of conical parts, and studied the relative density of compacts at different angles under impact loads. Lu et al.5 used the PFC3D numerical simulation software to establish each group’s cold pressing model by changing the powder size distribution, obtaining the relative density change and force chain distribution during the pressing process. Shun et al.6 derived the viscoelastic constitutive equation of HVC by using the DEM, and simulated the two-dimensional plane unit flow characteristics of particles and the density distribution of green compacts in the HVC process by PFC2D. They obtained the waveform of stress propagation inside the compact and analyzed the effects of the friction coefficient, bidirectional pressing, and height-to-diameter on the density distribution of the compact based on the simulation results. Ping et al.7 used PFC2D software to investigate the effects of friction, collision speed, and shear modulus force transmission during collision process, and studied the movement patterns of particles during the HVC process. The study found that during pressing, particles can vibrate and rotate within a small area around their original position. Wei et al.8 simulated the HVC process using the DEM with PFC2D software, studying changes in stress magnitude and directionality and the relationship between stress transmission and force chains. Dong and Li9,10 simulated the dynamic response of aluminum powder particles under the HVC process based on the discrete element.

The forming equipment for the HVC process is diverse, including hydraulic energy storage equipment, gravity energy storage equipment, mechanical energy storage equipment, and gas pressure energy storage equipment, etc. The representative of pneumatic energy storage devices is the split Hopkinson pressure bar device, which was proposed by J. Hopkinson in 187. Its principle is to instantly release the high-pressure gas inside the high-pressure gas chamber to drive the projectile inside the gun barrel, which then collides with the upper die and drives the upper die to press the powder. Its advantages are that the impact speed can reach dozens of meters per second, the construction cost is low, it is clean and pollution-free, and it can obtain the input and output waveform of dynamic load. Zhou11 established a concrete the split Hopkinson pressure bar test model based on the DEM to analyze the microscopic dynamic mechanical properties of concrete under loading. Zhang et al.12 established a three-dimensional model of HVC of powders using the DEM, and the simulated results were compared with the transmitted wave forms measured by the split Hopkinson pressure bar experiments, analyzing the propagation of particle disturbance in three-dimensional cases. Luo et al.13 used the DEM to establish a 3D model of aluminum powder and compared it with the results of the split Hopkinson pressure bar experiments for verification, analyzing the particle motion.

In summary, the DEM is reliable for studying the HVC process of powders at the mesoscale. However, current research mainly focuses on two-dimensional circular particles, with less attention on three-dimensional spherical particles and a limited number of particles, which does not match reality. Split Hop pressure bar experiments can provide key parameters such as incident and transmitted waves that reflect the dynamic loading process. However, current models for the HVC process of iron-based powders do not fully correspond to the split Hopkinson pressure bar experiments, and mesoscale studies often focus on changes in the velocity of particles and one-dimensional stress wave theory in groups. In actual pressing, three-dimensional conditions are much more complex than two-dimensional models, especially regarding the voids in the particle coordination system. Therefore, this paper establishes a three-dimensional particle model for the HVC process that is completely consistent with the split Hopkinson pressure bar experiments using the PFC3D software based on the discrete element principle. The simulation results are compared with the experimental results, and the model is used to simulate the single-impact loading process of iron-based powders, with dynamic analysis of the particle movement and force conditions.

Modeling theory and methods

Numerical simulation object

The Hopkinson bar device, as shown in Fig. 1, was composed of the striker bar, incident bar, and transmission bar as the main components, and was referred to as the Split Hopkinson Pressure Bar device, abbreviated as SHPB. The Fig. 1 legend was shown in Table 1. Its principle was to generate a compressive stress wave by contacting the striker bar with the incident bar at a certain speed. The stress wave propagated on the incident and transmission bars, completing the dynamic impact compaction loading and unloading of the compacted material. The kinetic energy of the striker bar was continuously dissipated through the stress wave until it was dissipated14.

The material of the striker bar, incident bar, transmitted bar, and energy absorption bar of the SHPB simulated in this paper was 18Ni high-strength steel with a yield strength of 2 GPa. The relevant parameters of the material are shown in Table 2.

The modeling theory and method based on DEM

Basic principles and processes

The basic idea of DEM was that the powder body was regarded as composed of independent moving discontinuous particle units with independent geometric and physical properties, assuming that the particles were rigid or elastoplastic. The powder body research object was divided into a finite number of independent units, whose motion rules followed Newton’s second law. Iterative methods such as the static relaxation method or dynamic relaxation method were used for cyclic iterative calculation to determine the forces and displacements between all particle units under each time step, and update the positions of all units. The motion law of the whole object and the simulated image were obtained by calculating the motion law of the individual particle unit. PFC3D software was commonly used in numerical simulation based on the DEM. The particles were assumed to be rigid, but overlap was allowed in the mechanical relations to simulate the contact forces between the particles. In the calculation of PFC, it was not necessary to define the macroscopic constitutive relationship and corresponding parameters for the material, these traditional mechanical properties and parameters were automatically obtained through the program, and they were defined by the geometric and mechanical parameters of the particles, such as particle size, stiffness, friction, strength of the bonding medium and other micro-mechanical parameters. In the initial state, the powder particles had many pores of various sizes due to their discrete characteristics, and the particle distribution was uneven, and the initial force was uneven due to the uneven surface of the particles. The force disturbance between the particles was transmitted by the force chain, so the force difference between the particles at different positions would be very large, which was also one of the important reasons why ordinary pressing technology could not obtain high-quality relative density and density uniformity compact. In this paper, PFC3D was used to establish a powder model of the HVC process. The particle generation mode selected in the numerical simulation was distributed. Different forces and confining pressures applied to particles were applied to each other. The initial accumulation of particles was closer to the initial accumulation state of powder in actual production and experiment, and the algorithm flow of generating random accumulation particles is shown in Fig. 2.

Contact model between particles

In numerical simulation, the idea of using a soft ball model to simulate the contact process of particulate matter was first proposed by Cundall and Strack in 197914. After years of development, it has become the main numerical simulation method for the study of discrete particulate matter. In this study, the parallel constrained linear equation in PFC3D software was an improved soft ball contact model, which could transmit force and torque and simulate the rotation phenomenon when particles interacted with each other. Figure 3 illustrates the simplified form of this model. It set springs with constant normal and tangential stiffness evenly on the circular contact surface between the two balls, and concentrated the stress on the contact point to simulate the force of particles when they contacted.

In this model, the normal force was represented by a spring-dashpot system, whereas the tangential force was modeled by a spring-dashpot-slider system. The corresponding stiffness and damping parameters were determined based on Hertzian contact theory, as expressed below:

where E* is the equivalent elastic modulus, R* is the equivalent radius of curvature, xr is the reference gap, and ν is Poisson’s ratio. The damping coefficients were computed as:

where m represents the particle mass.

All contact-model parameters, including stiffness (Kn, Kt) and damping coefficients (βn, βt), were calibrated based on theoretical derivations and experimental findings from16. These values are appropriate for iron-based powders with particle sizes of 0.25–0.45 mm and an elastic modulus of approximately 200 GPa, conditions representative of the material investigated in this study. The specific parameters used are summarized in Table 3.

In the simplified model, the normal force was simplified into a spring and a damper, the tangential force was simplified into a spring, damper and slider, and the elastic coefficient and damping coefficient were introduced. xr was the reference gap. When the reference gap xr was larger than the actual gap between particles, particle collisions happened. kn was the normal stiffness, kt was the tangential stiffness, βn was the normal damping coefficient, βt was the tangential damping coefficient, and µ was the friction coefficient.

According to the linear parallel constraint equation, the force Fz on the application point between two elements could be decomposed into linear force F and parallel constraint force \(\:\overline{F}\), and the torque Mz could be completely represented by parallel constraint torque \(\:\overline{M}\)17, the equation for the problem was given by

The linear force F could be decomposed into normal force \(\:{F}_{n}\) and tangential force \(\:{F}_{t}\). It could be expressed as

As could be seen from Fig. 3, both normal and tangential forces were composed of linear springs and damping elements.

The equation for the normal force was given by

where \(\:{\dot{U}}_{n}\) was the normal component of the relative velocity of the particles; \(\:{F}_{n}^{l}\) was the normal spring force between the particles; \(\:\:{F}_{n}^{d}\) was the normal damping force between the particles; \(\:{m}_{c}\) was the effective inertial mass, which was determined by the mass \(\:{m}_{a}\) and \(\:{m}_{b}\) of the two particles colliding with each other, as described by the Eq.

The tangential force needed to determine whether the particle has slippage, so the following reference force formula should be introduced

where \(\:\:{{(F}_{t}^{l})}_{0}\)was the tangential force provided by a linear spring; \(\:\varDelta\:{U}_{\varvec{t}}\) was the tangential relative displacement between particles; \(\:{F}_{t}^{*}\) was the reference force.

When the maximum static friction force \(\:{F}_{t}^{\mu\:}\) between particles was equal to \(\:{\mu\:F}_{t}^{l}\), it was greater than the reference force \(\:{F}_{t}^{*}\), the particles did not slip. In this case, the tangential force was expressed as

where \(\:{\dot{U}}_{t}\) was the tangential component of particle relative velocity.

When the relative slippage occurred, the tangential force was expressed as

So the linear force at the point of operation between two particles could be expressed as

In the same way, the parallel constraint force \(\:\overline{F}\) could also be decomposed into the normal force \(\:{\overline{F}}_{n}\) and tangential force \(\:{\overline{F}}_{t}\). The parallel constraint moment \(\:\overline{M}\) could also be decomposed into bending moment \(\:{\overline{M}}_{w}\) and torque \(\:{\overline{M}}_{n}\), the equation was as follows

where \(\:{\overline{k}}_{n}\), \(\:{\overline{k}}_{t}\) were the normal and tangential stiffness coefficients in parallel constraints, respectively; \(\:\varDelta\:{U}_{n}\), \(\:\varDelta\:{U}_{t}\) were the normal and tangential relative displacements of particles; A was the circular area of the cross section of the overlapping part between particles; R was the radius of the cross section circle; ∆θn, ∆θw were the relative angles of torsion and bending.

The equation of motion

DEM took each individual particle as the research object, used the method of spatial grid division to search and determine the location of each particle, and stored and recorded all the particle history information. The motion state of particles was completely calculated according to Newton’s second law17, and its linear motion equation and rotation equation were expressed as follows3

where mp was the mass of the unit particle; vi was the linear velocity of the unit particle; g was the acceleration of gravity; fi was the I-th contact force vector of the particle (i = 1, 2, 3,…, N); \(\:{w}_{i}\) was the angular velocity of the unit particle; \(\:{I}_{i}\) was the inertia of the unit particle rotation; \(\:{r}_{i}\) was the vector of the unit particle’s center of mass pointing to the contact point.

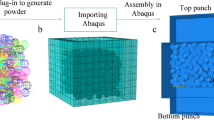

DEM modeling

Based on the above discrete element analysis and computation theory, the HVC process of iron-based powder was simulated using the discrete element software PFC3D 6.0. The actual particles were not ideal spherical shapes, but for the convenience of computation, they were assumed to be spherical particles in the study. Meanwhile in order to facilitate the setting and calculation of model size parameters: 9288 spherical particles with a radius of 0.25–0.45 mm were generated in a cylinder with a diameter of 16 mm and a height of 12.96 mm, as shown in Fig. 4, and the particle size was evenly distributed within the range (0.25–0.45 mm). Before loading, a servo motor was used to apply a confining pressure and pre-pressure of 10 kPa to deposit powder particles. When the kinetic energy of each particle in the system was close to zero, the pressure was stopped, forming an initial powder accumulation with an initial porosity 0.32. A single-cycle sinusoidal wave was applied to the incident bar with an amplitude of 5 m/s and a frequency of 20 kHz. The loading duration of 50 µs corresponds exactly to one full sine cycle, ensuring that the loading represents a single-cycle impact rather than continuous multi-cycle excitation. The total simulation time was 0.4 ms. The contact was linear contact. The friction coefficient of iron-based powder in its loose state was between 0.2 and 0.5, there was no fixed value, this manuscript takes 0.5 as the research parameter. The material was iron-based powder. And the elastic modulus of industrial pure iron was between 190 GPa and 210 GPa, and this paper chose 200 GPa, the specific were shown in Table 4. Based on the research and results presented in Ref.16, this paper also selected the same stiffness coefficient to carry out the simulation and modeling.

Model verification

Figure 5 showed the incident, reflection, and transmission waveforms recorded during the HVC simulation of iron-based powder. This figure is basically consistent with the waveform trend diagram collected in the SHPB test (Fig. 6), which indicates that the simulation model was reliable. From Fig. 5, it can be seen that the transmission wave curve rose in a sawtooth pattern during the loading process. This was because powder particles were arranged in a discrete manner with gaps between them. Under the action of high-speed impact loads, the particles transmit disturbances through high-frequency collisions, so the transmission wave exhibits a vibration phenomenon.

Analysis of stress wave propagation characteristics

From Fig. 5, it can be seen that the displacement and deformation of the sample under large stress waves occurred after the incident wave had been transmitted. Therefore, the paper observed the transmission characteristics of stress waves between particles after 0.2 ms (corresponding to 16000 time steps). Figures 7, 8, 9 and 10 showed the fluctuation distribution of the axial cross-section of iron-based powder particles at different time steps. At the beginning of loading, the right particles were first subjected to an impact force and generated a velocity. At the same time, due to the initial stage of compaction, the pores between particles were relatively large, which could affect the propagation of impact disturbances. Therefore, only particles located at the right of the billet would gain higher velocity due to the impact load as shown in Fig. 7. At this point, it could be observed that the velocity of the peripheral particles was significantly higher than that of the particles in the center of the billet. At the same time, the velocity of the particles presented an approximately symmetrical state with the center of the billet as the axis of symmetry, showing a clear “I” shaped shear band. As shown in Fig. 8, with the progress of compaction, the shape of the shear band changed from a “one” shape to an irregular sawtooth shape. As shown in Figs. 9 and 10, after step 19,000, as the pressing continues, the overall particle velocity of the steel billet gradually increases, and the right particle velocity also relatively decreases. The velocity distribution in the steel billet was also more uniform, with the number of particles gradually decreasing in the low-speed zone, while the low-speed zone gradually shrank towards the bottom.

Due to the higher particle velocities at this early stage, a wider velocity scale (0–20 m/s) is applied for clarity. The contour illustrates the spatial distribution of particle motion during the high-velocity compaction process.

As with Fig. 7, a wider velocity scale (0–20 m/s) is used to capture the high-velocity range observed in this stage. The contours represent particle motion patterns within the powder column during compaction.

A unified velocity scale (0–3 m/s) is applied for this and Fig. 10, reflecting the reduced particle velocities during the later stages of compaction. The contour highlights localized particle motion and shear band development.

Using the same velocity scale as Figure 9 (0–3 m/s), this contour illustrates particle rearrangement and the concentration of motion within the shear bands as compaction nears completion.

The shear band would destroy the uniformity of the green body and promote local densification. When the shear band forms, the particles within the would produce relative sliding and rotation along the shear direction, resulting in a different arrangement of particles in this region from other regions. This would cause the density within the shear to be different from that of the surrounding regions, and as the shear band evolves, if its development was uneven or excessive, it would destroy the uniformity of the density, resulting in different densities in different parts of the green body. However, during the evolution of the shear band, the interaction between particles was enhanced, and some might be squeezed more closely, forming a region of higher density locally. At the same time, the shear band was prone to cracks nearby, which provided the stress conditions the expansion of cracks.

Because the initial accumulation of powder particles was unevenly distributed and randomly interlaced, at the beginning of pressing, the right of the green compact and the surface of the loading plate were subjected to force first, resulting in an uneven overall force on the powder, forming a more obvious transmission shear band. However, due to the self-organizing properties of the powder, the particles subjected to disturbance had better fluidity, so the phenomenon of force distribution gradually improved during the pressing process.

Analysis of particle velocities and contact forces at different locations

Analysis of the velocity of particles in the loading direction

Since the model was an axisymmetric figure, nine evenly distributed points were selected on one side of the green body model for observation and analysis, as in Fig. 11. The particle positions were encoded as 1, 2, 3, 4, 5, 6, 7, 8, and 9, respectively.

Figure 9 showed the velocity-time curves of the particles in the loading direction. It could be seen from the figure that the impact collision occurred around 0.2 ms. In the early stage of impact, the initial compaction of the particles had a large number of pores and was arranged in a staggered manner, the particles 7, 8, and 9 on the far right of the green body would gain a very high velocity at the moment of impact, the velocities were different, so there was a relatively large vibration at 0.2 ms. It could also be seen from Figs. 11 and 12 that the wave forms of the particles at the far right (balls 7, 8, and 9) were similar to sine waves. As the disturbance was downward, the energy gradually attenuated, and the wave surface also changed gradually. At the same time, we could also see that the particle velocity near the mold was higher. This would lead to uneven density of the green. From the mesoscale, there were two reasons, one was the difference in particle stacking. The faster particles would collide and fill with higher momentum near the mold, making the particle stacking near the mold wall more compact, while the particle velocity in the central area of the mold was relatively slow, and the stacking density might be, resulting in different densities in different parts of the green body. The other was the different pore distribution. The particles near the mold wall moved at high speed, which better discharge the air in the pores, and the porosity was low; while the particles in the internal area moved at a slower speed, and the air was difficult completely discharge, resulting in a relatively high porosity, which led to the overall uneven pore distribution of the product.

Analysis of the velocity of particles in the direction perpendicular to the loading direction

Comparison analysis of particle velocities perpendicular to the loading direction was conducted by observing the differences in particle velocities from the center to the edge of the sample in the same height. Particles in the first column, the second column, and the third column were compared and analyzed, respectively. As shown in Fig. 13, the three colors in each column from bottom to top (from the center to the edge) were black, red, and blue, respectively.

As could be seen from Fig. 13, the graphs of all particles were similar to sine waves, and at the same time, the velocities in the three figures showed a trend of decreasing from the center to the edge, which indicated that the particles inside the sample could obtain higher impact velocities, and particle velocities at the edge of the sample would decrease due to the friction force of the die wall.

The particles (ball 1/2/3) at the far left of the sample had the highest vibration frequency and the smallest amplitude. The waveform the particles (ball 4/5/6) in the middle of the sample was closest to a sine wave. The particles (ball 7/8/9) near the impact load had the lowest vibration frequency and the largest amplitude. This was due to the discretization of powder particles, the interlocking arrangement, the voids and the self-organizing nature of the particles. The attenuation of the particle velocity curve of ball 1/2/3 was less than that of ball 4/5/6, further indicating that the particles in the lower part of the sample had less space to move, so they tended to move more perpendicular to the load direction. This weakened the friction between the mold wall and the particles to a certain extent, thus reducing energy loss.

Formation of force chains under impact loading conditions

The force chain was a network-like structure formed by the contact between particles under the action of their own gravity or external load. Under natural conditions, the force chain would be evenly distributed in the particle system. Strong chains played a major supporting role, which was small in number but could carry most of the external loads in the particle system. The short force chain was a large number of network force chains around the strong connection, and its number was huge, but the force strength was small, which played the role of supporting the strong chain. In the process of the formation of the force chain, the force chain network would produce a series of changes such as strengthening, growth, fracture, and reconstruction, which led to many strange phenomena, including the fact that the particle matter was different from the continuous matter.

In order to study the formation law of the force chain of metal powder under impact load, the structural information of the particle force chain at the same time as Fig. 7 was selected for observation and analysis. Figures 14, 15, 16 and 17 showed the macroscopic cloud diagram of the formation process of the force chain network of metal powder particles under impact loading, in which green represented the strong chain and blue represented the weak force chain. It could be seen from the figure that under the impact loading, the incident stress applied to the particles first formed a precursor wave, which transmitted momentum to the particles. The particles vibrate and form a large number of weak force chains. At the same time, with the transmission of the incident wave, a strong chain was first formed at the rightmost end of the sample (loading position), as shown in Fig. 14. With the progress of pressing, the strong chain was increased, while the weak chain was reduced, and the contact between the particles at the right end was closer, as shown in Fig. 15. Then the strong chain kept growing to the left, and there were a lot of weak chains around the strong chain, as shown in Figs. 16 and 17. With the disappearance of the shock wave, the force chain was reduced, and the distribution of the force chain is more uniform.

Analysis of the force on particles perpendicular to the loading direction

Figure 18 shows the comparison of the contact forces on the left, middle and right particles perpendicular to the loading direction during the impact loading process. The colors of the three particle curves in each column were black, red and blue. As can be seen from the figure, each particle had multiple collisions. At the beginning of loading, particles (ball 7/8/9) of the right side (red curve) had a maximum force of about 18 N, and particles (ball 1/2/3) in contact with the mold (black curve) had the least force of about 4 N. The particles (ball 4/5/6) in the middle of the compact had the same force trend as other particles, but the peak force was relatively small. At present, the theory of powder HVC process was that the first stage of powder forming was the dense stage of particle rearrangement and void filling. The second stage was mainly the deformation stage of elastic-plastic deformation of particles. As can be seen from Fig. 18, in the early loading stage, particles were displaced after being impacted, resulting in multiple collisions, so the particle stress curve fluctuated greatly. After entering the deformation stage, the force of all particles was basically the same and the vibration frequency was similar.

As shown in Fig. 18, the particle force decay at the bottom of the green body was less, which indicated that the bottom region was relatively well stressed during the compaction process. Therefore, within the scope and assumptions of this paper, without considering heat transfer, simply extending the compaction time allowed these to have more time to interact and rearrange. Over a longer period of time, the particles could further fill the pores under the continuous action of force, reduce the stress, and thus improve the densification degree of this region and the overall.

Conclusions

Based on particle-scale DEM, an SHPB test model of iron-based powder was developed using PFC3D software, and the dynamic compaction process was simulated. The mechanical response of the particle system was analyzed from the perspectives of particle motion, velocity attenuation, force chain formation, and inter-particle contact forces.

The results show that particle motion near the loading end dominates the initial compaction response, with stress wave propagation inducing localized shear banding and layer-by-layer velocity attenuation from the mold wall toward the sample center. The evolution of force chains, transitioning from weak precursors to stable strong chains, governs momentum transfer and particle rearrangement. High-frequency inter-particle collisions contribute to particle hardening, enhancing densification by promoting particle rearrangement and gap filling.

The coupled 3D DEM–SHPB modeling framework developed in this study offers a powerful tool for analyzing meso-scale powder compaction mechanisms and can support the optimization of dynamic powder metallurgy processes in future applications.

Data availability

All data generated or analysed during this study are included in this published article.

References

Xu, Z. Y. & Meng, F. J. Investigation of the flow and force chain characteristics of metal powder in high–velocity compaction based on a DEM. J. Korean Phys. Soc. 1, 1976–8524 (2021).

Yang, X. Experimental and modelling on influence of process parameters in powder HVC. Australian J. Mech. Eng. 1, 1233618 (2016).

Zhang, W. et al. Characteristic analysis of the stress propagation of metal powder in high velocity compaction using DEM. J. Phys. Soc. Jpn. 89, 044602 (2020).

Li, H. Y. et al. Relative density of conical parts under impact loading based on discrete element. Powder Metall. Technol. 41, 322–329 (2023).

Wang, H. L. et al. Compacting relative density and force chain analysis of powders with different particle size ratios based on discrete element. Powder Metall. Technol. Vol. 39, 490–498 (2021).

Zheng, Z. S., Xu, D. & Lei, X. Y. Numerical simulation and influential factors analysis of density distribution in high velocity compaction. J. Mater. Eng. 7, 10–14 (2012).

Hu, X. P. & Liu, J. Ma. Research on the influential factors of contact force between metal particles based on the DEM. Mach. Des. Res. 31 (5), 101 (2015).

Zhang, W. Multi-scale Mechanics and Mechanism of Densification in High Velocity Compaction of Metal Powder (Hefei University of Technology, 2019).

Liu, L. D. J. et al. High velocity compaction simulation and dynamic mechanical analysis of particles based on DEM. Powder Metall. Technol. 05, 1 (2020).

Li, L. Research on High Velocity Compaction Mechanism and Numerical Simulation of Iron Based Powder (Xi’an Technological University, 2021).

Zhou, X. et al. Multi-scale modeling of the concrete SHPB test based on DEM-FDM coupling method. Constr. Build. Mater. 1, 1 (2022).

Zhang, L. D. et al. High velocity compaction simulation and dynamic mechanical analysis of particles based on DEM. Powder Metall. Technol. 38, 350–357 (2020).

Luo, X. L. et al. 3D numerical simulation of aluminum powders under impact loading based on DEM. China Mech. Eng. 29, 2515–2519 (2018).

Si, B. W. Characterization Study for Dynamic Indentation Testing of Metals Based on a Split Hopkinson Pressure Bar System (Taiyuan University of Technology, 2023).

Cundall, P. A. & Strack, O. D. L. A discrete numerical model for granular assemblies. Geotechnique 29 (1), 47–65 (1979).

Luo, X. L. Study on Dynamic Mechanical Response of Metal Powder Under Impact Loading Condition Based on 3DDEM(Ningbo University, 2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52275508).

Author information

Authors and Affiliations

Contributions

M.L(Miao Liu): Conceptualization (lead); Methodology(lead); Software (lead); Writing-original draft (lead). Y.C.(Yan Cao): Funding acquisition (lead); Supervision (lead). C.R.N(Chaorui Nie): Writing – review & editing (supporting)W.C.(Wen Cheng) checked the language.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, M., Cao, Y., Nie, C. et al. Research on the high velocity compaction process of iron-based powder based on the DEM. Sci Rep 15, 31557 (2025). https://doi.org/10.1038/s41598-025-16691-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-16691-1