Abstract

Fully mechanized top-coal caving inevitably results in a certain thickness of retained coal above the roadway, which compromises roof stability and increases the difficulty of roof management. This study presents a dynamic disaster phenomenon in the Binchang mining area of China, where high-energy seismic events (HESEs) induced roof collapse in roadways with retained top coal. Disaster characteristic analysis indicates that in high-stress zones, the support system in roadways with retained top coal gradually deteriorates under mining-induced stress loading, and HESEs lead to roof support failure and roof collapse. A mechanical model of the anchored coal mass in the roof was established, and a dynamic instability criterion for the roadway roof was derived by considering the mode of dynamic disturbance. PFC2D simulations show that when the lateral pressure coefficient exceeds 1.25 and a HESE occurs within 17 m of the roadway, 84.19% of the total kinetic energy is contributed by the vertical velocity component, greatly intensifying roof damage. However, compared with conventional support, the extended cable bolt design reduces dynamic energy by 57.41%. The results imply that roof collapse in retained top coal roadways induced by HESEs can be significantly reduced by eliminating dynamic sources through main roof fracturing and enhancing roof reinforcement with extended cable bolts.

Similar content being viewed by others

Introduction

Fully mechanized top-coal caving is widely used in thick coal seam mining due to its high recovery efficiency and cost-effectiveness1,2,3,4. However, this method inevitably leaves a layer of retained coal above the roadway, which significantly compromises roof stability and may lead to roof collapse, especially in high-static stress areas5,6,7. In addition, high-energy seismic events (HESEs), as a kind of dynamic load caused by the instability of large-scale coal and rock mass, propagates in the form of vibration waves and acts on the mining area, and the resulting stress increment may lead to the damage or instability of the roadway8,9,10,11. n retained top-coal roadways, HESEs can easily cause the failure of roof anchorage and induce roof collapse, making them one of the major hazards encountered during top-coal caving mining8,12,13,14.

Scholars have conducted extensive research on the seismogenic mechanisms of HESEs and their potential to induce dynamic disasters15,16,17,18,19. HESEs are typically induced by stress adjustment and redistribution during excavation, with shear failure as the predominant rupture mode9,20,21. These events are characterized by rapid and concentrated energy release as a result of intense in-situ stress redistribution, and often act as direct triggers for dynamic disasters such as rockbursts and roof collapses22,23. During such events, the impulsive high-energy loading generated by HESEs can significantly degrade the mechanical integrity of coal and rock masses, leading to instability of the surrounding strata and, in severe cases, large-scale structural failure24,25,26,27. This effect is especially pronounced in roadway sections with complex roof structures or in regions subjected to high static stress, where HESEs induced stress disturbances readily initiate roof fracturing and collapse, ultimately triggering compound dynamic disasters28,29,30.

Roof collapse disasters result from the failure of the roadway roof and anchorage, where progressive deterioration under mining-induced stress culminates in sudden instability, with weak roofs exhibiting a heightened susceptibility to collapse31,32,33,34. Numerous studies have systematically investigated roof collapse in coal mine roadways from the perspectives of failure mechanisms, influencing factors, and control strategies35,36,37,38. Increasing mining depth exacerbates in-situ stress concentrations and thermal effects, further compromising roadway stability39. Additionally, dynamic disturbances such as seismic activity and blasting-induced stress waves have been identified as major triggers of roof collapse40. Geological structures, layered roof conditions, intense dynamic loading, and time-dependent support degradation further increase the risk of failure41,42,43,44. Several scholars have proposed stress-relief techniques, energy-absorbing support systems, and deep-hole preconditioning blasting as effective measures to mitigate HESEs9,45,46. Dou et al.47 introduced targeted regional stress‑field control to identify high‑risk zones and guide proactive stress relief for HESE prevention. Zhang et al.48 revealed that strong mining‑induced earthquakes mainly result from key thick roof strata fracturing, highlighting the value of deep‑hole energy‑release measures. Tao et al.49 proposed hydraulic fracturing of thick hard strata to release elastic energy and suppress HESEs. Zhu et al.50 emphasized the importance of timely mesh installation, increased support stiffness, and coordination between primary and secondary support systems near longwall recovery roadways, where support failure and dynamic loading occur most frequently. Similarly, Li et al.51 demonstrated the effectiveness of composite support combining bolting and grouting. Sun et al.52 proposed early roadway excavation as a proactive depressurization method to reduce roof deformation and enhance mining safety. Shi et al.53 further proposed proactive depressurization to reduce energy buildup prior to excavation.

Although extensive research has been conducted on the mechanisms of roof collapse and HESEs, studies focusing on the dynamic failure mechanisms of roof anchorage systems under transient disturbances such as HESEs remain limited. In particular, there is a lack of research on the degradation behavior of support systems and the instability criteria for anchorage structures under dynamic loading. In this context, the present study investigates a roof collapse induced by a HESE during the mining of the 301 top-coal caving face in the Binchang mining area, Shaanxi Province, China. This research focuses on the stability of roadways with retained top coal and employs a combination of theoretical modeling and numerical simulation to reveal the mechanical mechanisms of roof instability under dynamic loading, while proposing corresponding control strategies.

Engineering background

Geological conditions

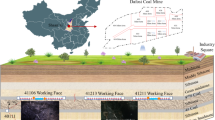

This study focuses on a certain coal mine located northwest of the Binchang mining area, Shaanxi Province, China (Fig. 1a). The coal seam depth in this mine ranges from approximately 800–1000 m, with an average thickness of 12 m. The research object of this study is the return air roadway of the 301 working face in the mine (Fig. 1c). The 301 working face is the second mining face in the third panel area. To the northwest, it is adjacent to the gob area of the 302 working face, with a coal pillar of 6 m width between the two faces. To the southeast, there is a 200 m wide isolation coal pillar separating the second and third panels. The mining method employed at the 301 working face is fully mechanized top-coal caving. The coal seam thickness ranges from 8.1 m to 15.6 m, with an average of approximately 12.1 m. The coal seam dip ranges from 0° to 8°, with an average dip of 4°, and the coal seam depth is nearly 1000 m. The X3 syncline structure is present within the 301 working face. In situ stress measurements indicate that the working face lies within a high-stress region, with a vertical stress of approximately 24.18 MPa and a maximum horizontal stress of approximately 38.23 MPa.

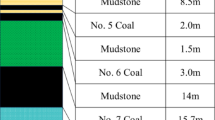

Mine basic conditions: (a) location of the mine, (b) columnar diagram of borehole 31 − 2, and (c) engineering map of the 301 working face. This map is based on the standard map No.GS(2022)4316 downloaded from the standard map service website of National Administration of Surveying, Mapping and Geoinformation of China (http://bzdt.ch.mnr.gov.cn/) with no modification to the base map.

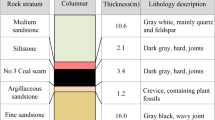

The 31 − 2 borehole column near the 301 working face is shown in Fig. 1b. The immediate roof of the working face is composed of sandy mudstone with a thickness of 1.25 m, whereas the basic roof consists of fine-grained sandstone with a thickness of 10.79 m. The immediate floor and basic floor are made up of carbonaceous mudstone (1.4 m thick) and mudstone (8.17 m thick), respectively. The coal seam is characterized by strong rockburst potential, whereas the basic roof sandstone and basic floor mudstone exhibit low rockburst potential.

The cross-section of the return airway of the 301 working face is rectangular, measuring 6 m in width and 4 m in height, and is excavated along the coal floor. The roof support system consists of 7 bolts and 5 cables. The anchor cables are prestressed steel strands of size 1 × 19-φ21.8 mm, with a spacing of 1000 mm. The bolts are high-strength prestressed compression bolts of size φ22 × 2800 mm, with a spacing of 950 mm×1000 mm. Both roadway ribs are reinforced with 3 cables and 6 bolts per side. The roadway rib bolt pattern maintains a spacing of 900 mm×1000 mm for the bolts and 1200 mm×1000 mm for the cables. The anchor cable lengths are 7 m for the roof and 4.2 m for the ribs. The support cross-section of the return airway of the 301 working face is shown in Fig. 2.

Mining-induced high-energy seismic events

Si et al.54 quantitatively defined HESEs. Following their classification methodology, a total of 14,008 seismic events recorded in the extraction area of the 301 working face were analyzed. The variation of the correlation coefficient between the upper and lower energy limits with respect to energy magnitude is illustrated in Fig. 3. As shown, the minimum energy value reliably recorded is 1 × 103.89 J; seismic events below this threshold may have been excluded because of incomplete data acquisition. For the 301 working face, the energy threshold for HESEs is determined to be 1 × 105.57 J. Events exceeding this energy level are classified as HESEs.

In addition to mining-induced seismic events generated by its own extraction activities, the 301 working face is also affected by seismic disturbances originating from adjacent working faces. Based on the timing of adjacent face extraction passing through the roof collapse area, the reliably recorded seismic events were divided into three time periods, with their planar distributions shown in Fig. 4. Under the combined influence of mining disturbances from both adjacent and current working faces, the fracturing of high-stress coal and rock masses led to frequent occurrences of seismic events, including HESEs. These repeated seismic disturbances imposed sustained dynamic loading on the surrounding rock of the 301 working face return airway, causing cumulative structural damage to the coal mass. On September 29, 2021, a HESE near the return airway of the 301 working face generated intense dynamic loading, leading to instability of the surrounding rock structure and resulting in a roof collapse accident.

Characteristics and mechanism of the roof collapse induced by HESEs

Characteristics of roof collapse induced by HESEs

Fracture distribution characteristics of the roof

A total of five boreholes were arranged from a point 10 m away from the roof collapse area toward the stop line, with a spacing of 20 m between adjacent boreholes and a depth of 9 m for each borehole. A borehole imager was employed to monitor the progression of roof cracks and the separation of strata above the roadway. The layout of the boreholes and the imaging results are shown in Fig. 5.

Roof borehole imaging revealed that no bedrock was present within the 9-meter depth range of all the boreholes, suggesting a thick top coal layer in the roof, characteristic of a thick top coal roadway. Within the upper 0–3 m of the roof, vertically developed fractures and loose, fragmented coal were identified. The installed roof bolts, with a length of 2.8 m, were insufficient to achieve effective anchorage in this fractured zone. Moreover, many horizontal fractures have been detected at depths of 6–9 m. According to suspension theory55 the 7 m cables used in the roof support system fail to suspend the weak roof strata to a stable overlying rock mass, nor can they effectively compress and constrain the fractured coal mass. As a result, the bolts and cables support system could not provide effective anchorage to the roof and ultimately failed under strong dynamic loading.

Field observations of roadway failure characteristics

At 20:16 on September 29, 2021, a HESE with an energy release of 4.67 × 105 J was detected by the SOS microseismic monitoring system in front of the 301 working face. Seismic event occurrence was accompanied by perceptible ground vibrations and triggered roof collapse in the return airway approximately 320 m ahead of the working face. The damage zone of the roadway was approximately 55 m, with the roof collapse reaching a height of approximately 2 m. The incomplete collapse failure mode was exhibited by the roof in the affected area, with a distinct interface observed after the collapse. The collapsed coal body was fragmented, with no significant horizontal ejection characteristics observed. In certain areas of the roof, bolts and cables exhibited signs of tensile failure, whereas no noticeable floor heaving or rib bulging was observed in the roadway. The locations of the seismic source and roof collapse are shown in Fig. 1c. The damage to the roadway is shown in Fig. 6.

The roadway failure characteristics observed in the 301 working face indicate both distinctions and connections between this incident and typical roof collapse and rockburst disasters. The event exhibited distinct features of conventional roof collapse, such as clearly defined detachment surfaces and visible caving zones, while also displaying strong dynamic characteristics commonly associated with rockburst, including intense seismic signals and violent ground shaking underground. As a result, existing theories that independently explain either rockburst or roof collapse mechanisms are insufficient to guide the prevention and control of such compound disasters. This highlights the urgent need for targeted research into roof collapse mechanisms specifically induced by HESEs.

Mechanism of the roof collapse induced by HESEs

Process of roof collapse induced by HESEs

Figure 7 systematically illustrates the instability evolution mechanism of the anchored structure in roadway surrounding rock under the influence of seismic events, revealing the entire process from crack initiation and propagation to roof collapse. As shown in Fig. 7a, the initial state features a stable anchored system effectively maintaining the integrity of the surrounding rock, with the roof coal body in a state of static equilibrium and the bolts (or cables) providing continuous support. Under a high in-situ static stress environment (horizontal stress: 38.23 MPa; vertical stress: 24.18 MPa), dynamic disturbances from nearby seismic events (Fig. 4) cause the system to enter the stage shown in Fig. 7b, where cracks initiate at the interface between the anchorage and the surrounding rock due to strength mismatches. Simultaneously, cracks begin to develop within the anchored structure itself, leading to a gradual loss of anchorage strength.

As seismic disturbances persist (Fig. 4), these cracks extend and coalesce, resulting in delamination under the combined effects of self-weight and dynamic loading. The internal cracking of the anchorage system further develops, and its structural integrity continues to degrade (Fig. 7c). When HESE occurs in close proximity to the roadway (Fig. 1c), the system reaches the stage shown in Fig. 7d, where the roof coal body loses stability and collapses due to the combined effects of strong dynamic and static loads. The anchored support structure fails entirely, culminating in a roof collapse disaster induced by HESEs.

Mechanical model of roof collapse induced by heses

As shown in Fig. 7, under the sustained influence of seismic events, cracks initiate and progressively separate at the interface between the anchorage structure and the surrounding rock. This results in an integrated anchorage zone undergoing coordinated deformation. Therefore, the roof anchorage system can be reasonably simplified as a simply supported beam structure. A schematic diagram of this simplified model is shown in Fig. 8. In the diagram, \(\:{\sigma\:}_{s}\) and \(\:{\sigma\:}_{d}\) represent the static and dynamic stresses acting on the anchoring structure, respectively, \(\:{\sigma\:}_{i}\) represents the anchoring stress, and \(\:G\) represents the stress due to the self-weight of the anchoring structure.

The deep beam problem illustrated in Fig. 8 can be solved via the displacement variational method56. Given that both sides of the roadway are fixed supports and that the structure is symmetric with respect to both the x-axis and y-axis at the roadway ends, the boundary conditions are as follows:

The Rayleigh–Ritz method can be employed to solve this problem. with the displacement function assumed as follows:

For plane stress problems, the strain energy density \(\:\:{U}_{1\:}\)is expressed as shown in Eq. (3)

Where E and \(\mu\) represent the elastic modulus and Poisson’s ratio of the anchorage structure, respectively.

By integrating Eq. (4), the strain energy U of the anchorage structure can be obtained as follows:

where \(J=\frac{{2{{(1 - \mu )}^2}E}}{{\left( {1 - {\mu ^2}} \right)(1 - 2\mu )}}\) and \(K=\frac{{1 - 2\mu }}{{2(1 - \mu )}}\).

According to the Rayleigh–Ritz method, the coefficients \(\:A\) and \(\:B\) can be determined via Eq. (5):

where \({f_x}\) and \({f_y}\) are the body forces acting on the anchorage structure in the horizontal and vertical directions, respectively. m is the mass per unit volume of the anchorage structure, and g is the gravitational acceleration. \({f_x}\) and \({f_y}\) represent the surface forces on the anchorage structure. S denotes the cross-sectional area of the anchorage structure, and l represents its external boundary. Specifically, \({f_x}=0\), \({f_y}=mg\), \({u_1}=\left( {1 - \frac{{{x^2}}}{{{a^2}}}} \right)\frac{{xy}}{{ab}}\), and \({v_1}=1 - \frac{{{x^2}}}{{{a^2}}}\).

By solving Eq. (5), the expressions for coefficients \(\:A\) and \(\:B\) are obtained as follows:

Substituting Eq. (6) into Eq. (2) yields:

In a plane strain problem, the relationship between stress and displacement is given as follows57:

By substituting Eq. (7) into Eq. (8), the following expression is obtained:

Through analysis, it is found that the instability of the anchorage system initiates from the failure of the roadway surface rock. That is, when \({\sigma _x}={\sigma _t}\), the rock surrounding the roadway is destroyed. Under this condition, the resultant force acting on the anchorage structure can be expressed as:

Where \({\sigma _t}\) is the tensile strength of the anchorage structure.

Assuming that the coal–rock mass can be considered an isotropic and continuous medium, the dynamic stress yielded by the seismic waves can be expressed as58,59:

Where \({\sigma _{dP}}\) and \({\sigma _{dS}}\)re the induced dynamic normal stress and shear stress within the coal‒rock mass when the P-waves and S-waves arrive, respectively; \(\rho\) is the density of the coal‒rock media; \({C_P}\) and \({C_S}\) are the propagation velocities of the P-waves and S-waves, respectively; \({v_{Pp}}\) and \({v_{Sp}}\) are the particle vibration velocities induced by the propagation of the P-waves and S-waves, respectively.

The peak particle velocity (PPV) of the vibration wave in the medium attenuates according to Eq. (11)60,61:

where \(\:{v}_{P}\) is the particle vibration velocity induced by the propagation of the seismic wave, which includes \({v_{Pp}}\) and \({v_{Sp}}\); \({v_{p0}}\) is the peak particle vibration velocity around the seismic source; L is the distance from the seismic source; and \(\alpha\) is the attenuation coefficient, which is influenced by the propagation medium.

By combining Eqs. (11) and (12), we obtain the dynamic stress at a certain location when the seismic wave arrives from its source:

Assuming that the initial dynamic stress at the seismic source is given by \({\sigma _0}=\rho C{v_{P0}}\), the dynamic stress attenuation equation. can be simplified as follows:

Substituting Eq. (14) into Eq. (10) yields:

When the angle between the center of the HESE above the roof and the center of the anchoring structure is \(\beta\), the criterion for judging the dynamic instability of the roadway roof is as follows:

When \(F>0\), the roadway roof is likely to experience a collapse. An analysis of Eq. (16) indicates that the static load, dynamic load, and support capacity are the key factors influencing the occurrence of such disasters.

Instability of roadways with retained top coal under varying conditions

To systematically investigate the influence of various factors on the occurrence of roof collapse disasters incuded by HESEs, numerical simulations were conducted via PFC2D discrete element software on the basis of the geological and production conditions of the 301 working face.

Numerical modelling and simulation scheme

Considering the balance between modelling accuracy and computational efficiency in PFC2D numerical simulations, a roadway model was established on the basis of the mechanical properties of the surrounding rock and geological conditions of the 301 working face, as shown in Fig. 9. The model dimensions are 30 m × 30 m, consisting of a 13.7 m thick coal seam, a 12 m thick sandstone roof, and a 4.3 m thick mudstone floor. The roadway is positioned along the coal seam floor, with a cross-section of 6 m in width and 4 m in height. The numerical model was constructed under plane strain conditions. On the basis of in situ stress measurements and subsequent simulation requirements, both the initial horizontal and vertical stresses were uniformly set to 20 MPa.

In the numerical model, a particle expansion method was employed to define a sinusoidal wave as the dynamic loading input. As analyzed in Sect. "Characteristics of roof collapse induced by HESEs", the HESE associated with the roof collapse was monitored with an energy magnitude ranging from 1 × 105 J to 1 × 106 J, and the seismic source was located above the roadway roof. A large amount of monitoring data indicates that roof-type seismic events with this energy level typically exhibit dominant frequencies in the range of 30–60 Hz62. Therefore, in this simulation, the HESE was modelled with a frequency of 30 Hz and a duration of two wave cycles.

The failure and instability of roadway surrounding rock under the influence of HESEs are closely related to the in-situ stress environment in which the surrounding rock is located. The initial stress in the model varies due to different geological conditions, such as the depth of the roadway. The lateral pressure coefficient is a physical quantity used to characterize the in-situ stress state. It is defined as the ratio of the maximum horizontal stress to the vertical stress at a given point, as shown in Eq. (17).

Where \(\gamma\) is the lateral pressure coefficient, \({\sigma _H}\) is the maximum horizontal stress, and \({\sigma _V}\) is the vertical stress.

In this numerical model, the lateral pressure coefficient is used to represent the initial stress state of the roadway. The vertical stress was set to 20 MPa, while the lateral pressure coefficient was varied as 1.0, 1.25, and 1.5 to simulate the influence of different static stress levels on the stress evolution and failure behavior of the surrounding rock under identical dynamic loading conditions.

On the basis of extensive experimental results and field monitoring data, different levels of seismic event energy correspond to distinct peak amplitudes of stress waves. The relationship between seismic event energy and the peak amplitude of dynamic loading is summarized in Table 1.

At the same initial stress level, the dynamic response characteristics of the roadway surrounding rock are closely related to the magnitude of the dynamic load. In this simulation, the initial vertical and horizontal stresses were both set to 20 MPa. A reference point was selected 12 m directly above the roadway center (X = 0, Y = 3.3), where four different magnitudes of dynamic loading (10 MPa, 30 MPa, 60 MPa, and 100 MPa) were applied to investigate the effect of the dynamic load intensity on the surrounding rock behavior.

In addition, to investigate the influence of dynamic loading at different distances and positions on the dynamic failure behavior of roadway surrounding rock, a dynamic load of 60 MPa was selected as the reference intensity. The load was applied at three vertical positions (12 m, 17 m, and 22 m) directly above the roadway center to simulate the effect of seismic source depth on the stress evolution and deformation characteristics of the surrounding rock. Furthermore, to evaluate the influence of the horizontal location of HESE on the surrounding rock, the distance between the seismic source and the center of the roadway was maintained at 12 m, with an intensity of 60 MPa. Taking the center of the roadway (X = 0, Y = − 8.7) as the origin, dynamic loads were applied at angles of 0°, 30°, 60°, and 90° counter clockwise from the line connecting the center of the roof. These loading positions were used to simulate the impact of different seismic source orientations on roadway stability.

The quality of roadway roof support significantly influences the failure characteristics and energy release of the surrounding rock under dynamic loading. The model is initialized with a vertical stress of 20 MPa and a lateral pressure coefficient of 1. A dynamic load of 60 MPa is applied 17 m above the center of the roadway (X = 0, Y = 8.3), with a frequency of 30 Hz and a duration of 2 cycles. Numerical simulations are conducted to investigate the failure of roadway surrounding rock under identical initial stress and dynamic load conditions, utilizing four different support methods (no support, bolts support only, combined bolts and cables support, and bolts and extended cables support). The simulated roof support parameters of the roadway are consistent with the actual on-site roof support parameters. In the first three support schemes, the bolt length is 2.8 m, the roof cable length is 7 m, and the rib cable length is 4.8 m. Considering that the retained top coal thickness is 9.7 m and the coal seam is overlain by stable sandstone, the extended anchor cable length in the simulation was set to 11.7 m according to the suspension theory. The numerical models of the roadway under different support forms are shown in Fig. 9a and d.

Parameter setting and validation

In PFC2D numerical simulations, no precise theoretical approach currently exists to directly convert the macroscopic mechanical properties of rock into the corresponding microscopic parameters of the particles. Therefore, model calibration is typically performed through repeated trial‒and‒error simulations64. Standard coal and rock samples with a height-to-diameter ratio of 2:1 were constructed for uniaxial compression tests via the particle flow method. The particles were bonded via the parallel bond model. The calibration process was considered successful when the simulated uniaxial compressive strength (UCS) and elastic modulus (E) deviated by less than 10% from laboratory test results (Table 2), and the stress–strain curves exhibited consistent stages as shown in Fig. 10.

Table 3 lists the mesoscopic parameters of the parallel bond model for different rock formations. The ratio \(\:{k}_{n}/{k}_{s}\) represents the normal-to-shear stiffness of the particles. \(\:{E}^{\text{*}}\) is the elastic modulus of the particles, \(\:\mu\:\) denotes the particle friction coefficient, and \(\:\rho\:\) is the particle density. The ratio \(\:\overline{{k}_{n}}/\overline{{k}_{s}}\) corresponds to the bond normal-to-shear stiffness ratio. \(\:\overline{{E}^{\text{*}}}\) denotes the bond elastic modulus. \(\:\overline{{\sigma\:}_{c}}\) and \(\:\overline{{\tau\:}_{c}}\) are the bond tensile and shear strengths, respectively. \(\:\overline{\varphi\:}\) refers to the bond friction angle. The microscopic parameters of the bolts and cables were calibrated according to the yield strength (300 MPa) of the steel used in the reinforcement elements65. The contact interfaces between the support elements and the surrounding rock were used to represent the bonding effect of the resin grout during the anchoring process, as well as the confining action provided by the bolts and anchor cables on the roadway.

Determination of the dynamic load source parameters

To simulate the effects of dynamic loads from HESE on roadway damage patterns, verifying the stress wave attenuation law of simulated HESE is essential.

The HESE stress wave propagation and attenuation validation model, along with the monitoring point arrangement, are shown in Fig. 11. The model dimensions are 30 m × 10 m, where the red particles represent the seismic source and the blue particles correspond to the monitoring points. The dynamic loading effect of the seismic source is simulated by applying particle expansion. The applied stress wave is a sinusoidal wave with a source strength of 100 MPa, a frequency of 30 Hz, and an action time of 2 cycles. The transmission boundary is set around the model to simulate an infinite medium, and an initial stress of 20 MPa is applied to the model in both the horizontal and vertical directions. The micromechanical parameters in the dynamic load validation model are identical to those used in the main roadway simulation (Table 2), ensuring consistency and the reliability of the comparative results. The monitoring points are arranged on the right side of the seismic source particles at 1 m intervals, and the peak stresses at various locations from the seismic source are recorded through these monitoring points.

The velocity–time curves at selected monitoring points in the model are shown in Fig. 12. As the distance between the monitoring point and the seismic source increases, the vibration onset time is delayed, and the PPV decreases accordingly. Since transmissive boundaries were applied around the model, no wave reflection occurred when the stress waves reached the model boundaries. This configuration effectively eliminates boundary reflections, ensuring that the stress wave propagation and attenuation induced by the HESE in the coal and rock medium are free from boundary interference.

In this roof collapse accident, a total of 14 sensors received vibration wave signals, and Fig. 13a shows the fitted relationship between the peak particle velocity (PPV) and the distance of the sensors for this HESE. The seismic wave attenuates as a power function (Eq. (12)) with the distance between the seismic source and the sensors. Accordingly, the attenuation coefficient \(\:\alpha\:\) of the PPV with distance for this HESE was determined to be 0.0000789. According to Eq. (16), the attenuation coefficient of the HESE stress wave was 0.0000789. Figure 13b compares the theoretical and simulated attenuations of the dynamic stress. The Pearson correlation coefficient \(\:r\) is 0.99377, indicating a strong correlation between the two.

In summary, the application of PFC2D provides a reliable approach for simulating stress wave propagation and attenuation in coal and rock, allowing for accurate analysis of the surrounding rock failure mechanisms of roadway surrounding rock under HESE conditions.

Analysis of the simulation results

Effect of the lateral pressure coefficient

The distribution of the velocity field in the roadway surrounding rock under different initial stress states, along with the failure of the surrounding rock, is shown in Fig. 14. As the lateral pressure coefficient increases, the velocity of the roadway roof increases in response to HESE. When the initial vertical and horizontal stresses are equal, the roadway roof experiences significant fracturing, although the velocity of the fragmented rock mass remains relatively low. When the lateral pressure coefficient is increased to 1.25, the degree of roof fracturing decreases slightly, but the velocity of some fractured coal masses increases. At a lateral pressure coefficient of 1.5, the high-velocity zone in the roof expands further, whereas the overall degree of coal mass fragmentation continues to decrease.

Coal or rock ejection is one of the key characteristics for distinguishing different types of dynamic disasters. Compared with roof collapse induced by HESEs, both rockburst and rockburst-induced roof collapse events exhibit pronounced horizontal ejection features. Therefore, the severity of damage to the roadway surrounding rock can be quantitatively assessed by the kinetic energy of the surrounding rock particles near the roadway. The progression of disaster incubation can be analyzed by examining the proportion of kinetic energy contributed by the horizontal or vertical velocity components of the surrounding rock particles.

The total kinetic energy of the i-th particle in the surrounding rock is given by:

The velocity of a surrounding rock particle can be decomposed into horizontal and vertical components; thus, the kinetic energy of the particle can be expressed as:

where \({v_{iV}}\) is the vertical velocity and where \({v_{iH}}\) is the horizontal velocity of the i-th particle.

Thus, the kinetic energy of the roadway surrounding rock can be obtained from Eq. (20):

Let \({E_V}\) and \({E_H}\) represent the kinetic energy contributed by the vertical velocity and horizontal velocity of the surrounding rock particles, respectively. Then we have \({E_V} = \mathop \sum \limits_{i = 1}^j \frac{1}{2}{m_i}{v_{Vi}}^2\) and \({E_H} = \mathop \sum \limits_{i = 1}^j \frac{1}{2}{m_i}{v_{Hi}}^2\) .

Figure 15 illustrates the distribution of kinetic energy in the roof region of the roadway and the proportion of kinetic energy contributed by the vertical velocity of surrounding rock particles under different lateral pressure coefficients. As the lateral pressure coefficient increases, the kinetic energy of the rock mass above the roadway roof initially decreases and then increases, with a lateral pressure coefficient of 1 serving as the turning point. The kinetic energy contributed by the vertical velocity of the particles increases significantly with increasing lateral pressure coefficient. In all the cases, the vertical velocity remains the dominant contributor to the total kinetic energy. Specifically, when the lateral pressure coefficient is 1.0, the proportion of kinetic energy provided by the vertical velocity is 55.98%, whereas at a coefficient of 1.5, this proportion increases to 84.19%. These findings suggest that under lower lateral pressure coefficients, the roadway is more prone to developing into a typical rockburst, while under higher lateral pressure coefficients, failure is more likely to evolve into roof collapse induced by HESEs.

Effects of HESEs

(1) Intensity of the HESEs.

The velocity field and fracture distribution of the roadway surrounding rock under different seismic event intensities are illustrated in Fig. 16. As the seismic event intensity increases, the velocity in the roof region increases accordingly, and the proportion of high-velocity zones expands. The dynamic failure characteristics of the roof coal mass become more pronounced. At a HESE intensity of 10 MPa, fractures are induced in the roof coal mass, forming an arch-shaped failure zone with relatively low particle velocity and low fracture density. When the intensity increases to 30 MPa, the height of the arch-shaped fractured zone increases to approximately 3.7 m, accompanied by an increase in the coal particle velocity within the zone. At 60 MPa, the fracturing within the roof intensifies, particularly within the 2 m region above the roadway, and the velocity of the fragmented coal particles increases further. At a HESE intensity of 100 MPa, large fractured coal blocks form within the arch-shaped failure zone, and these fragments also exhibit high velocities. The intensity of roof damage is significantly heightened. Additionally, cracking is observed in the middle of the roadway floor. These simulation results indicate that HESE intensity has a significant influence on the severity and evolution of dynamic disasters.

(2) Distance of the HESEs.

Figures 17 and 18 present the distribution characteristics of the velocity field and fracture density, respectively, at different distances between HESE and the roadway. At a constant HESE intensity, the particle velocity of the surrounding rock decreases with increasing distance, and the damage severity caused by the HESE is significantly reduced.

When the HESE is located 12 m above the roadway, the roof coal mass is extensively fractured, and the fragmented coal exhibits high velocities. The overall fracture density above the roof is high. As the distance increases to 17 m, the extent of fracturing in the roof decreases, the velocity of fractured coal drops considerably, and high fracture density is concentrated mainly at the corners of the roof–sidewall junctions. When the distance reaches 22 m, the roof remains largely intact, with only a few fractures developing near the surface. The overall fracture density of the surrounding rock is relatively low.

(3) Location of HESEs.

The distributions of the velocity field in the surrounding rock at different relative positions between the HESEs and the roadway center are shown in Fig. 19. As the angle between the seismic source and the roadway center increases, the main failure zone in the surrounding rock gradually shifts from the roof to the sidewalls of the roadway. When the included angle is 30°, the extent of damage to the roof is reduced, and the high-velocity zone is mainly concentrated in the upper right part of the roof. At an angle of 60°, the primary failure region shifts to the left sidewall and the upper-left corner, with fracture development appearing more scattered. When the angle reaches 90°, the high-velocity zone is located mainly along the left sidewall, where fractures are fully developed and penetrate through the sidewall. The fragmented coal in this region shows minimal interaction with the surrounding rock mass. Moreover, a clearly penetrative fracture also appeared in the right sidewall.

The kinetic energy of the surrounding rock in the roadway at various locations of the HESE and the proportion of kinetic energy contributed by the horizontal velocity are shown in Fig. 20. As the angle between the seismic source and the roadway center increases, the total kinetic energy of the surrounding rock decreases, whereas the proportion of kinetic energy provided by the horizontal velocity component shows an overall increasing trend. When the included angle is small, the kinetic energy is predominantly contributed by the vertical velocity of the surrounding rock particles. In contrast, at larger angles, the horizontal velocity becomes the main contributor. During a roadway roof collapse disaster, the kinetic energy of the collapsed coal is attributed mainly to the vertical velocity. As the HESE incidence angle increases, the horizontal dynamic stress component becomes more significant, leading to stress concentration and crack development in the sidewalls, the dominant failure mode transitions from roof collapse to sidewall instability. Therefore, the relative position of the HESE to the roadway has a significant influence on the type of disaster that occurs in the roadway. Specifically, when the angle between the HESE and the center of the roadway is small, the roadway is more prone to experience a roof collapse induced by HESEs, resulting in more severe damage. Conversely, when the angle is large, the roadway is more likely to experience a typical rockburst disaster.

Effect of roof support

Figure 21 shows the velocity field distributions of the surrounding rock under different support methods. When the roadway roof is supported only by bolts, fractures develop above the anchorage zone and gradually penetrate through it. The roof anchorage structure behaves as an integral body and tends toward overall downwards movement. When combined bolts and cables support is applied, fractures still develop within the roof anchorage zone, and the coal mass inside the fractured area has a relatively low particle velocity. However, significant bending deformation occurs along the surface of the roof. When the roof is supported with bolts in combination with extended cables, the integrity of the surrounding rock remains relatively intact, and the particle velocities are low. Under these conditions, the dynamic load from the HESE causes minimal damage to the surrounding rock. These results indicate that the roof support method plays a critical role in controlling roadway failure under dynamic loading. The combined use of bolts and extended anchor cables can effectively mitigate the destructive effects of HESEs.

Figure 22 illustrates the kinetic energy of the surrounding rock particles and the proportion of vertical kinetic energy under different support methods. The application of support measures effectively reduces the kinetic energy of the surrounding rock under dynamic loading. Compared with the use of bolts support alone on the roadway roof, the combined bolts and cables support significantly improves roadway stability. Under identical dynamic loading and initial stress conditions, the lowest total kinetic energy of the surrounding rock particles was observed in the scheme using both bolts and extended cables, with a value of 1.84 × 104 J. This represents an 86.6% reduction compared with the unsupported case, which exhibited a total kinetic energy of 1.37 × 105 J. In both the bolts-only and the bolts-cables support cases, over 70% of the total kinetic energy is contributed by the vertical particle velocity. In contrast, both the unsupported scheme and the extended cables support scheme exhibit a more balanced energy distribution, with a proportion of vertical kinetic energy of approximately 50%. These results indicate that the use of only bolts and conventional bolts and cables support systems are insufficient to form a suspended anchorage structure in the roof. Under dynamic loading, cracks tend to develop along the anchorage interface, leading to delamination failure and higher vertical velocities. In contrast, the use of extended anchor cables enables the formation of a more stable anchorage structure in the roof coal mass. This allows the surrounding rock to respond as an integrated body, absorbing dynamic energy more uniformly in both the horizontal and vertical directions.

Discussion

Compared with conventional roof collapse disasters caused solely by static loading, roof collapse induced by HESEs is more sudden and destructive. Consequently, control strategies for such compound disasters should shift from the traditional focus on roof subsidence control to a more comprehensive approach that addresses strong dynamic loading, elevated static stress, and support system performance.

Based on Eq. (16), the stability coefficient of the anchorage structure can be expressed as:

According to Eq. (16), when the stability coefficient of the anchorage structure equals 1, the roadway roof is at the threshold of instability. A higher stability coefficient indicates better stability of the roadway roof. Therefore, the stability of the anchorage structure can be improved through the following three measures: (1) reducing the stress level in the roadway roof, (2) attenuating the dynamic stress induced by HESEs, and (3) increasing the support strength of the roof structure.

On this Base, a control strategy for roof collapse disasters induced by mine seismic events is proposed, as illustrated in Fig. 23. Specifically, the stress level in the surrounding rock can be reduced by employing pressure relief techniques, such as large-diameter boreholes. To mitigate the dynamic stress from HESEs, the dynamic source intensity \(\:{\sigma\:}_{0}\) can be reduced through presplitting of thick and hard low-level roof strata via controlled blasting. Additionally, a weak buffer zone can be artificially created between the dynamic source and the roadway roof to increase the attenuation coefficient \(\:\alpha\:\) of the HESE stress wave, which can increase energy dissipation and reduce its impact on the roadway. Finally, the support strength \(\:{\sigma\:}_{i}\) of the anchorage structure can be improved through optimized support design and reinforcement strategies, such as the use of extended anchor cables and the addition of passive support elements to improve the system’s resistance to dynamic loads.

This study is based on a single case in the 301 working face of the Binchang mining area. While the findings provide insight into the roof collapse mechanism and support optimization under HESEs, future work will expand simulations and comparative analyses to different geological conditions to further validate and generalize the proposed control strategies.

Conclusion

This study systematically investigates the failure mechanism of roof collapse induced by HESEs using theoretical analysis and numerical simulations. The findings offer valuable insights and practical guidance for addressing related engineering challenges. The main conclusions are summarized as follows:

(1) Roof collapse induced by HESEs exhibits distinct dynamic failure characteristics, setting it apart from typical roof collapses and rockbursts. It is primarily governed by high in situ stress, intense dynamic loading from HESEs, and deterioration of support systems, particularly under thick top coal conditions.

(2) The cause and evolution of the roof collapse induced by HESEs in the return airway of the 301 working face were analyzed. The collapse was triggered by a HESE (4.67 × 105 J) occurring near the roof under high in situ stress (\(\:{\sigma\:}_{v}\)= 24.18 MPa, \(\:{\:\sigma\:}_{H}\)= 38.23 MPa). The event caused a sudden release of accumulated elastic energy due to insufficient anchorage (2.8 m bolts and 7 m cables), ultimately resulting in dynamic roof collapse.

(3) Numerical simulations identified the key conditions leading to roof collapse induced by HESEs. Roof failure intensified when the lateral pressure coefficient exceeded 1.25 or the HESE intensity surpassed 60 MPa within 17 m of the roadway. Optimized support using extended anchor cables reduces the surrounding rock kinetic energy by 57.41% compared with conventional support, demonstrating its effectiveness in mitigating the dynamic effects of HESEs.

(4) Considering the dynamic loading effects of HESEs, a mechanical model of roof collapse induced by HESEs was established. Based on this model, prevention and control strategies were proposed, focusing on eliminating or attenuating dynamic load sources and strengthening support systems.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Wang, J., Yang, S., Wei, W., Zhang, J. & Song, Z. Drawing mechanisms for top coal in Longwall top coal caving (LTCC): A review of two decades of literature. Int. J. Coal Sci. Technol. 8, 1171–1196 (2021).

Wang, G. et al. Research and practice of intelligent coal mine technology systems in China. Int. J. Coal Sci. Technol. 9, 24 (2022).

Yang, L. et al. Influence of loose gangue thickness on top coal recovery ratio in extrathick coal seam in Longwall top coal caving. Comp. Part. Mech. 10, 1281–1294 (2023).

Zhang, J. et al. Theoretical and experimental investigation on top coal drawing mechanism considering overburden pressures in Longwall top-coal caving. Rock. Mech. Rock. Eng. 58, 2901–2927 (2025).

Liu, Y., Li, J., Duan, Y., Qin, T. & Liu, Z. Study on the influence of roadway structural morphology on the mechanical properties of weakly cemented soft rock roadways. Sustainability 15, 821 (2023).

Yang, S., Yue, H., Li, Q. & Chen, Y. Study on failure behaviors of roofs with varying thicknesses in Longwall coal mining working face. Rock. Mech. Rock. Eng. 57, 6259–6282 (2024).

Wang, H. et al. Experiment research on the control method of automatically retained entry by roof cutting pressure relief within Thick hard main roof Longwall top coal caving panel. Eng. Fail. Anal. 168, 109085 (2025).

Wang, Q. et al. Roof-cutting and energy-absorbing method for dynamic disaster control in deep coal mine. Int. J. Rock. Mech. Min. Sci. 158, 105186 (2022).

Wang, Z., Liu, R., Wang, T., Zhang, Y. & Ren, X. Energy release efficiency and mechanisms of Mining-Induced High-Energy earthquakes in China. Rock. Mech. Rock. Eng. 58, 5579–5593 (2025).

Song, C. et al. Moment tensor and stress field inversions of Mining-Induced seismicity in A Thick-Hard roof zone. Rock. Mech. Rock. Eng. 57, 2267–2287 (2024).

Song, J. et al. Moment tensor inversion of mining-induced seismic events and forward modeling of critical fault slip to prevent rockbursts. J. Rock. Mech. Geotech. Eng. 17, 2987–3000 (2025).

Peng, S. S. Topical areas of research needs in ground control – A state of the Art review on coal mine ground control. Int. J. Rock. Mech. Min. Sci. 25, 1–6 (2015).

Galvin, J. M. Ground Engineering - Principles and Practices for Underground Coal Mining (Springer, 2016).

Wang, G. & Pang, Y. Surrounding rock control theory and Longwall mining technology innovation. T J. Coal Sci. Technol. 4, 301–309 (2017).

Wasilewski, S. Gas-dynamic phenomena caused by rock mass tremors and rock bursts. Int. J. Rock. Mech. Min. Sci. 30, 413–420 (2020).

Chai, Y. et al. Experimental investigation into damage and failure process of coal-rock composite structures with different roof lithologies under mining-induced stress loading. Int. J. Rock. Mech. Min. Sci. 170, 105479 (2023).

Yu, B., Peng, M., Tai, Y. & Guo, S. Assessment and control of the mine tremor disaster induced by the energy accumulation and dispersion of thick-hard roofs. Int. J. Rock. Mech. Min. Sci. 34, 925–941 (2024).

Zhang, J., Dong, X., Bai, J. & Jia, L. The mechanism and prevention of rockburst induced by the instability of the composite hard-roof coal structure and roof fractures. Eng. Fract. Mech. 310, 110512 (2024).

Gai, Q., Gao, Y., Huang, L., Shen, X. & Li, Y. Microseismic response difference and failure analysis of roof and floor strata under dynamic load impact. Eng. Fail. Anal. 143, 106874 (2023).

Kozłowska, M., Orlecka-Sikora, B., Dineva, S., Rudziński, Ł. & Boskovic, M. What governs the Spatial and Temporal distribution of aftershocks in Mining‐Induced seismicity: insight into the influence of coseismic static stress changes on seismicity in Kiruna mine. Swed. Bull. Seismol. Soc. Am. 111, 409–423 (2020).

Song, J. et al. Application of bayesian method for mining-induced tremors: A case study of the Xinjulong coal mine in China. Int. J. Rock. Mech. Min. Sci. 174, 105635 (2024).

Liu, G. et al. Numerical study on the impact instability characteristics induced by mine earthquake and the support scheme of roadway. Shock Vib. 2021 (1), 7697905 (2021).

Du, F. et al. Rockburst mechanism and the law of energy accumulation and release in mining roadway: a case study. Int. J. Coal Sci. Technol. 9, 67 (2022).

Zhao, Y. et al. Study of the rock mass failure process and mechanisms during the transformation from Open-Pit to underground mining based on microseismic monitoring. Rock. Mech. Rock. Eng. 51, 1473–1493 (2018).

Liu, J., Xu, S., Li, Y. & Lei, G. Analysis of rock mass stability based on Mining-Induced seismicity: A case study at the Hongtoushan copper mine in China. Rock. Mech. Rock. Eng. 52, 265–276 (2019).

Khan, M., Xueqiu, H., Jia, G. & Dazhao, S. Accurate prediction of indicators for engineering failures in complex mining environments. Eng. Fail. Anal. 155, 107736 (2024).

Ma, Z., Zhao, X. & Li, S. Mechanism of rockburst induced by roadway repair under intense mining: A case study. Front Earth Sci. 12, 1387797 (2024).

Lu, C. et al. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock. Mech. Min. Sci. 76, 18–32 (2015).

Zhao, S., Gao, M., Xu, D., Yu, X. & Zhao, H. Fracture characteristics of Thick-Roof coal roadway subjected to duplicated shock waves. Sustainability 15, 5308 (2023).

Du, K., Bi, R., Khandelwal, M., Li, G. & Zhou, J. Occurrence mechanism and prevention technology of rockburst, coal bump and mine earthquake in deep mining. Geomech. Geophys. Geo-energ Geo-resour. 10, 98 (2024).

Gu, S., Jiang, B., Wang, G., Dai, H. & Zhang, M. Occurrence Mechanism of Roof-Fall Accidents in Large-Section Coal Seam Roadways and Related Support Design for Bayangaole Coal Mine, China. Adv. Civ. Eng. 6831731 (2018). (2018).

Li, Z. et al. Research on failure criteria and collapse height of roadway roof strata based on energy accumulation and dissipation characteristics. Energy Sci. Eng. 9, 2461–2473 (2021).

Shen, B. Coal mine roadway stability in soft rock: A case study. Rock. Mech. Rock. Eng. 47, 2225–2238 (2014).

Wu, W., Bai, J., Feng, G. & Wang, X. Investigation on the mechanism and control methods for roof collapse caused by cable bolt shear rupture. Eng. Fail. Anal. 130, 105724 (2021).

He, F. L., Wang, X. M., Zhang, D. Q. & He, S. S. Study on parameters of support for control of roof fall and rib spalling in large fully mechanized top coal caving end face. Adv. Mater. Res. 616–618, 421–425 (2013).

Liu, X., Fan, D., Tan, Y., Wang, X. & Alexey, A. Failure and instability mechanism of anchored surrounding rock for deep chamber group with super-large section under dynamic disturbances. Rock. Soil. Mech. 42, 3407–3418 (2021).

Wang, H. et al. Study on the dynamic evolution characteristics of deformation and collapse of the extra-thick hard roof. J. Min. Sci. Technol. 6, 548–557 (2021).

Dai, L. et al. Quantitative principles of dynamic interaction between rock support and surrounding rock in rockburst roadways. Int. J. Rock. Mech. Min. Sci. 35, 41–55 (2025).

Wang, B., Liu, H., Liu, D., Zhang, J. & Lin, H. Study on deformation mechanism and surrounding rock strata control in End-Mining Retracement roadway in closely spaced coal seams. Appl. Sci. 15, 436 (2025).

Tian, S., Xu, X. & Li, Z. Disaster-inducing mechanism in a roadway roof near the driving face and its safety-control criteria. Saf. Sci. 115, 208–214 (2019).

Wang, H. et al. Field investigation of a roof fall accident and large roadway deformation under geologically complex conditions in an underground coal mine. Rock. Mech. Rock. Eng. 51, 1863–1883 (2018).

An, Y., Zhang, N., Zhao, Y. & Xie, Z. Field and numerical investigation on roof failure and fracture control of Thick coal seam roadway. Eng. Fail. Anal. 128, 105594 (2021).

Lin, H., Yang, R., Li, Y. & Fang, S. Deformation mechanism and control technology of coal roadway with thin Sand-mudstone interbed roof. Min. Metall. Explor. 40, 421–433 (2023).

Peng, K., Chang, L., Dechuan, Y., Shihui, L. & Ruiju, J. Study on the dynamic response and roadways stability during mining under the disturbance of hard roof break. Sci. Rep. 14, 15301 (2024).

Kaiser, P. K. & Moss, A. Deformation-based support design for highly stressed ground with a focus on rockburst damage mitigation. J. Rock. Mech. Geotech. Eng. 14, 50–66 (2022).

Zhang, X. et al. Energy reduction and earthquake mitigation via deep-Hole blasting of Thick roofs in deep mines. Geotech. Geol. Eng. 43, 210 (2025).

Dou, L. et al. Detection and targeted control of regional stress field for coal burst prevention. Geohazard Mech. 1, 69–76 (2023).

Zhang, Q., Zou, J., Chi, M., Jiao, Y. Y. & Yan, X. Strong mining-Induced earthquakes produced by the fracturing of key strata during deep coal mining. Int. J. Geomech. 24, 04024080 (2024).

Tao, G. et al. Mechanism of mining-induced earthquakes triggered by Thick hard rock strata fracture and application of hydraulic fracturing control technology. Phys. Fluids. 37, 067119 (2025).

Zhu, W., Xu, J. & Xu, G. Mechanism and control of roof fall and support failure incidents occurring near Longwall recovery roadways. J. South. Afr. Inst. Min. Metall. 117, 1063–1072 (2017).

Li, Y. et al. Failure analysis and control measures of deep roadway with composite roof: a case study. Int. J. Coal Sci. Technol. 9, 2 (2022).

Sun, X. et al. Stability control measures for roof cutting and NPR supporting of mining roadways in fault areas of kilometre-deep coal mine. J. Mt. Sci. 20, 3051–3065 (2023).

Shi, Z., Wang, J., Hao, J. & Qin, B. Proactive intervention depressurization control for pre-mining roof fall and mining impacts. Sci. Rep. 15, 10719 (2025).

Si, G., Cai, W., Wang, S. & Li, X. Prediction of relatively High-Energy seismic events using Spatial–Temporal parametrisation of Mining-Induced seismicity. Rock. Mech. Rock. Eng. 53, 5111–5132 (2020).

Cao, F. & Fang, T. Application and analysis of bolt support in mine driving roadway. Math Probl. Eng. 2022 (1), 2521555 (2022).

Shi, X. Experimental Study on Roof Collapse Caused byRockburst in Deep Driving Coal Roadway Basedon Multi-source Information (China University of Mining and Technology, 2021).

Xu, Z. A Concise Tutorial on Elasticity (Higher Education Press, 2018).

Cao, A., Fan, J., Mu, Z. & Guo, X. Burst failure effect of mining-induced tremor on roadway surrounding rock. J. China Coal Soc. 35, 2006–2010 (2010).

Li, Z., He, X., Dou, L. & Song, D. Comparison of rockburst occurrence during extraction of Thick coal seams using top-coal caving versus slicing mining methods. Can. Geotech. J. 55, 1433–1450 (2018).

Wang, C., Cao, A., Zhang, C. & Canbulat, I. A new method to assess coal burst risks using dynamic and static loading analysis. Rock. Mech. Rock. Eng. 53, 1113–1128 (2020).

Liu, Y. et al. Prediction method of coal burst based on Attenuation characteristics of seismic cluster energy. J. China Coal Soc. 47, 1523–1533 (2022).

Liu, S. Classification of Seismic Source Mechanisms of Strong Mine Tremors in Deep Coal Mines and Assessment of its Disaster-causing Effects (Anhui University of Science and Technology, 2024).

Zhu, G. et al. Numerical inversion of dynamic behavior of fault slip instability induced by stress waves. J. Min. Saf. Eng. 38, 370–379 (2021).

Lu, A. et al. Numerical simulation study on Pressure-Relief effect of protective layer mining in coal seams prone to rockburst hazard. Rock Mech. Rock. Eng. 57 (8), 6421–6440 (2024).

Jing, H., Wu, J., Yin, Q., Shi, X. & Zhao, Z. Particle flow simulation of rock burst and roof fall of deep coal roadway under dynamic disturbance. Chin. J. Rock. Mech. Eng. 39, 3475–3487 (2020).

Funding

This research was carried out by the National Key R&D Program of China (Grant No. 2022YFC3004603), the National Natural Science Foundation of China (Grant No. 52227901), the Open Fund of Key Laboratory of Safe and Efficient Coal Mining, Ministry of Education (Grant No. JYBSYS202301), the Postdoctoral Fellowship Program (Grade C) of China Postdoctoral Science Foundation (Grant No. GZC20241923) are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Xiaotao Ma: Conceptualization, Methodology, Software, Writing-Original draft preparation. Linming Dou: Conceptualization, Formal analysis, Funding acquisition. Kunyou Zhou: Visualization, Investigation, Funding acquisition. Yanjiang Chai: Supervision, Data curation. Anye Cao: Resources, Project administration. Anliang Lu: Software. Jinrong Cao: Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

Not applicable.

Consent to publish

All authors of this article consent to publish.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, X., Dou, L., Zhou, K. et al. Roof collapse in a retained top coal roadway induced by high-energy seismic events: implications from a case study. Sci Rep 15, 31376 (2025). https://doi.org/10.1038/s41598-025-16896-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-16896-4