Abstract

Physical simulation experiments of CO2 flow adsorption under various stratigraphies were conducted in the coal seam CO2 injection project for gas replacement, as CO2 is in the flow state and the mechanism of CO2 adsorption in the flow state in the coal seam is still unclear. In the process of CO2 flow adsorption, the results indicate that seepage in the horizontal stratigraphic direction is predominant, while diffusion in the vertical stratigraphic direction is predominant. The ratio of CO2 flow adsorption in the horizontal stratigraphic direction is primarily distributed below 50%, and seepage is the dominant process during the CO2 flow adsorption test. Conversely, the ratio of adsorption in the vertical stratigraphic direction is typically greater than 50%, and diffusion is the dominant process. During the control test, when the outlet was sealed (one-way CO2 injection without return), the seepage impact diminished while the diffusion effect intensified, resulting in an increase of the saturated CO2 adsorption quantity to 1.3 to 4.8 times that of the flow adsorption system. In the CO2 replacement of CH4 project, when CO2 penetrates a specific distance, the extraction holes are sealed, thereby prolonging the diffusion period of CO2 to ensure complete adsorption in competition with CH4, ultimately enhancing the utilization efficiency of CO2.

Similar content being viewed by others

Introduction

Anthropogenic carbon dioxide (CO2) emissions and the effects of climate change on the environment have emerged as a significant global concern. To address this challenge, researchers are investigating diverse carbon capture and utilization (CCU) technologies1,2,3,4. China possesses abundant coal carbon resources, presenting significant potential for exploitation and utilization5,6,7,8. Coalbed methane (CBM) can substitute coal due to its substantial CO2 adsorption capacity, facilitating carbon sequestration and the generation of new energy sources. However, the majority of coal seams exhibit low permeability, rendering conventional extraction methods ineffective9,10. Coal seams are classified as low-permeability coal seams11,12,13and the efficacy of standard extraction methods is suboptimal. Current prevalent techniques for coalbed methane extraction include hydrodynamic permeability augmentation technology14gas injection replacement, and protective layer mining, among other permeability modification methods. CO2-enhanced coal bed methane mining (CO2-ECBM) ensures production safety and alleviates the greenhouse effect, emerging as a novel method for the effective extraction of coal bed methane in China. It has emerged as a method for the efficient extraction of coalbed methane in China15,16,17,18,19.

To enhance the efficiency of CO2-enhanced coalbed methane extraction, researchers have investigated the fundamental mechanisms of CO2-driven gas. In the examination of the CBM storage and transportation mechanism, utilizing the dual pore medium theory20,21during CO2-enhanced CBM extraction (CO2-ECBM), CO2 initially experiences Darcy-non-Darcy composite seepage through the macroscopic fissure system (pore size > 100 nm), subsequently diffusing into the micro- and nano-pore system (pore size < 10 nm), where it then competes for adsorption with CH4. The efficacy of CO2 permeation and diffusion is a critical determinant in enhancing CBM extraction. Zhang Lei et al.22 conducted a binary gas adsorption and displacement experiment to elucidate the mechanisms of CO2 seepage and diffusion during gas injection and displacement. Their findings revealed that seepage displacement predominated in the initial phase of the experiment, while diffusion displacement became dominant in the latter phase. Li Jinghua et al.23 categorized the gas injection displacement impact into two sub-effects: pressure potential difference and gas injection, which enhance CH4 desorption. They discovered that the CO2-induced enhancement of desorption is predominantly observed in the first phase of the experiment. Yang Hongmin et al.24 discovered that in the N2 gas injection test, the displacement and desorption effects of gas injection are predominant in the initial phase, the displacement effect diminishes during the intermediate phase as the replacement effect intensifies, and in the final phase, there is an equilibrium between the displacement and replacement interactions.

In the multi-physical field coupling process of CO2-driven gas, researchers have systematically elucidated the independent functions of each mechanism by constructing an idealized single-component adsorption system and mitigating the effects of competing adsorption interactions, thereby revealing the coupled kinetic behavior of seepage, diffusion, and adsorption of CO2 in the coal matrix. Zunguo Zhang et al.25 conducted a concurrent experimental investigation of coal adsorption and deformation, analyzed the CO2 adsorption/desorption characteristics of coal, developed a model for CO2 adsorption/desorption in coal samples, and clarified the correlation between the adsorption/desorption deformation of coal samples and the adsorption quantity and equilibrium pressure. Zheng Yi26 conducted kinetic studies on CO2 adsorption, revealing that the highest absolute adsorption capacity of CO2 was approximately threefold that of CH4 under identical temperature and pressure conditions, signifying a superior CO2 adsorption capacity in shale compared to CH4. Zhang Mingjie et al.27 conducted isothermal adsorption studies of anthracite coal on CO2 gas utilizing the gravimetric method, examining the variations in the density of the adsorbed phase and the quantity of adsorbed molecular layers of CO2. Zunguo Zhang et al.28 examined the dynamic diffusion features of CO2 in coal prior to adsorption equilibrium using a single pore diffusion model, discovering a significant correlation between adsorption equilibrium time and the particle size of coal samples. Wang Shuifeng et al.29 conducted high-temperature and high-pressure CO2 adsorption experiments, examined the density distribution characteristics of various pore phases under temperature and pressure variations, and categorized the CO2 micro-sequestration modes in coal beds into three distinct adsorption types. Wang Jianmei et al.30 conducted high-pressure adsorption experiments of supercritical CO2 on anthracite, revealing a mutation point in the high-pressure adsorption process and indicating that the coal’s microstructure could be altered to improve the adsorption capacity of the anthracite surface. Several academics31,32,33 investigated the adsorption behavior of CO2 molecules under varying temperatures, pressures, and moisture levels, concluding that low temperatures and high pressures enhance CO2 adsorption, whereas water molecules impede it. Certain academics34,35,36 conducted adsorption and desorption experiments on laminated specimens with varying inclination degrees in a laboratory setting, discovering that both permeability and adsorption rate augmented as the inclination angle of the coal rock surface increased.

The aforementioned studies have conducted various investigations into the adsorption mechanisms of individual gases via seepage and diffusion; however, during the process of CO2 displacing gas, CO2 exists in a flowing state, and there is a paucity of research regarding the interplay between seepage and diffusion in the context of CO2 flow adsorption. This paper enhances the conventional adsorption test method by maintaining the flow state of CO2 during testing. It examines the influence of varying injection pressures and laminar structures on the evolution of seepage and diffusion in the CO2 flow adsorption process, integrating factors such as CO2 adsorption amount, injection quantity, exit flow rate, and flow adsorption ratio.

Experimental methodology

Sample collection and Preparation

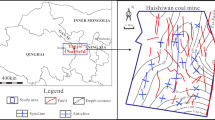

Coal samples were collected from the S2207 tape transit lane of Changzhi Yuwu Coal Industry in Shanxi Province. The coal rank is bituminous, with a density of 1.39 g/cm³ and porosity ranging from 5.14 to 6.64%. Upon sampling, the specimens were promptly wrapped with vacuum cling film to prevent air exposure and thereafter transported to the laboratory for the extraction of Φ50mm×100 mm cylinders based on horizontal and vertical stratification. The test samples S1, S2, S3, S4, S5, and S6 are illustrated in Fig. 1. S1, S2, and S3 represent horizontal stratification (parallel to the axial line), whereas S4, S5, and S6 denote vertical stratification (perpendicular to the axial line). S4, S5, and S6 are vertical strata, oriented perpendicular to the axis. Table 1 presents the findings of the industrial analysis of the coal samples. The coal samples were subjected to a vacuum drying oven, heated to a continuous temperature of 100 °C to 105 °C for 24 h, then cooled to room temperature and set aside for future use. Figure 1 illustrates the sample preparation process. First of all, the retrieved raw coal will be cut out parallel surfaces by rock cutter (DJ-4 cutter) in accordance with the direction of the stratification, and the distance between the two parallel surfaces is greater than or equal to 120 mm, and then the cut and flattened coal samples will be placed on the operation platform of the core drilling machine (DJ-4 automatic core drilling machine), and the coal cores are drilled through the drilling bit with a diameter of 50 mm, and finally the cutter will be utilized to cut the 120 mm coal cores into specimens with a diameter of 100 mm. The final cutter is used to cut the 120 mm coal core into 100 mm specimen.

Experimental apparatus

The two variables, laminar structure and gas injection pressure, were designated as orthogonal factors to establish an orthogonal control test system, comprising a total of six test groups, as illustrated in Table 2. Subsequent to the flow adsorption test, the specimens were positioned in a drying oven and subjected to a continuous temperature of 100 °C to 105 °C for 24 h, following which they were removed and allowed to cool to room temperature for a control test backup. The entire testing procedure was conducted on a specimen measuring Φ50mm×100 mm.

Figure 2 illustrates the schematic diagram of the test setup, which primarily comprises a high-pressure gas supply system, adsorption system, pressurization system, thermostatic control system, data collecting system, and evacuation system. The high-pressure gas supply system comprises 99.99% CO2, a pressure reduction valve, a mass flow meter (model: MF4701), among other components. The diameter of the adsorption chamber in the adsorption system is 72 mm, the length is 213 mm, the maximum loading value of axial pressure is 300 MPa, and the maximum peripheral pressure is 80 MPa. Coal samples are placed in the adsorption system, and the axial and peripheral pressures are exerted for the samples by the pressure pumps in the pressurization system. The range of the pressure sensor model is 0 ~ 50 MPa.The mass flow meter monitors the real-time CO2 inlet and output flow rates, as well as the cumulative flow rate. A constant temperature control system maintains a stable and adjustable temperature for both the coal body and the injected gas. The data collection system comprises a paperless recorder and a computer for the gathering of temperature and flow rate data, while the vacuum system is employed to eliminate residual gas in the coal samples to reduce experimental interference.

The test procedure is illustrated in Fig. 3 Upon completion of the preparatory work prior to the test, CO2 flow adsorption is conducted as follows: (1) Connect the experimental apparatus according to the schematic diagram and verify the system’s airtightness; (2) apply a circumferential pressure of 5.0 MPa to the shaft, then evacuate the system; (3) open the cylinder and adjust the injection pressure to 0.6 MPa per the test protocol, simultaneously opening the inlet and outlet valves as well as the mass flow meter. The flow adsorption was deemed to achieve dynamic equilibrium when the flow meters at both the inlet and outlet indicated identical readings, signifying the conclusion of the flow adsorption test; (4) Substitute the coal samples, reiterate the procedures outlined in (1)-(2), modify the gas injection pressure to 0.8 MPa and 1.0 MPa, and replicate the aforementioned operation. A control test was established to determine whether the air exit is open in the two test groups. During the control test, the outlet valve remained closed while the intake maintained the programmed pressure to continuously inject CO2, and the test concluded when the input flow meter indicated zero flow.

In order to minimize the test error, each group of tests was repeated three times under the same conditions, and the inlet and outlet flow rate patterns were the same in the three tests, with the error of flow rate less than 5% in the horizontal lamination direction, the error of flow rate less than 10% in the vertical lamination direction, and the error of flow adsorption amount of the coal samples was less than 5%, which illustrated the reproducibility and stability of the test, and the article chose to repeat the test once due to the limitation of the article’s length.

The flow adsorption test primarily examined the variations in flow velocity at both the inlet and outlet, the pattern of adsorption quantity throughout the flow adsorption process, and the CO2 flow adsorption ratio. Additionally, it investigated the seepage and diffusion effects along with their transformation mechanisms based on the alterations of these parameters during the CO2 flow adsorption process. This study’s control experimental system inhibited the pressure gradient-driven seepage mass transfer impact by implementing a closed boundary condition at the gas outlet, subsequently analyzing the diffusion-dominated mechanism effect.

Results and analysis

Changes in gas flow rate

Figure 4 illustrates that the import and export flow rates during the CO2 flow adsorption test, oriented along the horizontal laminae, exhibited a two-stage pattern over time: the entrance flow rate shown a sudden decline followed by a gradual decrease, while the outlet flow rate displayed a rapid increase succeeded by a gradual decline. In the CO2 flow adsorption test conducted in the vertical stratification direction, the entrance flow rate exhibited a similar trend to that observed in the horizontal stratification, but the output flow rate shown a rapid initial increase followed by a gradual rise over time. The disparities in the two stratigraphic structures resulted in divergent outlet flow trends, with seepage prevailing in the horizontal stratigraphic orientation, while the injected phase was preferentially conveyed along the predominant fracture network, exhibiting a pulsed flow response at the outlet (the outlet flow rate peaked within a brief timeframe), accompanied by diffusive adsorption-induced swelling of the coal matrix and a reduction in seepage rate; diffusion predominated in the vertical stratigraphic direction, with transport impeded by adsorption potential well trapping and the retention effects of the pore network, leading to a diminished transport rate. The vertical laminar flow is primarily governed by diffusion, with CO2 being absorbed through adsorption potential traps and pore retention effects. The transport process exhibits typical unsteady-state mass transfer, and the output flow rate commences after an approximate diffusion time lag of 80 min.

Upon comparison with the magnified map of outlet flow rate in Fig. 4, it is evident that the gas injection pressure in the horizontal laminar direction exerts a substantial modulation effect on the gas breakthrough characteristics: as the gas injection pressure increases from 0.6 MPa to 1.0 MPa, the response time of the peak outlet flow rate exhibits a notable reduction (1400 s→502 s→436 s), concurrently, the peak flow rate demonstrates a nonlinear growth pattern (41.8 ml/min→56.5 ml/min→59.8 ml/min). 56.5 ml/min to 59.8 ml/min. The flow rate increased by 35.2% with an injection pressure of 0.8 MPa and diminished to 5.8% at 1.0 MPa. A substantial negative correlation exists between gas injection pressure and seepage rate following flow adsorption equilibrium in the vertical laminae direction: the equilibrium flow rate exhibits a consistently declining trend (6.06 ml/min → 5.68 ml/min → 5.37 ml/min) as gas injection pressure is incrementally raised from 0.6 to 1.0 MPa, resulting in an overall reduction of 11.4% in flow rate with a pressure increase of 66.7%. The literature37 indicates that the parallel and vertical laminae orientations exhibit comparable pore size distribution characteristics; however, the connectivity between macropores and microfractures in the parallel laminae direction, along with the connectivity between mesopores and macropores with pore sizes under 500 nm, is more pronounced. This leads to enhanced effective porosity and improved pore-fracture connectivity, resulting in accelerated seepage velocity in the horizontal laminae direction under identical pressure differentials.

CO2 flow adsorption and permeability changes

The difference in cumulative flow rates obtained from coal samples at both the inlet and outlet of the flowmeter allows for the derivation of the adsorption amount over time curve during the test, as illustrated in Fig. 5. The adsorption amount of CO2 in both laminar flow directions increases with rising injection pressure. Furthermore, as the injection pressure gradually increases, its influence on the adsorption amount diminishes, particularly in the horizontal laminar direction, where the injection pressure ranges from 0.6 MPa to 0.8 MPa. The saturated adsorption amount rose from 0.50 mol to 2.13 mol when the injection pressure increased to 1.0 MPa, with a saturated adsorption amount of 2.25 mol at this pressure level. The saturated adsorption quantity rose from 1.72 mol to 2.35 mol, and subsequently to 2.36 mol, when the injection pressure along the vertical laminations escalated from 0.6 MPa to 0.8 MPa, and then to 1.0 MPa. With the exception of the 0.6 MPa injection pressure, the saturated CO2 flow adsorption quantities of the two-layer structures were comparable at the other injection pressures. However, the duration required to achieve the saturated adsorption amount for the horizontal layer was consistently shorter than that for the vertical layer, with the time difference between the two layers being an order of magnitude. The configuration of the layer significantly influenced the adsorption rate.

This research employs real-time monitoring of upstream and downstream pressures and outlet flow rates of coal samples to use the Darcy equation for deriving changes in the permeability of the coal body during CO2 flow adsorption.

Where k is the permeability of the coal sample (in m²); L is the length of the coal sample, L = 100 mm; P0 is the atmospheric pressure, P0 = 0.1 MPa; \({{{{\upmu}}}_\text{g}}\)is the gas viscosity, \({{{{\upmu}}}_\text{g}}\)= 0.0179 Pa·s; Q is the flow rate at the outlet end(in mL/min); A is the cross-sectional area of the coal sample, A = 1963.5 mm²; P1 and P2 are the absolute pressures at the inlet and outlet ends of the specimen(in Pa).

Figure 6 illustrates that the permeability of horizontal and vertical coal bodies exhibits distinct variations with respect to adsorption time. The permeability in the horizontal lamination direction rapidly attains its peak value before gradually declining, whereas the permeability in the vertical lamination direction is initially zero, subsequently increasing monotonically after a certain duration, with the rate of increase initially rapid and then decelerating. The alteration in permeability indicates that horizontal laminations possess greater effective porosity and enhanced pore-crack connectivity. Consequently, CO2 rapidly penetrates the coal matrix under differential pressure initially, followed by a gradual decrease in permeability due to the swelling effect induced by adsorption over time. Under identical pressure differentials, CO2 did not penetrate the coal matrix in the vertical lamination direction. After a duration, the seepage pathway within the coal matrix was established, resulting in a rapid increase in flow rate. Concurrently, as adsorption intensified, the rate of permeability enhancement diminished. The disparity between horizontal and vertical permeability is one order of magnitude. CO2 attains adsorption saturation rapidly in horizontal laminations due to seepage followed by diffusion, whereas in vertical laminations, it takes significantly longer to reach adsorption saturation due to diffusion and adsorption followed by seepage.

The test results indicate that, owing to the analogous pore size distribution characteristics of parallel and vertical laminations, the adsorption quantities of horizontal and vertical laminations are comparable at identical gas injection pressures, with a higher adsorption rate observed when seepage precedes diffusion. Initially, when seepage commences, the fissures and substantial pores within the coal matrix are preferentially occupied by adsorbed gas, subsequently diffusing to the substrate, ultimately resulting in a reduction of the coal body’s adsorption and expansion permeability. Conversely, when diffusion initiates first, the permeability of the coal at the injection end diminishes due to adsorption and expansion, thereby increasing the resistance to gas seepage and decelerating the adsorption rate in regions of the coal body distant from the injection point.

CO2 flow adsorption ratio changes

The adsorption ratio is defined as the quantity of CO2 adsorbed relative to the total amount of CO2 injected, as represented in Eq. (2). Diffusion serves as the intermediary process between seepage and adsorption; thus, the quantity of CO2 adsorbed can be likened to diffusion, while the total CO2 exiting the outlet can be compared to seepage. It is established that the adsorption ratio exhibits a positive correlation with diffusion and an inverse correlation with seepage, as delineated in Eq. (2). To examine the transformation mechanism between seepage and diffusion in the flow adsorption process, the adsorption ratio was employed as an index parameter to delineate the transition between the two.

Where: η is the adsorption ratio of the coal sample to the flowing CO2(in %); \({Q_{ad}}\) is the total amount of CO2 adsorbed by the coal sample༈in ml༉; \({Q_{in}}\) is the total amount of CO2 streaming through the inlet༈in ml༉; and \({Q_{out}}\) is the total amount of CO2 flowing through the outlet༈in ml༉.

Figure 7 illustrates the temporal variation of the CO2 flow adsorption ratio across various laminar directions. The variation in the CO2 flow adsorption ratio along the horizontal laminae occurs in three phases: a quick increase, a rapid reduction, and a gradual decline. Conversely, the CO2 flow adsorption ratio in the vertical direction did not experience a swift escalation. Upon comparing the flow adsorption ratios in the two stratigraphic orientations, it was determined that the adsorption ratio in the vertical stratigraphic direction significantly exceeded that in the horizontal stratigraphic direction. This disparity was ascribed to the enhanced permeability of the coal, which could precipitate the premature breakthrough of injected gases into the coal matrix, consequently diminishing the adsorption ratio38. The CO2 flow adsorption ratios in the horizontal laminar direction were predominantly below 50%, whereas those in the vertical laminar direction were markedly higher, typically surpassing 50%. This suggests that seepage primarily influenced the flow adsorption test in the horizontal laminar direction, while diffusion was the dominant factor in the vertical laminar direction. Simultaneously, over time, the ratio of diffusion in both types of laminae progressively diminishes, while the ratio of seepage escalates.

Table 3 indicates that an increase in injection pressure results in a pronounced negative pressure-sensitive feature in the horizontal laminar direction, whereas the vertical laminar direction exhibits a positive pressure-sensitive response. The positive connection between injection pressure and flow adsorption indicates that an increase in the injection pressure gradient in the horizontal laminar direction results in a synergistic amplification of seepage and diffusion, with the seepage effect prevailing. In the vertical stratigraphic orientation, gas injection pressure exhibits a negative correlation with seepage and a positive correlation with diffusion.

Controlled trial results and analysis

The control test is a standard adsorption test conducted at constant temperature and pressure, wherein the open system (simultaneous CO2 injection and exhaustion) is converted into a closed system (unidirectional CO2 injection without exhaustion). In contrast to the flow adsorption test, the control adsorption test mitigates the impact of seepage effects, resulting in an adsorption process characterized solely by diffusive adsorption.

Figure 8 illustrates the temporal variation of CO2 adsorption quantity during the control test. The saturation adsorption quantity remains consistent across different laminae at identical injection pressures, with horizontal laminae exhibiting a higher adsorption rate than vertical laminae. This suggests that the coal body laminae do not influence the saturation adsorption quantity but solely affect the CO2 diffusion adsorption rate. Figure 9 compares the CO2 saturation adsorption amounts in the two tests. The control test shows that when the air outlet is closed, the seepage effect decreases, CO2 accumulates in the cracks of the coal seam, the concentration gradient increases, and the diffusion effect is enhanced, which contributes to the increase of CO2 saturation adsorption amount to 1.3 ~ 4.8 times of that in the open system. At the same time, the increase of saturation adsorption with the increase of gas injection pressure in the control adsorption test was larger than that in the flow adsorption test, which was due to the fact that CO2 could not be discharged out of the coal body after the air outlet was closed, and the CO2 concentration in the fissure system increased rapidly with the increase of the gas injection pressure, which formed a potential difference in the concentration with the pore system, and diffusive adsorption behaviors occurred.

Alongside the examination of the exit seepage rate, two factors account for the disparity in adsorption: (1) within micropores or constricted pores, CO₂ molecules must diffuse to access the adsorption sites. In the open system, the seepage rate is augmented, causing gas to preferentially traverse the larger pores or fissures, while the diffusion rate within the micropores is insufficient, leading to a reduction in the effective adsorption surface area; (2) the coal matrix possesses a complex multiscale pore architecture comprising micropores, mesopores, and macropores. In the open system, the seepage rate is enhanced, and CO₂ mostly traverses the macropores or fissures, while the adsorption sites within the micropores remain underutilized due to inadequate gas residence time.

Discussions

In the process of CO2 driving CH4, CO2 exists in a flowing state. This research examines the influence of the laminar structure of coal bodies on the adsorption efficiency of CO2 flow, aiming to enhance the CO2 adsorption rate and ratio via the lens of laminar structure.

Upon conclusion of the CO2 flow adsorption test, the gas injection pressures were 0.6 MPa, 0.8 MPa, and 1.0 MPa. The saturated adsorption amounts in the horizontal laminae direction were 0.5 mol, 2.13 mol, and 2.25 mol, while in the vertical laminae direction, they were 1.72 mol, 2.35 mol, and 2.36 mol. The saturated adsorption amounts in both laminae directions were comparable. The saturated adsorption capacity of CO2 for both types of laminae is comparable; the saturated adsorption durations for horizontal laminae are 20,600s, 51,040s, and 66,300s, while for vertical laminae, they are 120,000s, 93,860s, and 81,600s, indicating that the saturated adsorption time for horizontal laminae is significantly less than that for vertical laminae. The permeability change curve indicates that the sequence of seepage and diffusion initiation significantly influences the CO2 flow adsorption rate. Seepage commences prior to diffusion in the horizontal laminae direction, whereas diffusion precedes seepage in the vertical laminae direction. Consequently, the CO2 flow adsorption rate is higher in the horizontal laminae direction than in the vertical laminae direction, resulting in substantial time and cost savings during the injection process. At injection pressures of 0.6 MPa, 0.8 MPa, and 1.0 MPa, the adsorption ratios following CO2 saturation in the horizontal laminar direction were 25.2%, 8.9%, and 5.9%, respectively. In contrast, the adsorption ratios in the vertical laminar direction were 42.2%, 46.0%, and 47.4%, respectively. The CO2 flow adsorption ratios in the horizontal laminar direction were significantly lower than those in the vertical laminar direction. A significant quantity of CO2 was squandered throughout the CO2 flow adsorption procedure in the horizontal laminae, hence elevating the injection cost. Ultimately, the control test results indicate that, under identical conditions, transitioning from an open system to a closed system resulted in an increase in saturated adsorption capacity of 388%, 69%, and 81% in the horizontal laminar direction, and an increase of 28%, 58%, and 76% in the vertical laminar direction, demonstrating a significant enhancement in CO2 adsorption capacity following the closure of the open system. The closure of the open system significantly enhanced the CO2 adsorption capability.

In the engineering application of CO2 substituting CH4, it is essential to consider both the temporal expenses and the costs associated with CO2 injection to optimize benefits and enhance CO2 adsorption, thereby increasing the ratio of CO2 replacement for CH4. Consequently, during the CO2 injection into coal beds, it is advisable to maintain the pumping hole switch, located farther from the injection hole, in an open position to facilitate the horizontal flow of CO2 along the laminae and improve the CO2 breakthrough time. Upon CO2 breakthrough, promptly seal all extraction points, allow for CO2 and CH4 replacement, enhance CO2 use efficiency, and thereafter reopen the extraction points after a designated interval to optimize advantages.

Conclusion

(1) In the CO2 flow adsorption test, CO2 rapidly penetrates the coal matrix along horizontal laminations. When compared to vertical laminations, the flow-saturated adsorption quantity remains comparable at identical injection pressures; however, the duration required is reduced, with the extent of reduction diminishing as injection pressure increases. Taking into account the temporal expenditure, the CO2 flow adsorption efficiency in horizontal laminations surpasses that of vertical laminations.

(2) In the CO2 flow adsorption process, the adsorption ratio in the horizontal laminar direction is considerably lower than in the vertical laminar direction, with the horizontal adsorption ratio predominantly below 50%, whereas the vertical adsorption ratio typically exceeds 50%. The CO2 adsorption capacity of the vertical layer surpasses that of the horizontal layer when factoring in the injection cost.

(3) Upon closure of the system outlet, the saturation adsorption of CO2 within the closed system markedly increased, with the saturation adsorption in the control test being 1.3 to 4.8 times greater than that of the flow saturation adsorption, while the laminate structure exhibited negligible influence on the saturation adsorption.

(4) Based on the impact of various laminations on CO2 flow adsorption duration, quantity, and ratio, along with the control test outcomes, the system may be sealed once CO2 permeates the coal matrix during the injection process, thereby minimizing both time and injection costs, ultimately optimizing benefits.

Data availability

Data is provided within the manuscript or supplementary information files.The datasets used and/or analysed during the current study available from the corresponding author on reason able request, you can contact Xiao Yang Zhang at zh_xiaoyang5025@163.com.

References

Lee, M. Y. et al. Current achievements and the future direction of electrochemical CO2 reduction: A short review. Crit. Rev. Environ. Sci. Technol. 50, 769–815 (2020).

Choi, J. et al. Electrochemical mineral carbonation: A sustainable approach to CO₂ capture and utilization. Carbon Capture Sci. Technol. 16, 100444 (2025).

Symonds, R., Shokrollahi, M., Hughes, R., Navarri, P. & Modler, R. Systematic approach to the design, modeling, and techno-economic-environmental analysis of CO2 capture technologies as part of the National CCUS assessment framework (NCAF). Carbon Capture Sci. Technol. 16, 100439 (2025).

Zuo, J. et al. Unraveling the coupling effect of micropore confinement and functional sites of carbon-based adsorbents on flue gas CO2 adsorption: A machine learning study based on multi-scale simulations. Carbon Capture Sci. Technol. 16, 100445 (2025).

Fan, L. Y. et al. Geological control of differential enrichment of deep coalbed methane in the Ordos basin. Coal Sci. Technology, 53, 203–215 (2024).

Fang, Z. M., Wang, R. D. & Yang, C. L. Opportunities and challenges in deep coalbed methane development. Journal China Univ. Min. & Technology, 54, 34–51 (2024).

Jiang, S. Y. & Wang, F. Strategic choice and development countermeasures for the commingled exploration and exploitation of coal measure natural gas in China. Nat. Gas. Ind. 40, 152–159 (2020).

Li, Y. et al. Progress and development direction of coalbed methane (coal-rock gas) exploration and development in the Ordos basin. Nat. Gas. Ind. 44, 63–79 (2024).

Xu, H. J. Geological Theory and Technology for Coalbed Methane Development with Thin and Medium Coal Seam Zones in Guizhou (China University of Mining & Technology, 2012).

Sun, K. M. Fluid-solid coupling theory of exploiting coal methane and improving production by gas injection in low permeability reservoir and its application. Chinese J. Rock. Mech. Engineering 12, 2081 (2005).

Zhou, Y. J., Li, Z. H. & Li, J. C. Study on key technology of combined pressure relief and permeability enhancement in low permeability hard coal seam. Coal Sci. Technology, 53, 57–65 (2025).

Zhang, Y. J. et al. Theoretical and applied research on hydraulic slit-fracture joint roof control and pressure relief of hard roof in Goaf roadway. J. China Coal Soc. 1–13. https://doi.org/10.13225/j.cnki.jccs.2023.1500 (2024).

Shi, Y., Wang, Z. L. & Xu, S. D. Application and effectiveness evaluation of hydraulic fracturing for roadway pressure relief in coal mines. Chinese J. Rock. Mech. Engineering, 44, 459–471 (2025).

Chai, J. et al. Identification of the degree of stress release and unloading in the underlying coal rock of protected seam mining. J. China Coal Soc. 1–13. https://doi.org/10.13225/j.cnki.jccs.2023.0895 (2024).

Bai, G., Zhou, X. H., Wei, S. P., Fan, C. J. & Li, X. M. Simulation and test of enhancement of gas drainage through CO2 injection into coal seam of low permeability. Coal Geol. Explor. 47, 77–84 (2019).

Li, Z. B. Thermal cracking and displacement for enhancing methane extraction by phase transition of liquid CO2 injection in coal seam. Xi’an Univ. Sci. Technology (2019).

Li, Z. B. et al. Seepage characteristic and mechanism during liquid CO2 displacing CH4 in coal seam. J. Min. Saf. Eng. 39, 1265–1271 (2022).

Bai, G. et al. Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: an experimental study. Energy 238, 121674 (2022).

Tambaria, T. N. & Sugai, Y. The effectiveness of the continuous and Cyclic method on CO2-ECBM. Nat. Resour. 15, 69–81 (2024).

Liu, S. Q. et al. The flow behavior of CH4 in nanopores of anthracite coal based on a non-ideal gas-flow simulation. China Univ. Min. Technol. 49, 36–43 (2020).

Liu, S. Q., Wang, H., Gao, D. Y. & Tripathy, A. Research advances on characteristics of pores and fractures in coal seams. Acta Sedimentol. Sin. 39, 212–230 (2021).

Zhang, L., Li, J. H., Guo, L. C., Zeng, S. P. & Li, J. C. Experimental study of both the displacement behaviour by CO2 and the characteristic of volumetric strain on methane saturated bituminous coal. China Univ. Min. Technol. 51, 901–913 (2022).

Li, J. H., Zhang, L., Xue, J. H., Zhang, C. & Huang, M. Q. Experimental study on the characteristic of binary gas displacement adsorption on coal in CO2-ECBM. J. China Coal Soc. 46, 385–395 (2021).

Yang, H. M., Feng, C. Y. & Chen, L. W. Analysis of replacement-displacement effect and its change mechanism in simulation experiment of nitrogen injection into coal seam. J. China Coal Soc. 41, 2246–2250 (2016).

Zhang, Z. G., Chen, Y., Tang, C., Ma, K. X. & Zhang, C. H. Deformation characteristics and model of coal adsorption/desorption on CO2. J. China Coal Soc. 47, 3128–3137 (2022).

Zheng, Y. Study of adsorption kinetics and competitive adsorption characteristics of CH4 and CO2 in shale. (Chongqing University, (2023). https://doi.org/10.27670/d.cnki.gcqdu.2023.001024

Zhang, M. J., Zhou, W., Yang, J., Liang, X. M. & Li, Z. Study on adsorption characteristics of anthracite coal to supercritical CH4-CO2 gas. J. Saf. Sci. Technol. 18, 81–87 (2022).

Zhang, Z. G., Li, D. D., Chen, Y. & Tang, C. Effect of gas pressure and particle size on dynamic diffusion-adsorption characteristics of CO2 in coal. J. Min. Sci. Technol. 9, 493–503 (2024).

Wang, S. F. et al. Adsorption characteristics and storage models of subcritical/supercritical CO2 in coal seams. Nat. Gas. Ind. 44, 152–168 (2024).

Wang, J. M. et al. Structural response characteristics and adsorption mechanism of anthracite coal under supercritical CO2. Nat. Gas. Ind. 44, 115–125 (2024).

Zhen, X. Z. et al. Study on CO2 adsorption and diffusion law of coal under different temperatures and pressures. Saf. Coal Mines. 54, 60–65 (2023).

Xin, X. X. et al. Comparative study on effect of microstructure characteristics on adsorption of CH4 and CO2 in anthracite based on molecular simulation. Coal Sci. Technol. 52, 106–114 (2024).

Zhang, J. C. et al. CO2 adsorption of anthracite with different moisture contents and its implications for geological storage. Coal Geol. Explor. 50, 96–103 (2022).

Nie, B. S., Lu, H. Q., Li, X. C., Li, L. & Lv, C. Q. Experimental study on the characteristic of coal deformation during gas adsorption and desorption process. J. China Coal Soc. 40, 754–759 (2015).

Chen, Y. L., Zhang, Y. N., Tang, J. X., Yang, J. J. & Li, G. D. Experimental study of the influence of bedding effect on methane adsorption-desorption and seepage. J. Min. Saf. Eng. 35, 859–868 (2018).

Ma, Z. Study on the influence of coal bedding direction on liquid CO2 induced fracturing. (China Univ. Min. & Technology. https://doi.org/10.27623/d.cnki.gzkyu.2020.001395 (2020).

Liu, S. Q. et al. Structure features of high rank coal in parallel bedding and vertical bedding based on low field Nu clear magnetic resonance. Coal Sci. Technol. 46, 110–116 (2018).

Fan, N. et al. Numerical study on enhancing coalbed methane recovery by injecting N2 /CO2 mixtures and its geological significance. Energy Sci. Eng. 8, 1104–1119 (2020).

Funding

This study was funded by Fundamental Research Project of Liaoning Provincial Department of Education, China [grant numbers LJ222410147037]; Inner Mongolia Autonomous Region Science and Technology Major Project, China [grant numbers 2021ZD0034-2]; and Liaoning Technical University Discipline Innovation Team Funding Project[grant numbers LNTU20TD-11].

Author information

Authors and Affiliations

Contributions

Author Bing Liang: Funding acquisition, Resources. Author Xiaoyang Zhang: Writing – original draft, Data curation, Investigation.Author Weiji Sun: Project administration, Supervision, Writing – review & editing. Author Xintao Chen: Writing – review & editing, Investigation. Author Shiyao Zhang: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liang, B., Zhang, X., Sun, W. et al. Analysis of the seepage-diffusion law and transformation mechanism in the CO2 flow adsorption test under various laminae. Sci Rep 15, 32110 (2025). https://doi.org/10.1038/s41598-025-16983-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-16983-6