Abstract

To break through the limitations of traditional rectangular microchannel processing methods for microfluidic devices, this paper proposes a processing technique based on a holographic combined femtosecond laser beam. The phase and topology of the hologram are adjusted by SLM to flexibly control the spot width and energy distribution of a generated Bessel beam, thus realizing high-precision and multi-size processing. To achieve high-precision microchannel sidewalls and bottom surfaces, the positive first-order Bessel beam is shifted at an appropriate position after the zero-order light by using a blazed grating to obtain the suggested holographic combined beam required for processing. At a laser power of 0.98 W, compared with using only the Gaussian beam (bottom roughness Ra of 0.361 μm, MRR of 882.219 μm³/s) and the Bessel beam (Ra of 0.377 μm, MRR of 3490.590 μm³/s), processing with the combined beam reduces Ra to 0.128 μm, a reduction by factors of 2.8 and 2.9, respectively. Meanwhile, the MRR increases to 6786.362 μm³/s, representing improvements by factors of 7.7 and 1.9, respectively. Under this power, when the phase value s increases by 4 pixels, the microchannel width increases by 3.2 μm, and when the topological charge n increases by 4 pixels, the microchannel depth decreases by 0.7 μm. This novel method, which enables smooth surfaces without the need for post-processing, offers a new option for the high-quality, efficient, and flexible fabrication of curable resin microfluidic devices.

Similar content being viewed by others

Introduction

UV-curable resins are widely used in microfluidic devices due to their low cost and rapid prototyping properties1,3. Their excellent mechanical properties, chemical resistance and thermal stability ensure the long-term stability of microchannels during operation4. In addition, high optical transparency and good biocompatibility give them unique advantages for the visualisation and analysis of microfluidic devices and biomedical applications5,6, making them ideal materials for preparing microfluidic devices. Microscale fluidic devices are moving towards greater miniaturization, high density, and high performance and show a wide range of applications in microfluidics and MEMS (microelectromechanical systems)7,8. While injection moulding offers low-cost fabrication, its inflexibility in structural modifications due to time-consuming mold fabrication9 highlights the need for alternative methods like laser processing. Photolithography can achieve high processing precision10, but the process is complex and costly; chemical etching is economical and efficient11, but there are environmental pollution problems. In contrast, laser micromachining has high precision and good controllability, especially ultrafast laser, with its extremely high instantaneous power density and nonlinear effect, showing unique advantages in microfluidic processing12. Rectangular microchannels have significant advantages in capillary flow in microfluidic devices13,14, but their main challenge is achieving high-precision vertical walls and uniform bottom surfaces.

Ultrafast laser processing technology has shown unique advantages in the field of precision micromachining due to its non-thermal “cold” processing characteristics. The technology has been shown to be an effective choice for high quality micromachining through a nonlinear absorption mechanism for both absorptive and transparent materials, and the ability to precisely control the state of the material at the submicron scale15,16,17,18. Wang et al.19 used femtosecond lasers to directly ablate poly (methylmethacrylate) at varying energies to achieve microfluidic channels with controlled surface wettability. Beam shaping techniques can meet the requirements of specific structures or applications20, and can significantly improve the resolution and topographic accuracy in microchannel processing. Durnin et al.21 firstly proposed the concept of non-diffractive beams and generated Bessel beams by SLM (Spatial light modulator) modulation. Antti Vasara et al.22,23 proposed a hologram based on the solution of scalar fluctuation equations to generate non-diffractive beams method and verified the formation of arbitrary order Bessel beams and rotating asymmetric beams. The holograms enable customized shaping of arbitrary two-dimensional spatio-temporal light fields by modulating the spatial structure of the electron beam24. Zhai et al.25 demonstrated that a spatial light modulator is superior to a cone lens in modulating higher-order Bessel beams and is more flexible26. Pravin Vaity et al.27 utilized an SLM to modulate Bessel beams of different orders by controlling the radial wave vector to adjust the beam ring radius. Except for the zero order, the higher-order Bessel beams have a singularity at the phase center and form a vortex phase structure around it, which endows the beam with orbital angular momentum and is suitable for high-precision micromachining28,29, which is especially widely used in drilling and microchannel machining. The spot diameter and order of the Bessel beam can be flexibly adjusted by tuning the phase difference and topological charge number30. Higher-order Bessel beams can be generated by utilizing techniques such as holographic hypersurfaces31, higher-order S-wave plates and axial cone mirrors32, and spatial light modulation27.

Bessel beams are able to keep the diameter of the central primary flap stable over long distances due to their long focal depth and diffraction-free properties33, which can maintain high energy density over a wide range of depths during processing. Higher-order Bessel beams carry orbital angular momentum, and the light intensity distribution is more uniform34, which results in more uniform material removal and ensures consistent depth and shape of the microchannels. Shashi Prakash et al.5 realized rectangular and “U” shaped microchannels on a PMMA surface using a higher-order Bessel beam combined with chemical etching. Ottavia Jedrkiewicz et al.35 used SLM modulation to generate a Bessel beam for inducing microchannels on a diamond surface in multifunctional microfluidics. The modulation of higher-order Bessel beams via SLM produces zero-order diffracted light, which must be removed during machining to prevent interference with the processed area. By optimizing the SLM voltage36, Dammann grating37, and blazed grating38, the incident Gaussian beam can be separated into zero-order and non-zero-order diffracted beams. The grating period influences the position of the non-zero-order diffracted beam39, and effectively utilizing zero-order light can significantly improve light efficiency.

In this paper, we propose a new method of combined beam processing microchannels based on femtosecond higher-order Bessel beams. Different from the traditional holographic modulated Bessel beam method, this method does not remove the zero-order light, but places it in the appropriate position in front of the Bessel beam, and uses the synergistic effect of the zero-order light and the Bessel beam to realize the efficient machining of the rectangular microchannel. The spot diameter and energy distribution are flexibly controlled by adjusting the phase value and topological charge in the Bessel beam’s hologram. The blazed grating is used to modulate the position of the Bessel beam, successfully creating a combined beam for microchannel processing on a UV Curable Resin substrate. Experimental results demonstrate that this method achieves rectangular microchannels with a smooth surface, uniform inner walls, and a high material removal rate, offering a promising solution for microfluidic and MEMS device fabrication.

Theory

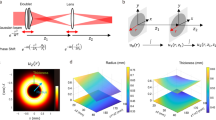

An axicon introduces a radial phase delay to the incident beam through its tapered surface, resulting in an outgoing beam with a tapered phase front, which in turn interferes with itself in spatial propagation to form a Bessel beam with a ring-shaped light intensity distribution34,40. According to the actual structure of the axicon shown in Fig. 1, when is greater than, the beam is blocked; when is less than or equal to, the beam is transmitted and undergoes a phase delay. The following equations describe the phase modulation principles underpinning the holographic beam shaping. These relationships inform the design of the axicon and blazed grating phases, enabling precise control over the Bessel beam properties. The axicon function L(a)26 is:

where \(\:{a\:=\:({x}^{2}+{y}^{2})}^{1/2}\), denotes the distance from the center of the axicon to each ray. The wave vectors \(\:\:=\:\sqrt{{k}_{r}^{2}+{k}_{z}^{2}\:}\:=\:\raisebox{1ex}{$2\pi\:$}\!\left/\:\!\raisebox{-1ex}{$\lambda\:$}\right.\), \(\:{k}_{r}\) and \(\:{k}_{z}\) are the radial and longitudinal wave vectors, respectively, and \(\:\lambda\:\) represent the wavelengths. \(\:\beta\:\) is the refractive angle of the positive axicon. \(\:m\) is the refractive index. \(\:{r}_{A}\) is the radius of the positive axicon. \(\:i\) represents the imaginary unit, which satisfies \(\:{i}^{2}\:=\:-1\).

The SLM is equivalent to an axicon with a flexible and adjustable base cone angle34. By changing the phase value of the hologram radius s, the effect is equivalent to changing the refraction angle of the axicon, and the hologram is designed as a rectangle with a size of 1272 × 1024 and a pixel interval of 12.5 μm to accommodate the SLM. Using a uniform plane wave of unit amplitude incident on a circular finite aperture hologram of radius, the incident beam needs to satisfy, and the transmittance function is22:

\(\:A\left(\theta\:\right)\) is the complex-valued angular spectral function of Eq. \(\:exp(-\raisebox{1ex}{$2\pi\:ir$}\!\left/\:\!\raisebox{-1ex}{${r}_{1}$}\right.)\) is a linearly varying phase factor that produces a tapered beam; \(\:{r}_{1}\) is a constant that can be customized when designing the hologram. \(\:(r,\theta\:)\) is polar and has a value of 0 in the z-plane. \(\:T(r,\theta\:)\) is limited to a numerical magnitude of (0,1). If \(\:A\left(\theta\:\right)=exp\left(in\theta\:\right)exp\left(ikz\right)\), where \(\:exp\left(in\theta\:\right)\) is the vortex phase. \(\:n\) is the topological charge and also denotes the order of the Bessel beam, where one rotation of the light field produces a phase of \(\:2{\uppi\:}n\); a positive \(\:n\) denotes a right-handed rotation of the light field, and a negative \(\:n\) denotes a left-handed rotation of the light field29. z is the distance of propagation along the optical axis. Then the transmittance function can be rewritten as \(\:T(r,\theta\:)\):

he phase used to generate ordinary Bessel beam holograms \(\:{\varPhi\:}_{1}(r,\theta\:)\):

The diagonal of the rectangular modulation window of the SLM is 2R. Vortex light field distribution:

\(\:X\) and \(\:Y\) are the generated matrix \(\:X\) and matrix \(\:Y\). \(\:{xy}_{ratio}\) is the aspect ratio of the ellipse. Vortex phase distribution \(\:{\varPhi\:}_{2}(x,y)\):

\(\:arg\left(\right)\) is to find the phase angle transportation. The ordinary Bessel light field is compounded with the vortex light field to form a higher-order Bessel light field with a phase distribution of \(\:\varPhi\:\):

Gaussian beam generated by the femtosecond laser produces a higher-order Bessel beam by loading the hologram computed by A on the spatial light modulator (SLM), and the generation principle is shown in Fig. 2, with the light field distribution:

\(\:{w}_{0}\) denotes the radius of the Gaussian beam waist. \(\:{r}_{2}\) denotes the radius of the femtosecond beam. Under appropriate Fourier transform conditions, it is converted to an \(\:n\)th-order Bessel beam. Its light field distribution is:

\(\:{J}_{n}\) is a Bessel function of the first type of \(\:n\)th order. In order to facilitate the modulation of the optical field, an optical Fourier transform is performed through the lens to obtain the spectrum in polar coordinates. For an arbitrary light field \(\:E\left( {\rho \:,\varnothing \:} \right)\) to \(E(r,\theta \:)\), the transformation can be written mathematically in a cylindrical coordinate system:

\(\:f\) is the focal length of the design hologram. The blazed grating light field distribution is:

In \(\:{Z}_{v}^{u}(r,\theta\:)\), \(\:v\) is the radial order, and \(\:u\) is the azimuthal frequency. Figure 2 shows that a blazed grating can separate the beam into − 1, 0, and + 1 order. The main energy of the Bessel beam is concentrated in the + 1 order. A blazed grating is used to modulate the position of the Bessel beam so that the zero-order light arrives at the proper position in front of the Bessel light to form a combined beam.

As shown in Fig. 3(a), as s increases, the neighboring phase difference \(\:L\:(L\:=\:2\pi\:)\) remains constant, which is manifested by the increase in Bessel rings in the hologram. The number of rings is equal to \(\:s/L\). The non-diffractive length of the Bessel beam and the diameter of the Bessel spot can be adjusted by changing s. The Bessel beam has the highest peak intensity in the center ring. The transverse intensity distribution of the beam includes multiple sets of concentric rings, with the maximum intensity concentrated in the center ring, which has the highest peak intensity.

When the spatial light modulator modulates the phase, the unevenness of its internal reflective dielectric mirrors is prone to cause errors, which require iterative phase compensation based on the laser wavelength41,42. In order to achieve better modulation, it is necessary to make the center of the incident beam coincide with the center of the phase hologram loaded into the cone lens of the spatial light modulator. However, the method of adjusting the center position of the spot in the optical path tends to destabilize the optical system. Superimposing only phase compensation is not ideal, and offsetting the hologram can also enhance the modulation effect43. The offset hologram is based on the Fourier transform displacement theorem, which takes the displacement signal in the spatial domain, converts it to the frequency domain for processing, and then converts it back to the spatial domain after processing.

The spatial domain function \(\:g(r,\theta\:)\) is Fourier transformed to the frequency domain function \(\:G(\rho\:,\varPhi\:)\):

\(\:(r,{\uptheta\:})\) is the spatial domain polar coordinate position. \(\:(\rho\:,\varPhi\:)\) are frequency domain polar coordinates. The Fourier variation displacement equation in polar coordinates is \(\:{G}^{{\prime\:}}(\rho\:,\varPhi\:)\):

\(\:{r}_{0}\) is the radial translation in the frequency domain. \(\:{\theta\:}_{0}\) is the angular translation in the frequency domain. \(\:{e}^{-i2\pi\:\rho\:{r}_{0}cos(\varPhi\:-\:{\theta\:}_{0})}\) is the phase shift factor. The shifted spectrum \(\:{G}^{{\prime\:}}(\rho\:,\varPhi\:)\) of the hologram is transferred back to the spatial domain by the inverse Fourier transform to obtain the actual hologram.

Materials and methods

Materials

In this study, microchannels were processed using a UV-cured resin plate with a thickness of 2 mm and an area of 50 × 50 mm2, as shown in Fig. 4(a), and its AFM height-scan image is shown in Fig. 4(b). The resin is a commercially available photopolymer made by 3D printing with UV curing. Its main chemical components include acrylic urethane as a prepolymer matrix, trimethylolpropane triacrylate (TMPTA) as an active diluent, and a mixed photoinitiator system consisting of 1-hydroxycyclohexyl phenyl ketone (Irgacure 184) and bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide (Irgacure 819). Additionally, small amounts of additives such as stabilizers and surfactants were added. Its physical properties are shown in Table 1. Before laser irradiation, the samples were immersed in an ultrasonic cleaner containing an anhydrous ethanol solution for about 10 min and then blown dry using compressed dry air.

Methods

The experimental optical path diagram is shown in Fig. 5. A femtosecond laser source (Femto-IR-50-40, Huaray) with a wavelength of 1035 nm was selected for the experimental system, with a maximum output power of 40 W, a maximum pulse energy of 50 µJ, a maximum repetition frequency of 800 kHz, and a pulse width in the range of 300 fs to 10 ps. Since the initial spot diameter of the femtosecond laser beam is 3 mm and the liquid crystal window of the SLM is 16 mm × 12 mm, in order to fully utilize the spatial light modulator and improve the quality of the modulated beam, the beam was extended to 12 mm and collimated. The laser produces linearly polarized light, so a LCOS-SLM (X13138-03, Hamamatsu) was selected, which can modulate horizontally linearly polarized light. In order to align the polarization direction of the incident beam with that of the liquid crystal molecules to obtain higher purity linearly polarized light, we used a combination of a half-wave plate (HWP, AHWP10M-980, Thorlabs) and a polarizing beam-splitting prism (PBS, CCM1-PBS253/M, Thorlabs) to modulate the direction of the laser beam’s polarization, which also acts as an energy attenuation device to control the transmission of laser energy. To avoid light intensity attenuation, oblique incidence is used, and it is important to ensure that the angle between the incident and reflected beams in the LCOS-SLM is less than 10°.Since the LCOS-SLM is loaded with a phase distribution that results in diffraction, leading to distortion of the beam profile, it is necessary to reduce the accumulation of aberrations in the optical path by using the \(\:4f\) system, which consists of two achromatic double-glued lenses (Lens1 and Lens2) with focal lengths of \(\:{f}_{1}\) = 750 mm and \(\:{f}_{2}\) =400 mm, respectively. After the \(\:4f\) system beam reduction process, the beam diameter meets the pupil requirement of a flush-focused near-infrared focusing objective (OL, NIR-50-95, × 50, NA = 0.67, EVENOPTICS), ensuring that the beam incident on the focusing objective contains all the modulation information. During actual processing, a CCD1 (DCC3240M, Thorlabs) and a light source (LED Spotlight, Thorlabs) were used to form a microscopic imaging system for real-time observation of processing results. A short-wavelength pass dichroic mirror (DM) transmits a portion of the laser light to the CCD2 (DCC3240N, Thorlabs), which is used to observe the effect of the modulated beam. Figure 6(a) shows that a blazed grating is used to separate the zero-level light to form a combined beam. The long depth-of-focus property of the Bessel beam is utilized so that the focal planes of the Bessel light and the zero-level light are different. When the Bessel beam is focused, the zero-level light is in an upward defocused state away from the focal point. The UV Curable Resin is placed perpendicular to the combined beam and fixed to the processing platform. By further lowering the focal position, the zero-level light was focused and the Bessel beam was in a negative out-of-focus state. Each experiment was performed five times to ensure the reliability and reproducibility of the results.

Laser scanning confocal microscopy (LSCM; VK-X1000; KEYENCE), scanning electron microscopy (SEM; Sigma 300; ZEISS) and atomic force microscopy (AFM; MM8; BRUKER) were used to characterize the profile morphology and roughness of the microchannels. Surface roughness was quantified as the arithmetic mean height Ra as an indicator of processing quality. To further evaluate the energy utilization efficiency and processing capability of different beams, this study introduces the MRR (material removal rate) as a quantitative index. Material removal rate MMR44:

\(\:S\) is the cross-sectional area of the microchannel, \(\:v\) is the laser scanning speed, and \(\:{n}_{p}\) is the number of laser scans; a single scan is used in this study and \(\:{n}_{p}\) is taken as 1.

Results and discussion

Optimization of light field uniformity

As observed by the CCD2 camera in Fig. 5, the modulated light spot Fig. 7(a) after loading the hologram of Fig. 7(k) exhibits an obvious inhomogeneity of energy distribution. Calculating the intensity distribution at selected Bessel spot center-axis positions reveals a large deviation of intensity values at the two peak positions in Fig. 7(e), and the left part of the intensity of the 3D spot in Fig. 7(h) is missing. Incident light occurs off-axis or tilted, and the angle of incidence increases and deviates from the near-axis condition, leading to a significant increase in aberration on the refractive plane and affecting the uniformity of the spot intensity45. The quality of the Bessel beam was optimized by superimposing the vortex phase Fig. 3(b) and aberration-corrected phase in the SLM with appropriate offsets (shifted by 80 pixels to the left and 20 pixels upward for the hologram in Fig. 7(l). The vortex phase can optimize the Bessel beam quality34, and the offset adjusts the phase distribution of the higher-order Bessel beam, which makes up for the deficiency of the aberration-corrected phase and the vortex phase, and homogenizes the spot energy distribution. The optimized modulated spot shape and energy uniformity Fig. 7(f) and (i) are significantly improved. It can be observed in Fig. 7(a) and (b) that there is a distinct zero-order light at the center of the Bessel spot. To achieve an effective separation of the Bessel beam from the zero-order light, a strategy of superimposing the axicon hologram with the blazed grating hologram (Fig. 7(n)) is adopted in Fig. 7(m). After separating the zero-order light, the energy of the Bessel beam is mainly concentrated in the positive first-order diffraction direction, while the energy in the negative first-order direction is relatively low, making it impossible to effectively remove the material. Therefore, the negative first-order diffraction light is not removed in this paper.The phase difference makes the center of the separated Bessel spot Fig. 7(d) off-axis, and for the blazed grating hologram Fig. 7(o) deflected by 9 pixels, the center of the Bessel spot Fig. 7(c) comes back to the axis, and Fig. 7(g) and (j) show a significant improvement in the quality of the beam.

(a) Spot of unoptimized Bessel beam, (b) Spot of optimized Bessel beam, (c) Spot of optimized combined beam, (d) Spot of unoptimized combined beam, (e), (f), (g) Intensity profiles at the center of the spot, (h), (i), (j) 3D intensity maps of the spot; (k), (l), (m) Holograms of the modulated spot, (n) Blazed grating hologram and its magnification, (o) Deflected blazed grating hologram and its enlargement.

Comparison of the quality of microchannels processed by different beams

In order to verify the processing quality of the SLM-modulated combined beam in terms of microchannels, the microchannels were etched on the surface of the UV Curable Resin using the beams before and after modulation, respectively, with a femtosecond laser \(\:{E}_{out}\) (output power) of 0.98 W, a \(\:{F}_{pul}\) (pulse repetition frequency) of 800 kHz, and a scanning speed of 0.03 mm/s.

Firstly, the surface was processed with an unmodulated beam, and the surface profile was measured to be 11.322 μm in depth and 7.491 μm in width, and the MRR was 882.219 µm3/s. In Fig. 9(a) and (b), the material surface near the microchannels shows debris adherence, recast layers in some areas, pitting ablation craters, and melt residue at the bottom of the microchannels. The microchannels were profiled as shown in Fig. 10(b), revealing a “V”-shaped morphology. After removing the sidewall on one side of the microchannel in Fig. 9(c), the bottom roughness (Ra) was measured to be 0.361 μm using an atomic force microscope.

(a) Unmodulated beam processing effect: LSCM image, (b) Unmodulated beam processing effect: SEM image, (c) Unmodulated beam processing effect: AFM image, (d) Bessel beam processing effect: LSCM image, (e) Bessel beam processing effect: SEM image, (f) Bessel beam processing effect: AFM image, (g) Combined beam processing effect: LSCM image, (h) Combined beam processing effect: SEM image, (i) Combined beam processing effect: AFM image.

The hologram (s = 8 pixels, n = 3) in Fig. 8(a) was loaded into the SLM, and the modulated higher-order Bessel beam is shown in Fig. 8(b). The measured depth of the machined surface profile is approximately 9.894 μm, the width is approximately 12.846 μm, and the MRR is 3545.821 µm3/s. No sputtered molten residue or obvious recast layer is observed on the surface of the microchannels in Figs. 9(d) and (e), but ablation pits are still present at the bottom. Contour scanning results in Fig. 10(b) show that the microchannel cross-section is approximately rectangular. In Fig. 9(f), the roughness (Ra) at the bottom of the microchannel measured by AFM is 0.377 μm.

When the femtosecond laser is focused on the interior of a transparent body material, the high energy density of the laser pulse triggers a plasma effect, which causes microbursts and modification of the material46,47, where the molecular chains of the UV curable resin material are broken or rearranged, resulting in the formation of tiny, highly absorptive structures. When these structures appear on the front side of the focus, a significant ablation crater is formed after laser scanning, where the highly absorptive structures within the material are removed or transformed48, and subsequent laser scanning becomes less effective in generating plasma, with a significant reduction in the rate of ablation-crater formation. Secondary scanning with a Bessel beam can significantly solve this problem, but it greatly reduces processing efficiency. For this reason, the separated zero-level light was combined with the Bessel beam to form a combination of processing and modification beams, which successfully overcame the above defects and significantly improved the processing quality through the complementary effect of energy distribution.

The hologram with s = 8 pixels, n = 3 in Fig. 8(c) is loaded into the SLM, separating the zero-order light and positioning it directly in front of the positive first-order diffraction light of the third-order Bessel beam (Fig. 8(d)), forming a combination of processing and modification beams, which works as shown in Fig. 6(a). Figure 10(b) and (d) show that the depth and width of the microchannels processed with the combined beam are both the highest, approximately 19.134 μm and 13.338 μm respectively. Compared with the unmodulated beam and the Bessel beam, after using the combined beam, the MRR was 6786.362 µm3/s, which increased by 7.7 times and 1.9 times respectively, and the bottom roughness value Ra of the microchannel decreased by 2.8 times and 2.9 times respectively. As shown in Fig. 9(g) and (h), the overall homogeneity of the microchannel bottom improved after processing with the combined beam, and no obvious ablation pits or melt splatter were observed. Further AFM analysis in Fig. 9(i) shows that the surface roughness Ra at the microchannel bottom is 0.128 μm, which is significantly better than that achieved using the unmodulated or Bessel beam. Figure 10(a) and (c) show that the roughness profile using the combined beam has the least undulation and the lowest roughness value, verifying that the quality of the microchannel bottom surface is improved by using the combined beam, while Fig. 10(b) demonstrates that the resulting microchannel cross-sectional profile is closer to the ideal rectangular shape.

The zero-level light action principle is shown in Fig. 6(b). Zero-level light has high energy concentration, which can rapidly break through the processing threshold of the material and realize efficient material removal34,45. When processing microchannels, zero-level light can form very precise contour edges on the material surface, ensuring clear and sharp cuts. The principle of Bessel beam action is shown in Fig. 6(c), where its long focal depth and uniform annular energy distribution allow further modification of the machined area, removing the V-shaped sidewalls and deepening the depth of the microchannel, as well as melting the tiny bumps and rough areas created by laser scanning within the microchannel. This allows the material to reflow and solidify to fill in the ablation craters, thus optimizing the quality of the inner wall of the microchannel and its shape contour. Both synergize in energy distribution and nonlinear effects to reduce heat buildup and heat-affected zones. Slightly jagged marks were present in the microchannel exit profile, affecting machining stability due to the unsteady movement of the 3-axis displacement stage and the clamping device during the traveling process. Compared with Gaussian and Bessel beams, the combined beam showed significant advantages in material removal rate, surface quality, and thermal effect control, providing a new processing idea for UV Curable Resin microchannel machining and verifying the feasibility of SLM-modulated processing and modification beams for microchannel machining. Compared with previously reported methods for fabricating rectangular microchannels using CO2 lasers and masks5 or femtosecond lasers combined with chemical etching49, the method proposed in this study is more flexible and convenient.

Machining parameter optimization

Effect of grating period on microchannel quality

The grating period determines the distance between the separated zero-level spot and the Bessel spot37,38, and different spot distances will have varying effects on the beam interference. To optimize the effect of compound processing, = 0.98 W, = 800 kHz, the scanning speed set to 0.03 mm/s, and a 3rd-order 8Pixel hologram (Fig. 8(c)) was loaded. The start value of the grating period is set to 10, the termination value is set to 25, and the step size is taken to be 5. Figure 11(a), (d), (g) and (j) are superimposed sequentially. When the grating period is equal to 10, the Bessel beam is outside the framing range of the CCD2 camera, and the framing range is adjusted upward so that the spot of the combined beam (Fig. 11(b)) is exposed in the framing range. As the grating period increases, the distance between the Bessel spot and the zero-order spot decreases. When the grating period is less than or equal to 15, Fig. 11(b) and (e) show that the distance between the zero-order light and the positive first-order Bessel spot is far away. The action of the zero-order laser shows irregular spot ablation, and after the action of the composite Bessel spot, ablation craters are formed at the ablation spots (Fig. 11(c)and (f)). When the grating period is 20, Fig. 11(h) shows that the composite position of the zero- order spot and the positive first-order Bessel spot is appropriate, with no ablation pits in Fig. 11(i), and the morphological uniformity is good. When the grating period is 25, the distance between the zero-order light and the positive first-order Bessel spot in Fig. 11(k) is too small, causing the laser energy to concentrate in the central region of the microchannel. The concentration of laser energy in the center of the microchannel region exacerbates the heat buildup, leading to a melt flow pattern at the bottom of the microchannel, as shown in Fig. 11(1).

Effect of scanning speed on microchannel quality

Adjusting \(\:{E}_{out}\) = 0.98 W, \(\:{F}_{pul}\) = 800 kHz, and loading the hologram (Fig. 8(c)) with a 3rd-order 8Pixel, the scanning speed is set from 0.01 mm/s to 0.09 mm/s with a step size of 0.02 mm/s. Figure 12(d)-(f) show that at a scanning speed greater than or equal to 0.07 mm/s, the number of pitting ablation pits increases, with the presence of ablation pits and some unremoved molten deposits, and the roughness gradually increases. Figure 13(b) shows that at 0.11 mm/s, the overall structure presents a “V” shape. When the scanning speed is too fast, the interaction time between the beam and the material is shortened, and the energy intensity and uniformity are weakened, which is insufficient to completely melt the material and form a uniform molten region. When the scanning speed is 0.05 mm/s, the depth of the microchannel is 11.259 μm, and the width is 10.731 μm. At this speed, the roughness curve shown in Fig. 13(a) and (c) is the smoothest, and the roughness value shown in Fig. 13 is the smallest (Ra = 0.308 μm). It can be seen from Fig. 12(c) that the morphology and bottom profile of the microchannel have good uniformity, effectively removing debris residue and irregular morphology. The microchannel exhibits a rectangular morphology, and the smoothness and homogeneity of the wall surface are improved. The structure is flat and clear, with no accumulation of melt or spattering of debris. In Fig. 13(b), the microchannel structure shows a nearly rectangular slot cross-section. The self-recovering property of the Bessel beam is fully utilized. The focusing intensity of the beam remains stable, and the interaction time between the beam and the material is long, allowing the beam to repair its morphology during the propagation process. The uniform transfer of energy is maintained when the laser interacts with the material, ensuring uniform melting of the material and consistency of the morphology. Figure 12(a) and (b) show that the roughness increases again at a scanning speed less than or equal to 0.03 mm/s, and the bottom topography takes on a honeycomb shape. The interaction time of the beam with the material is too long, leading to excessive energy accumulation. The melted photosensitive resin may flow or expand, resulting in the honeycomb feature of the bottom morphology. Figure 13(d) shows that the scanning speed has a significant effect on the morphology of the cut area, with the depth and width gradually increasing as the scanning speed decreases, and the rectangular convergence increases.

(a) Roughness profile curves of the bottom of the microchannel at different scanning speeds, (b) Profile curves of the microchannel at different scanning speeds, (c) Roughness values of the bottom of the microchannel at different scanning speeds, (d) Microchannel sizes for different scanning speeds.

Flexible regulation

Effect of hologram radius phase values on microchannel widths

The high flexibility of the SLM in generating combined beams and modulating the width of the microchannels was verified by varying the phase value of the hologram radius s, to modulate the axicon phase hologram and thus the spot size of the higher-order Bessel beams. As the phase value s of the hologram radius increases, the depth of focus becomes shorter, and vice versa50. During processing, the focal points of different holograms are focused on the same horizontal plane. The dimensions of the higher-order Bessel beams with different phase values and the parameters of the formed microchannels are shown in Table 2, and the spot images of the higher-order Bessel beams are shown in Fig. 14(d)-(f). \(\:{F}_{pul}\) = 800 kHz, \(\:{E}_{out}\) = 0.98, the scanning speed is 0.05 m/s, and the. The hologram radius of the higher-order Bessel beams is the same, but the depth of focus varies.

The holograms shown in Fig. 14(a)-(c) are loaded sequentially in the SLM, and the holograms are adjusted to optimize the beam quality. The images of the combined beams produced are shown in Fig. 14(g)-(i). The measured widths of the LSCM profiles were 23.510 μm, 20.318 μm, and 17.113 μm, respectively, and the depths were approximately 10.360 μm. Figure 15(a) shows the 3D morphology of a flat and well-defined microchannel structure, with no melt buildup or debris splattering. In Fig. 15(c), the roughness curve of the bottom of the microchannel is smooth. Comparison of Figs. 15(b) and (d) shows that the width of the microchannel increases with the phase value s of the hologram radius, while the depth remains nearly constant. As the phase value s of the hologram radius increases, the size of the annular spot increases, the width of the central main lobe increases, and the interaction region of the beam with the material becomes wider. However, the energy distribution of the beam in the axial direction does not change significantly, and the change in the depth of beam interaction is small. As shown in Fig. 15(d), when the phase value s of the hologram radius increases by 4 pixels, the width increases by approximately 3.2 μm.

(a) LSCM images of microchannels processed by combined beams generated from holograms with different phase values, (b) The combined beam generated by holograms with different phase values processes the contours of microchannels, (c) Roughness curves of microchannel bottoms processed by combined beams from holograms with different phase values, (d) Microchannel width and roughness for hologram processing at different phase values.

Effect of topological charge number on the depth of microchannels

\(\:{F}_{pul}\) = 800 kHz, \(\:{E}_{out}\)= 0.98 W, the scanning speed is 0.05 m/s. The phase value of the hologram radius is set to 24 pixels, and the adjusted topological charges are taken to be 1, 5, and 9, which correspond to the order of Bessel light as 1, 5, and 9. Loading the holograms of Fig. 16(a-c), the ring geometries of the Bessel beams of different orders, along with the parameters of the formed microchannels, are shown in Table 3, and the spot images of the modulated combined beams are shown in Fig. 16(j-l).

(a)-(c) Holograms with different phase values, (d)-(f) Spot images of higher-order Bessel beams generated by holograms with different phase values; (g)-(i) LSCM images of higher-order Bessel beams generated by holograms with different phase values, (j)-(l) Spot images of combined beams generated by holograms with different phase values.

The LSCM profile scan shows that the microchannel width is about 23.637 μm, and the depths are 11.062 μm, 10.358 μm, and 9.663 μm, respectively. As shown in Fig. 17(a), the microchannels exhibit good surface quality and improved bottom height homogeneity. In Fig. 17(b), the cross section of the microchannel is close to a rectangular profile. Analysis of the roughness profile in Fig. 17(c) shows that the bottom of the microchannel is smooth. Notably, comparison of the experimental data in Figs. 17(b) and (d) reveals that the depth decreases by approximately 0.7 μm for every 4-unit increase in topological charge n, while the channel width remains relatively stable. The spot of the higher-order Bessel beam shows a vortex-like shape, and the number of topological charges in the beam increases with the increasing order. The vortex effect of the spot in Fig. 16(d)-(f) is gradually enhanced, the energy flow to the peripheral annulus is increased, and the energy density of the center main lobe is reduced. The intensity of light per unit volume decreases, as shown in Fig. 16(g)-(i), and the depth of the microchannel decreases slightly. Regulating the laser energy has a large impact on the microchannel depth. To meet the specific requirements of the microchannel depth, the microchannel depth can be flexibly regulated in small increments by adjusting the order of the Bessel beam, which further improves the controllability of the processing. The flexibility of the SLM for microchannel depth regulation in generating higher-order Bessel vortex beams is verified by adjusting the topological quantum charge number.

(a) LSCM images of microchannels processed by combined beams generated from holograms with different topological charges, (b) The combined beam generated by holograms with different topological charges processes the contours of microchannels, (c) Roughness curve of the microchannel bottom processed by combined beams from holograms with different topological charges, (d) Microchannel depth and roughness for hologram processing at different phase values.

Conclusion

This paper proposes a Bessel beam-based combined beam for processing rectangular microchannels on UV-curable resin, offering excellent uniformity, flexibility, and controllability. A spatial light modulator is used to phase-shape the femtosecond laser and modulate it into a combined beam of a zero-order light and a positive first-order Bessel beam. This approach achieves -quality, effective modification of the depth and width of the microchannels. By adjusting the number of cycles of the blazed grating, the zero-order light is separated from the center of the Bessel beam and placed at the front side to form a suitable combined beam. This optimizes the material removal rate, geometric shape, and processing quality of the rectangular microchannel, allowing a single scan to achieve rectangular microchannel processing. At a scanning speed of 0.03 mm/s, the MRR is 6786.362 µm3/s, and the AFM shows an average roughness value of 128 nm. Compared with the unmodulated and Bessel beams, the MRR improved by 7.7 and 1.9 times, respectively, and the average roughness was reduced by 2.8 and 2.9 times. There was no melt splashing on the surface of the microchannels, and the quality of the microchannel bottoms was significantly improved, verifying the method’s feasibility. For the 0.05 mm/s scans, the average line roughness values for the three phases were 0.277 μm, 0.328 μm and 0.298 μm. The average line roughness values for the three orders are 0.331 μm, 0.316 μm, and 0.305 μm. At a laser power of 0.98 W, when the phase value s of the hologram radius increases by 4 pixels, the microchannel width increases by 3.2 μm; when the topological charge n increases by 4 units, the microchannel depth decreases by 0.7 μm. Adjusting the phase of the axicon phase function and the topological charge of the vortex optical field function allows flexible control of the Bessel beam’s spot diameter and vortex phase angle, enabling multi-size rectangular microchannel processing. Altogether, we demonstrate the use of a femtosecond shaping combined beam processing method on UV-curable resin, which not only achieves a high material removal rate, good uniformity, and high controllability but also produces a smooth surface that can be used directly without any post-processing. By enabling single-scan fabrication of smooth microchannels with tunable dimensions, this method addresses key challenges in microfluidic device manufacturing, such as reducing post-processing steps and enhancing throughput for applications like point-of-care diagnostics and organ-on-a-chip systems.

Data availability

The datasets used and analyzed during the current study available from the corresponding author on reasonable request.

References

Mokkapati, V. et al. Microfluidic chips fabrication from UV curable adhesives for heterogeneous integration. In 2012 IEEE 62nd Electronic Components and Technology Conference, 1965-1969 (IEEE, 2012).

Kuo, S. M. et al. A rapid process for fabricating microfluidic devices with a Low-Cost UV curable resin. Adv. Mater. Res. 189, 3441–3445 (2011).

Gong, H. et al. Custom 3D printer and resin for 18 μm× 20 μm microfluidic flow channels. Lab. Chip 17(17), 2899–2909 (2017).

Zhang, C. et al. Embedded 3D Printing for Microchannel Fabrication in Epoxy-Based Microfluidic Devices. Polymers 16(23), 3320 (2024).

Prakash, S. & Kumar, S. Fabrication of rectangular cross-sectional microchannels on PMMA with a CO2 laser and underwater fabricated copper mask. Opt. Laser Technol. 94, 180–192 (2017).

Grosvirt-Dramen, A. UV-curable PDMS for additive manufacturing of microfluidic devices (2018).

Koo, J. & Kleinstreuer, C. Liquid flow in microchannels: experimental observations and computational analyses of microfluidics effects. J. Micromech. Microeng. 13(5), 568 (2003).

Zhang, X., Jones, P. & Haswell, S. J. Attachment and detachment of living cells on modified microchannel surfaces in a microfluidic-based lab-on-a-chip system. Chem. Eng. J. 135, S82–S88 (2008).

Prakash, S. & Kumar, S. (2015) Fabrication of microchannels: a review. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 229 (8), 1273–1288. https://doi.org/10.1177/0954405414535581

Sato, H. et al. Improved inclined multi-lithography using water as exposure medium and its 3D mixing microchannel application. Sensors and Actuators A: Physical. 128(1), 183–190 (2006).

Peng, Y. et al. Fabrication of high-performance microfluidic SERS substrates by metal-assisted chemical etching of silicon scratches. Surf. Topogr. Metrol. Prop. 10(3), 035008 (2022).

Bai, S. et al. 3D microfluidic Surface-Enhanced Raman Spectroscopy (SERS) chips fabricated by all‐femtosecond‐laser‐processing for real‐time sensing of toxic substances. Adv. Funct. Mater. 28(23), 1706262 (2018).

Kolliopoulos, P. et al. Capillary-flow dynamics in open rectangular microchannels. J. Fluid Mech. 911, A32 (2021).

Kolliopoulos, P. et al. Capillary flow of evaporating liquid solutions in open rectangular microchannels. J. Fluid Mech. 938, A22 (2022).

Sugioka, K. & Cheng, Y. Femtosecond laser processing for optofluidic fabrication. Lab. Chip. 12 (19), 3576–3589 (2012).

Gattass, R. R. & Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2(4), 219–225 (2008).

Gao, L., Zhang, Q. & Gu, M. Femtosecond laser micro/nano processing: from fundamental to applications. Int. J. Extreme Manuf. 7(2), 022010 (2024).

Rizvi, N. H. Femtosecond laser micromachining: Current status and applications. Riken Rev. 107–112 (2003).

Wang, Z. K., Zheng, H. Y. & Xia, H. M. Femtosecond laser-induced modification of surface wettability of PMMA for fluid separation in microchannels. Microfluid. Nanofluid. 10, 225–229 (2011).

Qi, Y. et al. Research progress of laser beam shaping technology. Laser Optoelectron. Prog 61(5), 0500005 (2024).

Durmin, J. Exact solutions for nondiffracting beams. J. Opt. Soc. Am. A. 4 (4), 651–654 (1987).

Vasara, A., Turunen, J. & Friberg, A. T. Realization of general nondiffracting beams with computer-generated holograms. JOSA A 6(11), 1748–1754 (1989).

Vasara, A., Turenen, J. & Friberg, A. T. General diffraction-free fields produced by computer-generated holograms. In 1989 Second International Conference on Holographic Systems, Components and Applications. 85-89 (IET, 1989).

Cao, Q. et al. Spatiotemporal hologram. Nat. Commun. 15(1), 7821 (2024).

Zhai, Z. et al. Realizing high-order bessel vortex beams with high-level phase holograms. IOP Conf. Ser. Mater. Sci. Eng. 569, 032039. https://doi.org/10.1088/1757-899X/569/3/032039 (2019).

Zhai, Z. et al. Tunable axicons generated by spatial light modulator with high-level phase computer-generated holograms. Appl. Sci. 10(15), 5127 (2020).

Vaity, P. & Rusch, L. Perfect vortex beam: Fourier transformation of a Bessel beam. Opt. Lett. 40(4), 597–600 (2015).

Liu, H. et al. Generation of high-order bessel orbital angular momentum vortex beam using a single-layer reflective metasurface. IEEE Access. 8, 126504–126510 (2020).

Yang, Y. et al. Highly efficient nonlinear vortex beam generation by using a compact nonlinear fork grating. Opt. Lett. 48(24), 6376–6379 (2023).

Zamboni-Rached, M., Nobre-Pereira, J. & Quaglio, J. Shaping high-order diffraction-free beams through continuous superposition of Bessel beams. arXiv preprint arXiv:2402.02828 (2024).

Meng, X. et al. Launcher of high-order Bessel vortex beam carrying orbital angular momentum by designing anisotropic holographic metasurface. Appl. Phys. Lett. 117(24), 31 (2020).

Baltrukonis, J. et al. High-order vector Bessel-Gauss beams for laser micromachining of transparent materials. Phys. Rev. Appl. 16(3), 034001 (2021).

Hongsheng, Q. et al. Research on ultrafast laser processing method using tunable bessel beam. Infrared Laser Eng. 53(8), 20240185-1–20240185-9 (2024).

Liang, G. et al. Application of array Bessel beam generated by superposition method in electronic glass cutting. Opt. Lasers Eng. 181, 108384 (2024).

Jedrkiewicz, O. et al. Pulsed Bessel beam-induced microchannels on a diamond surface for versatile microfluidic and sensing applications. Opt. Mater. Express 7(6), 1962–1970 (2017).

Zhu, Y. et al. Eliminating zeroth-order light of spatial light modulator with voltage optimization. arXiv preprint arXiv:2211.05302 (2022).

Wu, J. et al. Removal of Zero-Order Beam Interference using Dammann Grating Grayscale Map. Laser Optoelectron. Progress 61(4), 0411008 (2024). (in Chinese)

Zhai, Z. et al. Flattop beam shaping using hybrid gratings. IEEE Photonics J. 14(4), 1–5 (2022).

Zhai, Z. et al. Beam shaping with high energy utilization and uniformity using gradient orthogonal gratings. Appl. Opt. 60(17), 5104–5109 (2021).

McGloin, D. & Dholakia, K. Bessel beams: diffraction in a new light. Contemp. Phys. 46(1), 15–28 (2005).

Xiao, M. et al. Impact of spatial light modulator pixel pitch on the accuracy of aspheric testing. Chin. J. Lasers 44(1), 0104002 (2017). (in Chinese)

Songtao, G., Yongxin, S. & Huaijiang, Y. High precise testing of asphere with computer-generated hologram and error evaluation. Acta Opt. Sin. 33(6), 0612003 (2013).

Wang, J. et al. Achieving higher spatial resolution in complex amplitude modulation using a pixel shift-based dual-phase modulation method. Opt. Rev. 1-9 (2025).

Li, G. et al. Surface quality and material removal rate in fabricating microtexture on tungsten carbide via femtosecond laser. Micromachines 14 (6), 1143 (2023).

Ando, T. et al. Mode purities of Laguerre–Gaussian beams generated via complex-amplitude modulation using phase-only spatial light modulators. Opt. Lett. 34(1), 34–36 (2008).

Asgari Sabet, R. et al. Laser nanofabrication inside silicon with spatial beam modulation and anisotropic seeding. Nat. Commun. 15(1), 5786 (2024).

Teng, Y. et al. Recent research progress on femtosecond laser induced microstructures in glasses. Int. J. Optomechatron. 6(2), 179–187 (2012).

Wu, D. et al. Laser ablation behavior and mechanism of Cf/C–SiC composites under different laser energy densities. Compos. Part. B: Eng. 276, 111359 (2024).

Kurnoothala, R., Vishnubhatla, K. C. & Srivastava, S. HF-free and fast fabrication of long, rectangular microchannels in fused silica: novel femtosecond laser irradiation geometry. Opt. Mater. 122, 111682 (2021).

Yao, Z. et al. High-efficiency fabrication of computer-generated holograms in silica glass using a femtosecond Bessel beam. Opt. Laser Technol. 135, 106729 (2021).

Acknowledgements

These research results were obtained at Key Laboratory of High-end Laser Manufacturing Technology and Equipment of Shandong Province in China, Discipline Innovation and Wisdom Introduction Base of High-end Laser Intelligent Manufacturing Technology and Equipment in China, the Department of Physical Electronics in the Faculty of Engineering at Tel Aviv University in Israel, and the National Institute of Laser Enhanced Sciences at Cairo University in Egypt.

Funding

Higher Education Discipline Innovation and Intelligence Program [D21017]; Key Research and Development Program (International Science and Technology Cooperation) of Shandong Province (2024KJHZ002); Natural Science Foundation of Shandong Province (ZR2023ME156); the Talent Category of the ‘Double Hundred Plan for Foreign Experts’ of Shandong Province (WSR2023055); National Natural Science Foundation of China (52405492); Natural Science Foundation of Qingdao (24-4-4-zrjj-68-jch).

Author information

Authors and Affiliations

Contributions

Yao Fei Ma: Writing - manuscript, methodology, data collation. Sun Shufeng: Supervision, resources, project management, financing and acquisition. Wang Jin and Walid Tawfik: Verification. Fengyun Zhang and Xuecheng Gao: Data management. Zhihao Qu : Software. Tao Wei and Yong Zhu: Conceptualization. Xia Bingkun: Data content management. Tal Ellenbogen: Investigation. Harith Bin Ahmad and Pingping Wang: Validation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, Y., Sun, S., Wang, J. et al. Research on microchannel fabrication in UV curable resin using combined beam processing. Sci Rep 15, 31296 (2025). https://doi.org/10.1038/s41598-025-17195-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-17195-8