Abstract

As an information carrier, current signal directly reflects the electromechanical coupling between the stator and rotor of an induction motor. In this study, a detection method of winding fault based on current information is proposed to identify fault and realize feature decoupling for an induction motor. Unlike most current analysis methods, this method combines the electromagnetic field distribution with the feature frequency of the current signal to achieve the detection of the stator winding fault. With mathematical models, the phase, amplitude, and frequency of the three-phase current are mapped into a spatial coordinate system, which can help to identify the faults of the induction motor by a balance structure. To further identify the fault features, the projections of the coupled magnetic fields are combined with the feature frequencies, which can be used to extract accurately the electromechanical information on the stator and rotor. And the proposed methods are verified by a test bench of motor fault. The results show that the proposed methods can effectively detect a stator winding fault of the frequency conversion motor using the distributions of the magnetic motive forces and the feature frequencies of the current signals. The method proposed in this study provides a new tool for the fault detection and condition monitoring of induction motors.

Similar content being viewed by others

Introduction

The induction motor is a typical industrial product that plays an important role in driving technology. In machine tools, printing machines, electric vehicles, and other precision mechanical devices, the induction motor is required to work stably and reliably to satisfy the strict running requirements. An unreliable running of the induction motor may degrade product quality and increase processing costs. Thus, monitoring the running states of an induction motor is an important guarantee for determining whether the induction motor works in a good state. One of the main tasks of monitoring running state is to detect the motor fault. However, researchers have focused on the fault identification of the induction motor and reducing concerns regarding the fault detection. Up to now, most motor fault detections rely on the noise, temperature, and vibration in the motor operation. Unfortunately, the information often appears when the motor fault is severe, which may delay the time when the fault is discovered. By contrast, the current signal has the advantages of being less affected by electromagnetic interferences and reflecting the internal running states of the induction motor directly, so some studies have focused the fault detection of induction motor on the motor current signal.

Failure surveys1,2 show that the typical failure percentages of induction motors are as follows: stator-related faults 38%, rotor-related faults 10%, bearing-related faults 40%, and other faults 12%. The stator-related faults include winding fault, short circuit, loss of supply phase; the rotor-related faults are broken bar, broken end-ring; the bearing-related faults refer to the faults of supporting bearings; other faults have static and dynamic eccentricities. Previously, motor current signature analysis (MCSA) was used to detect broken rotor bar with the signal processing methods3,4,5,6,7. Didier, et al.3 proposed to detect the broken rotor bar of the induction motor with the line current discrete Fourier transform (DFT). Aydin, et al.4 developed a new method for the detection and diagnosis of broken rotor bars faults in three-phase induction motors under no-load conditions. Karami, et al.5 presented a filtering technique using Unscented Kalman Filter (UKF) and Extended Kalman Filter (EKF) as a state estimation tool to achieve the on-line detection of broken bars of induction motors. And, MCSA was also used in the detection of the rotor-related faults. Fernao Pires, et al.8 proposed a new method entitled motor square current signature analysis to detect the rotor fault. Pires, et al.9 presented a new approach based on the current and a virtual flux, the virtual flux can improve the noise ratio of signal and allows the identification of a rotor cage fault independently. For the bearing-related faults occupying relatively high levels, some studies try to analyze them with current signal10,11,12,13,14,15. Blödt, et al.12 described a new analytical model for the influence of rolling-element bearing faults on induction motor stator current. Zarei, et al.13 presented a method based on Park’s vector approach for bearing fault detection using three-phase stator current analysis. Deekshit Kompella, et al.14 proposed the monitoring stator current by means of frequency spectral subtraction using various wavelet transforms to suppress dominant components. In the detections of other faults, Akar16 presented the detection of a static eccentricity fault in a closed loop operating induction motor driven by inverter. Cakır, et al.17 described an approach for detection of the supply unbalance condition in induction motors by using data mining process.

The stator-related fault is an important type of induction motor failures. Compared to other types of motor faults, the detection method of the stator-related faults is insufficient. In recent years, the relevant studies are being performed18,19,20,21. Ben Khader Bouzid, et al.18 employed the compensation of the negative sequence current to isolate the negative sequence current due to the stator fault. Jover Rodriguez, et al.19 presented a reliable method for the detection of stator winding faults based on monitoring the line/terminal current amplitudes. Owing to the frequency is important information for determining induction motor fault, the above research studies use signal processing methods to find the slip frequency and harmonics around the power supply frequency in the current spectrum to determine motor fault. If the feature frequency of stator fault is not obvious, the stator fault may not be determined. Clearly, it is not sufficient to identify the stator faults by the frequency information alone. As a typical electromechanical device, an induction motor is a coupling body for mechanical motion and electrical behaviour. The motion of the rotor depends on the magnetic fields generated by the stator currents, so the winding structure of the stator determines the distribution of the magnetic fields. When the stator winding fails, the magnetic field distribution is changed, and the change may indicate that the induction motor is in an abnormal state or has a fault. Consequently, as an auxiliary of the current signal analysis, the magnetic field distribution is the focus of this study, and the combination of the electromagnetic coupling and feature frequency will be considered in the detection of motor faults.

In this paper, a fault detection method based on current information is proposed to identify the winding fault of induction motors. Unlike other studies related to this subject, the fault detection depends on the combination of current signal frequency and magnetic field distribution. For the fault detection of induction motor, the three-phase current signals collected from an induction motor are transformed into a mapping space to identify the stator-related faults. To further identify the impacts of the fault on the driving components, the current signals are subsequently transformed into the magnetic motive forces (MMFs) of the motor stator and rotor by electromagnetic induction theories. With Hilbert demodulation, the current signals are demodulated, and the feature frequencies of the current signal are extracted. Then, the MMFs are decomposed according to the frequency components of the current signals, so a model combining the magnetic field distribution with the feature frequencies is established, which can intuitively show the feature frequencies causing the fluctuations in the magnetic field. Finally, the proposed detection method is verified by the experiment of simulated winding fault on the test bench of frequency conversion motor fault, and the results indicate that the detection method using the current information is effective for the winding fault. This study provides a new tool for the fault detection and condition monitoring of induction motors.

Motor fault detection based on current information

With analysis of the single-phase current signal, the feature frequencies of the stator and rotor can be extracted to identify faults of the induction motors22. However, the single-phase current signal only reflects the driving state of homopolar coil for the stator, and it cannot systematically describe the dynamic behaviours of the rotor. In contrast, the three-phase current can describe the internal mechanical and electrical characteristics of the induction motor23. Therefore, the motor fault detection method based on the three-phase current signal should be concerned.

Three-phase current signal analysis in motor fault detection

In an induction motor, the symmetric structure of stator windings forms a balance to ensure that the rotor works in a stable state. For the three phases, U, V, and W, the phase difference between the three current signals is 120°. If the axis angle of the U-phase winding is regarded as the origin of the coordinate system, the currents of the three phases, U, V, and W, are expressed as follows:

where iU, iV, and iW are the currents of phases U, V, and W, respectively; I is the phase current amplitude; and ω is the angular frequency.

Normally, MCSA uses the modulated frequency components to identify the fault of an induction motor24; that is, the sideband components in the current spectrum are the parameters used to identify the faults. The frequency fs of the sideband component can be expressed as follows:

where f0 is the power supply frequency, and s is the slip of the induction motor.

Considering only the frequencies of the sideband components, the currents of phases, U, V, and W in Eq. (1) can be represented as follows:

where is is the amplitude of the sideband component, f0 + fs and f0 - fs are the sideband components.

Under the conditions of rated and high loads, the frequency fs can be used as an effective feature for the fault identification of an induction motor. However, under the conditions of light loads and low speeds, fs will be close to the supply frequency f0 and thus spectrum leakage may subsume the sideband components. Additionally, the form of the pulse width modulation (PWM) wave output by the frequency converter is similar to that of a rectangular wave during low-speed operation, which can lead the harmonics of the supply frequency to interfere with the identification of the fault features. The fluctuations caused by the load will promote the modulation of the current signal, which also increases the difficulty of detecting sideband components. In these cases, it is not reasonable to detect motor faults based on the current spectrum. Therefore, traditional current analysis needs to be improved to detect motor faults accurately.

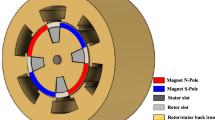

Winding fault detection with the current signal

When currents pass through the coils of the stator, the air-gap between the stator and rotor will be filled with a coupled magnetic field owing to the electromagnetic induction effect, and the driving forces of the magnetic rings on the stator and rotor are opposite. In the fault of motor stator, a faulted stator winding interacts with a healthy rotor. The faulted stator winding may produce spatial harmonics of any wave number in the air-gap field25. In Fig. 1, there is a fault in a winding of the stator, and the winding impedance and current amplitude will thus be changed. Following the change to the magneto-resistance of the coupled magnetic field, the induced magnetic field will cause fluctuations. The fluctuations feedback into the stator current as new harmonic components through magnetic field changes. Seen from the stator, the frequency of new harmonic component is expressed as follows:

where, fr is the frequency of new harmonic component, p the number of pole-pairs, n the number of rotor bar, and λ is the number of frequency multiplication.

According to MCSA, the feature frequencies of the stator faults exist in the current spectrum in a modulated form, which means that the feature frequency is difficult to detect from the current spectrum19. It is not easy to detect winding fault simply by discovering the amplitudes of harmonic components, and it should require other information to discover the motor fault. A healthy induction motor with a symmetric power supply has three balanced phase currents, and the coupled magnetic field is ideally a symmetry system. Therefore, the three-phase current can be used to calculate the balance of stator currents, which may be an effective method for the detection of winding fault in the induction motor.

Spatial spiral projection of three-phase current

For the winding fault of a stator, the phases of the three-phase current are often in an unbalanced state. Although it is an important feature, the phase information of the current signal is not reflected in the current spectrum. Next, a new model is presented to represent the symmetry system of the current signals. The proposed model combines the amplitudes and phases of the three-phase current signals to form a spatial spiral projection. The projection space is composed of time axis, phase axis, and amplitude axis, and is described as follows:

where i(t) is the current signal, p(t) is the spiral projection of the current signal, and ejt is the base of the spiral projection. Then, the current signals can be transformed into:

The spiral projection is similar to Park’s transformation26. Equation (5) can be used to project the three current signals onto a coordinate space according to the coordinate axis using Euler formula. The spiral projection in orthogonal space not only preserves the amplitudes of the waveforms but also shows the phase information; the frequency of the projected waveform is the same as that of the original signal. Additionally, the projected coordinates can unify the stator and rotor to establish a measurement coordinate system. The form of the spatial spiral projection in the measurement coordinate system can reflect changes in the coupled magnetic fields, and the model of the spatial spiral projection is shown in Fig. 2. In the spiral projection, the three-phase current of a healthy induction motor is shown with balanced phases and amplitudes, otherwise the three-phase current is characterized by an asymmetric structure. For a healthy stator, one phase current is fixed as the reference signal with a supply frequency f0, and the other two phases are shown with the same phase difference of 120° in the projection space. The three current signals in the spatial projection are stretched to form three spiral structures, and the spiral structures maintain a balance under the normal operation of the induction motor. If the induction motor is running in an abnormal state, the balanced structure will be disrupted, which indicates that the induction motor is faulty.

Feature decoupling of three-phase current signals

In feature decoupling of three-phase current signals, the magnetic field distribution is combined with the feature frequency to further find the cause of the stator fault, which will provide a new way for the fault detection of induction motor.

Model of magnetic motive forces based on three-phase current

Based on the spiral projection of the three-phase current signals, the coupled magnetic field inside the induction motor is associated with the current signals. Here, MMFs are used to indicate the intensity and driving ability of the coupled magnetic field. The waveforms of the pulsating MMFs generated by the three-phase current are expressed as follows:

where MU, MV, and MW are the MMFs of three-phase current signals iU, iV, and iW, respectively, FΦ is the effective amplitude of the pulsating MMFs, and θ is the initial phase angle.

Then, Eq. (7) is transformed into:

Let

where FM is the amplitude of the synthetic MMF. Owing to the phase difference between the three current signals, only the cosine components are retained in M(t, θ). FM is defined as follows:

where p is the number of pole pairs, N is the winding number, kN1 is the winding factor, and I is the armature current.

Equation (10) describes the relationship between the stator current and the electromagnetic field of the induction motor. It is clear that the current signal is proportional to the electromagnetic driving force. With the spatial projection, the MMFs are mapped to a plane, and the distribution of the magnetic potential can be obtained by:

Similarly, the three-phase current signals can be expressed as follows:

The three current signals in the spatial projection coordinates are represented as:

Then, the distribution of the coupled magnetic field can be obtained from the projected current signals; thus, the MMFs can further express the change in the coupled magnetic field.

Feature extraction of the current signal

Owing to the fact that the current signal is a typical modulated signal, the feature frequencies of the motor faults are concentrated around the power supply frequency in the current spectrum. When the slip of the induction motor is extremely low, which makes it difficult to identify the fault frequency in the current spectrum. To obtain the frequencies of the multiple components in the stator current, Hilbert transform is applied for demodulation of the current signals27,28, as follows:

where I(t) is the current signal, and t is the time variable. Equation (13) can be rewritten as follows:

The current spectrum normally contains multiple sideband components. To obtain the fault frequency ft, the Hilbert transform of the current signal I(t) is expressed as:

where

The imaginary part of Eq. (15) is the phase shift of the current signal sequence by the phase π/2. For the current signal of each phase, the feature signal is constructed as the absolute value of the Hilbert transform of the phase current. The instantaneous angular velocity (in rad/s) is given as follows:

The Hilbert transform can realize the demodulation of instantaneous information for the current signal through A(t), θ(t), and ω(t).

Feature decoupling of current signals

With the demodulation of the three-phase current, and the current signals are transformed into the coupled magnetic field. The feature decoupling combines the feature frequency and MMF to determine the cause of the coupled magnetic field fluctuation. To describe the influences of each frequency component on the coupled magnetic field, the MMFs of the rotor and stator are projected onto the coordinates according to different frequencies, and the MMFs are then reconstructed in 3D space according to the feature frequencies. Based on the spatial distributions of the MMFs, the magnetic field distributions of the rotor and stator under different frequencies can be identified intuitively, allowing the fault pattern of the induction motor to be detected. The process of feature decoupling is illustrated in Fig. 3.

Simulations

A simulation is used to describe the fault detection and feature decoupling with the three-phase current signals. For the three-phase current signals, it is assumed that A1 = A2 = A3 = 10 A, f1 = f2 = f3 = 50 Hz and θ = 0, so the current signals are represented by:

Figure 4 shows the waveform of the three-phase current signals with a phase difference of 120°. Figure 4(a) shows the time-domain waveform of the three-phase current signal, and the spectrum of the single-phase current signal is shown in Fig. 4(b). The current signals are transformed by Fourier transform, the current spectrum is obtained first, and the main frequency of the spectrum is taken as the projection frequency to obtain the spiral projection. Otherwise, a mesh projection will be obtained, which is not suitable for current signal analysis. With Eqs. (5) and (6), the spiral projection and plane mapping of the three-phase current signals are shown in Fig. 4(c) and (d), respectively. Figure 4(c) shows the distribution of the three-phase current in the projection space and the combination of the phase and amplitude with the timeline. Figure 4(d) shows the projections of the phase and amplitude of the three-phase current on a plane, and the three-phase current signals form a symmetrical X-shape on the plane. The ideal three-phase current signal presents a symmetric regular pattern in space mapping. In Fig. 4(c), the frequency of the current signal is determined by the number of circles in an unit time. And the amplitude and phase of the current signal are determined by the position of the symmetric structure in Fig. 4(d).

Time domain, frequency domain, and spiral projection of ideal three-phase current signals: (a) time domain of the ideal three-phase current signals, (b) frequency domain of one phase current signals after demodulation, (c) spiral projection of ideal three-phase current signals, and (d) plane mapping of ideal three-phase current signals.

In Sect. 3, the coupled magnetic fields of the stator and rotor are characterized by Eqs. (10)~(13) to express the MMFs of the rotor and stator, and the distributions of the ideal MMFs on the rotor and stator are shown in Fig. 5. Ideally, the projections of the MMFs in Cartesian coordinates are a standard circle, which indicates that the electromagnetic driving forces are uniformly distributed in the air-gap between the stator and rotor. The MMFs of the rotor and stator have similar independent distribution forms of the driving magnetic field. Similarly, the distributions show that the orbit of the ideal rotor centre is regular and periodic.

When the induction motor has a stator fault, there are multiple frequency components around the frequency of the power supply. In this case, the distributions of the MMFs are changed from a regular form, and the distribution form can also be described by the simulation. It is assumed that the one-phase current signal includes a load frequency of 40 Hz and a slip frequency of 2 Hz, and the corresponding amplitudes are 2 A and 1 A, respectively. Meanwhile, a noise with the amplitude of 0.3 A and frequency of 40 Hz is added to the current signal to simulate the fluctuations in the load. The time and frequency domains with multiple frequency components are shown in Fig. 6(a) and (b), respectively. It can be seen that the current signals with multiple frequency components exhibit a modulation phenomenon, as shown in Fig. 6(a). Figure 6(c) and (d) show the distributions of the MMFs on the stator and rotor; both distributions have the same structure, but the amplitudes are different. Compared with the ideal current signal, it is not difficult to observe that the distributions of the MMFs will be changed with changes in the frequencies and amplitudes of the current signal. In Fig. 6(d), the projection form has been changed with multiple frequency components, and it is no longer a standard circle. Thus, this can provide a piece of evidence to reveal the cause of stator fault of the induction motor using the distributions of the MMFs.

Time and frequency domains of current signals including multiple frequency components: (a) time domain of the current signal, (b) frequency domain of the current signal after demodulation, (c) distributions of the coupled magnetic field on the stator, and (d) distributions of the coupled magnetic field on the rotor.

In Fig. 6, the distributions of the MMFs on the stator vary periodically with the frequency of the current signal, which can explain why the rotor has the same frequency fluctuation as the frequency of the current signal in the running state. Similarly, multiple frequency components can cause multiple magnetic field fluctuations, which will not only directly affect the stability of the rotor operation but also reduce the output efficiency of the induction motor. If the MMFs of the stator and rotor are extracted according to different frequency components, the distribution of the MMFs can be used to analyze the causes of the motor fault intuitively. Figure 7 shows the MMF distributions with multiple frequencies. In Fig. 7, the current of the stator acts directly on the MMF distribution of the rotor, resulting in the rotor generating frequency oscillations at 40 Hz. The results agree with the frequencies of the initial setting, and the fluctuation and noise frequencies in the simulation signal are directly reflected in the coupled magnetic field between stator and rotor. According to the distributions of the MMFs on the different frequencies, the information causing the magnetic field fluctuations is also used to analyze the operating state of the induction motor.

Experiments

To verify the effectiveness of the proposed methods, we experimentally tested the proposed methods with a test bench of frequency conversion induction motor, as shown in Fig. 8. The test bench consists of three-phase power supply, frequency converter, AC frequency conversion motor, gear transmission system, torque loading, control system, and signal acquisition system.

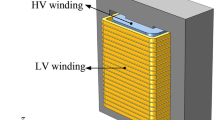

Frequency conversion induction motor is an important alternating current (AC) induction motor, which has been widely used in industries, especially in some works with efficient transmission and frequently speed regulation. Once the frequency conversion induction motor fails, it directly affects the subsequent driving and production line operation. In addition, when the frequency converter drives the induction motor to run, it provides the power supply conditions of equal voltage and current, which avoids the disturbances caused by the imbalance of voltage and current from the power grid, resulting in the stator winding fault of the induction motor being easier to identify. Thereby, frequency conversion induction motor was used as a test object. The tested motor is an AC frequency conversion induction motor (1LE0002, SIEMENS) with a Y-connection and two poles, and its work parameters are 380 V/50 Hz, 3 hp (2.2 kW), 4.8 A, and 5200 rpm as the maximum speed. The tested motor is driven by a frequency converter (VFD-037B, DELTA Electronics). The tested motor and a two-stage gearbox are connected through a coupling, and the speed ratio of the gearbox is three. Torque loading is provided by a magnetic powder brake of 50 N·m. The clamp current sensor is used to obtain the driving current signals of the tested motor, which does not require invasive access to the motor or additional equipment/sensors for measurement.

During the test, the speed of the tested motor is set to 1000 rpm (a running frequency of 16.7 Hz), and the torque loading is adjusted to 5 N·m. The sensors used consist of vibration and current sensors; the clamp current sensor obtains the three-phase current signals of the tested motor, and the vibration sensor is used as the auxiliary sensor to detect the radial vibration of the output shaft. The data acquisition system uses a 4-channel sampling card (NI 9234, National Instruments), and the sampling frequency of the current signal is set to 2000 Hz, which can reduce the phase errors of the three-phase current signals. The experimental system is shown in Fig. 9.

For the tested motor, the three-phase currents of the power supply are provided by the frequency converter, and one power supply line is connected with a rheostat of 6 kW in parallel to simulate the winding fault. The change of the winding impedance and the imbalance of the three-phase current amplitudes are simulated by adjusting the resistances of the rheostat. The AC frequency conversion motor is tested in both the healthy and faulted states. Figure 10 shows the spectrum and spiral projection of the current signals under the healthy state. In the test, the amplitudes of the three-phase current signals obtained by three clamp current sensors are basically the same, then the three-phase current signals are demodulated using the Hilbert transform to obtain the frequency components. The frequency of 16.6 Hz is used as the projection frequency for the spiral projection of the three-phase current signals. As shown in Fig. 10, the current signals of the healthy state are regular, and the projected signal is also consistent with the simulation results.

Spectrum information and spiral projection of the current signals for the healthy state: (a) time domain of the single-phase current signal, (b) frequency domain of the single-phase current signal, (c) spatial spiral projection of three-phase current signals, (d) phase-amplitude projection of three-phase current signals.

When the resistance of the rheostat is reduced, the single-phase current signal exhibits a decrease in the stator current amplitude and a change in the current signal phase, which represents the winding fault. For the current spectrum, the healthy and faulty states of the stator winding are difficult to distinguish by frequency alone. However, in the spiral projection, the change in the amplitude of the current signal can cause an imbalance between the phases and amplitudes of the three-phase current signals29,30,31. In Fig. 11, the time domain, frequency domain, and spiral projection of the three-phase current signals for the winding fault are shown. Compared with the spiral projection of the three-phase current under the healthy state, the fault information is easily reflected by the change in the current phase signal. With Fig. 11(b) and (d), there are some differences in the amplitudes of the feature frequencies, and it can not be judged whether the tested motor has failed from the frequency. In Fig. 11(d), the projection form of the one-phase current signal is obviously distorted, and the phase angle between the other currents tends to be the same, which indicates that the amplitudes of the current signals are unbalanced. The experiment shows that the spiral projection can help to identify the winding fault of the frequency conversion motor.

Spectrum information and spiral projection of the current signals for a winding fault: (a) time domain of the single-phase current signal, (b) frequency domain of the single-phase current signal, (c) time domain of the three-phase current signals, (d) frequency domain of the fault-phase current signal, (e) spatial spiral projection of three-phase current signal, (f) phase-amplitude projection of three-phase current signals.

To clarify the cause and degree of fault, the distributions of the MMFs on the stator and rotor are calculated to analyze the cause of the stator fault. Here, the distributions of the coupled magnetic fields and feature frequencies under a winding fault are analyzed simultaneously. The combination of the MMFs and feature frequencies can facilitate understanding of the internal characteristics of the induction motor and the impacts of failure. Meanwhile, the influences of the stator winding fault on the dragging loads are analyzed. Figure 12 shows the combination of the MMF distributions and feature frequencies. Figure 12(a) and (b) are the distributions of the MMFs on the stator and the rotor, respectively. And the distribution forms are associated with the structures of the stator and rotor. Figures 12(c) and (d) show the distributions of the MMFs on the stator and rotor, respectively.

As observed in Fig. 12(c) and (d), the supply frequency of the current signals is 16.6 Hz, and the corresponding speed is 996 rpm, which indicates that the actual speed of the tested motor is consistent with the set speed. The MMFs corresponding to a frequency of 16.6 Hz is the main power driving the rotor motion. Under the stator winding fault, the form of the MMFs distributions has been distorted as an ellipse owing to the change in amplitude of the one-phase current signal. Thus, the amplitude difference of the MMF distributions on the stator and rotor is large, and the result is that the rotor operates in an unstable state. As shown in Fig. 12(c), the MMFs on the stator corresponding to a frequency of 16.6 Hz are distributed uniformly, and the driving magnetic field is a healthy condition. And the distributions of the MMFs at the frequencies of 83.2 Hz (5th harmonic) and 116.4 Hz (7th harmonic) also belong to a normal state. However, in Fig. 12(d), the MMFs on the rotor corresponding to a frequency of 16.6 Hz are distributed unequally, and the form of spatial distribution is elliptical, which indicates that the orbit of the rotor section centre has changed. Moreover, the distributions of the MMFs at the frequencies of 83.2 Hz produces agitation, which may be the cause of the magnetic field fluctuations on the rotor. For the rotor of the tested motor, the distributions of the MMFs corresponding to high frequencies are in an offset state, and the spatial distributions of the MMFs have oscillatory fluctuations. The experimental results show that the distributions of MMFs can directly reflect a stator winding fault of the induction motor, and it is demonstrated that electromagnetic coupling information is an effective means of detecting induction motor faults.

Discussions

Using current signals to detect the motor fault represents an effective approach for monitoring the operational states of motors. Current information can be directly utilized to identify faults in frequency conversion induction motors, particularly in scenarios where conventional detection methods are either impractical or infeasible, such as fault diagnosis in deep submersible pumps and underwater drive motors. Consequently, the proposed method is critical to fault detection and industrial applications involving frequency conversion motors.

In this experiment, the proposed method was verified on a frequency conversion induction motor. The frequency converter outputs voltage and current with consistent amplitudes, thereby mitigating the impact of voltage and current imbalances originating from the power grid on the motor’s operational state. Given the similarity between spatial spiral projections for imbalance and winding faults and the test results, distinguishing these faults through spatial projection forms alone proves challenging. In analyzing current signals and MMF distributions, it is imperative to focus on the interplay between feature frequencies and coupled magnetic fields to accurately identify stator fault types. In practical fault detection, in addition to employing the aforementioned information, sidebands of supply frequency and temperature information should be considered, as it constitutes critical information for differentiating motor faults.

For the detection of winding faults in frequency conversion motors, there are differences in feature frequency identification between frequency conversion motors and induction motors. The fault identification of induction motors primarily focuses on the amplitude variations at the power supply frequency and its 3rd and 5th harmonics. However, due to the influence of the control and drive mode of a frequency converter, the fault identification of frequency conversion motors must additionally account for harmonic components at frequencies (6n ± 1)f0 (where n = 1, 2, 3,……, N). Moreover, the slip frequency of frequency conversion motors is generally lower than that of induction motors, which is an important feature information. In industrial applications, electromagnetic coupling information plays a crucial role in the fault detection of induction motors, as it not only facilitates fault detection but also reflects changes in operational states.

Conclusions

This study provides a practical method for detecting the winding fault of frequency conversion induction motor using current information. The proposed method combines the MMF distributions with the feature frequencies of current signals to detect motor fault, and is different from the winding fault detections using current and vibration signals in previous studies32,33,34,35,36. In this study, the mathematical models of the spiral projection and MMF distribution are given to detect the stator fault of the induction motor. With the Hilbert transform, the feature frequencies of the current signal are extracted. Combined with the MMFdistributions on the stator and rotor, the feature decoupling based on three-phase current signals is achieved to evaluate the healthy state of an induction motor. Experiments are performed to verify the effectiveness of the proposed method in the stator winding fault of a frequency conversion motor, and satisfactory results are obtained. As a non-intrusive detection method based on the current information, the method is important for the fault identification and condition monitoring of induction motors.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

IEEE Motor Reliability Working Group. Report of large motor reliability survey of industrial and commercial installations. IEEE Trans. Ind. Appl. IA-21, 4:853–872 (1986).

Nandi, S., Toliyat, H. A. & Li, X. Condition monitoring and fault diagnosis of electrical motors-a review. IEEE Trans. Energy Convers. 20 (4), 719–729 (2005).

Didier, G., Ternisien, E., Caspary, O. & Razik, H. A new approach to detect broken rotor bars in induction machines by current spectrum analysis. Mech. Syst. Signal Process. 21, 1127–1142 (2007).

Karami, F. & Poshtan Javad, Poshtan, M. Detection of broken rotor bars in induction motors using nonlinear Kalman filters. ISA Trans. 49, 189–195 (2010).

Aydin, I., Karakose, M. & Akin, E. A new method for early fault detection and diagnosis of broken rotor bars. Energy. Conv. Manag. 52, 1790–1799 (2011).

Singh, G. & Naikan, V. N. A. Detection of half broken rotor bar fault in VFD driven induction motor drive using motor square current MUSIC analysis. Mech. Syst. Signal Process. 110, 333–348 (2018).

Cho, K. R., Lang, J. H. & Umans, S. D. Detection of broken rotor bars in induction motors using state and parameter Estimation. IEEE Trans. Ind. Appl. 28 (3), 702–709 (1992).

Fernao Pires, V., Kadivonga, M., Martins, J. F. & Pires, A. J. Motor square current signature analysis for induction motor rotor diagnosis. Measurement 46, 942–948 (2013).

Pires, D. F., Fernao Pires, V., Martins, F. & Pires, A. J. Rotor cage fault diagnosis in three-phase induction motors based on a current and virtual flux approach. Energy. Conv. Manag. 50, 1026–1032 (2009).

Blödt, M., Granjon, P., Raison, B. & Rostaing, G. Models for bearing damage detection in induction motors using stator current monitoring. IEEE Trans. Industr. Electron. 55 (4), 1813–1822 (2008).

Zarei, J. & Poshtan, J. An advanced park’s vectors approach for bearing fault detection. Tribol. Int. 42, 213–219 (2009).

Deekshit Kompella, K. C., Venu Gopala Rao, M. & Srinivasa Rao, R. Bearing fault detection in a 3 phase induction motor using stator current frequency spectral Subtraction with various wavelet decomposition techniques. Ain Shams Eng. J. 9, 2427–2439 (2018).

Ben Salem, S., Bacha, K. & Chaari, A. Support vector machine based decision for mechanical fault condition monitoring in induction motor using an advanced Hilbert-Park transform. ISA Trans. 51, 566–572 (2012).

Singh, S., Kumar, A. & Kumar, N. Motor current signature analysis for bearing fault detection in mechanical systems. Procedia Mater. Sci. 6, 171–177 (2014).

Benbouzid, M. E. H., Vieira, M. & Theys, C. Induction motors’ faults detection and localization using stator current advanced signal processing techniques. IEEE Trans. Power Electron. 14 (1), 14–22 (1999).

Akar, M. Detection of a static eccentricity fault in a closed loop driven induction motor by using the angular domain order tracking analysis method. Mech. Syst. Signal Process. 34, 173–182 (2013).

Cakır, A., Calıs, H. & Kucuksille, E. U. Data mining approach for supply unbalance detection in induction motor. Expert Syst. Appl. 36, 11808–11813 (2009).

Ben Khader Bouzid, M., Champenois, G. & Tnani, S. Reliable stator fault detection based on the induction motor negative sequence current compensation. Electr. Power Energy Syst. 95, 490–498 (2018).

Jover Rodriguez, P. V. & Arkkio, A. Detection of stator winding fault in induction motor using fuzzy logic. Appl. Soft Comput. 8, 1112–1120 (2008).

Widodo, A. & Yang, B. Wavelet support vector machine for induction machine fault diagnosis based on transient current signal. Expert Syst. Appl. 35, 307–316 (2008).

Sharifi, R. & Ebrahimi, M. Detection of stator winding faults in induction motors using three-phase current monitoring. ISA Trans. 50, 14–20 (2011).

Ghate, V. N. & Dudul, S. V. Optimal MLP neural network classifier for fault detection of three phase induction motor. Expert Syst. Appl. 37, 3468–3481 (2010).

Elbouchikhi, E., Choqueuse, V., Auger, F. & Benbouzid, M. Motor current signal analysis based on a matched subspace detector. IEEE Trans. Instrum. Meas. 66 (12), 3260–3270 (2017).

Mirafzal, B. & Demerdash, N. A. O. Induction machine broken-bar fault diagnosis using the rotor magnetic field space-vector orientation. IEEE Trans. Ind. Appl. 40 (2), 534–542 (2004).

Joksimovic, G. M. & Penman, J. The detection of inter-turn short circuits in the stator winding of operating motors. IEEE Trans. Ind. Appl. 47 (5), 1078–1084 (2000).

Bacha, K., Salem, S. B. & Chaari, A. An improved combination of hilbert and park transforms for fault detection and identification in three-phase induction motors. Electr. Power Energy Syst. 43, 1006–1016 (2012).

Abdel Malek, M. B., Abdelsalam, A. K. & Hassan, O. E. Novel approach using hilbert transform for multiple broken rotor bars fault location detection for three phase induction motor. ISA Trans. 80, 439–457 (2018).

Antonino-Daviu, J. et al. Transient detection of eccentricity-related components in induction motors through the Hilbert-Huang transform. Energy. Conv. Manag. 50, 1810–1820 (2009).

Samsi, R., Ray, A. & Mayer, J. Early detection of stator voltage imbalance in three-phase induction motors. Electr. Power Syst. Res. 79, 239–245 (2009).

Ukil, A., Chen, S. & Andenna, A. Detection of stator short circuit faults in three-phase induction motors using motor current zero crossing instants. Electr. Power Syst. Res. 81, 1036–1044 (2011).

Martins, J. F., Pires, V. F. & Amaral, T. Induction motor fault detection and diagnosis using a current state space pattern recognition. Pattern Recognit. Lett. 32, 321–328 (2011).

Chattopadhyay, S., Karmakar, S., Mitra, M. & Sengupta, S. Symmetrical components and current Concordia based assessment of single phasing of an induction motor by feature pattern extraction method and radar analysis. Electr. Power Energy Syst. 37, 43–49 (2012).

Gangsar, P. & Tiwari, R. Comparative investigation of vibration and current monitoring for prediction of mechanical and electrical faults in induction motor based on multiclass-support vector machine algorithms. Mech. Syst. Signal Process. 94, 464–481 (2017).

Orji, U. A. et al. Fault detection and diagnostics for non-intrusive monitoring using motor harmonics. 2010 Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, : 1547–1554. (2010).

Gunal, S., Ece, D. G. & Gerek, O. N. Induction machine condition monitoring using notch-filtered motor current. Mech. Syst. Signal Process. 23, 2658–2670 (2009).

Acosta, G. G., Verucchi, C. J. & Gelso, E. R. A current monitoring system for diagnosing electrical failures in induction motors. Mech. Syst. Signal Process. 20, 953–965 (2006).

Acknowledgements

We would like to thank the National Natural Science Foundation of China (Grant 52275544) and all the authors of this paper for their supports.

Funding

This research was funded by the National Natural Science Foundation of China (Grant 52275544).

Author information

Authors and Affiliations

Contributions

F. L. conceived the study and wrote the main manuscript text. C. H. and L. L. completed experiments. X. Z. and D. L. contributed figures and analyses. X. W. checked the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Code availability

The codes for all analyses reported in the manuscript are available on reasonable request.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, F., Hou, C., Liang, L. et al. Winding fault detection based on current information of induction motors. Sci Rep 15, 31521 (2025). https://doi.org/10.1038/s41598-025-17368-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-17368-5